Patents

Literature

130results about How to "Mechanical properties are not affected" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

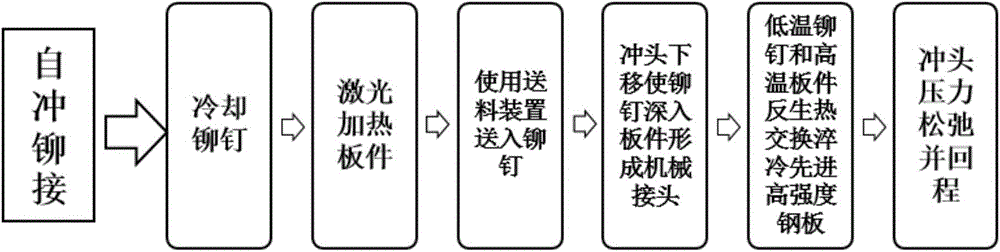

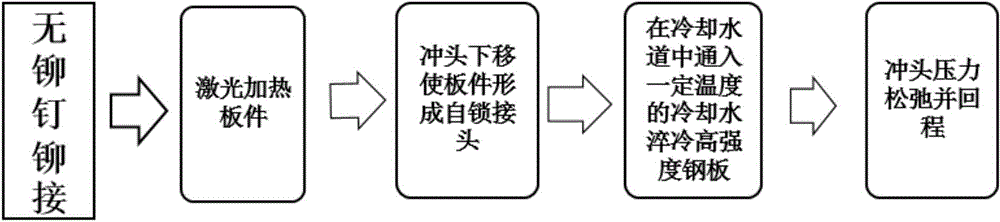

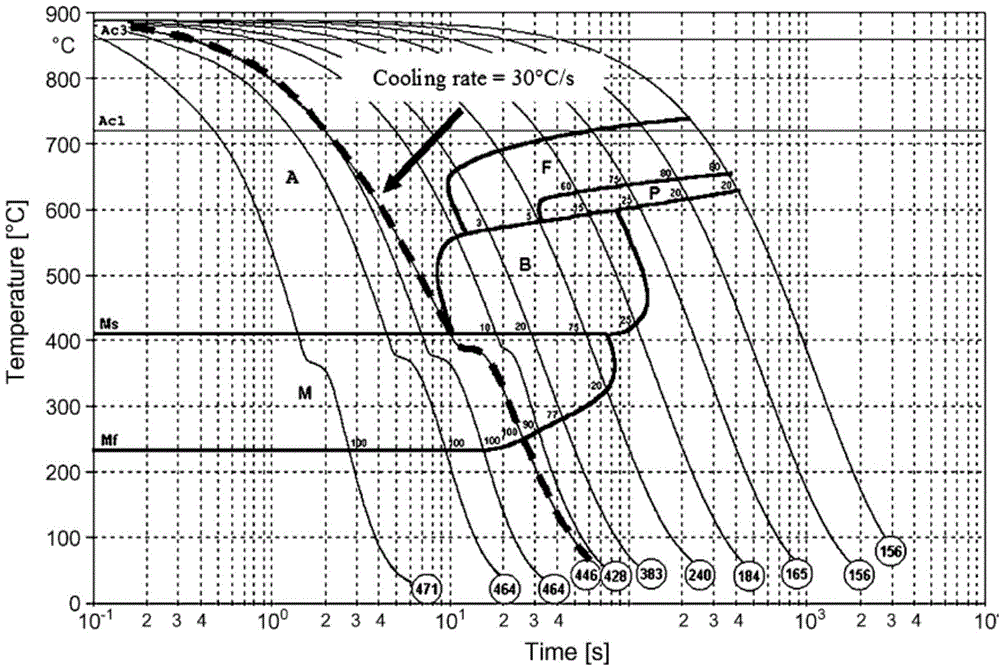

Riveting method of ultrahigh strength steel plates or aluminum alloy plates

The invention discloses a riveting method of ultrahigh strength steel plates or aluminum alloy plates and aims to solve the problems that ultrahigh strength steel plates cannot be riveted and joints are difficult to effectively weld since rigid and crispy metallic compounds occur to welding spots when the ultrahigh strength steel plates and the aluminum alloy plates are under spot welding. The riveting method includes the steps of 1, performing liquid nitrogen cooling on rivets in a cooling chamber before riveting so as to cool the rivets to below 0 DEG C; 2, placing an upper plate and a lower plate on a first compound female die, and holding down the upper and lower plates with a first compound binder ring; 3, heating riveting areas of the upper plate with a first fiber-optic heater to a threshold; 4, heating riveting areas of the lower plate with a second fiber-optic heater to a threshold; 5, feeding the low-temperature rivets to a central light through hole of the first compound binder ring, and pressing the rivets for riveting with a first compound punch; 6, co-pressing the rivets with the first compound punch and the first compound female die to turn out ring feet of the rivets to obtain rivet fasteners; 7, releasing the first compound punch to allow it to move up and return.

Owner:JILIN UNIV

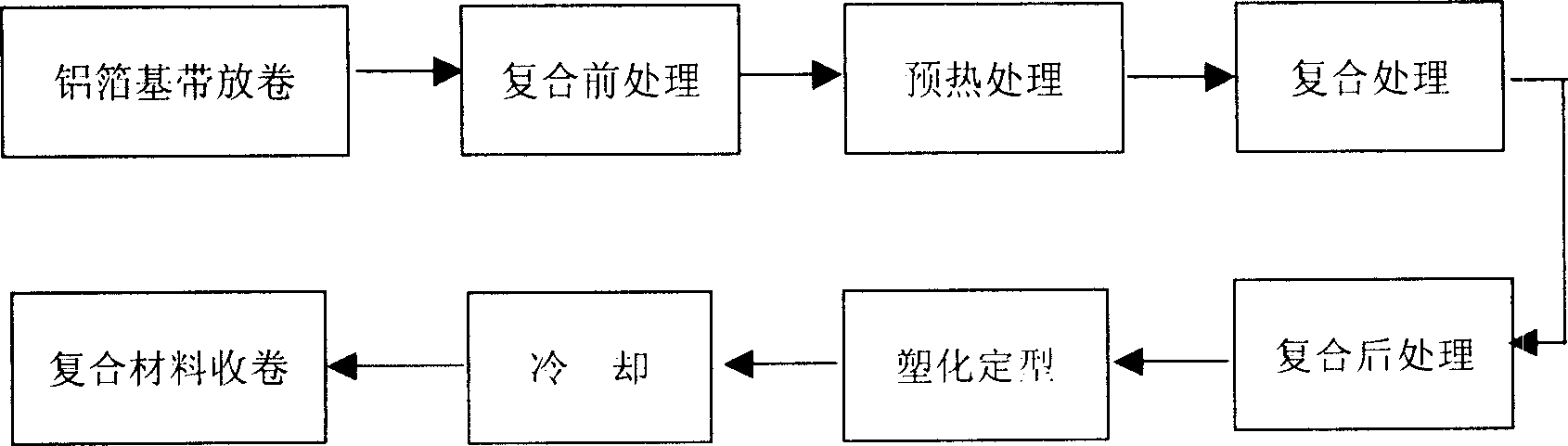

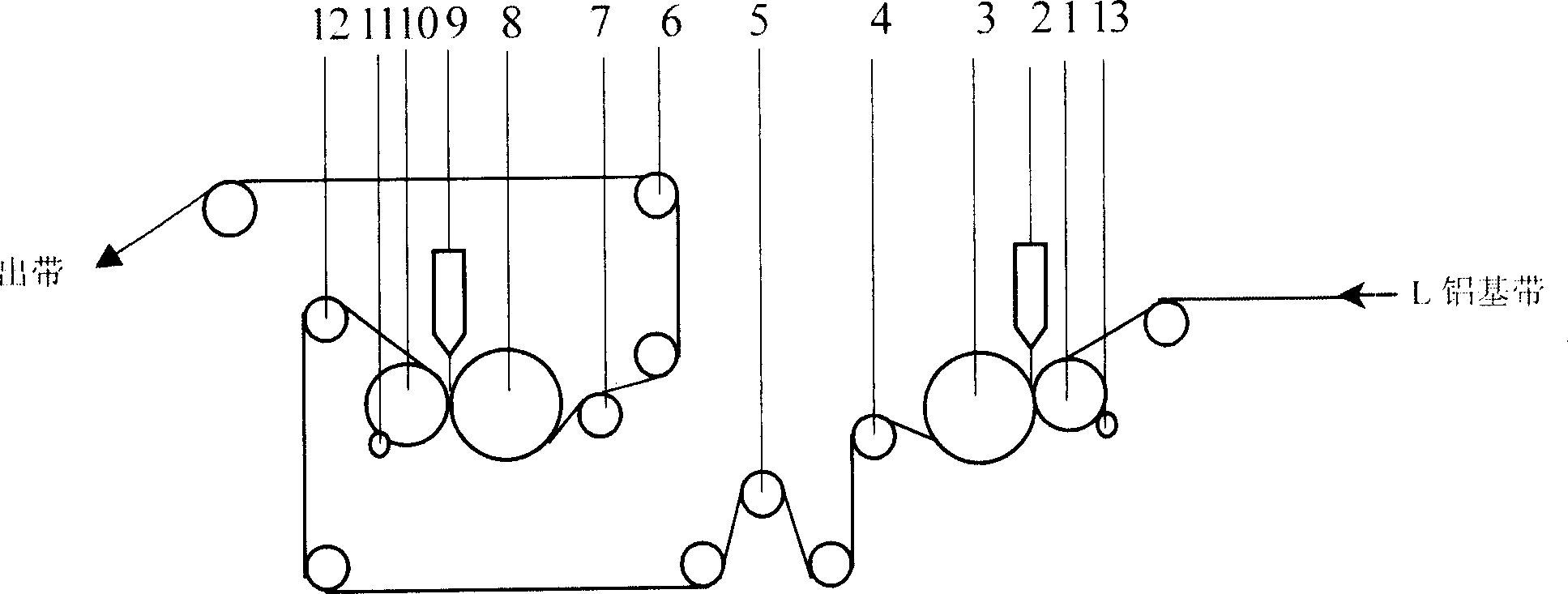

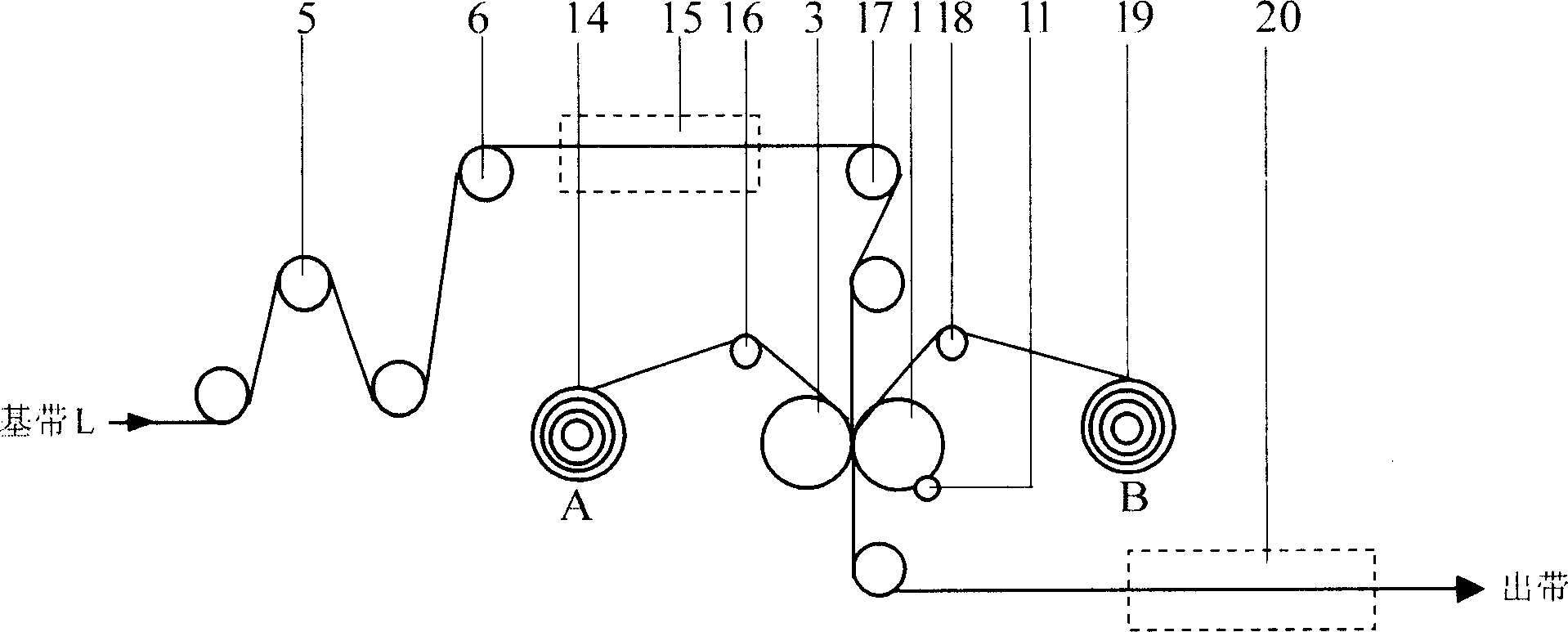

Method for mfg. sub light smooth type aluminium plastic compound band

ActiveCN1792605AReduce weightSave materialSynthetic resin layered productsBeltsPlastic filmAluminum foil

A process for preparing the dull and smooth aluminum-plastic band includes such steps as choosing an aluminum foil as basic band, pre-treating, extruding out at least one plastic film layer onto one or two surfaces of basic band, rolling while heating, and heat-treating by controlling the temp between Vicat softening point and fusion point for obtain dull and smooth surface. It can be used for optical cable or electric cable for high moisture tight effect.

Owner:上海网讯新材料科技股份有限公司

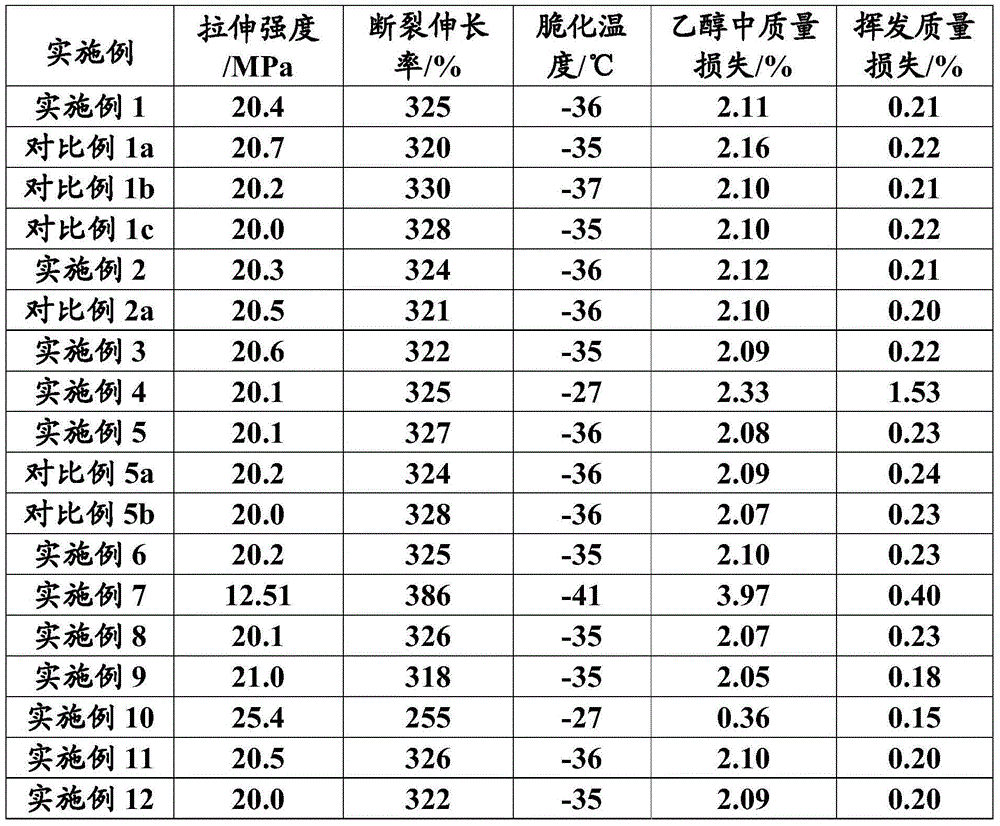

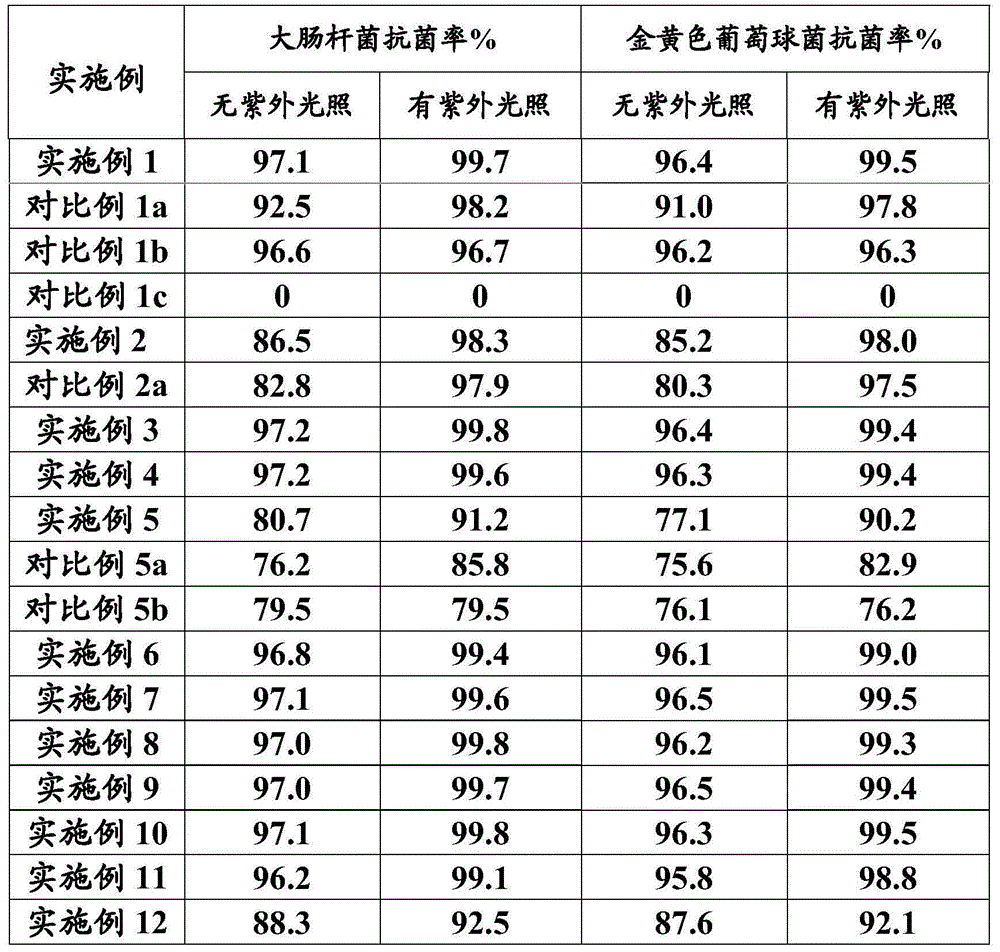

Antibacterial polyvinyl chloride material, preparation method and application thereof

ActiveCN105218964AImprove antibacterial propertiesMechanical properties are not affectedSurgeryPlasticizerPolyvinyl chloride

The invention relates to an antibacterial polyvinyl chloride material. The antibacterial polyvinyl chloride material comprises polyvinyl chloride resin, wherein the material comprises the following compounds in every 100 parts of polyvinyl chloride resin as basic resin by weight: (A) 2-10 parts of a combined antibacterial agent by weight, the combined antibacterial agent comprising at least one of an antibacterial agent A selected from titanium dioxide and silver-supported nano titanium dioxide and an antibacterial agent B selected from a polyquaternium antibacterial, wherein the weight ratio of the antibacterial agent A to the antibacterial agent B is 1: 3 to 4: 3; (B) a plasticizer; and (C) an optional stabilizer. The antibacterial polyvinyl chloride material comprises the specific combined antibacterial agent, so that the polyvinyl chloride material has strengthened antibacterial ability and has a good mechanical property. The invention also relates to preparation and application of the polyvinyl chloride material, and the material can serve as a medical polymer material, particularly a medical catheter material, particularly a tracheal catheter material.

Owner:BEIJING UNIV OF CHEM TECH +1

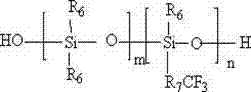

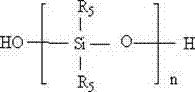

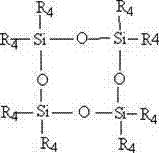

Preparation method for fluorine silicon phosphorus-containing anti-dropping flame-retardant polyethylene terephthalate

ActiveCN102391488AMechanical properties are not affectedReduce manufacturing costMonocomponent copolyesters artificial filamentFiberPolyethylene terephthalate glycol

The invention discloses a preparation method for fluorine silicon phosphorus-containing anti-dropping flame-retardant polyethylene terephthalate. The preparation method is characterized by comprising the following steps of: performing prepolymerization on a phosphorus-containing copolymerization flame retardant to synthesize phosphorus-containing copolymerization flame retardant prepolymer; performing dehydration reaction on trifluoalkyl siloxane and octaalkylcyclotetrasiloxane; adding dihydroxy siloxane and a catalyst, and reacting to synthesize dihydroxy fluorosiloxane; performing esterification on terephthalic acid and glycol; adding a catalyst B and a stabilizing agent; adding the phosphorus-containing copolymerization flame retardant prepolymer and the dihydroxy fluorosiloxane for polycondensation; and after the reaction is finished, cooling by using water and granulating to prepare the fluorine silicon phosphorus-containing anti-dropping flame-retardant polyethylene terephthalate. The product prepared by the method has high flame-retardant and anti-dropping properties and can serve as a raw material for producing films with the flame-retardant property of 94ULV-0 level or VTM-0 level, flame-retardant fibers and textiles with the flame-retardant level I and higher level, and V0-level flame-retardant plastic products.

Owner:四川东方绝缘材料股份有限公司

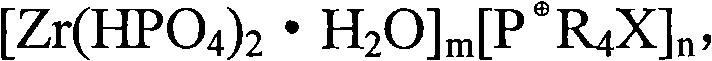

Water-boiling-resistant and flame-retardant polypropylene composite material with high glow-wire ignition temperature and preparation method

ActiveCN107434878ASolve serious problemsImprove flame retardant charcoal efficiencyPolypropylene compositesAntioxidant

The invention provides a water-boiling-resistant and flame-retardant polypropylene composite material with a high glow-wire ignition temperature and a preparation method. The water-boiling-resistant and flame-retardant polypropylene composite material with the high glow-wire ignition temperature is composed of the following materials: 72-76 parts of PP resin, 24-28 parts of a nitrogen phosphorus intumescent-type flame retardant, 0.1-0.2 part of an anti-dripping agent, 0.2-0.3 part of an antioxidant, 0.4-0.6 part of a lubricant, and 0.1-0.2 part of a high-efficiency synergist. The flame-retardant polypropylene composite material prepared by the method guarantees the material to pass a UL94 1.6mm-V0 test and achieve high-efficiency flame retardance, and at the same time the flame-retardant polypropylene composite material has performance such as a high glow-wire ignition temperature (875 DEG C, GWIT), water boiling resistance (100 DEG C), precipitation resistance, low smoke and thermal oxygen ageing and discoloring resistance (150 DEG C).

Owner:ORINKO NEW MATERIAL CO LTD

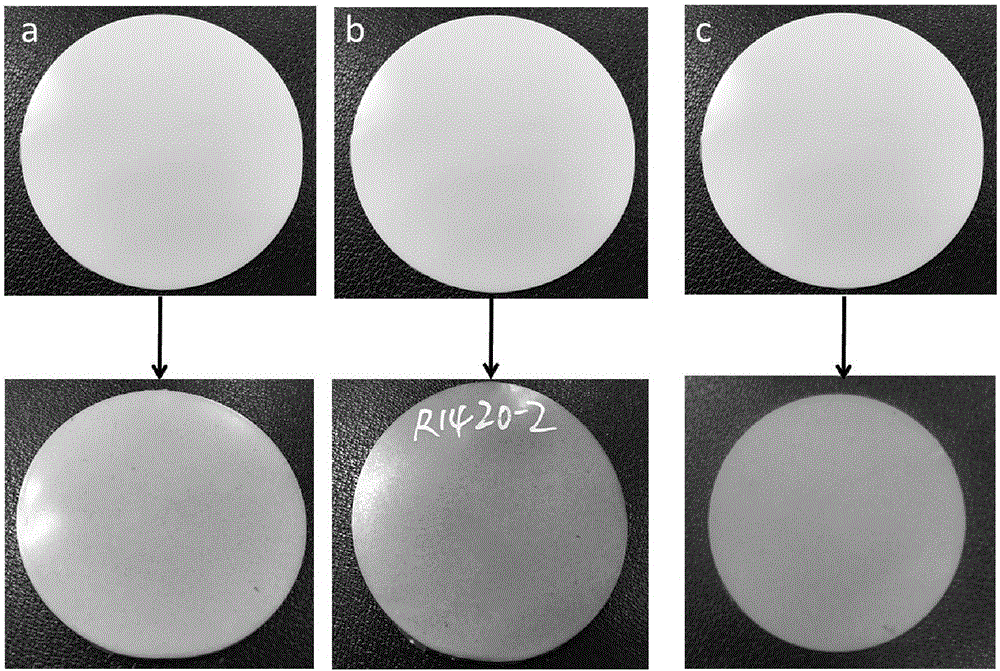

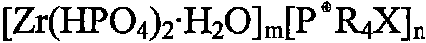

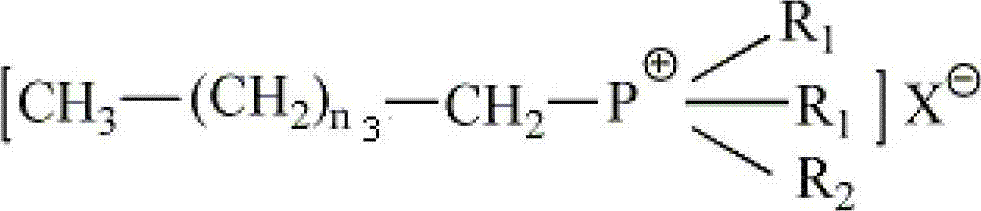

Quaternary phosphonium salt pillared layered zirconium phosphate material, and preparation method and application thereof

The invention discloses a quaternary phosphonium salt pillared layered zirconium phosphate material, and a preparation method and an application thereof. The chemical formula of the quaternary phosphonium salt pillared layered zirconium phosphate material is as follows, R is methyl, butyl, phenyl or alkane with the length of a carbon chain of 8-20; X is Cl or Br; and m is 1, and n is 0.00288-0.174462. The preparation method comprises the steps of utilizing methylamine to prop up an interlayer spacing interval of zirconium phosphate, obtaining a methylamine-zirconium phosphate precursor, then adding a quaternary phosphonium salt into the methylamine-zirconium phosphate precursor for continuously carrying out reaction for a certain time, replacing the methylamine in the precursor and obtaining the quaternary phosphonium salt pillared layered zirconium phosphate material with white or light gray external appearance, and the quaternary phosphonium salt pillared layered zirconium phosphate material can be added into plastics, rubber, fibers, coatings, adhesives, paper and other materials for preparing an antibacterial or flame-retardant functional material, and be also used for removing algae in water and governing large-area red tide and water blooms in fresh water.

Owner:JINAN UNIVERSITY

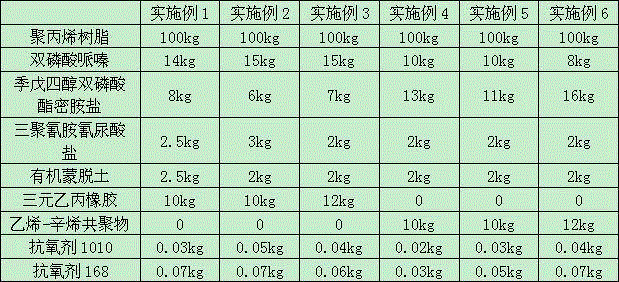

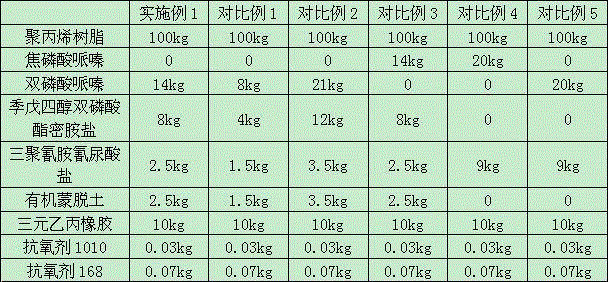

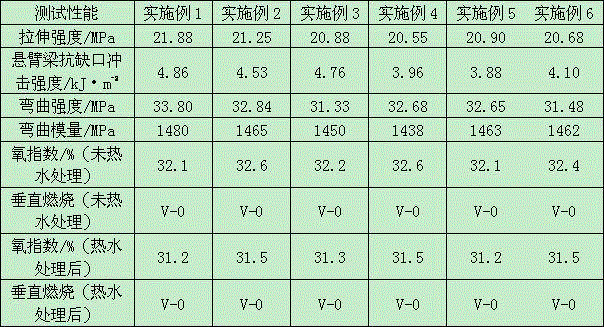

Halogen-free flame-retardant polypropylene material and preparation method thereof

ActiveCN105061887AGood flame retardant synergyImprove flame retardant performancePentaerythritolAntioxidant

The invention discloses a halogen-free flame-retardant polypropylene material and a preparation method thereof. The halogen-free flame-retardant polypropylene material comprises components in parts by weight as follows: 100 parts of polypropylene resin, 20-35 parts of a halogen-free composite flame retardant, 5-20 parts of a toughening agent and 0.05-0.12 parts of a complex antioxidant, wherein the halogen-free composite flame retardant comprises diphosphonate piperazine, pentaerythritol diphosphate melamine salt, melamine urate and organic montmorillonite in the weight ratio being (5-20) : (5-20) : (1-5) : (1:5). According to the halogen-free flame-retardant polypropylene material, a halogen-free composite flame retardant system comprises diphosphonate piperazine, pentaerythritol diphosphate melamine salt, melamine urate and organic montmorillonite and has an excellent flame-retardant synergistic effect and excellent high-temperature resistance, particularly, hydrolysis-resistant performance can be acquired without any treatment, and the flame retardant system is not easily hydrolyzed in the forming process.

Owner:JIANGYIN SULI CHEM

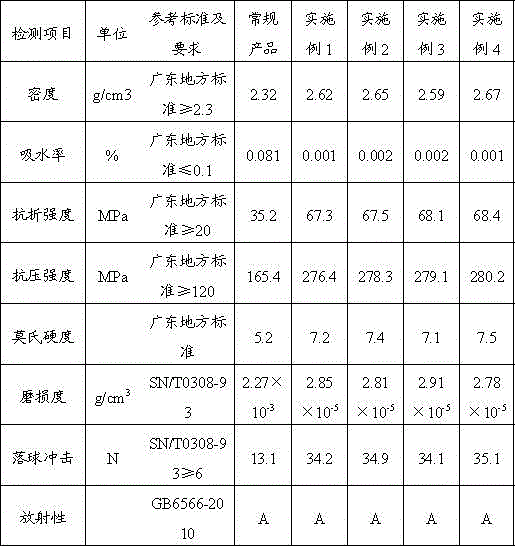

Super-strength and anti-wear artificial quartz stone plate and production method thereof

The invention relates to a building finishing decoration material, relates to an artificial quartz stone plate, and especially relates to a super-strength and anti-wear artificial quartz stone plate and a production method thereof. The artificial quartz stone plate is produced from, by mass, unsaturated polyester resin, short-cut basalt fibers, silicon nitride whiskers, calcium sulfate whiskers, an inorganic silicon material, a pigment, a coupling agent, a medium temperature curing agent and a promoter, and the artificial quartz stone plate is obtained from above components through the method. The artificial quartz stone plate has the advantages of high hardness, good wear resistance, greatly improved flexural strength, greatly improved compression and shock resistance, excellent high-temperature and low-temperature resistance, no cracking in sudden cooling or heating environment, and widened application field.

Owner:SHANDONG YUANGEN CHEM TECH RES & DEV CO LTD

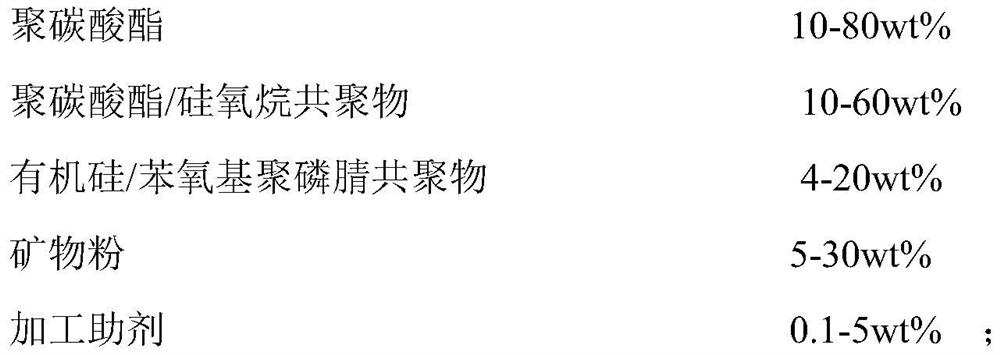

Low-smoke-density low-heat-release halogen-free flame-retardant PC material and preparation method and application thereof

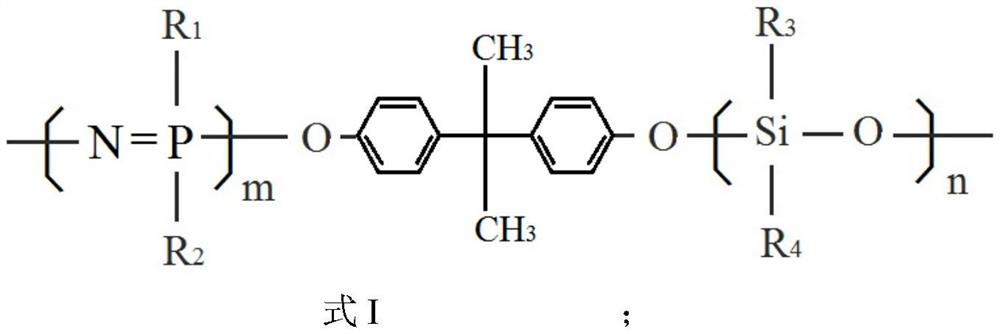

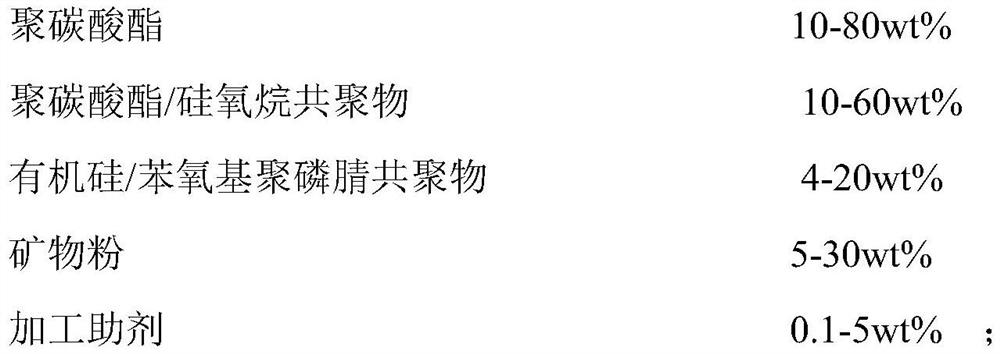

ActiveCN112409770AImproved smoke density and heat release propertiesDesign sciencePolycarbonateOrganosilicon

The invention belongs to the technical field of polymer composite materials, and discloses a low-smoke-density low-heat-release halogen-free flame-retardant PC material and a preparation method and application thereof. The low-smoke-density low-heat-release halogen-free flame-retardant PC material is prepared from the following raw materials in percentage by weight: 10-80wt% of polycarbonate, 10-60wt% of polycarbonate siloxane copolymer, 4-20wt% of organic silicon / poly(bis(phenoxy)phosphazene) copolymer, 5-30wt% of mineral powder and 0.1-5 wt% of processing aid. The structural formula of the organosilicon / poly(bis(phenoxy)phosphazene) copolymer is shown as a formula I in the specification. The balance of mechanical properties, flame retardancy and processability of the PC material is fullyconsidered, the organic silicon / poly(bis(phenoxy)phosphazene) copolymer is creatively adopted as the flame retardant and smoke suppressant, and the smoke suppression and heat absorption effects of the inorganic mineral powder are assisted, so that the smoke density and heat release amount of the material during combustion are effectively reduced.

Owner:SICHUAN COREMER CO LTD

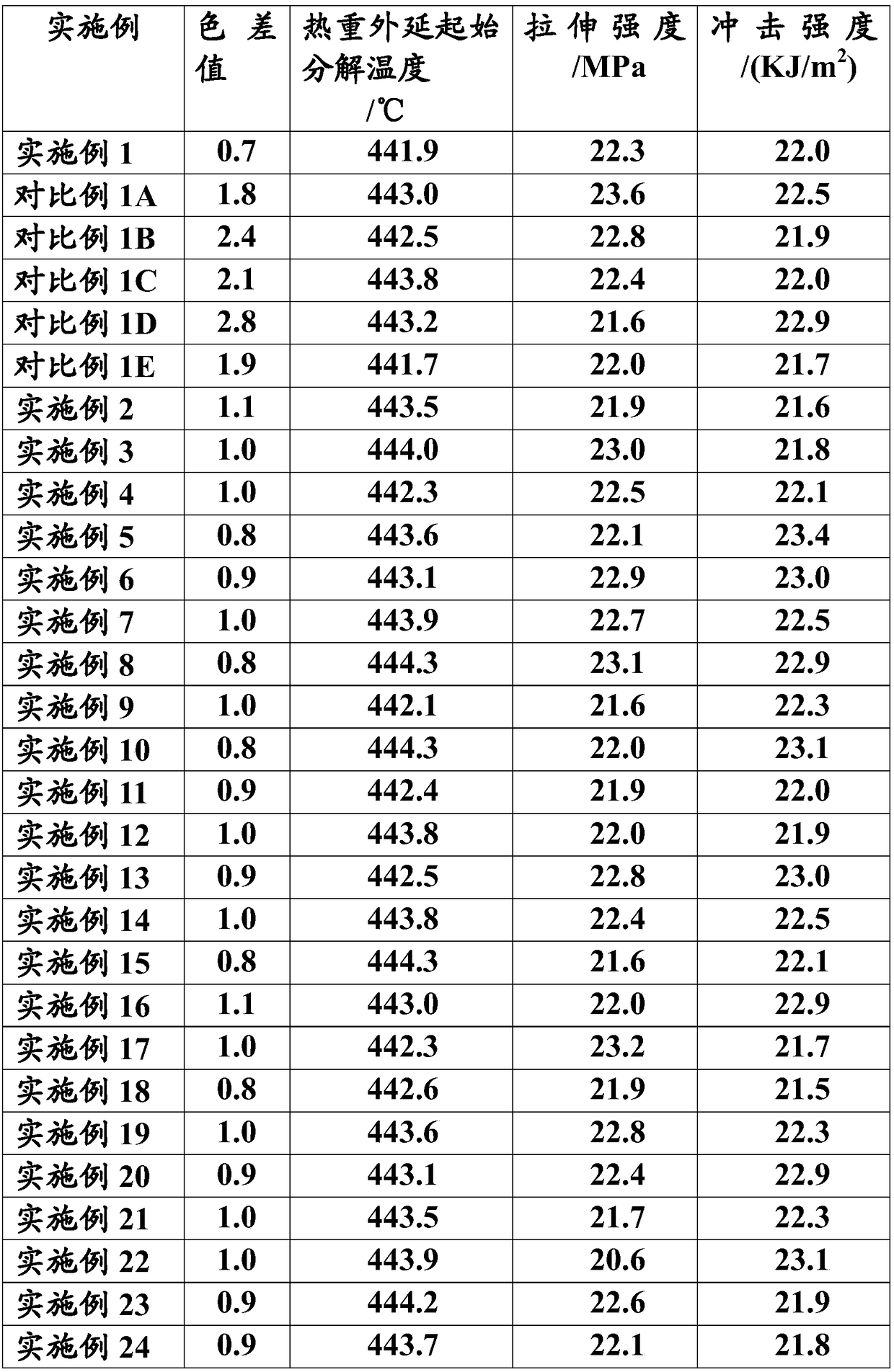

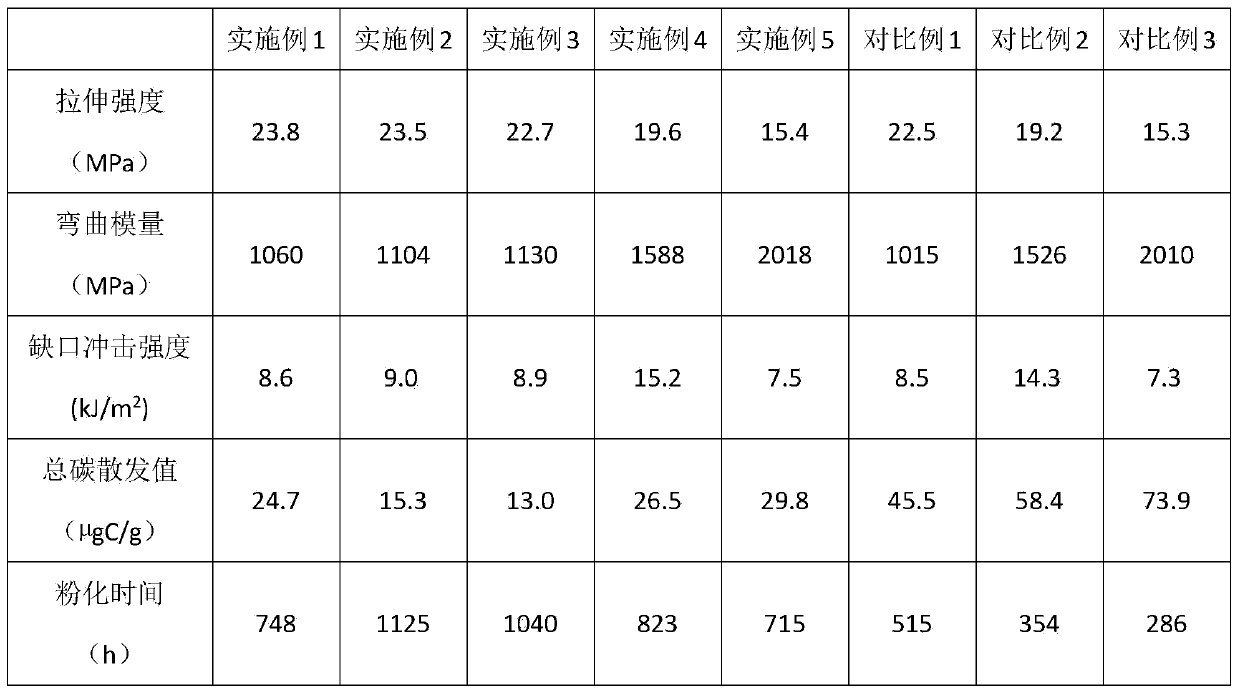

Illumination aging resisting polycarbonate/styryl resin composition and preparing method thereof

ActiveCN101210105AImprove anti-separation performanceGood light aging resistanceMolecular sievePolycarbonate

The invention discloses a polycarbonate / styryl resin composition which has light fastness and aging resistance and a preparation method thereof. The components and mixture ratio (weight proportion) of the composition are that: 50 percent-80 percent of polycarbonate, 10 percent-50 percent of styryl resin, 0.1-5 percent of molecular sieve, 0.1-1.0 percent of antioxidant 168, 0.1-1.0 percent of antioxidant 245, 0.1-2.0 percent of ultraviolet absorber, 0.1-2.0 percent of free radical quencher, etc. The resin composition prepared by the technical proposal of the invention can not only improve the anti-precipitation efficiency of light stabilizer in a composite material system to lead the prepared polycarbonate / styryl resin composition has better light fastness and aging resistance performance, but also has the advantage that all the physical mechanical performances and thermodynamic property of the material are basically not affected; furthermore, the method presented for improving the light fastness and aging resistance of polycarbonate / styryl resin composition has simple preparation technique and low production cost.

Owner:CHONGQNG PRET NEW MATERIAL +2

Preparation method of fast crystallization type polylactic acid composite material

The invention relates to a method for producing quick crystalline polylactide compound material by nano nucleating agent in situ belonging to the compound material field. The inventive method has the lactide or lactide as material, mixes the nano nucleating agent for a hot melting polycondensation to get polylactide / nano nucleating agent compound material. The crystal speed of the compound material is increased relative to the pure polylactide material. The method has a simple craft, a low cost, and gets the compound material with a good processing performance, mechanical property and a completely biodegradation which is applied in many fields.

Owner:SHANGHAI TONG JIE LIANG BIOMATERIALS

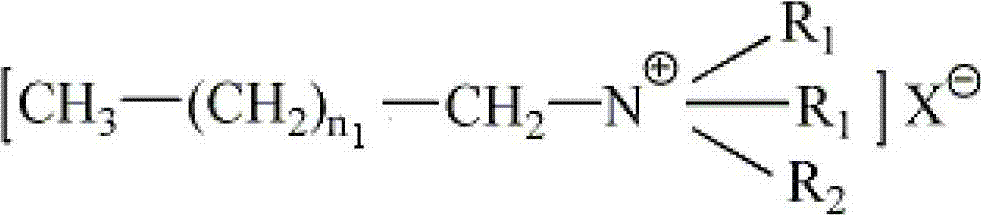

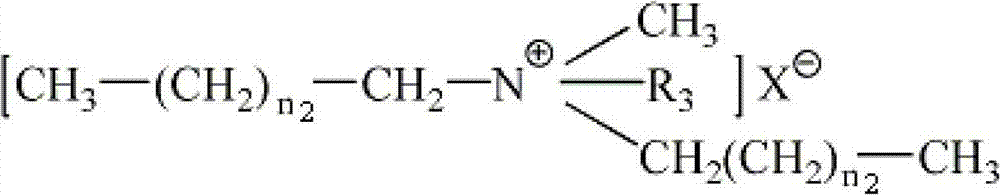

Quaternary ammonium cation and quaternary phosphonium cation-containing modified clay, its preparation and application

ActiveCN102816461AGood stabilityGood weather resistanceCoatingsInorganic compound additionQuaternary ammonium surfactantWeather resistance

Belonging to the field of organic-inorganic hybrid materials, the invention provides a quaternary ammonium cation and quaternary phosphonium cation-containing organic cation modified clay, its preparation method and application. The preparation method comprises: reacting a suspending solution of a sodium base treated clay mineral with quaternary ammonium cations and quaternary phosphonium cations, conducting filtering, washing, drying and crushing, thus obtaining the quaternary ammonium cation and quaternary phosphonium cation-containing organic cation modified clay with a synergistic effect. The organic cation modified clay provided in the invention has good stability, excellent weather resistance, and no toxicity. The organic cation modified clay contains quaternary ammonium cation modified clay and quaternary phosphonium cation modified clay simultaneously, and shows a synergistic antibacterial activity, so that it can be applied to plastics, rubber, fibers, coatings, adhesives, paper, wood-plastic composite materials and a variety of polymer materials to improve the antibacterial property, the flame retardance and the barrier property of polymers, and has no influence on the mechanical properties of the polymers.

Owner:JINAN UNIVERSITY

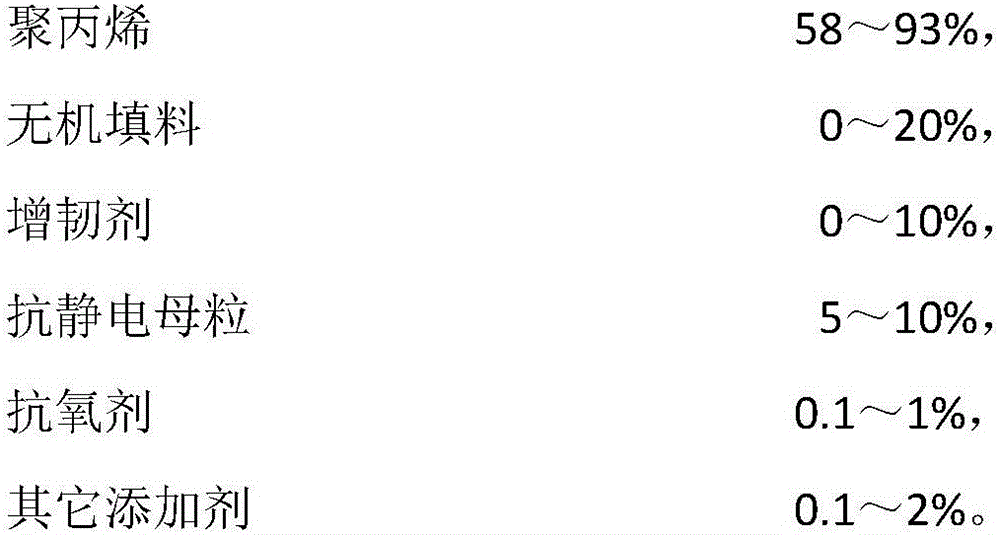

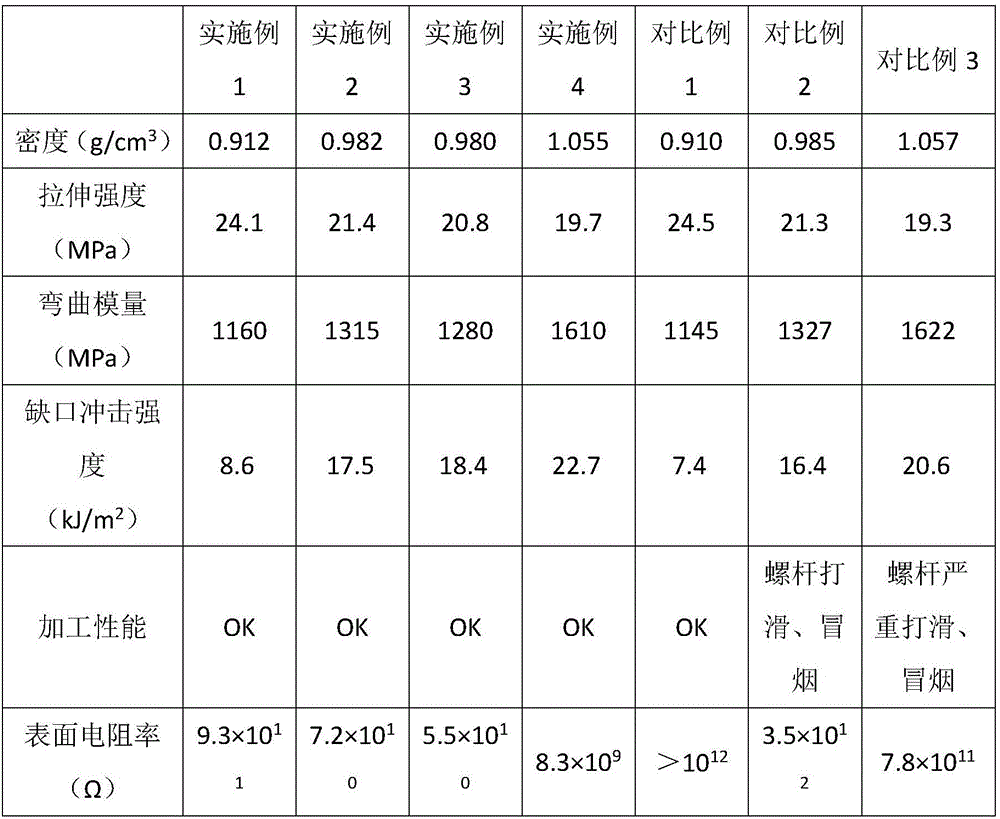

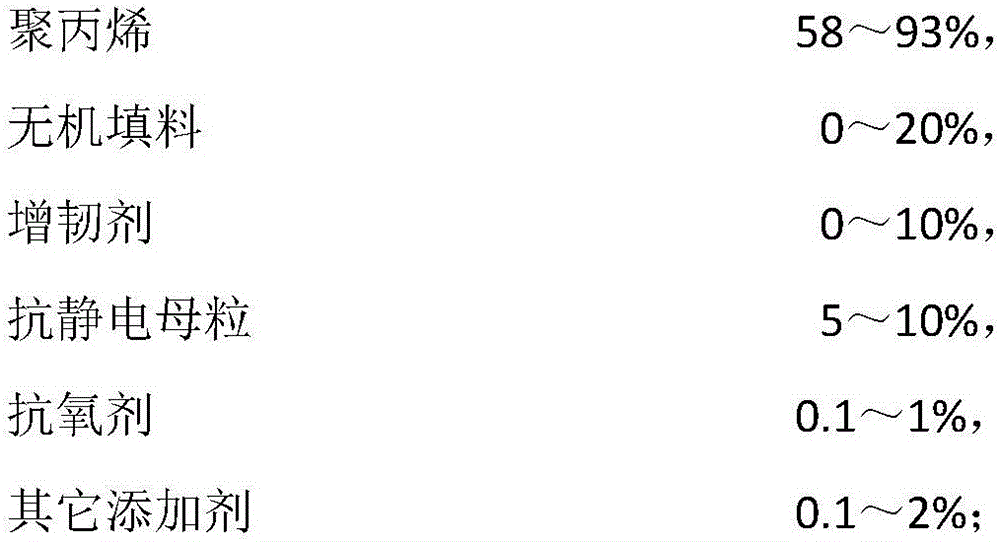

Easily processed efficient antistatic polypropylene composite material and preparation method thereof

InactiveCN106751004AEfficient antistatic propertiesImprove antistatic performancePolypropylene compositesAntistatic agent

The invention discloses an easily processed efficient antistatic polypropylene composite material and a preparation method thereof. The polypropylene composite material is prepared from, in weigh percentage, 58-93% of polypropylene, 0-20% of inorganic fillers, 0-10% of toughening agents, 5-10% of antistatic master batches, 0.1-1% of antioxidants and 0.1-2% of other additives. The antistatic master batches comprise, in weigh percentage, 77-89% of carrier resin, 10-20% of antistatic agents and 1-3% of lubricants. The prepared polypropylene composite material has an efficient antistatic performance, surface resistivity can reach 10<9> ohms, original mechanical properties of the material can be kept, and the preparation method is simple, practical and easy in production and avoids the problems of screw slip, smoking and the like.

Owner:SHANGHAI PRET COMPOSITES +4

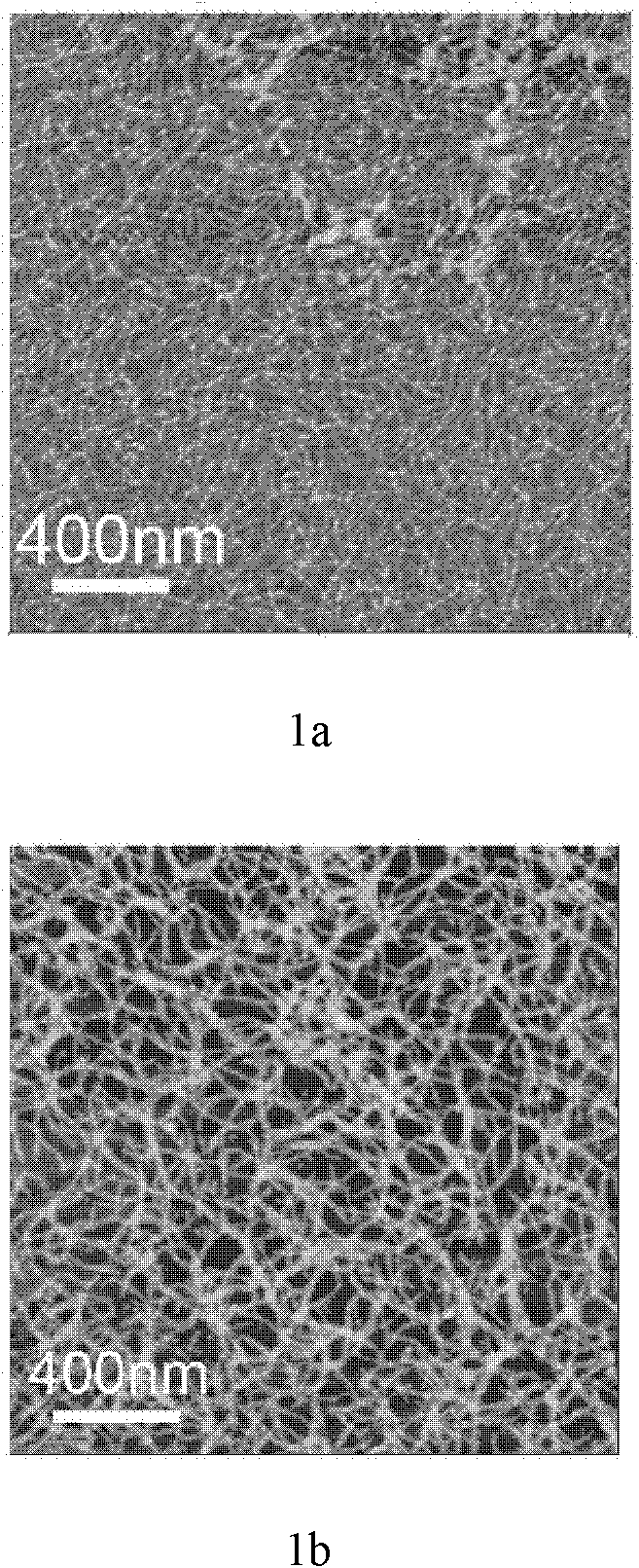

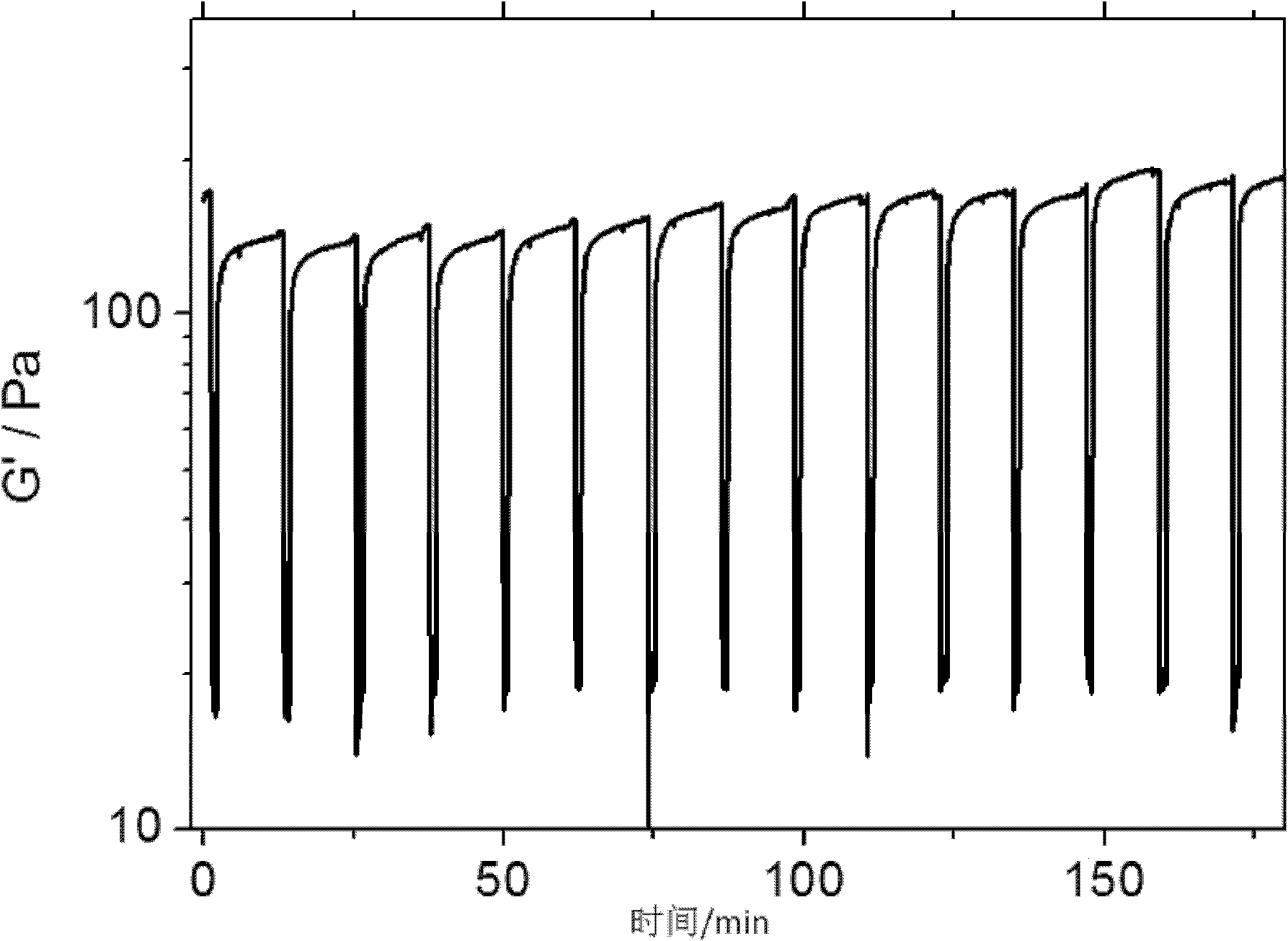

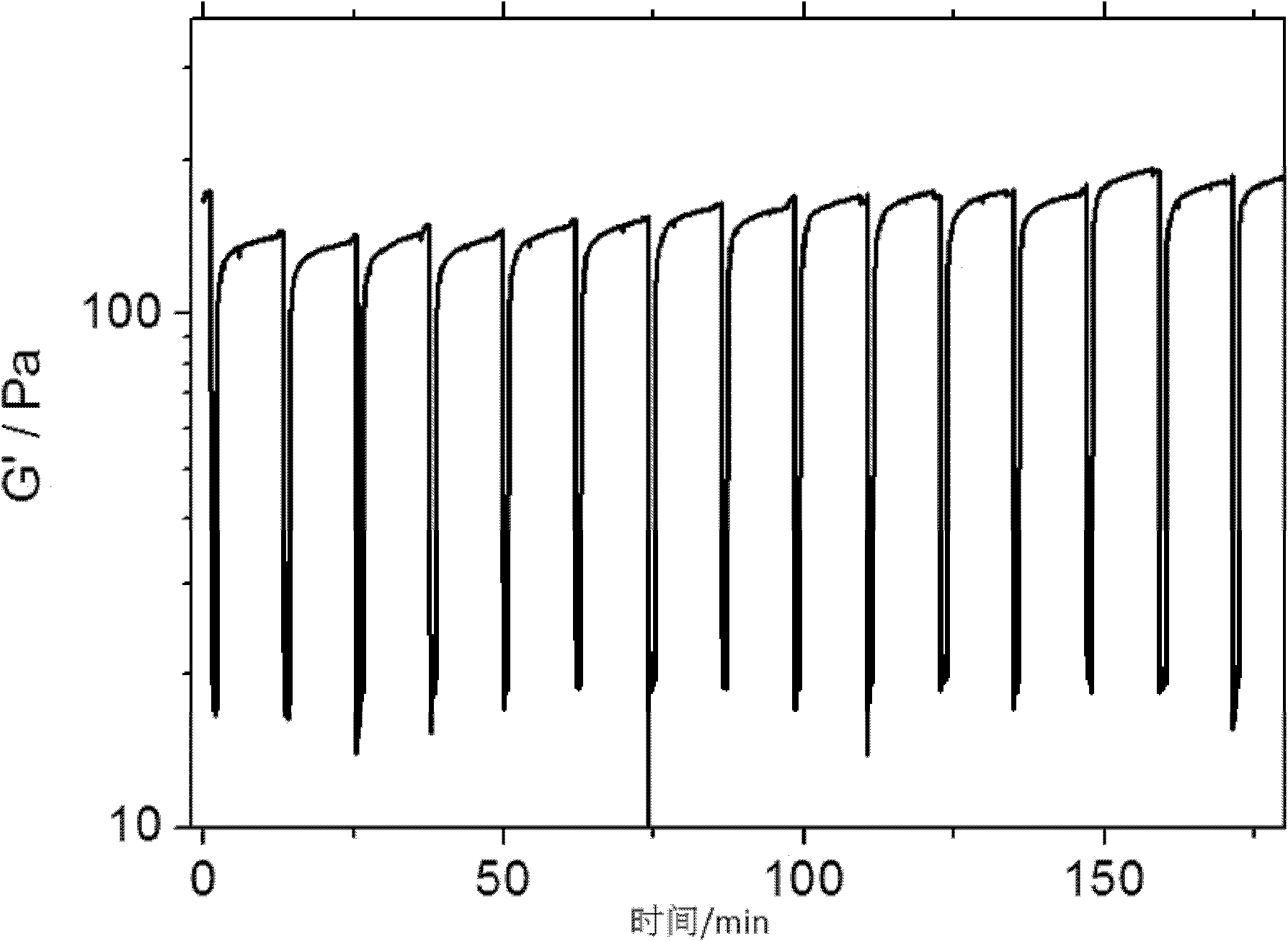

Preparation method of injectable polypeptide hydrogel

InactiveCN102408575AImprove hydrophobicityPromote formationAerosol deliverySurgeryCrystallographyBiocompatibility Testing

The invention relates to a preparation method of injectable polypeptide hydrogel. The preparation method comprises the steps of: dissolving ion compensation polypeptide in 3-20 mM MX aqueous solution under assistance of ultrasonic vibration, and carrying out self-assembly on the obtained solution to obtain the injectable polypeptide hydrogel, wherein the ion compensation polypeptide chain is composed of alternately arranged hydrophobic and hydrophilic amino acids, the hydrophilic amino acid is in charge periodic complementation arrangement, the hydrophobic amino acid is methionine, in the ioncompensation polypeptide aqueous solution, the concentration of the ion compensation polypeptide is 5-30 mg / mL, M is Na or K, and X is Cl, Br or I. The obtained hydrogel has good biocompatibility anddegradability, can be changed into fluid under the action of mechanical force, can rapidly restore after mechanical damage, is especially suitable for injection by an injector, and is convenient for use.

Owner:NANJING UNIV

Polyethylene material resistant to electron beam irradiation as well as preparation and application thereof

The invention discloses a polyethylene material resistant to electron beam irradiation. The polyethylene material is prepared from the following components: A) 100 parts by weight of polyethylene resin; B) 1-9 parts by weight of a primary antioxidant; C) 1-9 parts by weight of an auxiliary antioxidant; D) 1-9 parts by weight of a hindered amine light stabilizer; E) 2-10 parts by weight of an ultraviolet light absorber; and F) 1-10 parts by weight of a light shielding agent. After the polyethylene material resistant to electron beam irradiation is irradiated by 25 kGy dosage of electron beams,the color change of the polyethylene material before and after irradiation is small, in addition, the mechanical property and the thermal stability can be basically not affected, and the radiation resistance of the material is improved. The invention further relates to preparation and application of the irradiation-resistant polyethylene material. The material can be used as a medical polymer material, such as a medical catheter material.

Owner:BEIJING UNIV OF CHEM TECH +1

Alkali-activated cementing material and preparation method thereof

ActiveCN108249788AReduced alkali dissolution pathwayMechanical properties are not affectedCement productionAlkali activatedMaterials science

The invention relates to an alkali-activated cementing material and a preparation method thereof. Raw materials comprise a powder raw material, an activator and a nano component, wherein the activatoris a water glass solution and / or a sodium hydroxide solution, and the mass ratio of water in the activator to the powder raw material is a preset water-cement ratio. The preparation method of the alkali-activated cementing material comprises the following steps of: (1) mixing the nano component with the activator, adding water until the preset water-cement ratio is achieved so as to obtain an activator mixed solution, and placing the activator mixed solution for aging; (2) optimizing the content of the activator in the activator mixed solution so as to obtain an optimized activator mixed solution; and (3) mixing the powder raw material with the optimized activator mixed solution, performing stirring, and carrying out curing to obtain the alkali-activated cementing material. The amount ofalkali release of the alkali-activated cementing material can be reduced to 3% or below, and a scumming phenomenon of the alkali-activated cementing material can be eliminated completely.

Owner:CHINA BUILDING MATERIALS ACAD

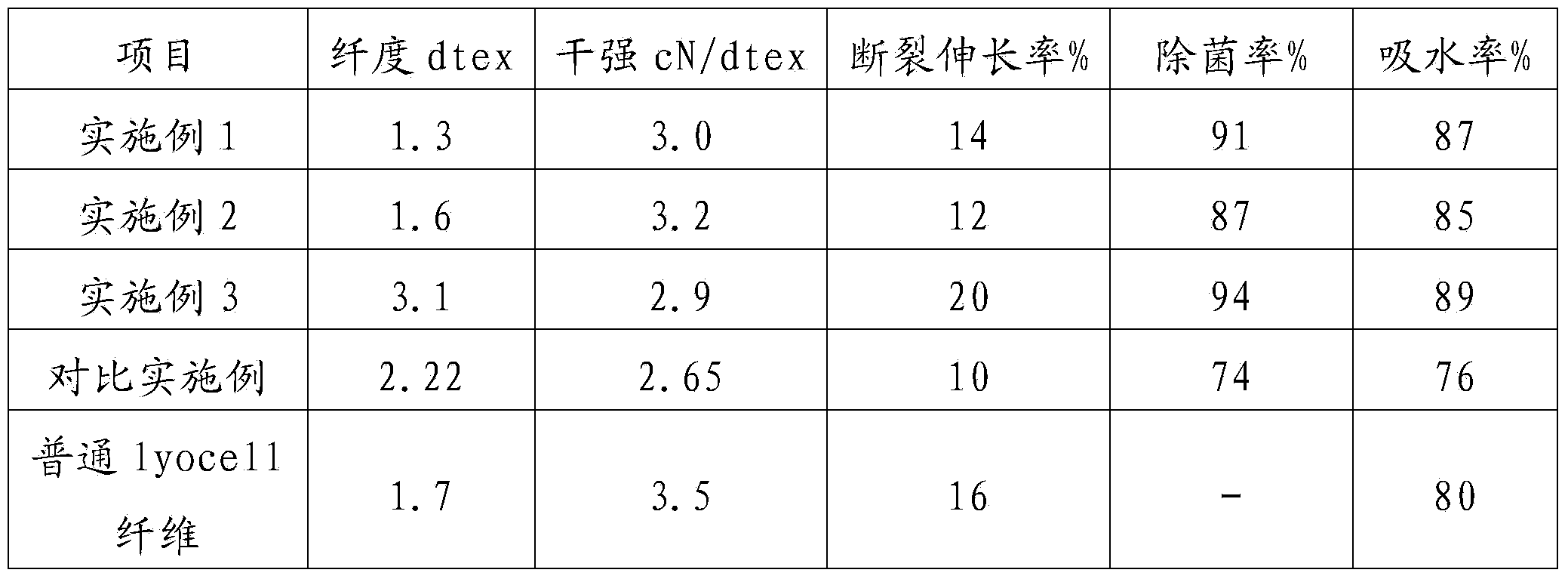

Bamboo charcoal Lyocell fiber and preparation process thereof

ActiveCN103556248AGood antibacterial effectGood moisture absorption and dehumidificationArtificial filaments from cellulose solutionsInorganic pigment treatmentMoisture absorptionCellulose pulp

The invention discloses a bamboo charcoal Lyocell fiber and provides a preparation method thereof. The preparation method comprises the following steps: performing surface modification treatment on bamboo charcoal, then mixing the bamboo charcoal with a concentrated NMMO (N-Methylmorpholine-N-oxide) water solution, mixing the mixture with activated cellulose pulp for dissolving, vacuumizing, performing heat preservation, extracting redundant water continuously to obtain a spinning raw solution, and finally, spinning to prepare the bamboo charcoal Lyocell fiber with bamboo charcoal content of 3wt%-20wt%. Through the preparation method, no extra reagent is introduced, so that the recycling of the solvent is facilitated, and the mechanical property of the fiber is not reduced; meanwhile, the prepared bamboo charcoal Lyocell fiber is excellent in performance of bacteria removal, bacteriostasis, moisture absorption and moisture removal.

Owner:SHANDONG YINGLI IND

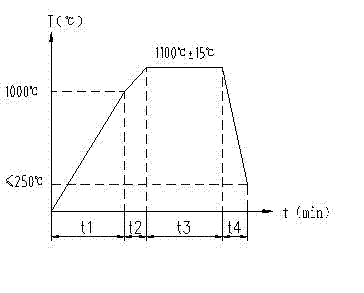

Manufacturing method of composite board seal head made from high-strength austenite nickel-iron-chromium alloy and austenite stainless steel

The invention discloses a manufacturing method of composite board seal head made from high-strength austenite nickel-iron-chromium alloy and austenite stainless steel. The manufacturing method comprises the following steps of: medium-temperature heat forming; after heat forming, carrying out a solution treatment process; and carrying out a pressing process, wherein the pressing process satisfies technological conditions as follows: a empty furnace is heated to 1000+ / -75 DEG C, a seal head circular plate is placed in the furnace at a temperature greater than or equal to 800 DEG C, and is then heated to 1100+ / -15 DEG C along with the furnace; the seal head circular plate is maintained at the temperature for 2-4h, and is then discharged from the furnace to be pressed for more than 2 times while the seal head circular plate is hot; the temperature of the seal head is measured at any time during the pressing process; and when the temperature of the seal head is lower than 850 DEG C, the seal head circular plate is put back into the furnace against to be heated, and the final pressing temperature of the seal head circular plate is no less than 850 DEG C. The manufacturing method disclosed by the invention employs processes of radial finishing polishing treatment before the composite board seal head is pressed, middle-temperature heat forming, and solution treatment after heat forming.

Owner:NANJING DUBLE METAL EQUIP ENG

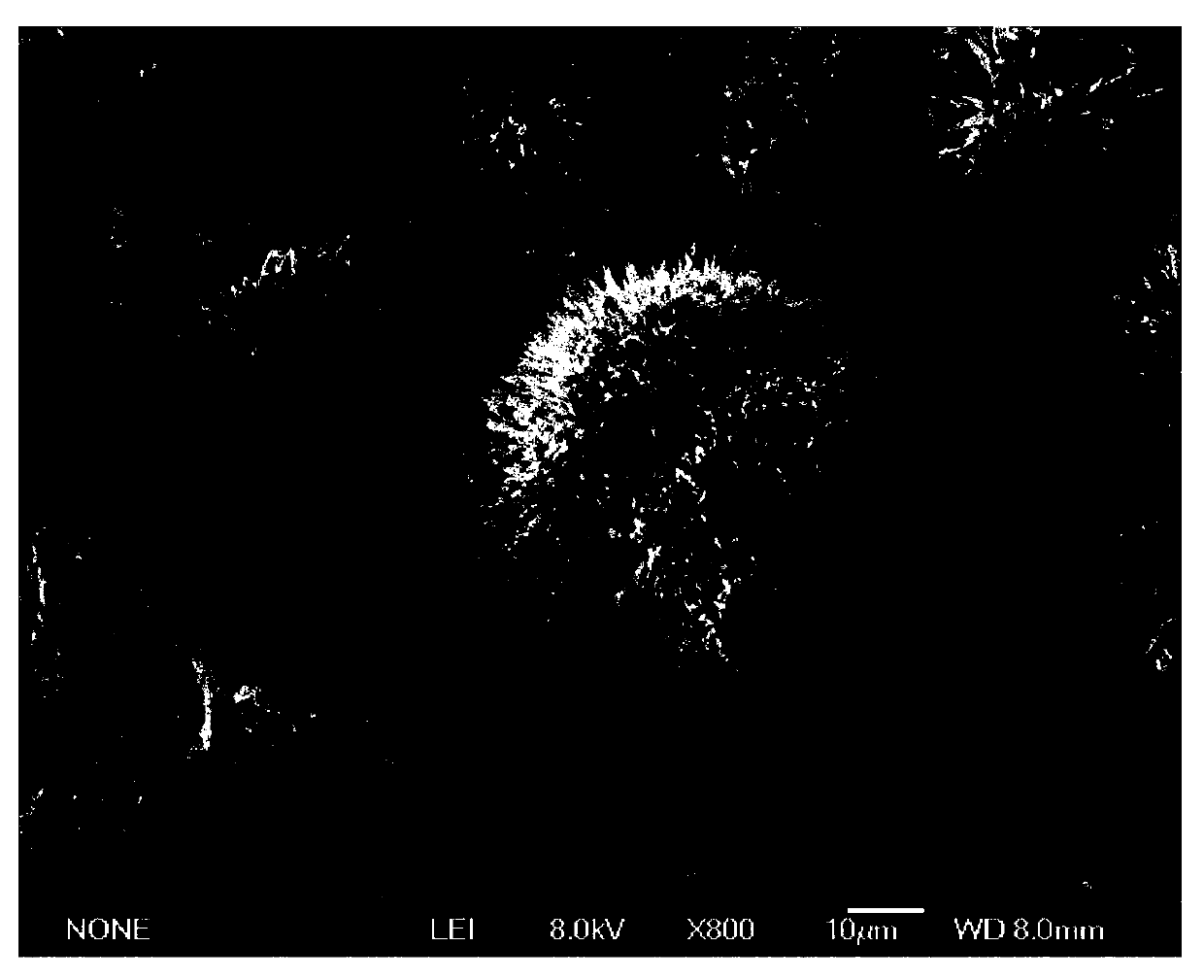

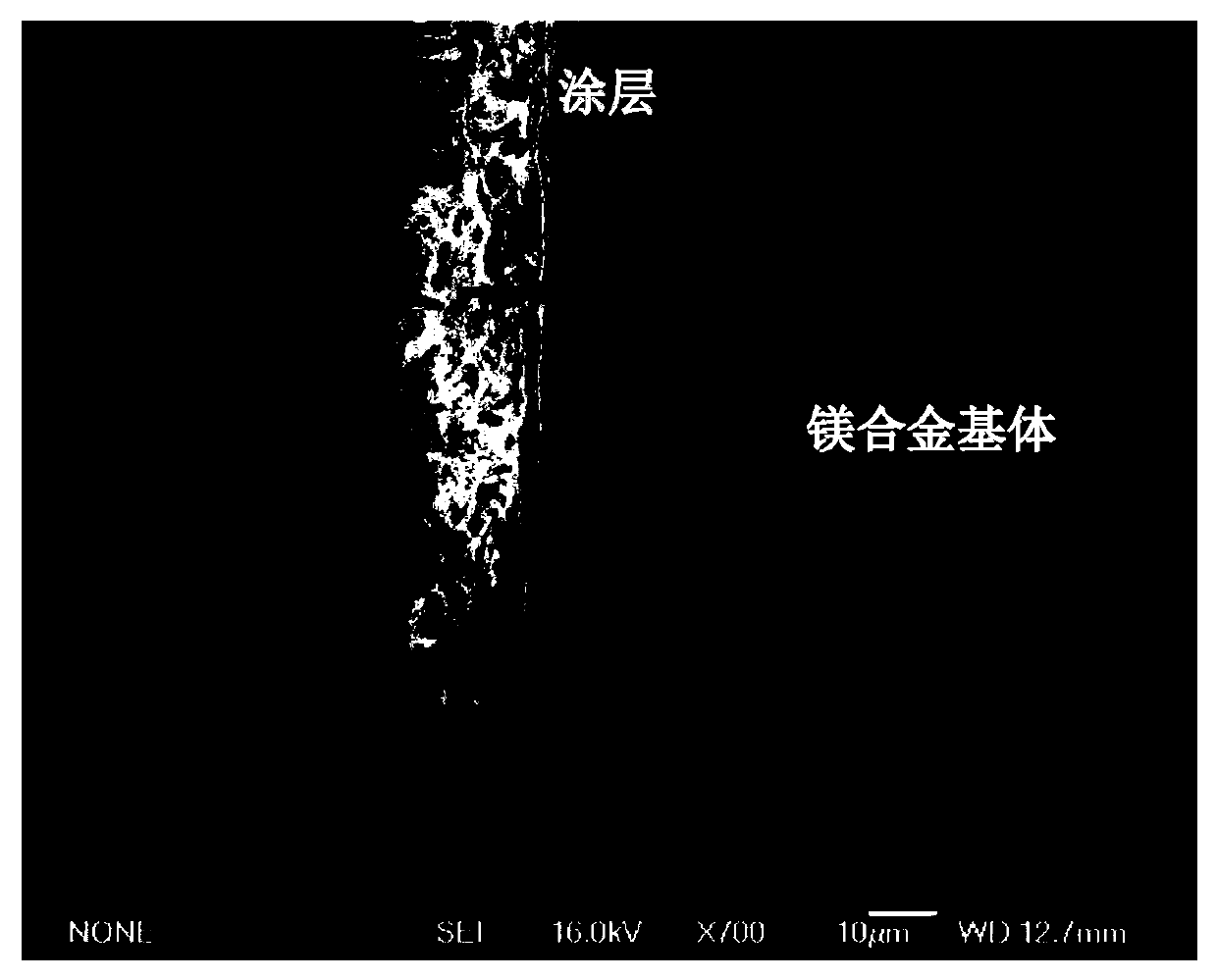

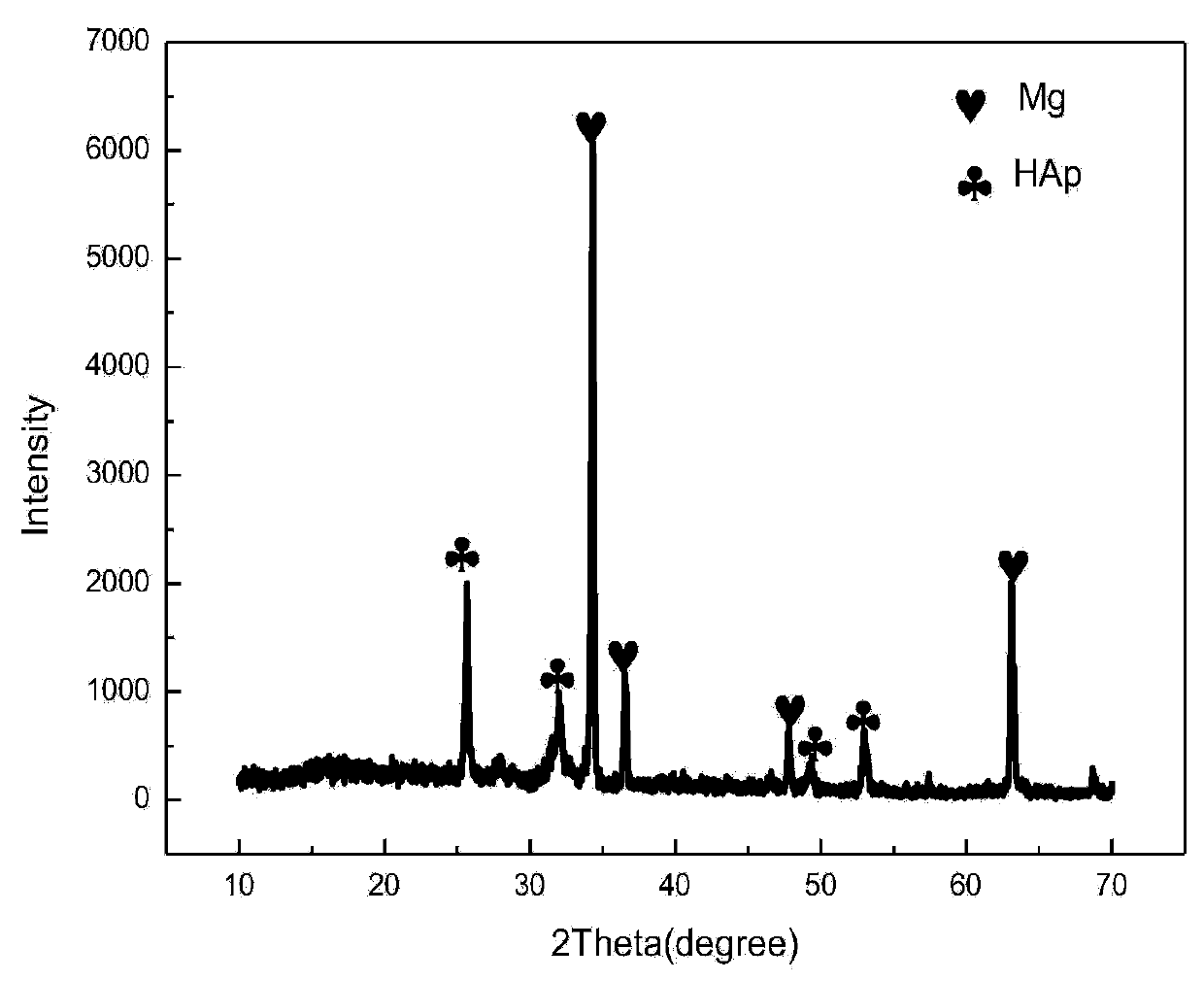

Acicular hydroxyapatite micro-nanostructure coating on magnesium alloy surface and preparation method thereof

ActiveCN109758605AReduce adverse effectsUniform and dense structureCoatingsProsthesisMicro nanoElectrolytic agent

The invention belongs to the technical field of surface modification of degradable magnesium alloy implants, and particularly relates to an acicular hydroxyapatite micro-nanostructure coating on the magnesium alloy surface and a preparation method thereof. The preparation method comprises the following steps of immersing a pretreated magnesium alloy substrate in an electrolyte solution for electrochemical deposition, using a platinum electrode as a cathode and magnesium alloy as an anode, turning on a DC stabilized power supply, performing electrochemical deposition and then performing alkaliheat treatment to obtain the hydroxyapatite coating on the magnesium alloy surface. The electrolyte solution for the electrochemical deposition has simple formula, has no accelerator or oxidant, and does not need to adjust the pH value. The electrochemical deposition method with low temperature and low current density is easy to control and low in cost. The prepared hydroxyapatite coating is uniform and dense, has high purity and good corrosion resistance and has the acicular micro-nano structure, which is beneficial to adhesion and growth of the cells on the surface of the coating. The implantation success rate of the magnesium alloy implants can be improved.

Owner:QINGDAO UNIV OF SCI & TECH

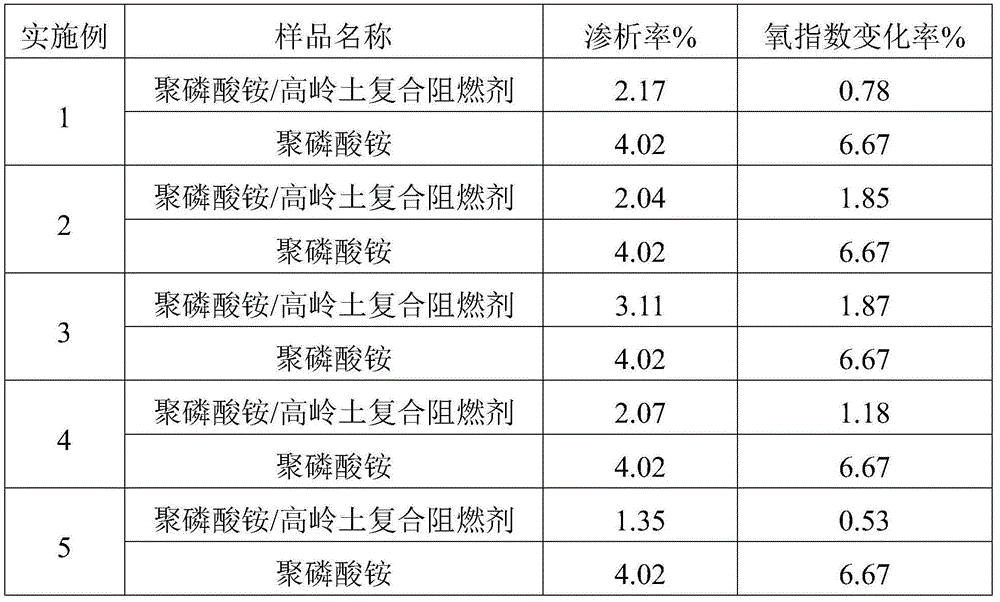

Preparation method for ammonium polyphosphate/kaolin composite flame retardant

InactiveCN105061811AImprove anti-dialysis performanceGood compatibilityAmmonium polyphosphateChemistry

The invention discloses a preparation method for an ammonium polyphosphate / kaolin composite flame retardant. The preparation method specifically comprises the following process steps: (1) calcining superfine water-washed kaolin for 1 to 2 hours at 600 to 900 DEG C to obtain calcined kaolin; (2) performing surface modification on ammonium polyphosphate by using cyanurtriamide to obtained modified ammonium polyphosphate, wherein the modifying temperature is 100 to 250 DEG C, the modifying time is 1 to 2 hours, and the using amount of the cyanurtriamide is 5 to 25 percent of the mass of the ammonium polyphosphate; (3) mixing the calcined kaolin and the modified ammonium polyphosphate in a mass ratio of 1:2-6, and performing compounded surface modification by using a modifier to obtain the ammonium polyphosphate / kaolin composite flame retardant, wherein the modifying temperature is 60 to 120 DEG C, the modifying time is 15 to 60 minutes, and the using amount of the modifier is 0.5 to 3 percent of the total mass of the calcined kaolin and the modified ammonium polyphosphate. According to the preparation method for the ammonium polyphosphate / kaolin composite flame retardant, the water solubility and the hygroscopicity of the ammonium polyphosphate can be reduced obviously; the dialysis resistance of an ammonium polyphosphate filled polymer product can be improved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

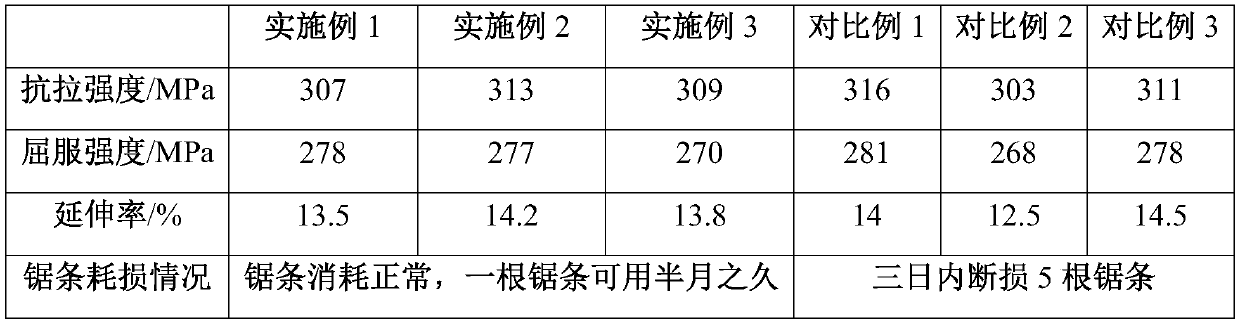

Heat treatment processing technology for 6082 aluminum alloy medium-thickness plate

InactiveCN110952050AIncreased adhesive wearAdhesive wear is reducedTemperature control deviceFurnace typesIngotMaterials science

The invention belongs to the technical field of aluminum alloy manufacturing, and relates to a heat treatment processing technology for a6082 aluminum alloy medium-thickness plate. An original technology sequence of an aluminum alloy ingot subjected to soaking-sawing and surface milling-hot rolling-solid solution and quenching-stretching-aging is adjusted as the ingot subjected to sawing and surface milling-soaking and hot rolling-solid solution and quenching-stretching-aging, through changing the technology sequence, the consumption of saw blade in the sawing and surface milling process is reduced, the production efficiency is improved, and the performance is not affected.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

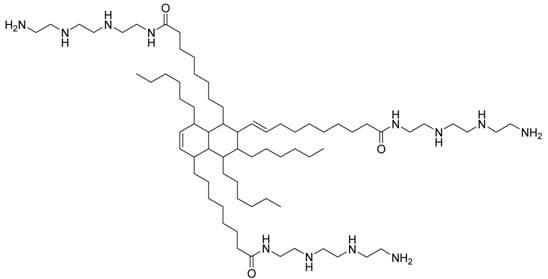

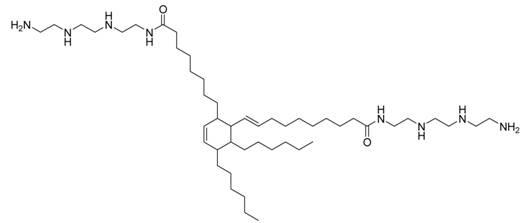

Amide-type aid and preparation method thereof

ActiveCN102320906AImprove wetting stateEasy to dispersePressure gas generationChemistryAdhesive system

The invention relates to an amide-type aid and a preparation method thereof, which belong to the field of the manufacture of a compound solid propellant. The amide-type aid is produced through the reaction of triethylene tetramine and linoleic acid dimer, and the wetting states of the solid particles of the solid propellant and an adhesive system can be markedly improved, so that the solid particles are easily dispersed, the structural strength for blocking the flow at the inner part of a medicine slurry is reduced, the yield value and the viscidity of the medicine slurry are decreased, and meanwhile, the mechanical performance of the propellant is not influenced.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

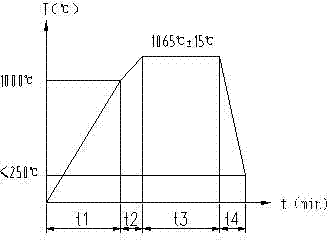

Method for manufacturing nickel-molybdenum alloy seal head

The invention relates to a method for manufacturing nickel-molybdenum alloy seal head. Technological conditions in the pressing process include that an empty furnace is heated to reach the temperature of 1000+ / -80 DEG C, a seal head disk enters the furnace at the temperature higher than or equal to 850 DEG C, the seal head disk is heated to reach the temperature of 1065+ / -15 DEG C along with the furnace after entering the furnace, the temperature is kept for 20-30min, and then the seal head disk is tapped off and is pressed at least twice while the seal head disk is hot. Technological conditions for solid solution of the pressed seal head includes that the empty furnace is heated to reach the temperature of 1000+ / -80 DEG C, the seal head and a seal head anti-deformation tool enter the furnace after being fixed at the temperature higher than or equal to 850 DEG C, the seal head is heated to reach the solid solution temperature of 1065+ / -15 DEG C along with the furnace after entering the furnace, and the seal head is tapped off and rapidly water-cooled after the temperature is kept for 30-45min, so that the high-strength nickel-molybdenum alloy seal head is obtained.

Owner:NANJING DUBLE METAL EQUIP ENG

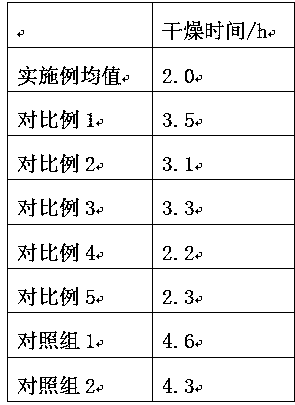

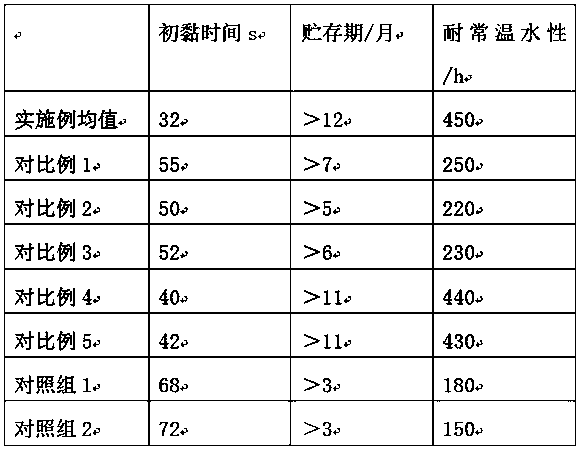

Modified polyvinyl alcohol adhesive for plywood

InactiveCN109294486ALarge specific surface areaGood compatibilityNon-macromolecular adhesive additivesStarch adhesivesPolymer scienceAdhesive

The present invention discloses a modified polyvinyl alcohol adhesive for plywood and relates to the technical field of plywood. The modified polyvinyl alcohol adhesive for the plywood is made of thefollowing components: starch composite modified polyvinyl alcohol, activated nano zeolite powder, rosin resin, hydroxymethyl cellulose, dehydrated sorbitol fatty acid ester and deionized water. The provided adhesive for the plywood has good water resistance and at the same time has a quick drying effect.

Owner:含山县金中环装饰材料有限公司

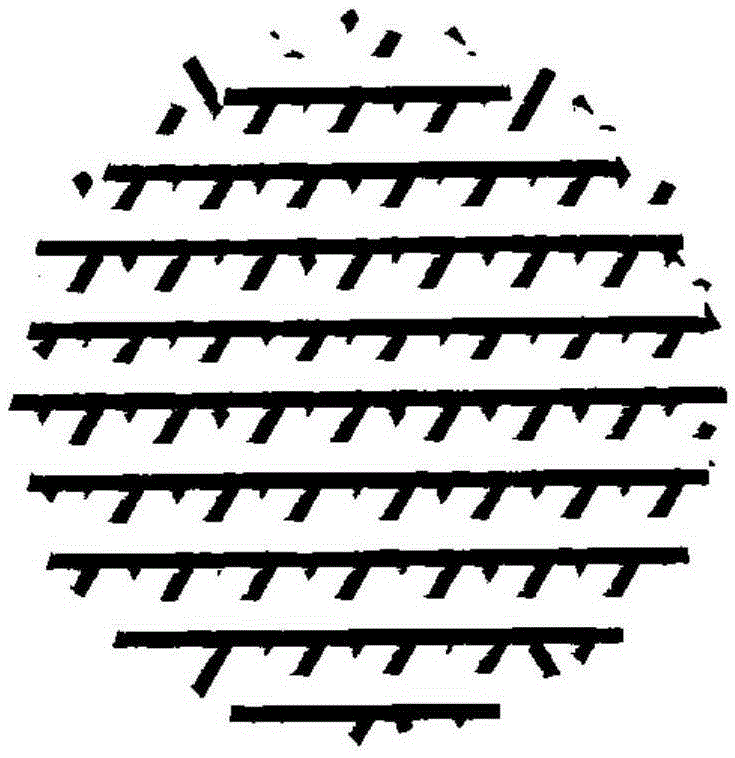

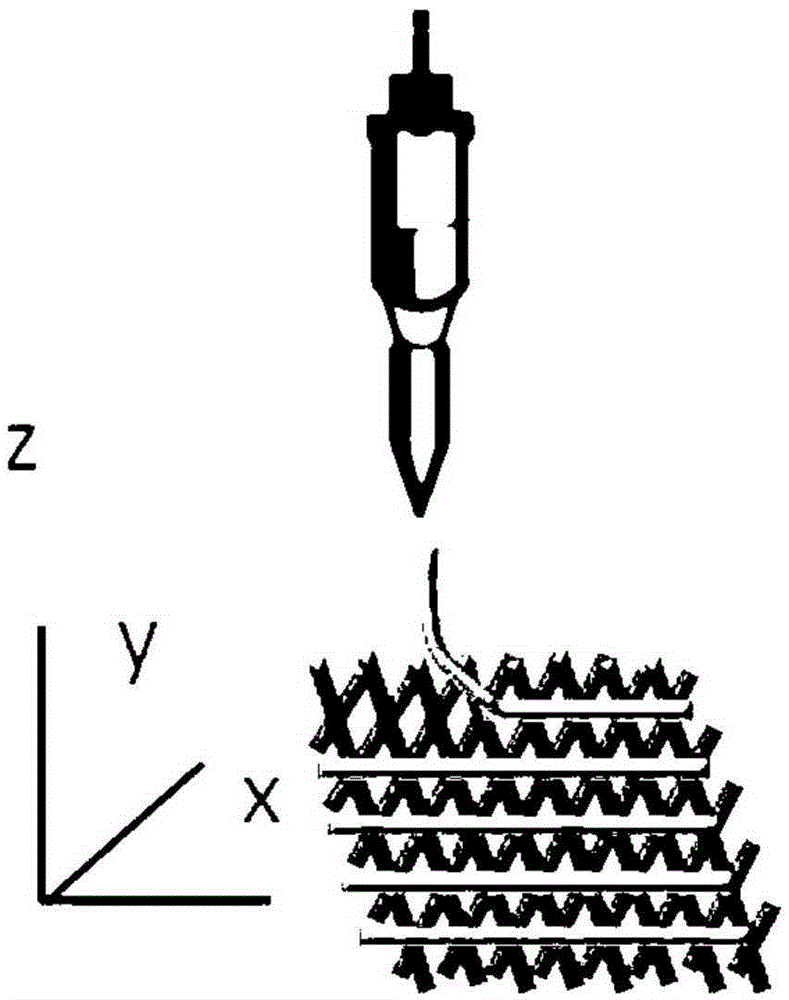

Bionic bone repair material having good machinery performance and biological activity and preparation method thereof

PendingCN106620879AImprove biological activityAchieve activityCoatingsProsthesisBiological activationBiological materials

The invention discloses a bionic bone repair material having good machinery performance and biological activity and a preparation method thereof. The preparation method comprises the following steps: 1) using a rapid moulding technology for performing three-dimensional printing on a large aperture PCL rack to obtain a primary structure; 2) activating the surface of the PCL rack having the primary structure; 3) employing collagen network for performing three-dimensional function activation on the PCL rack having the primary structure to obtain a Col-PCL rack having a secondary structure; and 4) employing nano hydroxyapatite particles for bionic mineralization on the Col-PCL rack to obtain an AP-Col-PCL rack having a third structure; The product combines a rapid moulding technology and a biomaterial three-dimensional modification technology, constructs the bionic bone repair material AP-Col-PCL having good machinery performance and biological activity which, and can be used for bone defect research and clinical treatment.

Owner:GUANGDONG REGEN-MED SCI & TECH LTD

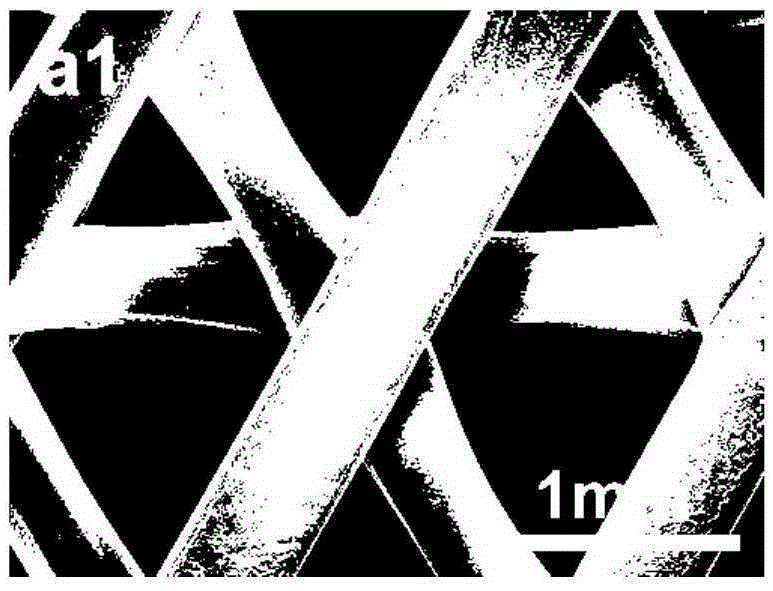

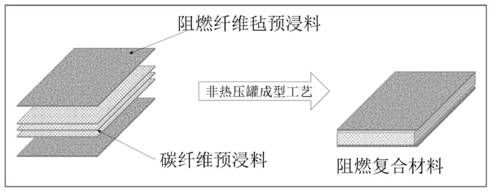

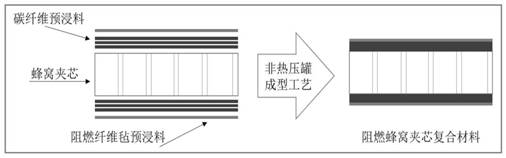

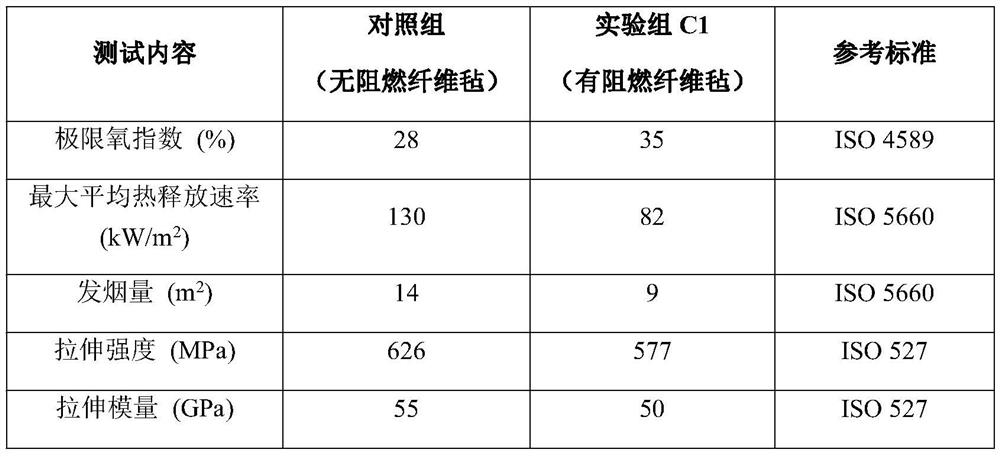

Structural flame-retardant functional composite material and preparation method thereof

ActiveCN112009038AAvoid destructionImprove flame retardant performanceSynthetic resin layered productsLaminationFiberCombustion

The invention provides a structural flame-retardant functional composite material which comprises a flame-retardant fireproof fiber felt and a composite material, and the surface of the composite material body is coated with the flame-retardant fireproof fiber felt. The invention further provides a preparation method of the structural flame-retardant functional composite material. The preparationmethod comprises the following steps: (1) preparing the flame-retardant fireproof fiber felt; (2) pre-impregnating the fiber felt; and (3) preparing the flame-retardant composite material. Compared with the prior art, a surface flame-retardant structure is adopted, the flame-retardant functional structure layer with the functions of flame retardance, heat insulation, smoke suppression and the likeis concentrated on the surface of the composite material based on the combustion behavior that the composite material expands from outside to inside after being ignited, and in the process that the composite material is on fire, the structure can be used as a fireproofing suit to isolate flame and heat outside the composite material so that the internal structure of the material is protected, andthe damage of a flame retardant to the composite material matrix is avoided.

Owner:NINGBO NOTTINGHAM NEW MATERIALS INST CO LTD +1

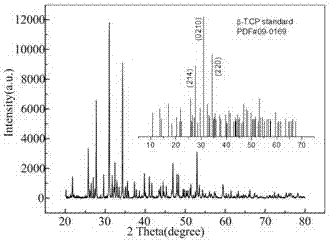

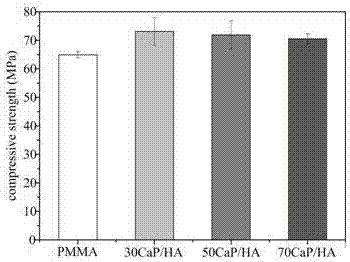

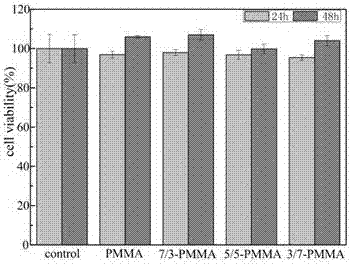

Compound bone cement with high inorganic components as well as preparation method and application of compound bone cement

ActiveCN107041970AMechanical properties are not affectedGood biocompatibilityProsthesisBenzoyl peroxideApatite

The invention discloses compound bone cement with high inorganic components. The compound bone cement contains a solid-phase component and a liquid-phase component, wherein the solid-phase component contains P(MMA-co-MPS) surface-modified hydroxyapatite, polymethyl methacrylate, beta-tricalcium phosphate and benzoyl peroxide, and the liquid-phase component contains methyl methacrylate and dimethyl terephthalate; the mass volume ratio of the solid-phase component to the liquid-phase component of the compound bone cement is 1 to (2.5-3.5); and the sum of P(MMA-co-MPS) surface-modified hydroxyapatite and methyl methacrylate is 35%-40% of weight of the solid-phase component. According to the compound bone cement, tricalcium phosphate (beta-TCP) and P(MMA-co-MPS) surface-modified hydroxyapatite are compounded, and meanwhile, the proper modification degree of p(MMA-co-MPS) to hydroxyapatite is adjusted, so that the mechanical performance of the raw materials is guaranteed, meanwhile, the biological activity of the material is increased, and the degradation speed of the material is proper; and therefore, the compound bone cement has excellent mechanical properties and biological properties.

Owner:SUN YAT SEN UNIV

Preparation method of high-performance heat-insulating composite plate

The invention discloses a preparation method of a high-performance heat-insulating composite plate. The preparation method of the high-performance heat-insulating composite plate particularly comprises the following steps: firstly, preparing cellulose toughened silicon dioxide aerogel particles from a cotton raw material as a raw material; secondly, mixing and stirring the prepared cellulose toughened silicon dioxide aerogel particles and cement uniformly; thirdly, sequentially adding a polycarboxylic acid water reducer, river sand, nanometer titanium dioxide, a foam stabilizer, a curing agentand deionized water, and mixing and stirring uniformly; fourthly, adding a foaming agent and stirring to prepare slurry; and finally, putting the prepared slurry into a mold to perform compression molding, and maintaining, demolding and cutting to prepare the high-performance heat-insulating composite plate. The prepared composite plate has excellent mechanical property and high heat-insulating property.

Owner:DONGGUAN JIAQIAN NEW MATERIAL TECH CO LTD

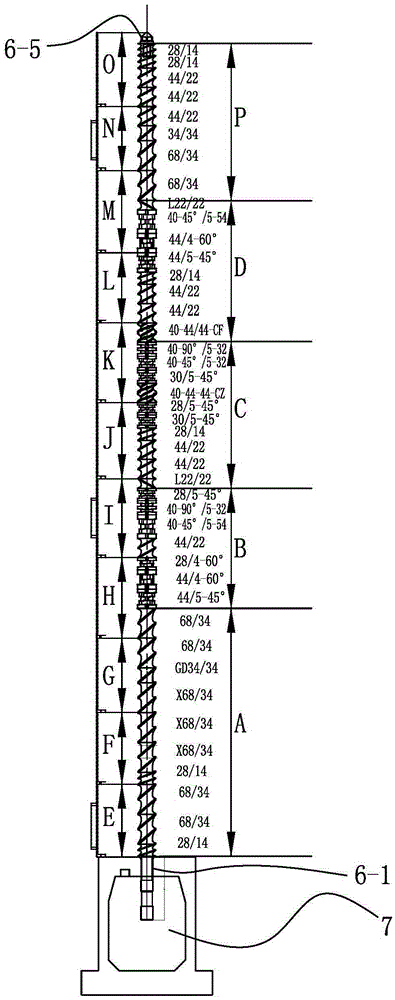

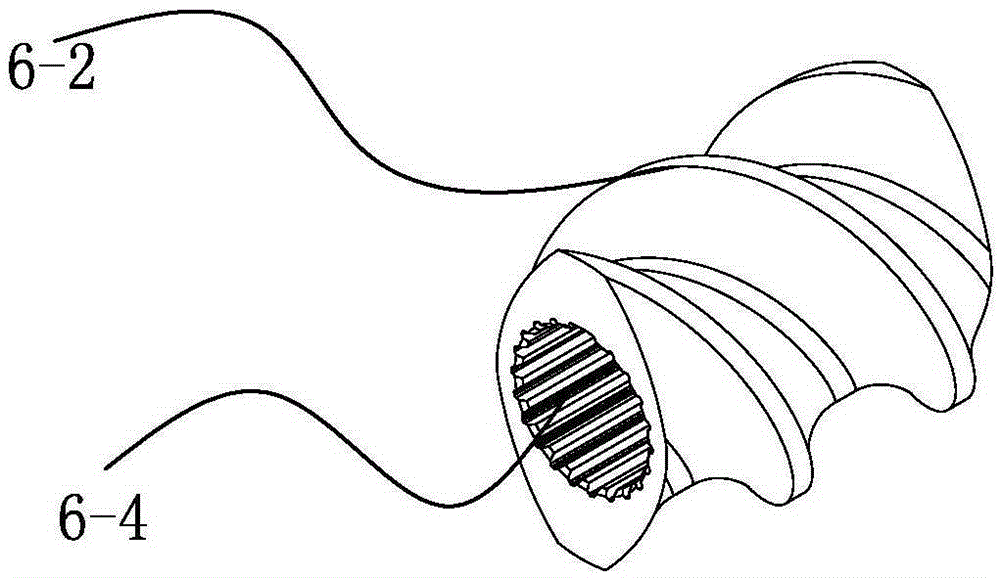

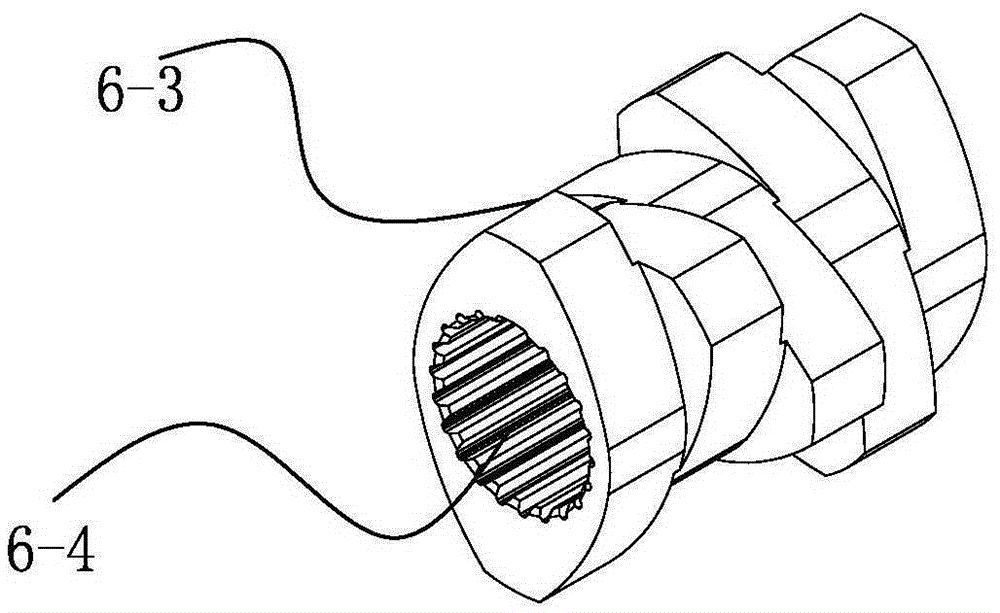

Screw assembly for nano-powder master batch processing

The invention relates to a screw assembly for nano-powder master batch processing. The screw assembly comprises a double-screw extruder and an extruder barrel arranged on the double-screw extruder. Two parallel screws (6) are arranged in the extruder barrel, and a plurality of screw parts of different specifications are installed on each screw (6). The screws (6) are symmetrically arranged in the extruder barrel and rotate in the same direction; by the adoption of the double-screw rotating extrusion mode, friction heat generated when raw materials are extruded is small, the screw meshing shearing effect on the raw materials is stable and uniform, and raw material mixing and plastic quality are good; due to double-screw meshing rotating work, the screw assembly does not affect the mechanical properties of the raw materials, energy is saved, and production cost is lowered.

Owner:嘉兴高正新材料科技股份有限公司

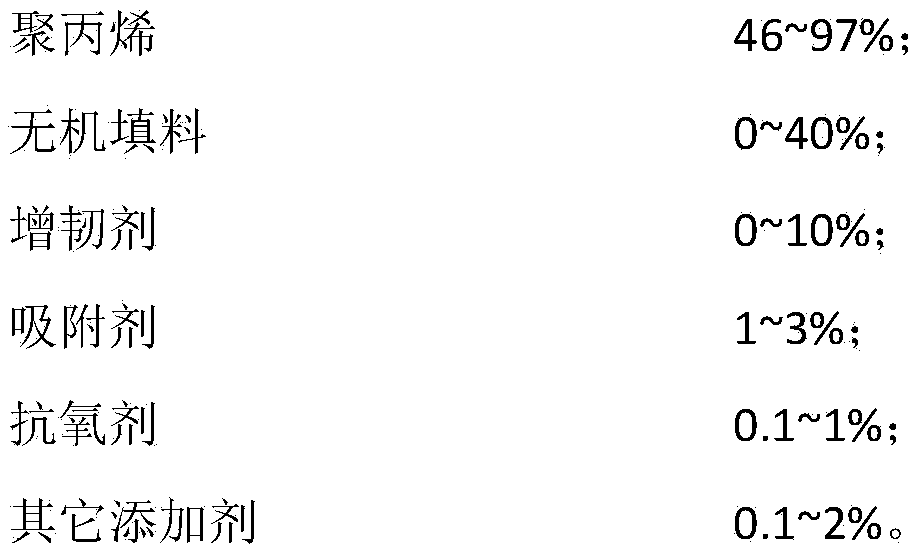

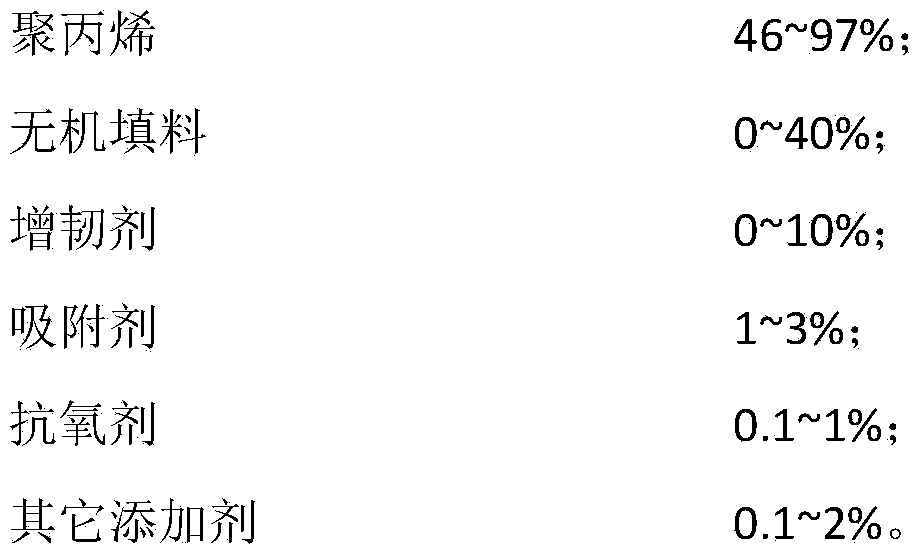

Heat-resisting oxygen aging polypropylene composition with low dispersity and preparation method of heat-resisting oxygen aging polypropylene composition

InactiveCN103724916AReduce sporadicImprove heat and oxygen aging resistanceDispersityPolymer science

The invention discloses a heat-resisting oxygen aging polypropylene composition with low dispersity and a preparation method of the heat-resisting oxygen aging polypropylene composition. The composition is prepared from the following raw materials by weight: 46-97% of polypropylene, 0-40% of inorganic filler, 0-10% of toughening agent, 1-3% of absorbent, 0.1-1% of antioxidant, 0.1-2% of other additives. The preparation method comprises the following steps: weighing the raw materials according to weight percentage, putting the raw materials into a high-speed mixer to dry-blend for 5-15 minutes, adding the mixed raw materials into a double-screw rod extruder, smelting and extruding, subsequently cooling and pelleting so as to prepare the polypropylene composition, wherein a first zone is 190-200 DEG C, a second zone is 200-210 DEG C, a third zone is 210-220 DEG C and a fourth zone is 205-215 DEG C, the retaining time in the whole extrusion process is 1-2 minutes, and the pressure is 12-18Mpa. The heat-resisting oxygen aging polypropylene composition has the advantages that low molecular weight compounds are effectively adsorbed and the dispersity is reduced as the additives are added into the polypropylene composition, acid substances, residual catalyst and the like in the composition are adsorbed and cleaned, so that the heat-resisting oxygen aging property is improved.

Owner:ZHEJIANG PRET NEW MATERIALS +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com