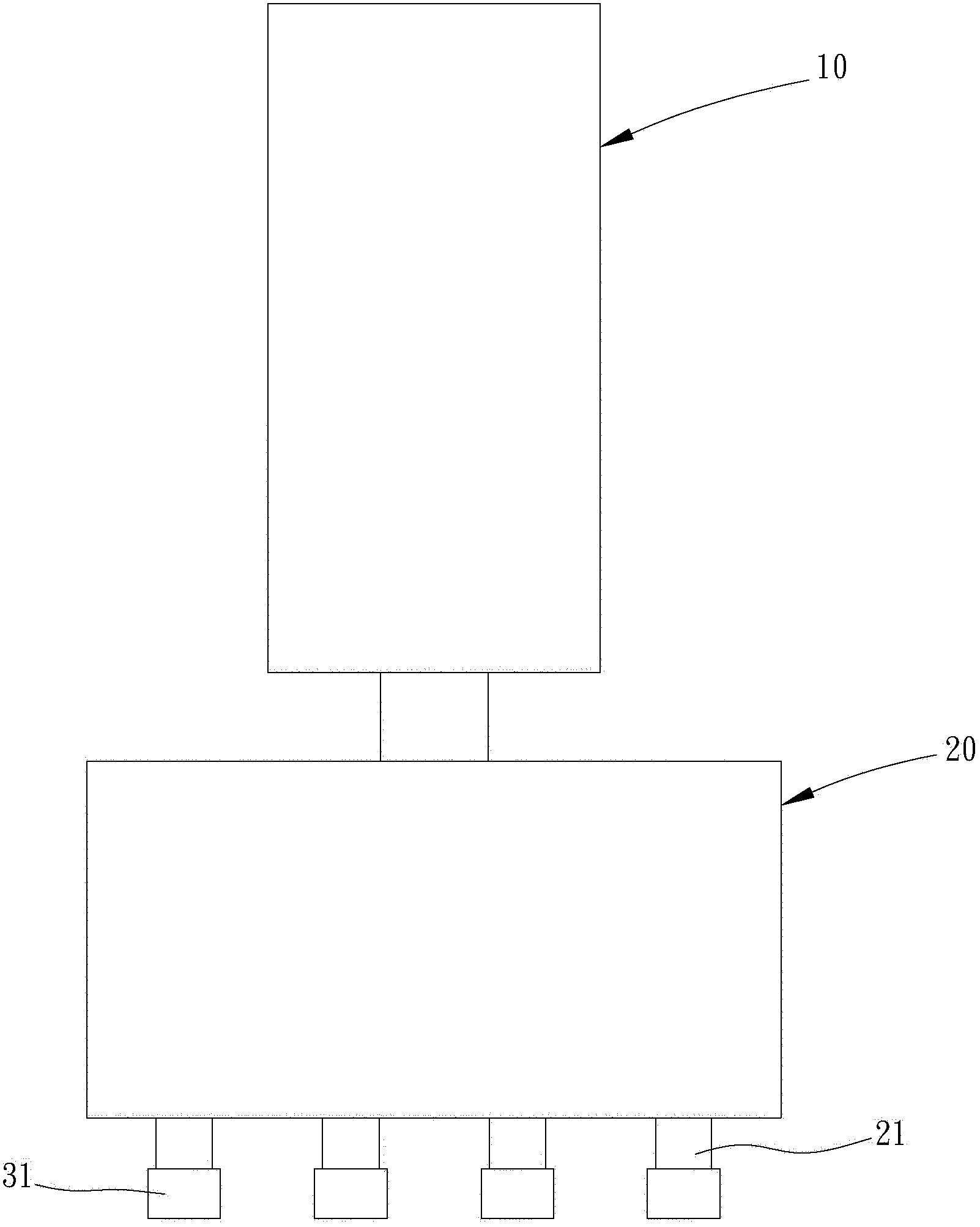

Patents

Literature

91results about How to "Short demoulding time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

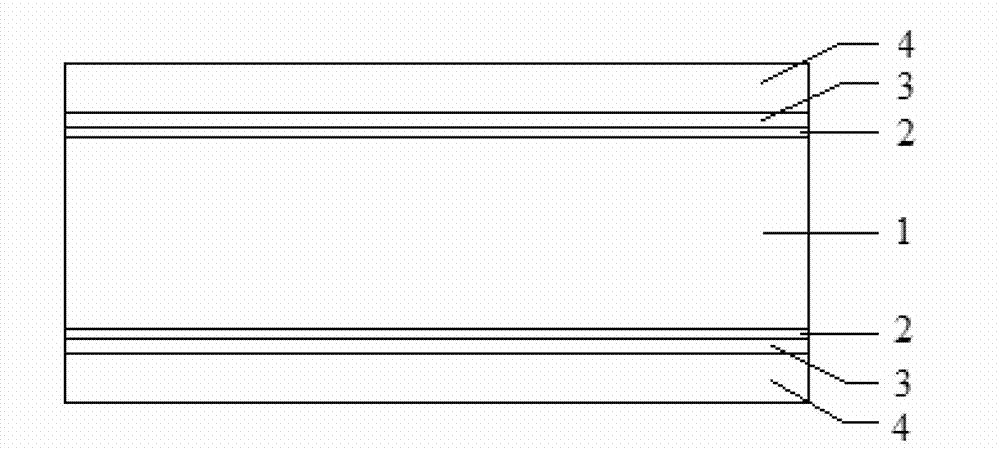

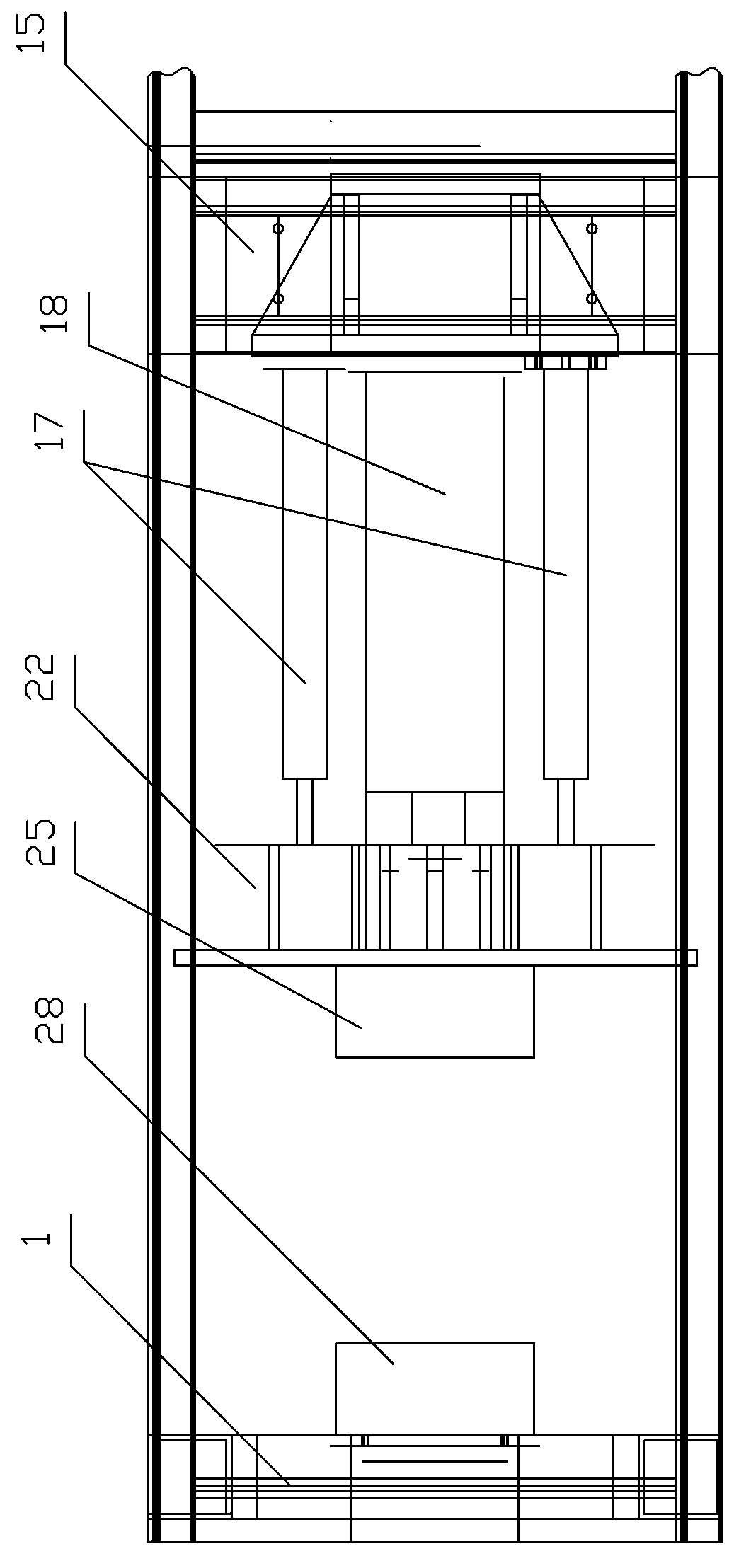

Double layer sandwich foamed concrete composite solid wall plate

InactiveCN1987008AShort demoulding timeIncrease productivityConstruction materialSolid waste managementFiberFoam concrete

A dual-layer sandwich-type solid wall slab is composed of two surficial thin cement slabs and a foam concrete core layer. It is proportionally made of fast hardening sulphoaluminate cement, powdered coal ash, river sand, fibers, hydrogen peroxide as foaming agent, and stabilizer. Its advantages are light weight, high surface strength and high insulating effect.

Owner:贵州华骏集团节能环保材料有限公司

Environment-friendly flame-retardant polyurethane wood-imitation material

The invention belongs to the field of chemical synthesis, and in particular relates to an environment-friendly flame-retardant polyurethane wood-imitation material, which is characterized by comprising a component A and a component B, wherein the component A consists of polyether polyalcohol, a foam stabilizer, a catalyst, a foaming agent and a flame retardant; and the component B is polymethylene polyphenyl polyisocyanate. A method for preparing the environment-friendly flame-retardant polyurethane wood-imitation material comprises the following steps of: mixing and stirring the component A and the component B, injecting the components into a constant-temperature die at the temperature of between 40 and 50 DEG C, reacting and curing for 10 to 13 minutes to obtain the environment-friendly flame-retardant polyurethane wood-imitation material. The invention has the advantages that due to the adoption of the reaction type catalyst, the generation of volatile gas is prevented, and the harm to the health of human bodies is reduced greatly; water is used as the single foaming agent instead of the conventional hydrochlorofluorocarbon (HCFC)-141B foaming agent, so that the consumption of an ozone layer is reduced effectively; and demolding can be performed after 10 to 13 minutes during production, so that the production efficiency is improved greatly.

Owner:SHANGHAI DONGDA POLYURETHANE

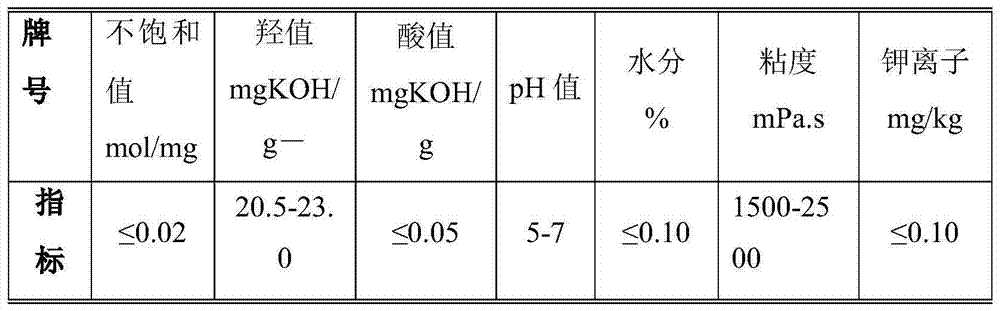

Method for synthesis of low-unsaturation degree, high-molecular weight and high-activity polyether polyol

The invention relates to a method for synthesis of low-unsaturation degree, high-molecular weight and high-activity polyether polyol and belongs to the field of chemical engineering. An initiator and an epoxy compound undergo a polymerization reaction in the presence of a catalyst to produce the low-unsaturation degree, high-molecular weight and high-activity polyether polyol. In the polymerization reaction process, the epoxy compound and the catalyst are added into the reaction system by three steps and through the polymerization reaction, the low-unsaturation degree, high-molecular weight and high-activity polyether polyol is obtained. The low-unsaturation degree, high-molecular weight and high-activity polyether polyol has regular molecular weight distribution, low viscosity, a low unsaturation value and high activity. Compared with the universal soft-foam polyether polyol in the market, the low-unsaturation degree, high-molecular weight and high-activity polyether polyol can effectively improve foam resilience. The low-unsaturation degree, high-molecular weight and high-activity polyether polyol can be used for preparation of various molding foam and has the characteristics of high activity and short demolding time.

Owner:SHANDONG BLUSR DONGDA CHEM

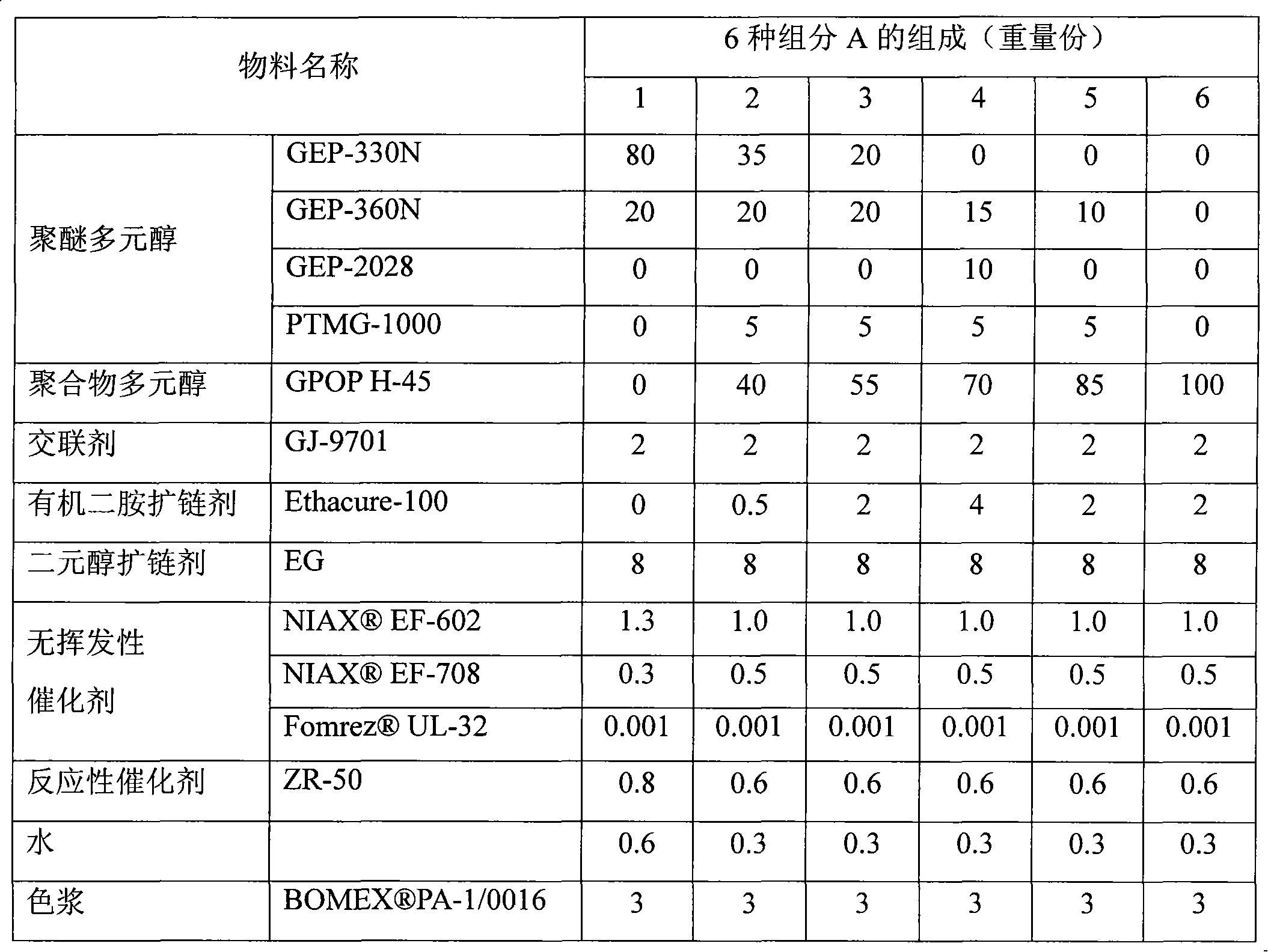

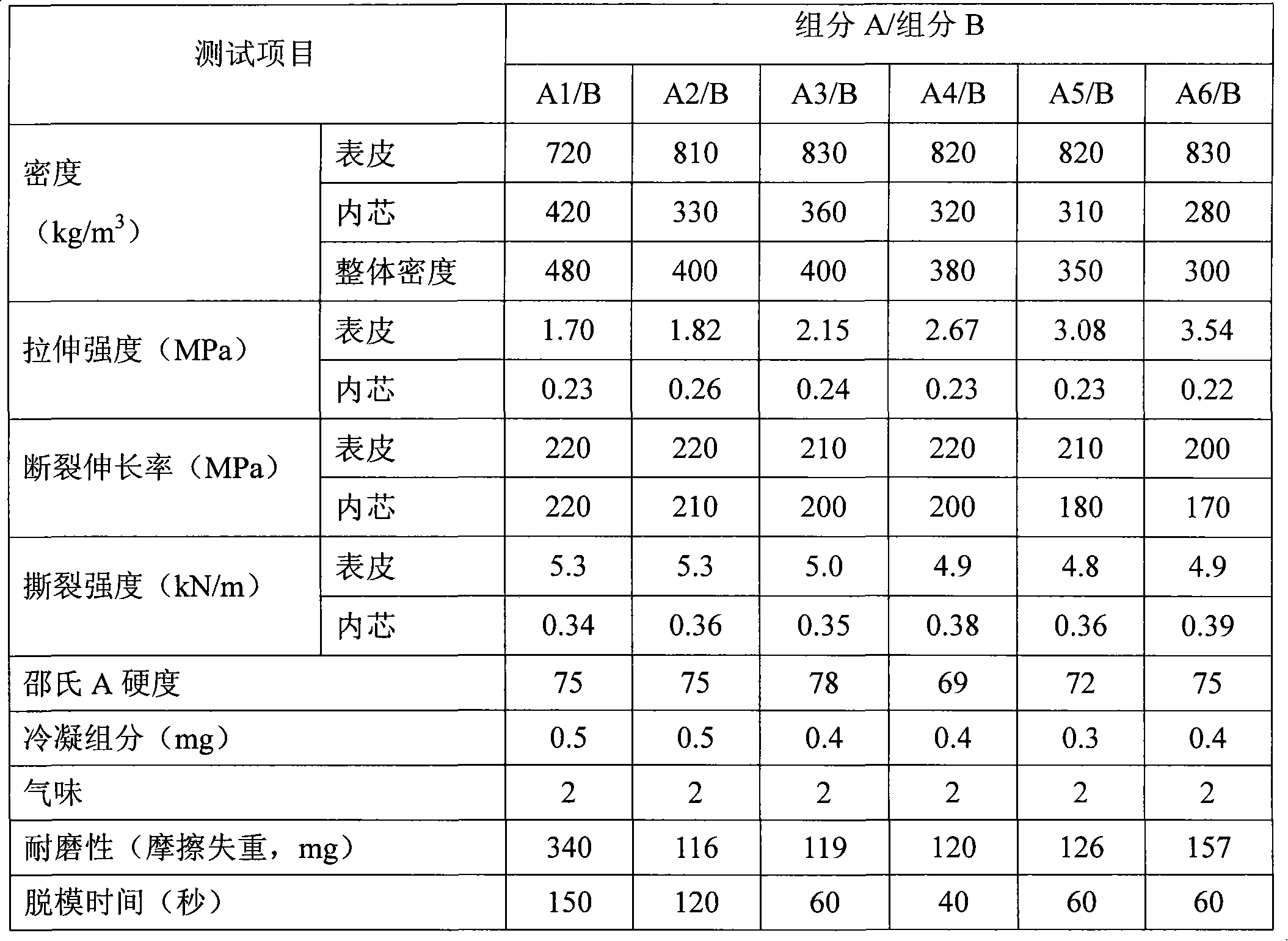

Integral skin polyurethane-urea composition, preparation method and application thereof

The invention discloses a quick demoulding water-blown low-density integral skin polyurethane-urea composition which comprises a polyalcohol mixture component A and a modified isocyanate component B, wherein the component A is a polyalcohol mixture which comprises polyether glycol, polymer polyol, a cross linking agent, organic diamine, a divalent alcohol chain extender, a nonvolatile catalyst and / or a reactive catalyst, water and color paste; the component B is allophanate modified isocyanate containing 22-31 wt percent of NCO and is formed by polymerizing methyl diphenylene diisocyanate (MDI) and polyalcohol with molecular weight of 62-3000. The component A and the component B according to a weight ratio of 100:40-100 are polymerized into integral skin polyurethane-urea with integral intensity of 260-400 kg / m, and the integral skin polyurethane-urea can be demoulded within 60 seconds.

Owner:湖州合达图宏新材料技术股份有限公司

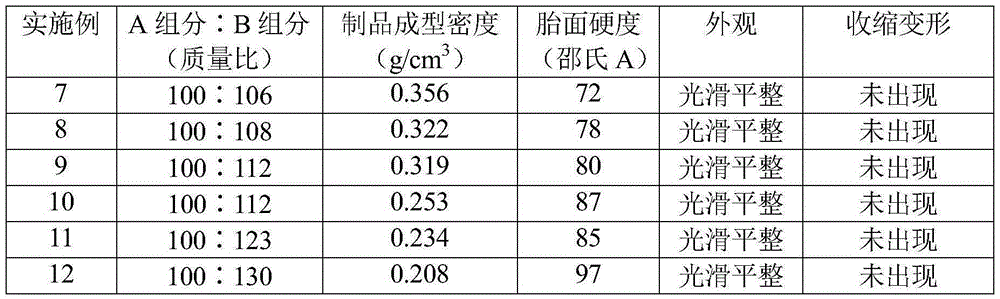

Polyurethane solid tire material and preparation method thereof

The invention relates to a polyurethane solid tire material. The polyurethane solid tire material comprises a component A and a component B, wherein the component A is a mixture prepared by mixing polyester polyol, a chain extender, a foaming agent, a catalyst A and a foam stabilizer according to a mass ratio of 100:(5 to 30):(0.3 to 3.0):(0.3 to 3.0):(0.3 to 2.5), the component B is prepared by prepolymerizing isocyanate, polyester polyol and polyether polyol under the existence of a side reaction inhibitor according to a mass ratio of 100:(20 to 50):(0 to 30), and the polyester polyol in the component A and the component B is prepared by prepolymerizing binary acid and polyhydric alcohols under the action of a catalyst B. The component A and the component B are fully mixed, and are then injected into a mold for reaction to form, and demolding and aging are performed, so as to prepare a tire product. The prepared tire product has the advantages of low density, stable size, high tread hardness, good abrasion resistance and good bonding capability with other accessories of the tire.

Owner:JIAXING HEXIN CHEM IND

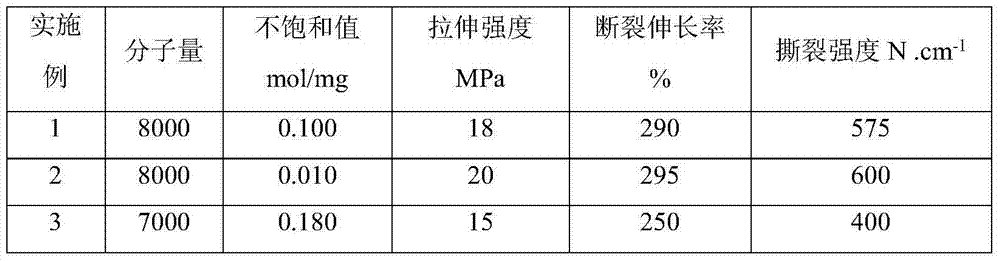

Preparation method of polyether polyol with high molecular weight, low unsaturation degree and high primary hydroxyl group content

The invention relates to a preparation method of polyether polyol with high molecular weight, low unsaturation degree and high primary hydroxyl group content, belonging to the field of chemical engineering. According to the preparation method, a treating agent is used for treating the polyether polyol with high molecular weight and low unsaturation degree, which contains bimetallic catalyst DMC; ethylene oxide is added for end capping; an adsorbent is used for treating the product of the end capping; filtration is finally carried out to obtain the polyether polyol with high molecular weight, low unsaturation degree and high activity, wherein the molecular weight of the polyether polyol is 8000-15000 and the primary hydroxyl group mole fraction is 85-93%. The prepared polyether polyol with high molecular weight, low unsaturation degree and high primary hydroxyl group content has the characteristics of high activity, short demoulding time and good physical mechanical property; by using the polyether polyol as a raw material, the prepared high-resilience moulding foam product is suitable for the preparation of various automotive trim materials. The invention expands the application of the polyether polyol to PU big high-resilience foam and one-step moulding foam.

Owner:SHANDONG BLUSR DONGDA CHEM

Coal ash-based mullite light heat-insulation brick and preparation method thereof

The invention relates to a coal ash-based mullite light heat-insulation brick and a preparation method thereof. According to the adopted technical scheme, the preparation method comprises the steps of: firstly, preparing 50-90wt% of coal ash and 10-50wt% of alumina serving as raw materials, adding 0.5-5.0wt% of swelling agent, 25-60wt% of water and 0.1-1.0wt% of water reducer relative to the raw materials, mixing 3-15min to obtain pug; then adding foam made by 0.5-2.0wt% of foaming agent relative to the raw materials, uniformly stirring, adding 1-5wt% of gel, 0.1-1.0wt% of thermosetting resin and 1-3wt% of curing agent relative to the raw materials, stirring 3-15min, moulding by casting, naturally drying for 3-10h, demoulding, baking for 12-24h at a temperature of 60-120 DEG C; and finally, preserving the heat for 3-12h at a temperature of 1150-1550 DEG C to obtain the coal ash-based mullite light heat-insulation brick. The preparation method has the characteristics of resource saving, environment friendliness, short demoulding time, short drying period and suitability for large-scale industrial production; and the coal ash-based mullite light heat-insulation brick has the advantages of high strength, low volume density and low heat conductivity coefficient.

Owner:WUHAN UNIV OF SCI & TECH

High-transparency polyurethane elastomer

InactiveCN102040720AAvoid easy to be oxidized and discoloredAvoid defects that cannot be exposed to air for a long timePolyurethane elastomerPolyol

The invention discloses a high-transparency polyurethane elastomer, which is of a system of three components, namely a prepolymer component, a polymer component and a chain extender component, wherein in the prepolymer component, diisocyanate reacts with polyalcohol to generate a prepolymer, the NCO of which is 6 to 10 percent, the diisocyanate is preferably selected from toluene diisocyanate 80 (TDI-80), and the polyalcohol is polyepoxy propane ether polyalcohol, the number average molecular weight of which is in a range of 400 to 3,000 and the functionality of which is 2; and the polymer component is prepared from polyepoxy propane ether polyalcohol, catalyst and anti-ageing agent, wherein the molecular weight of the polyepoxy propane ether polyalcohol is 1,000 to 5,000, and the functionality of the polyepoxy propane ether polyalcohol is 2 or 3. When the product is produced, the temperatures of the polymer component and the chain extender component are controlled at 30 + / - 5 DEG C, the polymer component and the chain extender are mixed in a certain ratio and stirred uniformly, then the polymer component and the chain extender are mixed with the prepolymer component in a certain ratio, and the mixture is placed and cured for 20 to 30 minutes at the temperature of between 70 and 80 DEG C to obtain a product with excellent abrasion resistance and impact resilience. The high-transparency polyurethane elastomer is mainly used for manufacturing high-elasticity ice skate wheels or skateboard wheels.

Owner:SHANDONG INOV POLYURETHANE

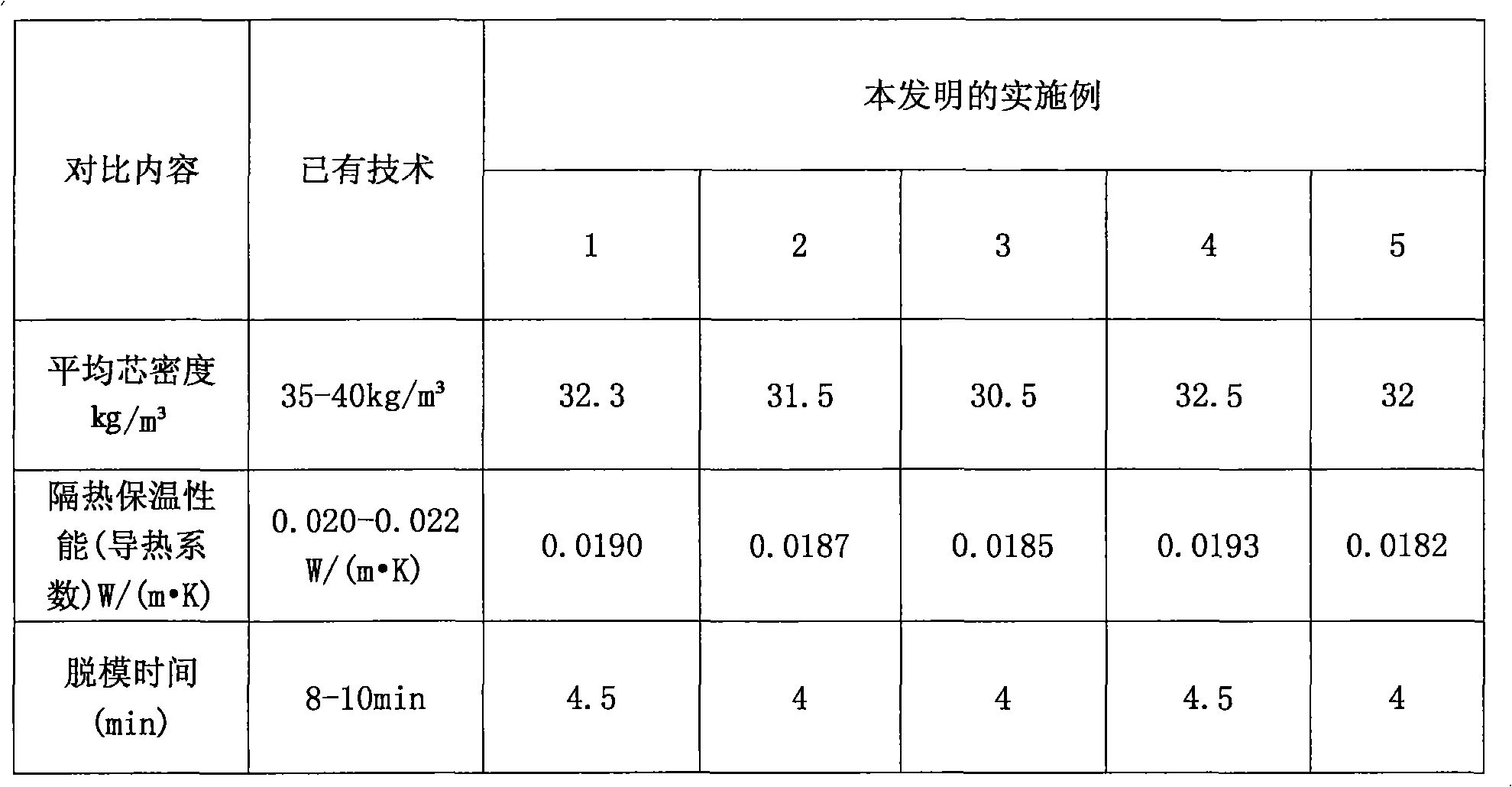

Polyurethane rigid foam combination material

The invention provides a polyurethane hard foam compound material, belonging to the foam plastic technical field. The compositions in weight portions are: 30 to 50 portions of sucrose polyether, 20 to 30 portions of amine polyether, 20 to 50 portions of dihydric alcohol polyether, 1 to 1.5 portions of catalyst I, 0.2 to 0.6 portions of catalyst II, 0.5 to 1.5 portions of catalyst III, 2 to 2.5 portions of silicon oil, 1.5 to 2.5 portions of water and 12 to 30 portions of foaming agent. The polyurethane hard foam compound material has the advantages that the heat preservation performance is good; when the material is used as a thermal insulation material or a heat preservation material of a refrigerator and a cooler, the electrical energy is saved; the average core density is low, thereby lowering the raw material use level of the polyurethane hard foam compound material and isocyanate; moreover, when the material is used for the injection molding of the refrigerator and the cooler, the demoulding time is short, thereby improving the work efficiency.

Owner:CHANGSHU YITONG POLYURETHANE PROD

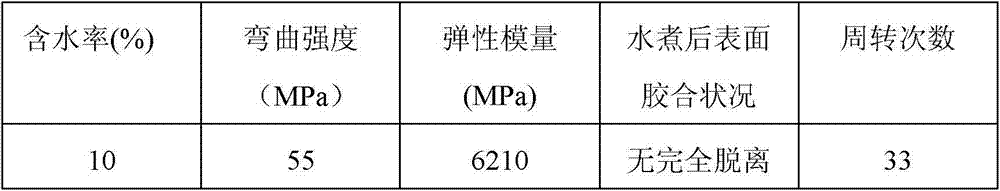

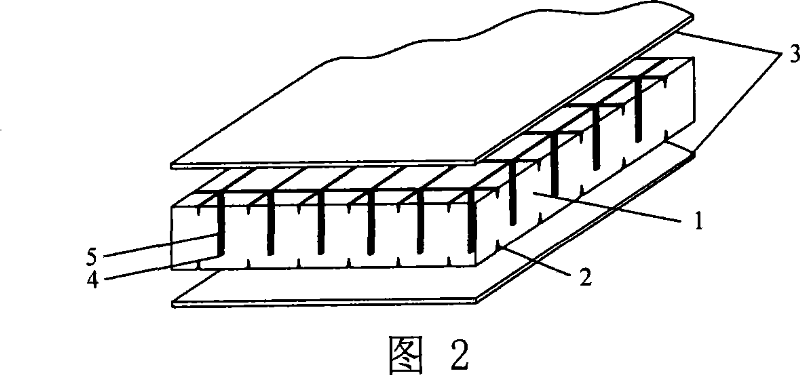

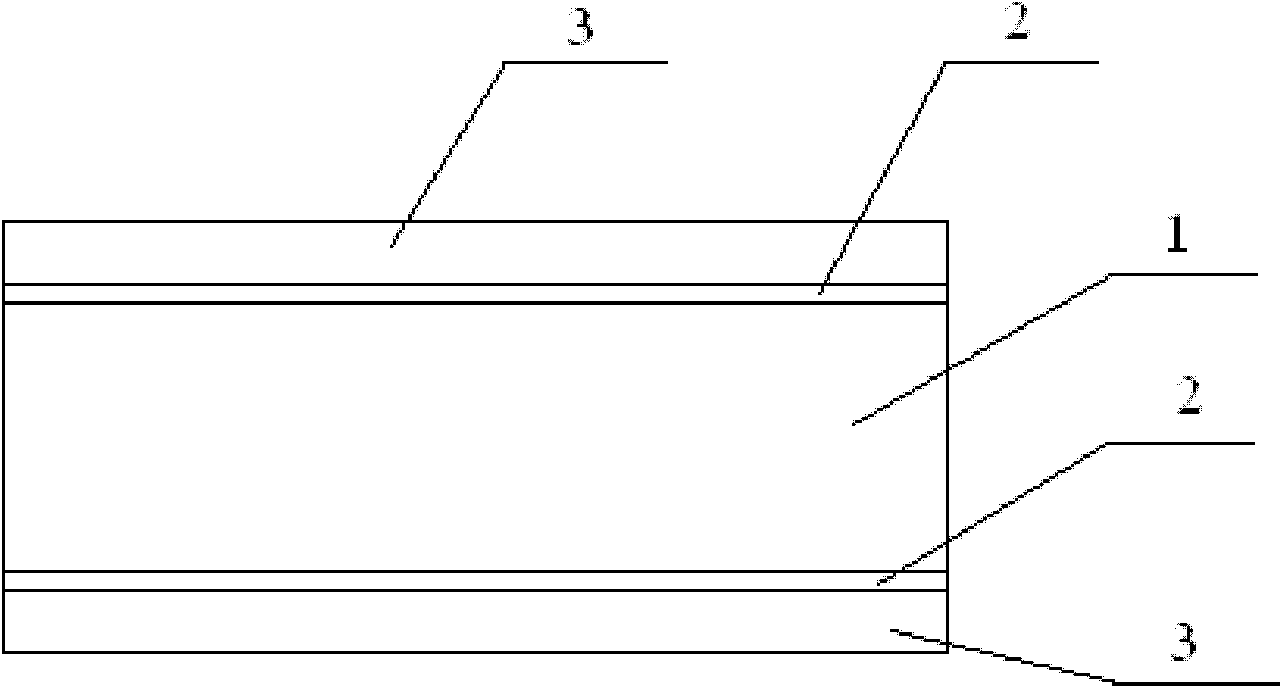

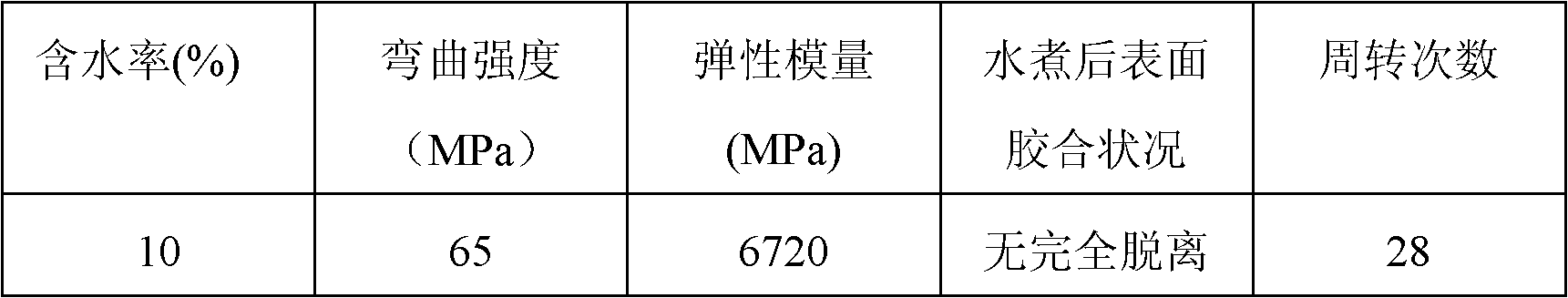

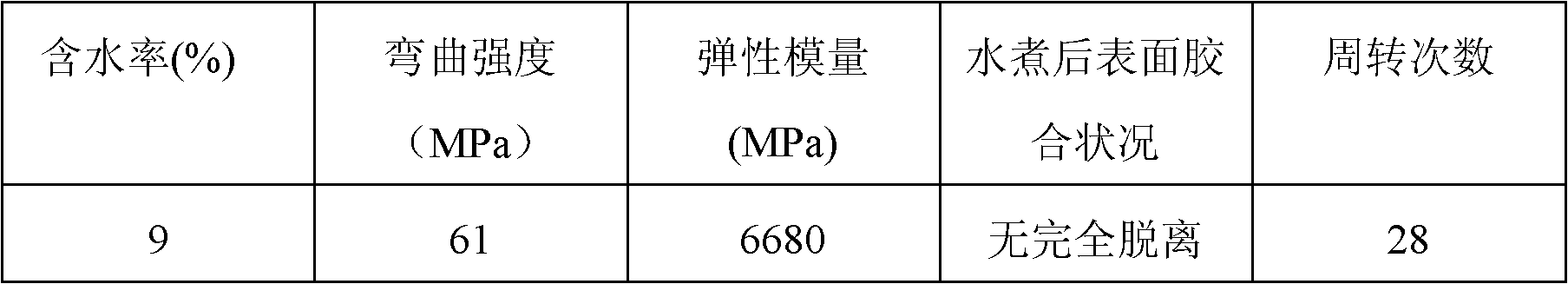

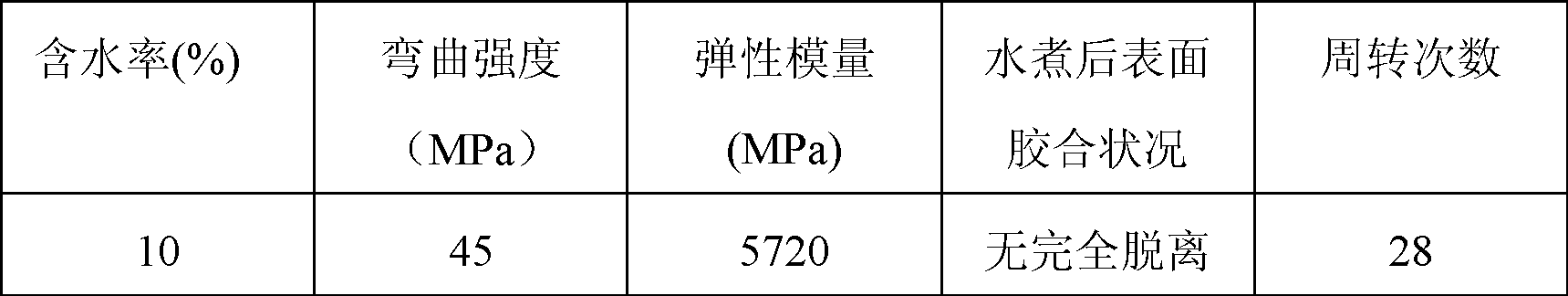

Plastic-coated wooden building template and preparation method thereof

InactiveCN103031948AEasy constructionReduce usageSynthetic resin layered productsWood layered productsPolyolefinFlexural strength

The invention discloses a plastic-coated wooden building template and a preparation method thereof, which relate to a building template and a preparation method thereof and mainly solve the problems that a high-cost performance building template prepared by the current preparation method is low in turnover times and poor in mechanical properties. The preparation method comprises the following steps: firstly, manufacturing a core plate by using a waste template; secondly, manufacturing a polyolefin veneer coated with non-woven fabric; thirdly, gluing double sides of a wood veneer, putting the wood veneer between the polyolefin veneer coated with the non-woven fabric and the core plate, with the same operation for upper and lower surfaces; and finally, pressing. The turnover times of the plastic-coated wooden building template is as high as 30-35 times, which is 10-17% higher than that of the current building template, so that the using cost of the plastic-coated wooden building template is reduced; the plastic-coated wooden building template has the bending strength of 52-55 MPa and an elasticity modulus of 6050-6210 MPa; the plastic-coated wooden building template is high in strength and good in toughness; the preparation method is simple, low in cost and easy to implement, and is applicable to large-scale popularization and application; and the plastic-coated wooden building template has relatively high economic and social benefits and can be applied to the building engineering.

Owner:安徽省崃山建材有限公司

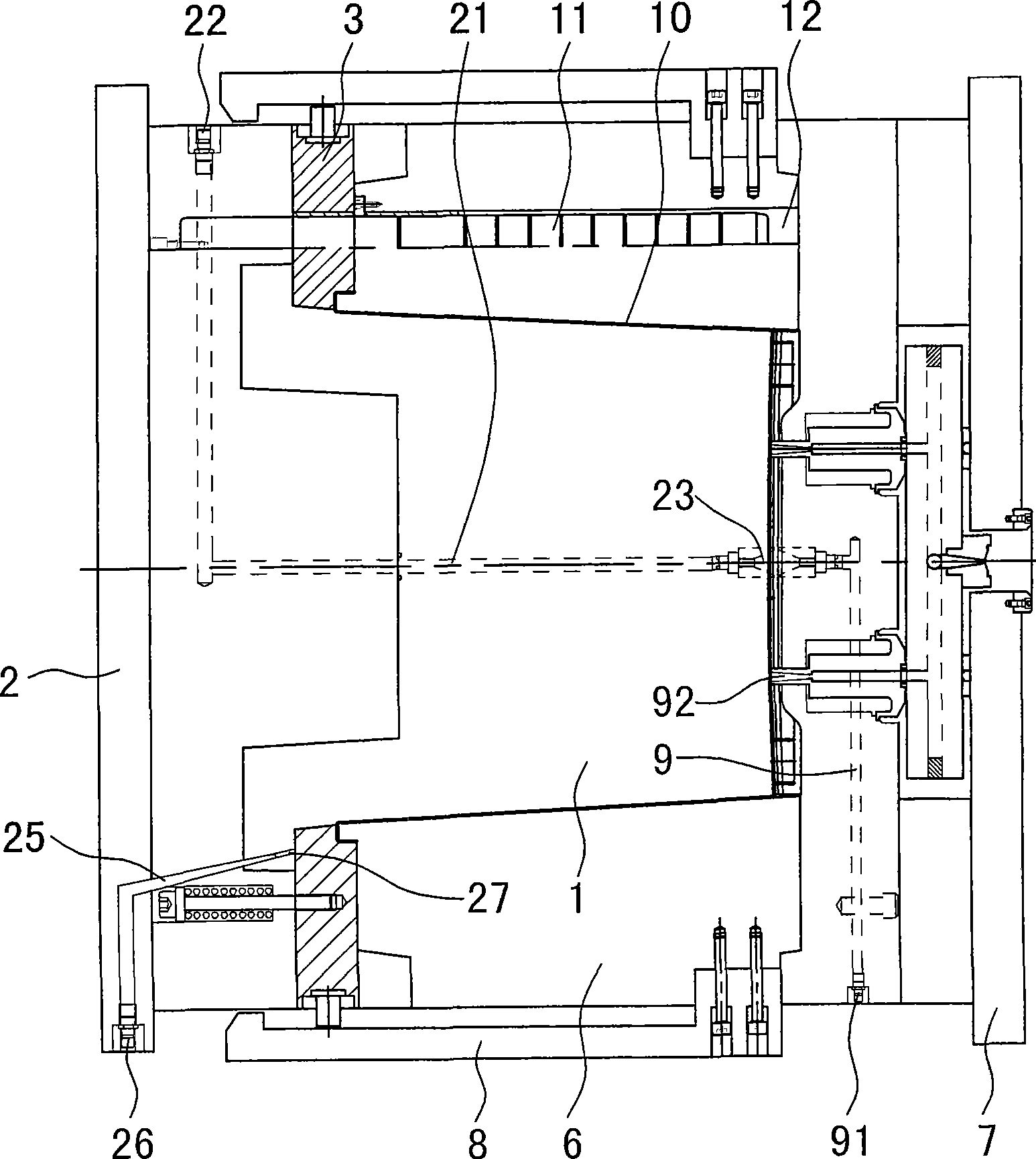

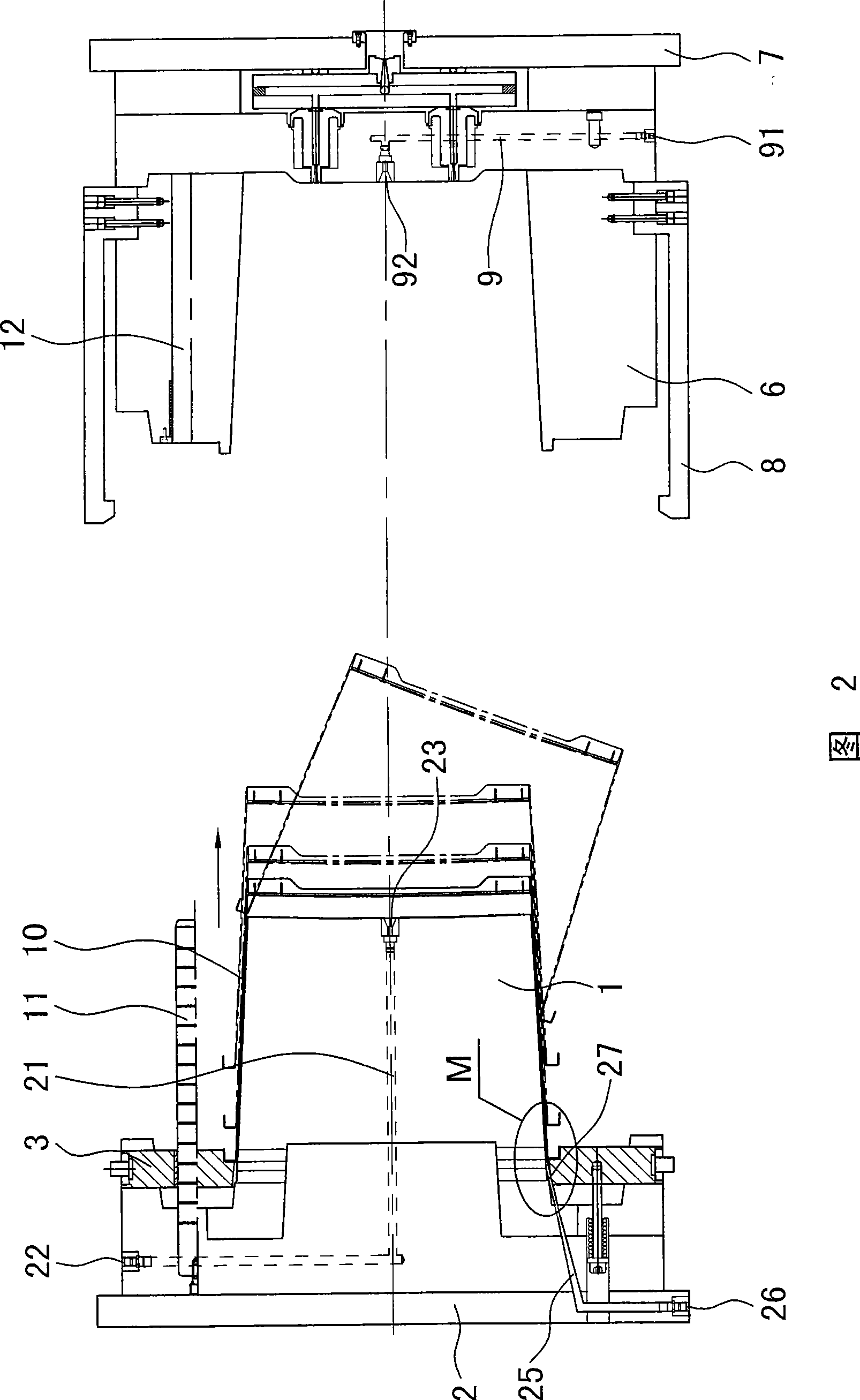

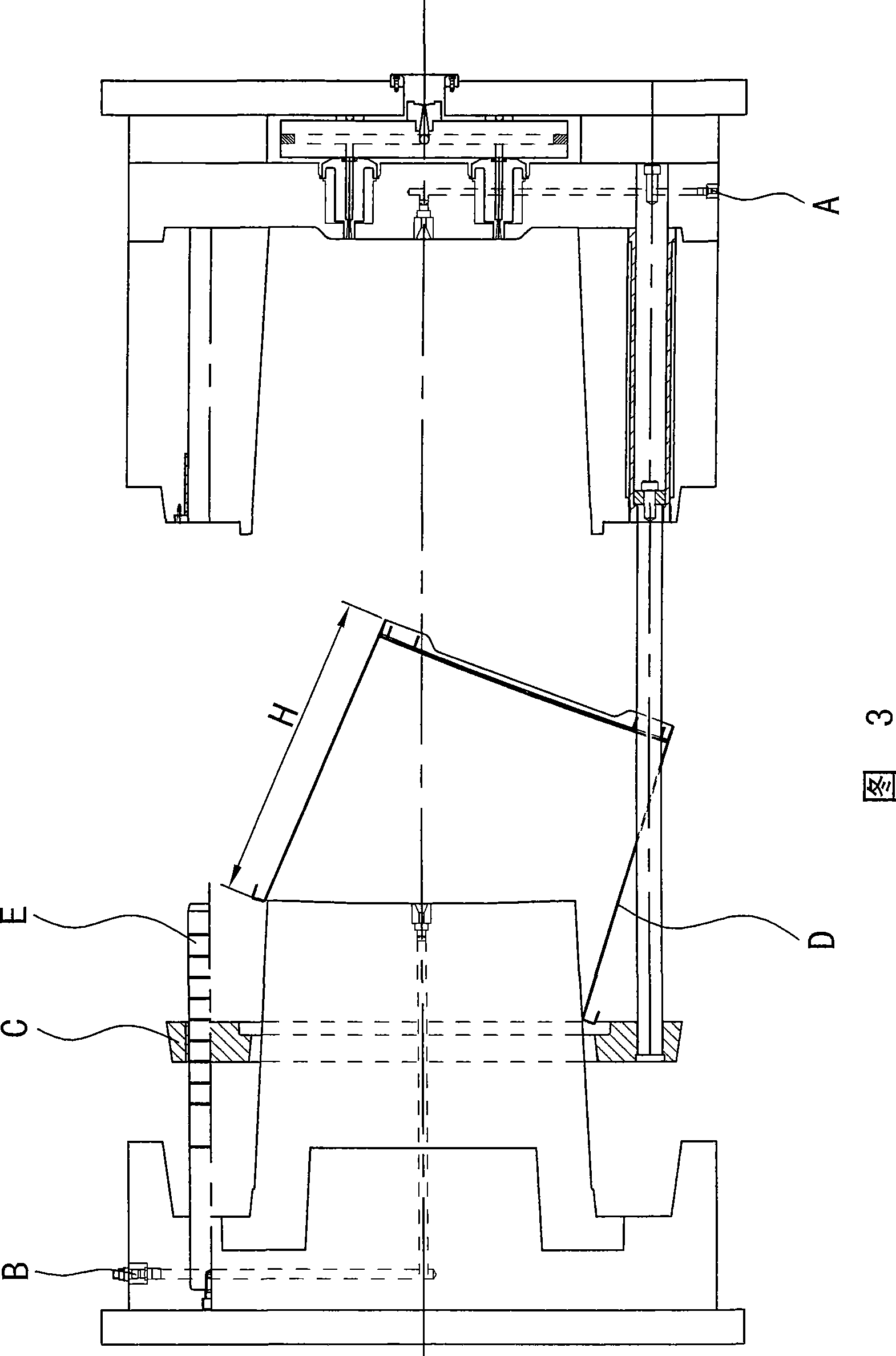

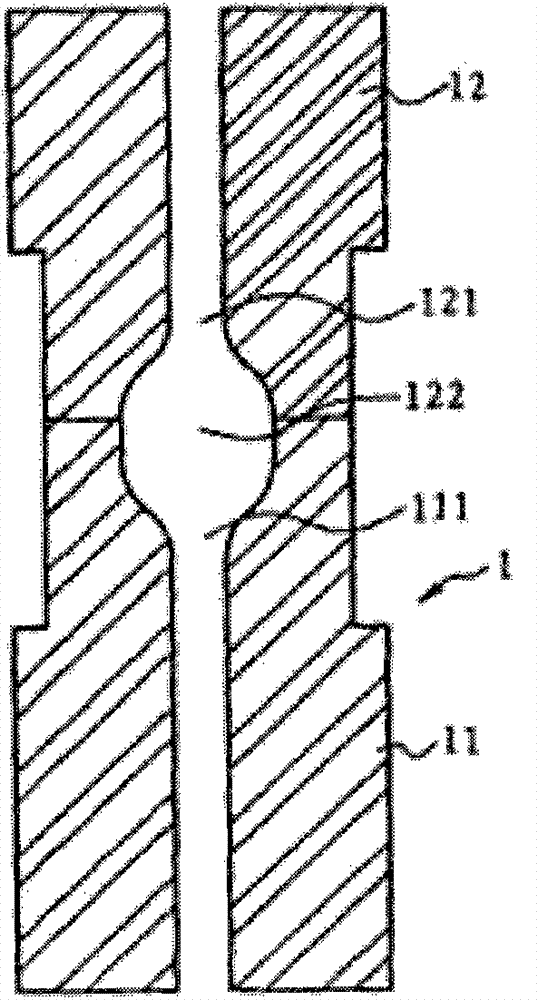

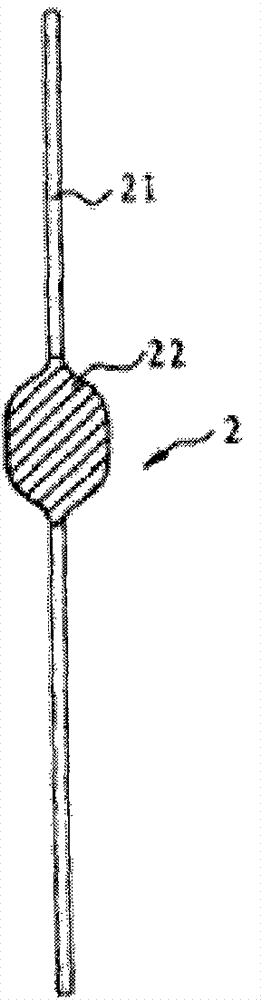

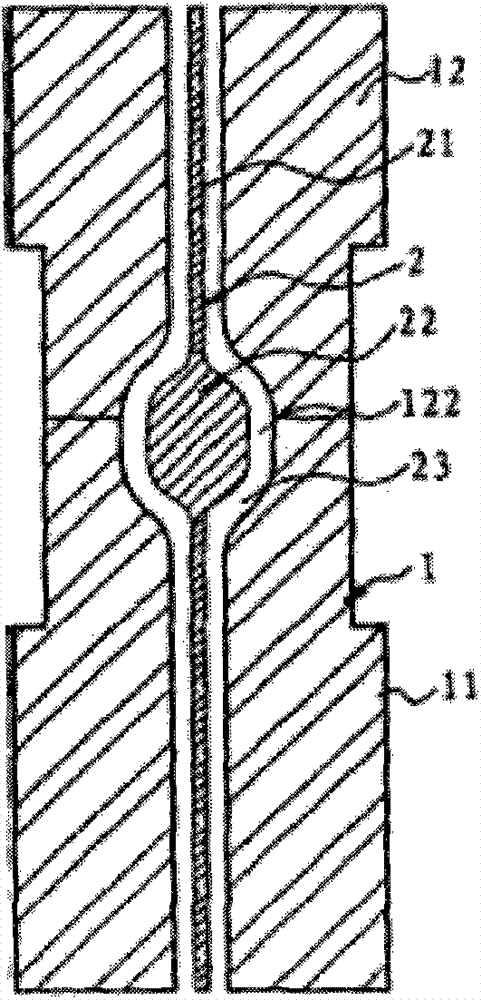

Plastic die parting-plane air-admission stripper

InactiveCN101422938AShort demoulding timeIncrease productivityCompletion timeInjection molding machine

A plastic mold split surface gas inlet demoulding mechanism consists of a convex mold and a concave mold, wherein, a pulling slab is arranged on the convex mold, a pulling hook is arranged on the concave mold, and the pulling hook is contacted with the pulling slab.The mechanism is characterized in that the concave mould is provided with a blowing passage which is provided with a gas inlet and a gas outlet, the convex mold is provided with a top wind passage and a plurality of split surface gas inlet passages, the top wind passage is provided with a wind inlet and a wind outlet, the gas inlet passages of the spit surfaces are respectively provided with a wind injecting port and a wind blowing port, the gas flow produced from the wind blowing ports is positioned in the gap between the convex mold and the plastic production. The demoulding time of the demoulding mechanism is short, the plastic production can automatically fall off within the molding completion time of the injection molding machine, and therefore, the production efficiency is improved. On the other hand, the pulling path of the pulling slab is short, the influence to the mold is small, and the service life is long.

Owner:李新贵

Three-component polyurethane elastomer composition with high wear resistance

ActiveCN101747618AAvoid easy to be oxidized and discoloredAvoid defects that cannot be exposed to air for a long timePrepolymerIsocyanate

The invention relates to a three-component polyurethane elastomer composition with high wear resistance, which comprises a prepolymer component, a polymer component and a chain extender component, wherein diisocyanate reacts with polyol to obtain a prepolymer of which the NCO content is 6%-10%, wherein the diisocyanate is preferably TDI-80, and the polyoxypropylene polyol of which the molecular weight is 400-3000 and the functionality is 2 is adopted; the polymer component is prepared from polyoxypropylene polyol of which the molecular weight is 1000-5000 and the functionality is 2 or 3, reinforcing agent, catalyst and anti-aging agent; and in the process of production, the temperature of the polymer component and the temperature of the chain extender component are controlled at 30+ / -5 DEG C, after the polymer component and the chain extender component are mixed and stirred uniformly according to a certain proportion, the mixture is mixed with the prepolymer component according to a certain proportion, the mixture is placed and solidified at 70-80 DEG C for 20 minutes, and the obtained product has excellent wear resistance and impact resilience. The invention is mainly used for manufacturing high-elastic skate wheels or skateboard wheels.

Owner:SHANDONG INOV POLYURETHANE

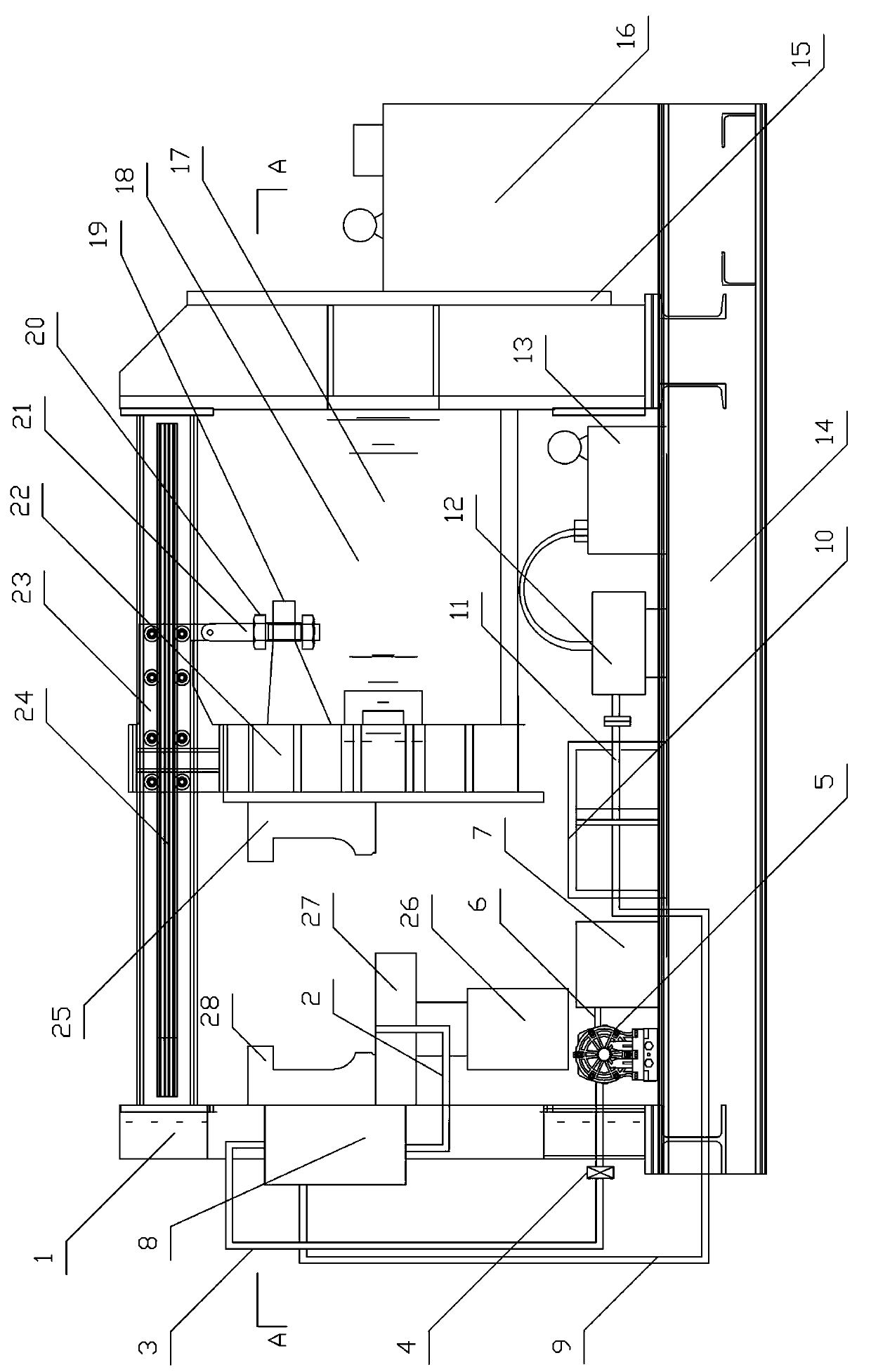

High-pressure slurry injector with quick ceramic forming and die releasing functions

ActiveCN103786249ASimple structureReduce manufacturing costFeeding arrangmentsDiaphragm pumpLeft half

The invention discloses a high-pressure slurry injector with quick ceramic forming and diereleasing functions. The high-pressure slurry injector comprises a frame-shaped framework. A slide rail is arranged on the top of the framework, the framework is provided with a slide seat, a pressing die head is hoisted on the slide seat, a right half ceramic forming die and a left half ceramic forming die are respectively mounted on the pressing die head and a left-side support of the framework, a bottom die and a lifting cylinder are arranged below the left half ceramic forming die, a slurry injection system is mounted on a base of the framework, and a hydraulic integrated pump station is mounted on the right side of the framework. The high-pressure slurry injector is characterized in that a master pressurization cylinder and two auxiliary cylinders for opening and closing the dies are arranged between a right-side support of the framework and the pressing die head in a connected manner; the slurry injection system comprises a mud blank forming die, a pneumatic diaphragm pump and a slurry injection pipe, the forming dies are connected with one end of the slurry injection pipe, a high-pressure slurry storage tank is communicated with the other end of the slurry injection pipe, and an outlet of the pneumatic diaphragm pump is communicated with the high-pressure slurry storage tank via a slurry supply pipe B; the high-pressure slurry injector is provided with a pressurization device. The high-pressure slurry injector has the advantages that the dies can be closed accurately, the pressure is stable, the die releasing time is short, products are good in quality and high in qualified rate, and the high-pressure slurry injector is mainly used for manufacturing ceramic blanks.

Owner:HUBEI XISHUI KEMEI MACHINERY

Powdery talcum foaming agent

InactiveCN103265318AShort demoulding timeImprove stabilityCeramicwarePolymer scienceSodium phosphates

The invention discloses a powdery talcum foaming agent. The foaming agent comprises acidified talcum, high-viscosity attapulgite clay powder, active attapulgite clay, sodium dodecyl sulfate, sodium percarbonate, sodium polyacrylate, sodium pyrophosphate and sodium poly[(naphthaleneformaldehyde)sulfonate]. The finished product of the powdery talcum foaming agent is produced by stirring ingredients of the powdery talcum foaming agent, milling the ingredients into powder and packaging the powder. The powdery talcum foaming agent has the advantages that the powdery talcum foaming agent has strong foaming capacity, high foam expansion and high foam yield in unit volume, has good foam outer membrane tenacity and is not easy to break, has good foam stability, can not be defoamed for a long time, is exquisite in foam, is uniform in sizes of holes generated in media and has low bleeding quantity and good compatibility of used media. The products produced by using the powdery talcum foaming agent not only can effectively control noise pollution but also have the functions of preserving heat and purifying air. The powdery talcum foaming agent is suitable for producing lightweight boards, lightweight walls and noise reducing products.

Owner:如皋市樊川贸易有限公司

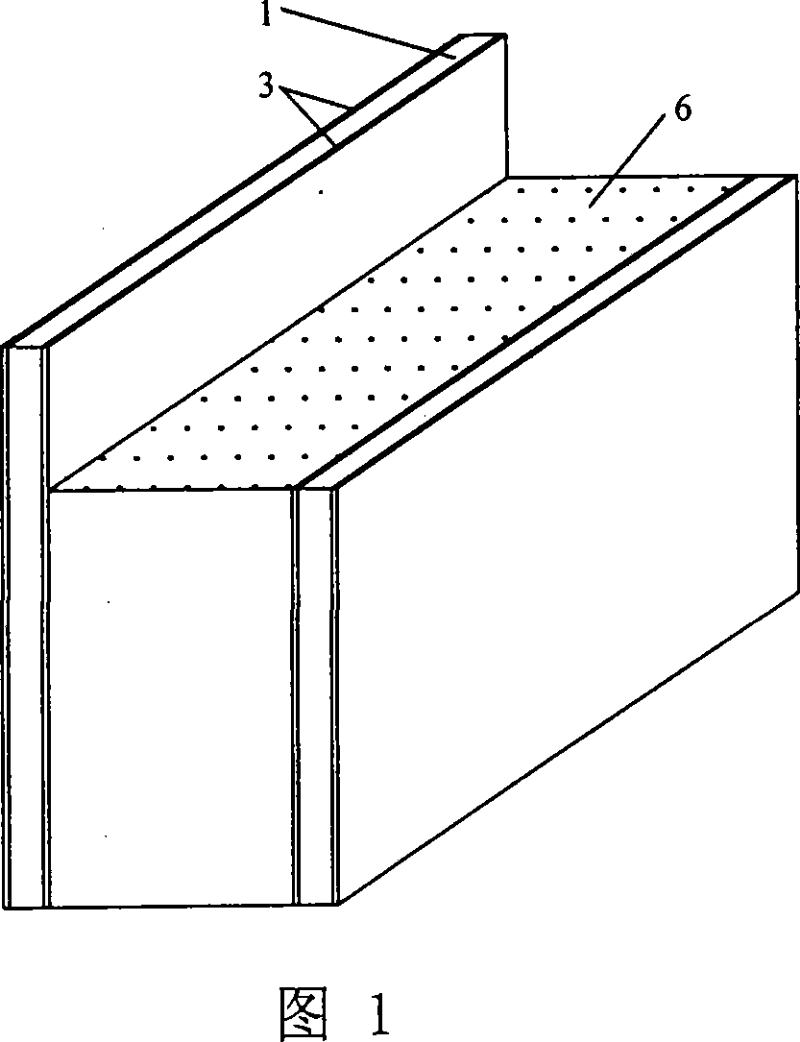

Composite material formwork

InactiveCN101042018AImprove mechanical performanceImprove bonding performanceConstruction materialForming/stuttering elementsFiberMaterials science

The composite material made mold plate comprises the core material, featuring in the slots on the surface of the core material, fiber cloth layer on the top and bottom surface of the core material, setting through holes that stuffed with resin pegs along the thickness direction of the core material at the crossing section of the slots based on requirement. It features in its lightness, high strength, obvious improvement of concrete building speed, not only being able to saving constructing expenses, but also applicable to construction under special conditions.

Owner:NANJING UNIV OF TECH

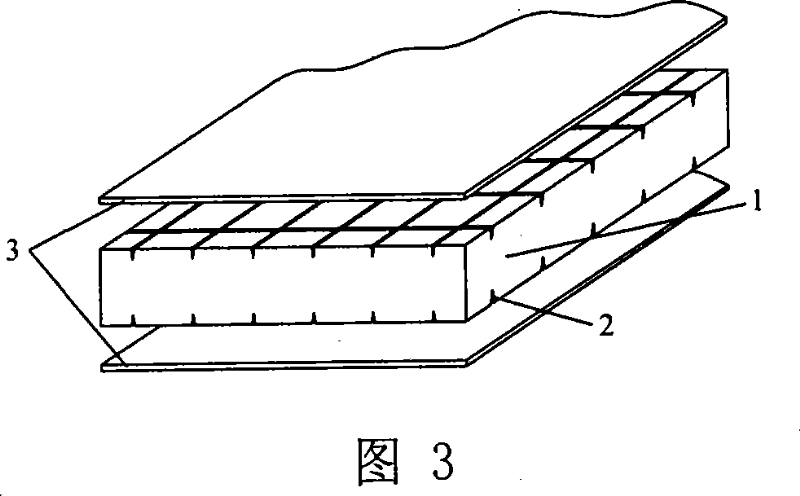

Plastic overlaid plywood building template with large turnover number and preparation method thereof

InactiveCN102425295AEasy to demouldReduce use costLaminationLamination apparatusTurnover timeAdhesive

The invention relates to a plastic overlaid plywood building template with a large turnover number and a preparation method thereof, in particular to a building template and a preparation method thereof. Due to the adoption of the plastic overlaid plywood building template with the large turnover number, the technical problems of the present wooden template or the overlaid plywood building template that a mould is difficult to remove and the turnover number is small during the application process can be solved. The plastic overlaid plywood building template with the large turnover number is characterized in that: a layer of polyolefine laminated surface is adhered on the upper surface and the lower surface of the wooden plywood template. The preparation method comprises the following steps that: after polyolefine material is extruded by a vertical-type three-roller plastic sheet machine set to obtain sheets, a layer of non-woven fabric covers the sheet to be extruded again to obtain the polyolefine laminated surface which is covered by the non-woven fabric; and adhesive is smeared onto the non-woven fabric, then the non-woven fabric which is smeared with the adhesive covers the upper surface and the lower surface of the polished wooden polywood to be pressed so as to obtain the plastic overlaid polywood building template with lage turnover number. The surface of the template is free from being adhered by the cement, the turnover times of the template are 25 to 30 times, and the template can be used for construction engineering.

Owner:卜凡华

Powdery kieselguhr foamer

InactiveCN103265307AReduce surface tensionShort demoulding timeCeramicwareSodium phosphatesPyrophosphate

The invention discloses a powdery kieselguhr foamer, wherein the essential of the technical scheme is as follows: the powdery kieselguhr foamer is composed of dried kieselguhr, high-viscosity attapulgite clay powder, sodium dodecyl sulphate, sodium percarbonate, sodium polyacrylate, sodium pyrophosphate and sodium naphthaldehyde sulfonate. The powdery kieselguhr foamer finished product is obtained by stirring, grinding and packaging the ingredients of the powdery kieselguhr foamer. The powdery kieselguhr foamer has the advantages of being strong in foaming capacity, high in foaming times, high in foam production amount per unit volume, good in the toughness of foam outer membranes with low possibility of breaking, good in foam stability, unable to defoam for a long time, fine in foam, uniform in the size of the holes generated in a medium, low in bleeding amount, good in the compatibility of the used medium, and the like. The products produced by virtue of the powdery kieselguhr foamer are capable of effectively controlling noise pollution, and have the functions of insulating heat and purifying air; and the powdery kieselguhr foamer is suitable for producing light-weight boards, light-weight wall bodies as well as silencing and noise-reducing products.

Owner:邹五华

Ultrasonic demoulding device and method for using ultrasonic demoulding device to make contact lens

The invention discloses an ultrasonic demoulding device and a method for using the ultrasonic demoulding device to make a contact lens; the ltrasonic demoulding device comprises an ultrasonic oscillator, a shock transmitting part and a mould, the shock transmitting part is arranged between the ultrasonic oscillator and the mould, the ultrasonic oscillator is used for generating an ultrasound, the ultrasound is transmitted to the mould by the shock transmitting part to make the mold produce a shock to enable the contact lens attached to the mould to remove from the mould; the method includes a mould pressing step, a curing step, a mould opening step and a demoulding step using the ultrasonic demoulding device for shock demoulding. Accordingly, the ultrasonic demoulding device and the method method for making the contact lens have the advantages that the demoulding time is very short, the production speed is improved, and after demoulding the contact lens is in a dry state, and the accuracy of a subsequent detection process can be improved.

Owner:视霸光学股份有限公司

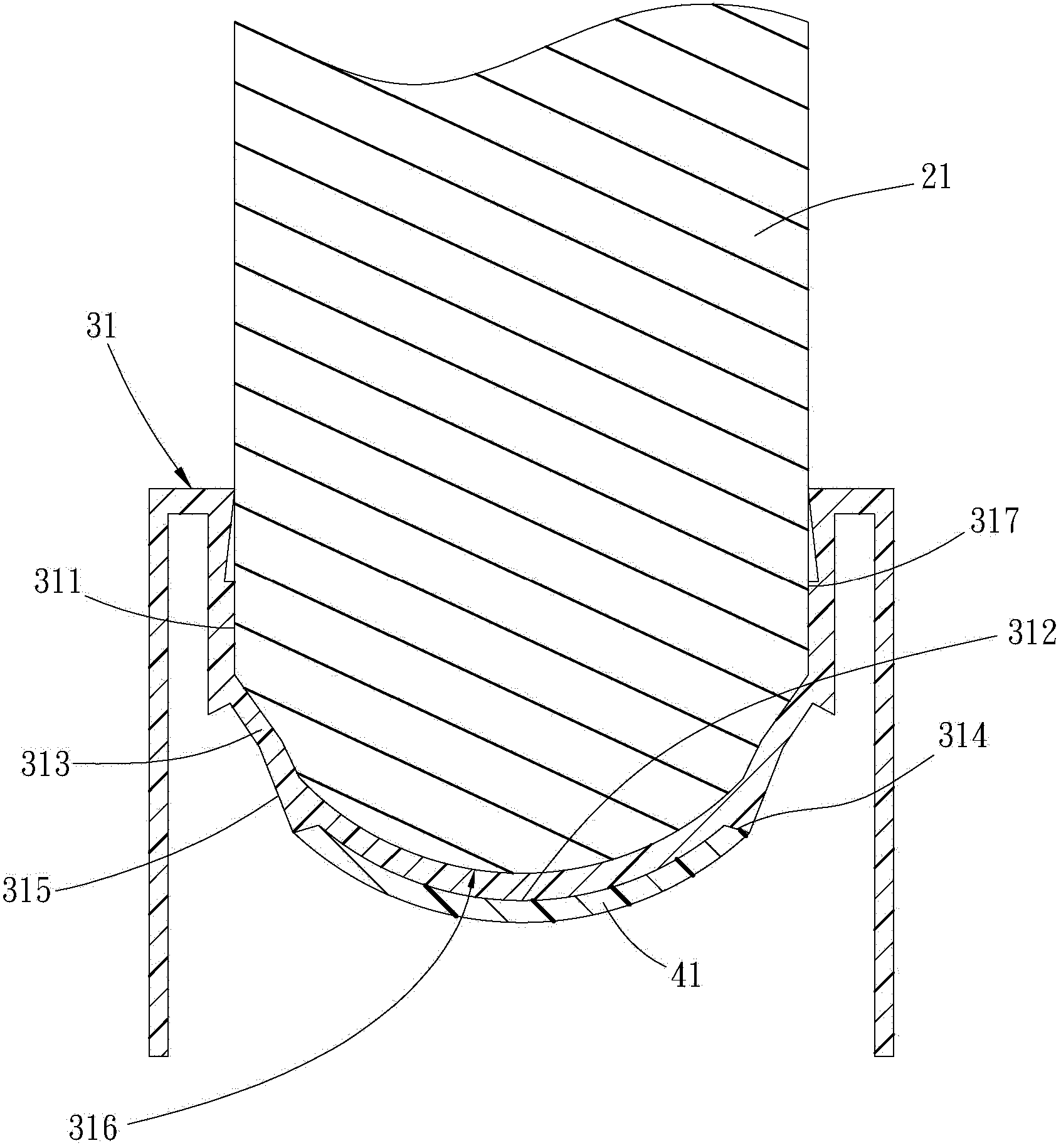

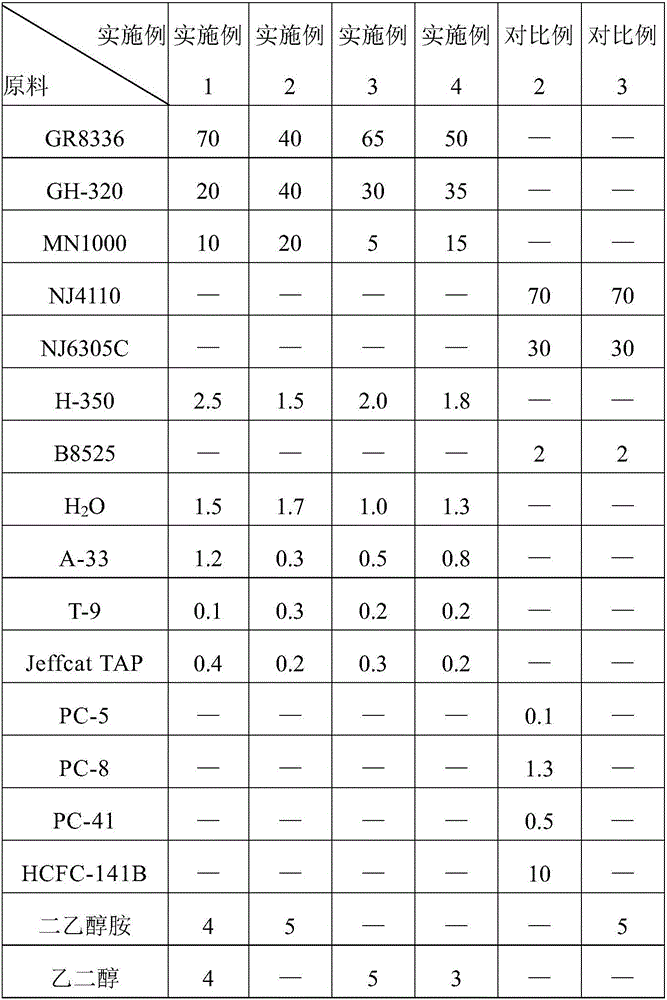

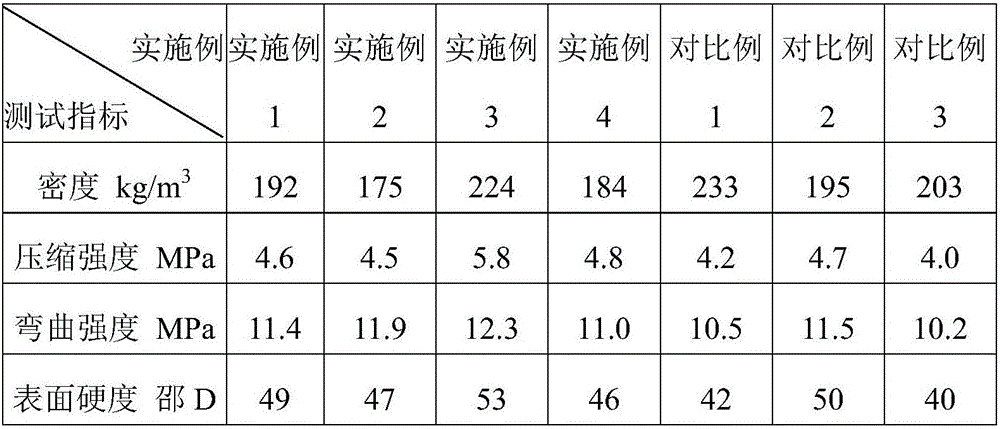

Combined polyether, polyurethane raw material composition, wood-like material and preparation methods thereof

The invention discloses a combined polyether, a polyurethane raw material composition, a wood-like material and preparation methods thereof. The combined polyether comprises the following components in parts by weight: 100 parts of polyether glycol, 1.5-2.5 parts of foam stabilizer, 0.8-1.7 parts of catalyst, 1.0-1.7 parts of water and 3-8 parts of crosslinking agent. The polyether glycol comprises polyether glycol A with the viscosity of 2500-4100 mPa.s, polyether glycol B with the viscosity of 2000-2800 mPa.s and polyether glycol C with the hydroxyl value of 163-173 mg KOH / g. When the density of the wood-like material is 175-224 kg / m<3>, the surface hardness reaches Shore D46-53, the compression strength is 4.5-5.8 MPa, and the bending strength is 11.0-12.3. The wood-like material has the advantages of high production efficiency and short stripping time, and can implement stripping for a common mold within 8-12 minutes. The wood-like material is foamed completely in water, and thus, is friendly to the environment and low in production cost.

Owner:SHANGHAI DONGDA POLYURETHANE

Building template with high cost performance and preparation method thereof

InactiveCN102936952AGood value for moneyCost-effectiveSynthetic resin layered productsLaminationTurnover timePolyolefin

The invention provides a building template with a high cost performance and a preparation method thereof, relates to the building template and the preparation method thereof and mainly solves the problems that the existing waste template cannot be regenerated and reused, a wood template is not easy to de-mould in a use process and the turnover time is low. The product is formed by respectively sticking one layer of a sticking layer on each one of upper and lower surfaces of a core plate. The method comprises the following steps of: taking nails and sorting the waste templates; vertically cutting; leveling; transversely combing, and vertically connecting and combing; transversely splicing; filling holes; drying; sanding double faces with a fixed thickness to prepare the core plate; preparing a non-woven fabric polyolefin sticking face; coating an adhesive on a non-woven fabric of the non-woven fabric polyolefin sticking face; and coating on the upper and lower surfaces of the core plate, and pressing to finish. The building template with the high cost performance disclosed by the invention adopts the core plate made of the waste template, solves the regeneration and reutilization problems of the waste templates, and greatly improves the cost performance of the building template; and the property that the surface activity of the polyolefin sticking face is low is utilized, the template is easy to de-mould, and the turnover time is high.

Owner:安徽省崃山建材有限公司

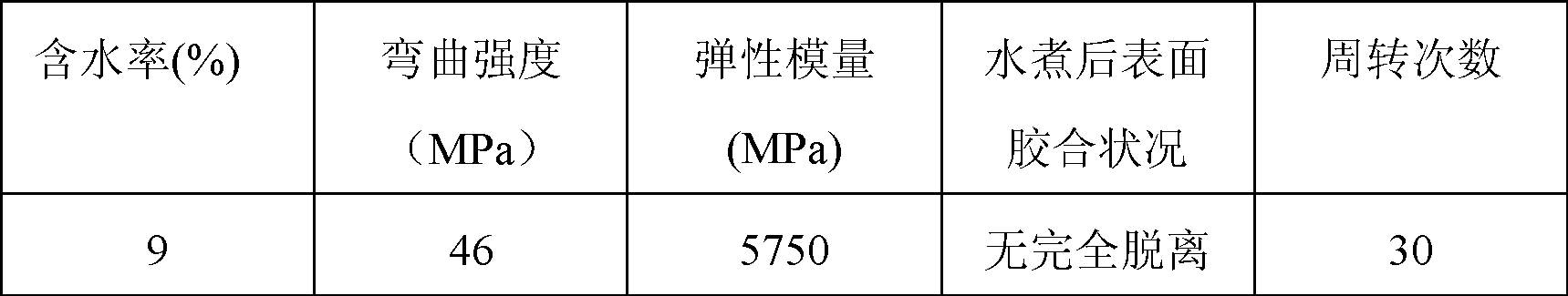

Environmentally-friendly storage-stable polyurethane composition for reaction injection molding and preparation method thereof

ActiveCN102336882AImprove hydrolysis resistanceMeet stability requirementsSalicylic acidPolypropylene

The invention discloses an environmentally-friendly storage-stable polyurethane composition for reaction injection molding and a preparation method thereof. The polyurethane composition is composed of a component A and a component B, wherein the component A comprises 50-90% of polyether polyol, 1-40% of chain extender, 0-10% of pigment, 0-5% of anti-aging agent and 0.01-3% of composite catalyst; the component B comprises 60-95% of diisocyanate and 5-40% of polypropylene oxide glycol; the composite catalyst is composed of an organic bismuth or organic zirconium catalyst and a hindered amine catalyst; and the hindered amine catalyst is prepared by the following steps: mixing 1 part of triethylene diamine with 2 parts of ethylene glycol or diethylene glycol, heating to 70-80 DEG C, stirring and dissolving, adding 15-30wt% of salicylic acid, and stirring and reacting for 1 hour at the temperature of 80 DEG C. The composition is stable in storage and environmentally friendly.

Owner:LIMING RES INST OF CHEM IND

Powdery basalt foaming agent

The invention discloses a powdery basalt foaming agent. The foaming agent comprises porous basalt, high-viscosity attapulgite clay powder, active attapulgite clay, sodium dodecyl sulfate, sodium percarbonate, sodium polyacrylate, sodium pyrophosphate and sodium poly[(naphthaleneformaldehyde)sulfonate]. The finished product of the powdery basalt foaming agent is produced by stirring ingredients of the powdery basalt foaming agent, milling the ingredients into powder and packaging the powder. The powdery basalt foaming agent has the advantages that the powdery basalt foaming agent has strong foaming capacity, high foam expansion and high foam yield in unit volume, has good foam outer membrane tenacity and is not easy to break, has good foam stability, can not be defoamed for a long time, is exquisite in foam, is uniform in sizes of holes generated in media and has low bleeding quantity and good compatibility of used media. The products produced by using the powdery basalt foaming agent not only can effectively control noise pollution but also have the functions of preserving heat and purifying air. The powdery basalt foaming agent is suitable for producing lightweight boards, lightweight walls and noise reducing products.

Owner:李兴乐

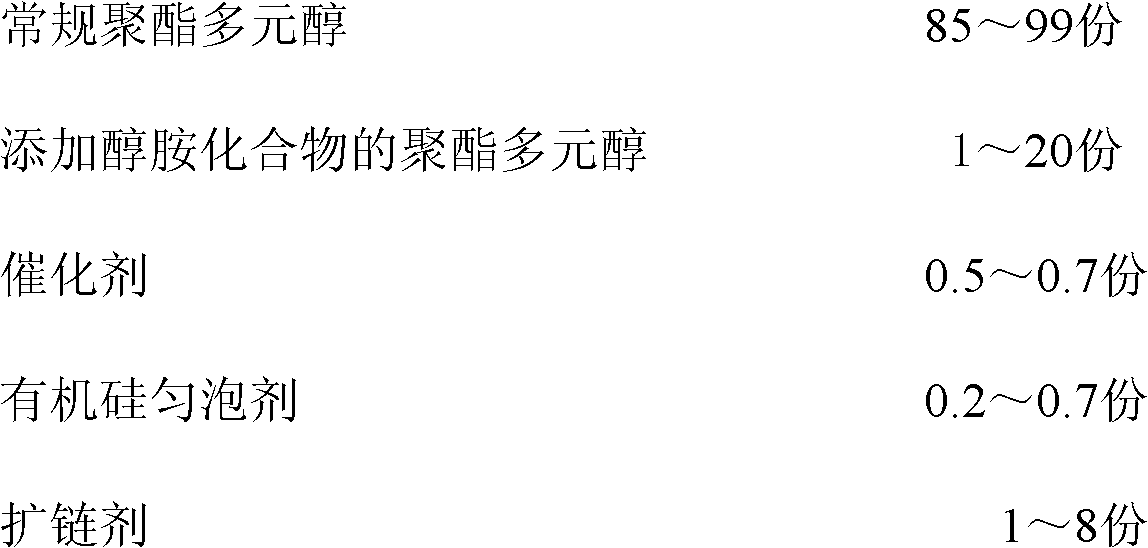

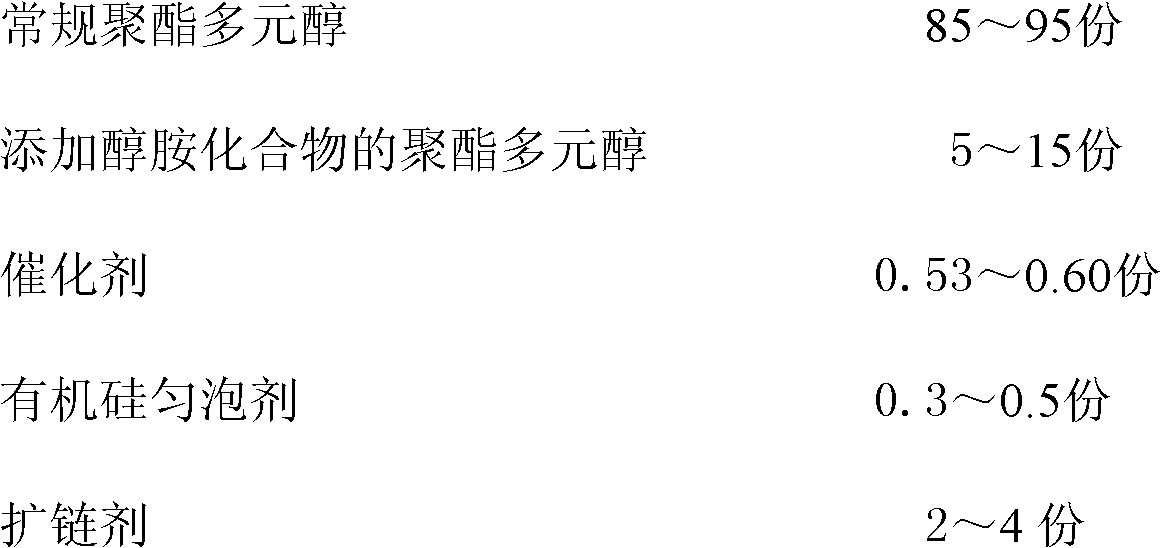

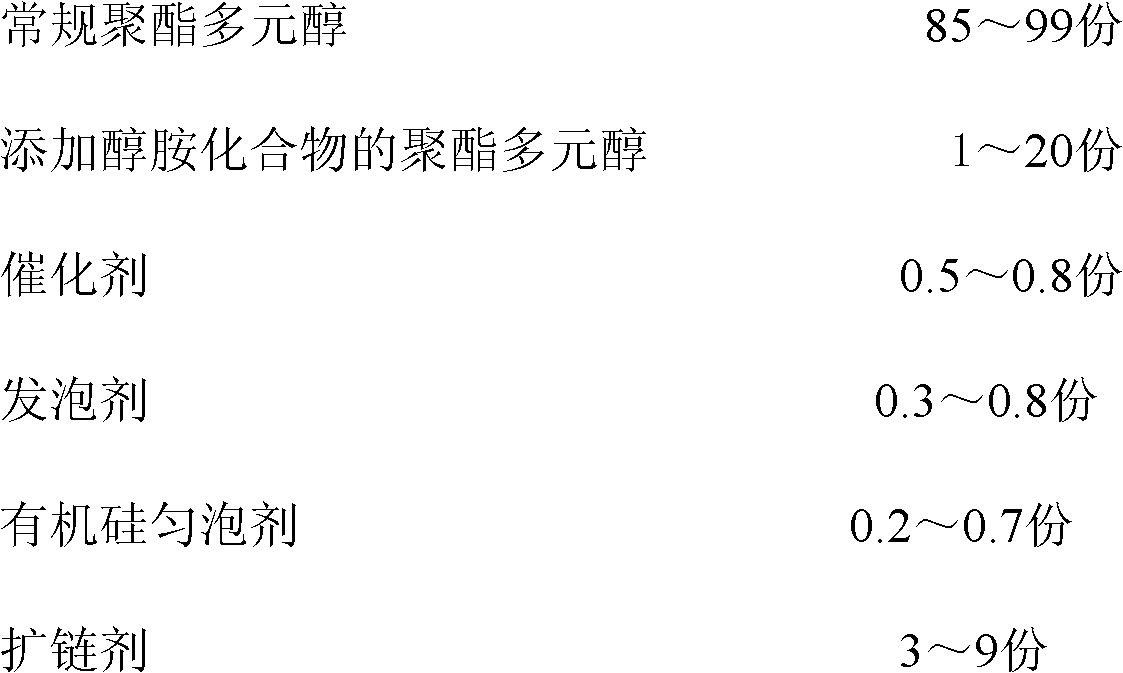

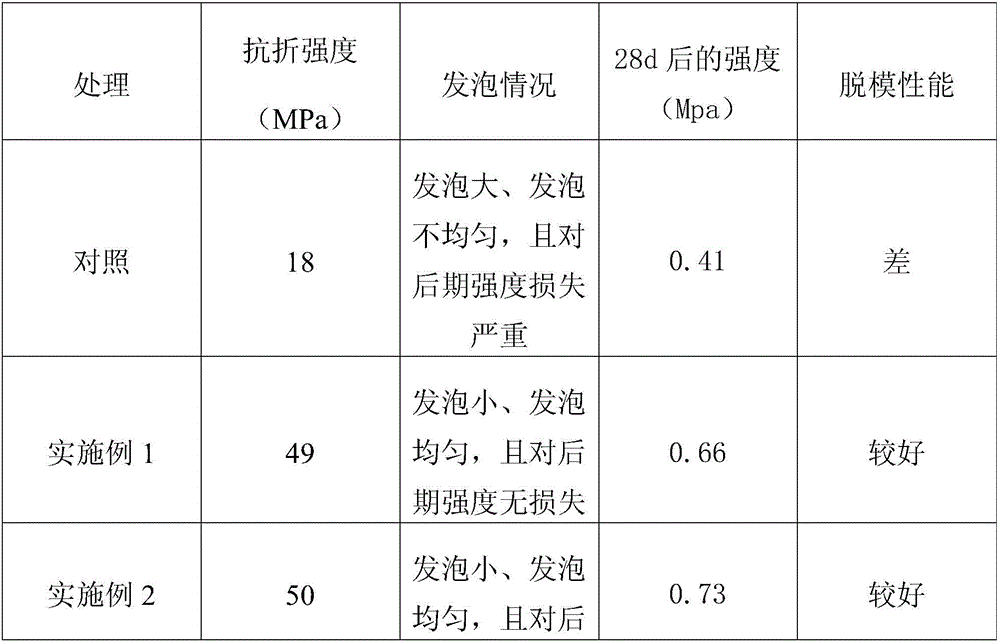

Polyurethane microporous elastomer added with alcohol and amine compound, and preparation method and application of polyurethane microporous elastomer added with alcohol and amine compound

The invention discloses a polyurethane microporous elastomer added with an alcohol and amine compound, and a preparation method and application of the polyurethane microporous elastomer added with the alcohol and amine compound. The polyurethane microporous elastomer is a reaction product of a polyurethane resin component A, and a polyurethane resin component B; the polyurethane resin component A is polyester polyol mixture added with the alcohol and amine compound; the polyurethane resin component B is a reaction product of polyester polyol, diisocyanate and liquefied diisocyanate; the polyurethane microporous elastomer added with the alcohol and amine compound is used for manufacturing a protective sole, and the basic requirement of physical properties and the production operation requirement of the protective shoe sole can be met; and specifically, the peel strength of a midsole and an outer sole which are manufactured by using the polyurethane microporous elastomer is improved by 19 to 28 percent compared with that of a common polyurethane sole, a small amount of catalyst is used, and the production of a polyurethane protective sole is reduced.

Owner:ZHEJIANG HUAFON NEW MATERIALS CO LTD

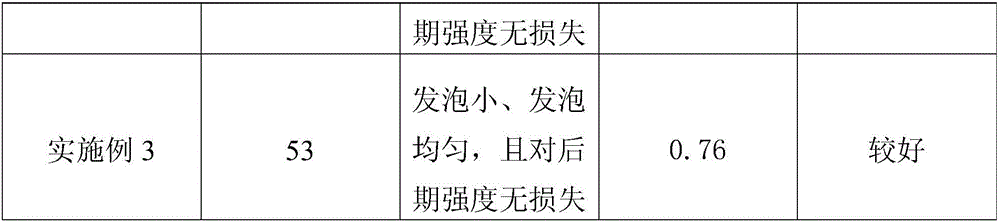

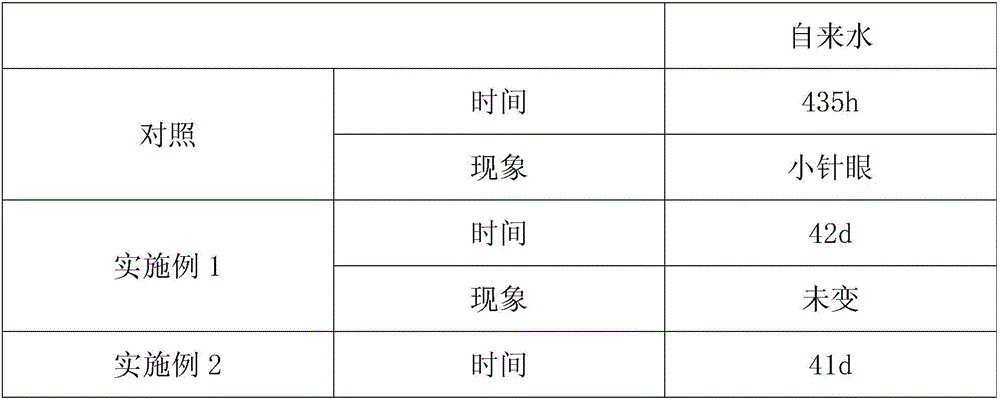

Novel silicate cement waterproof agent

The invention belongs to the technical field of building materials, and particularly relates to a novel silicate cement waterproof agent which is composed of, by weight, 1-3 parts of calcium chloride, 0.05-0.1 part of triethanolamine, 1-3 parts of sodium hydroxide, 0.05-0.1 part of sodium stearate, 1-5 parts of cellulose ether and 1-10 parts of plant cellulose membrane. The novel silicate cement waterproof agent enables silicate cement to set quickly and to foam uniformly, can lower water absorption rate and cause little later strength loss. The silicate cement waterproof agent enables the silicate cement to be short in demolding time and less prone to causing mold collapse. The silicate cement waterproof agent can lower water absorption rate of the silicate cement and causes little later strength loss to the silicate cement.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

Production technology of waterproof and heat-insulated integrated board

ActiveCN102806745AHigh bonding strengthAvoid chemical reactionsLaminationLamination apparatusChemical reactionPlasticizer

The invention discloses a production technology of a waterproof and heat-insulated integrated board. The production technology comprises the following steps of: firstly, compositing an enhanced isolating material at one side of a waterproof roll; pre-heating the waterproof roll composited with the enhanced isolating material by a pre-heating device; compositing an heat-insulated material at one side of the waterproof roll composited with the enhanced isolating material after pre-heating; and finally, covering another pre-heated waterproof roll on the surface of the heat-insulated material. By providing the enhanced isolating material at one side of the waterproof roll, not only can the bonding strength between the enhanced isolating material and the waterproof roll be enhanced, but also the waterproof roll and the heat-insulated material can be effectively isolated; the condition that the waterproof roll is contacted with the heat-insulated material for a long time to cause chemical reaction can be avoided; a plasticizer inside the roll is prevented from migrating; the quality of the product is ensured; a procedure of pre-heating the waterproof roll is added before the waterproof roll and the heat-insulated material are composited; and the phenomenon that a waterproof layer and an insulating layer are stripped after the board is molded can be avoided, and the performance and quality of the board are further improved.

Owner:SHENZHEN ZHUOBAO TECH

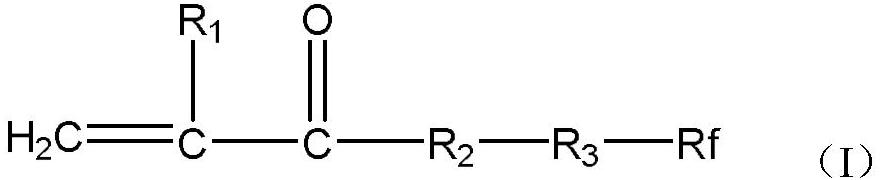

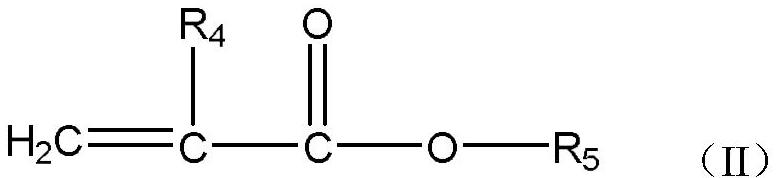

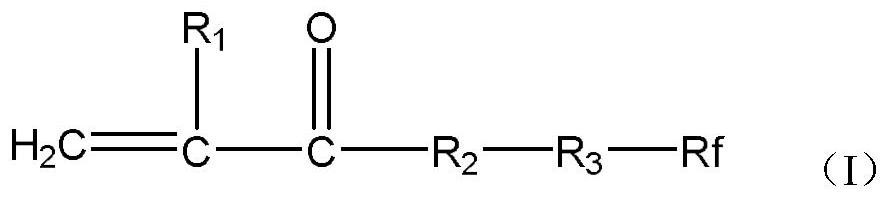

Short-fluorocarbon-chain acrylate polymer, preparation method thereof and application of short-fluorocarbon-chain acrylate polymer in release agent

The invention provides a short-fluorocarbon-chain acrylate polymer. The short-fluorocarbon-chain acrylate polymer is prepared from a short-fluorocarbon-chain acrylate monomer, an acrylate monomer, a vinyl-containing organosilicon monomer and an acrylic monomer through solution polymerization. The invention also provides a fluorine-containing resin release agent composition taking the short fluorocarbon chain acrylate polymer as a main body, the fluorine-containing resin release agent composition has good degradability, and the use of PFOA / PFOS substances is avoided. The release agent composition is uniform in film forming on the surface of a mold, short in demolding time, long in demolding life, not prone to high-temperature glue flowing, easy to remove from the surface of a finished product to be demolded, excellent in demolding performance and capable of being applied to the technical field of demolding of thermosetting resin, thermoplastic resin, various rubber workpieces and the like.

Owner:ZHEJIANG UNIV OF TECH

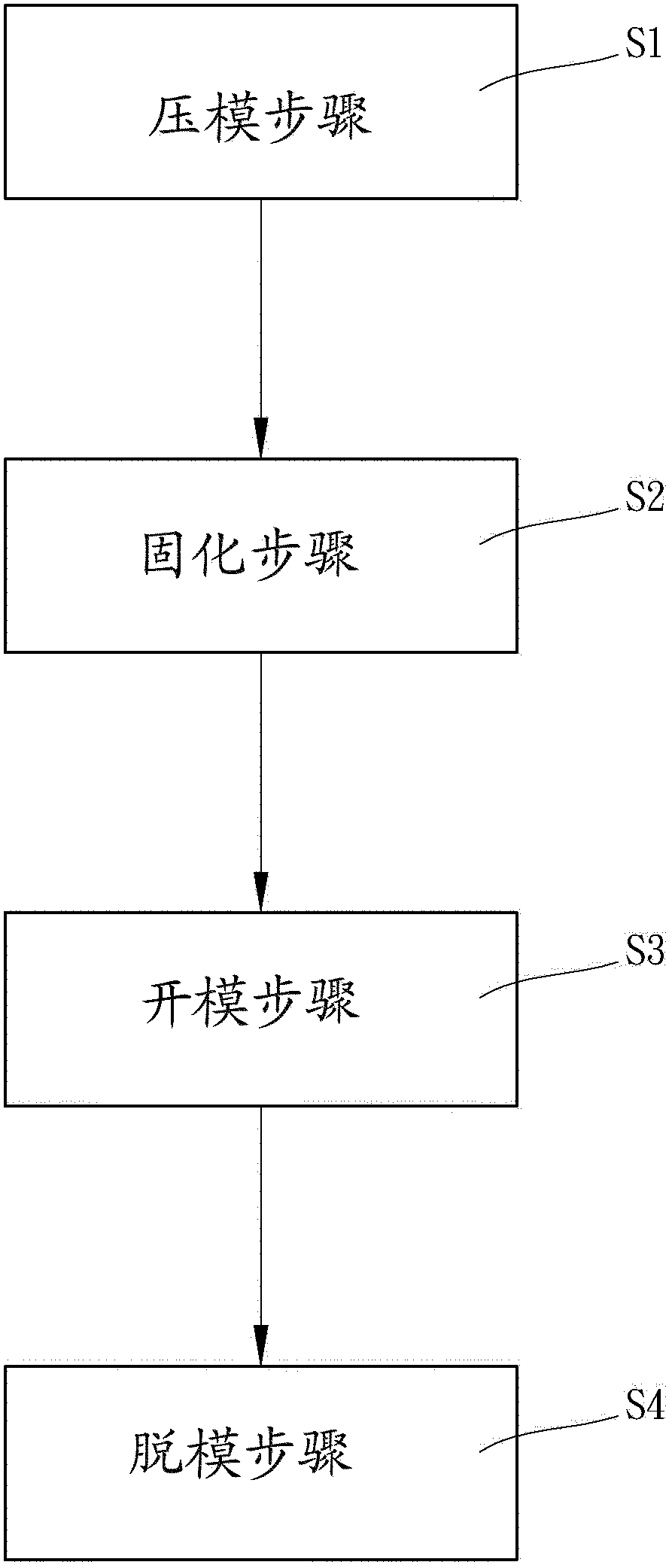

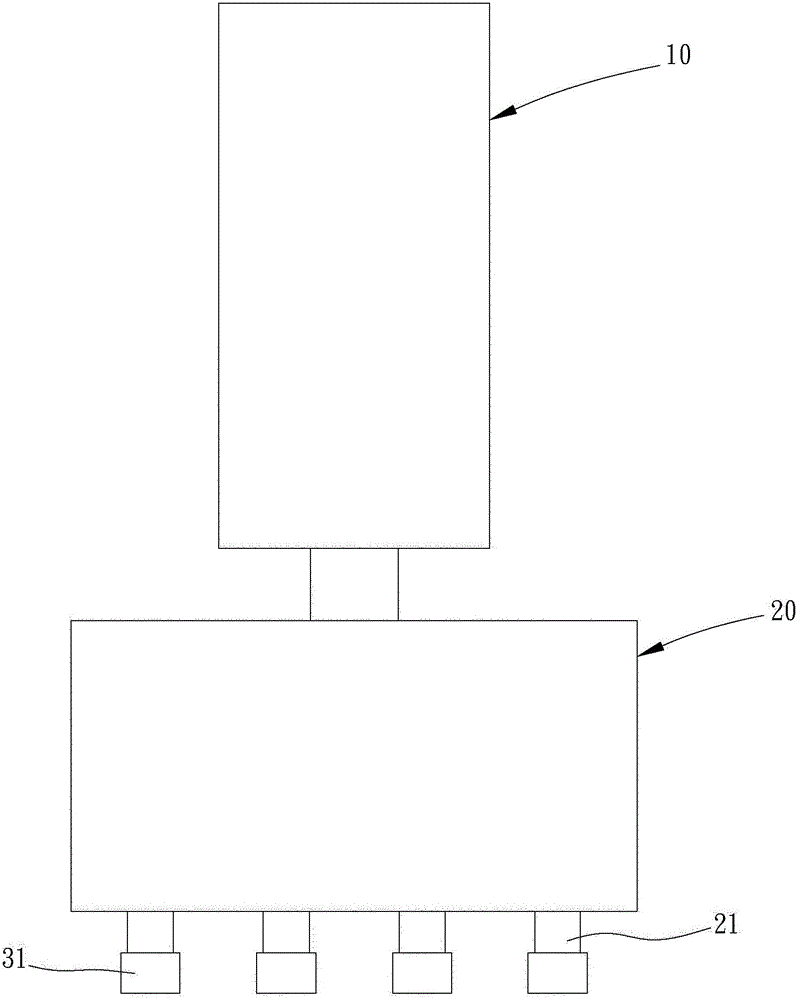

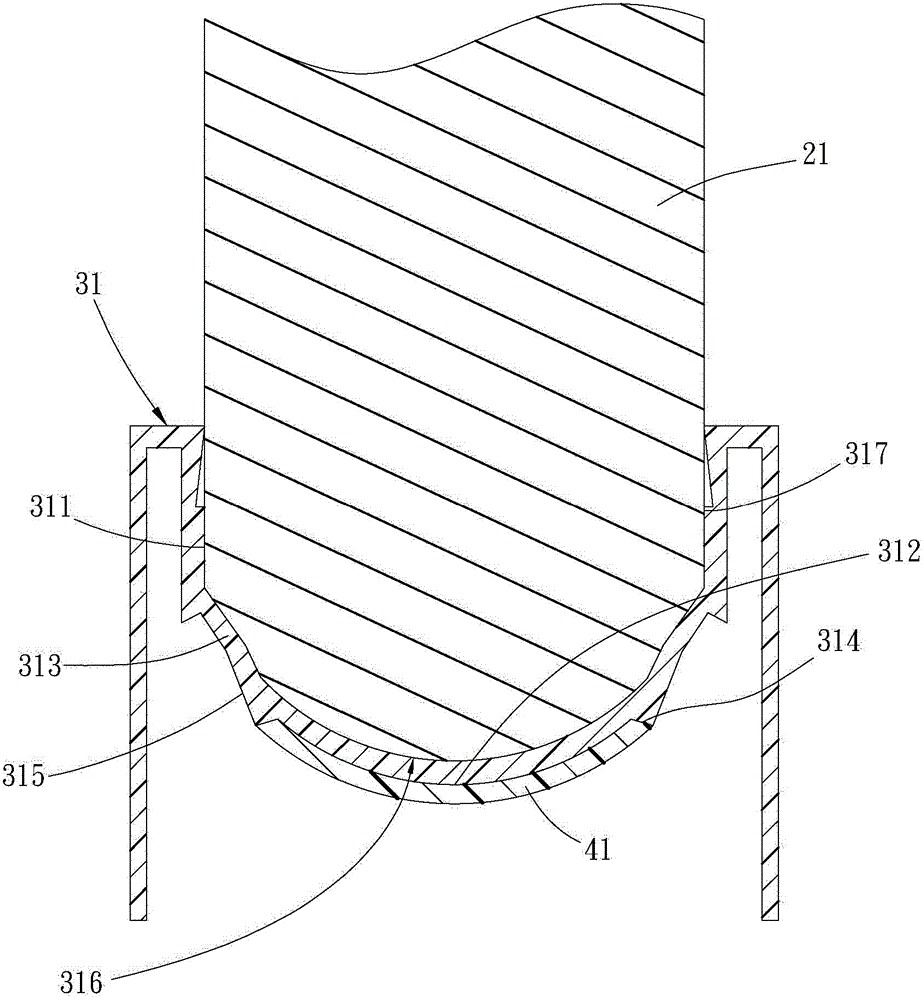

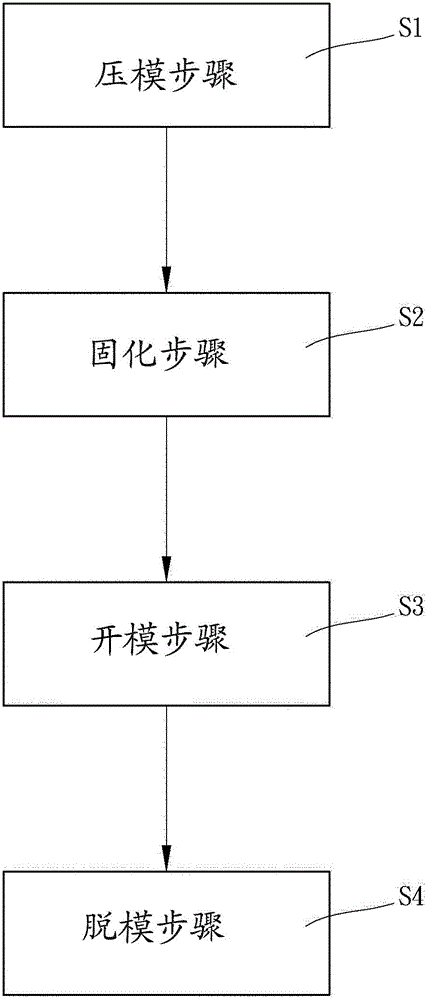

Ultrasonic demoulding device and its application to the method for manufacturing contact lenses

ActiveCN103465410BShort demoulding timeIncrease production speedOptical articlesUltrasoundContact lens

The invention discloses an ultrasonic demoulding device and a method for using the ultrasonic demoulding device to make a contact lens; the ltrasonic demoulding device comprises an ultrasonic oscillator, a shock transmitting part and a mould, the shock transmitting part is arranged between the ultrasonic oscillator and the mould, the ultrasonic oscillator is used for generating an ultrasound, the ultrasound is transmitted to the mould by the shock transmitting part to make the mold produce a shock to enable the contact lens attached to the mould to remove from the mould; the method includes a mould pressing step, a curing step, a mould opening step and a demoulding step using the ultrasonic demoulding device for shock demoulding. Accordingly, the ultrasonic demoulding device and the method method for making the contact lens have the advantages that the demoulding time is very short, the production speed is improved, and after demoulding the contact lens is in a dry state, and the accuracy of a subsequent detection process can be improved.

Owner:视霸光学股份有限公司

A production process of waterproof and thermal insulation integrated board

ActiveCN102806745BHigh bonding strengthAvoid chemical reactionsLaminationLamination apparatusChemical reactionPlasticizer

Owner:SHENZHEN ZHUOBAO TECH

Preparation method of sucrose polyether with high degree of functionality

The invention relates to a preparation method of sucrose polyether with high degree of functionality, and belongs to the technical field of preparation of polyether polyol. The preparation method of the sucrose polyether with high degree of functionality comprises the following steps of using a mixture of sucrose and polyol as an initiating agent, and performing loop-opening reaction with propylene epoxide under the condition of an alkaline catalyst, so as to obtain the sucrose polyether with high degree of functionality. The preparation method has the advantages that the preparation method isscientific and reasonable, the operation is simple, the implementing is easy, the degree of functionality of the polyether is effectively increased, the cost of the raw material is reduced at the same time, and the sucrose polyether can be widely applied to hard foam combining materials; the sucrose polyether can be continuously produced, the demolding time is short, the strength is high, and thesize stability is good.

Owner:耿佃勇

Manufacturing method of ceramic tube

A manufacturing method of a ceramic tube comprises the following steps: a, an external mold and a wax-based internal mold are manufactured; b, the wax-based internal mold is positioned inside a holding cavity, and a gap between the wax-based internal mold and the holding cavity is left to form a cavity; c, a powder is poured into the cavity, and the powder is hardened to form a tube blank; d, the external mold is removed from the tube blank; e, the wax-based internal mold is removed from the inside of the tube blank; and f, the tube blank is sintered to form a ceramic tube. During the Step c, the powder is hardened by a static pressure method, and static pressure is set as 100kPa-200kPa / cm<2>. The Step e contains the following steps: e1, high temperature radiation is applied on the position where the wax-based internal mold and the tube blank are contacted by the use of external equipment, the temperature of the position where the wax-based internal mold and the tube blank are contacted is raised to more than 500 DEG C within 3-5 s, and the state lasts for 2-6 s; and e2, double heating is carried out on the wax-based internal mold so as to make the wax-based internal mold flow out. According to the manufacturing method, the internal mold and the powder have a single material component; no chemical reaction happens during the manufacturing process; and demoulding time is fast and the tube will not be cracked.

Owner:王伟军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com