Heat accumulation and preservation polyurethane elastic fibers containing phase change microcapsules and preparation method of heat accumulation and preservation polyurethane elastic fibers

A phase change microcapsule, polyurethane elasticity technology, applied in the chemical characteristics of fibers, rayon manufacturing, single-component synthetic polymer rayon, etc., can solve the problems of poor heat storage function, limited thermal insulation capacity, poor efficiency, etc. The effect of excellent thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

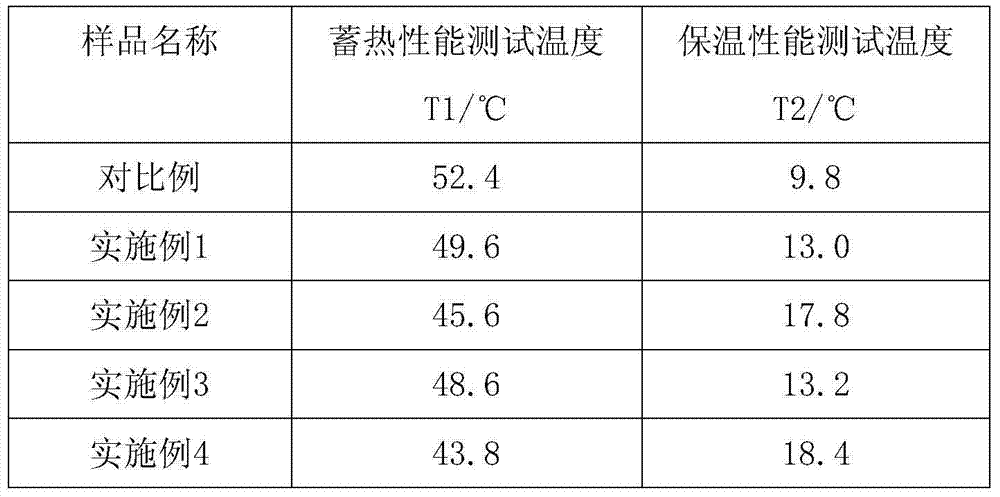

Examples

preparation example Construction

[0022] Preparation of phase-change microcapsules: Add a certain amount of distilled water, dispersant and other additives into the reaction kettle and stir to obtain a uniform water phase. Then a certain amount of acrylonitrile, styrene, methacrylic acid, C12-14 alcohol, and AIBN were mixed and added to the above water phase as an oil phase, homogenized at a speed of 1200 rpm for 30 minutes, purged with nitrogen, and the stirring speed was reduced to 300 rpm. Reaction at 60°C for 8h. After the reaction is complete, the product is processed, and the synthesized phase-change microcapsule suspension is vacuum-filtered, washed repeatedly with distilled water for 3 times, and vacuum-dried at 50° C. to obtain phase-change microcapsule A as a white dry powder.

[0023] Using the same method, the above-mentioned phase change material C12-14 alcohol is replaced by paraffin to prepare phase change microcapsule B.

[0024] The enthalpy of phase change microcapsule A is 124 J / g, the core...

Embodiment 1

[0027] Add 6.3kg of solvent dimethylacetamide (DMAC) to the reactor (RA1), start stirring, then add 9.50kg of polytetrahydrofuran ether glycol and 2.31kg of diphenylmethane diisocyanate to RA1, and react at 45°C for 2 hours The prepolymer PPS is obtained, and the PPS is transferred into the chain extension reactor (RA2). Add 13.0kg of cleaned DMAC to RA1, transfer the cleaned DMAC into RA2, start stirring, and when the temperature of RA2 cools down to about 10°C, add dropwise the mixed amine solution containing 0.174kg of ethylenediamine and 0.04kg of diethylamine into RA2 Carry out chain extension reaction and chain termination reaction, wherein the mass concentration of the mixed amine solution is 5.45%. After the reaction is complete, the resulting polymer is transferred into D-FETK. Add 120g phase-change microcapsule A in D-FETK, 18.1g anti-yellowing agent UDT, 36.2g anti-ultraviolet agent UTP, antioxidant CY24.1g, lubricating relieve agent magnesium stearate solution MGS...

Embodiment 2

[0029] Add 360g phase-change microcapsule A in D-FETK tank, other steps are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com