Polyurethane catalyst, preparation method thereof, polyurethane spraying rigid foam and polyurethane flexible foam

A polyurethane catalyst and polyurethane technology, applied in the field of polyurethane, can solve the problems of the influence of the physical properties of the polyurethane products, the increase of the steric hindrance of the N atom of the tertiary amine, the decrease of the molecular movement ability, etc., to achieve low odor mechanical properties, the method is simple and easy to implement, and the The effect of applying cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

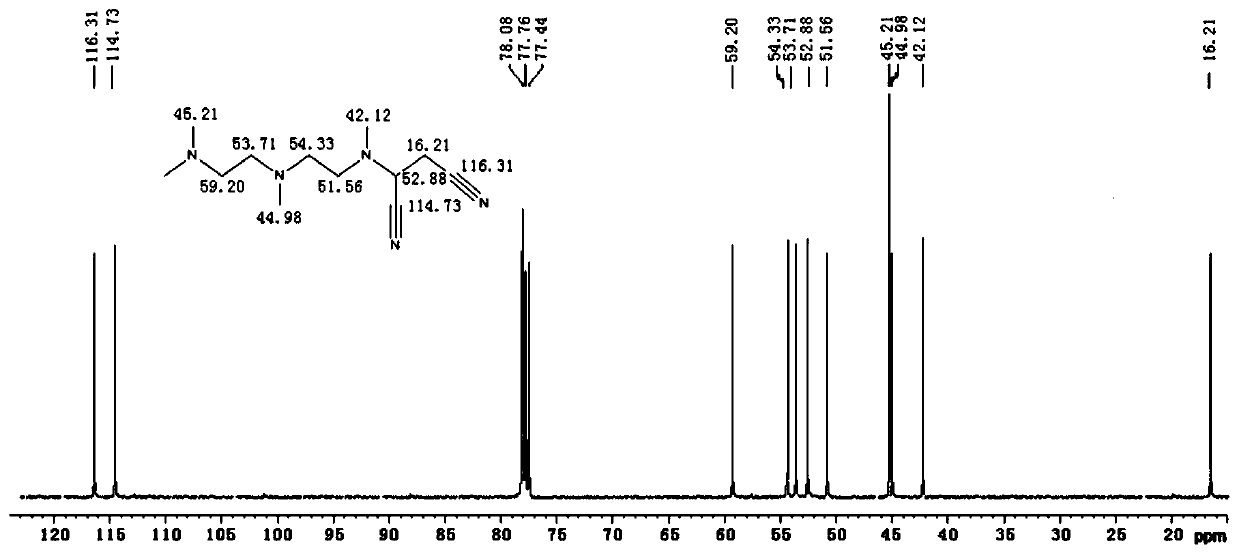

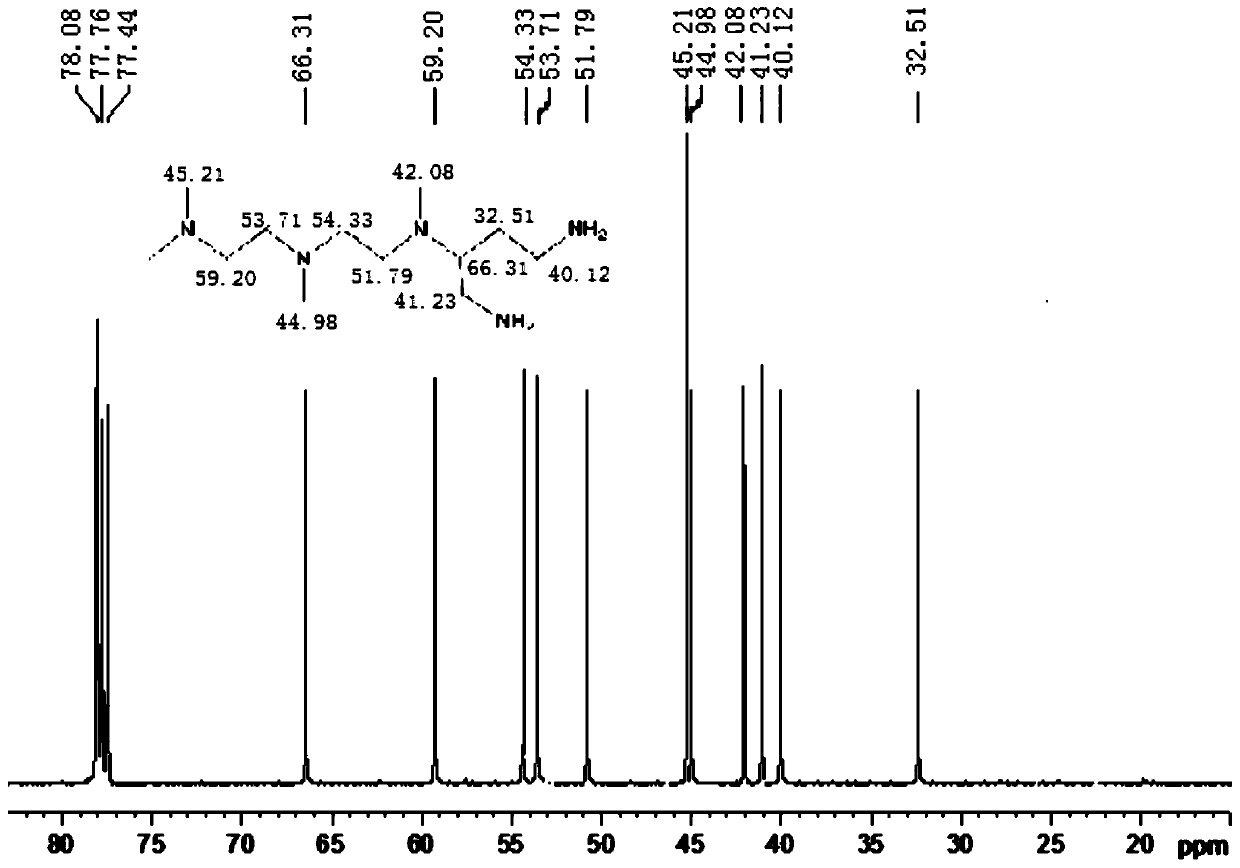

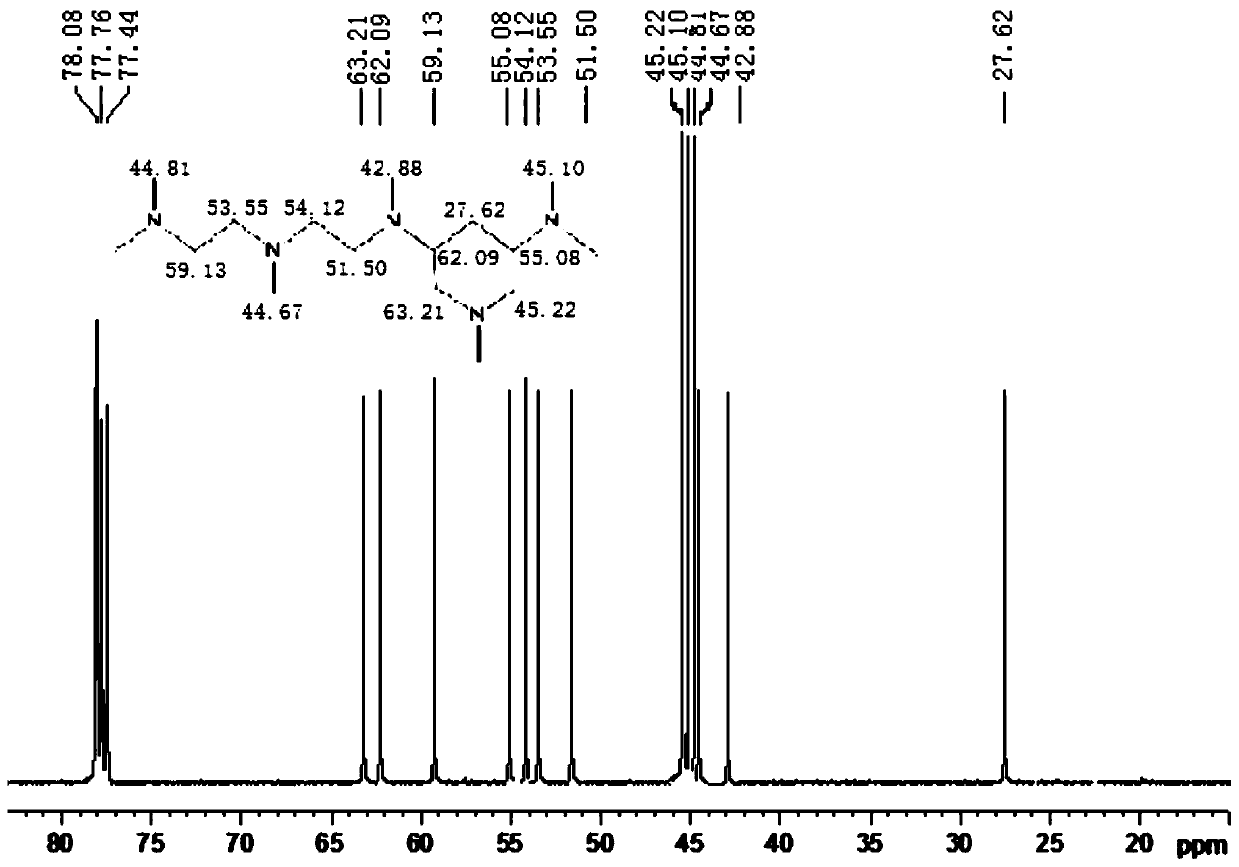

[0086] N,N,N’,N”-tetramethyl-N”-1,2-dicyanoethyldiethylenetriamine:

[0087] Put 300g of N,N,N',N"-tetramethyldiethylenetriamine into a three-necked round-bottomed flask, heat to 50°C, add 265g of 50wt% fumaronitrile solution in benzene dropwise, Control dropwise time is 2 hours.After dropwise finishes, make reaction carry out 6 hours again.The product that obtains carries out normal pressure 85 ℃ of distillations and removes benzene.The reaction solution is carried out rectification under vacuum again, under absolute pressure 1KPa, The number of theoretical plates in the rectification column is 35, the reflux ratio is 5:1, the temperature at the top of the collection column is 65-67°C, and the unreacted N,N,N',N"-tetramethyldiethylenetri Amine; collect fraction 2 at the top temperature of 182-184°C to obtain N,N,N',N"-tetramethyl-N"-1,2-dicyanoethyldiethylenetriamine. Bruker AVANCEⅢ400Hz nuclear magnetic resonance spectrometer was used for carbon spectrum analysis, and the s...

Embodiment 2、3

[0096] Embodiment 2,3 and comparative example 1-3

[0097] In the following B3 formula system for exterior wall spraying (B3 classification of high-rise building decoration materials for combustion performance, the fire rating of polyurethane materials added with flame retardants in this formula is B3), except for the foaming catalyst, the composition of the combined material is shown in the table below 2.

[0098] Table 2 Composition of the composite material except the foaming catalyst

[0099] components factory parts by mass Polyether 4110 Jiangsu Zhongshan Chemical Industry 65 Polyester PS-3152 Nanjing Stepan 35 Hard foam silicone oil AK8801 Mester 2.7 water self made 1.2 HCFC-141b Honeywell 45 Triethanolamine Longxi Chemical Industry 5.3 TCPP Jiangsu Changyu Chemical Industry 26 Niax-A33 Momentum 3.1 LCM-1 Jiangdian Chemical 0.55 Niax-D22 Momentum 0.25

[0100] The types an...

Embodiment 4、5

[0108] Embodiment 4,5 and comparative example 4-6

[0109] 50Kg / m 3 In the left and right modified MDI-based automotive high-resilience seat systems, the composition of the materials except for the foam catalyst is shown in Table 5 below.

[0110] Table 5 Except for the foaming catalyst, the formula of high resilience foam combination

[0111] components factory parts by mass F3135 Wanhua Chemical 85 POP2140 Wanhua Chemical 15 B8715 Evonik Chemicals 0.8 Diethanolamine DEOA Longxi Chemical Industry 0.7 water 4.3 Niax-A33 Momentum 0.45 Isocyanate Index 90

[0112] Adjust the dosage of the foaming catalyst in the following 5 groups of experiments, so that the starting time of each group is about 8s;

[0113] The types and amounts of the foaming catalysts of Examples 4, 5 and Comparative Examples 4-6 are shown in Table 6.

[0114] The foaming type catalyst kind and consumption of table 6 embodiment 4,5 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com