Silicon hybridization acrylate and cement composite grouting material and preparation method thereof

A technology of acrylate and grouting materials, which is applied in the field of new materials for municipal and construction projects. It can solve the problems of limited application range, low strength, and inability to play the role of anti-seepage and reinforcement, and achieves environmental friendliness, improved compatibility, and facilitates industrialization. The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A silicon hybrid acrylate composite grouting material and a preparation method thereof.

[0041] Step a: Weigh 7.5% acrylic acid (AA), slowly add 3.35% sodium hydroxide (NaOH) solution dropwise to the acrylic acid solution in an ice-water bath under magnetic stirring, and react at room temperature for 5 hours after the dropwise addition;

[0042] Step b: Mix 2% γ-(2.3 glycidoxy)propyltrimethoxysilane with 2% distilled water and stir for 2 hours;

[0043] Step c: Mix the solutions prepared in step a and step b, and after stirring for 2 hours, weigh 0.5% of N,N'-methylenebisacrylamide and 2% of triethanolamine and mix them uniformly in the mixed solution, and stir for 30 minutes to make it Mix well, and form A liquid after stirring evenly;

[0044] Step d: Weigh 1.0% ammonium persulfate and 0.2% ferrous sulfate, dissolve them in distilled water, and prepare liquid B;

[0045] Step e: Pour liquid A and liquid B into a 500ml separating funnel respectively, then quickly op...

Embodiment 2-5

[0047] A silicon hybrid acrylate-cement composite grouting material and a preparation method thereof.

[0048] Step a: Weigh 7.5% acrylic acid (AA), slowly add 3.35% sodium hydroxide (NaOH) solution dropwise to the acrylic acid solution in an ice-water bath under magnetic stirring, and react at room temperature for 5 hours after the dropwise addition;

[0049] Step b: Mix 2% γ-(2.3 glycidoxy)propyltrimethoxysilane with 2% distilled water and stir for 2 hours;

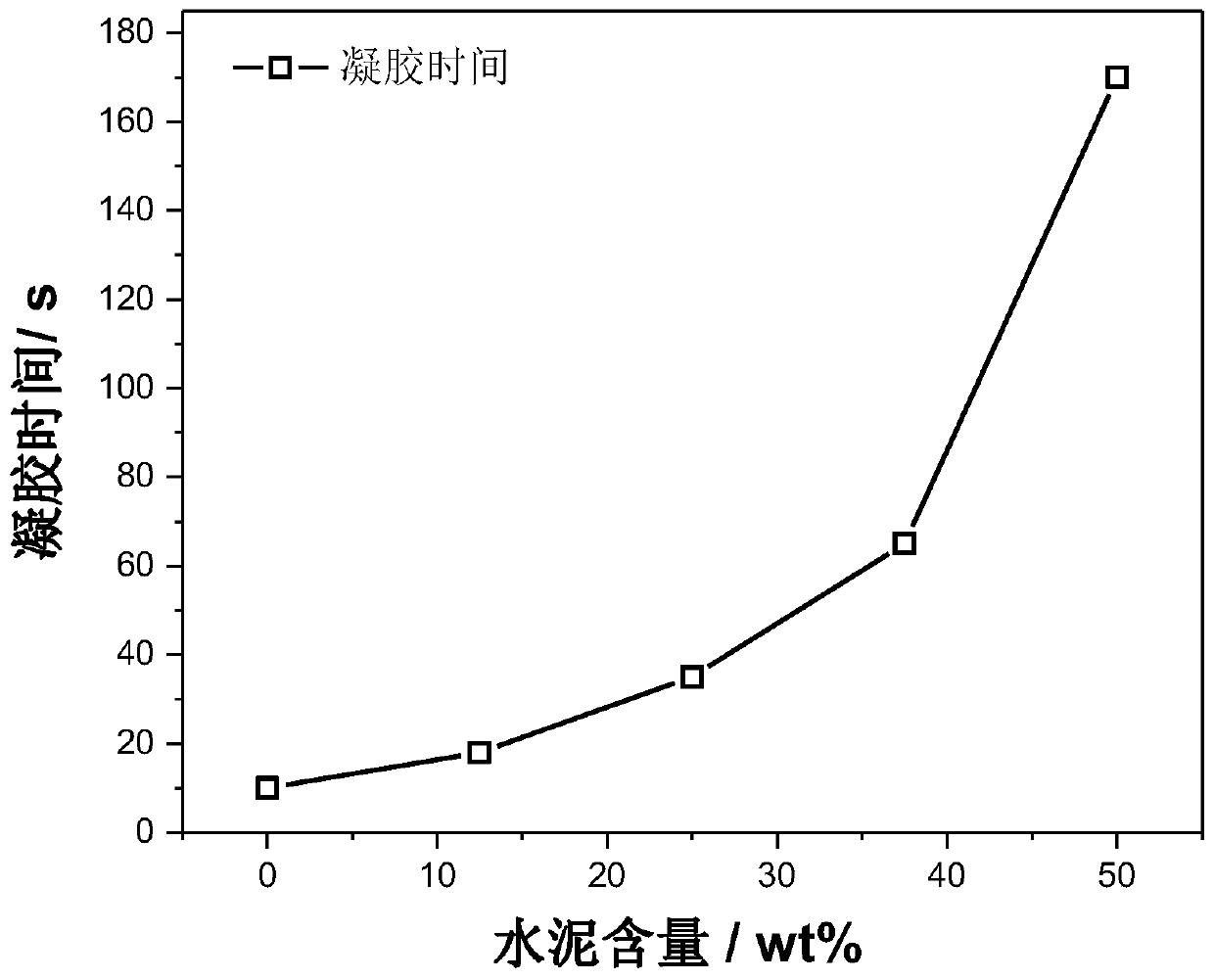

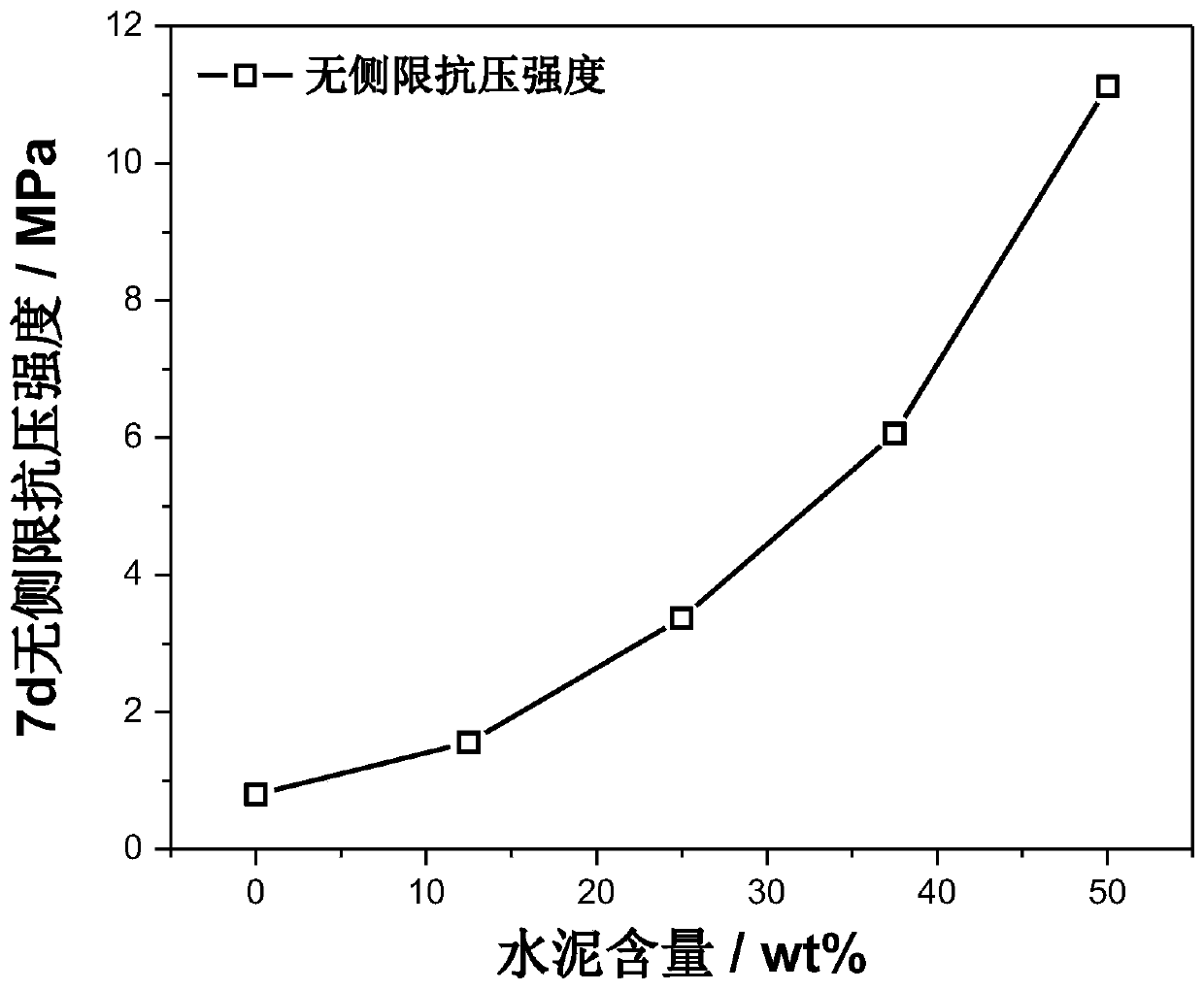

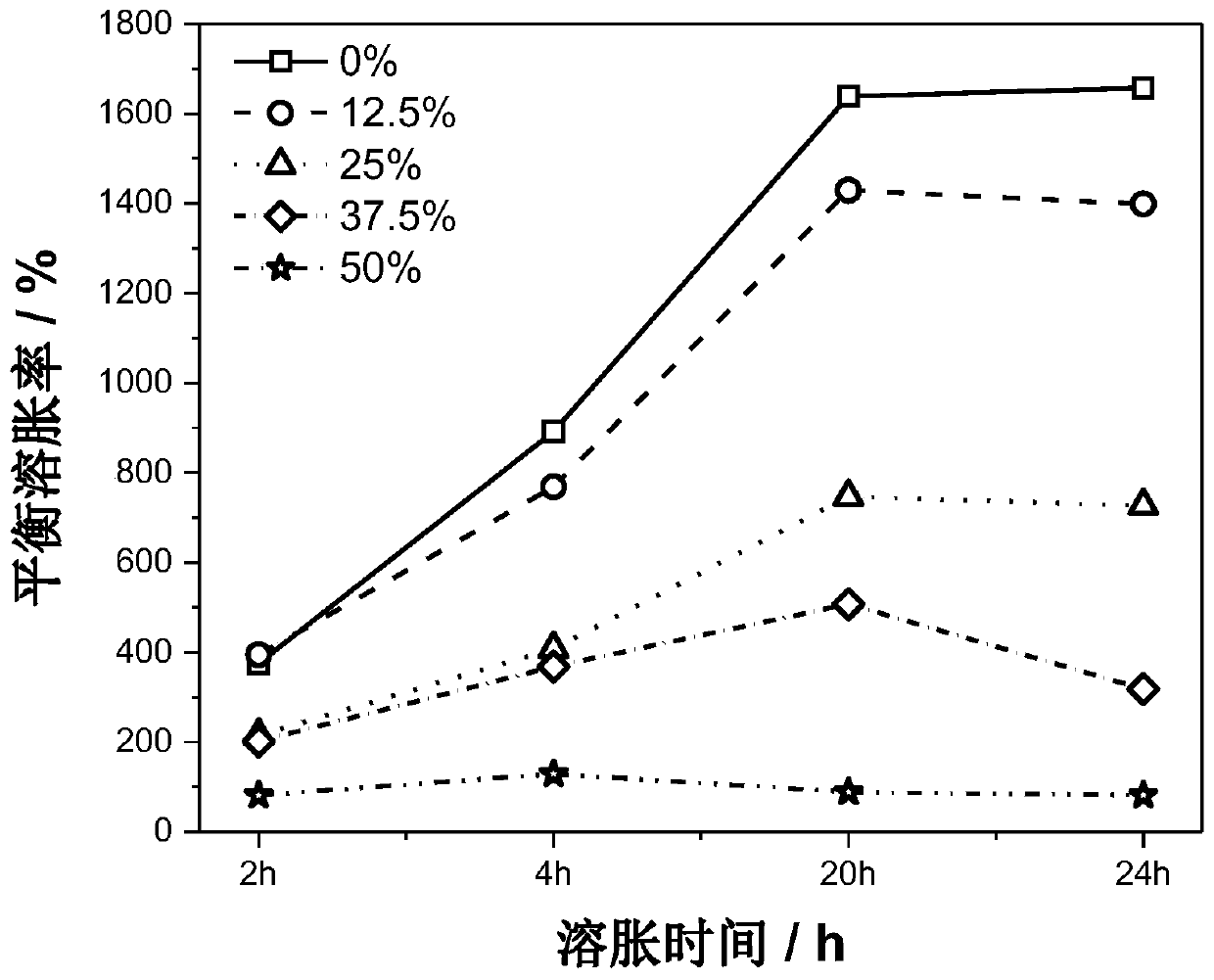

[0050] Step c: Mix the solutions prepared in step a and step b, and after stirring for 2 hours, weigh 0.5% of N,N'-methylenebisacrylamide and 2% of triethanolamine and mix them uniformly in the mixed solution, and stir for 30 minutes to make it Fully mix, finally add 52.5 cements of different mass fractions in the mixed solution, form A liquid after stirring; Wherein, the cement content is 12.5% in the embodiment 2, and the cement content in the embodiment 3 is 25%, and the cement content in the embodiment 4 is 37.5%...

Embodiment 6

[0054] A silicon hybrid acrylate-cement composite grouting material and a preparation method thereof.

[0055] Step a: Weigh 10% acrylic acid (AA), slowly add 5% sodium hydroxide (NaOH) solution dropwise to the acrylic acid solution in an ice-water bath under magnetic stirring, and react at room temperature for 5 hours after the dropwise addition;

[0056] Step b: Mix 1.5% methyl orthosilicate with 2% distilled water and stir for 2 hours;

[0057] Step c: Mix the solutions prepared in step a and step b, and after stirring for 2 hours, weigh 0.55% diisocyanate and 2.0% calcium chloride and mix them evenly in the mixed solution, stir for 30 minutes to make them fully mixed, and finally mix them in the mixed solution Add 50% of 62.5 cement and stir well to form A liquid;

[0058] Step d: Weigh 1.2% ammonium persulfate and 0.2% sodium bisulfite, dissolve them in distilled water, and prepare liquid B;

[0059] Step e: Pour liquid A and liquid B into a 500ml separating funnel resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Equilibrium swelling rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com