Preparation method of polyurethane elastic fiber with moisture absorption and moisture liberation performance

A technology of polyurethane elasticity and polyurethane urea, which is applied in the field of polymer textile materials and its preparation, can solve problems such as difficulties in realization, and achieve the effects of changing the characteristics of hydrophobicity, degradable cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

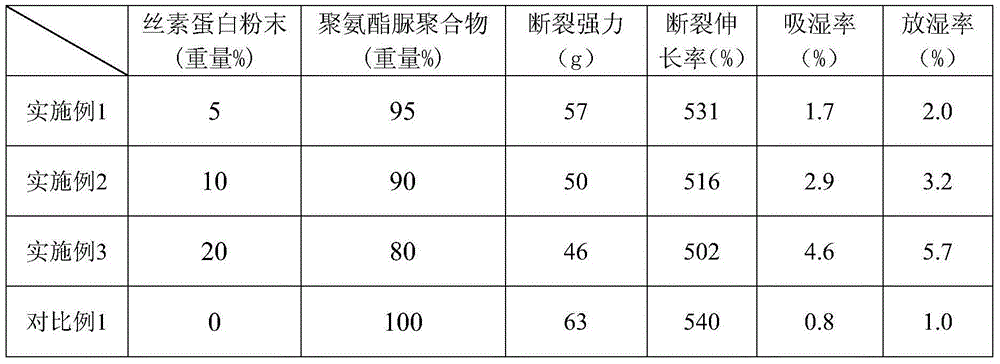

Embodiment 1

[0019] (1) Put 750 grams of polytetrahydrofuran ether glycol and 172 grams of diphenylmethane-4,4'diisocyanate in a reactor, and react at 86±2°C for 120 minutes to obtain an isocyanate group-terminated prepolymer, and then add 1.36Kg of dimethylacetamide dissolves the prepolymer to form a solution; then add 2.3 grams of 1,2-propylenediamine, 17 grams of ethylenediamine, and 0.3 grams of diethylamine to the prepolymer solution while stirring. The amine mixed solution formed in 713 grams of dimethylacetamide carries out chain extension reaction and chain termination reaction to obtain polyurethane urea stock solution;

[0020] (2) Grinding a mixture of 100 gram silk fibroin powder and 900 gram dimethylacetamide to make it into a uniform suspension;

[0021] (3) Measure polyurethane urea stock solution and silk fibroin suspension into a static mixer and mix evenly to form spandex blended spinning solution, wherein the weight ratio of silk fibroin powder to polyurethane urea polym...

Embodiment 2

[0024] The preparation process is the same as that in Example 1, except that step (3) controls the weight ratio of silk fibroin powder and polyurethane urea polymer to 10:90.

Embodiment 3

[0026] The preparation process is the same as that in Example 1, except that step (3) controls the weight ratio of silk fibroin powder and polyurethane urea polymer to 20:80.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com