Patents

Literature

192 results about "Chain termination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chain termination is any chemical reaction that ceases the formation of reactive intermediates in a chain propagation step in the course of a polymerization, effectively bringing it to a halt.

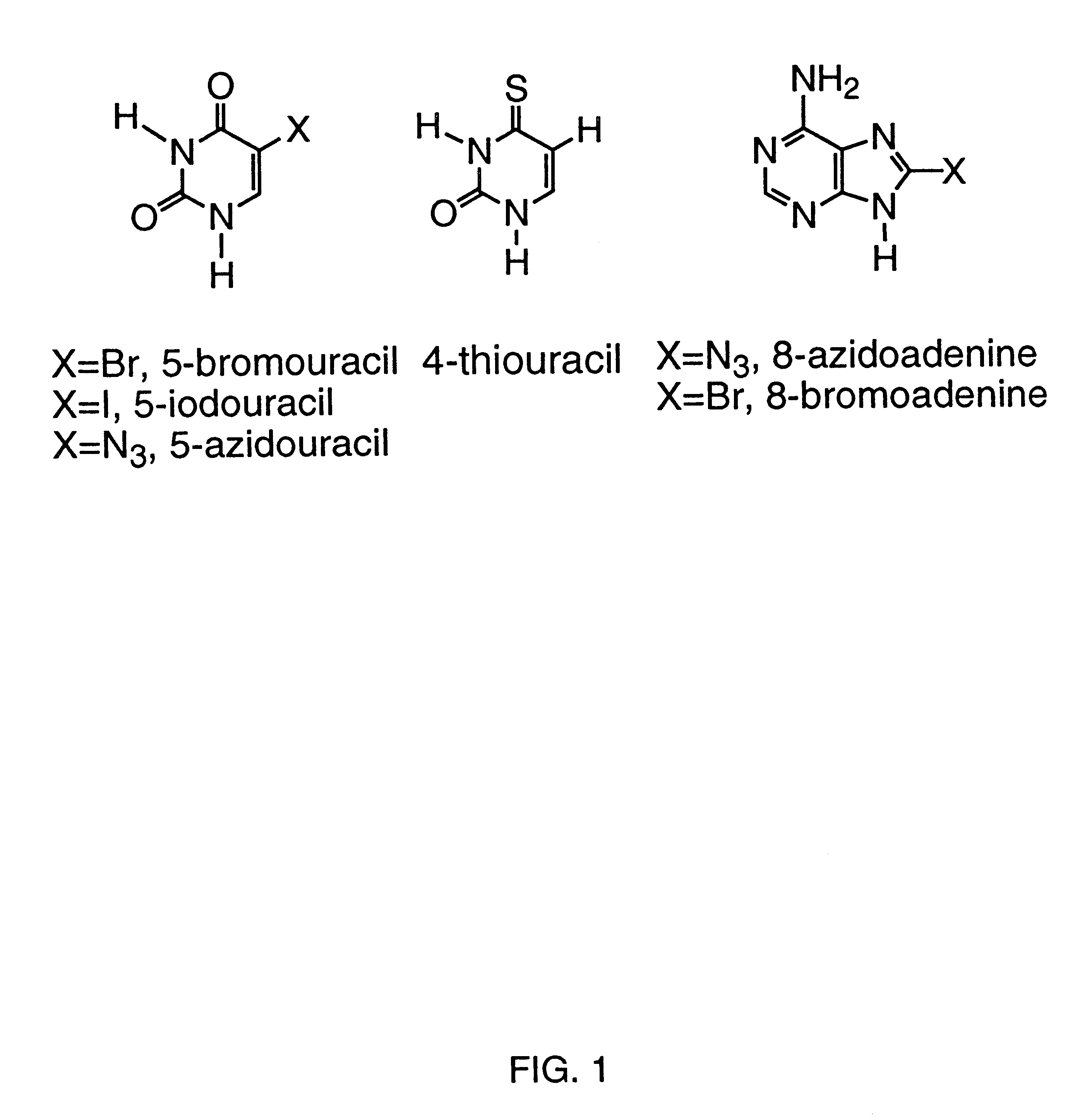

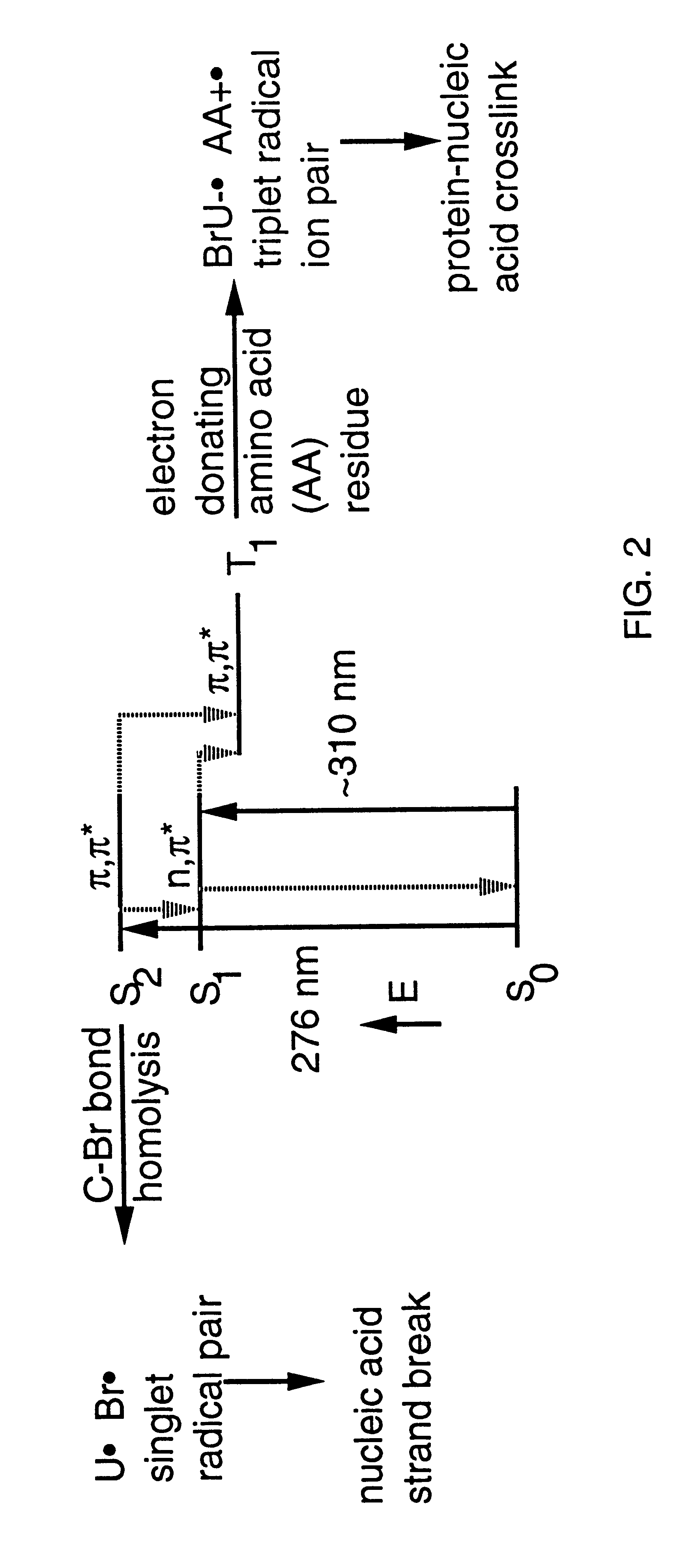

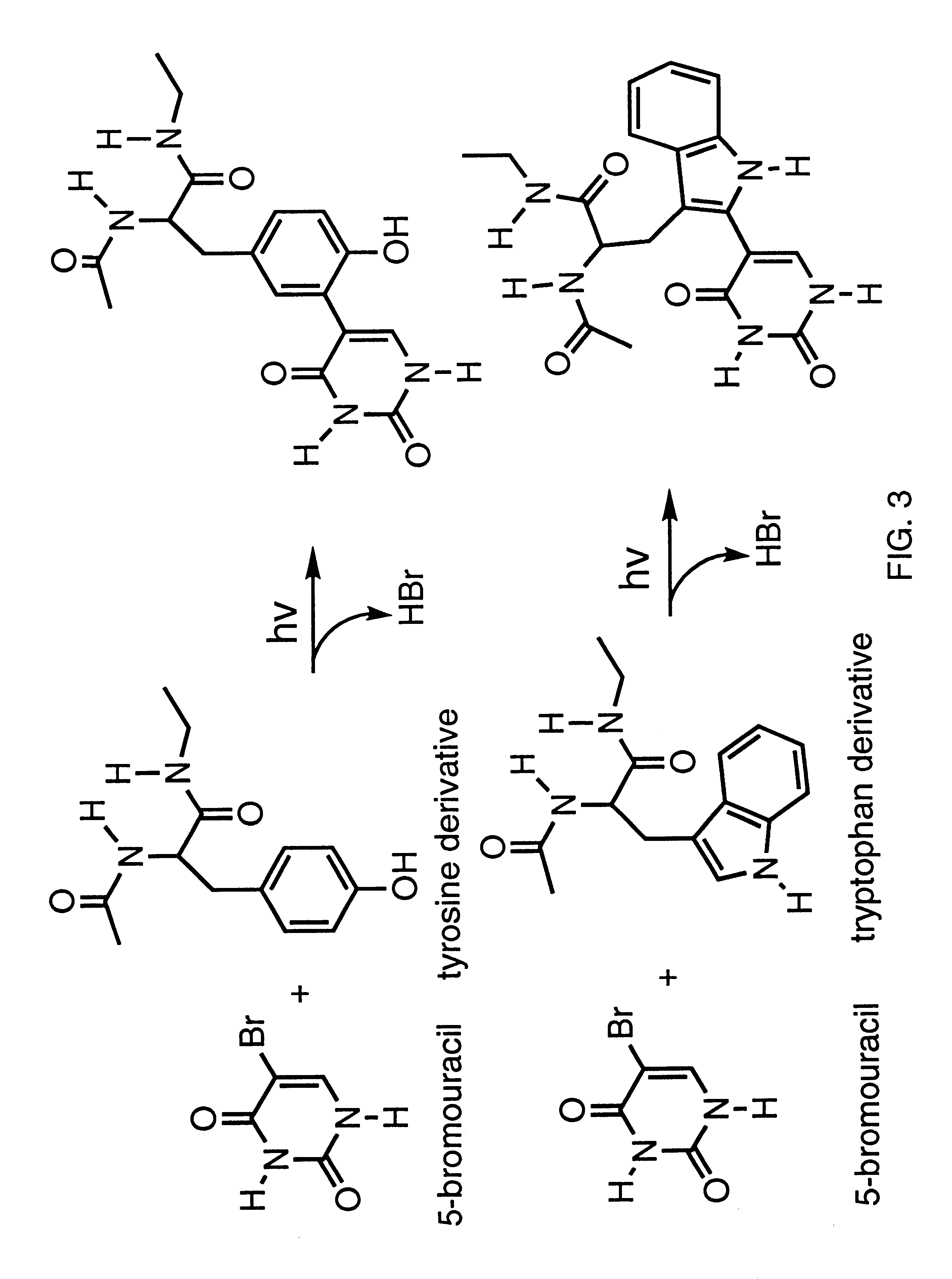

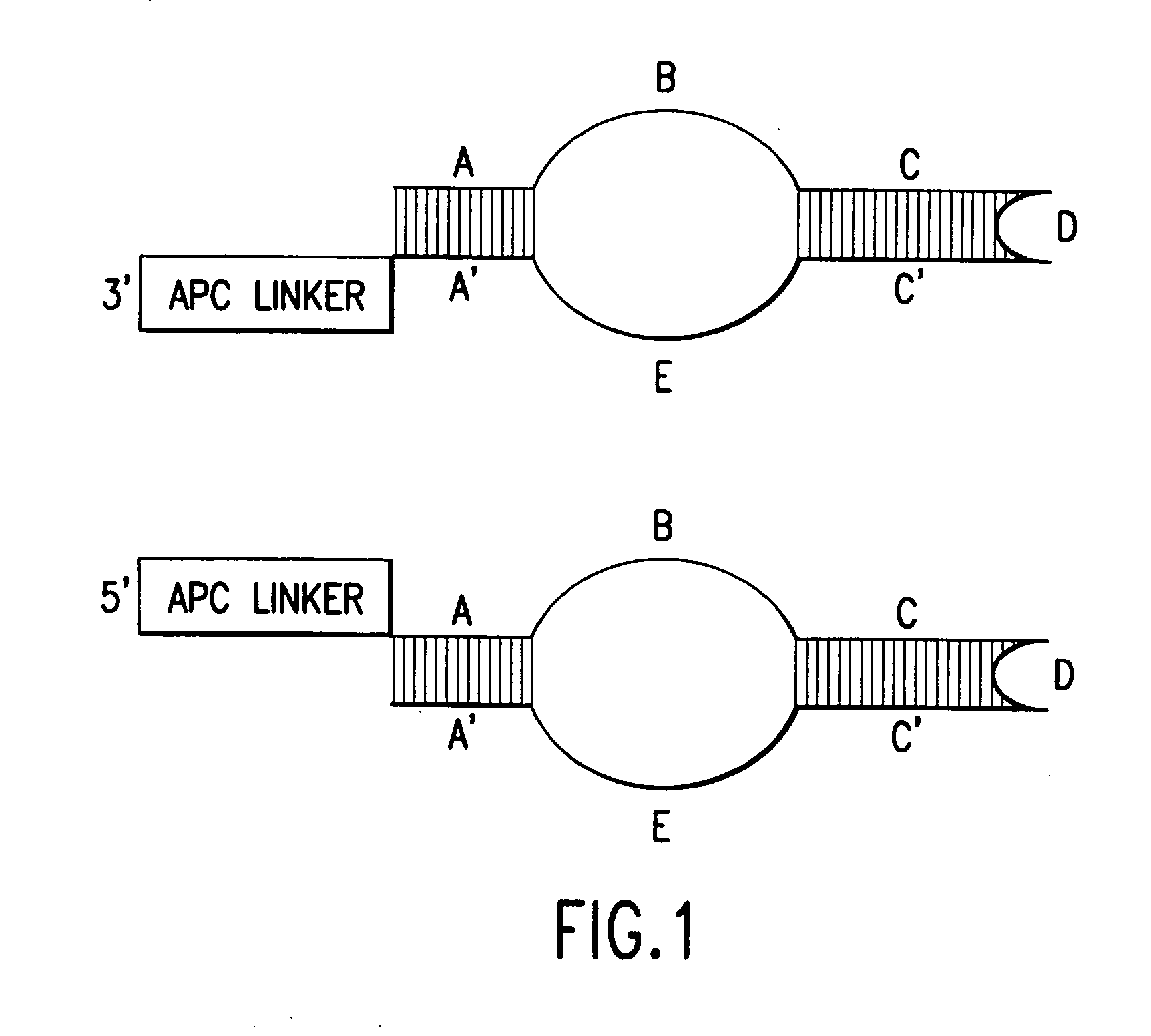

Systematic evolution of ligands by exponential enrichment: photoselection of nucleic acid ligands and solution selex

A method for identifying nucleic acid ligands to target molecules using the SELEX procedure wherein the candidate nucleic acids contain photoreactive groups and nucleic acid ligands identified thereby are claimed. The complexes of increased affinity nucleic acids and target molecules formed in the procedure are crosslinked by irradiation to facilitate separation from unbound nucleic acids. In other methods partitioning of high and low affinity nucleic acids is facilitated by primer extension steps as shown in the figure in which chain termination nucleotides, digestion resistant nucleotides or nucleotides that allow retention of the cDNA product on an affinity matrix are differentially incorporated into the cDNA products of either the high or low affinity nucleic acids and the cDNA products are treated accordingly to amplification, enzymatic or chemical digestion or by contact with an affinity matrix.

Owner:SOMALOGIC INC

Method for preparation of copolyorganosiloxanecarbonates of high clarity

Owner:SHPP GLOBAL TECH BV

Solvent Free Aqueous Polyurethane Dispersions and Methods of Making and Using the Same

ActiveUS20110306724A1Good performanceLow and high temperature storage performancePolyureas/polyurethane adhesivesPrepolymerSolvent

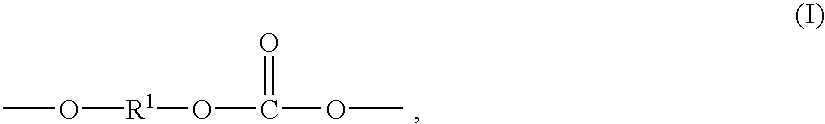

Substantially solvent-free aqueous polyurethane dispersions and methods of making and using the same are provided. The substantially solvent-free aqueous polyurethane dispersions are provided in a substantially solvent-free system of a prepolymer made by reacting at least one polyol, at least one polyisocyanate, at least one isocyanate-reactive compound comprising one or more ionic or potential ionic groups, and at least one isocyanate chain terminating agent.

Owner:VERSUM MATERIALS US LLC

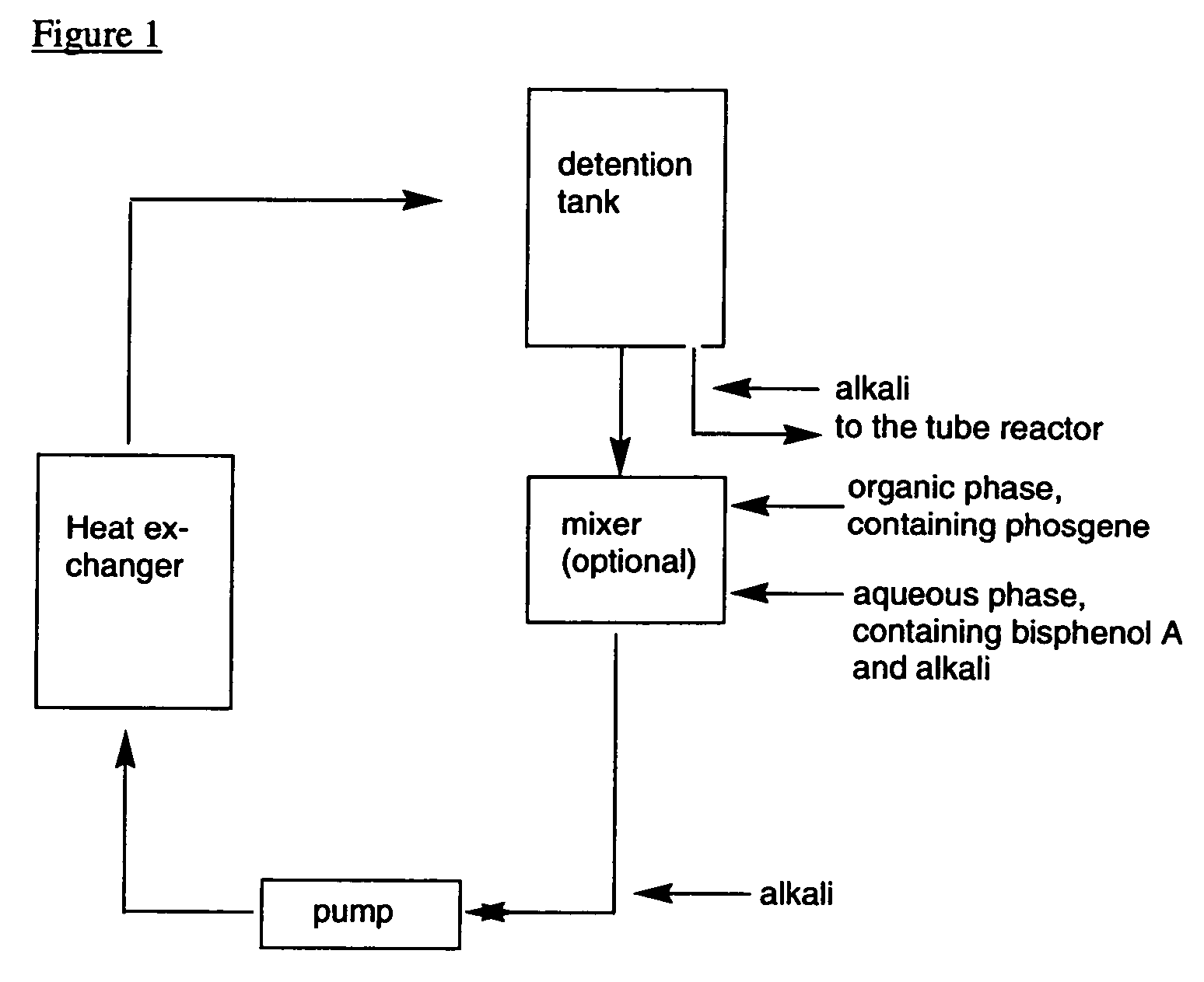

Method for preparation of copolyorganosiloxanecarbonates of high clarity

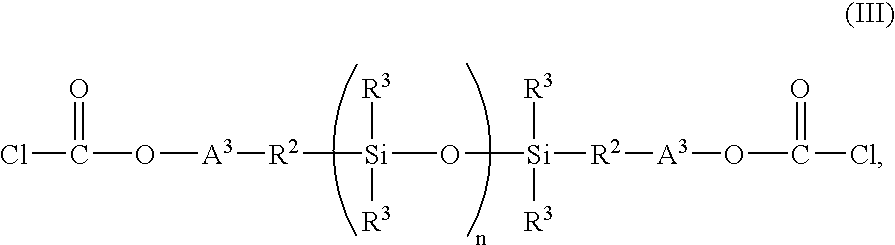

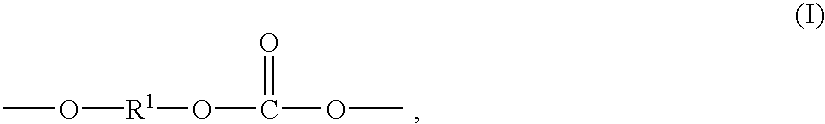

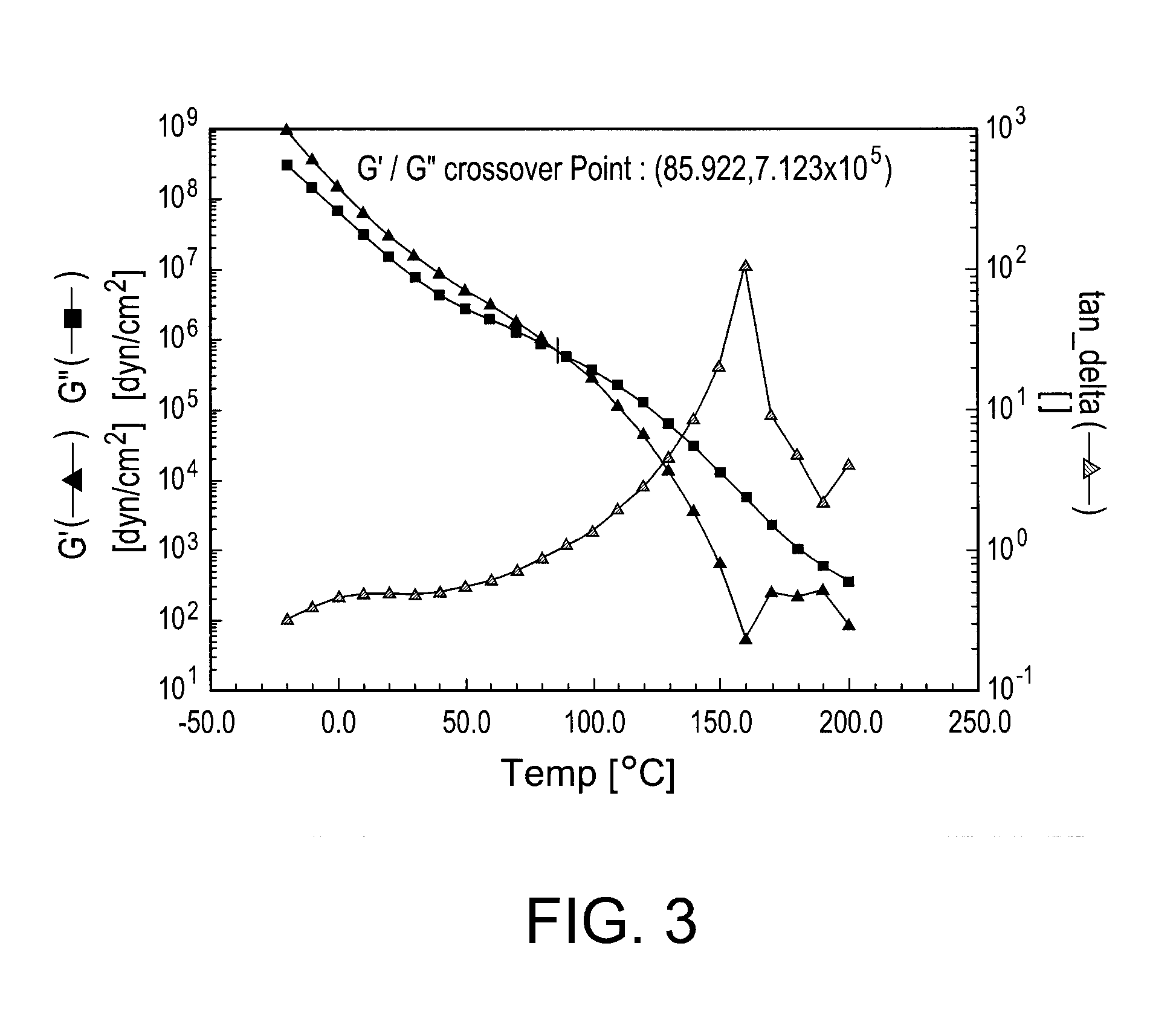

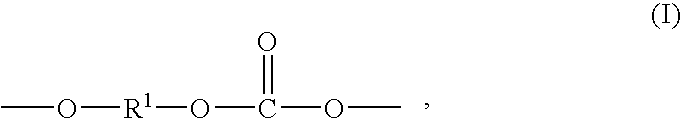

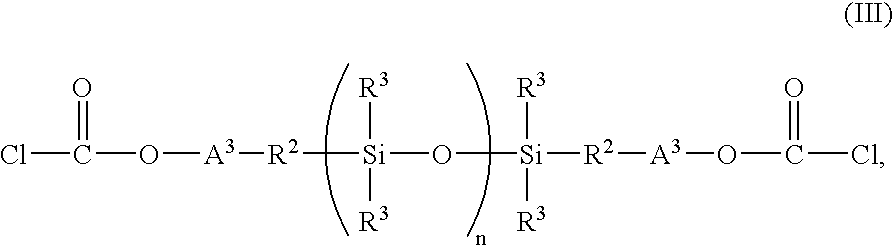

Copolyorganosiloxanecarbonates are prepared by first preparing an oligomeric aromatic polycarbonate, such as an oligomeric bisphenol A polycarbonate, in the presence of a tertiary amine as the only catalyst species; contacting the oligomeric polycarbonate mixture with a polyorganosiloxane bis(aryl)chloroformate, such as the bischloroformate of hydroxy-terminated eugenol polydimethylsiloxane; and introducing phosgene and / or chain termination agent either continuously or in stages. A feature of the process is the presence of dihydroxyaromatic compound in only one charge, at the beginning. The products have excellent physical properties, including transparency.

Owner:SHPP GLOBAL TECH BV

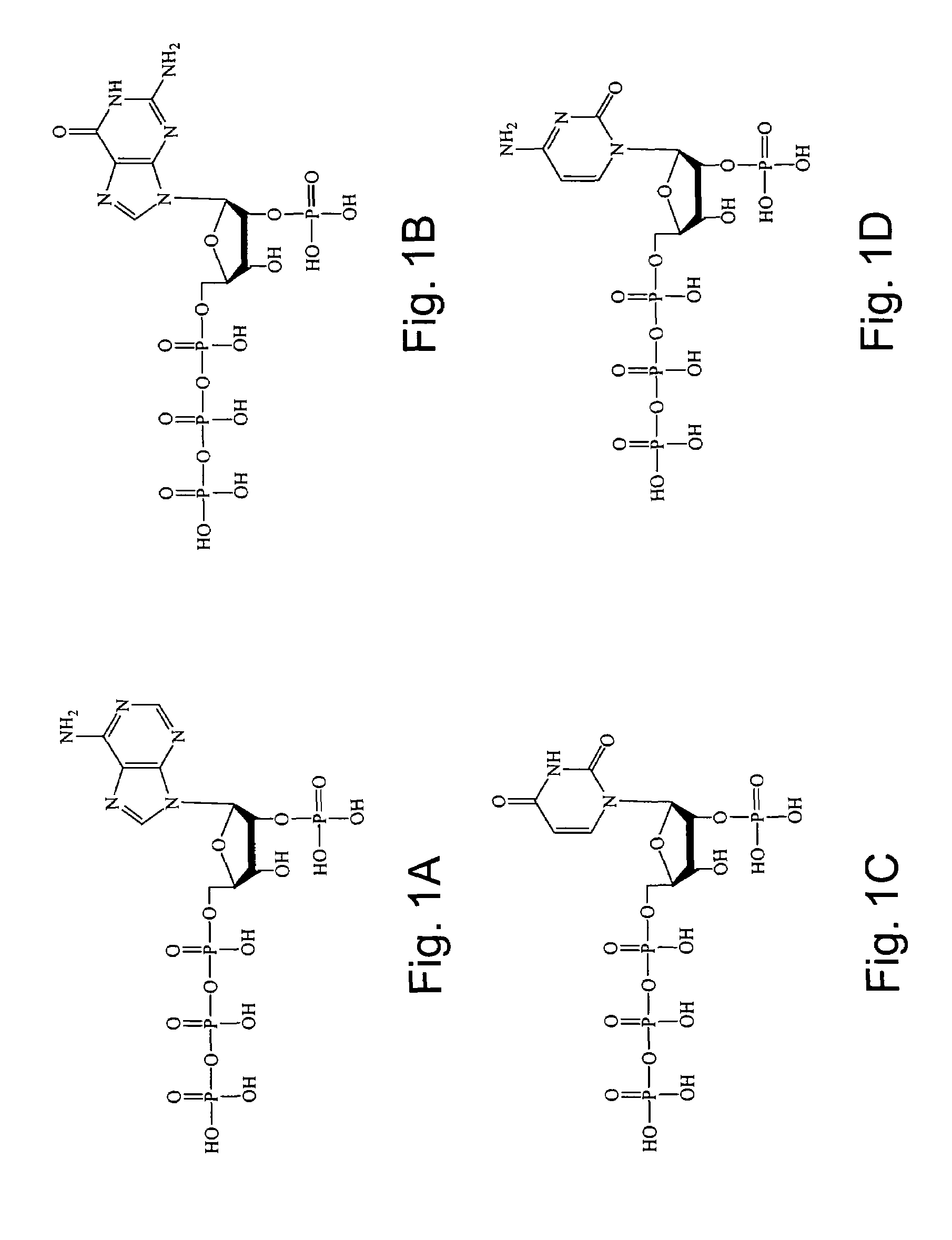

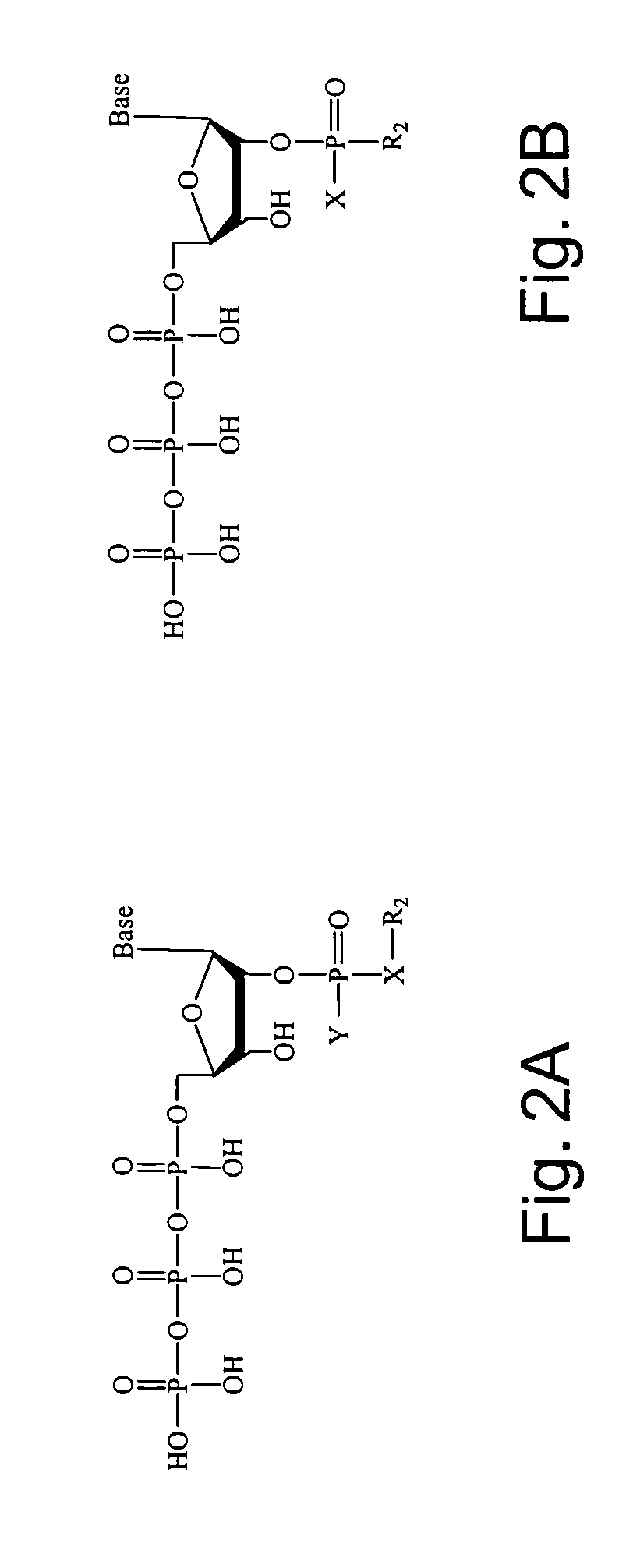

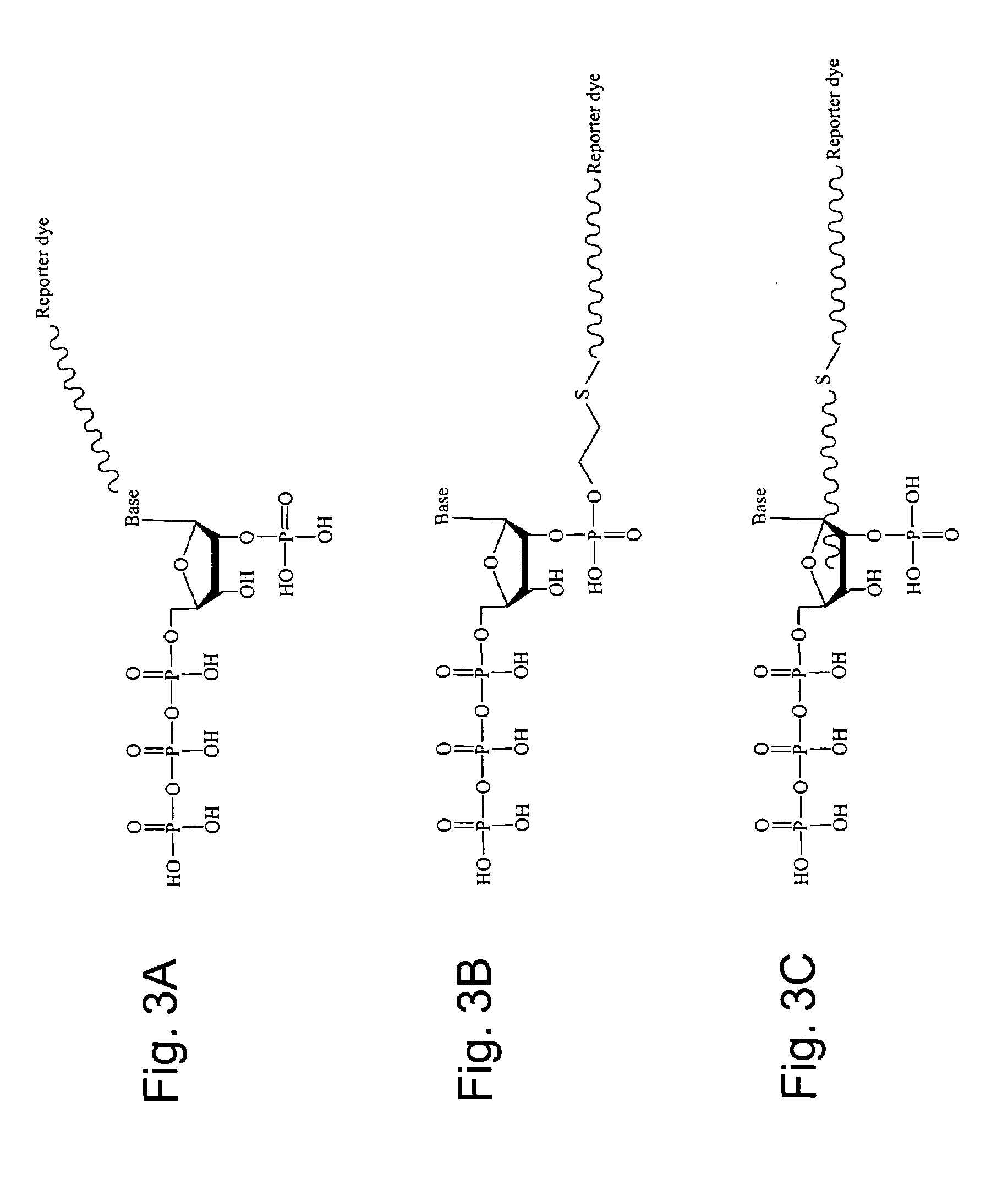

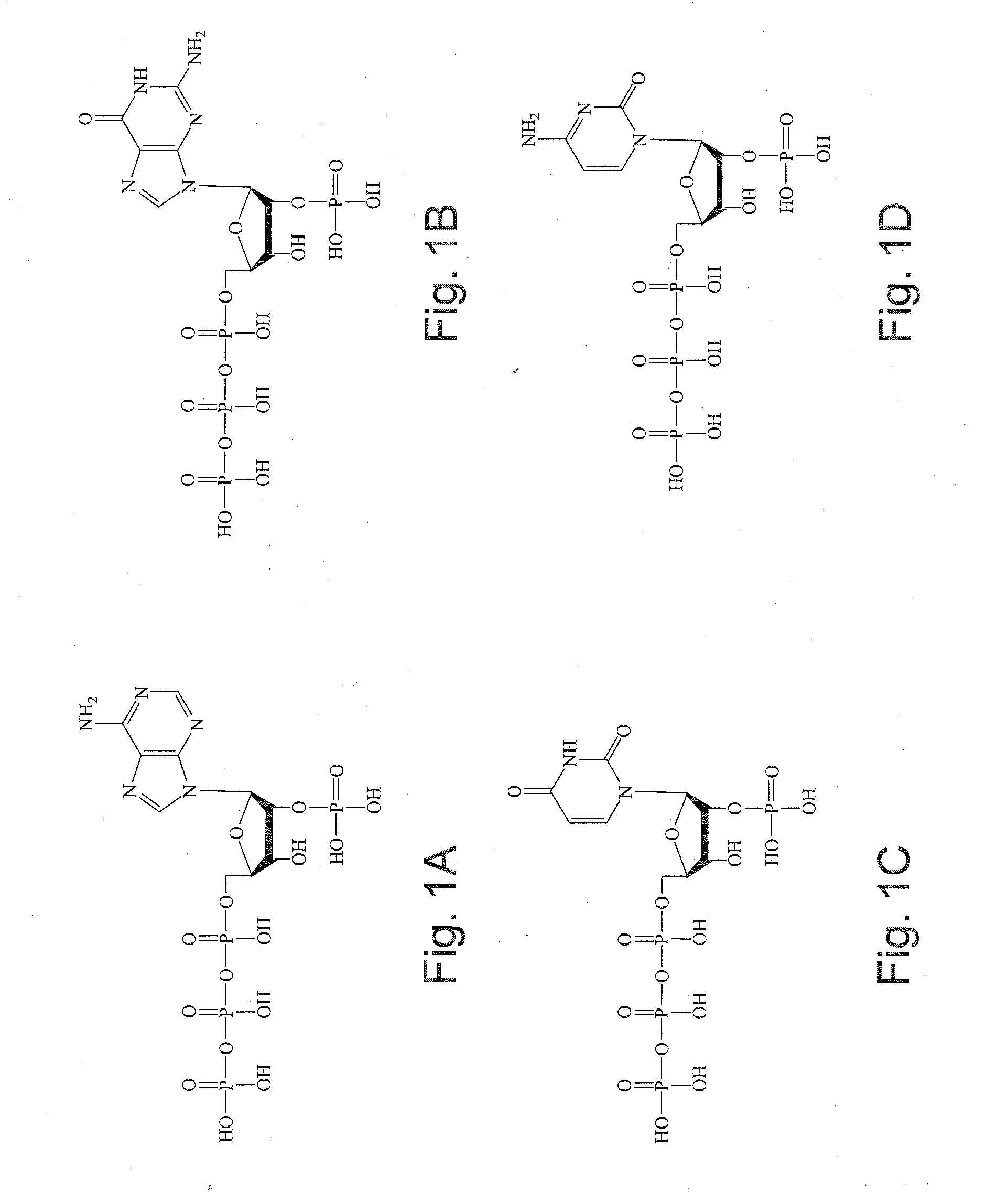

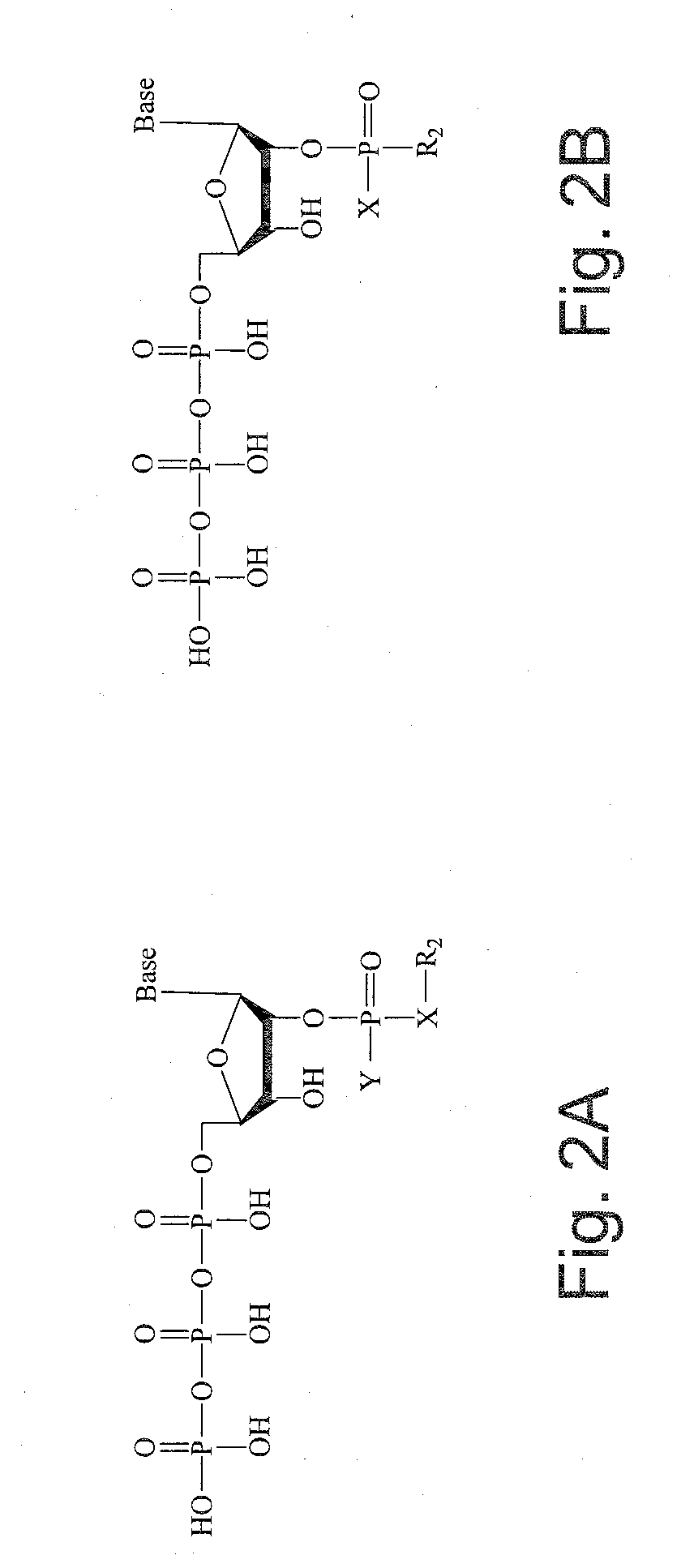

2'-terminator nucleotide-related methods and systems

ActiveUS7572581B2Easily substitutedSacrificing ease of useBioreactor/fermenter combinationsBiological substance pretreatmentsNucleotideComputational biology

The present invention provides methods of extending primer nucleic acids and sequencing target nucleic acids. The methods include the use of 2′-terminator nucleotides to effect chain termination. In addition to related reaction mixtures and kits, the invention also provides computers and computer readable media.

Owner:ROCHE MOLECULAR SYST INC

Process for the preparation of polycarbonates

An improvement in the continuous two-phase interfacial condensation process for preparing polycarbonate is disclosed. In the process that entails at least one diphenol, phosgene, at least one chain terminator, and optionally branching agents and is carried out in the presence of a catalyst the improvement comprising maintaining the concentration of the catalyst at a level of at least 0.012 mol per mol of diphenol.

Owner:COVESTRO DEUTSCHLAND AG

2'-Terminator Nucleotide-Related Methods and Systems

InactiveUS20090142810A1Easily substitutedSacrificing ease of useSugar derivativesMicrobiological testing/measurementNucleotideComputational biology

The present invention provides methods of extending primer nucleic acids and sequencing target nucleic acids. The methods include the use of 2′-terminator nucleotides to effect chain termination. In addition to related reaction mixtures and kits, the invention also provides computers and computer readable media.

Owner:ROCHE MOLECULAR SYST INC

Thermoplastic polyurethanes comprising polytrimethylene ether soft segments

InactiveCN101326212AReduce manufacturing costReduce energy consumptionMonocomponent polyurethanes artificial filamentAlcoholEther

Thermoplastic polyurethane prepared from reactants comprising: (a) polytrimethylene ether glycol; (b) diisocyanate; (c) diol chain extender; and (d) monofunctional alcohol chain terminator or monofunctional amine chain terminator; and manufacture and use thereof.

Owner:EI DU PONT DE NEMOURS & CO

Active group containing polyacrylate flexibilizer, preparation method thereof and epoxy resin adhesive modified by same

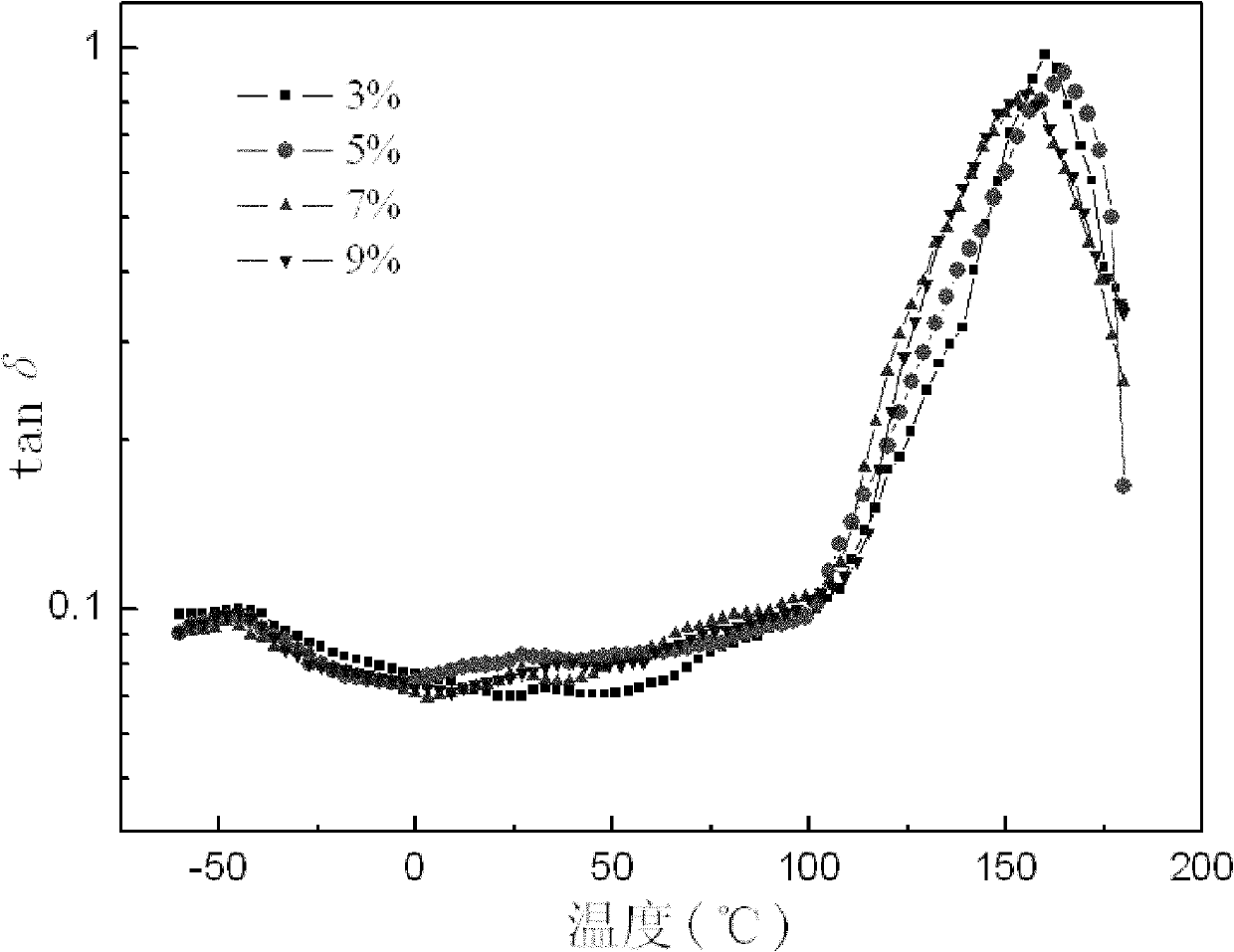

InactiveCN101993670AIncreased shear strengthHigh peel strengthMacromolecular adhesive additivesEpoxy resin adhesivesEpoxyPolymer science

The invention relates to an active group containing polyacrylate flexibilizer, a preparation method thereof and epoxy resin adhesive modified by the flexibilizer. The invention solves the problems that the existing polyacrylate modified epoxy resin adhesive has poor heat resistance, shear strength and peel strength are low, and the existing adhesive can not be used as structural adhesive. The flexibilizer is obtained by reaction of monomer, dispersion medium, initiator, chain transfer agent and chain terminator. Half of mixed solution of monomer and initiator and dispersion medium are added into a reactor, and then the rest of mixed solution and the chain transfer agent are added into the reactor, and finally the chain terminator is added, thus obtaining the flexibilizer by reaction. The adhesive contains component A and curing agent as well as component C DMP-30; wherein the component A is composed of flexibilizer and epoxy resin. The flexibilizer modified adhesive of the invention has good heat resistance, shear strength at 25 DEG C can reach 44.7MPa, and peel strength at 25 DEG C can reach 8.24kN / m. The adhesive of the invention can be used as structural adhesive.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

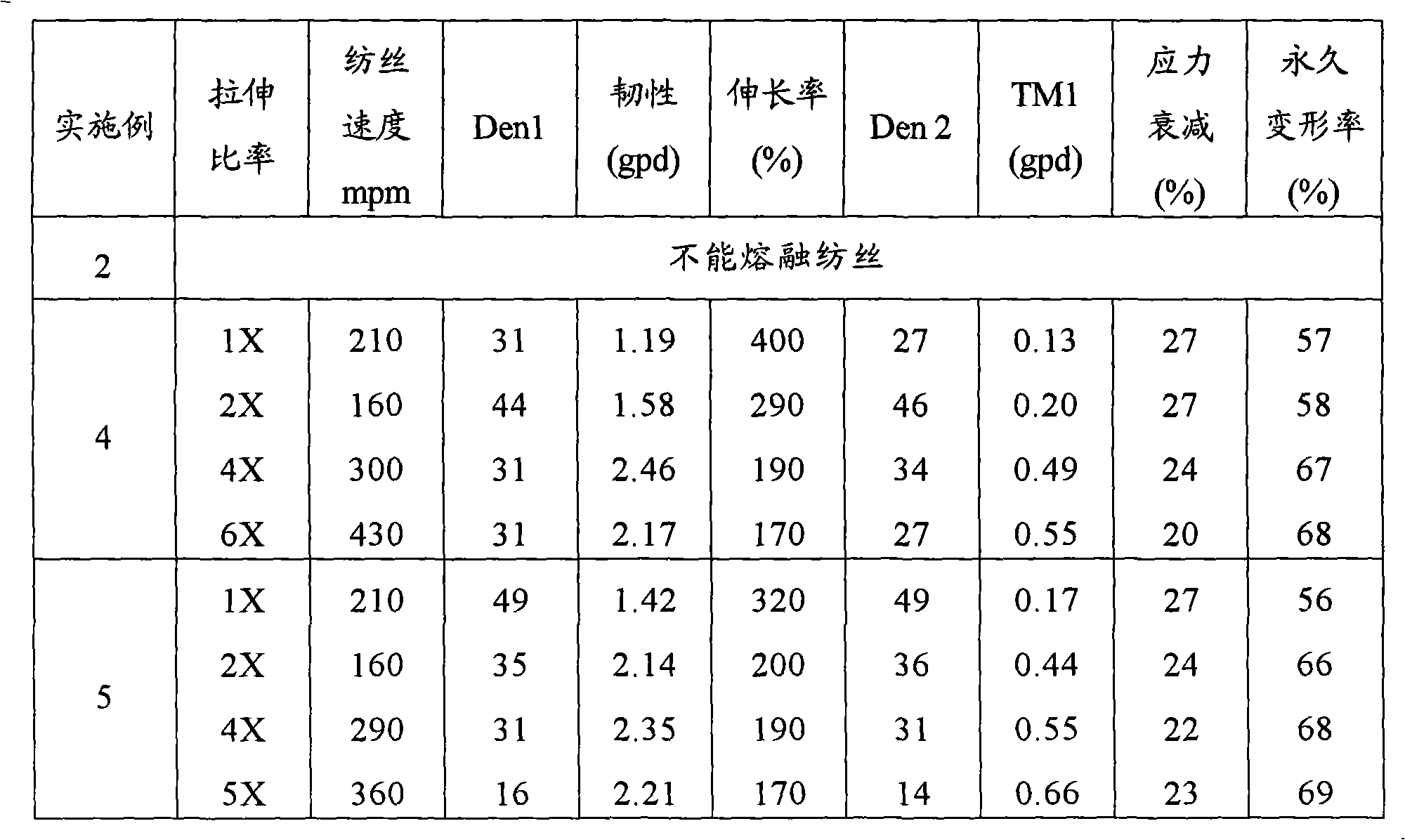

Method for preparing low-temperature finalizing polyurethane elastic fiber

ActiveCN102899740AReduce energy consumptionGood shaping effectMonocomponent synthetic polymer artificial filamentPolyesterPolymer science

The invention relates to a method for preparing a low-temperature finalizing polyurethane elastic fiber, comprising the steps of carrying out condensation polymerization on polyether diol PTMG, polyester diol PE, diphenylmethane diisocyanate MDI and tetramethyl benzene dimethyl diisocyanate m-TMXDI to obtain a carbamic acid ester prepolymer, fully dissolving the prepolymer by taking DMAC (Dimethyl Acetamide) or DMF (Dimethyl Formamide) as the solvent, carrying out chain extension and chain termination on the prepolymer by using a chain extender and a chain terminator to obtain polyurethane urea solution, and finally adding various functional auxiliaries in the polyurethane urea solution and preparing to obtain the polyurethane elastic fiber with low-temperature finalizing performance via a dry spinning system.

Owner:ZHEJIANG HUAFENG SPANDEX

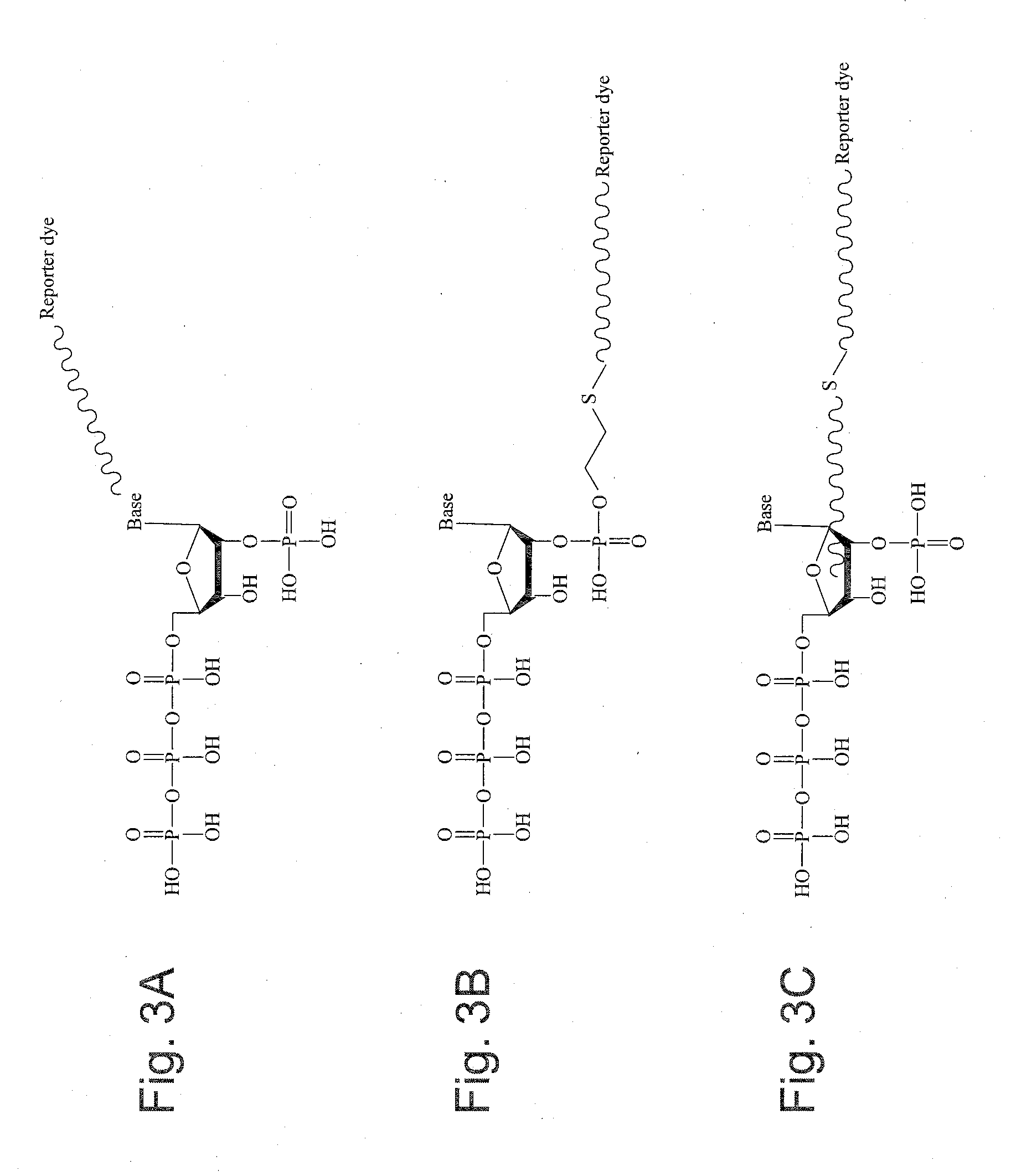

Molecular detection systems utilizing reiterative oligonucleotide synthesis

InactiveUS20050064414A1Sugar derivativesMicrobiological testing/measurementOligoribonucleotidesProtein target

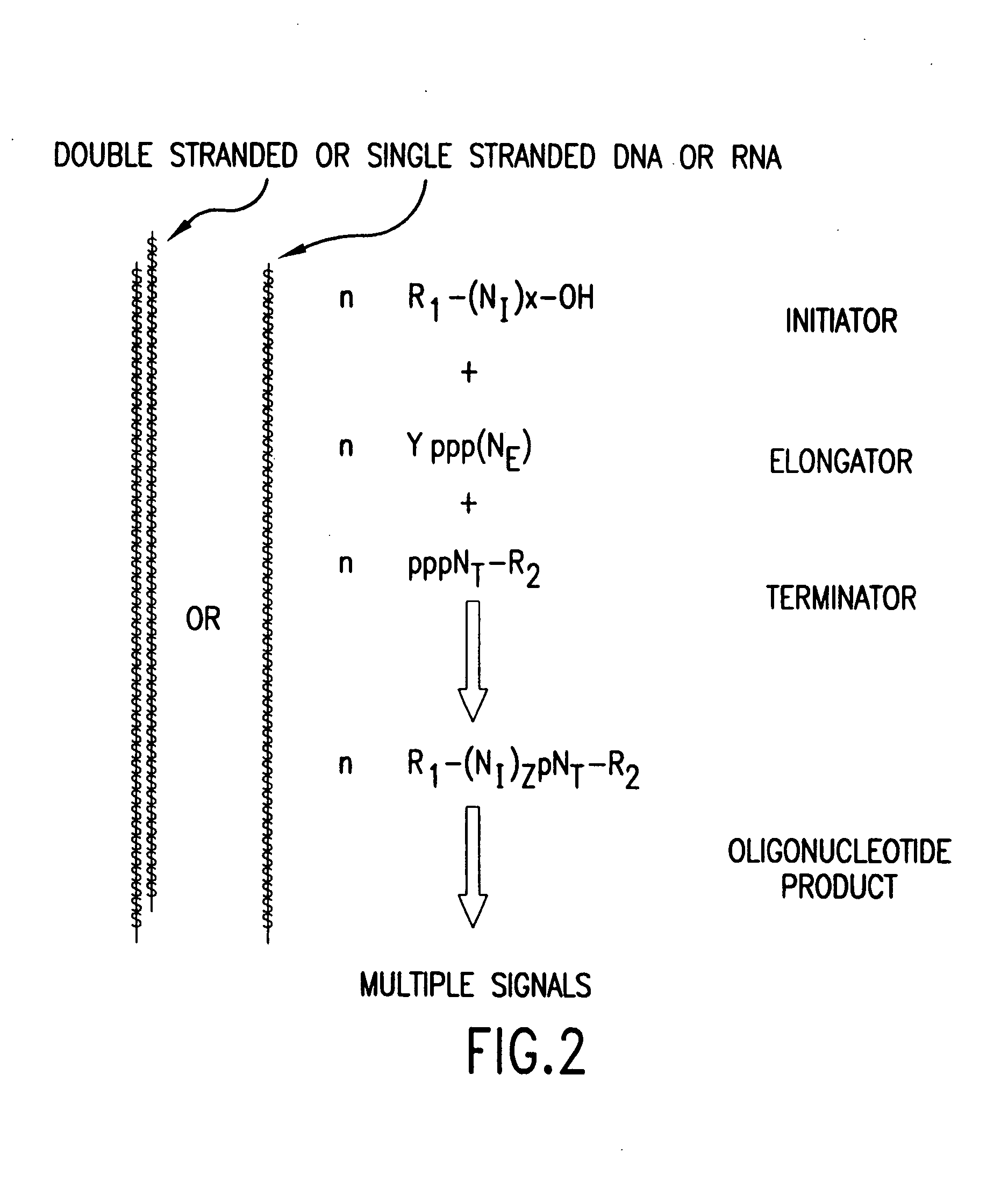

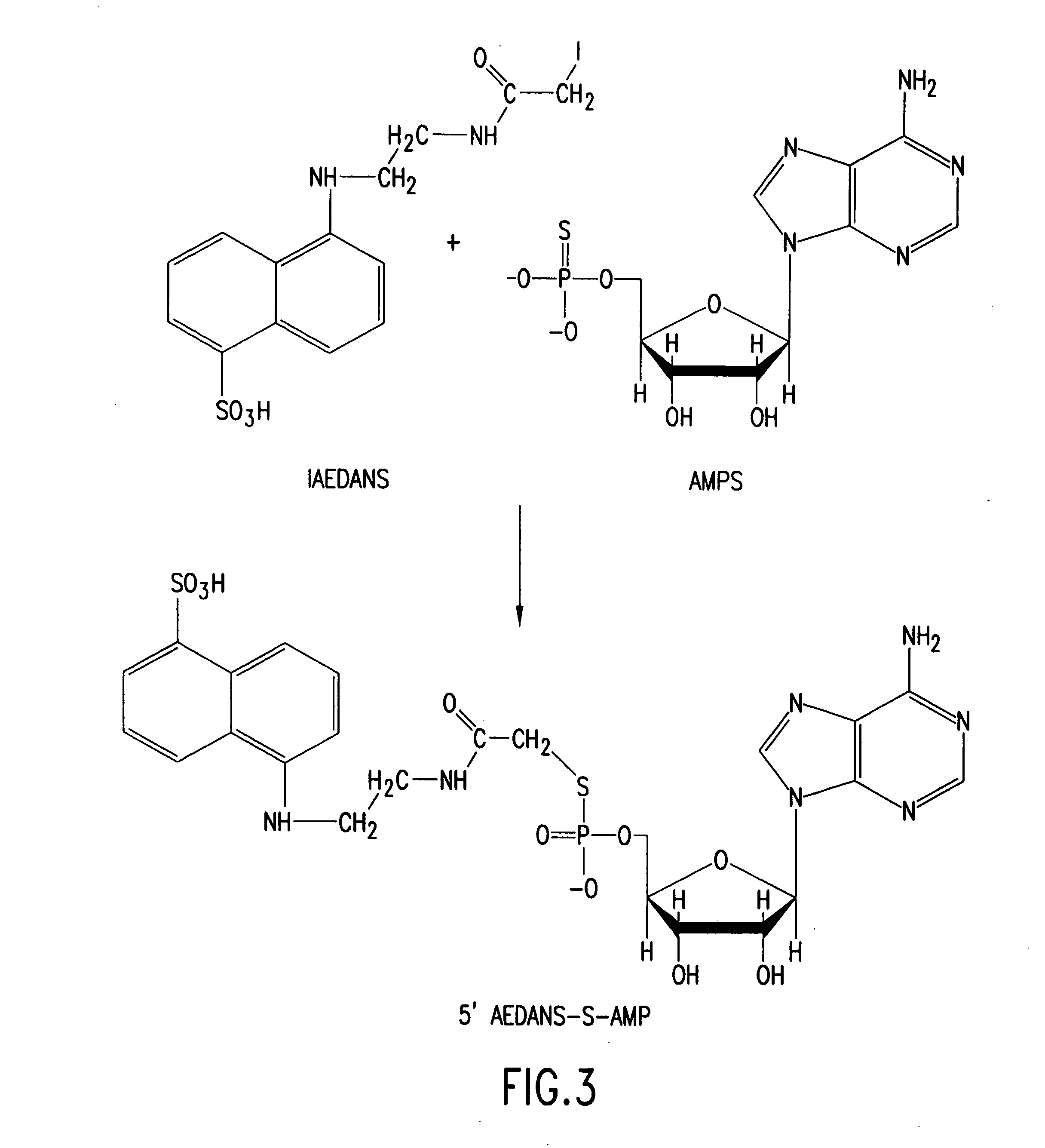

The present invention provides methods for detecting the presence of a target molecule by generating multiple detectable oligonucleotides through reiterative enzymatic oligonucleotide synthesis events on a defined polynucleotide sequence. The methods generally comprise using a nucleoside, a mononucleotide, and oligonucleotide, or a polynucleotide, or analog thereof, to initiate synthesis of an oligonucleotide product that is substantially complementary to a target site on the defined polynucleotide sequence; optionally using nucleotides or nucleotide anologs as oligonucleotide chain elongators; using a chain terminator to terminate the polymerization reaction; and detecting multiple oligonucleotide products that have been synthesized by the polymerase. In one aspect, the invention provides a method for detecting a target protein, DNA or RNA by generating multiple detectable RNA oligoribonucleotides by abortive transcription.

Owner:RIBOMED BIOTECHNOLOGIES INC

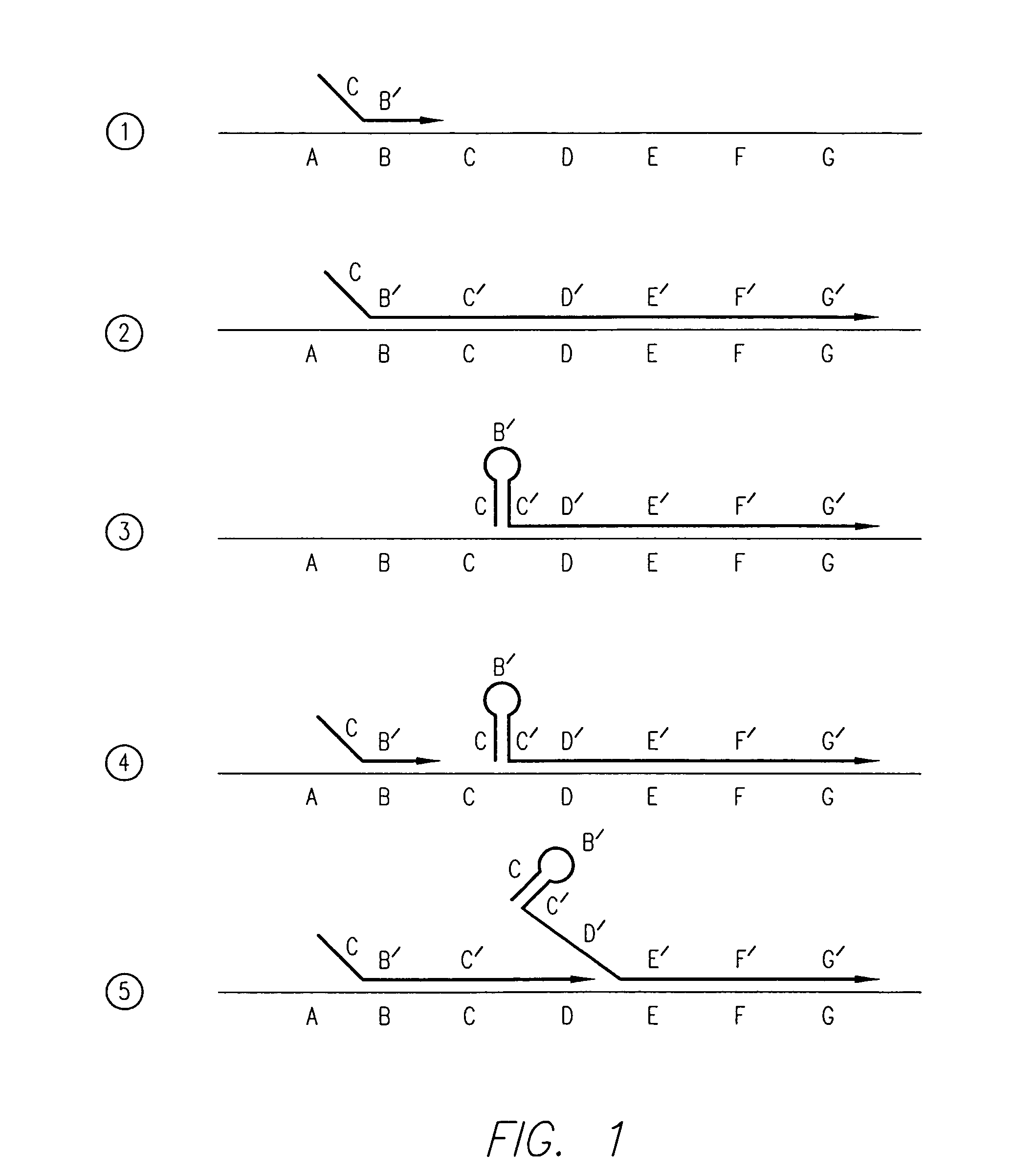

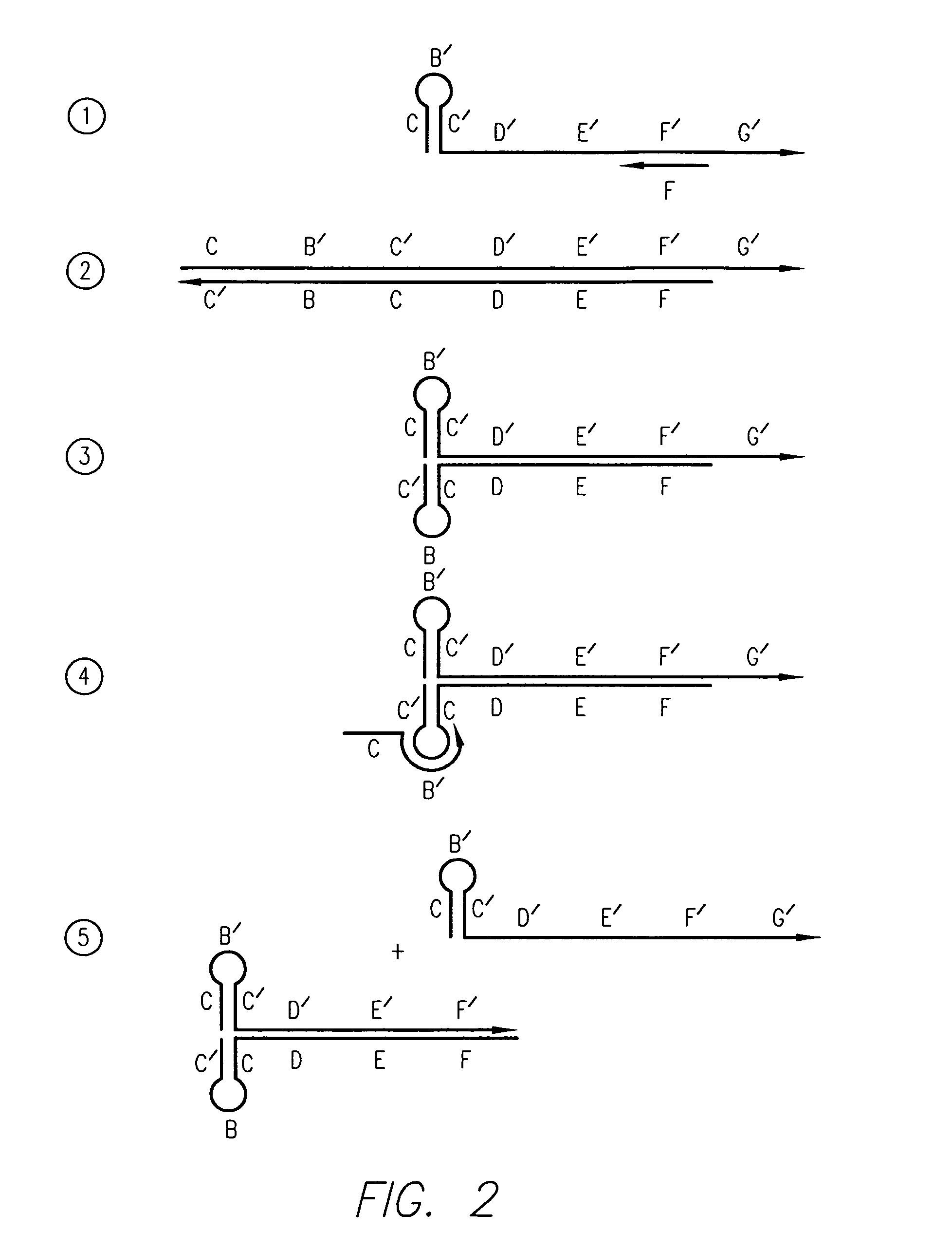

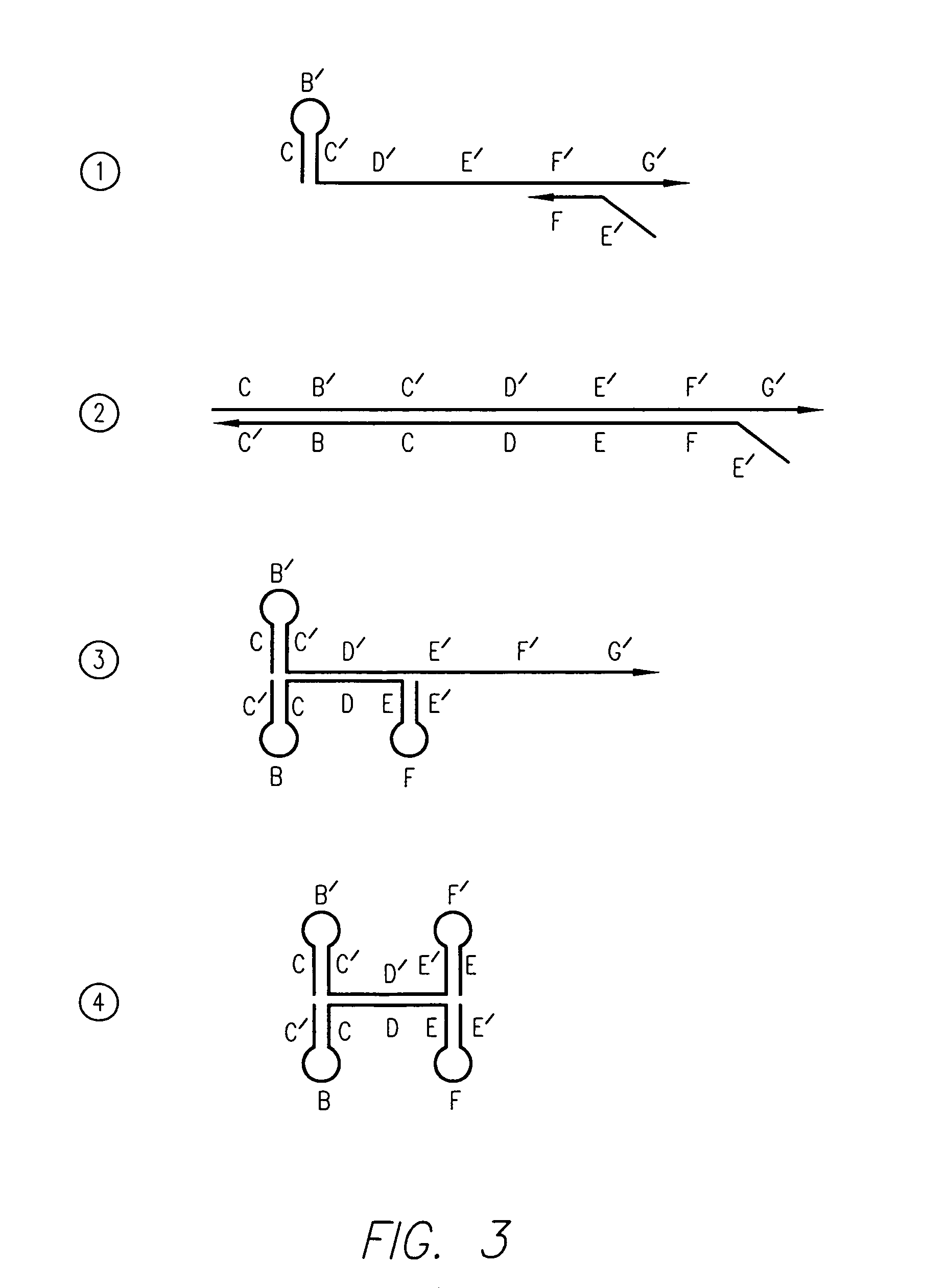

Processes for non-linearly amplifying nucleic acids

InactiveUS7264930B2Reduced thermodynamic stabilitySugar derivativesMicrobiological testing/measurementNucleic acid sequencingNucleic acid sequence

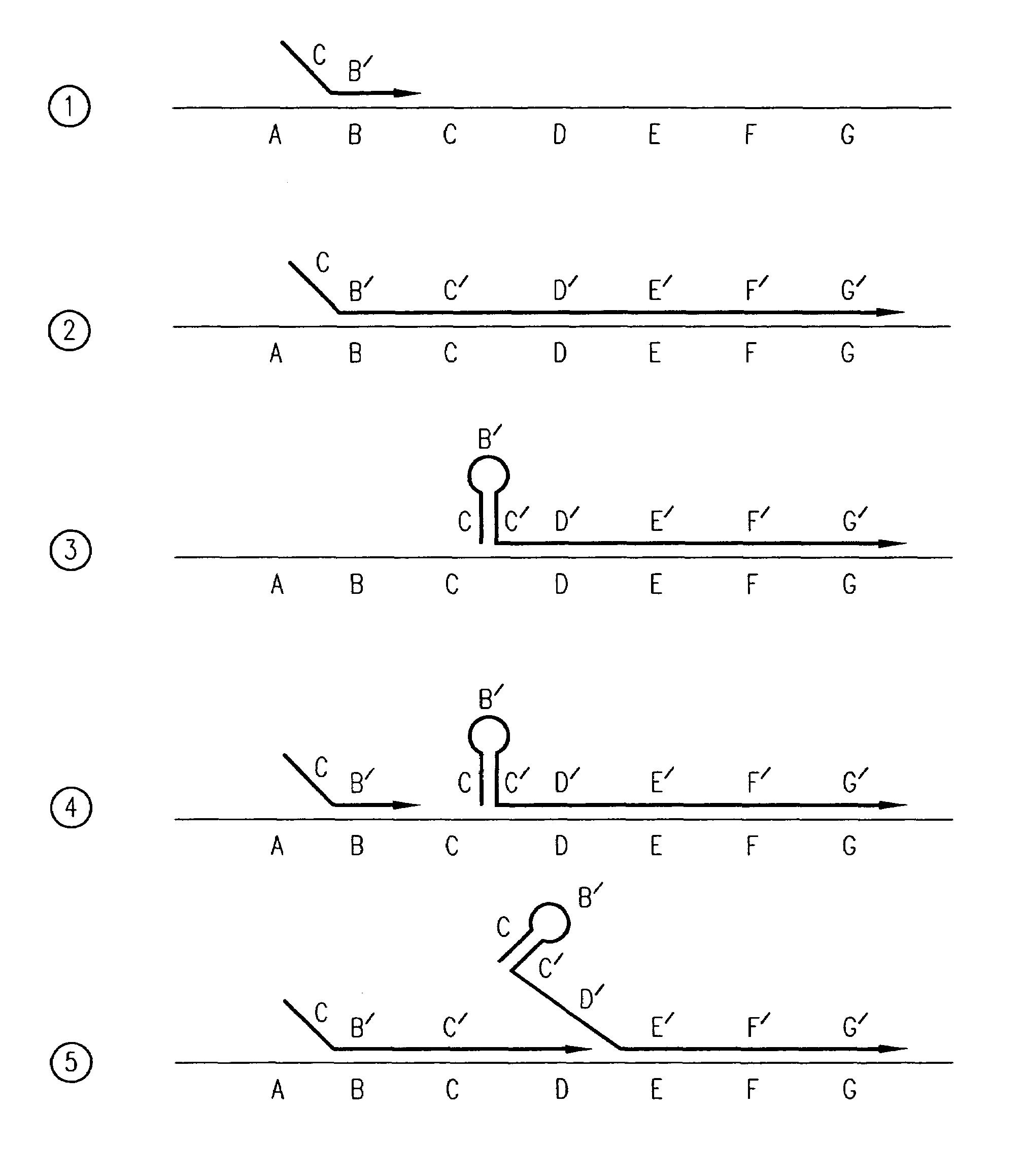

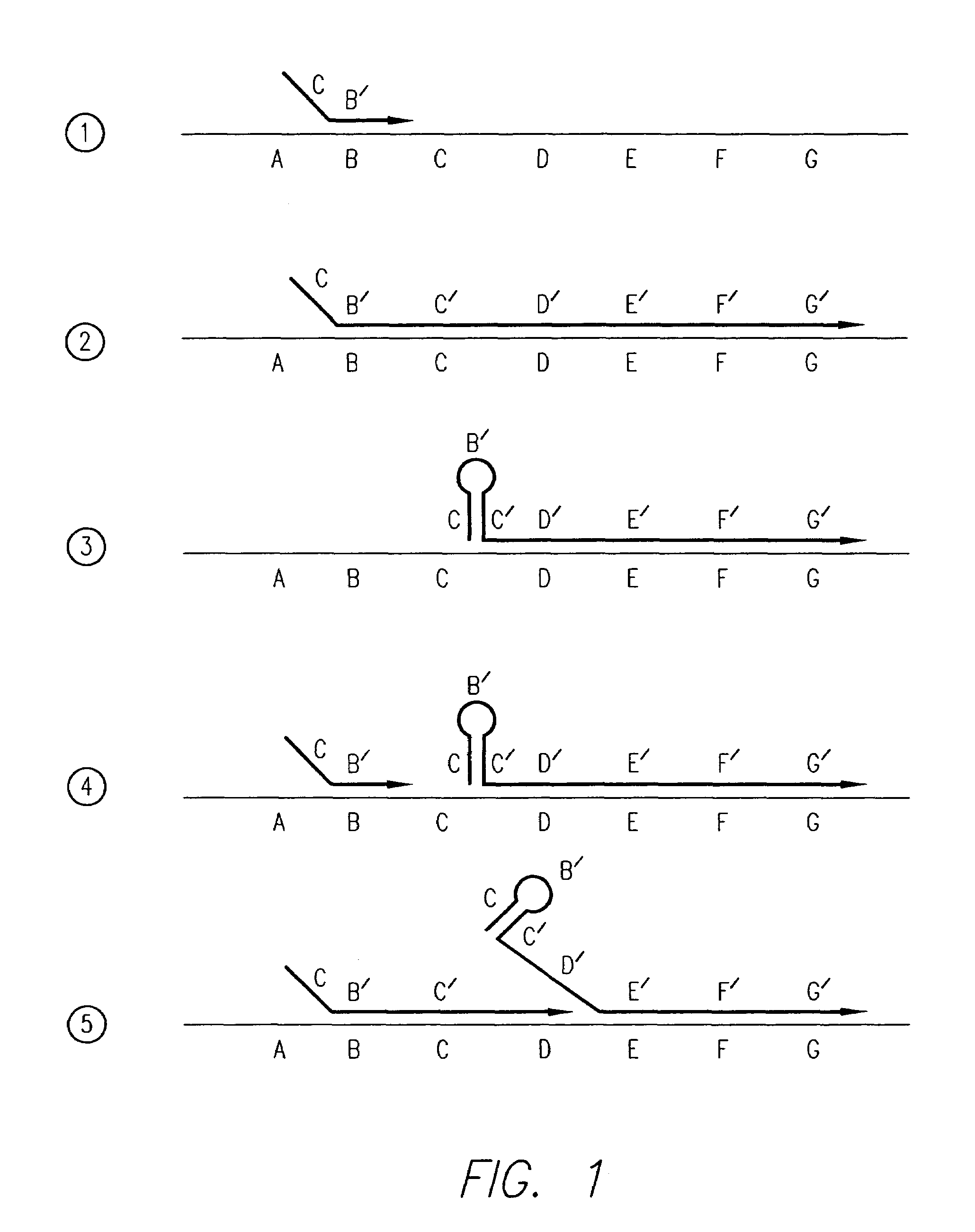

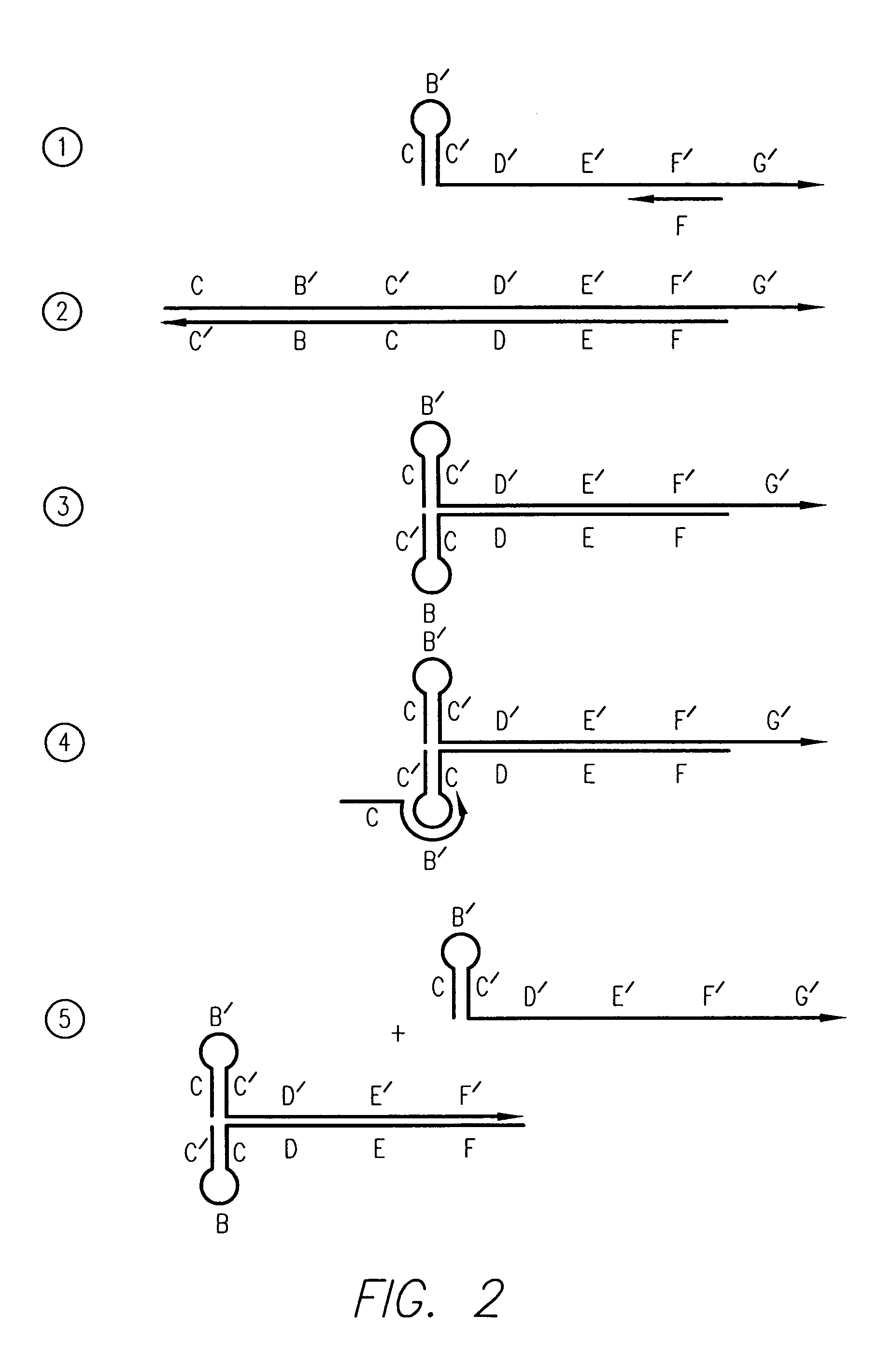

This invention provides novel processes for amplifying nucleic acid sequences of interest, including linear and non-linear amplification. In linear amplification, a single initial primer or nucleic acid construct is utilized to carry out the amplification process. In non-linear amplification, a first initial primer or nucleic acid construct is employed with a subsequent initial primer or nucleic acid construct. In other non-linear amplification processes provided by this invention, a first initial primer or nucleic acid construct is deployed with a second initial primer or nucleic acid construct to amplify the specific nucleic acid sequence of interest and its complement that are provided. A singular primer or a singular nucleic acid construct capable of non-linear amplification can also be used to carry out non-linear amplification in accordance with this invention. Post-termination labeling process for nucleic acid sequencing is also disclosed in this invention that is based upon the detection of tagged molecules that are covalently bound to chemically reactive groups provided for chain terminators. A process for producing nucleic acid sequences having decreased thermodynamic stability to complementary sequences is also provided and achieved by this invention. Unique nucleic acid polymers are also disclosed and provided in addition to other novel compositions, kits and the like.

Owner:ENZO DIAGNOSTICS

Oxidative thinner for heavy oil exploitation via steam injection and preparation thereof

ActiveCN101440275AHigh viscosity reduction rateLow viscosityDrilling compositionHydrolysateAcid substances

The invention relates to an oxidization viscosity reducer for viscous oil recovery by steam injection and a preparation method thereof. The oxidization viscosity reducer comprises components by weight percentage: 0.5 to 10 percent of component A, 0.5 to 10 percent of component B, 0.1 to 8 percent of component C, 0.1 to 5 percent of component D, and the balance being water, wherein the component Ais peroxide, the component B is transition metal salt of an organic acid, the component C is inorganic salt with the acidity shown in a hydrolysate, and the component D is an alkaline substance. The oxidization viscosity reducer can oxidize gelatine and asphaltine in viscous oil, reduce the viscosity of crude oil by changing a structure of the viscous oil through chain termination, oxidize to generate an acid substance at the same time, ensure that the viscous oil becomes a substance with the effect of a surfactant by adding the alkaline substance, and also play a role in viscosity reduction.The experiments show that the viscosity reduction rate can reach 99.9 percent when the viscosity reducer reacts with the crude oil for 24 hours at the temperature of 100 DEG C. The viscosity reducer has higher viscosity reduction rate, is applicable to the viscosity reduction of oil well stratums with high steam injection temperature, and also has good effect under relatively lower temperature conditions.

Owner:中国石化集团河南石油勘探局有限公司

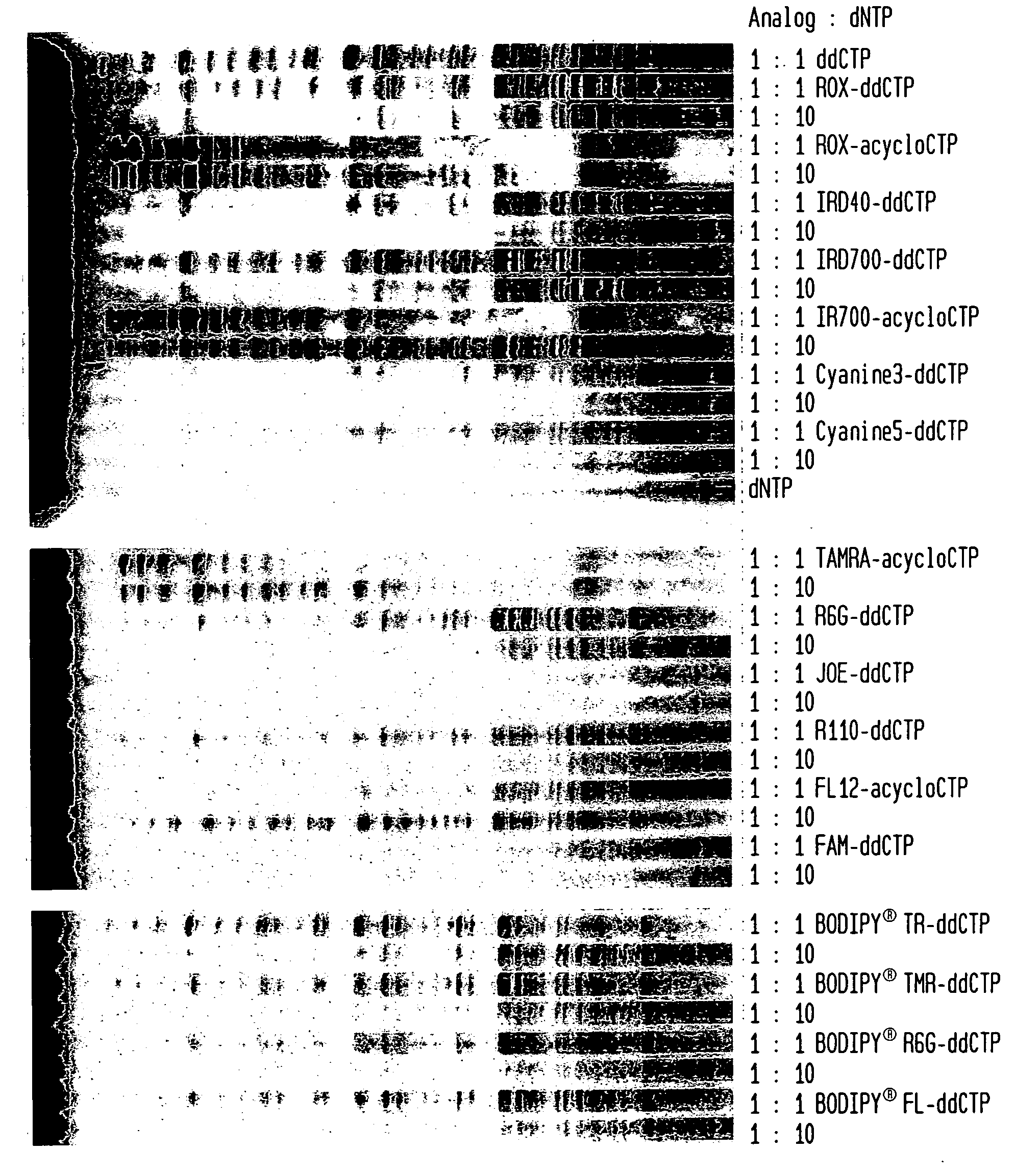

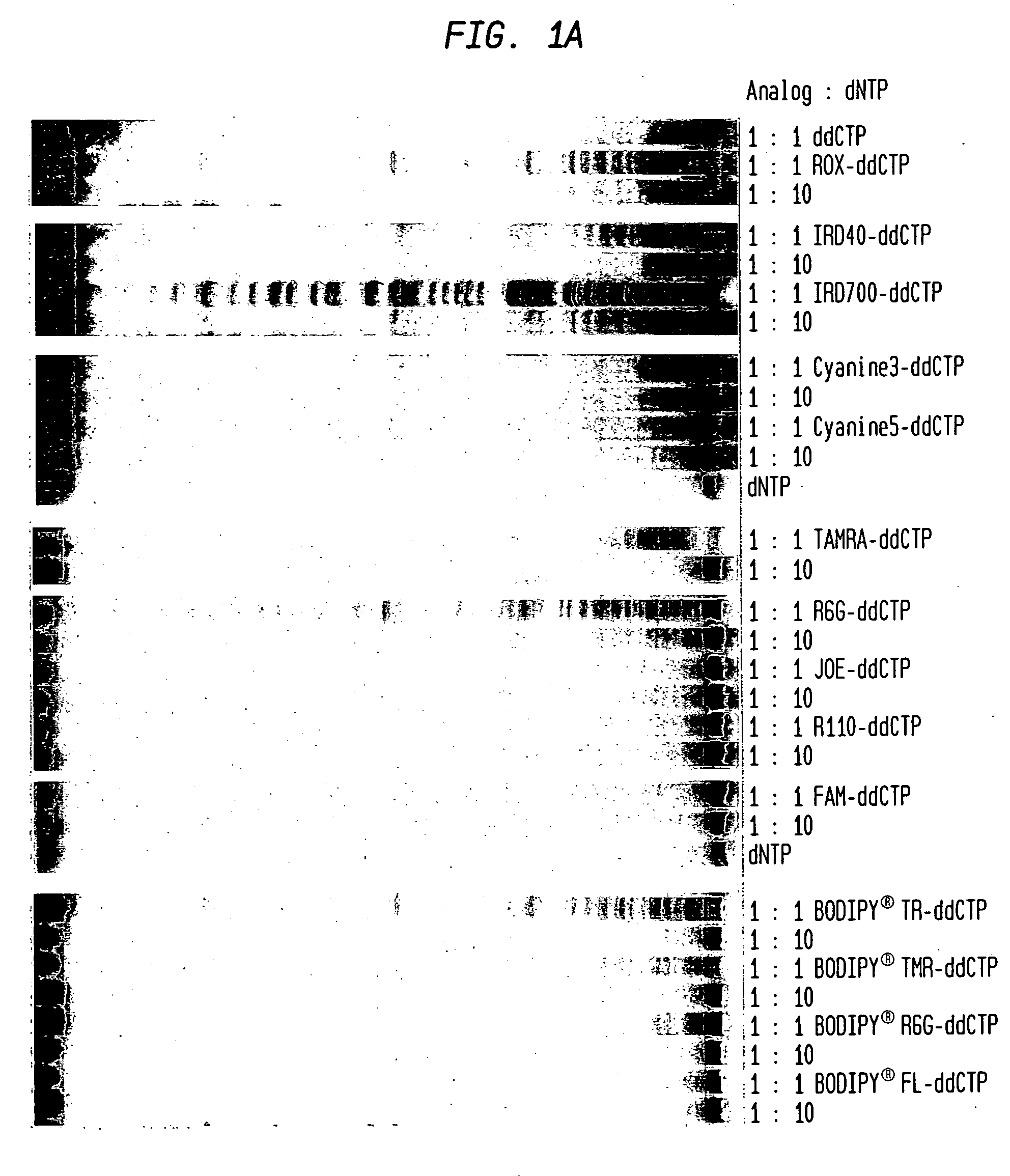

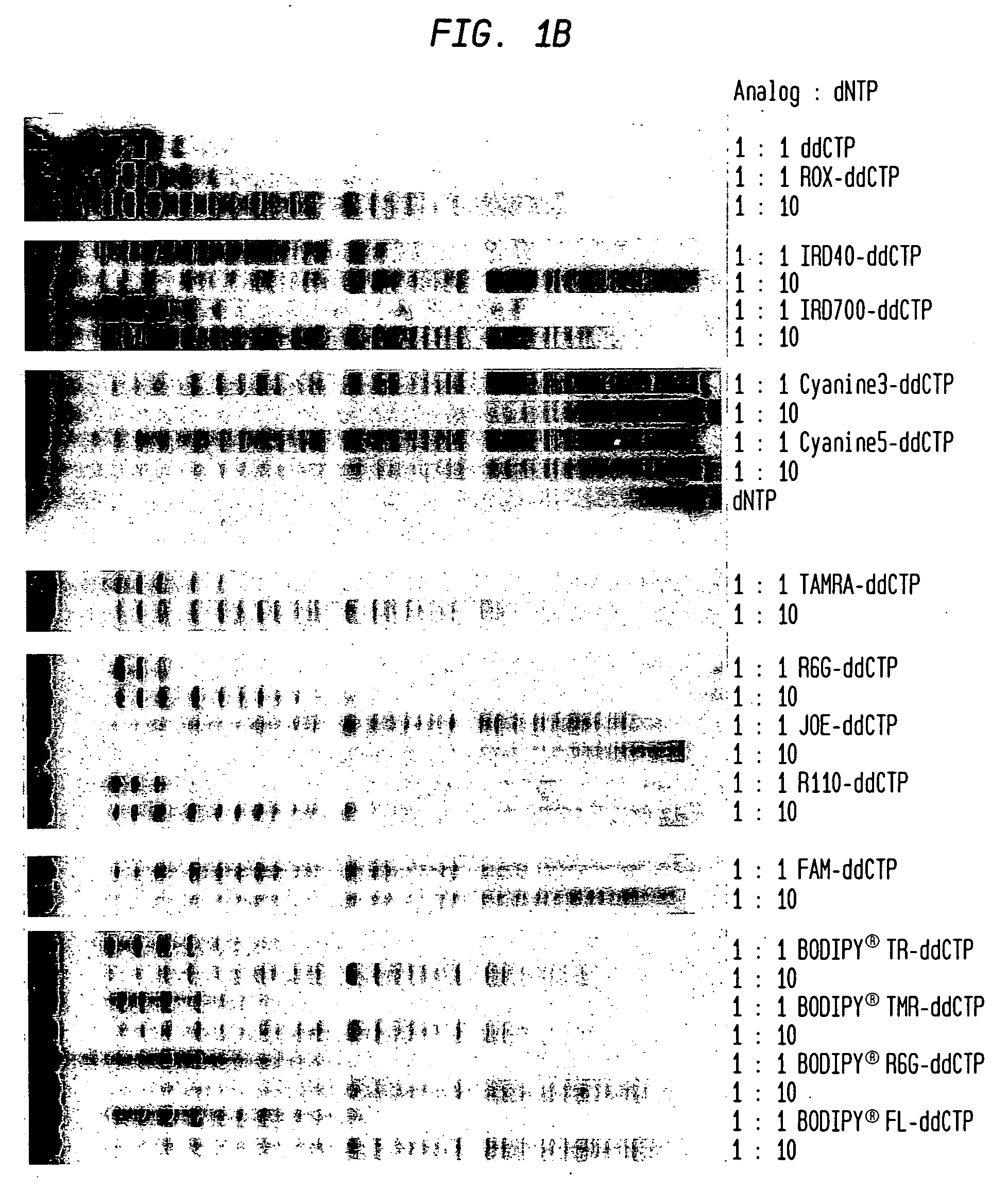

Incorporation of modified nucleotides by archaeon DNA polymerases and related methods

InactiveUS20060199214A1Efficiently incorporateEffective mergerBacteriaSugar derivativesEnzymeDNA polymerase

The present invention is directed toward improving the efficiency of chain terminator incorporation by Family B archaeon DNA polymerases. Previously, the low efficiency of ddNTP, and more especially dye-labeled ddNTP, incorporation has limited the usefulness of this group of DNA polymerases in protocols requiring chain terminator incorporation.

Owner:JACK WILLIAM +3

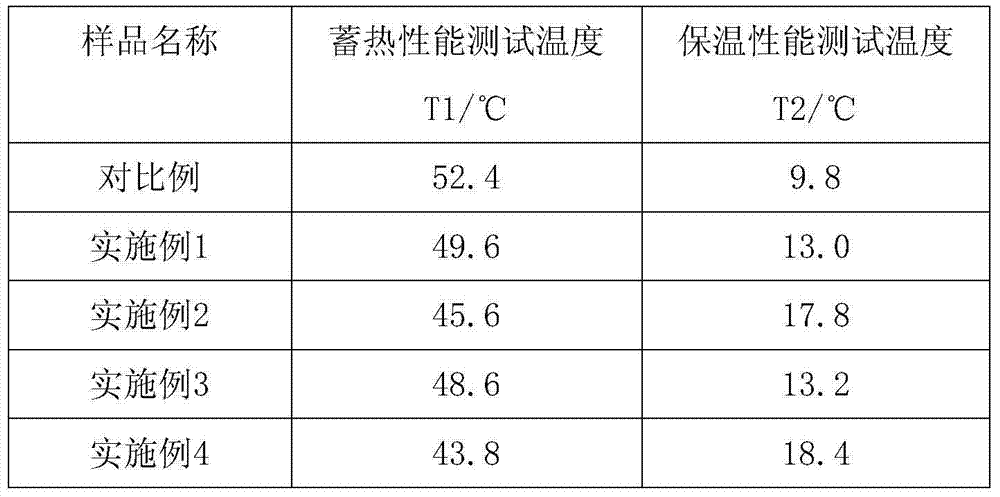

Heat accumulation and preservation polyurethane elastic fibers containing phase change microcapsules and preparation method of heat accumulation and preservation polyurethane elastic fibers

ActiveCN104726957AThermoregulationImprove insulation effectMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberPolymer science

The invention relates to heat accumulation and preservation polyurethane elastic fibers containing phase change microcapsules and a preparation method of the heat accumulation and preservation polyurethane elastic fibers. According to the heat accumulation and preservation fibers, the heat accumulation and preservation performance of polyurethane fibers can be improved by adding 0.5-5wt% of the phase change microcapsules into polyurethane elastic fibers. The preparation method specifically comprises the following steps: (1) preparing the phase change microcapsules with nuclear shell structures by adopting a suspension polymerization method; (2) performing condensation and polymerization by taking polyether diol and diisocyanate as synthetic monomers to form prepolymer, dissolving the prepolymer by adding a solvent, and adding mixed amine to perform chain extension reaction and chain termination reaction on the prepolymer to obtain a polyurethane urea solution; and (3) adding the prepared phase change microcapsules together with other auxiliary agents into the polyurethane urea solution, performing mixed curing, and treating a spinning stock solution subjected to curing by virtue of a dry spinning technology to prepare the heat accumulation and preservation polyurethane elastic fibers. The polyurethane elastic fibers prepared by the method provided by the invention contain a certain proportion of a phase change material, the fibers prepared by the method provided by the invention or textiles of the fibers have excellent heat accumulation and preservation performances.

Owner:ZHEJIANG HUAFENG SPANDEX

Kits for amplifying and detecting nucleic acid sequences

InactiveUS8445664B2Reduced thermodynamic stabilitySugar derivativesMicrobiological testing/measurementChemical reactionLinear amplification

This invention provides novel processes for amplifying nucleic acid sequences of interest, including linear and non-linear amplification. In linear amplification, a single initial primer or nucleic acid construct is utilized to carry out the amplification process. In non-linear amplification, a first initial primer or nucleic acid construct is employed with a subsequent initial primer or nucleic acid construct. In other non-linear amplification processes provided by this invention, a first initial primer or nucleic acid construct is deployed with a second initial primer or nucleic acid construct to amplify the specific nucleic acid sequence of interest and its complement that are provided. A singular primer or a singular nucleic acid construct capable of non-linear amplification can also be used to carry out non-linear amplification in accordance with this invention. Post-termination labeling process for nucleic acid sequencing is also disclosed in this invention that is based upon the detection of tagged molecules that are covalently bound to chemically reactive groups provided for chain terminators. A process for producing nucleic acid sequences having decreased thermodynamic stability to complementary sequences is also provided and achieved by this invention. Unique nucleic acid polymers are also disclosed and provided in addition to other novel compositions, kits and the like.

Owner:ENZO DIAGNOSTICS

Polyurethane urea elastic fiber having high heat resistance and fine shape-setting and process for preparing same

InactiveCN1621428AMonocomponent polyurethanes artificial filamentArtifical filament manufactureFiberDiphenylmethane

The present invention relates to a production method of polyurethane urea elastic fiber. The method comprises: reacting polytetramethylene ether glycol with a molecular weight of 1,500-2,000, 4,4'-diphenylmethanediol in a reactor equipped with a stirrer isocyanate and n-butanol to produce a prepolymer; dissolving the prepolymer in N,N-dimethylacetamide (DMAc) or dimethylformamide (DMF) to produce a prepolymer solution; and Add the prepolymer solution to the chain extender mixture composed of amine compound, trifunctional amine and diethylamine, and use the chain extender mixture to extend the chain of the prepolymer while performing chain termination, so that the All remaining isocyanate groups of the prepolymer react to produce an elastic polyurethane urea polymer. The polyurethaneurea elastic fiber produced by the present invention has high viscosity stability, excellent strength and improved heat resistance and settability.

Owner:TAEKWANG IND CO LTD

Spandex from poly(tetramethylene-co-ethyleneether)glycols blended with polymeric glycols

ActiveUS20070117953A1Monocomponent polyurethanes artificial filamentDry spinning methodsEthylene oxideDiamine

A polyurethaneurea composition comprises a reaction product of at least one diisocyanate compound, a polymeric glycol, a poly(tetramethylene-co-ethyleneether) glycol comprising constituent units derived by copolymerizing tetrahydrofuran and ethylene oxide (EO) wherein the portion of the constituent units derived from ethylene oxide is present in the poly(tetramethylene-co-ethyleneether) glycol from greater than about 37 to about 70 mole percent, at least one diamine chain extender, and at least one chain terminator. The invention further relates to the use of blends of polymeric glycols and poly(tetramethylene-co-ethyleneether) glycols as the soft segment base in spandex compositions. The invention also relates to new polyurethane compositions comprising polymeric glycols and poly(tetramethylene-co-ethyleneether) glycols, and their use in spandex.

Owner:THE LYCRA CO LLC

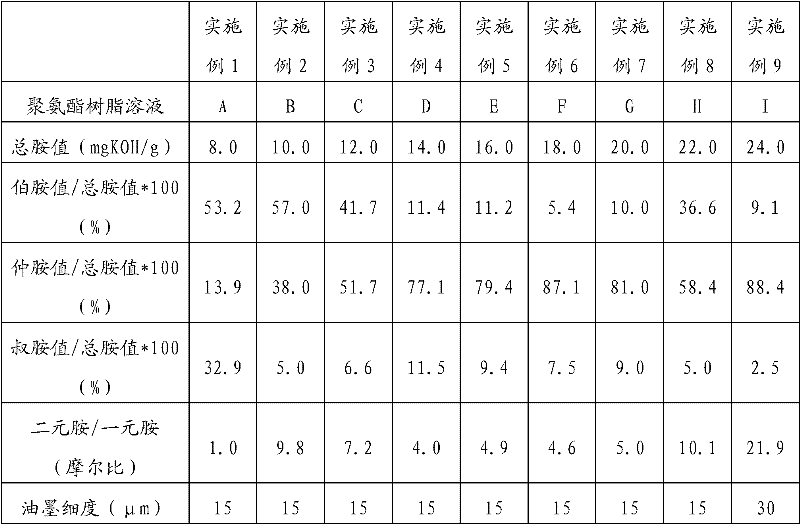

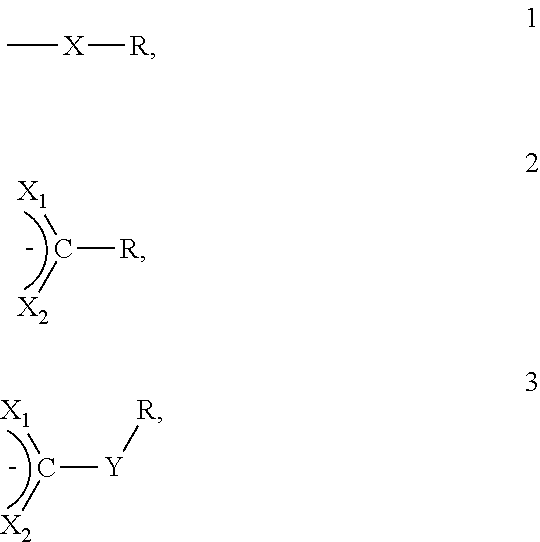

Amine composition and application thereof, polyurethane resin and preparation method and application thereof

ActiveCN102532451AGood anti-adhesionHigh composite strengthInksPolyurea/polyurethane coatingsAlcoholDiol

The invention provides an amine composition which consists of diamine and monoamine in the molar ratio of (1.1-17.1):1. The invention further provides polyurethane resin and a preparation method thereof. The total amine value of the polyurethane resin is 1.20-20.0 mgKOH / g; the primary amine value is 8.7-38.8 percent of the total amine value; the secondary amine value is 5.6-82.6 of the total amine value; and the tertiary amine value is 8.7-55.6 percent of the total amine value. The preparation method comprises the following steps of: mixing high molecular dihydric alcohol with diisocyanate ester; adding a catalyst, and reacting at the temperature of 30-100 DEG C for 2-8 hours to obtain a dibasic alcohol polymer; reacting with a low molecular active hydrogen compound and a low molecular polyhydroxy compound; adding diamine which accounts for 0-70.6 percent of 100 percent by weight of diamine in the amine composition, and expanding a chain in an ester solvent; and adding the rest of diamine in the amine composition and all monoamine, and undergoing chain expansion and chain termination reactions in an ester and / or amine solvent to obtain polyurethane resin. The prepared polyurethane resin has the advantages of high physical and mechanical properties and high-temperature stewing resistance.

Owner:苏州博莱特新材料有限公司

Polycarboxylic acid type ceramic dispersant as well as preparation method and application thereof

The invention belongs to the technical field of preparation of ceramic dispersants, and discloses a polycarboxylic acid type ceramic dispersant as well as a preparation method and application thereof. The preparation method comprises the steps of mixing 3-dimethyl(methacryloyloxyethyl) ammonium propane sulfonate, acrylic acid, a neutralizing agent and a chain transfer agent by agitating; heating to reach a temperature of 60 to 90 DEG C to obtain a mixed solution I; dropwise adding an initiator solution into the mixed solution I; heating to obtain a mixed solution II; adding a chain terminator into the mixed solution II; stopping heating; cooling by agitating until reaching room temperature so as to obtain the polycarboxylic acid type ceramic dispersant. The polycarboxylic acid type ceramic dispersant has an obvious reinforcement effect for ceramic biscuits; with the adoption of the polycarboxylic acid type ceramic dispersant, the application of a reinforcing agent can be decreased; quaternary ammonium cations are introduced to a main chain of polycarboxylic acid, so that the hydration capacity and heat stability of the polycarboxylic acid type dispersant can be improved; the preparation method has the advantages that the reaction is carried out under mild conditions, the synthesis process is simple, and the industrial production is easily carried out.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Preparation method for high-temperature-resistant and fatigue-resistant irradiation-crosslinked polyurethane fibers

ActiveCN105088392AImprove high temperature resistanceImprove fatigue resistancePhysical treatmentMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses a preparation method for high-temperature-resistant and fatigue-resistant irradiation-crosslinked polyurethane fibers. The preparation method is characterized by comprising the following steps of preparing an isocyanate-terminated polyurethane prepolymer from raw materials dihydric alcohol and diisocyanate, adding a butynediol catalyst and polyolefin powder into the prepolymer, and dissolving the polyurethane prepolymer with an aprotic polar solvent to obtain a prepolymer solution; adding a mixed amine solution into the prepolymer solution, and performing chain extension reaction and chain termination reaction to form a polyurethane urea solution; adding a crosslinking additive and a photosensitizer into the polyurethane urea solution to prepare a spandex spinning solution; after the spandex spinning solution is cured, preparing polyurethane fibers by adopting a drying spinning method, and improving three-dimensional crosslinked networks in the fibers by adopting irradiation crosslinking or ultraviolet crosslinking. The polyurethane fibers prepared by the method have the characteristics of high temperature resistance, fatigue resistance and aging resistance, and have broader prospect in the fields of high-end civilian use and industrial use.

Owner:DONGHUA UNIV

Lubricating Oil Compositions

ActiveUS20130274158A1Improve fuel economyLower performance requirementsGroup 6/16 element organic compoundsAdditivesPolyolefinPolyol

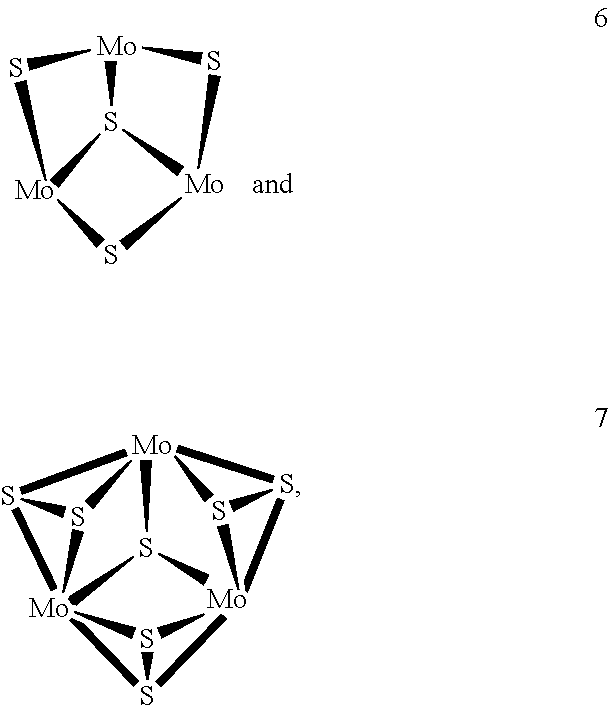

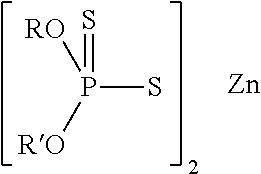

An internal combustion engine crankcase lubricating oil composition having a sulphated ash content of no greater than 1.2 mass %, based on the mass of the lubricating oil composition, and a phosphorous content of no greater than 0.1 mass %, based on the mass of the lubricating oil composition, which lubricating oil composition comprises or is made by admixing:(A) a crankcase base oil of lubricating viscosity, in a major amount; and(B) the following additives, in respective minor amounts:(B1) a polymeric friction modifier being the reaction product of(a) a functionalised polyolefin,(b) a polyether,(c) a polyol, and(d) a monocarboxylic acid chain terminating group; and(B2) at least one oil-soluble molybdenum compound.

Owner:INFINEUM INT LTD

Preparation method of rare earth aluminate polyurethane elastic fiber capable of emitting long blue afterglow

ActiveCN104404648ALow costEasy to manufactureMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberFluorescence

The invention relates to a preparation method of a rare earth aluminate polyurethane elastic fiber capable of emitting long afterglow. The method comprises several steps as follows: (1) fully reacting polyalcohol with diisocyanate and adding a solvent for fully dissolution to obtain a -NCO-terminated prepolymer polyurethane formate solution; (2) performing chain extension and chain termination on the prepolymer solution with a mixed amine solution to produce a polyurethane urea stock solution; (3) adding 10wt% of a rare earth aluminate luminescent material to a polyurethane urea solution for curing, and spinning the polyurethane elastic fiber from the polyurethane urea solution by the aid of a dry spinning system. The polyurethane elastic fiber prepared with an in-situ polymerization method can be excited by visible light or fluorescence to emit blue afterglow with the wavelength ranging from 450 nm to 500 nm and the strength of about 3 cd / m<2>, the fiber has the very lasting glowing effect, the service life of the afterglow is longer than 10 h, and the fiber is non-toxic and harmless and has no adverse effect on the environment and human bodies.

Owner:ZHEJIANG HUAFENG SPANDEX

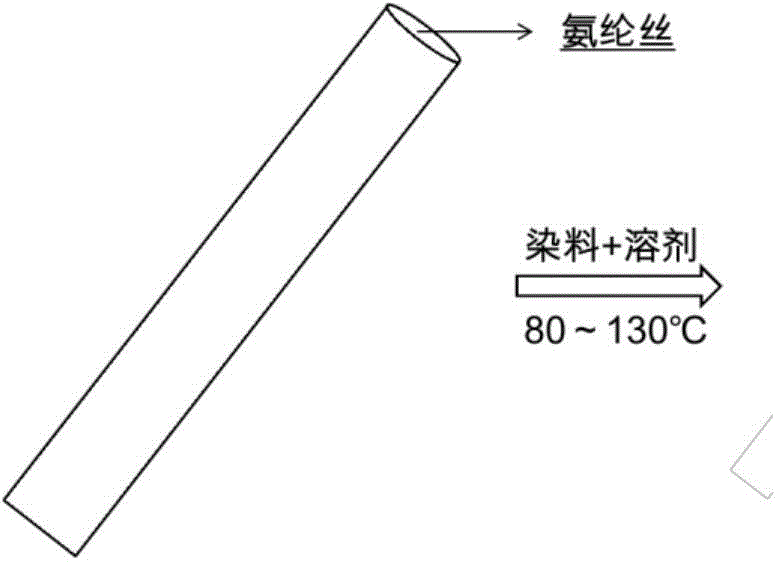

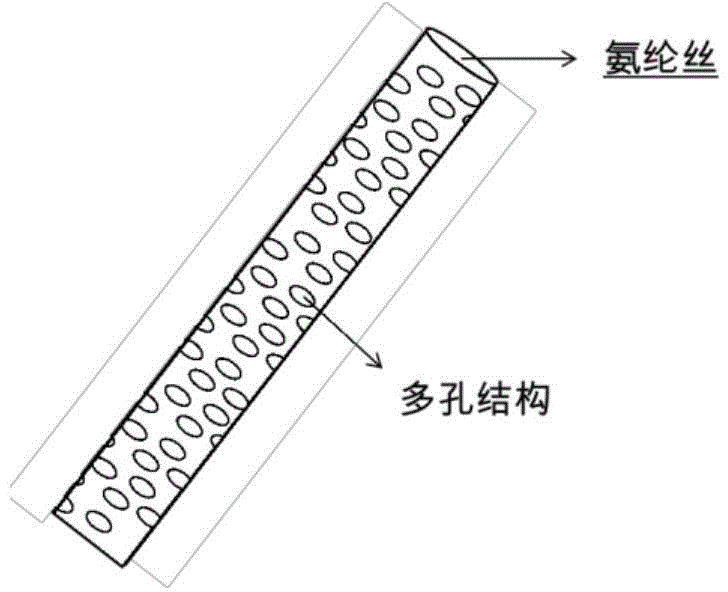

Preparation method of porous easy-dyeing spandex

ActiveCN104153033AImprove hydrophilicityImprove dyeing effectMonocomponent synthetic polymer artificial filamentDry spinning methodsCarbamateAntioxidant

The invention relates to a preparation method of a porous easy-dyeing spandex. The method is as below: adding polytetramethylene ether glycol PTMG, and 4,4- diphenyl-methane-diisocyanate 4,4-MDI in a first reactor for thorough prepolymerization reaction, so as to obtain an -NCO terminated prepolymer PP; fully dissolving the prepolymer PP in a high-speed dissolving machine by using N,N-dimethylacetamide DMAC as a solvent, so as to obtain a solution PPs containing -NCO terminated prepolymer; conducting chain growth and chain termination on the PPs in a second reactor by using a mixed amine DMAC solution containing a diamine chain extender, a monoamine termination agent and alcohol amine, so as to prepare -OH terminated polyurea carbamate solution; then, adding an antioxidant, a lubricant, a matting agent, an ultraviolet absorbent and polyvinylpyrrolidone PVP, stirring and dispersing; and finally, conducting spinning tension, high temperature drying, oiling and winding formation on the polyurea carbamate solution containing additives with the help of a dry spinning system, so as to obtain the porous easy dyeing spandex.

Owner:ZHEJIANG HUAFENG SPANDEX

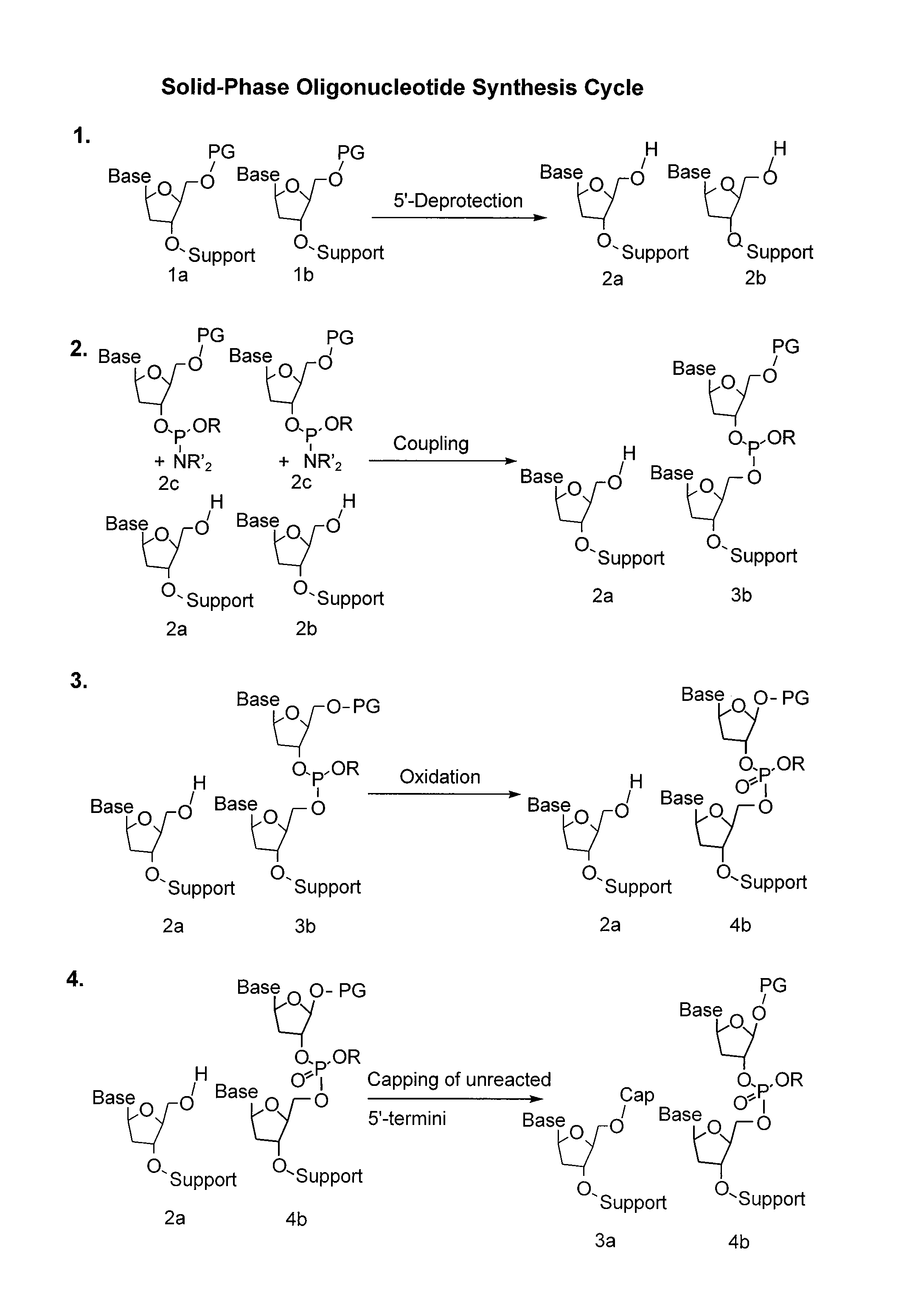

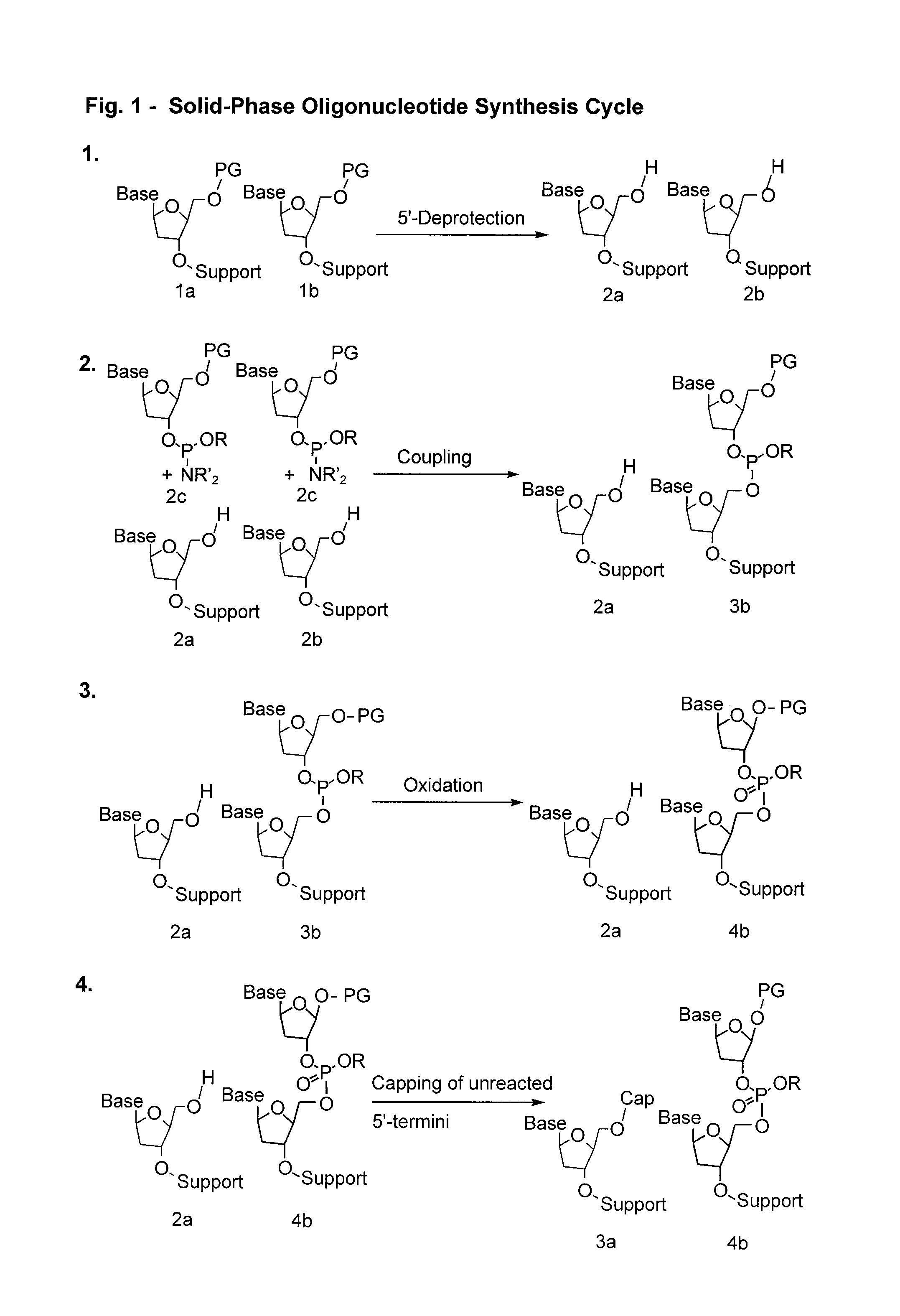

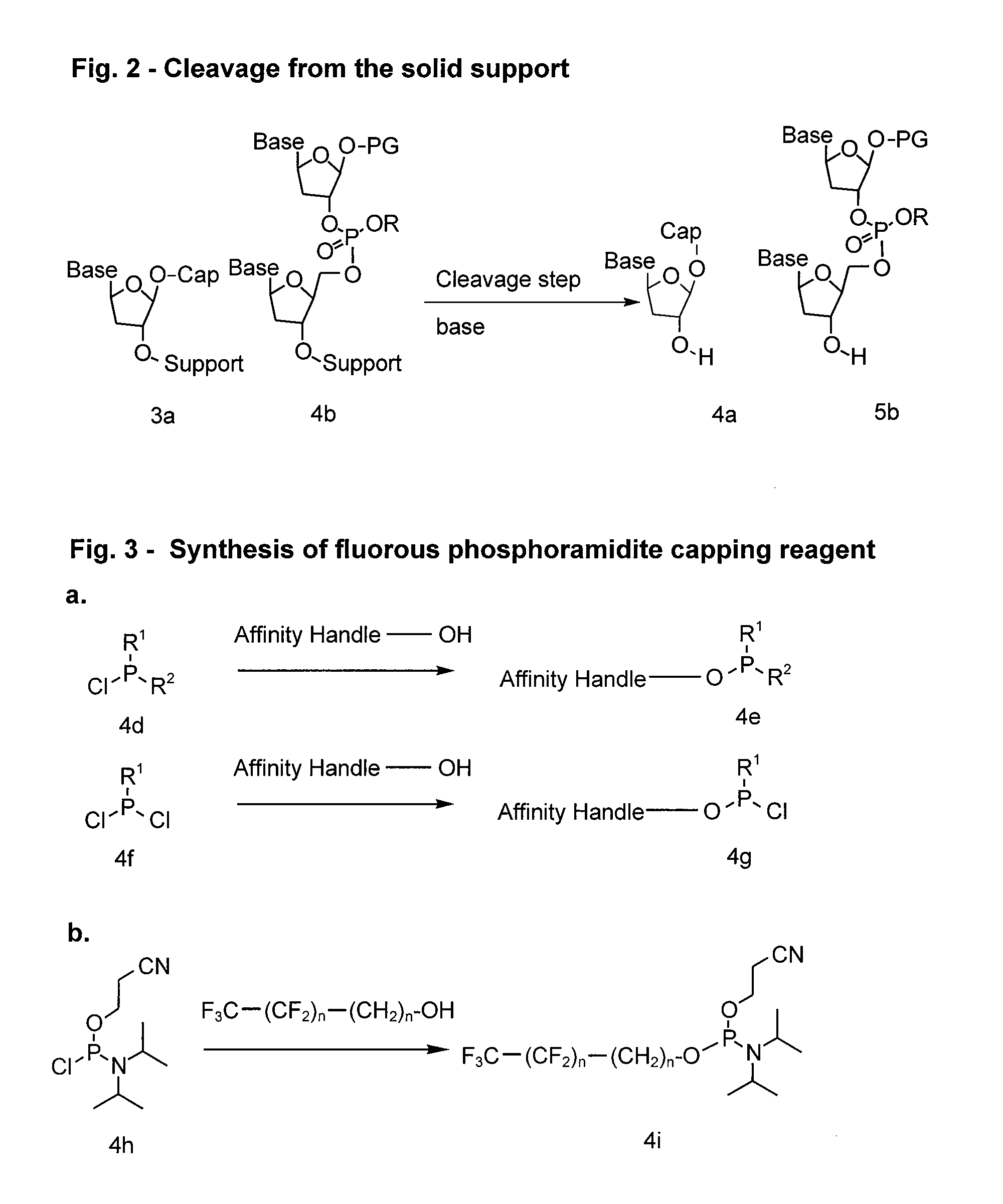

Compounds and methods for synthesis and purification of oligonucleotides

ActiveUS20080161548A1Sugar derivativesGroup 5/15 element organic compoundsCombinatorial chemistryOligonucleotide

The present invention provides methods of extending nucleic acids and purifying target nucleic acids. The methods include the use of capping reagents to effect chain termination and provide a handle for purification via fluorous affinity methods.

Owner:ROCHE MOLECULAR SYST INC

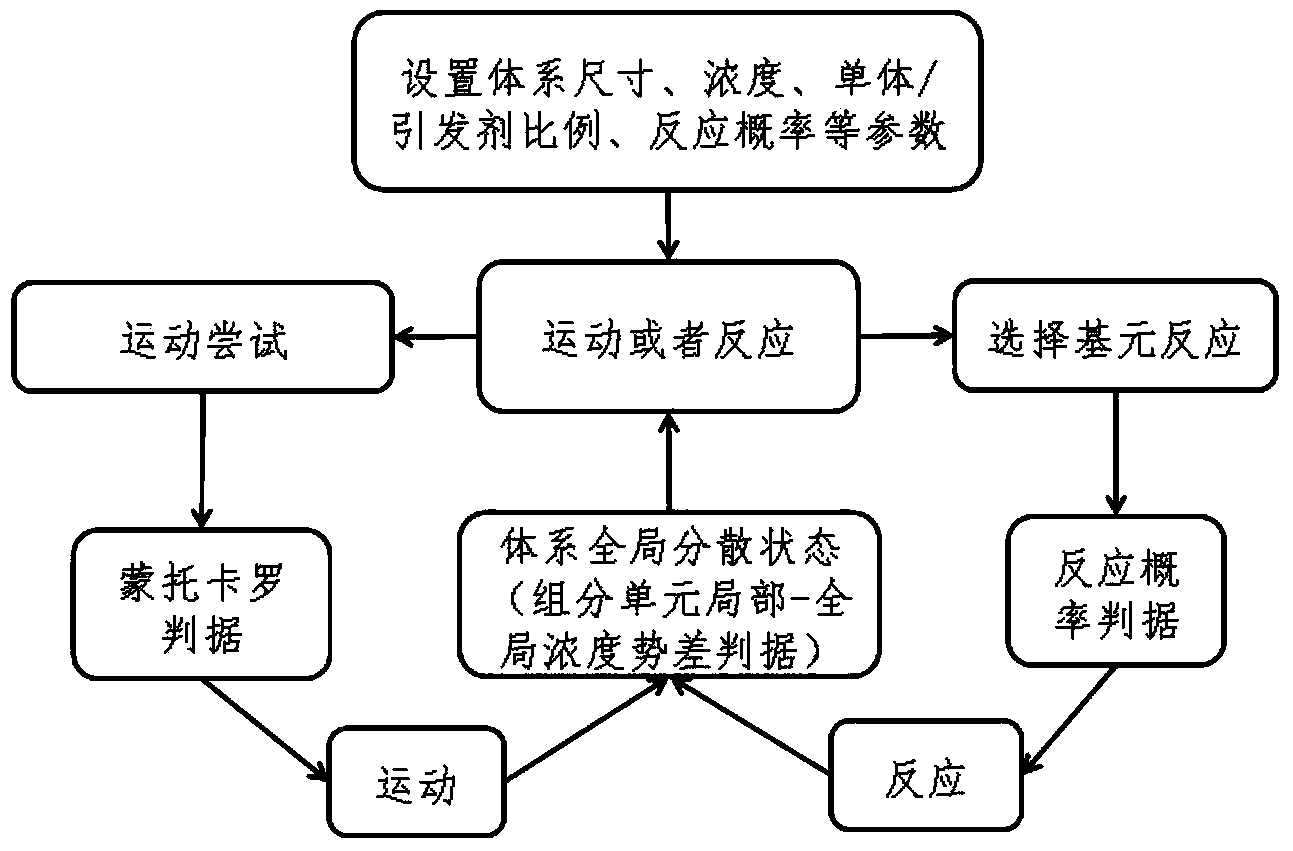

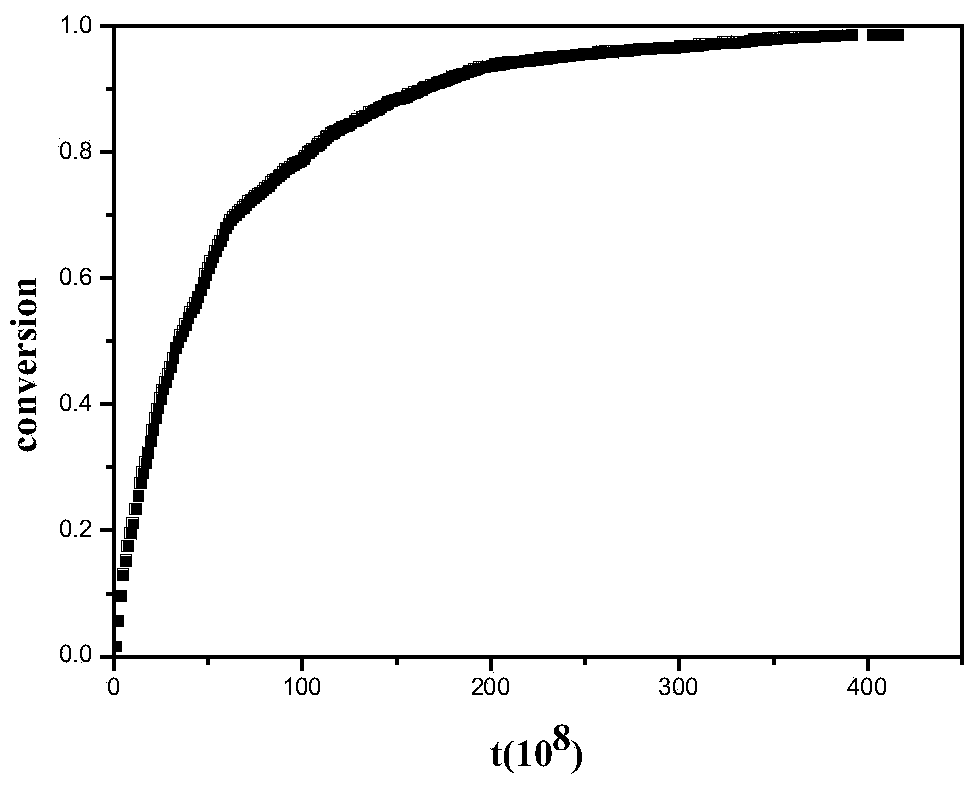

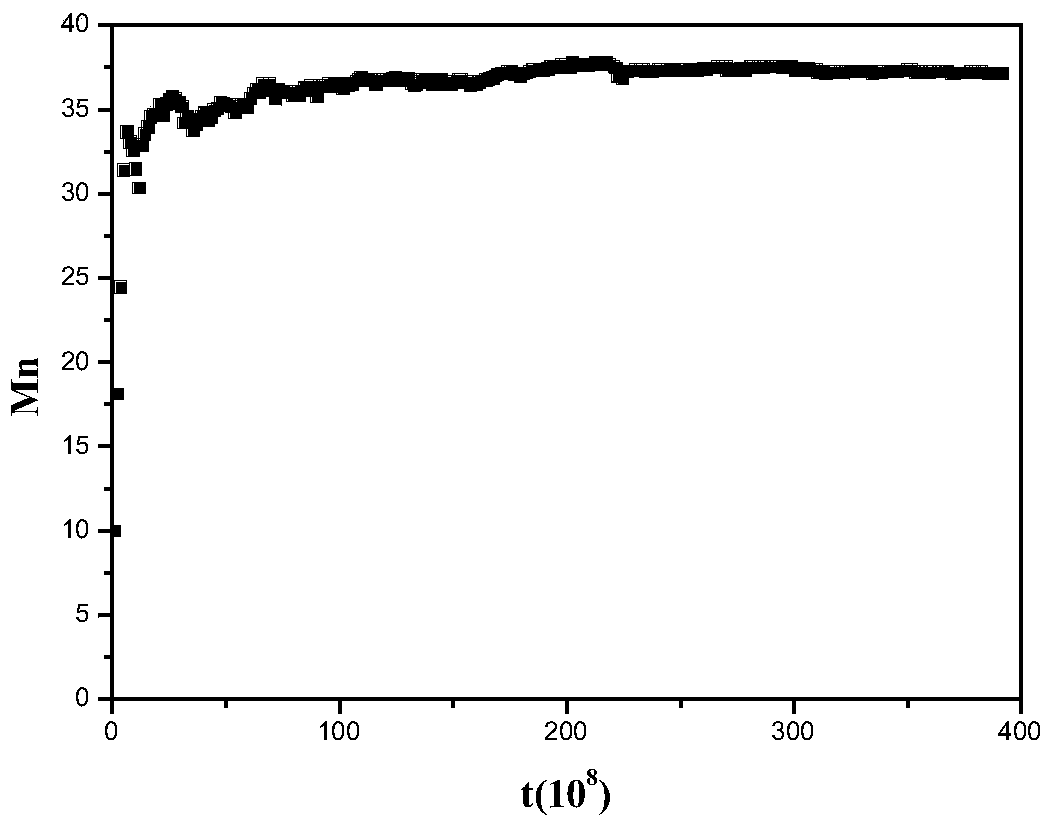

Monte carlo molecular simulation research method for kinetic process of polymerization reaction

InactiveCN104268405AWith concentration diffusion effectImproved Energy CriterionSpecial data processing applicationsStudy methodsMonomer

The invention relates to a monte carlo molecular simulation research method for the kinetic process of polymerization reaction. The method comprises the step that the polymerization reaction simulation process is divided into two parts, namely, a systemic movement part and a polymerization reaction part; when in the polymerization reaction part, the occurrence probability of triggering, chain growth, chain transfer, chain termination and other elementary reactions are controlled through different reaction probability; when in the systemic movement part, a local-global concentration potential difference which shows the difference of the local concentration and the global concentration of components is introduced to determine the concentration distribution state of each unit component in the system, in order to realize the balanced distributing state of the component unit in the polymerization reaction process; the monte carlo energy criterion for controlling unit particle movement involves a chemical key part and a non-key part. The method is simple and efficient; the problem of non-uniform distribution of the component unit in the simulation system caused by the consumption of an initiator and a monomer under the polymerization reaction can be avoided, and the kinetic process of the experiment system can be really reflected by being compared with the traditional molecular simulation method.

Owner:ANHUI UNIVERSITY

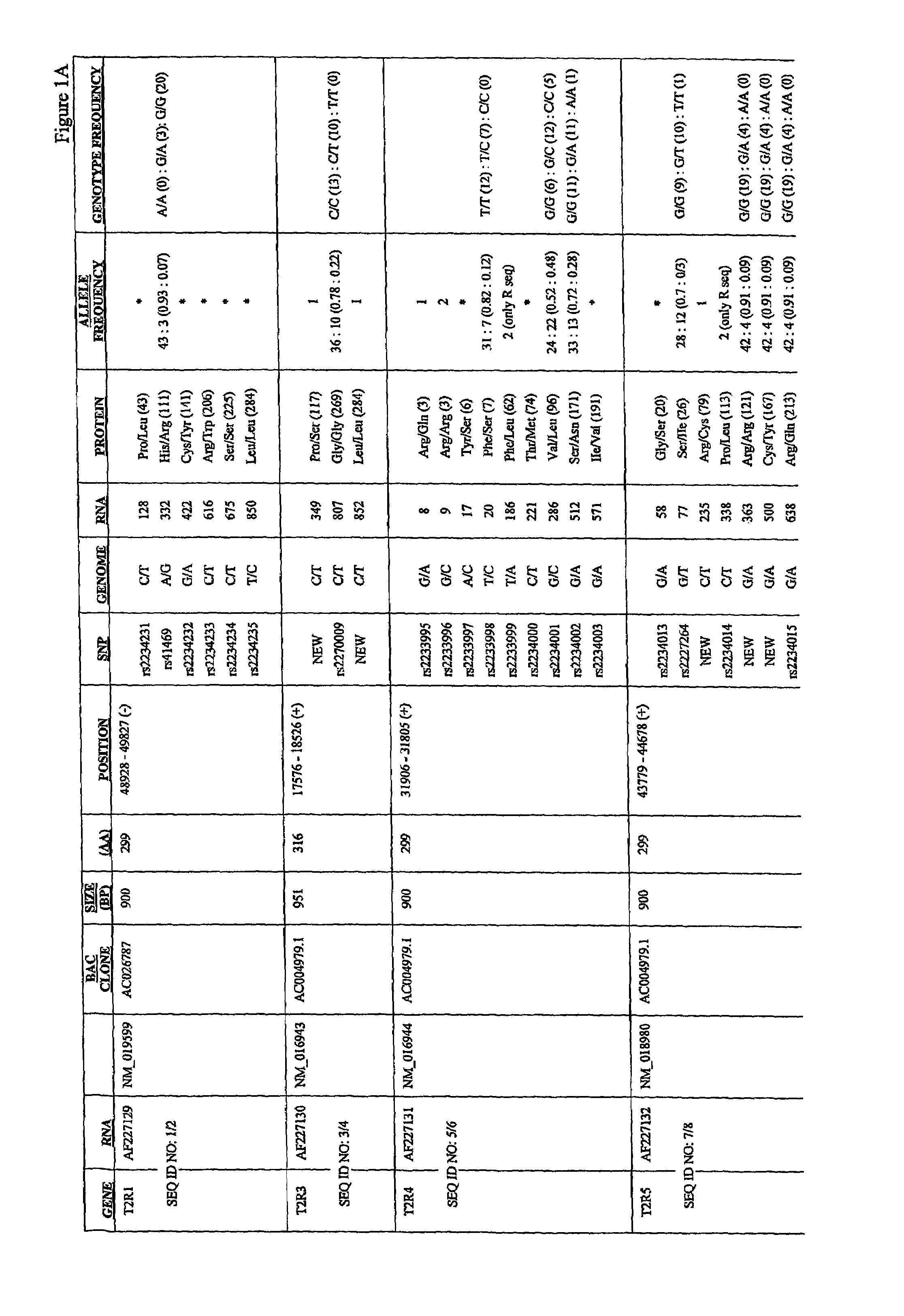

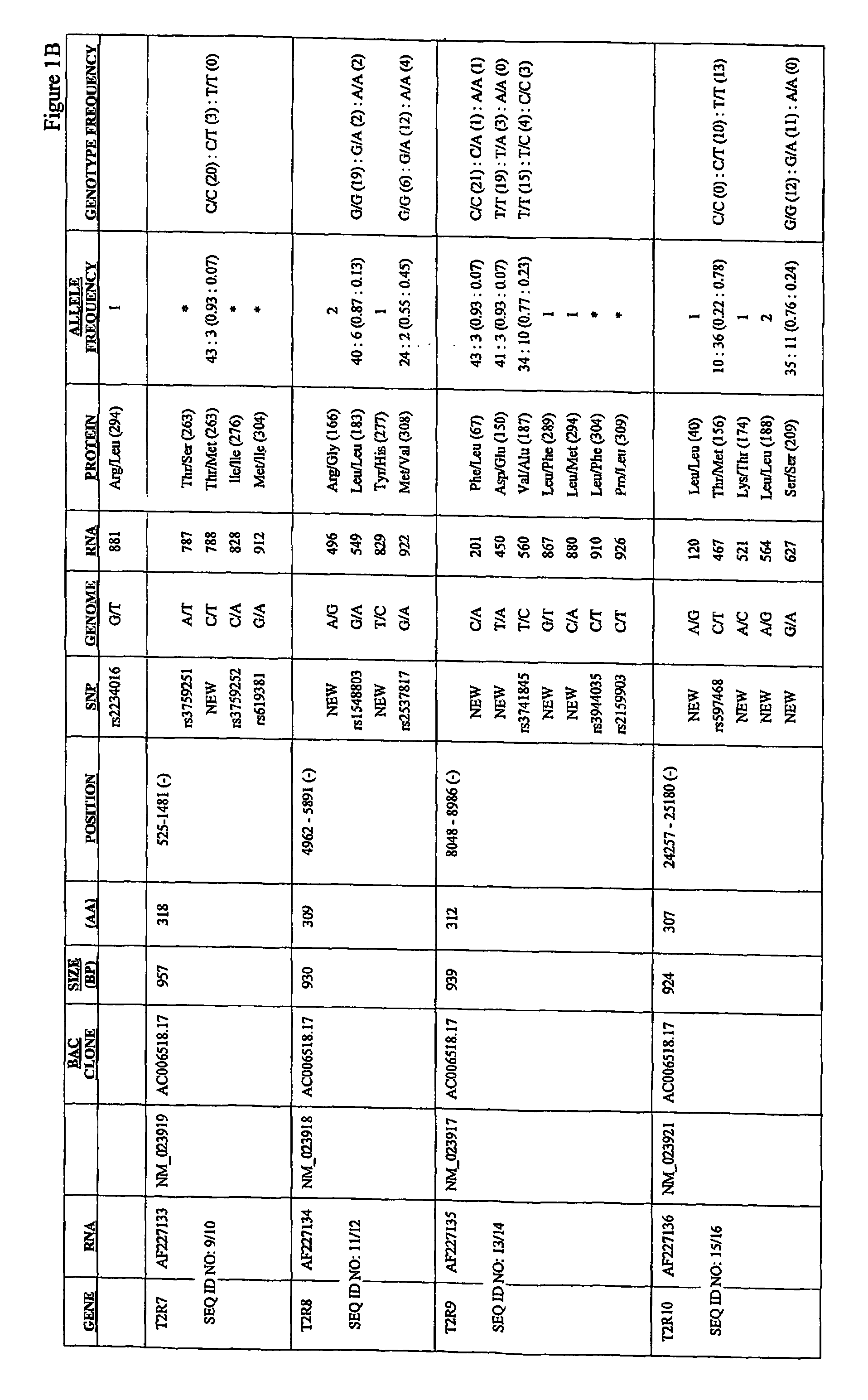

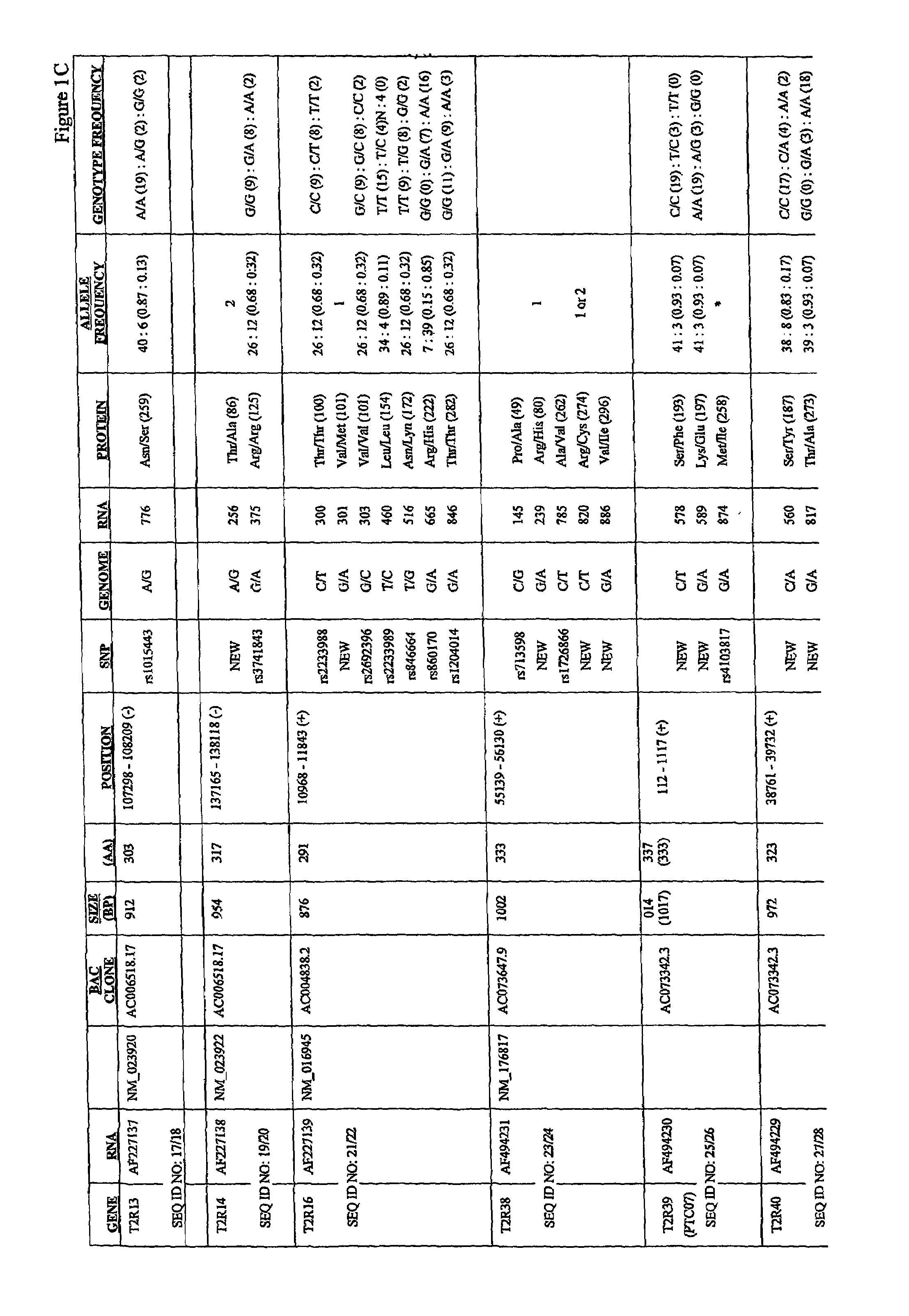

Variants of human taste receptor genes

Identified herein are different forms of bitter receptor genes that occur in different humans. These alleles are generated by numerous coding single nucleotide polymorphisms (cSNP's) that occur within the members of the T2R gene family. Some SNP's cause amino acid substitutions, while others introduce chain termination codons, rendering the allele non-functional. Differences in these genes are believed to have a large effect on those individuals' sense of bitter taste, such that these individuals perceive the taste of bitter substances differently than the rest of the population. The ability to assay this allelic information is useful in the development of flavorings and flavor enhancers, as it can be used to define large groups and populations who perceive bitter tastes differently. This in turn allows the taste preferences of these groups to be addressed at the molecular level for the first time.

Owner:UNITED STATES OF AMERICA

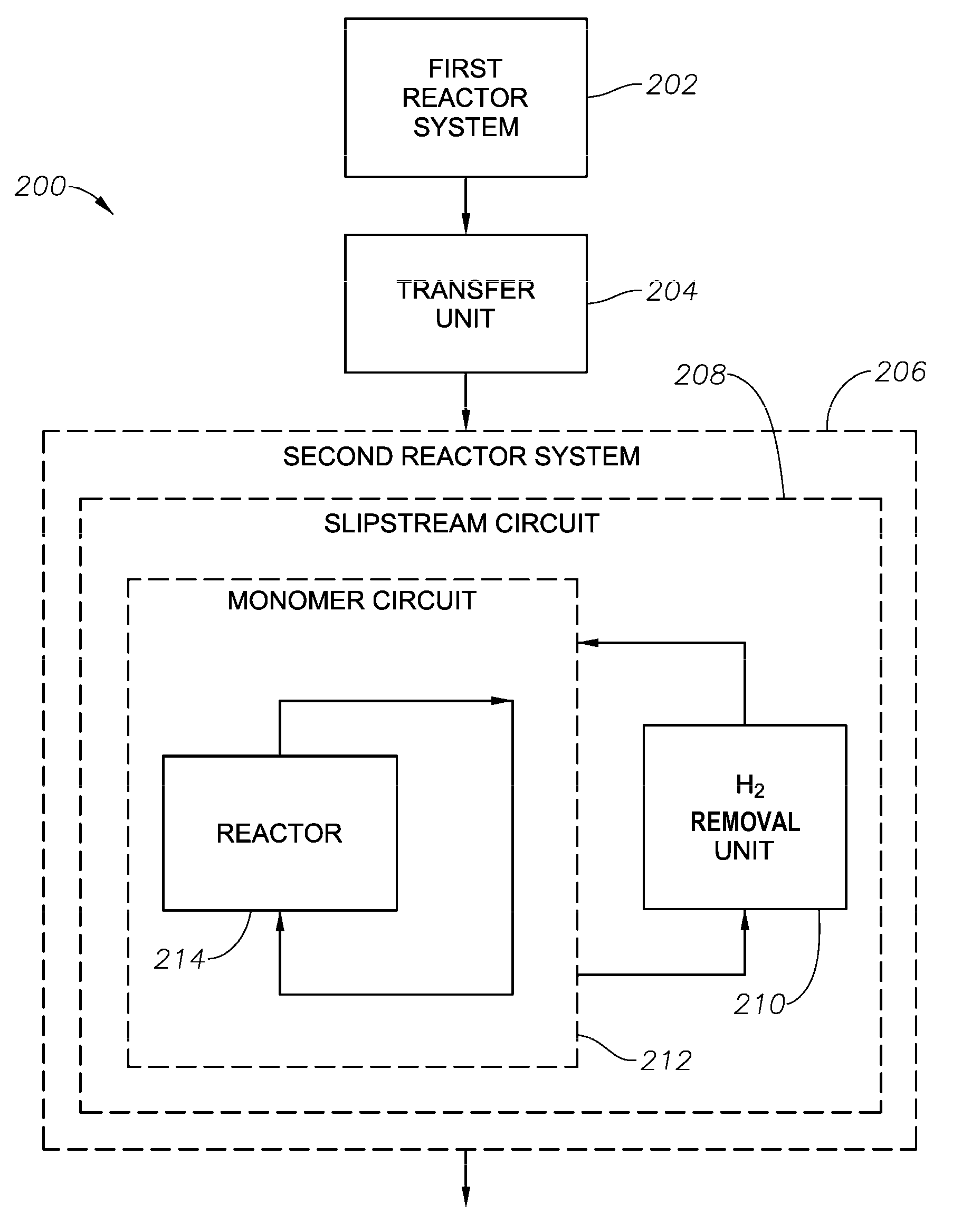

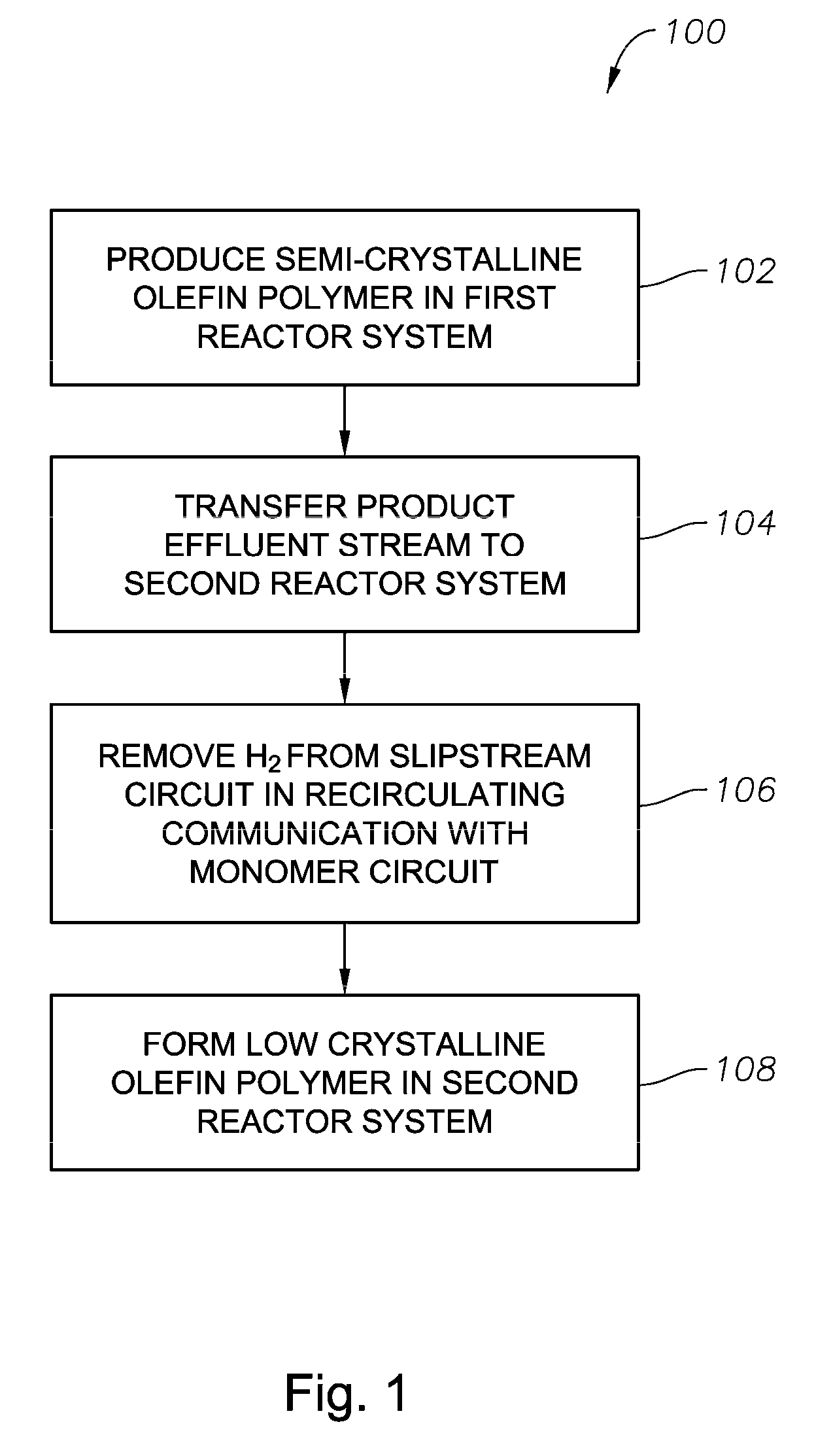

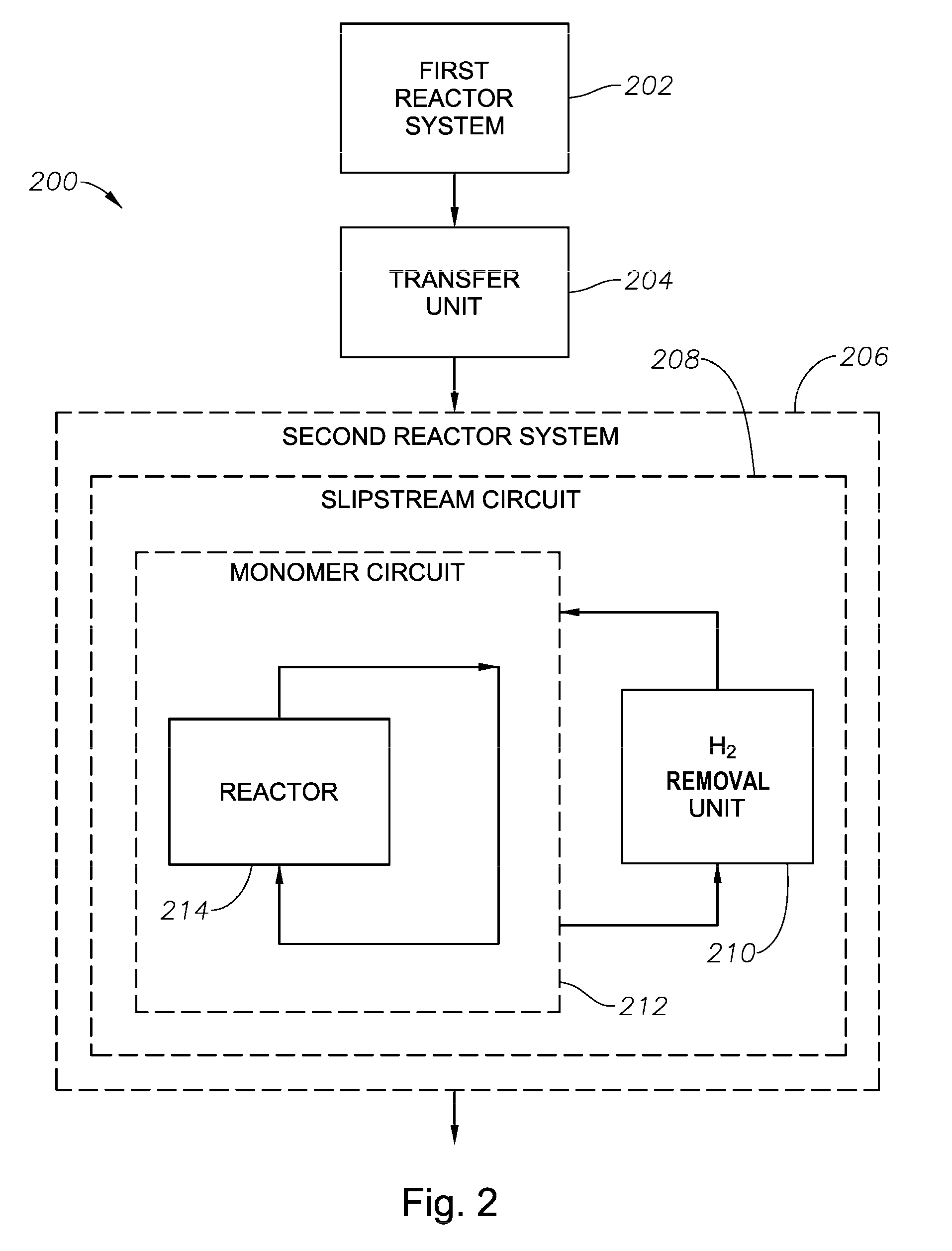

Copolymer production system and process

ActiveUS9000106B2Chemical/physical/physico-chemical stationary reactorsPolymer scienceReactor system

In a process for making a copolymer, a first product stream comprising a semi-crystalline polymer and a chain terminating agent is produced in a first reactor system. The first product is provided to a second reactor system wherein a low crystallinity polymer is produced in the presence of the semi-crystalline polymer. At least a portion of the chain terminating agent is removed from the second reactor system by an in-situ process.

Owner:EXXONMOBIL CHEM PAT INC

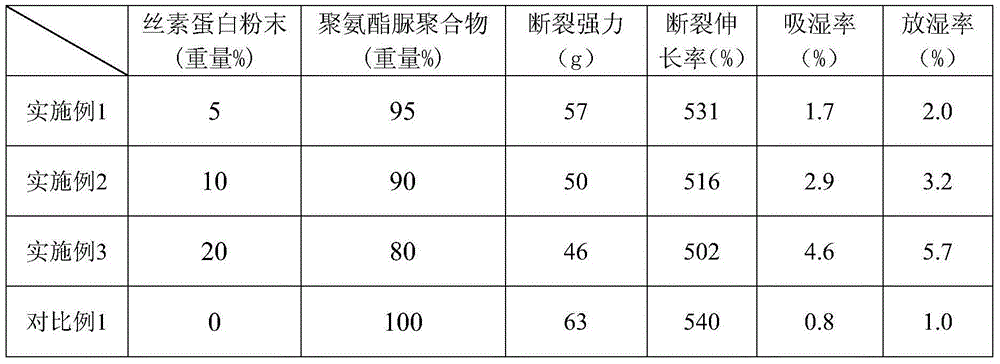

Preparation method of polyurethane elastic fiber with moisture absorption and moisture liberation performance

ActiveCN104153037AMoisture absorption and releaseChanging the hydrophobic propertiesConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsDiphenylmethaneMoisture absorption

The invention relates to a preparation method of a polyurethane elastic fiber with moisture absorption and moisture liberation performance. The method is as below: 1) successively conducting a prepolymerization reaction, a chain extension reaction and a chain termination reaction on raw materials of polytetramethylene ether glycol PTMG and diphenylmethane-4,4'diisocyanate 4,4'-MDI to obtain a polyurethane urea stoste; 2) grinding and dispersing a natural macromolecular fibroin powder in an organic solvent dimethylacetamide DMAC to obtain a fibroin suspension; 3) measuring and mixing the polyurethane urea stoste and fibroin suspension at the same time in a static mixer to form a spandex blended spinning solution; and 4) conducting spurting and filament stretching on the prepared spandex blended spinning solution by a dry method spinning system, and evaporating and drying the solvent, so as to obtain the polyurethane elastic fiber with moisture absorption and moisture liberation performance. Compared with conventional polyurethane elastic fiber, the product prepared by the invention has significantly improved moisture absorption and moisture liberation performance.

Owner:ZHEJIANG HUAFENG SPANDEX

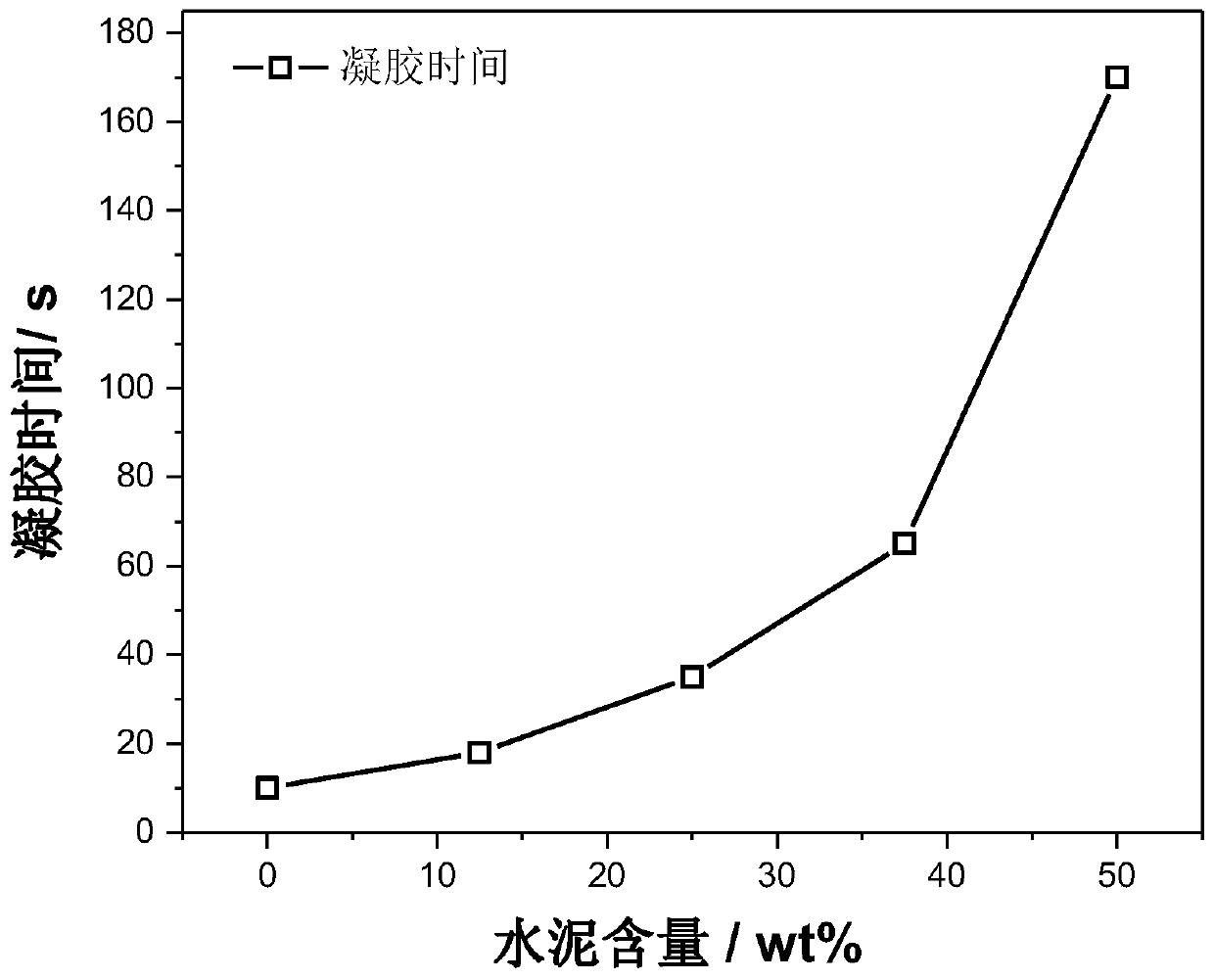

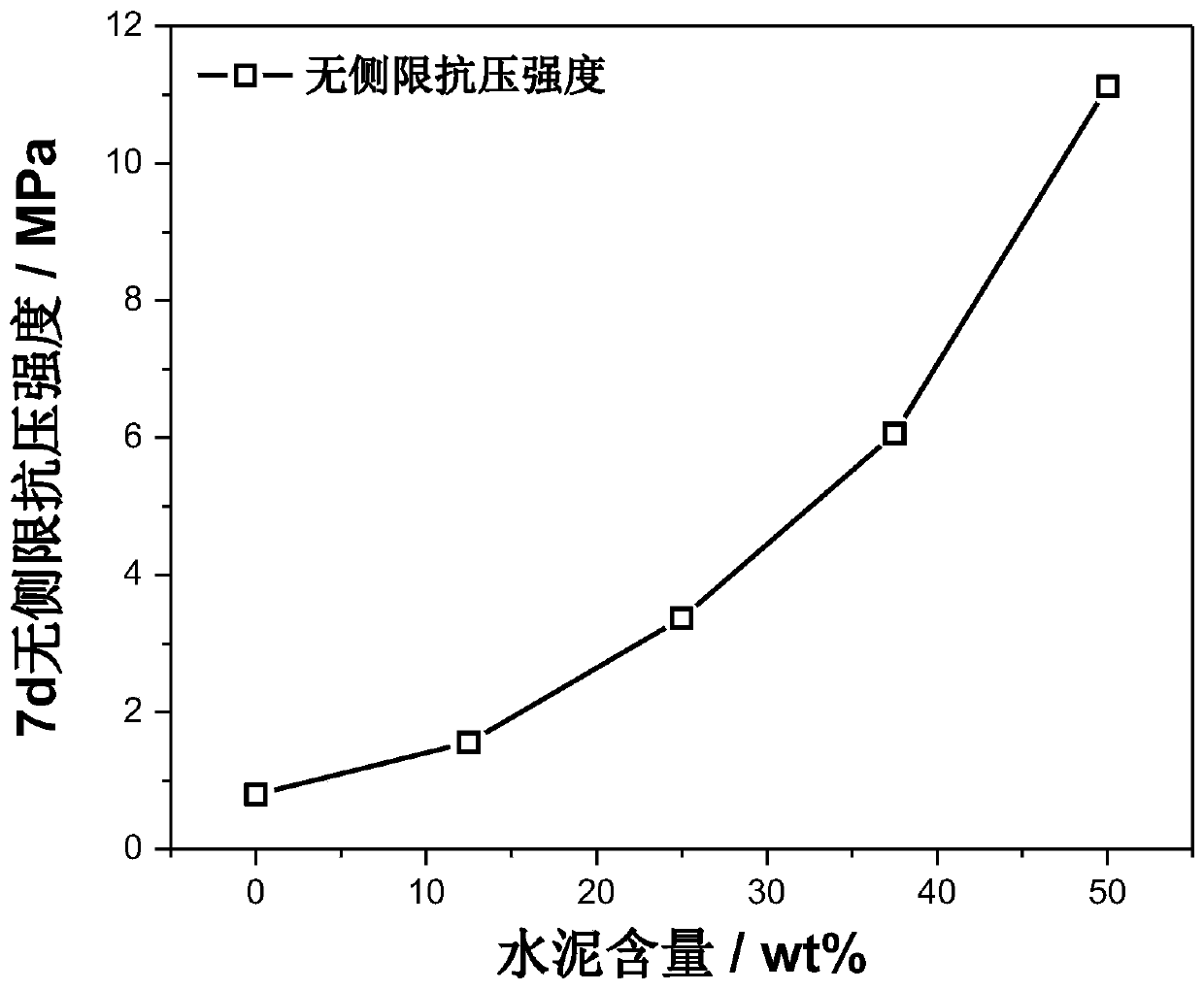

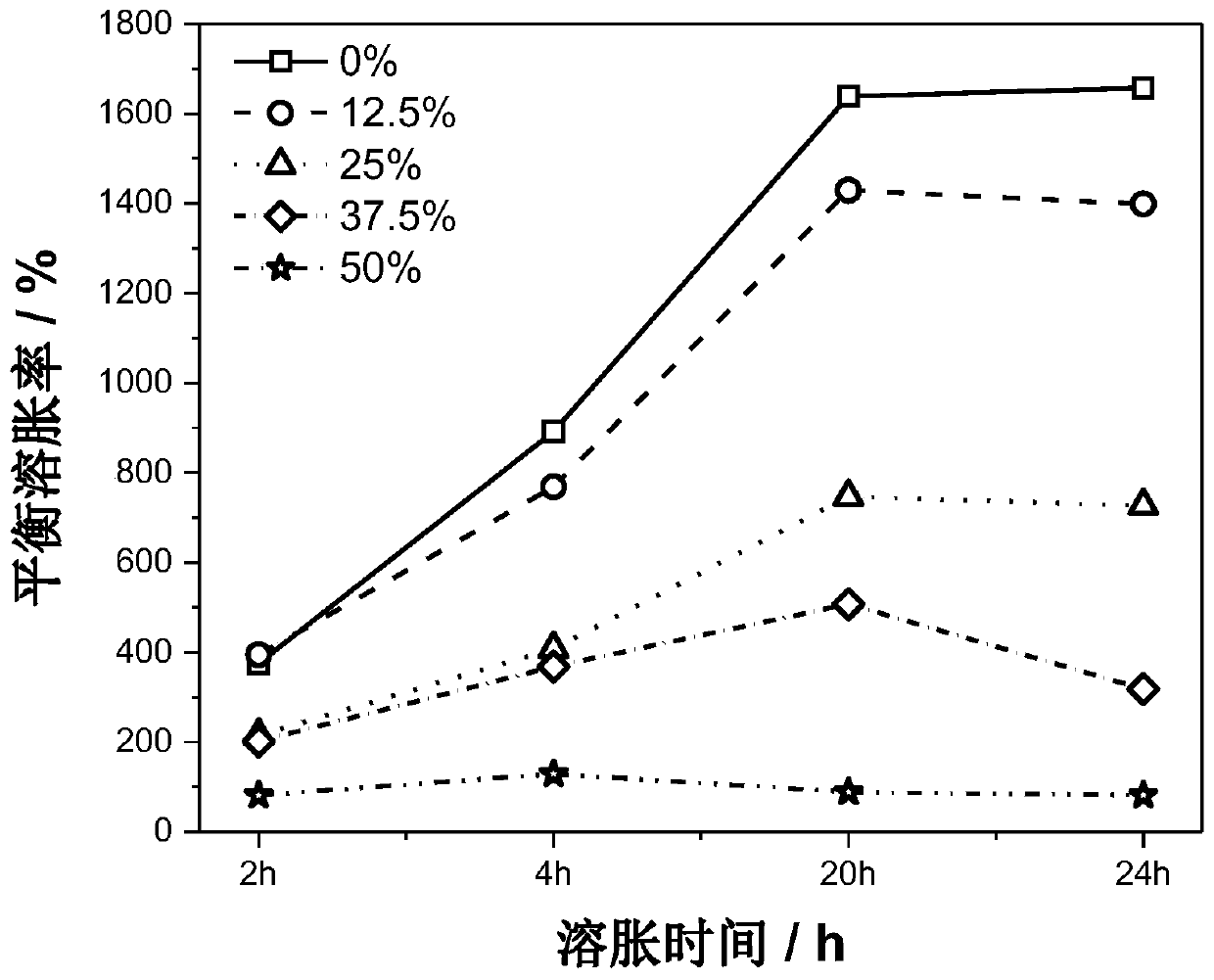

Silicon hybridization acrylate and cement composite grouting material and preparation method thereof

The invention discloses a silicon hybridization acrylate-cement composite grouting material and a preparation method thereof, and belongs to the technical field of new materials of municipal and construction projects. Inorganic binder cement and inorganic nanoparticles are introduced into an acrylate pre-polymer, a polymerization reaction is generated under the effects of a crosslinking agent, aninitiator and a promoter, and a mixture is polymerized to form a mesh complex hybridization gel body insoluble in water through the processes of chain initiation, chain growth and chain termination; siloxane modified acrylate can eliminate the difference between an organic material and an inorganic material (cement), improve the interaction between interfaces, and improve compatibility between polyacrylate resin and the cement; and the composite grouting material is less in environment pollution, does not generate dust pollution, belongs to an environment-friendly material, and can simultaneously solve the problems that an acrylate grouting material is low in strength, and a cement grouting material is poor in dry shrinkage resistance, durability and dispersion resistance.

Owner:BEIJING MUNICIPAL CONSTR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com