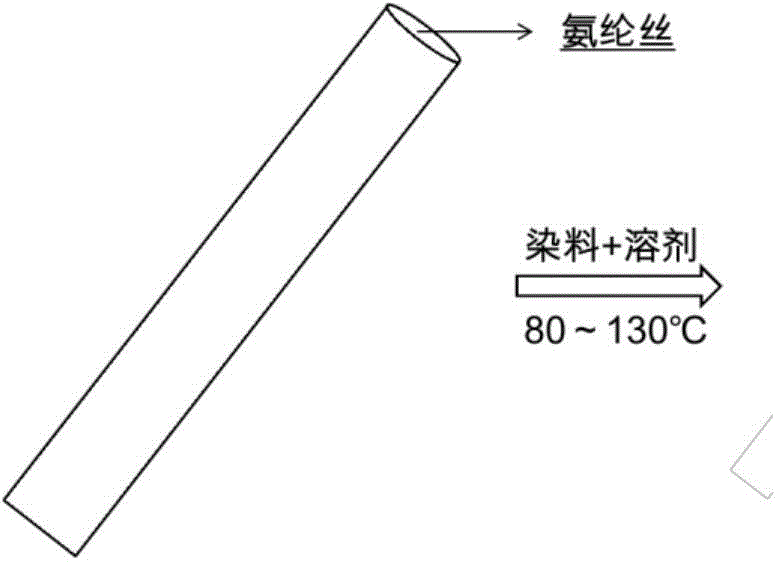

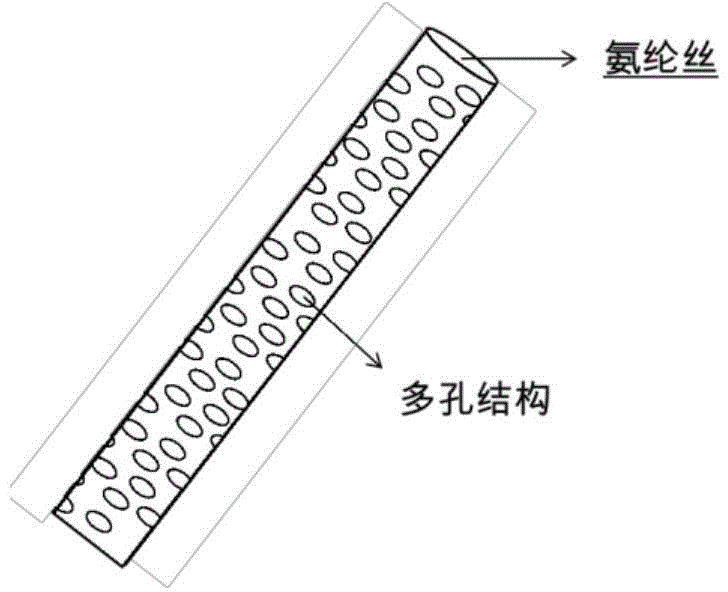

Preparation method of porous easy-dyeing spandex

A technology of spandex and solution, which is applied in the field of polyurethane elastic fiber material manufacturing, can solve the problem of little improvement in dyeing performance, achieve excellent biocompatibility and hydrophilicity, increase hydrophilicity, and increase the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1. Send 395.16kg of polytetramethylene ether glycol (molecular weight 1800) and 89.97kg of 4,4-diphenylmethane diisocyanate to the first reactor at the same time. The reaction time is 2hr and the reaction temperature is 80°C to obtain prepolymerized matter (PP);

[0028] Step 2. Transport 469.97kg of prepolymer and 573.91kg of N,N-dimethylacetamide (DMAC) solvent to the high-speed dissolving machine at the same time, and under the action of high-speed shear force, PP is fully dissolved to obtain the prepolymer Polymer solutions (PPs);

[0029] Step 3. 1043.88kg prepolymer solution and 286.57kg mixed amine DMAC solution (comprising 1.02kg propylenediamine, 7.72kg ethylenediamine, 0.99kg diethylamine, 0.42kg isopropanolamine), under the condition of rapid stirring Under this condition, chain growth and chain termination occur simultaneously to prepare a polyallophanate polymer solution;

[0030] Step 4. Add 27.48kg containing antioxidant, lubricant, matting agent a...

Embodiment 2

[0033] Step 1. Send 402.50kg of polytetramethylene ether glycol (molecular weight 1800) and 90.17kg of 4,4-diphenylmethane diisocyanate to the first reactor at the same time, the reaction time is 2hr, and the reaction temperature is 80°C to obtain prepolymerized matter (PP);

[0034] Step 2. Transport 487.12kg of prepolymer and 574.42kg of N,N-dimethylacetamide (DMAC) solvent to the high-speed dissolving machine at the same time, and under the action of high-speed shear force, PP is fully dissolved to obtain the prepolymer Polymer solutions (PPs);

[0035] Step 3. 1051.45kg prepolymer solution and 287.23kg mixed amine DMAC solution (including 1.03kg propylenediamine, 7.69kg ethylenediamine, 0.97kg diethylamine, 0.45kg isopropanolamine), under the condition of rapid stirring Under this condition, chain growth and chain termination occur simultaneously to prepare a polyallophanate polymer solution;

[0036] Step 4. Add 16.91kg containing antioxidant, lubricant, matting agent a...

Embodiment 3

[0039] Step 1. Send 375.87kg of polytetramethylene ether glycol (molecular weight 1800) and 83.52kg of 4,4-diphenylmethane diisocyanate to the first reactor at the same time, the reaction time is 2hr, and the reaction temperature is 80°C to obtain prepolymerized matter (PP);

[0040] Step 2. Transport 452.43kg of prepolymer and 554.82kg of N,N-dimethylacetamide (DMAC) solvent to the high-speed dissolving machine at the same time, and under the action of high-speed shear force, PP is fully dissolved to obtain the prepolymer Polymer solutions (PPs);

[0041] Step 3. 1043.88kg prepolymer solution and 273.27kg mixed amine DMAC solution (comprising 0.97kg propylenediamine, 7.12kg ethylenediamine, 0.94kg diethylamine, 0.52kg isopropanolamine), under the condition of rapid stirring Under this condition, chain growth and chain termination occur simultaneously to prepare a polyallophanate polymer solution;

[0042] Step 4. Add 14.44kg containing antioxidant, lubricant, matting agent an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com