Patents

Literature

40results about How to "Reduce sporadic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

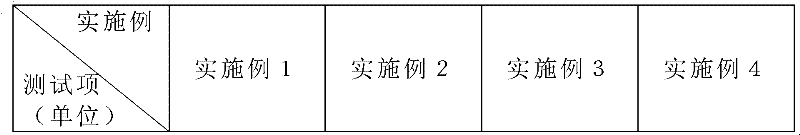

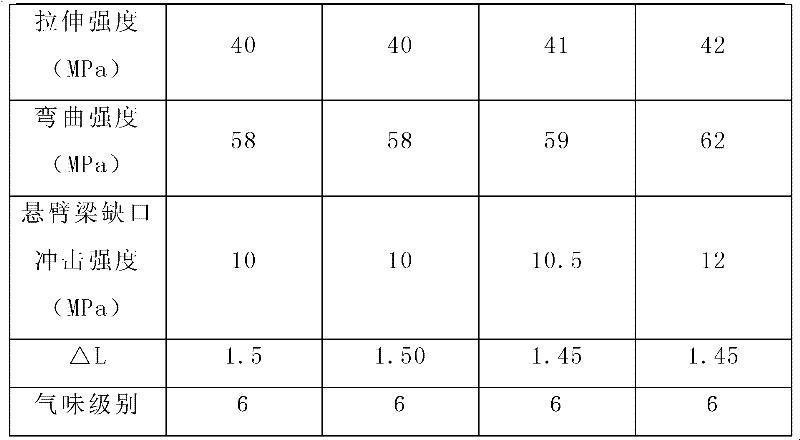

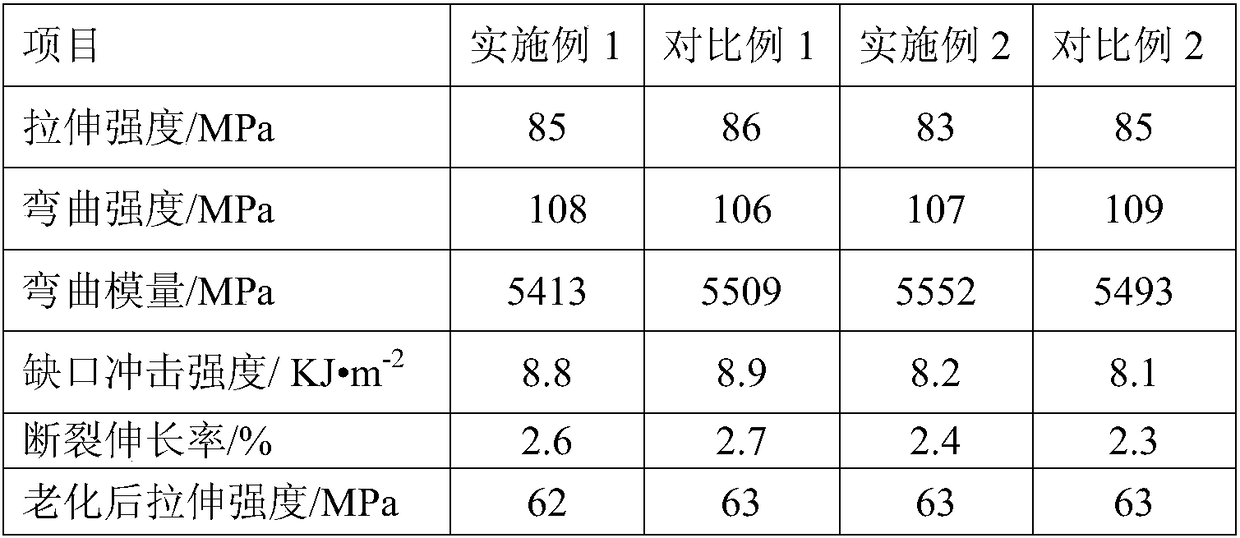

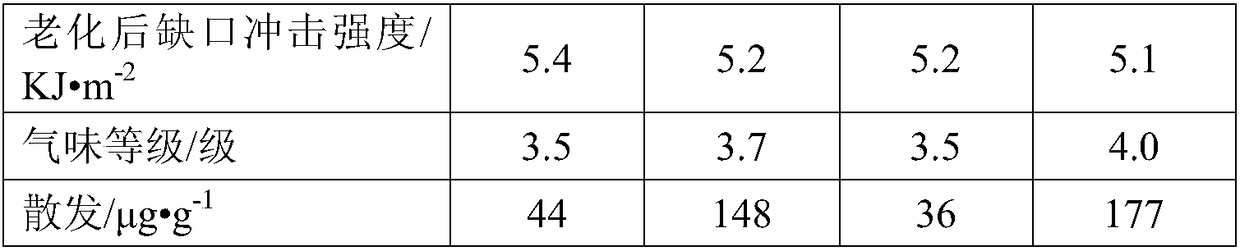

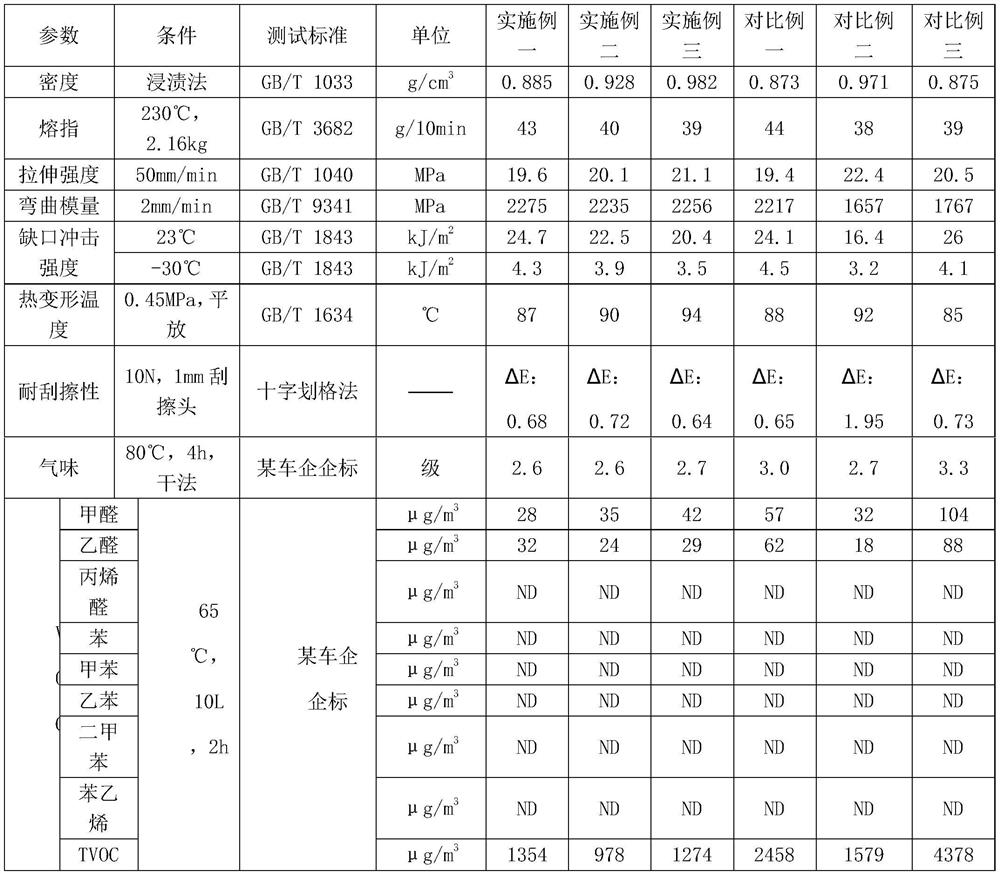

Low-odor scraping-resistant polypropylene material and preparation method thereof

The invention relates to a low-odor scraping-resistant polypropylene material and a preparation method of the low-odor scraping-resistant polypropylene material and belongs to the technical field of polypropylene materials. In order to solve the technical problems that the odor of the polypropylene material in the prior art is difficult to eliminate, the odor can be eliminated only through aiming at a certain single ingredient, the scraping resistance is poor, and the production cost is high when fluorine-containing polymers are adopted for production. The invention provides the low-odor scraping-resistant polypropylene material and also provides the preparation method of the polypropylene material, wherein the polypropylene material comprises acrylic resin, nanometer silicon dioxide, ultra-fine talcum powder, odor eliminating agents, disperse lubricating agents, antioxidants and hindered amine light stabilizers, the method comprises material mixing and squeezing granulation steps, and the low-odor scraping-resistant polypropylene material is obtained. The polypropylene material provided by the invention has the advantages of low odor and scraping resistance. The product obtained from the material has the advantage that the performance such as tensile strength, bending strength, cantilever beam notch impact strength and delta L is high. The method has the advantages that the process is simple, the operation is easy, raw materials are easy to obtain, and the industrial production is favorably realized.

Owner:浙江明江新材料科技股份有限公司

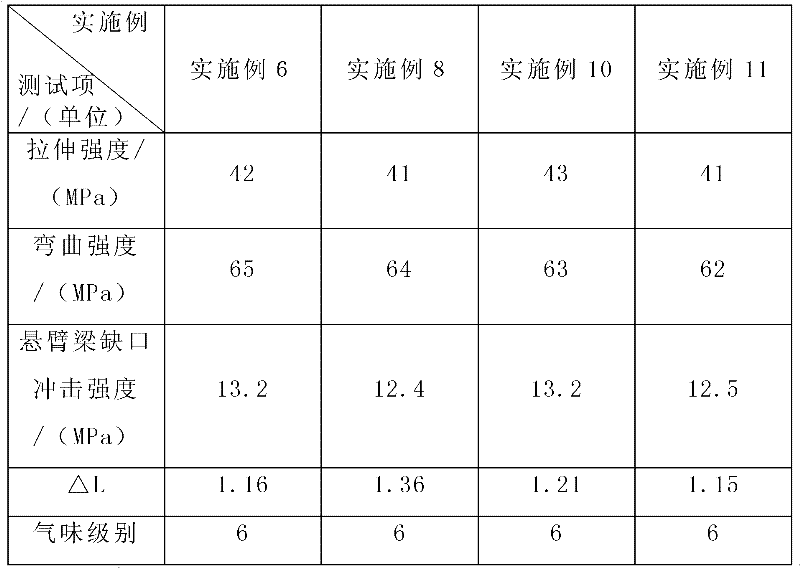

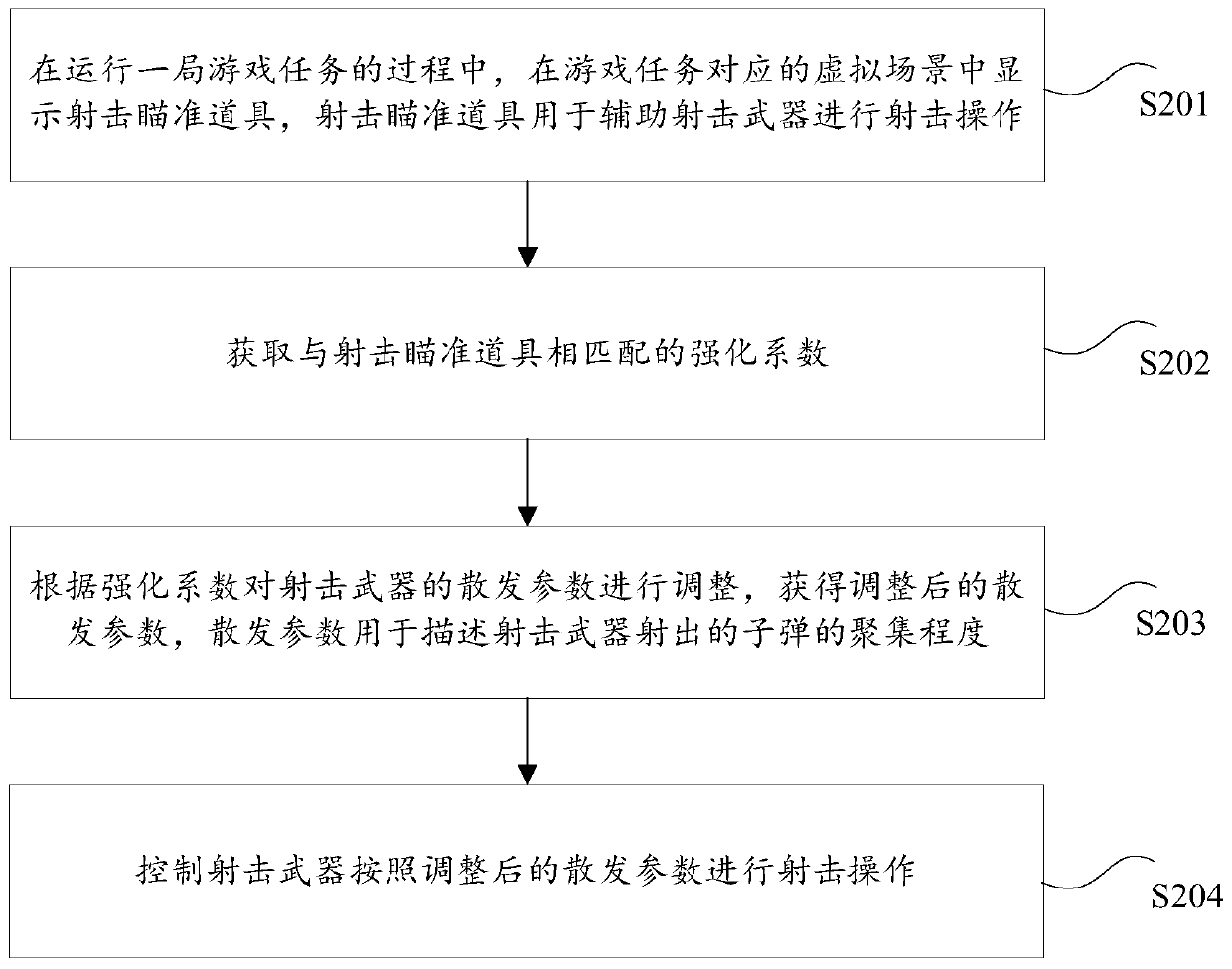

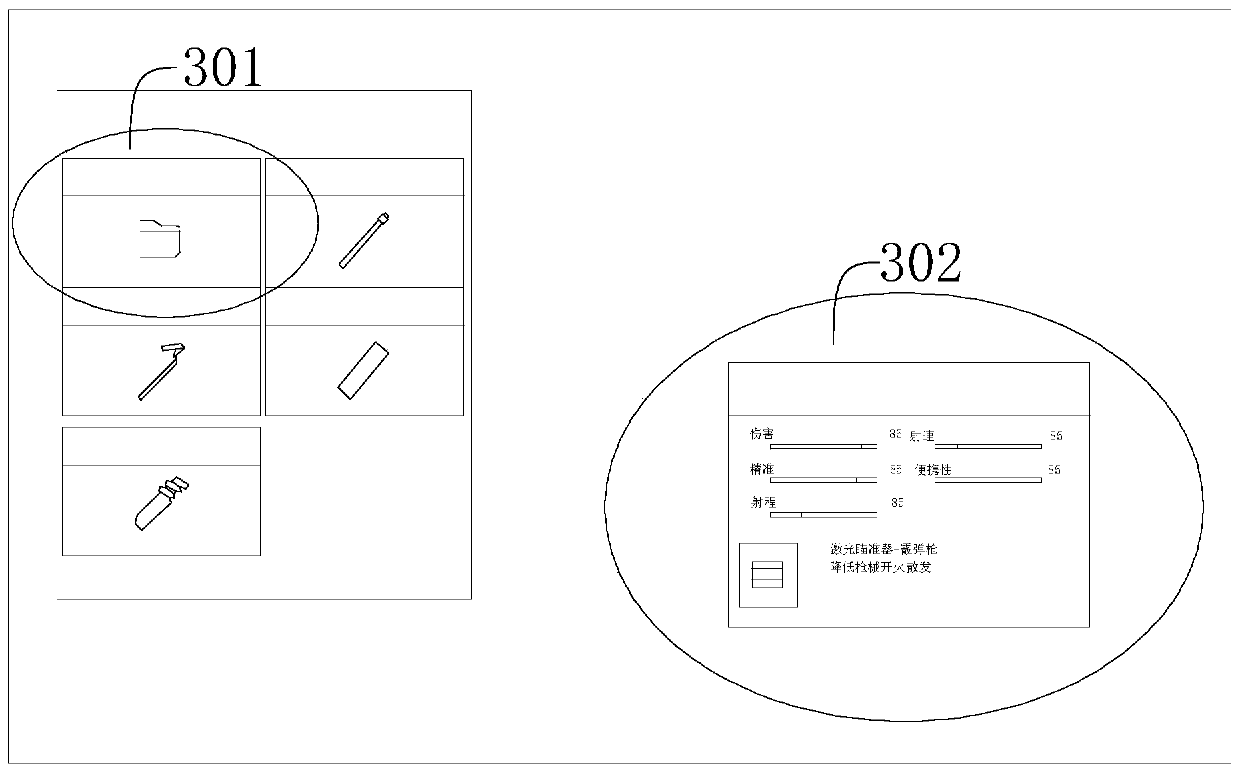

Operation control method and device, storage medium and electronic device

Owner:TENCENT TECH (SHENZHEN) CO LTD

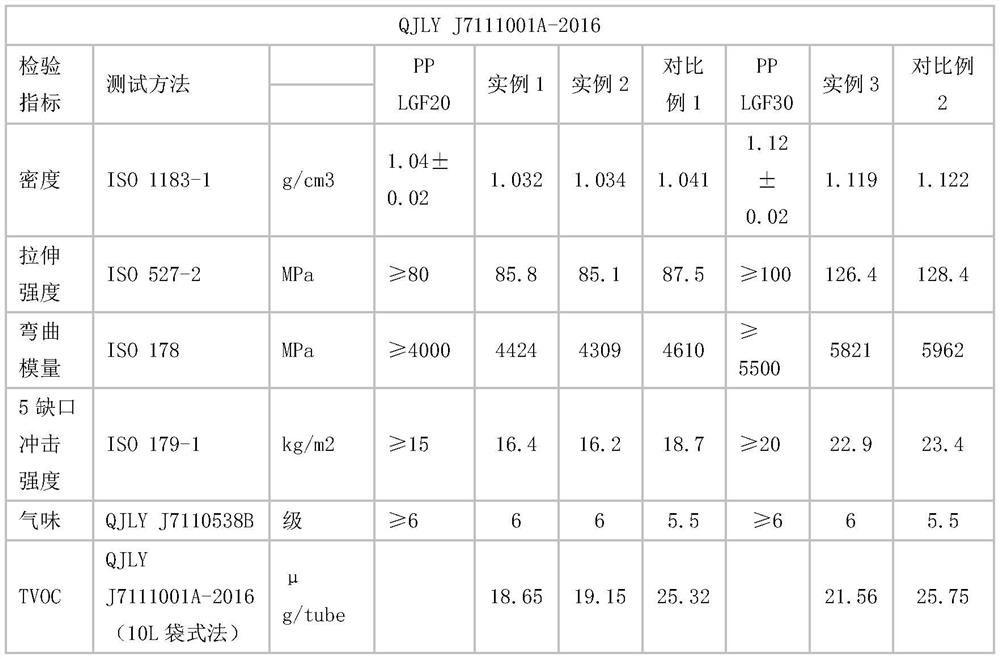

Low-emission low-odor glass-fiber-reinforced polypropylene composite material and preparation method therefor

The invention discloses a low-emission low-odor glass-fiber-reinforced polypropylene material and a preparation method therefor. The material is prepared from the following raw materials in parts by weight: 35-80 parts of polypropylene, 15-60 parts of glass fibers, 1.0-5 parts of compatibilizer and 0.1-1.5 parts of antioxidant. According to the material and the preparation method therefor, hindered phenol and hindered amine polymers are adopted as the antioxidant, an obtained sample has the same excellent aging resistance as that of a control sample, and the sample prepared by the method has alower odor level and lower emission performance.

Owner:CHONGQNG PRET NEW MATERIAL +4

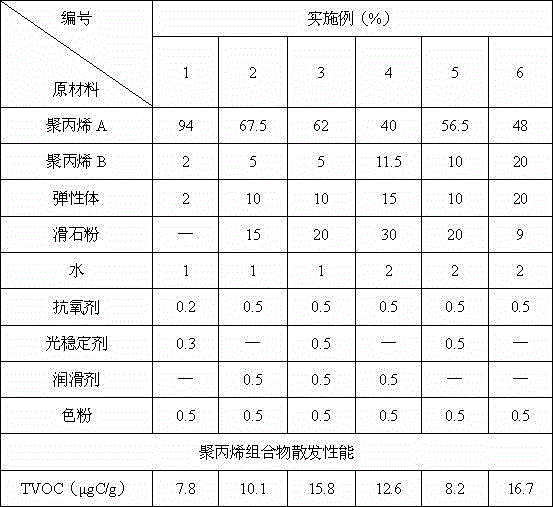

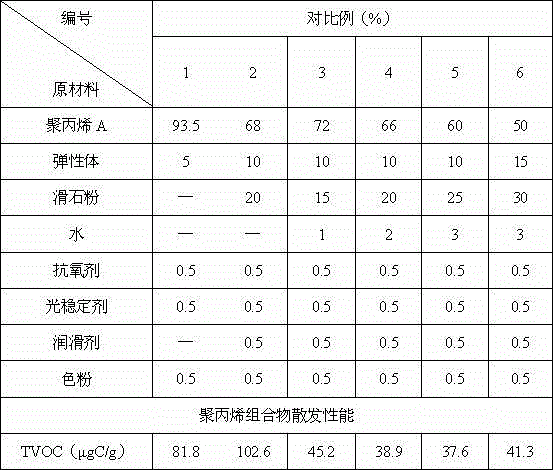

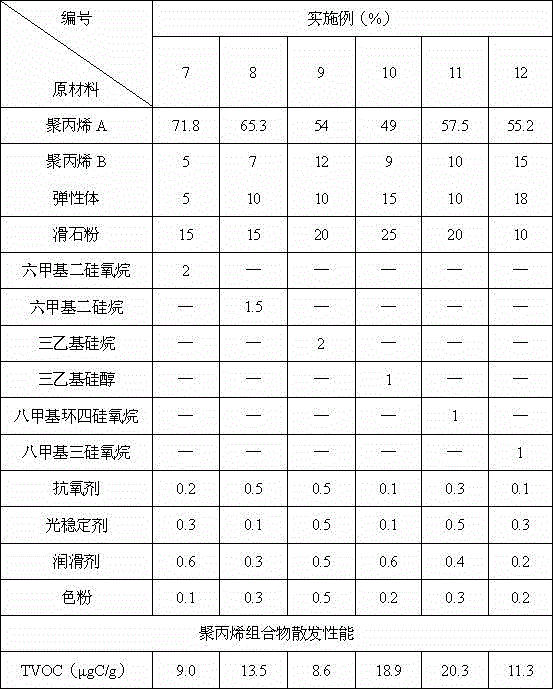

Vehicular low-emission polypropylene composition and preparation method thereof

The invention discloses a vehicular low-emission polypropylene composition and a preparation method thereof. The vehicular low-emission polypropylene composition comprises the following components in weight percentage: 40-94% of polypropylene A, 2-20% of polypropylene B, 2-20% of elastomer, 1-2% of liquid extractant, 0-30% of talcum powder and 1-3% of auxiliary agent. The preparation method comprises the following steps: firstly, mixing the polypropylene A, the polypropylene B, the elastomer, the liquid extractant and the auxiliary agent for 1-2 minutes in a high-speed mixer; secondly, adding the talcum powder and mixing for 3-5 minutes to obtain a premix; and finally, melting and extruding the premix by a twin-screw extruder, and performing two-stage vacuum granulation to obtain a finished product. Emission of free organic matters in the vehicular polypropylene can be reduced by introducing the polypropylene with a high melt strength and the liquid extractant; two-stage vacuum devolatilization can prolong the effective acting time of the time in the system, so that the prepared composition has a lower emission characteristic; and the preparation method is simple in process, low in equipment requirement and high in product yield.

Owner:KINGFA SCI & TECH CO LTD +2

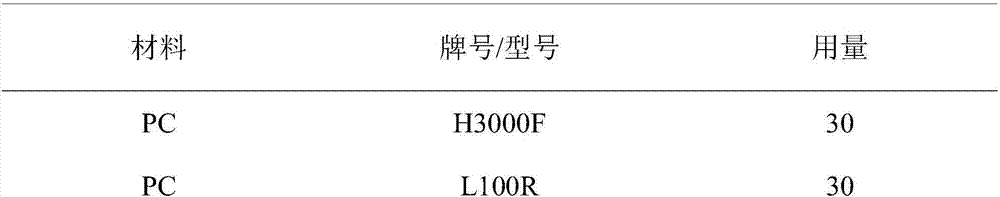

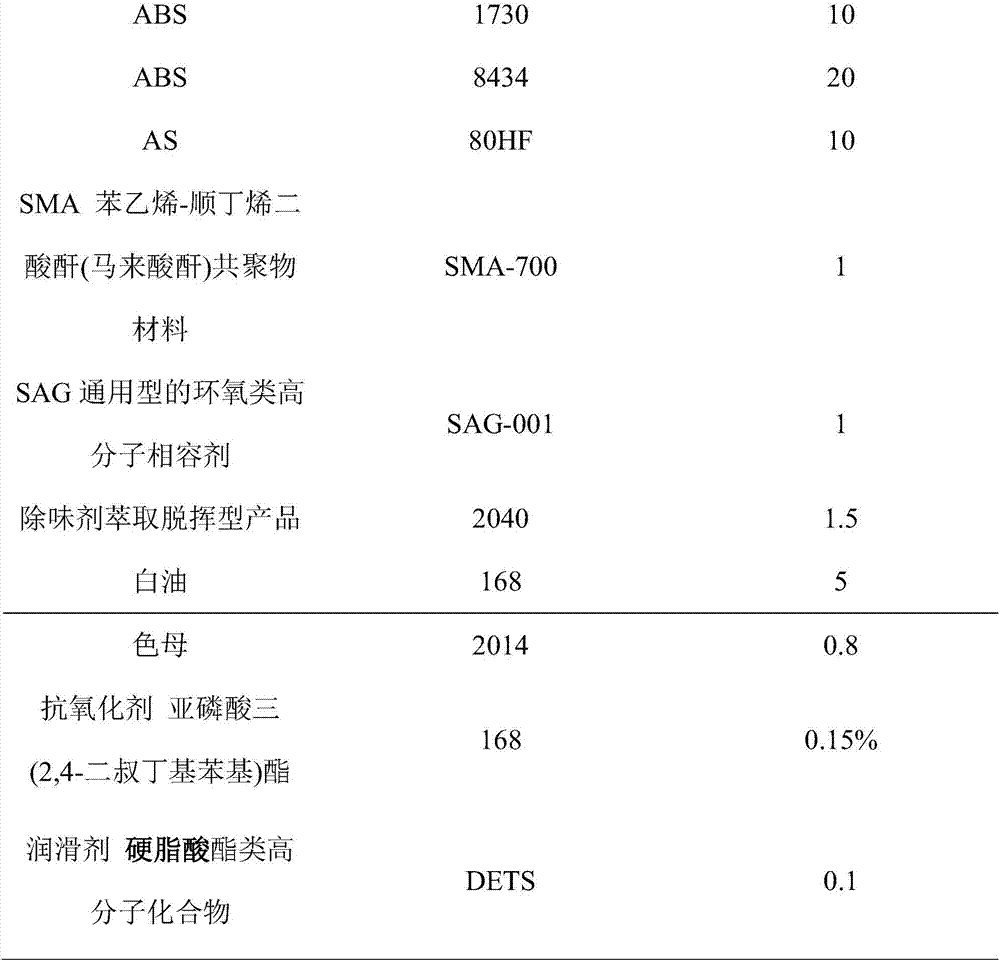

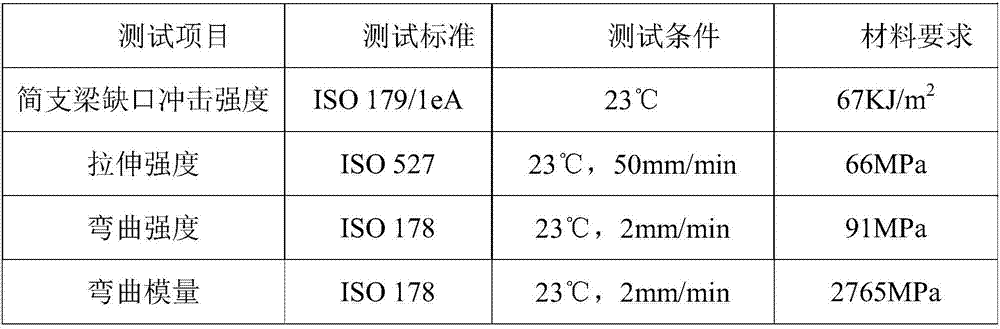

Low-odor spray-coating-free PC/ABS (polycarbonate/acrylonitrile butadiene styrene) material and preparation method thereof

The invention discloses a low-odor spray-coating-free PC / ABS (polycarbonate / acrylonitrile butadiene styrene) material and a preparation method thereof. The material is prepared from the following ingredients including 40 to 80phr of PC, 20 to 60phr of ABS, 5 to 10phr of AS, 0 to 1phr of lubricating agents, 1 to 1.5phr of deodorants, 0.5 to 1phr of heat stabilizers, 0.5 to 1phr of color masterbatch, 0 to 10phr of compatibilizers, 0 to 5phr of processing auxiliary agents, 0.1 to 0.5phr of antioxidants and 0 to 5phr of ultraviolet light absorbers. The material has the low odor and spray-coating-free appearance requirements; the odor grade is lower than or equal to 3.0; the appearance luster is good; the blackness is high; the thermal stability is high; the defects of flowing marks, melting and connecting wires, silver silks and the like cannot be easily generated; the spraying work procedure is omitted; the good spray-coating-free effect is achieved; through the creative selection on raw materials and auxiliary agents and the process innovation, a low-odor spray-coating-free PC / ABS material is produced, and is obviously superior to similar products in the market.

Owner:太仓市华鼎塑料有限公司

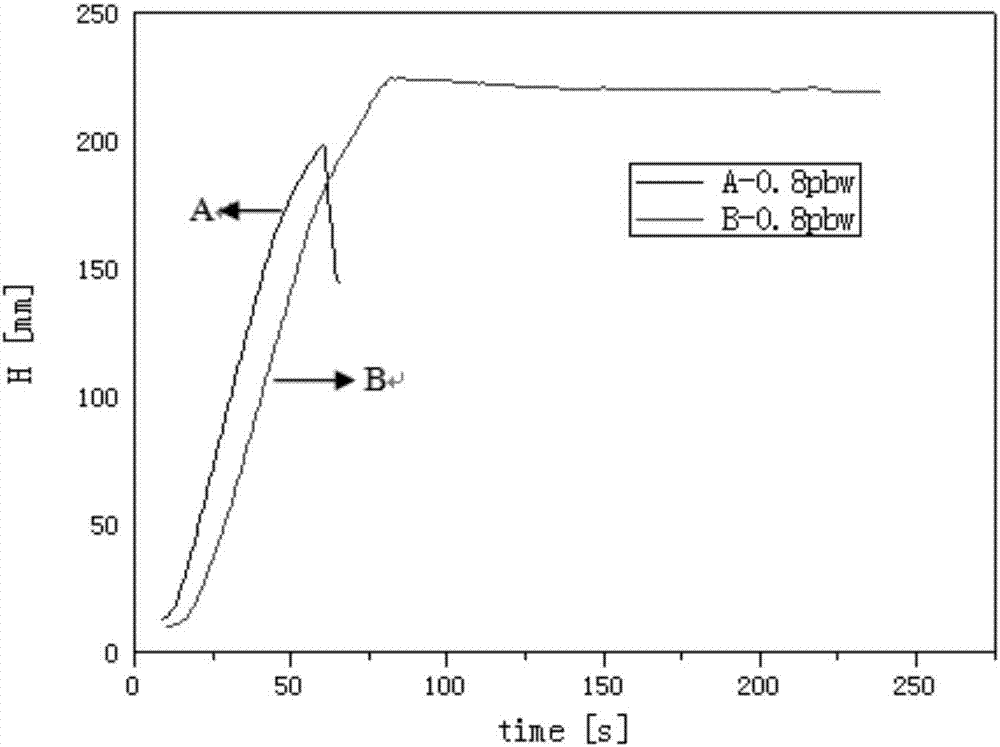

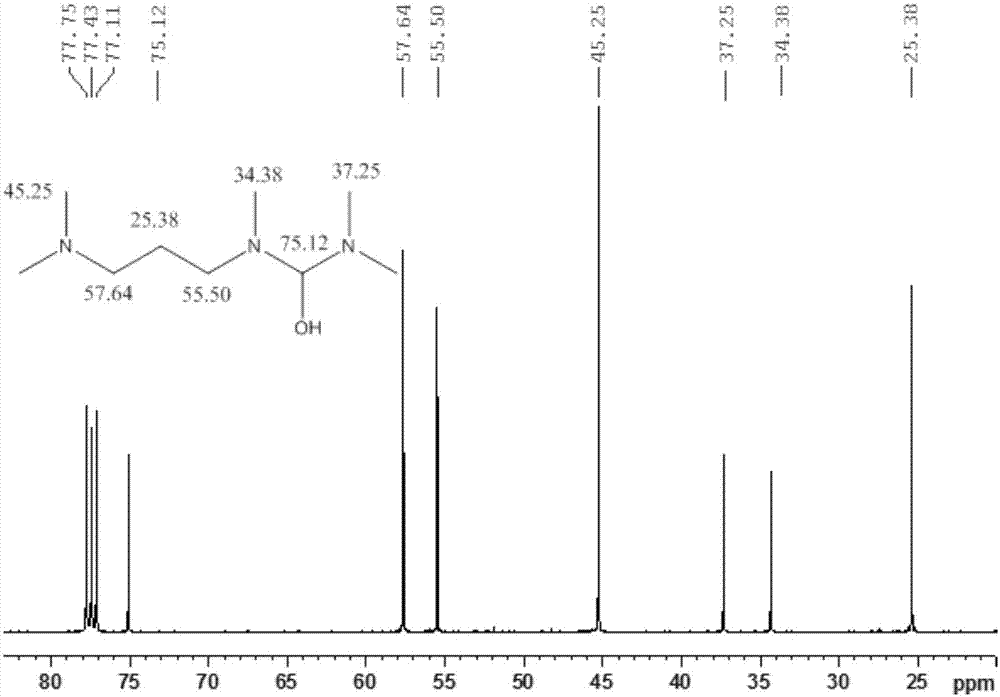

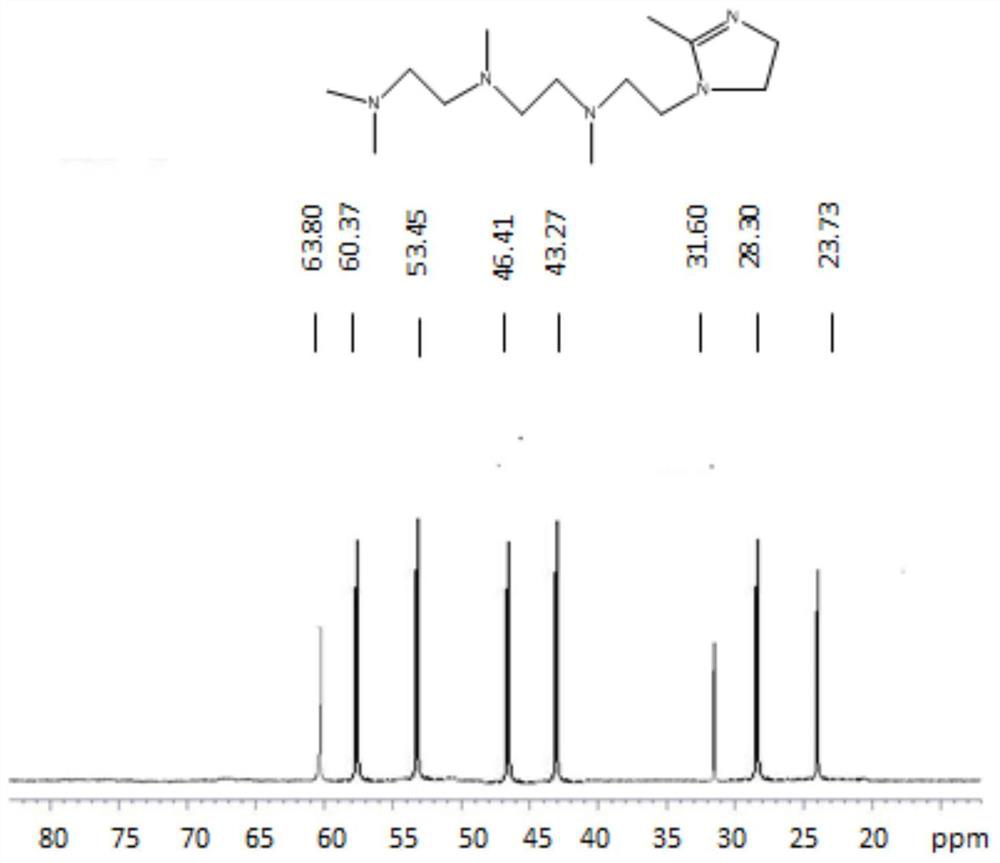

Low-diffusion reactive-type tertiary amine catalyst, and preparation method and application of same

The invention provides a low-diffusion reactive-type tertiary amine catalyst, and a preparation method and an application of same. The catalyst is composed of the compound I or the compound II, or isa mixture of the two compounds. The catalyst is mainly used for producing water-foaming soft polyurethane foam materials. The prepared polyurethane foam is excellent in physical performance and low inVOC and odor.

Owner:WANHUA CHEM GRP CO LTD

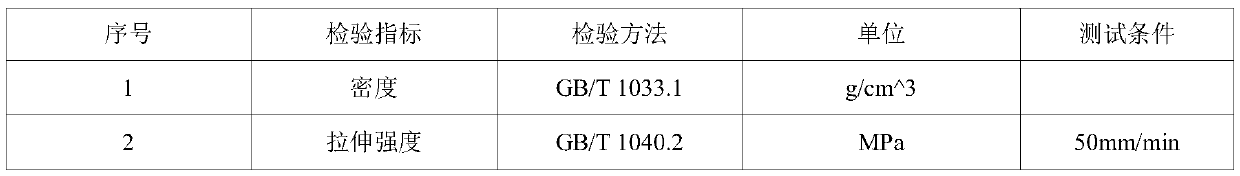

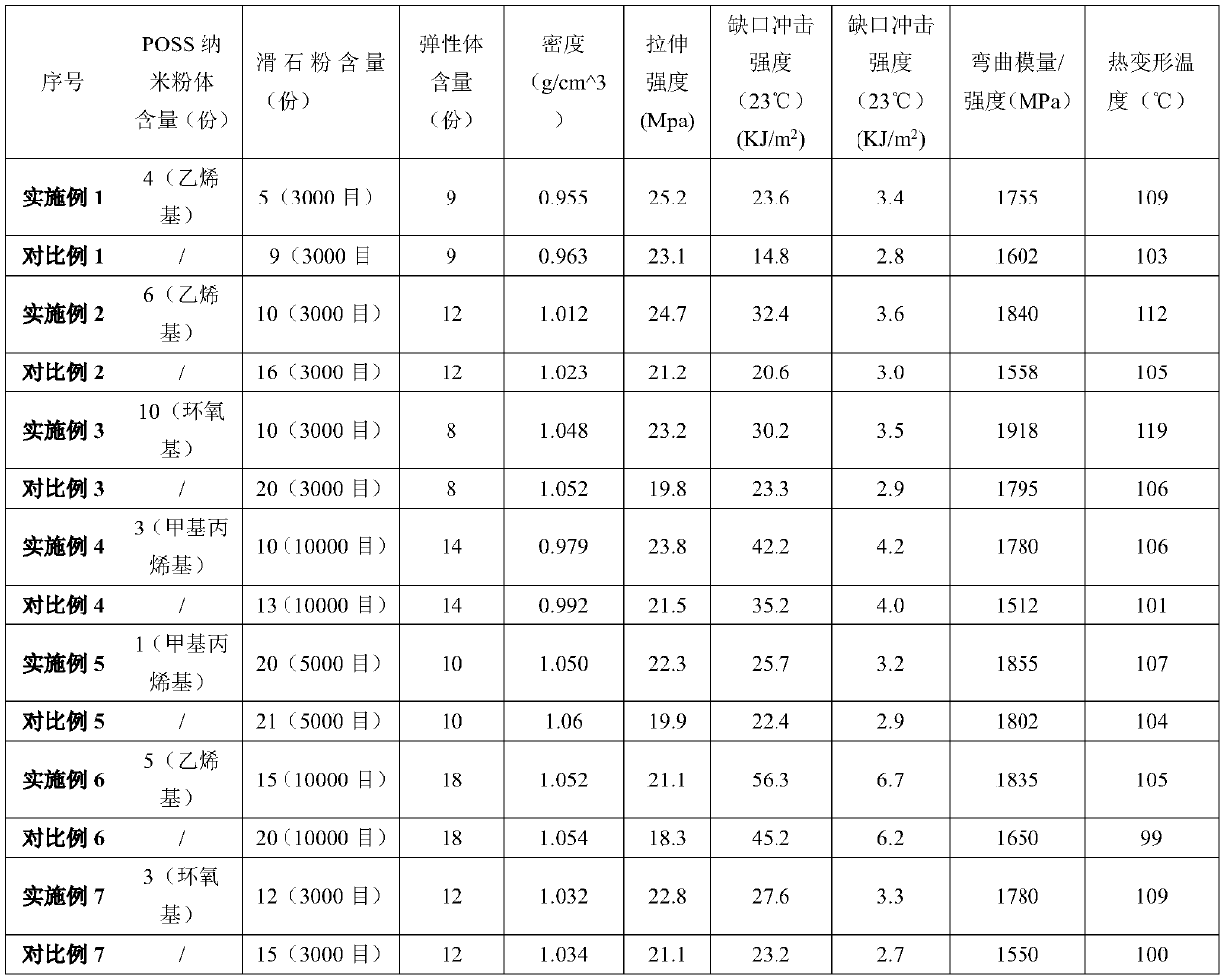

High-performance automotive modified polypropylene composite material based on functional POSS hybridization and preparation method thereof

The invention discloses a high-performance automotive modified polypropylene composite material based on functional POSS hybridization and a preparation method thereof. The modified polypropylene material is mainly composed of 1 to 10 parts of functionalized POSS nanometer powder, 45 to 90 parts of conventional polypropylene, 5 to 20 parts of talcum powder, 0 to 15 parts of an elastomer, 0.1 to 1.5 parts of an antioxidant and 0 to 3 parts of auxiliary agents. Compared with a traditional talcum powder modified polypropylene material, the material provided by the invention has the following advantages: due to introduction of functionalized POSS nanoparticles, the modified polypropylene material shows better mechanical properties; and specifically, the heat resistance and the low-temperatureimpact resistance of the modified polypropylene material are superior to the heat resistance and the low-temperature impact resistance of a common talcum powder filled polypropylene material mainly due to the fact that a functionalized POSS structure plays roles of a compatilizer and a nucleating agent in a system. Meanwhile, VOC and odor test results show that the modified polypropylene materialhas the characteristics of low VOC and low odor possibly due to the facts that the thermal stability is improved, and a hollow structure of POSS facilitates capturing unpleasant odor of small molecules.

Owner:SHANGHAI PRET COMPOSITES +3

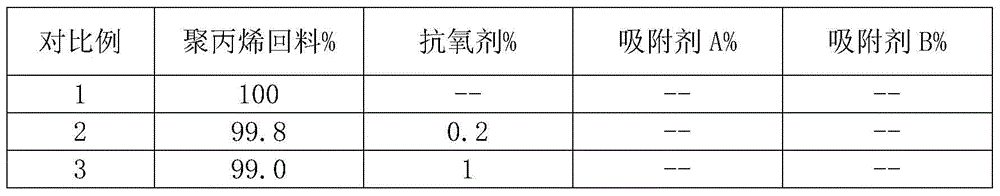

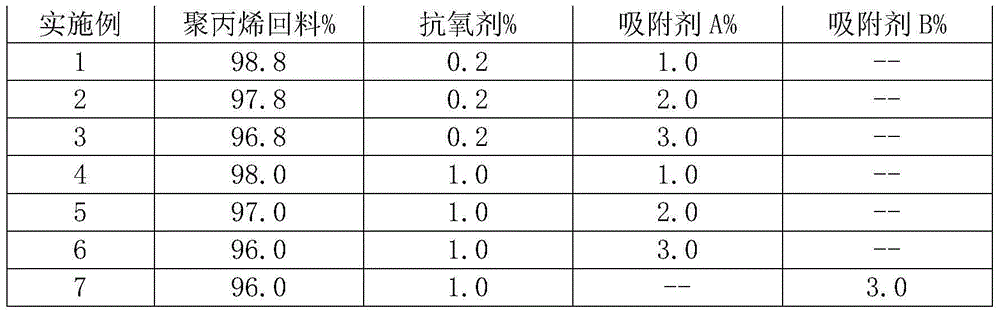

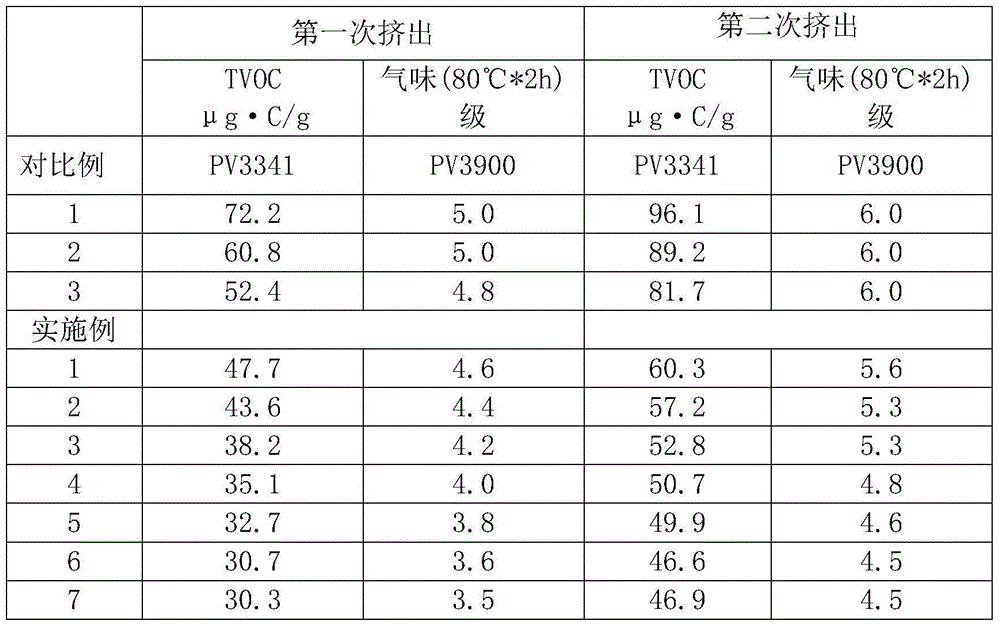

Low-emission polypropylene reclaimed material and preparation method thereof

The invention discloses a low-emission polypropylene reclaimed material and a preparation method thereof. The polypropylene reclaimed material is composed of the following components in percentage by weight: 96.0-98.8% of polypropylene reclaimed material, 1.0-3.0% of adsorbent and 0.2-1.0% of antioxidant. The secondary processing on the polypropylene reclaimed material can aggravate the degree of oxidative degradation. The adsorbent added into the polypropylene reclaimed material can effectively adsorb low-molecular compounds, and meanwhile, adsorb and remove the acidic substances and residual catalyst in the melt, thereby inhibiting the material from further degradation and further effectively reducing the influence of the oxidative degradation of the polypropylene reclaimed material on the emission performance in the secondary processing process.

Owner:CHONGQNG PRET NEW MATERIAL +2

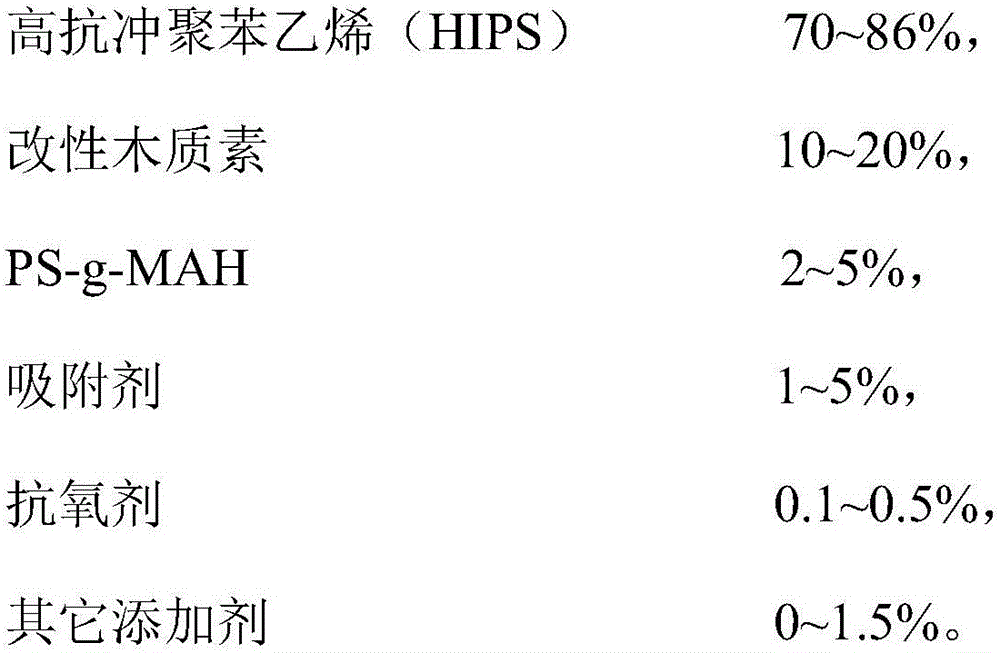

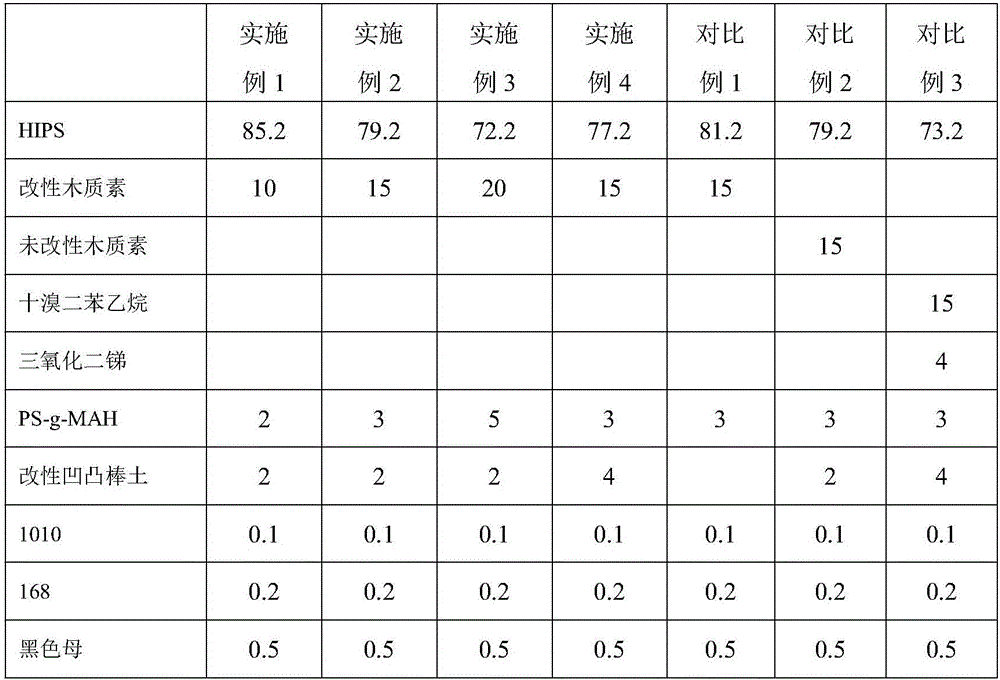

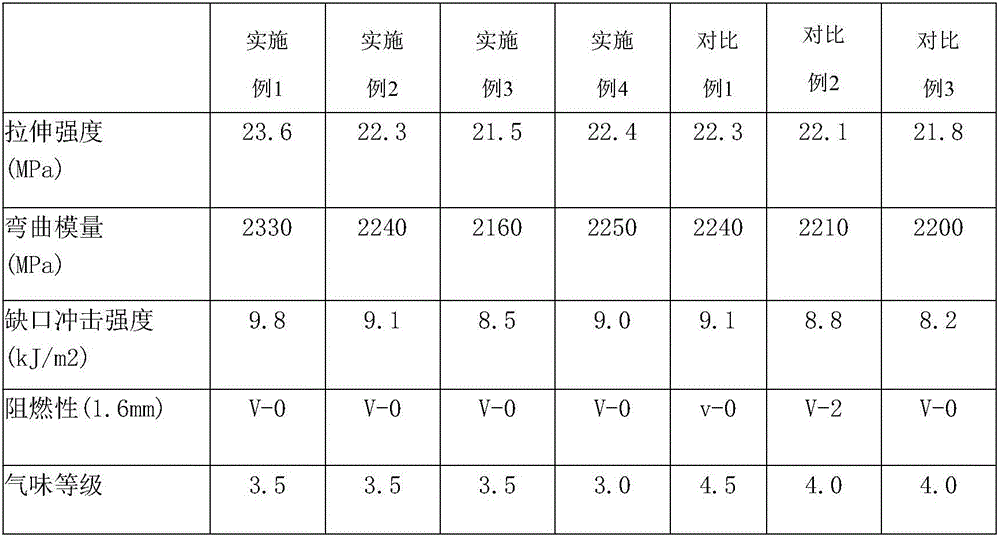

Low-emission flame-retardant polystyrene material and preparation method thereof

The invention discloses a low-emission flame-retardant polystyrene material and a preparation method thereof. The low-emission flame-retardant polystyrene material is prepared from the following raw materials in percentage by weight: 70-86% of HIPS, 10-20% of modified lignin, 2-5% of polystyrene-g-maleic anhydride, 1-5% of an adsorbent, 0.1-0.5% of an antioxidant and 0-1.5% of other additive. The low-emission flame-retardant polystyrene material has the advantages that (1) a traditional flame retardant is replaced with the flame-retardant element-grafted modified lignin containing nitrogen and phosphorus, the polystyrene material is prepared to maintain original mechanical property, and meanwhile, the polystyrene material also has low emission and a good flame-retardant effect; and (2) the prepared polystyrene material is simple in production technology, relatively low in cost and easy to industrialize.

Owner:SHANGHAI PRET COMPOSITES +4

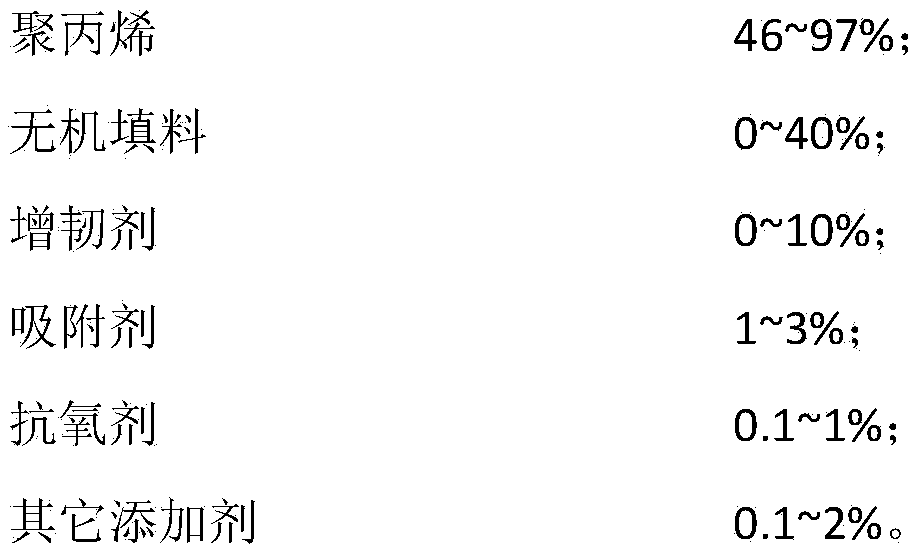

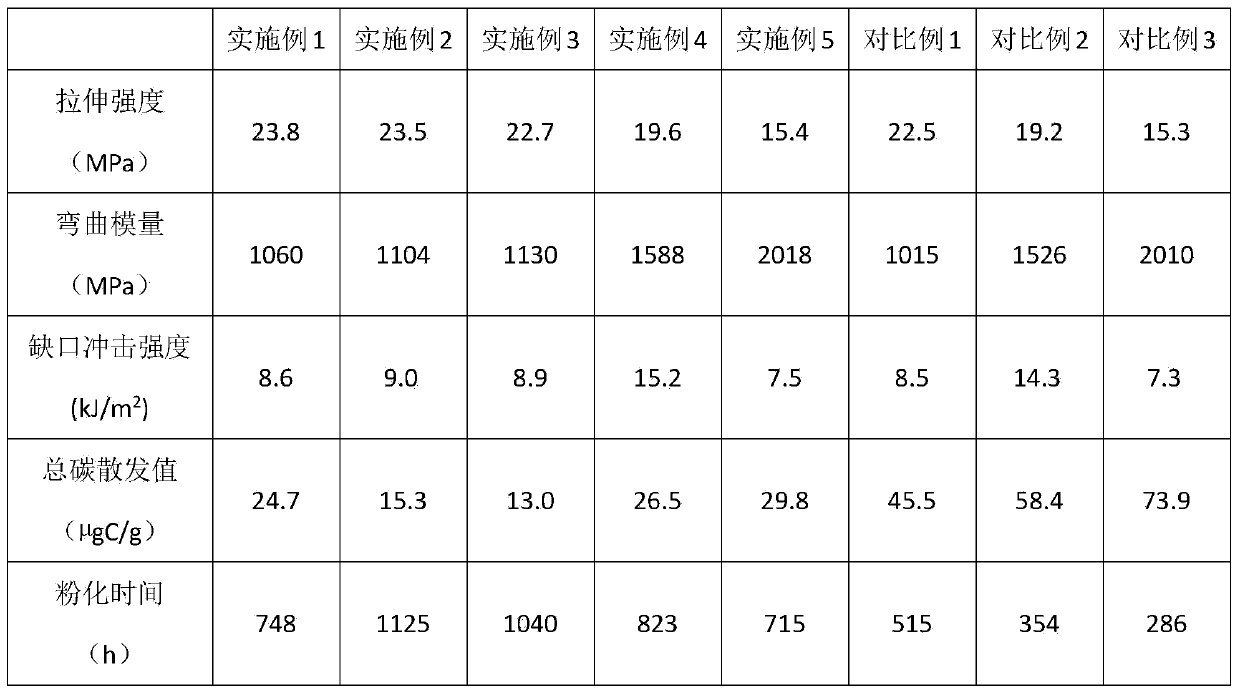

Heat-resisting oxygen aging polypropylene composition with low dispersity and preparation method of heat-resisting oxygen aging polypropylene composition

InactiveCN103724916AReduce sporadicImprove heat and oxygen aging resistanceDispersityPolymer science

The invention discloses a heat-resisting oxygen aging polypropylene composition with low dispersity and a preparation method of the heat-resisting oxygen aging polypropylene composition. The composition is prepared from the following raw materials by weight: 46-97% of polypropylene, 0-40% of inorganic filler, 0-10% of toughening agent, 1-3% of absorbent, 0.1-1% of antioxidant, 0.1-2% of other additives. The preparation method comprises the following steps: weighing the raw materials according to weight percentage, putting the raw materials into a high-speed mixer to dry-blend for 5-15 minutes, adding the mixed raw materials into a double-screw rod extruder, smelting and extruding, subsequently cooling and pelleting so as to prepare the polypropylene composition, wherein a first zone is 190-200 DEG C, a second zone is 200-210 DEG C, a third zone is 210-220 DEG C and a fourth zone is 205-215 DEG C, the retaining time in the whole extrusion process is 1-2 minutes, and the pressure is 12-18Mpa. The heat-resisting oxygen aging polypropylene composition has the advantages that low molecular weight compounds are effectively adsorbed and the dispersity is reduced as the additives are added into the polypropylene composition, acid substances, residual catalyst and the like in the composition are adsorbed and cleaned, so that the heat-resisting oxygen aging property is improved.

Owner:ZHEJIANG PRET NEW MATERIALS +2

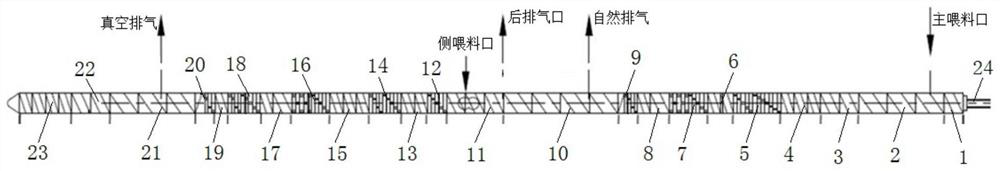

Low-density and low-diffusivity polypropylene material and preparation method thereof

The invention discloses a polypropylene material with low density and low diffusivity. The polypropylene material comprises the following components in parts by weight: 70-90 parts of polypropylene resin, 0.1-10 parts of elastomer, 3-10 parts of filler, 1-5 parts of deodorant, 1-5 parts of assistant master batch and 1-2 parts of foaming agent, the alloy material has the advantages of favorable flowability, low density and higher rigidity and toughness, and can satisfy the performance requirements for thin-walled automotive upholstery. The invention also discloses a preparation method of the material. The preparation method comprises the following steps: S1, weighing raw materials; S2, conveying polypropylene resin and an elastomer into a double-screw extruder through a main feeding assembly, uniformly mixing a deodorant and the auxiliary master batch, conveying the mixture into the double-screw extruder through an auxiliary feeding assembly, conveying a filler into the double-screw extruder through a side feeding assembly, mixing, melting, extruding, bracing, cooling and pelletizing to obtain an intermediate product; and S3, performing devolatilization treatment on the intermediateproduct to obtain the low-density and low-emission polypropylene material, and the preparation method is simple in process, easy in condition control and suitable for large-scale production.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

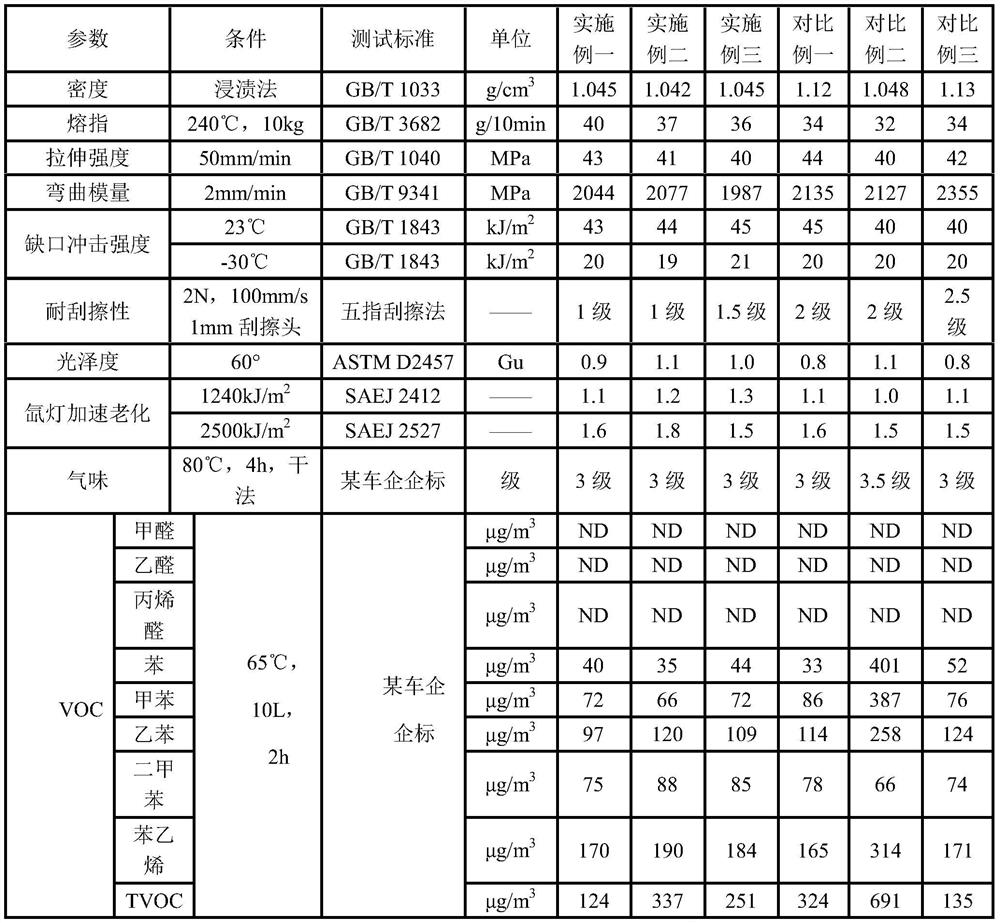

Matte low-density spraying-free material for automotive interiors and preparation method thereof

The invention discloses a matte low-density spraying-free material for automotive interiors. The matte low-density spraying-free material comprises the following components in percentage by weight: 10-40% of ASA high glue powder, 20-50% of polyamide resin, 5-25% of SAN resin, 5-10% of ASA-g-GMA resin, 3-10% of composite filler, 5-15% of auxiliary master batch, 1-5% of deodorant and 1-5% of anti-scratch additive. The composite filler comprises a silane modified filler and hollow glass beads; the diameter of the hollow glass beads is 15-100 microns, and the surfaces of the hollow glass beads aretreated by a silane coupling agent so that the hollow glass beads have relatively low odor and VOC, relatively low gloss, relatively good scratch resistance, weather resistance and processability andrelatively low material density. The invention further discloses a preparation method of the matte low-density spraying-free material for the automotive interiors, the process is simple, and large-scale production can be achieved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

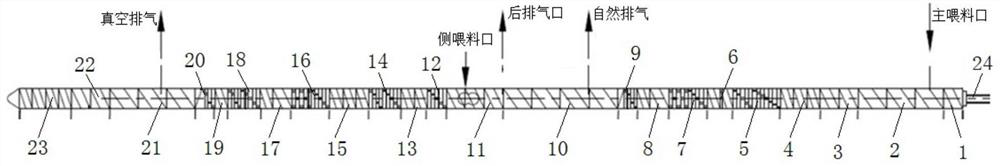

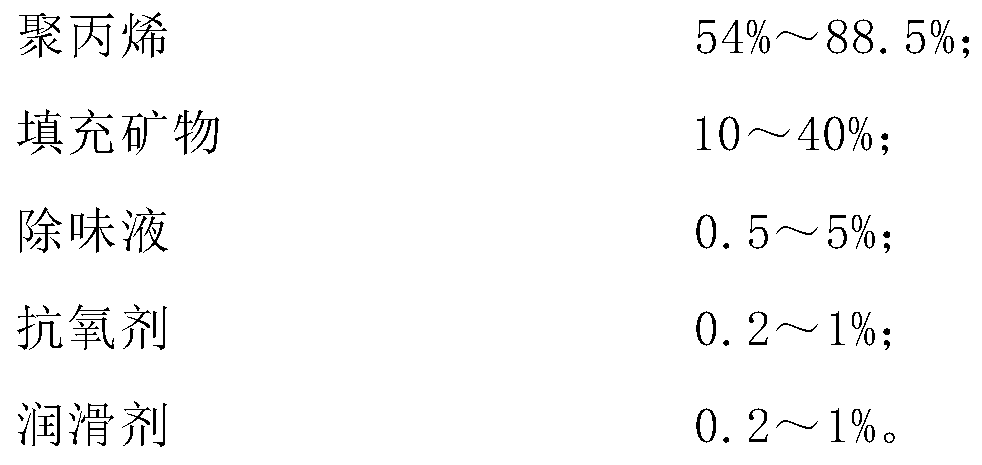

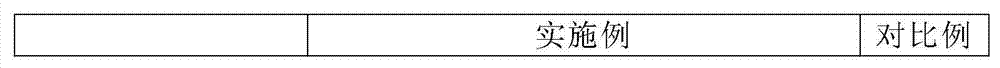

Low-odor mineral reinforced polypropylene composite material and preparation method thereof

The invention discloses low-odor mineral reinforced polypropylene composite material and a preparation method thereof. The material is prepared from the following components in percentage by weight: 54-88.5% of polypropylene, 10-40% of filling minerals, 0.5-5% of an odor removing liquid, 0.2-1% of an antioxidant and 0.2-1% of a lubricant. The preparation method comprises the following steps: mixing the raw materials except the odor removing liquid in a high-speed mixer and discharging; putting the mixed raw materials into a main feeding opening of a twin-screw extruder; metering and inputting the odor removing liquid from a side feeding opening by virtue of a centrifugal pump; vacuumizing; carrying out melt extrusion and prilling by virtue of the twin-screw extruder to prepare the low-odor mineral reinforced polypropylene composite material. Compared with the prior art, the low-odor mineral reinforced polypropylene composite material prepared by the reparation method provided by the invention is excellent in mechanical property, low in VOC and environment-friendly and can be widely used in the fields of automobiles, household appliances, sports articles and the like.

Owner:上海日之升科技有限公司

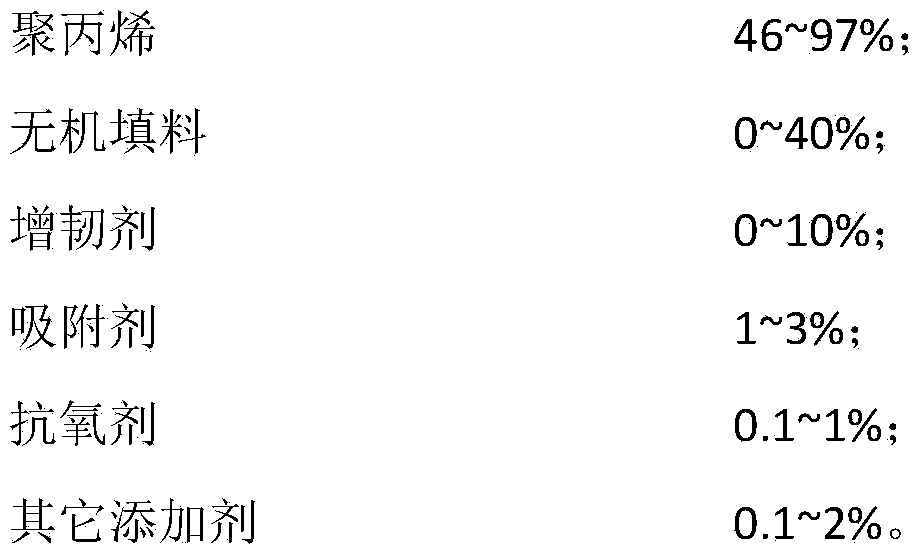

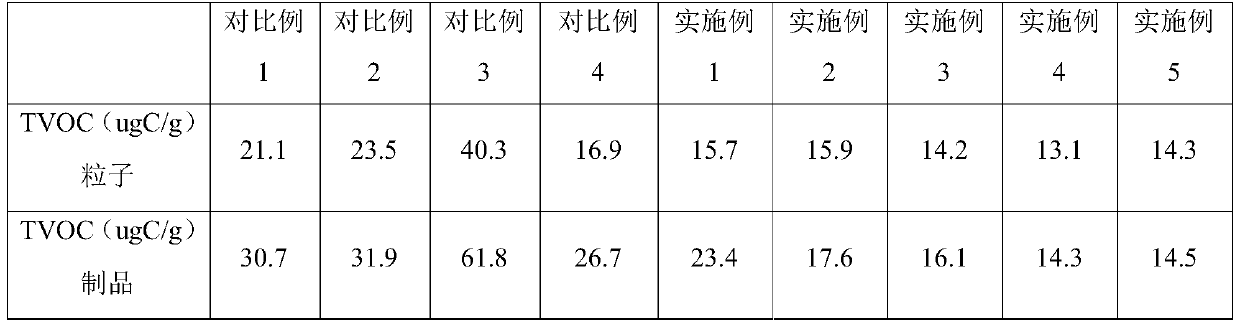

Scratch-resistant low-emission automobile interior PP composite material and preparation method thereof

InactiveCN111909460AImprove mechanical propertiesImprove scratch resistanceWeather resistancePolyketone

The invention discloses a scratch-resistant low-emission automobile interior PP composite material and a preparation method thereof. The composite material comprises the following components in partsby weight: 30-87.8 parts of a base material, 10-40 parts of reinforcing agents, 2-20 parts of a toughening agent, 0.1-10 parts of a scratch-resistant agent and 0.1-5 parts of additives. According to the invention, rigidity-toughness balanced co-polypropylene is used as the base material; calcium carbonate and talcum powder are used as reinforcing agents, so that the mechanical property of the compound is improved; aliphatic polyketone is adopted to replace a common scratch-resistant agent, so that the scratch resistance and the mechanical property of the material are improved, and meanwhile, the odor, VOC and other diffusivity of the low-molecular-weight scratch-resistant agent are reduced; the additives such as the antioxidant and the light stabilizer are adopted, so that the ageing resistance and the weather resistance of the material are improved. The PP composite material disclosed by the invention has the characteristics of balanced rigidity and toughness, excellent scratch resistance, excellent diffusivity and the like, well meets the requirements of automotive interior materials, and can be widely applied to the fields of machinery, building materials, sports and the like which need to slide or operate plastic parts.

Owner:5ELEM HI TECH CORP

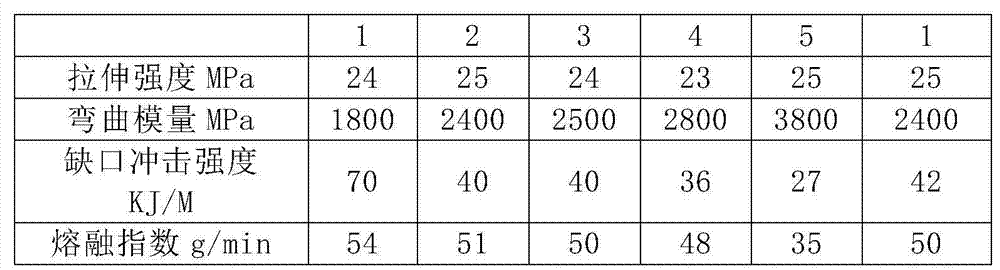

Low-emission PP material and preparation method thereof

The invention provides a low-emission PP material and a preparation method thereof. The low-emission PP material is prepared from the following components in parts by weight: 50-60 parts of PP, 30-40parts of glass fiber, 2-5 parts of a compatilizer, 3 parts of black masterbatch, 1-5 parts of antibacterial agent and 0.2 part of an antioxidant through a double-screw extruder; the TVOC content of the low-emission PP material is less than 50 [mu] gC / g, and the odor is less than grade 4. According to the low-emission PP material and the preparation method thereof, the synergistic effect of all thecomponents in the formula achieves the low-emission effect, the added antibacterial agent nano magnesium oxide and nano zinc oxide mixture plays an unexpected role in effectively reducing the odor and TVOC of the PP material, the preparation method of the low-emission PP material is simple, the used equipment is a common water brace double-screw extruder, and large-scale production is easily realized.

Owner:太仓市华鼎塑料有限公司

Low-emission high-performance long glass fiber reinforced PP composite and preparation method thereof

The invention discloses a low-emission high-performance long glass fiber reinforced PP composite and a preparation method thereof. Magnesium chlorate, potassium nitrate and propylene glycol are selected and synergistically interacted, the emission of the long glass fiber reinforced PP composite is effectively reduced, micromolecules of a product prepared from the long glass fiber reinforced PP composite are not prone to emitting due to the luminous effect and thermal effect, the stability of the composite is maintained, and meanwhile the mechanical property of the prepared PP composite can be effectively maintained. The PP composite has the excellent impact resistant property and low-emission property, the surface is smooth and free of floating fiber, and the PP composite is specially suitable for preparing products such as automobile parts, electronic product elements, instrument parts and aeronautical equipment parts.

Owner:HUIZHOU CHANGYI TECH

Low-emission low-warpage long glass fiber reinforced polypropylene composite material suitable for automobile skylight guide rail and preparation method and application of composite material

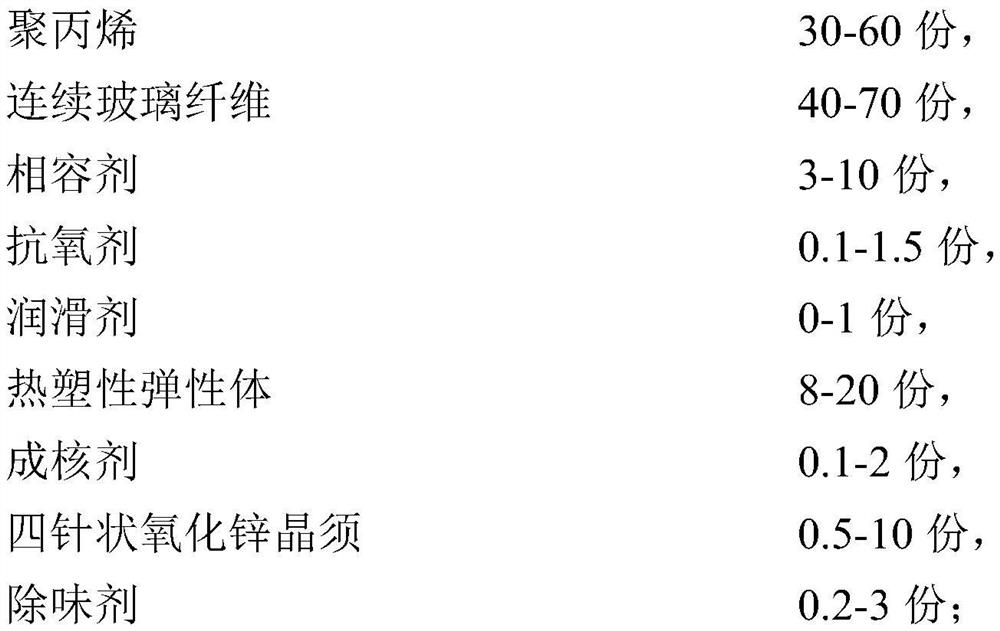

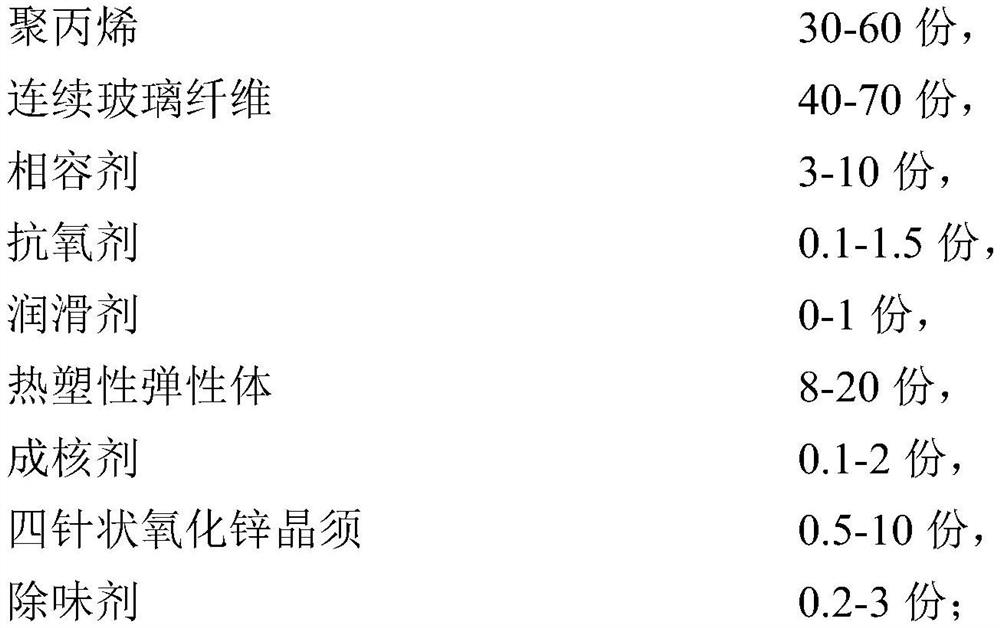

The invention discloses a low-emission low-warpage long glass fiber reinforced polypropylene composite material suitable for an automobile skylight guide rail, a preparation method of the composite material and an application of the composite material in preparation of the automobile skylight guide rail. The low-emission low-warpage long glass fiber reinforced polypropylene composite material comprises the following raw materials in parts by weight: 30-60 parts of polypropylene, 40-70 parts of continuous glass fibers, 3-10 parts of a compatilizer, 0.1-1.5 parts of an antioxidant, 0-1 parts ofa lubricant, 8-20 parts of a thermoplastic elastomer, 0.2-2 part of a nucleating agent, 0.5-10 part of tetrapod-like zinc oxide whiskers and 0.2-3 part of a deodorant. The deodorant comprises a porousaluminum-silicon compound, and the pore diameter of the deodorant is 0.05-20 [mu]m. The preparation method comprises the following steps: uniformly mixing polypropylene, a compatilizer, an antioxidant, a nucleating agent, dried tetrapod-like zinc oxide whiskers and a selectively added lubricant to prepare master batch, blending the master batch with a thermoplastic elastomer and a deodorant, carrying out melt extrusion, and finally, carrying out continuous glass fiber impregnation and coating.

Owner:中广核俊尔(浙江)新材料有限公司 +1

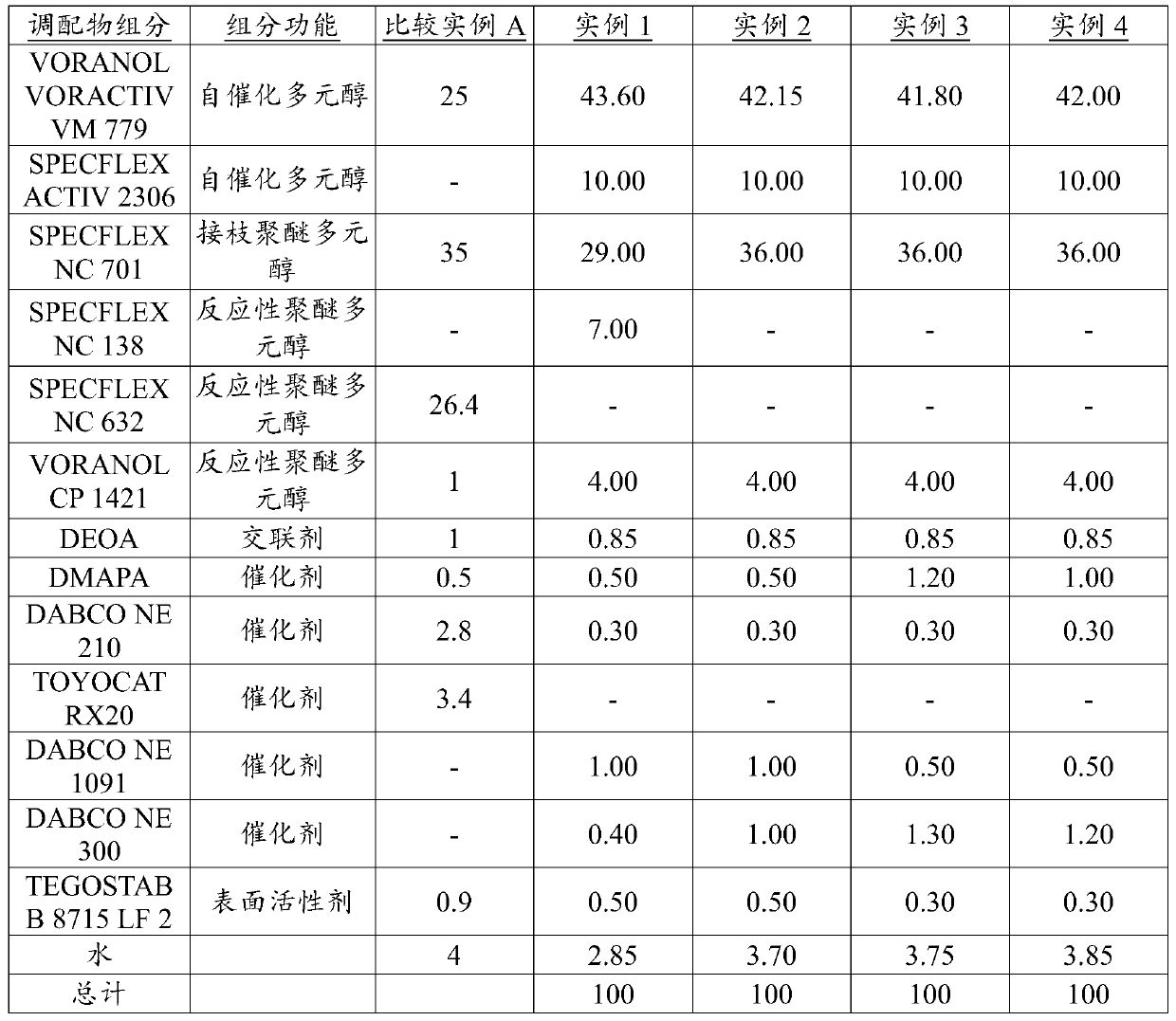

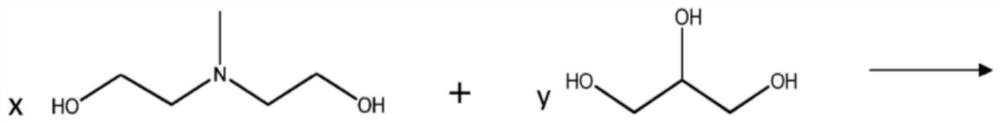

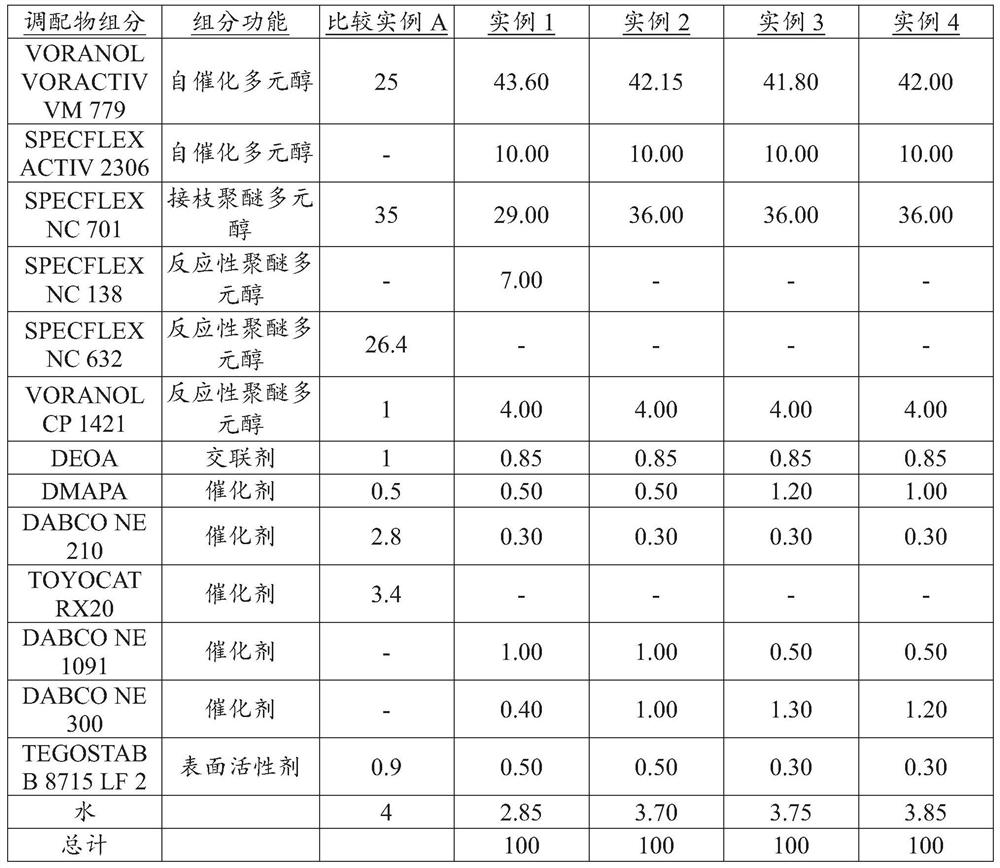

Polyurethane foam system

A reactive polyurethane foam-forming composition including (I) an isocyanate-containing material; and (II) a polyol-containing admixture of: (a) at least one autocatalytic polyol; (b) at least one grafted polyol; (c) at least one reactive polyether polyol; (d) at least one reactive catalyst; (e) at least one surfactant; and (f) water; and a process for making the above foam-forming composition.

Owner:DOW GLOBAL TECH LLC

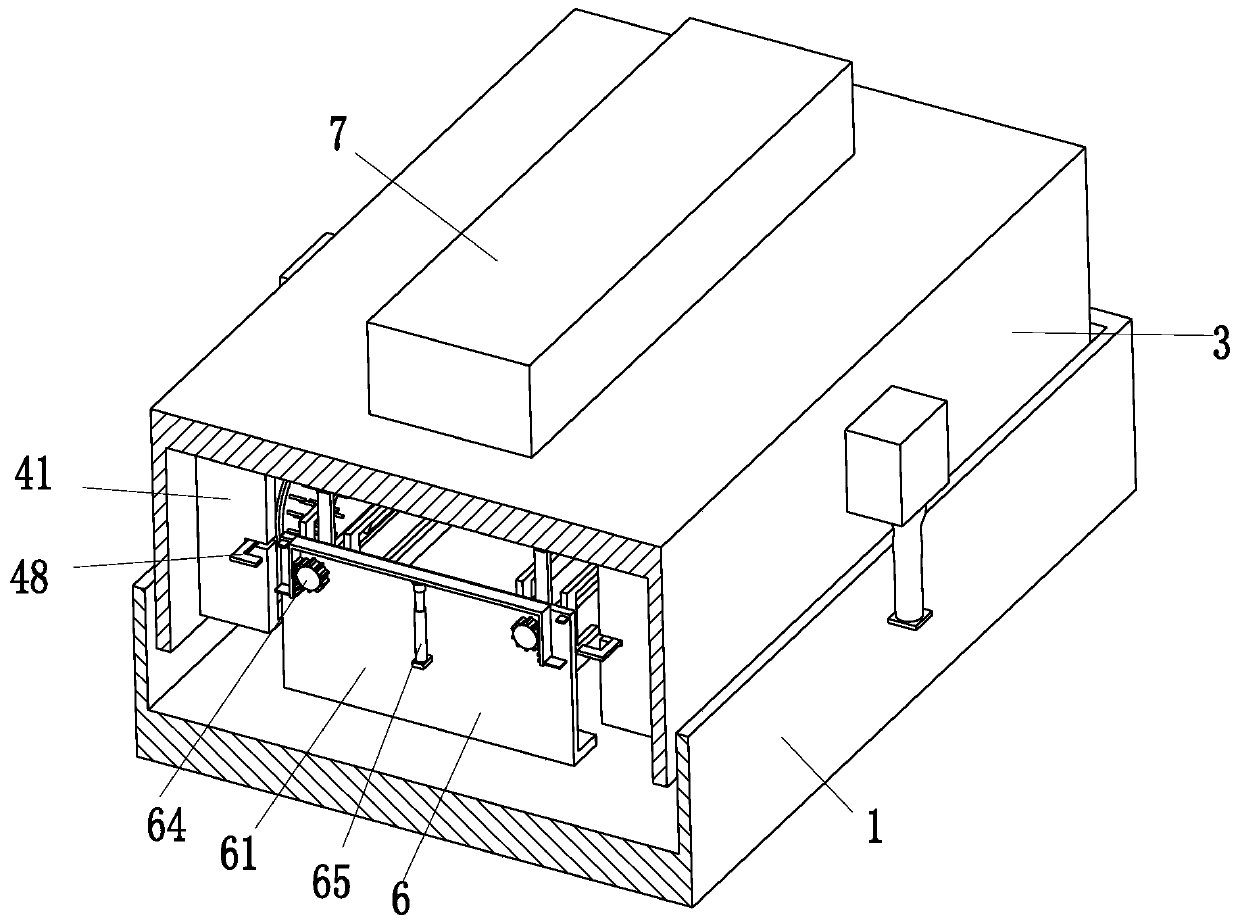

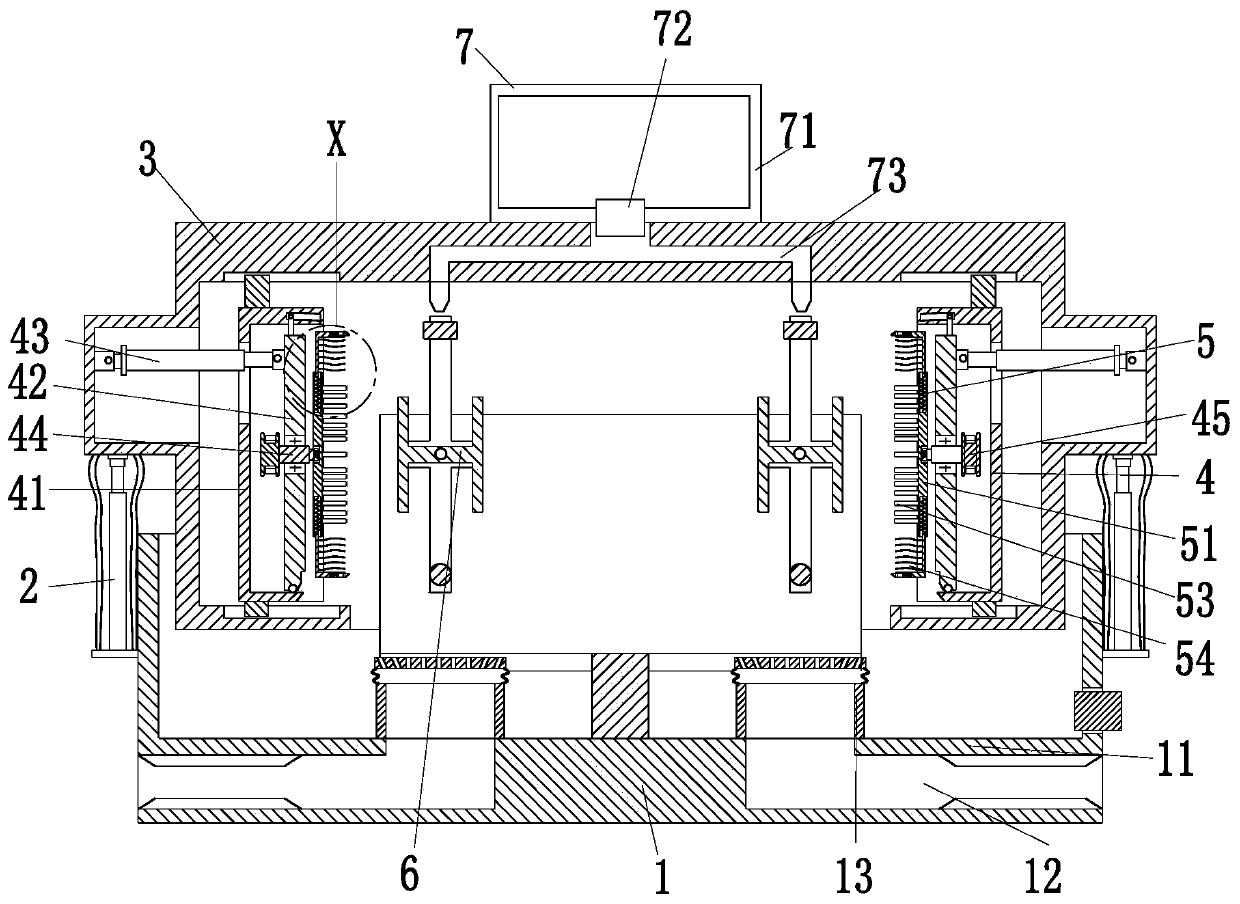

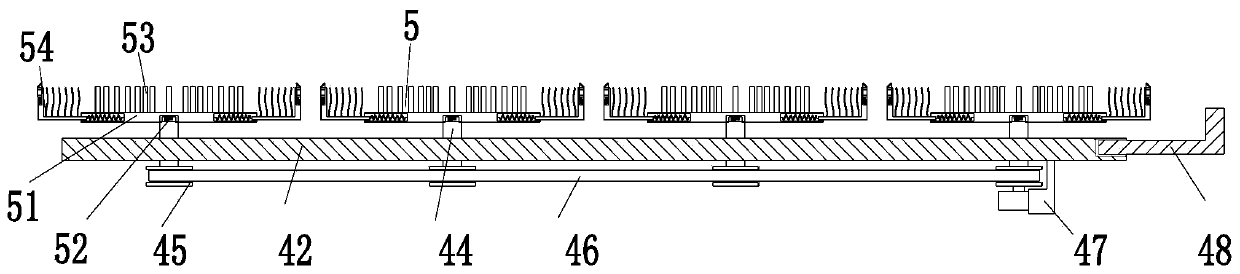

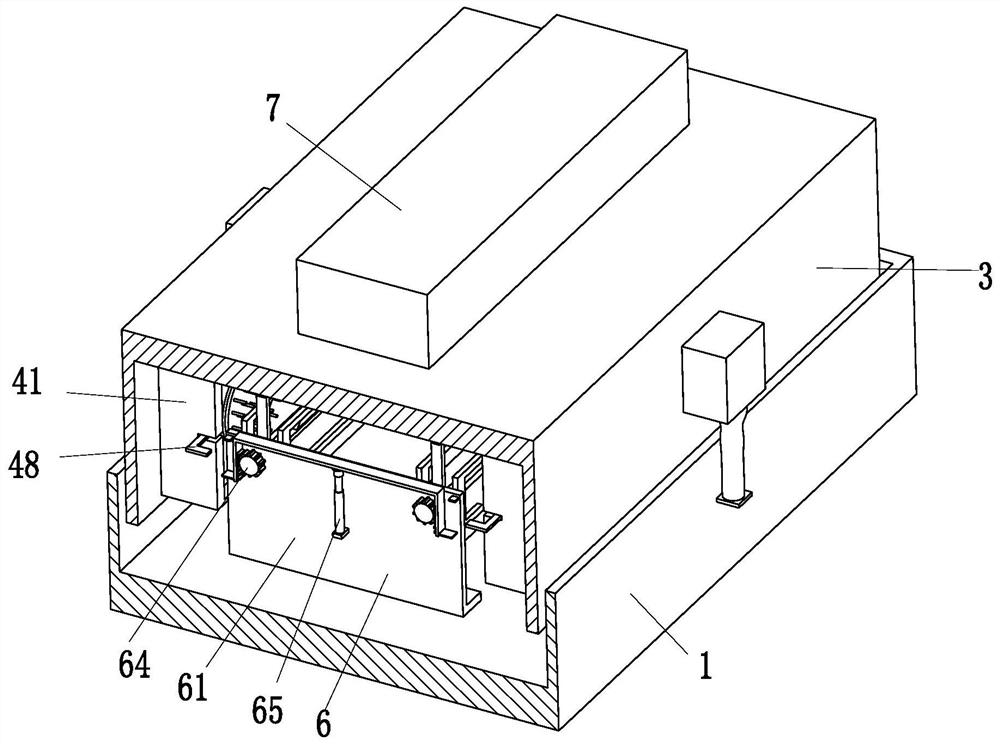

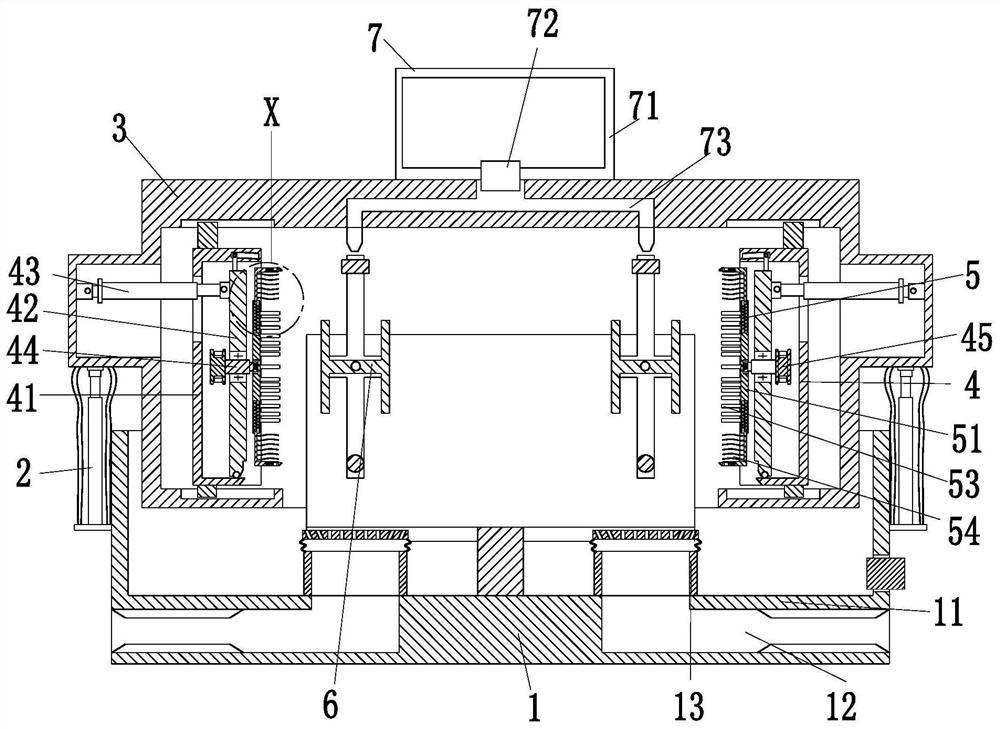

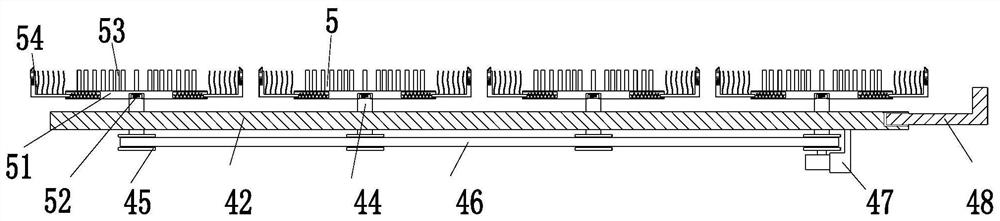

Culture dish appliance disinfecting and cleaning device

The invention relates to a culture dish appliance disinfecting and cleaning device which comprises a flushing base, a lifting air cylinder, an operating frame, two adjusting devices, cleaning units, aplacing device and a pickling device, wherein the flushing base is connected with the operating frame through the lifting air cylinder; the two adjusting devices are mounted at the left and right ends of the operating frame; the cleaning units are uniformly arranged in each of the adjusting devices from front to back; the placing device is mounted in the middle of the flushing base; and the pickling device is mounted at the upper end of the operating frame. The culture dish appliance disinfecting and cleaning device can solve the following problems: a culture dish needs to be cleaned after being used, manual cleaning is mostly adopted in the traditional cleaning manner, the culture dish is damaged when the strength is larger during the scrubbing process, fewer culture dishes are cleaned each time, assembly line type cleaning is not facilitated, and during the cleaning process, the smell of part of residual samples on the culture dish is smelly, and adverse reaction is likely to take place after the residual samples are in contact with the hands of a user to harm the health of the user.

Owner:山东博科消毒设备有限公司

Novel layered material composite long glass fiber reinforced polypropylene composite material and preparation method thereof

InactiveCN112457584AImprove the distribution effectImprove impregnation effectPolypropylene compositesGlass fiber

The invention discloses a novel layered material composite long glass fiber reinforced polypropylene composite material and a preparation method thereof. The formula of the composite material is prepared from the following components in parts by weight: 5-15 parts of a layered material, 35-65 parts of conventional polypropylene resin, 20-30 parts of glass fiber, 1-3 parts of a compatilizer, 1-2 parts of carbon black master batch, 0.5-1.5 parts of an antioxidant and 0.5-1.5 parts of a light-resistant additive. Compared with a common long glass fiber reinforced material with the same trademark on the market, the long glass fiber reinforced polypropylene composite material prepared by the invention has the advantages that the basic raw materials comprise a certain layered composite material,and thelayered material has the specific physical adsorption characteristic and layered structure characteristic, so that the problem of emission of odor VOC and the like in the production and subsequent use processes of the long glass fiber reinforced material is reduced, and meanwhile, the long glass fiber reinforced material has relatively good lubricity. The final product not only has excellent emission performance and is easy to demould, but also keeps higher physical properties, and can be widely applied to the fields of automobile materials, municipal engineering and the like.

Owner:SHANGHAI PRET COMPOSITES +3

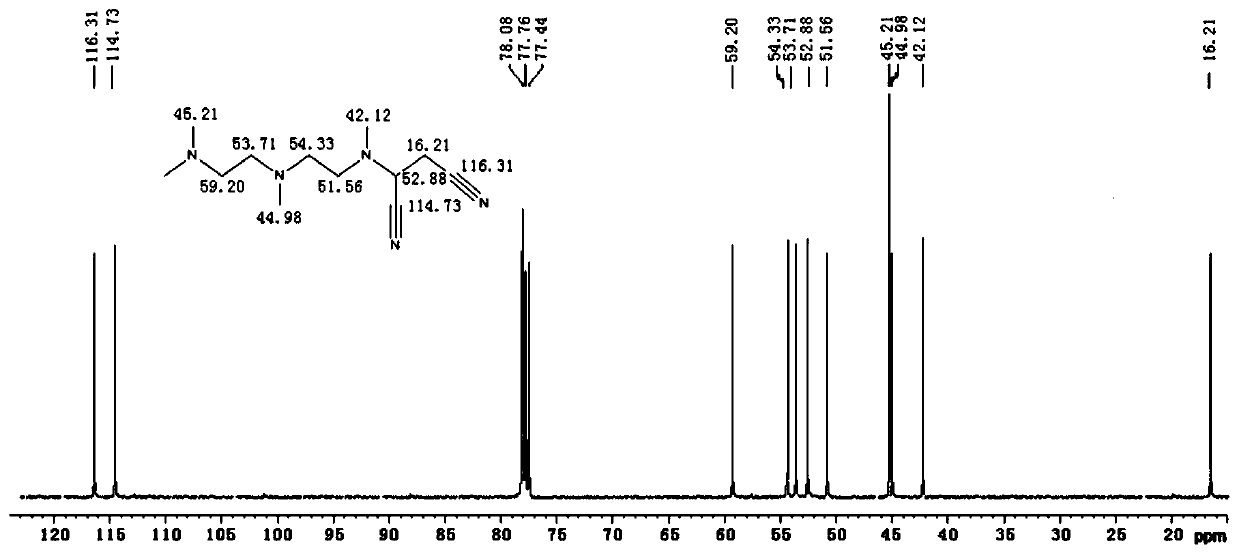

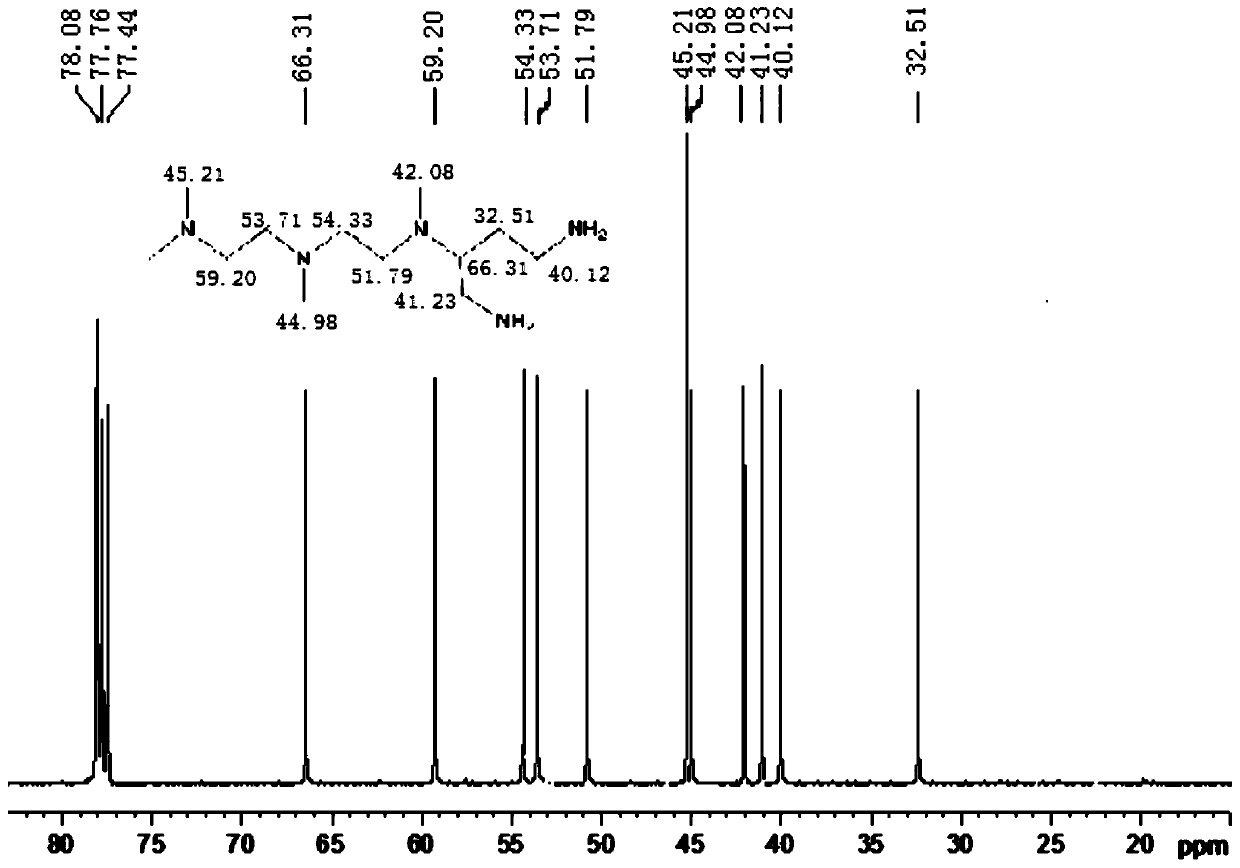

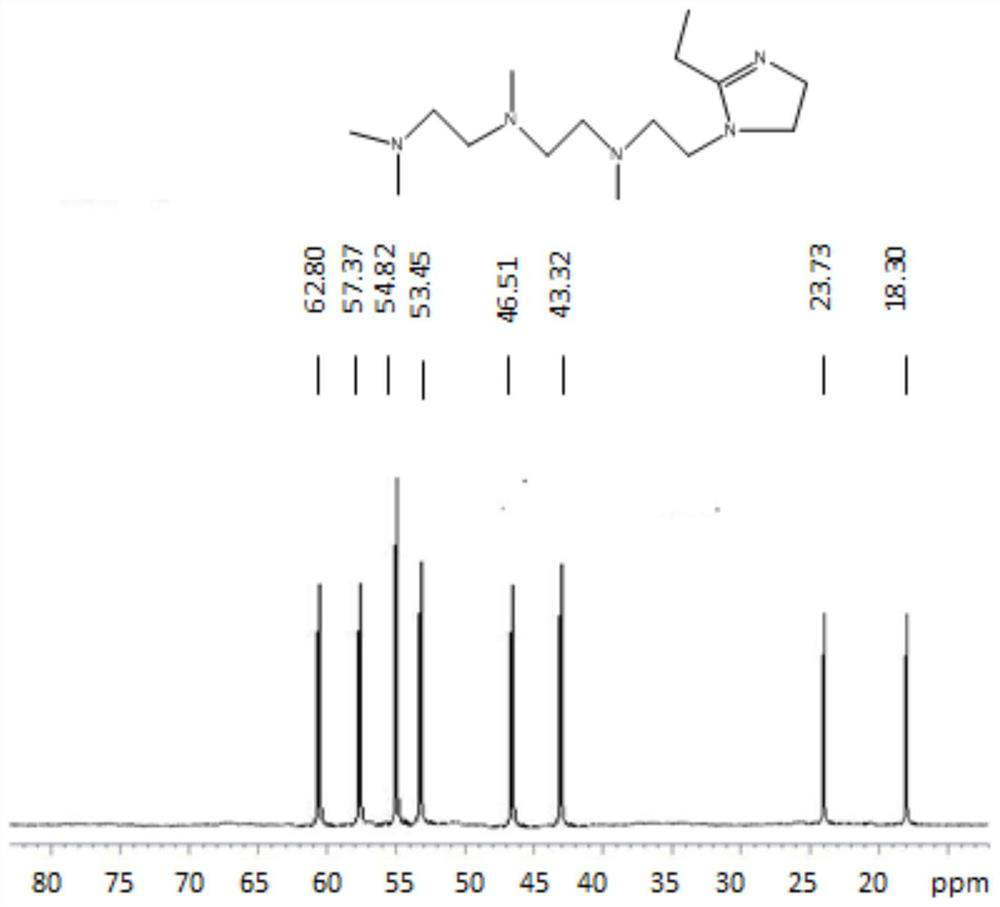

Polyurethane catalyst, preparation method thereof, polyurethane spraying rigid foam and polyurethane flexible foam

ActiveCN110790881ASmall smellLow odor, high activity, low application costCarboxylic acid nitrile preparationOrganic compound preparationPolymer sciencePolyol

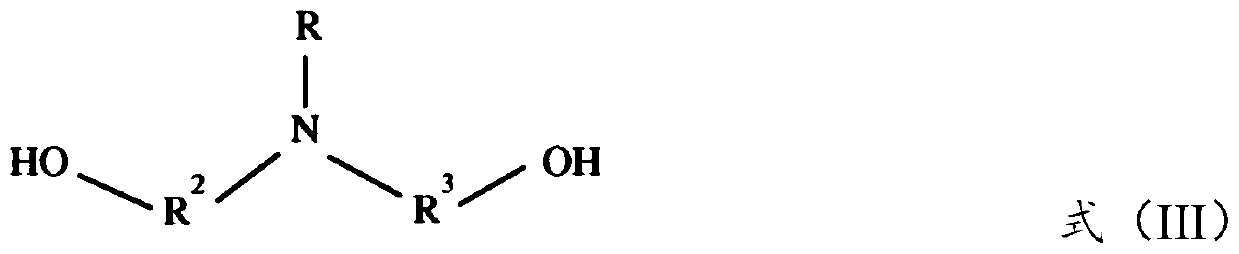

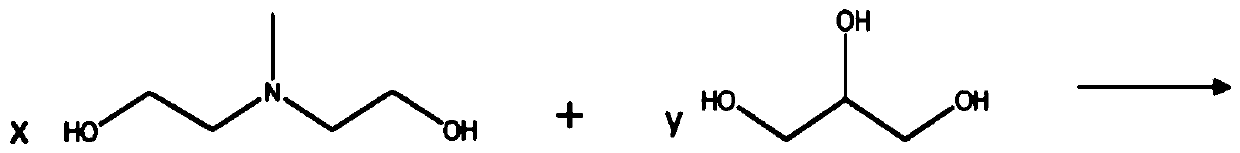

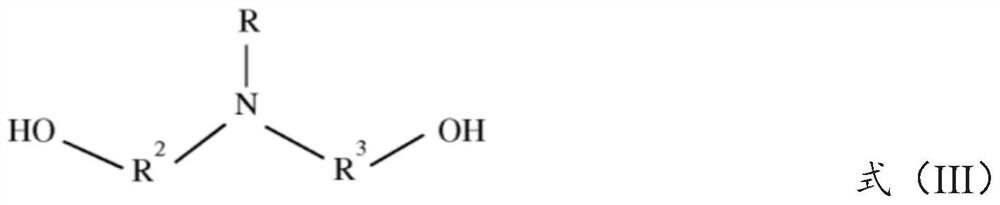

The invention discloses a polyurethane catalyst, a preparation method of the polyurethane catalyst, polyurethane spraying rigid foam and polyurethane flexible foam. The structural formula of the polyurethane catalyst is shown in the specification, wherein R1 is selected from -NH2,-N(CH3)2 and-NHCH3; and R2 is selected from -NH2,-N(CH3)2 and -NHCH3. The polyurethane catalyst can be used to preparepolyurethane foam plastics, including reacting an organic polyisocyanate and a polyol in the presence of a blowing agent, a foam stabilizer, and the catalyst. The catalyst has a diethylenetriamine skeleton, has high catalytic activity and selectivity, and especially has a strong catalytic effect on the reaction of isocyanate and water.

Owner:WANHUA CHEM GRP CO LTD

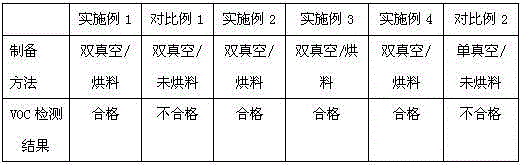

A kind of low VOC polypropylene composite material and preparation method thereof for automotive interior parts

The present invention and a low-VOC polypropylene composite material for automotive interior parts and a preparation method thereof, the low-VOC polypropylene composite material is composed of polypropylene, high-density polyethylene resin, filler, toughening agent, odor absorber, The antioxidant, the lubricant and the light stabilizer are mixed according to the parts by weight, pelletized by a double-vacuum parallel twin-screw extruder, and the pellets are put into an oven for drying. The VOC content of the polypropylene composite material prepared by the invention is low, meets the technical requirements of the air quality evaluation guideline in the car, is suitable for use on the interior parts of the car, improves its application range, reduces the production cost of the car, and meets its light weight. Quantitative requirements.

Owner:ORINKO NEW MATERIAL CO LTD

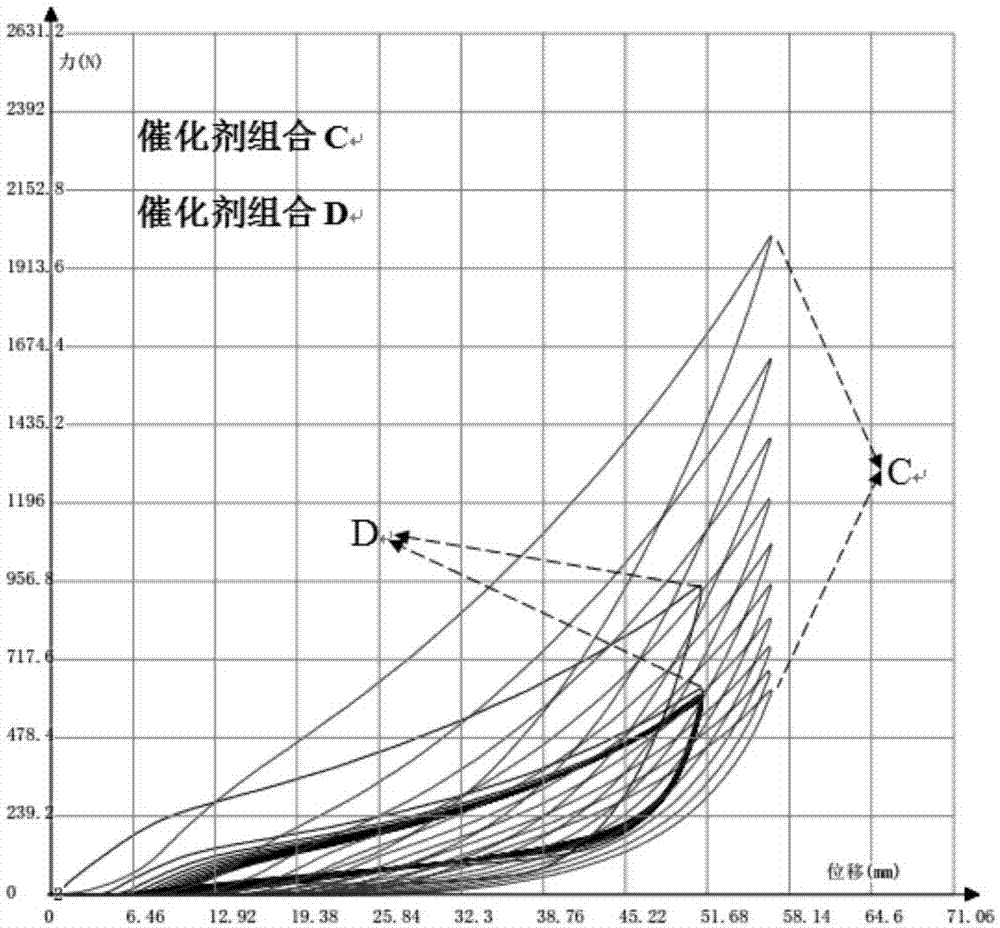

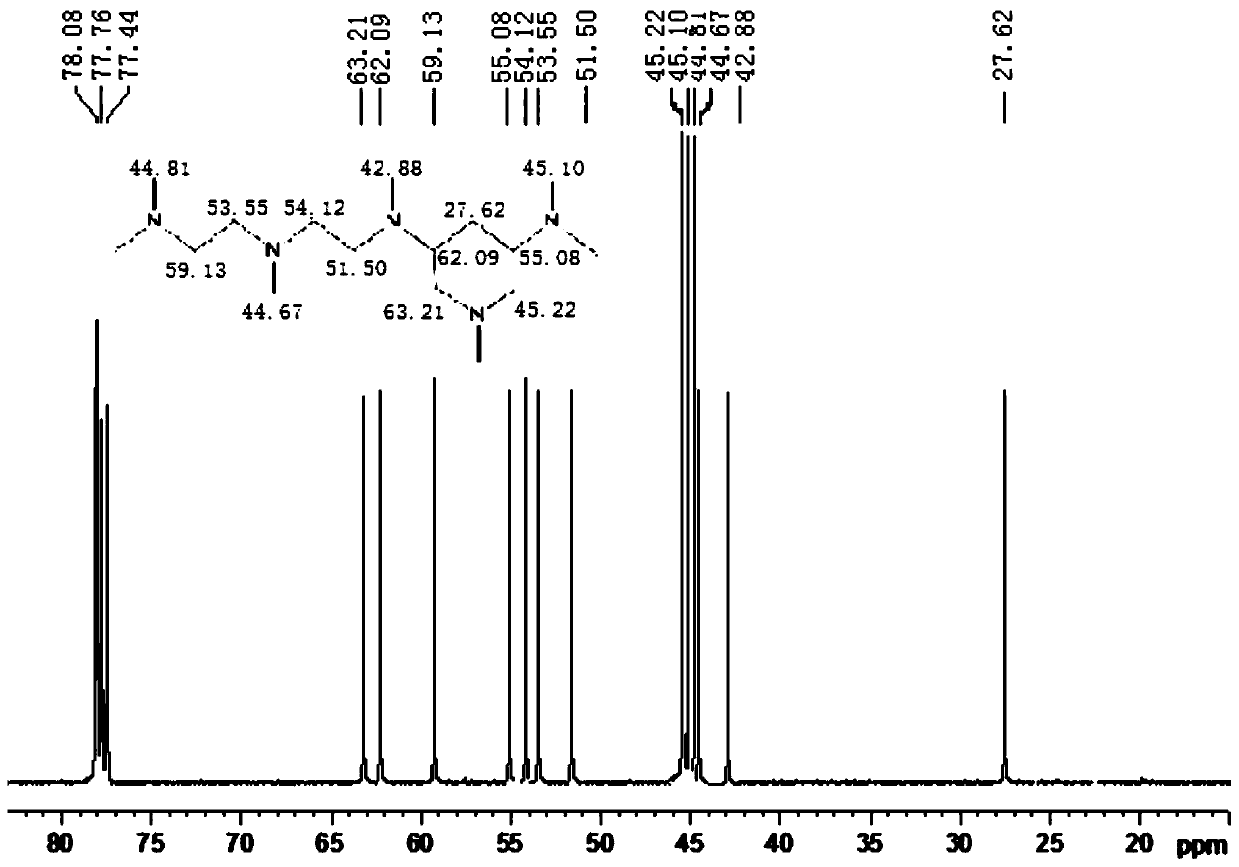

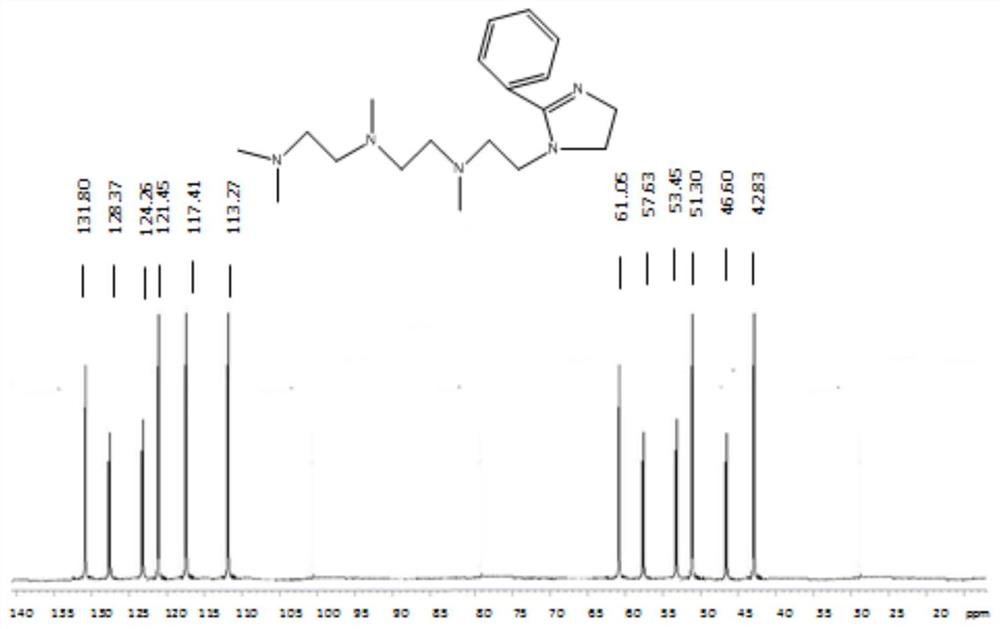

Heat-sensitive tertiary amine catalyst, quaternized derivative, preparation and application thereof

ActiveCN113072674AReduce sporadicGood storage stabilityOrganic chemistryChemical recyclingIsocyanatePerylene derivatives

The invention relates to a heat-sensitive tertiary amine catalyst, a quaternized derivative, preparation and application thereof, and belongs to the field of polymer synthesis. The structural formula of the heat-sensitive tertiary amine catalyst is shown as a formula I, wherein in the formula I, R1 is selected from substituted or unsubstituted C1-C10 alkyl, alkenyl, aryl or aralkyl, n is an integer, and n is more than or equal to 1 and less than or equal to 7. According to the invention, the obtained thermosensitive tertiary amine catalyst can efficiently catalyze foaming reaction of water and isocyanate at a temperature of 100 DEG C or below, wherein the catalytic effect of the thermosensitive tertiary amine catalyst is not weaker than that of BDMAEE and PMDETA; and the obtained thermosensitive tertiary amine catalyst can efficiently catalyze a gel reaction of polyol and isocyanate at a temperature of 100 DEG C or above, wherein the effect is not weaker than that of TEDA.

Owner:WANHUA CHEM GRP CO LTD

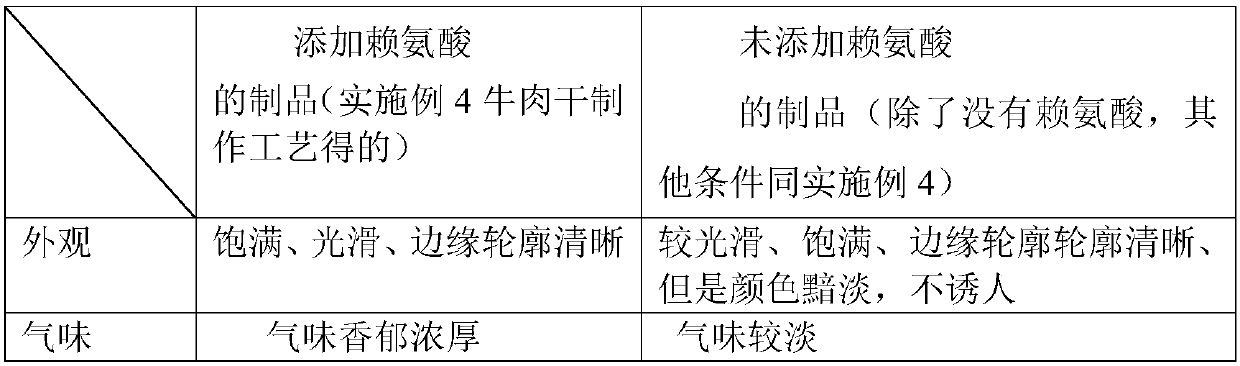

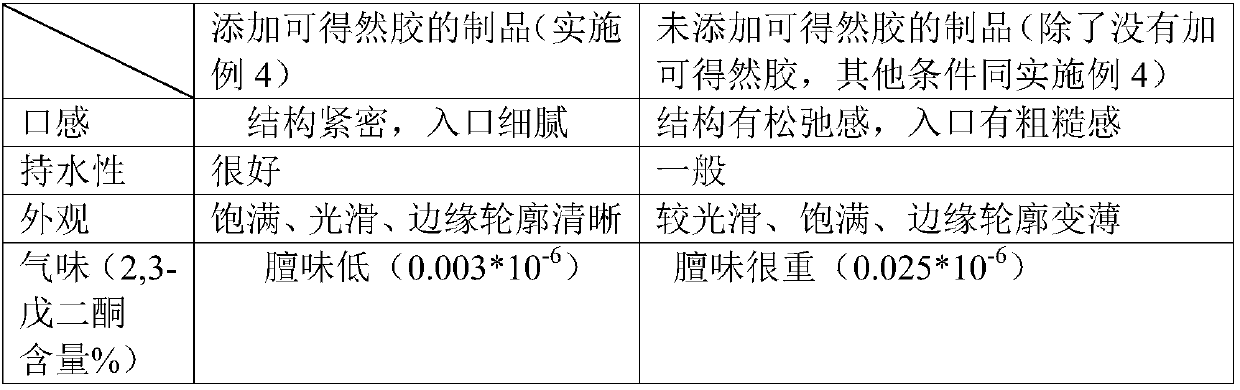

Method for preparing meal replacement stick by adopting tea

PendingCN109567187AStable flowAbundant resourcesFood ingredient as antioxidantFood freezingCooking & bakingBanana powder

The invention discloses a method for preparing a meal replacement stick by adopting tea. The method for preparing the meal replacement stick by adopting the tea comprises the following steps that fresh green tea is laid in a layered mode, water is sprayed layer by layer, stacking is carried out, and fermentation is carried out; the fermented tea is stacked into a large pile, the large pile is subjected to natural sedimentation, compression and stabilization, and then holes are dug for ventilation and aging; steaming, stage drying and crushing are carried out so as to obtain tea powder; and banana powder, corn flour, whey protein powder, the tea powder, beef powder, longan kernel powder and semen phaseoli powder are uniformly stirred so as to obtain powder, edible oil is added, uniform mixing is carried out, compression moulding is carried out, and baking and maturing are carried out. The method has the advantage that the basic nutrition needed by patients with obesity is provided.

Owner:宜昌清溪沟贡茶有限公司

Preparation method of modified polypropylene material with low volatile organic compounds (VOC)

The invention discloses a preparation method of a modified polypropylene material with low volatile organic compounds (VOC). The preparation method of the modified polypropylene material with the lowVOC comprises the steps of utilizing a vacuum feeding method for feeding a mixture of polypropylene, talcum powder, glass beads, a mold release agent, an antioxygen, a lubricant, a light stabilizer, calcium oxide and the like into a double-vacuum parallel twin-screw extruder, melting, extruding, cooling to the room temperature, drying, pelleting in a pelletizer, and obtaining the modified polypropylene material. According to the preparation method of the modified polypropylene material with the low VOC provided by the invention, through adopting a double-vacuum system, improving the rotating speed, and adding a VOC eluting agent into a side material port, the smell and the emission of the product are reduced; and meanwhile, multiple feeding hoppers are used for feeding, so that the feedingaccuracy is high, and the efficiency is high.

Owner:昆山禾振瑞新复合材料有限公司

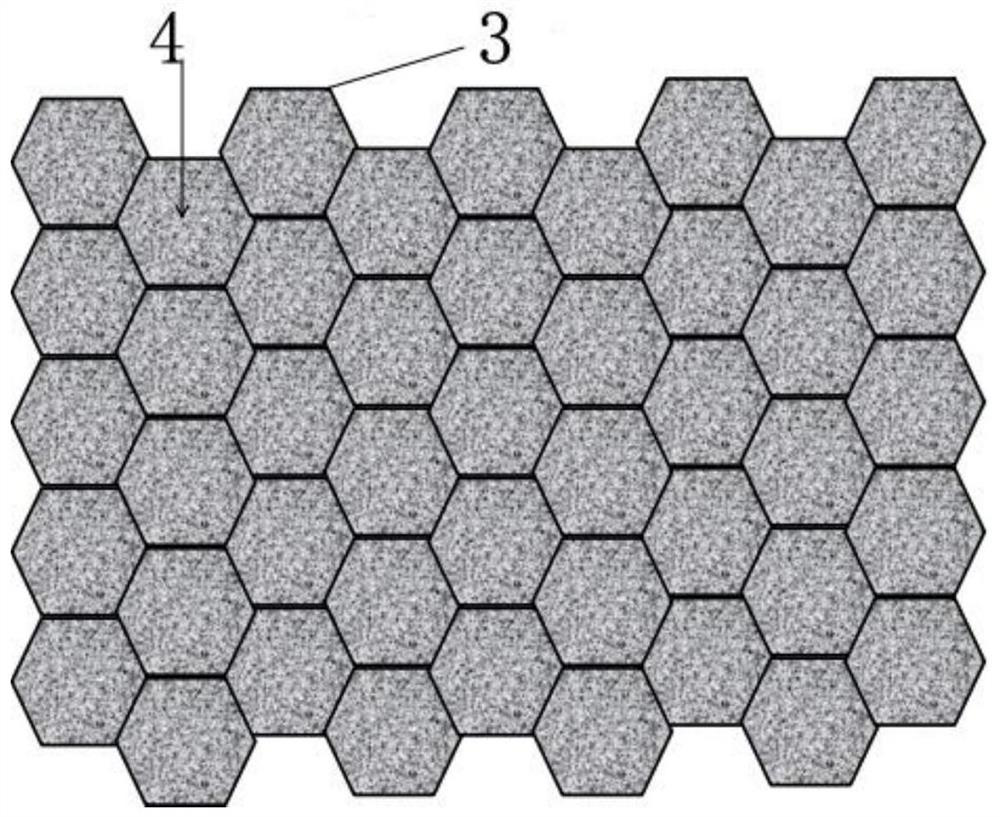

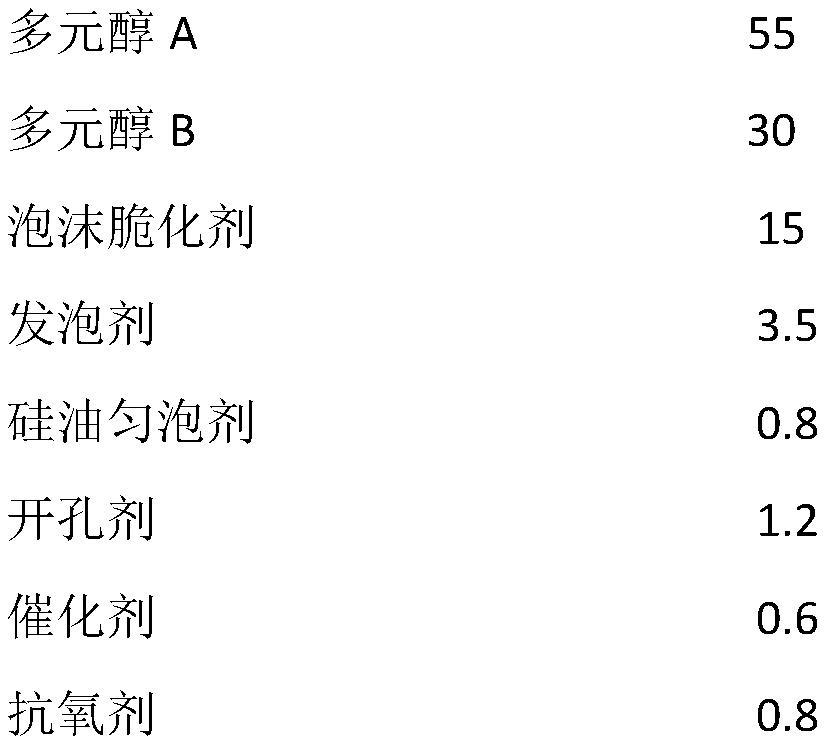

A foam press-filled honeycomb composite panel and its preparation method

ActiveCN111038010BEasy to prepareEasy to operateSynthetic resin layered productsPaper/cardboard layered productsPolyolHoneycomb

The invention discloses a foam press-filled honeycomb composite board and a preparation method thereof. The composite board consists of a fabric layer, a honeycomb composite core layer and a fabric layer in sequence from top to bottom. The honeycomb composite core layer is made of polyurethane sound-absorbing foam directly It is prepared by pressure filling into the honeycomb core, and the formula of the special polyol composition is 55-70 parts by weight of polyol A; 20-30 parts by weight of polyol B; 8-15 parts by weight of foam embrittlement agent, etc. The foam press-filled honeycomb composite panel adopts the process of press-filling polyurethane sound-absorbing foam to the honeycomb core and then compounding the fabric. The preparation method is simple and easy to operate. The production process has no three-waste pollution, which is safe and environmentally friendly. Embrittlement agent, the foam is brittle and can be quickly and directly pressure-filled into the honeycomb core, one step in place, high production efficiency.

Owner:浙江华江科技股份有限公司

polyurethane foam system

A reactive polyurethane foam-forming composition comprising: (I) an isocyanate-containing material; and (II) a polyol-containing blend of: (a) at least one autocatalytic polyol; ( b) at least one graft polyol; (c) at least one reactive polyether polyol; (d) at least one reactive catalyst; (e) at least one surfactant; and (f) water; and A process for preparing the foam-forming composition described above.

Owner:DOW GLOBAL TECH LLC

A device for disinfection and cleaning of petri dishes

The invention relates to a disinfection and cleaning device for petri dishes, which includes a washing base, a lifting cylinder, an operation frame, two adjustment devices, a cleaning unit, a placement device and a pickling device. The washing base is connected to the operation frame through the lifting cylinder. Two adjustment devices are installed at the left and right ends of the operation frame, each adjustment device is equipped with a cleaning unit uniformly from front to back, a placing device is installed in the middle of the flushing base, and a pickling device is installed at the upper end of the operation frame. The invention can solve the need to clean the petri dish after it is used up. Most of the traditional cleaning methods use manual cleaning. When scrubbing, the petri dish is damaged after the force is large, and the number of single cleaning is relatively small. Less, it is not conducive to assembly line cleaning, and during the cleaning process, some residual samples on the petri dish have an unpleasant smell, and adverse reactions may occur after contact with hands, thus endangering human health and other issues.

Owner:山东博科消毒设备有限公司

Anti-fogging headlight material and preparation method thereof

The invention discloses an anti-fogging headlight material and a preparation method thereof. The material disclosed by the invention comprises the following components in parts by weight: 60-80 partsof polyphenyl ether, 5-20 parts of a flow modifier, 5-15 parts of a flexibilizer, 5-20 parts of an enhancer, 1-5 parts of an interfacial modifier, 1-10 parts of a drying neutralizer and 0.5-2 parts ofother additives. The invention further discloses a preparation method of the anti-fogging headlight material. The material disclosed by the invention solves the headlight fogging problem, and has thecharacteristic of low material dispersion property. In addition, the anti-fogging headlight material disclosed by the invention further has moisture resistance and high rigidity, and the requirementthat the lamp assembly is not influenced by strong vibration is met. Furthermore, due to good flowability of the material, the requirement that the thickness of the parts of the headlight assembly isreduced can be met, and the manufacturing cost is reduced. The product further has the characteristics such as light weight, excellent dimensional stability, short molding cycle, high finished productyield and the like.

Owner:NANJING JULONG SCI&TECH CO LTD

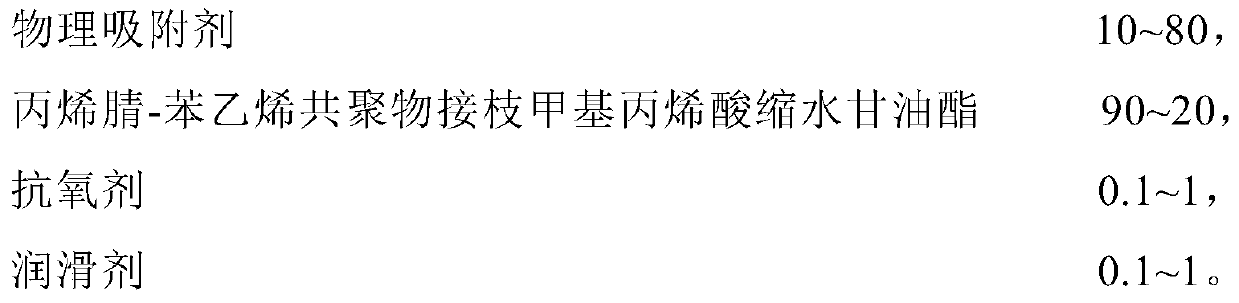

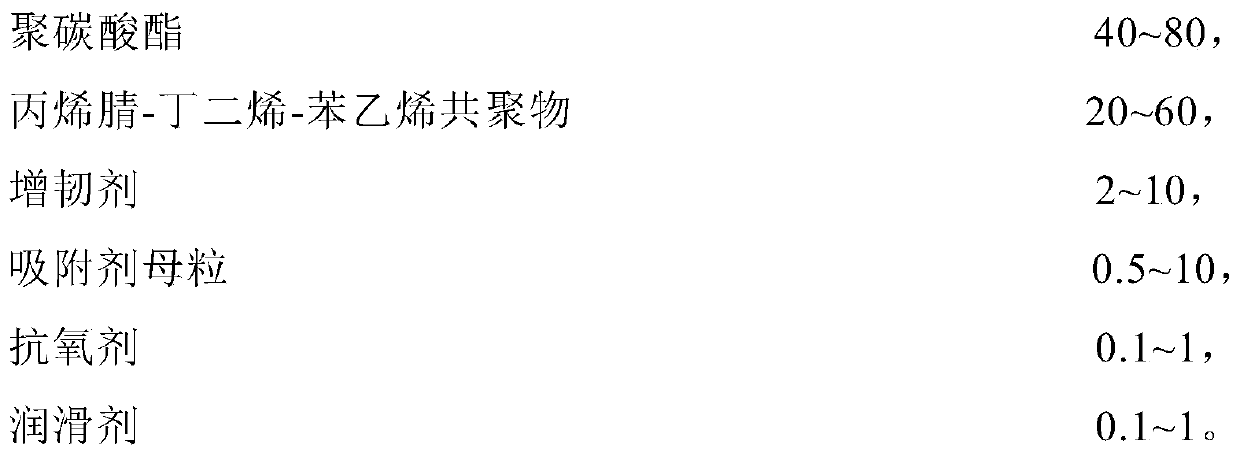

Adsorbent master batch and low-emission pc/abs alloy containing the master batch and preparation method

The invention relates to an adsorbent master batch, a low-sporadic-performance PC / ABS alloy with the same and a preparing method. The adsorbent master batch is prepared from, by weight, 10 parts to 80 parts of physical adsorbents, 20 parts to 90 parts of acrylonitrile-styrol-copolymer-grafted glycidyl methacrylate, 0.1 part to 1 part of antioxidants and 0.1 part to 1 part of lubricating agents; the low-sporadic-performance PC / ABS alloy with the adsorbent master batch is prepared from, by weight, 40 parts to 80 parts of polycarbonate, 20 parts to 60 parts of acrylonitrile-butadiene-styrene copolymers, 2 parts to 10 parts of toughening agents, 0.5 part to 10 parts of the adsorbent master batches, 0.1 part to 1 part of antioxidants and 0.1 part to 1 part of lubricating agents. Compared with the prior art, the adsorbent master batch, the low-sporadic-performance PC / ABS alloy and the preparing method have the advantage that the sporadic performance of a PC / ABS alloy material is obviously reduced.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com