Thermoplastic polyurethanes comprising polytrimethylene ether soft segments

A technology of thermoplastic polyurethane and methyl ether diol, applied in the direction of one-component polyurethane artificial filament, etc., can solve the problems of expensive, non-renewable and non-environmental friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

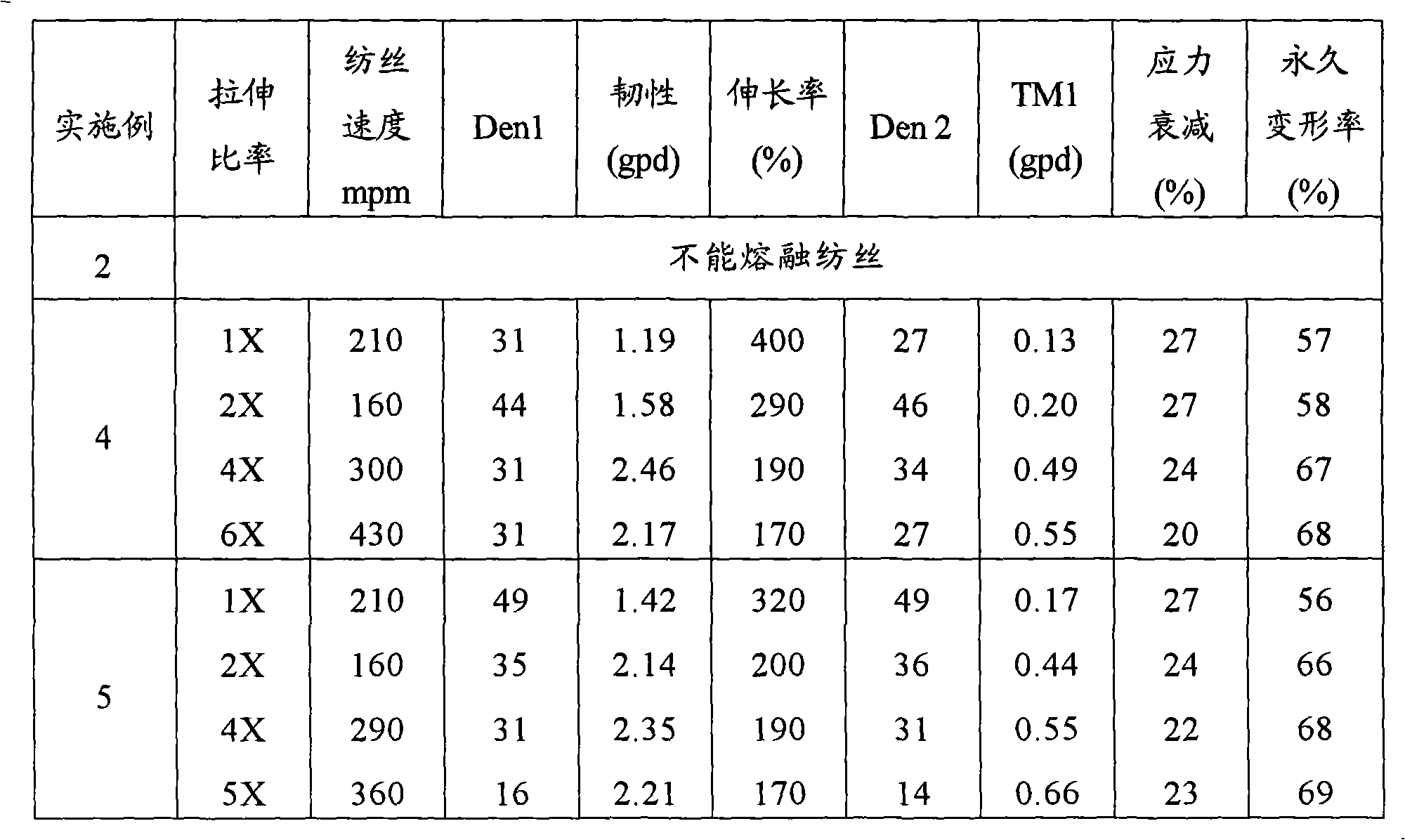

Examples

Embodiment 1

[0111] This example illustrates the preparation of a diisocyanate terminated polytrimethylene ether-urethane prepolymer.

[0112]Prepolymers were prepared as follows. Polytrimethylene ether glycol (2.885 kg) with a number average molecular weight of 2000 was dried to a moisture content below 500 ppm, and then added to a 5-L tank equipped with a mechanical stirrer, dropping funnel, thermocouple, and air inlet adapter (adapter). in a four-necked flask. IRGANOX 1098 antioxidant (2.3 g) (Ciba Specialty Chemicals, Tarrytown, NY) was added to the diol and mixed thoroughly. The mixture was then heated to 60°C under an inert nitrogen atmosphere. Molten (50°C) 4,4'-diphenylmethane diisocyanate (ISONATE 125M, Dow Chemical Company, Midland, MI) (1.665 kg) was slowly added to the mixture at a controlled rate to maintain the reaction temperature <70°C. The reactor temperature is maintained at 70 to about 80°C until the NCO:OH reaction is complete. The prepolymer product was degassed an...

Embodiment 2

[0114] This example is a comparative example illustrating the preparation of polyurethane using the prepolymer prepared in Example 1 and the diol chain extender, but without the monofunctional chain terminator.

[0115] An aliquot (800 g) of the diisocyanate-terminated polytrimethylene ether-urethane prepolymer prepared in Example 1 was transferred to another reactor and maintained at 60°C. To the prepolymer was added preheated 1,4-butanediol (78 g). (NCO:OH ratio 1.05:1), the mixing was continued for about 90 seconds until the diol was visually incorporated into the prepolymer. The reaction mixture was then poured into open molds and placed in an oven for post-cure at 110° C. for 16 hours.

Embodiment 3

[0117] This example illustrates the preparation of a diisocyanate-terminated polytrimethylene ether-urethane prepolymer that is used in subsequent reactions to react with chain extenders and chain terminators to prepare the inventive combination.

[0118] Polytrimethylene ether glycol (937.1 g) with a molecular weight of 2000 was dried and charged to a 2-liter four-necked flask equipped with a mechanical stirrer, dropping funnel, thermocouple, and gas inlet adapter. An antioxidant (mixture of IRGANOX 1076 and ETHANOX 300 (2.3 g)) was added to the polyol and mixed thoroughly. The mixture was then heated to 60°C under an inert nitrogen atmosphere. Molten (50°C) 4,4'-diphenylmethane diisocyanate (ISONATE 125M, 541 g) was slowly added to the mixture at a controlled rate to maintain the reaction temperature <70°C. The reactor temperature was maintained at 70 to 80°C until the NCO:OH reaction was complete. The prepolymer product was degassed and heat transferred to a clean dry pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com