Adsorbent master batch and low-emission pc/abs alloy containing the master batch and preparation method

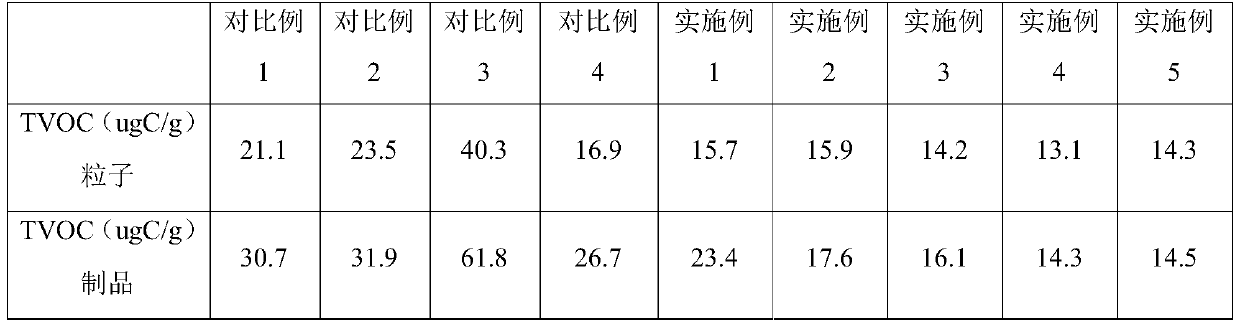

An adsorbent, low emission technology, applied in the field of low emission PC/ABS alloy and preparation, adsorbent masterbatch, can solve problems such as harm to human health and increased emission, to reduce emission, ensure desorption, The effect of reducing volatile organic compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

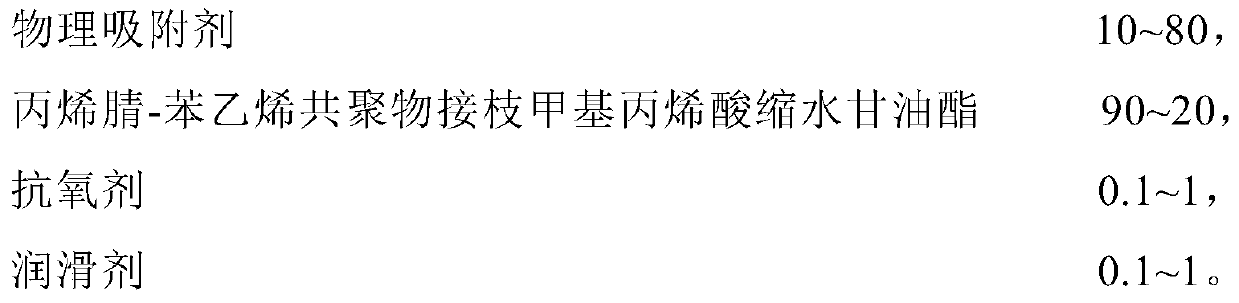

Method used

Image

Examples

Embodiment 1

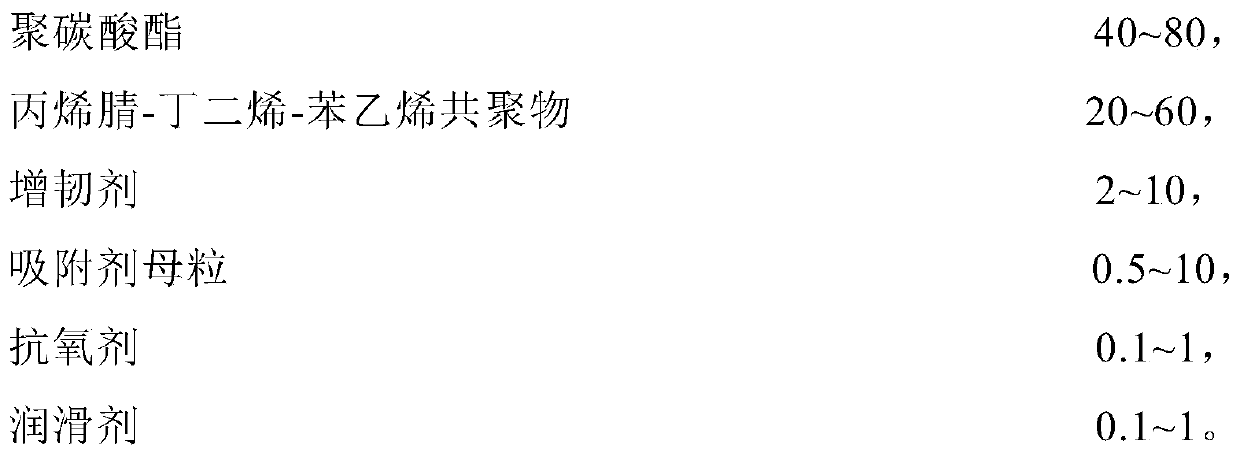

[0034] (1) Weigh each component by weight: PC-1100 is 30Kg, PC-2200 is 30Kg, ABS8391 is 35Kg, MBS (methyl methacrylate-butadiene-styrene copolymer): EXL-2620 is 5Kg, diatomite (5000 mesh) is 2Kg, SAN-g-GMA SAN-g-GMA (number average molecular weight 20,000, GMA content 8%) is 2KG, antioxidant 245 is 0.1Kg, antioxidant 168 is 0.1Kg, lubricant PETS (pentaerythritol stearate) is 0.5Kg, silicone powder 0.5kg;

[0035] (2) Place the prepared components in a medium-speed mixer and mix for 20 minutes to obtain the mixed material;

[0036] (3) Put the mixed material into a twin-screw extruder, control the screw speed to 500rpm, melt and extrude, and granulate to obtain the product. The twin-screw extruder includes ten temperature control zones, the temperature of temperature control zone 1-2 is 180-260°C, the temperature of temperature control zone 3-4 is 180-260°C, the temperature of temperature control zone 5-6 is 180°C ~260℃, the temperature of temperature control zone 7-8 is 180~...

Embodiment 2

[0038] (1) each component is taken by weight: diatomite (5000 orders) is 10Kg, SAN-g-GMA (number average molecular weight 50,000, GMA content 2%) is 90Kg, antioxidant 245 is 0.1Kg, Antioxidant 168 is 0.1Kg, lubricant PETS (pentaerythritol stearate) is 0.5Kg;

[0039] (2) Place the prepared masterbatch components in a medium-speed mixer and mix for 20 minutes to obtain the mixed material;

[0040] (3) The mixed material is placed in the internal mixer, the control speed is 20rpm, after blending for 5min, granulation;

[0041](4) Weigh each component by weight: PC-1100 is 30Kg, PC-2200 is 30Kg, ABS8391 is 35Kg, MBS (methyl methacrylate-butadiene-styrene copolymer): EM 505 is 5Kg , the diatomite masterbatch is 2Kg, the antioxidant 245 is 0.1Kg, the antioxidant 168 is 0.1Kg, the lubricant PETS (pentaerythritol stearate) is 0.5Kg, and the silicone powder is 0.5kg;

[0042] (5) Place the prepared product components in a medium-speed mixer and mix for 20 minutes to obtain the mixed...

Embodiment 3

[0045] (1) each component is taken by weight: diatomite (5000 order) is 50Kg, SAN-g-GMA (number average molecular weight 80,000, GMA content 5%) is 50Kg, antioxidant 245 is 0.1Kg, Antioxidant 168 is 0.1Kg, lubricant PETS (pentaerythritol stearate) is 0.5Kg;

[0046] (2) Place the prepared masterbatch components in a medium-speed mixer and mix for 20 minutes to obtain the mixed material;

[0047] (3) The mixed material is placed in the internal mixer, the control speed is 20rpm, after blending for 5min, granulation;

[0048] (4) Weigh each component by weight: PC-1100 is 30Kg, PC-2200 is 30Kg, ABS8391 is 30Kg, MBS (methyl methacrylate-butadiene-styrene copolymer): EM 505 is 5Kg , diatomite masterbatch is 5Kg, antioxidant 245 is 0.1Kg, antioxidant 168 is 0.1Kg, lubricant PETS (pentaerythritol stearate) is 0.5Kg, silicone powder is 0.5kg;

[0049] (5) Place the prepared product components in a medium-speed mixer and mix for 20 minutes to obtain the mixed material;

[0050] (6)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com