Heat-sensitive tertiary amine catalyst, quaternized derivative, preparation and application thereof

A technology of tertiary amine catalysts and derivatives, which is applied in the field of new heat-sensitive tertiary amine catalysts and their quaternary ammonium salt derivatives, which can solve problems such as poor storage stability, troubles in the spraying industry, and short shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

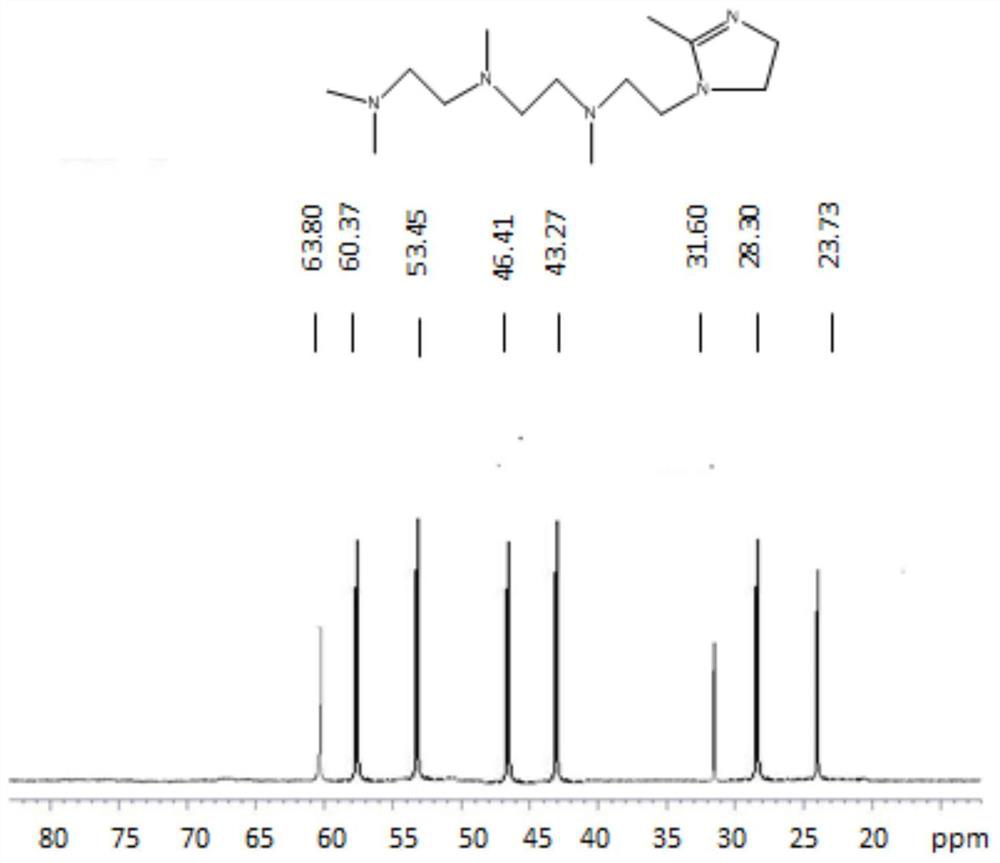

[0076] The preparation of embodiment 1 thermosensitive catalyst

[0077] One, the preparation of the thermosensitive catalyst shown in formula I structure:

[0078] 1) Preparation of the intermediate: Under the condition of 1MPa nitrogen protection, 300g of acetic acid and 946.5g of tetraethylenepentamine were reacted in a 5L reactor at 200°C for 1h under the action of 2000ml of tetrahydrofuran to obtain the intermediate, and the conversion rate reached 96%. Then water and tetrahydrofuran are azeotropically distilled until the water content is lower than 0.5%; after cooling, about 1120 g of tetraethylenepentamine imidazoline derivative intermediates are obtained;

[0079] 2) preparation of palladium series catalyst: 19.06g palladium sulfate and 3.12g ruthenium sulfate, 0.96g rhodium sulfate are dissolved in 70 ℃ of deionized waters and form the homogeneous solution of concentration about 30wt%; Then add 85.4g carrier diatomite, at 70 Rotate and impregnate at ℃ for 5.5 hours, ...

Embodiment 2

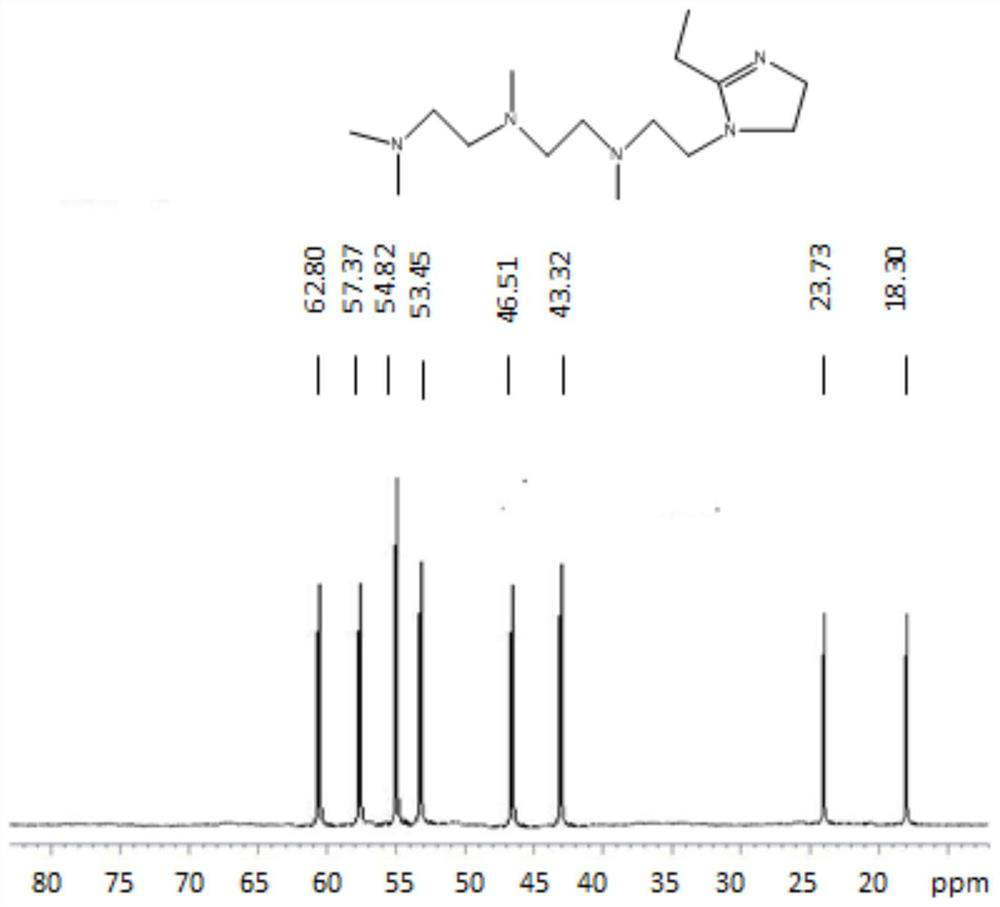

[0082] The preparation of embodiment 2 thermosensitive catalysts

[0083] 1) Preparation of intermediate: Using a synthesis process similar to that of Example 1, under 1MPa nitrogen protection conditions, 629g of propionic acid and 946.5g of tetraethylenepentamine were reacted in a 5L reactor at 200°C for 1h under the action of 2000ml of tetrahydrofuran The intermediate was obtained, the conversion rate reached 97%, and then the water and tetrahydrofuran were azeotropically distilled out until the water content was lower than 0.5%. After cooling, about 1295g of the imidazoline derivative intermediate of tetraethylenepentamine was obtained.

[0084] 2) Preparation of palladium series catalyst: 130.38g palladium nitrate and 1.255g ruthenium nitrate, 2.8g rhodium nitrate are dissolved in 80 DEG C of deionized water to form a homogeneous solution with a concentration of about 30wt%; then add 27.86g carrier alumina, and Rotate and impregnate at 80°C for 5.5 hours, then gradually ev...

Embodiment 3

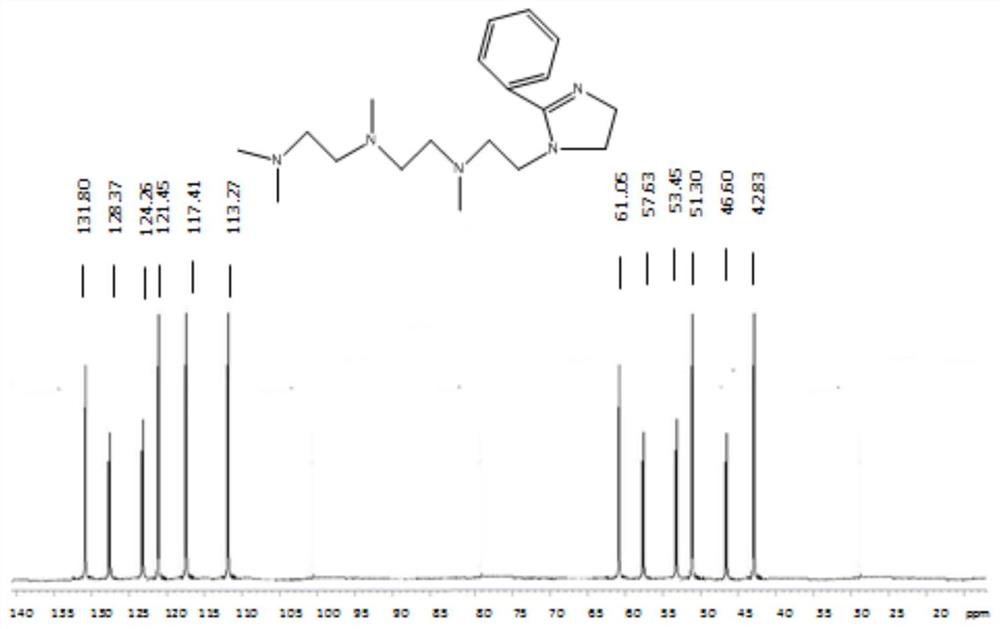

[0087] The preparation of embodiment 3 thermosensitive catalysts

[0088] 1) Preparation of intermediates: using a synthesis process similar to Example 1, under 1MPa nitrogen protection conditions, 488.48g of benzoic acid and 946.5g of tetraethylenepentamine were reacted in a 5L reactor at 200°C under the action of 2000ml of tetrahydrofuran The intermediate was obtained in 1 hour, and the conversion rate reached 98%, and then water and tetrahydrofuran were azeotropically distilled until the water content was lower than 0.5%; after cooling, about 1411 g of an imidazoline derivative intermediate of tetraethylenepentamine was obtained.

[0089] 2) Preparation of palladium series catalyst: 65.19g palladium nitrate and 6.72g ruthenium nitrate, 0.14g rhodium nitrate are dissolved in 80 DEG C of deionized water to form a homogeneous solution with a concentration of about 30wt%; then add 61.94g carrier silicon dioxide, Rotate and impregnate at ℃ for 5.5 hours, then gradually evaporate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com