Novel silicate cement waterproof agent

A technology of portland cement and waterproofing agent, which is applied in the field of building materials, can solve the problems of reducing water absorption, and achieve the effects of reducing water absorption, short demoulding time, and less strength loss in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

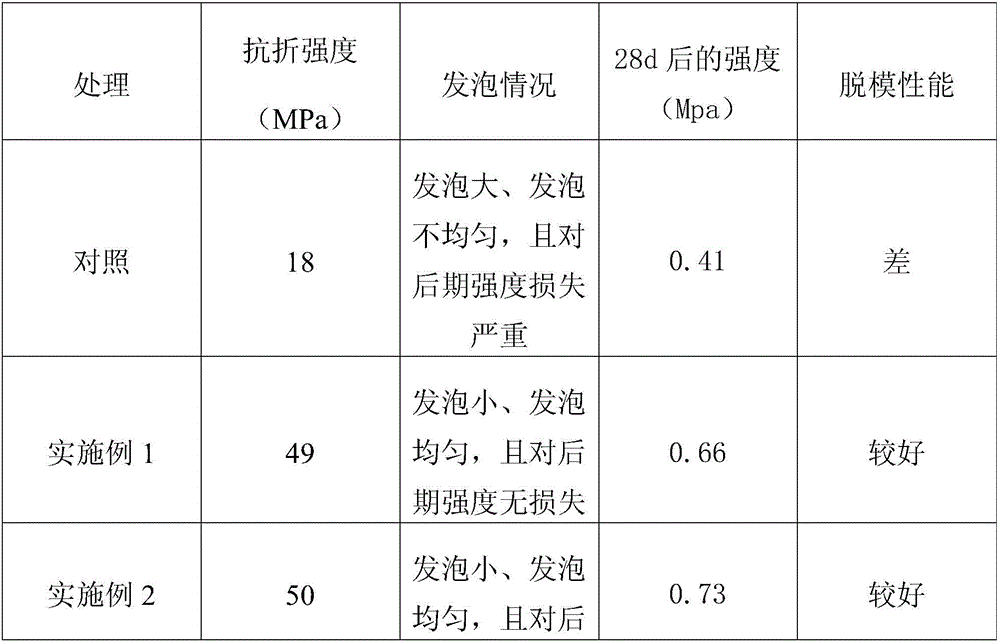

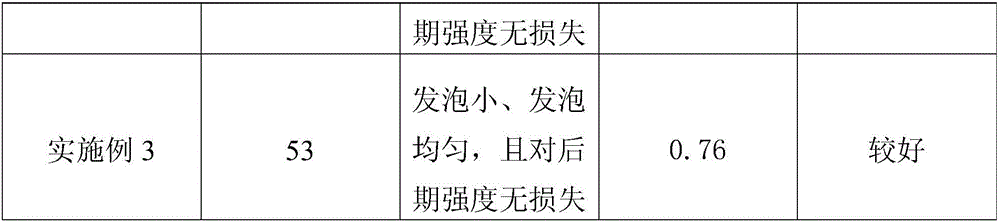

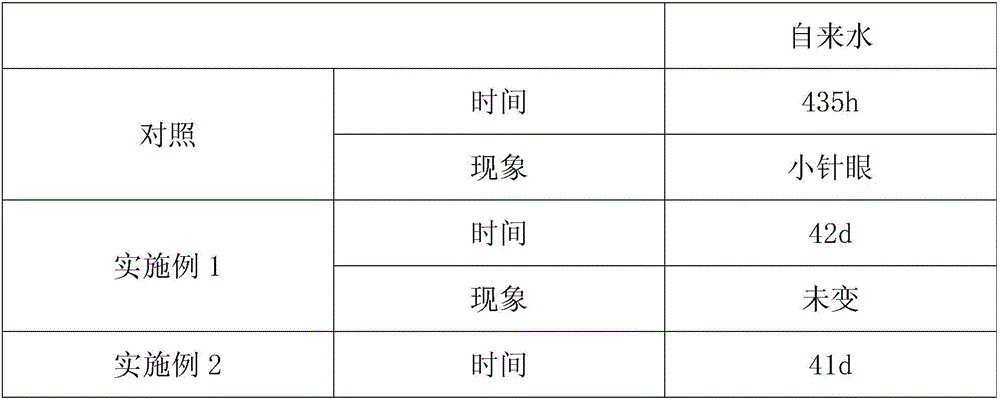

Examples

Embodiment 1

[0022] A novel portland cement waterproofing agent, which is composed of calcium chloride, triethanolamine, sodium hydroxide, sodium stearate, cellulose ether and plant cellulose film; said calcium chloride, triethanolamine, hydrogen The parts by weight of sodium oxide, sodium stearate, cellulose ether and plant cellulose film are respectively 1 part, 0.05 part, 1 part, 0.05 part, 1 part and 1 part; Methyl cellulose; the preparation method of described plant cellulose film, comprises the following steps:

[0023] (1) Using cassava distiller's grains as raw material, the plant cellulose is obtained through extraction;

[0024] The extraction is alkaline extraction, including: drying cassava distiller's grains → rolling → scouring with lye → dehydration → immersion in sodium carbonate solution → dehydration → dilute acid treatment and washing → dehydration → immersion in sodium carbonate solution → dehydration → dilute acid Process washing→water washing→dehydration→drying to ob...

Embodiment 2

[0029] A novel portland cement waterproofing agent, which is composed of calcium chloride, triethanolamine, sodium hydroxide, sodium stearate, cellulose ether and plant cellulose film; said calcium chloride, triethanolamine, hydrogen The parts by weight of sodium oxide, sodium stearate, cellulose ether and plant cellulose film are respectively 3 parts, 0.1 part, 3 parts, 0.1 part, 5 parts and 10 parts; Described cellulose ether is hydroxypropyl Methyl cellulose; the preparation method of described plant cellulose film, comprises the following steps:

[0030] (1) Using cassava distiller's grains as raw material, the plant cellulose is obtained through extraction;

[0031] The extraction is alkaline extraction, including: drying cassava distiller's grains → rolling → scouring with lye → dehydration → immersion in sodium carbonate solution → dehydration → dilute acid treatment and washing → dehydration → immersion in sodium carbonate solution → dehydration → dilute acid Process ...

Embodiment 3

[0036] A novel portland cement waterproofing agent, which is composed of calcium chloride, triethanolamine, sodium hydroxide, sodium stearate, cellulose ether and plant cellulose film; said calcium chloride, triethanolamine, hydrogen The parts by weight of sodium oxide, sodium stearate, cellulose ether and plant cellulose film are respectively 2 parts, 0.08 part, 2 parts, 0.07 part, 2 parts and 5 parts; Described cellulose ether is hydroxypropyl Methyl cellulose; the preparation method of described plant cellulose film, comprises the following steps:

[0037] (1) Using cassava distiller's grains as raw material, the plant cellulose is obtained through extraction;

[0038] The extraction is alkaline extraction, including: drying cassava distiller's grains → rolling → scouring with lye → dehydration → immersion in sodium carbonate solution → dehydration → dilute acid treatment and washing → dehydration → immersion in sodium carbonate solution → dehydration → dilute acid Process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com