Method for preparing nickel-based superalloy Rene80 directionally-grown column crystal/single crystal alloy and manufacturing parts

A nickel-based superalloy, directional growth technology, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of long manufacturing time and low yield, reduce manufacturing costs, improve utilization, shorten the The effect of the manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

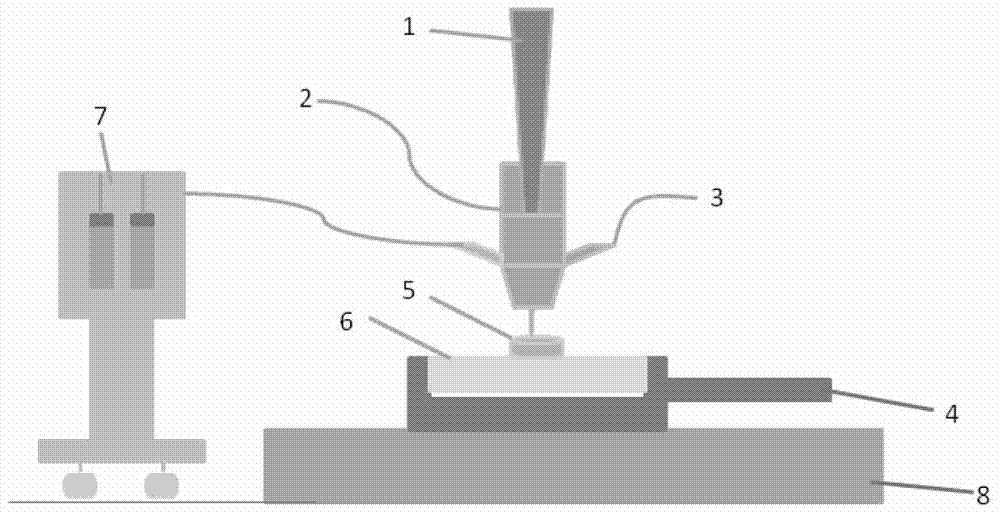

[0048] (1) Preparation of directional growth columnar crystals and single crystal alloys by laser beam continuous melting deposition

[0049] The bottom plate used in the experiment is Rene142 directionally solidified nickel-based alloy, and the thickness of the bottom plate is 2mm. The selected laser processing equipment is CO 2 The laser (maximum output power is 6KW), the laser wavelength is 1064nm, the focal length of the selected focusing lens is 270mm, the radius of the focal spot is 0.69mm, and the surface of the base plate is located at the focal plane of the laser.

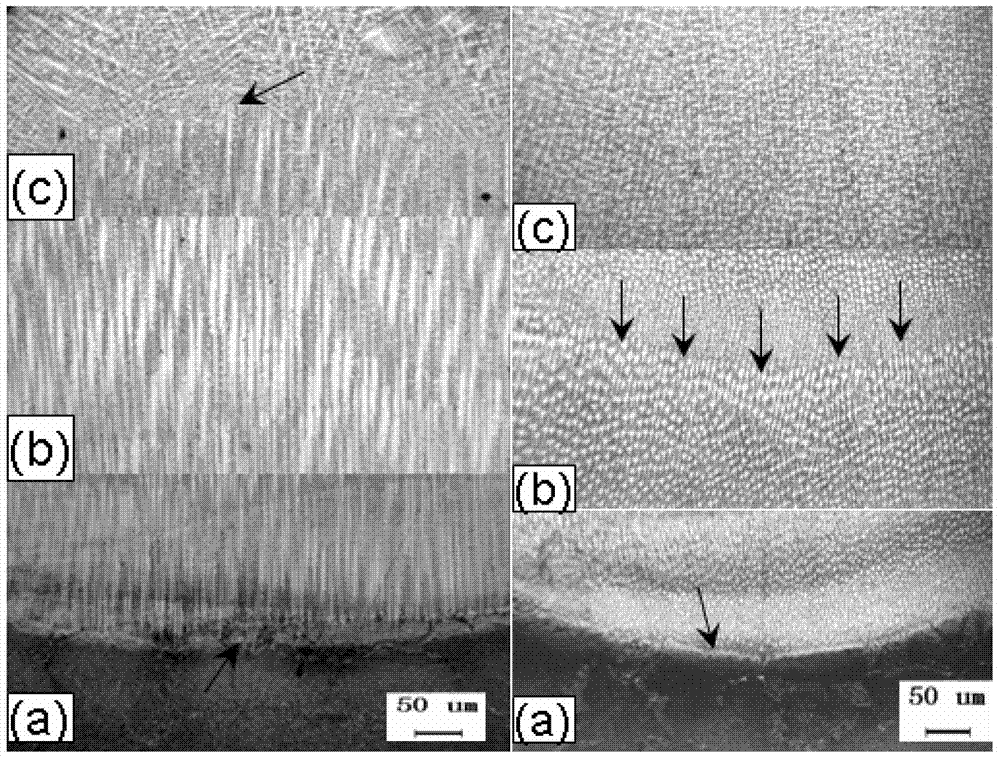

[0050] The crystal orientation of the base plate is parallel to the forming direction of the part in the part manufacturing process. First set important parameters: laser power 600W, laser movement speed 200mm / min, powder feeding speed 10g / m, protective gas flow 25L / min, carrier gas flow 15L / min, z-axis displacement 350um. Then turn on the gas feeding and powder feeding devices, and start the high-energy...

Embodiment 2

[0053] (2) Preparation of directional growth columnar crystals and single crystal alloys by laser beam continuous melting deposition

[0054] The bottom plate used in the experiment is Rene142 directionally solidified nickel-based alloy, and the thickness of the weldment is 2mm. The selected laser processing equipment is CO 2 The laser (maximum output power is 6KW), the laser wavelength is 1064nm, the focal length of the selected focusing lens is 270mm, the radius of the focal spot is 0.69mm, and the surface of the base plate is located at the focal plane of the laser.

[0055] The substrate crystal orientation is perpendicular to the forming direction of the part during part fabrication. First set important parameters: laser power 600W, laser movement speed 200mm / min, powder feeding speed 10g / m, protective gas flow 25L / min, carrier gas flow 15L / min, z-axis displacement 350um. Then turn on the gas feeding and powder feeding devices, and start the high-energy beam. At this t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com