Patents

Literature

44results about How to "Size qualified" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing end socket of voltage stabilizer for nuclear power

ActiveCN102248362ASize qualifiedQualified shapeFurnace typesHeat treatment furnacesHot stampingNuclear power

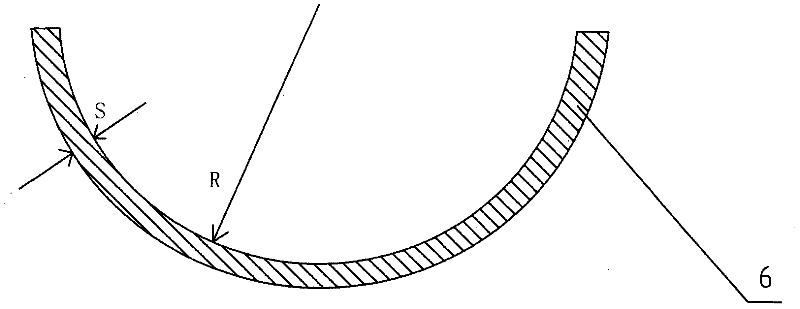

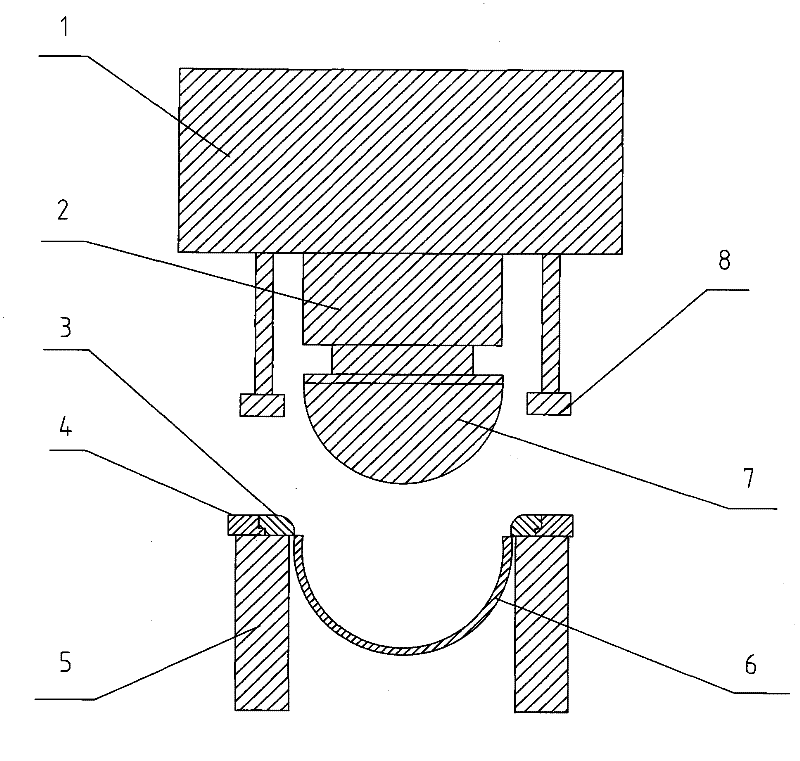

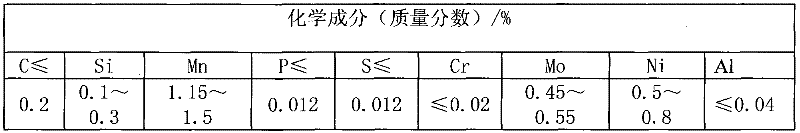

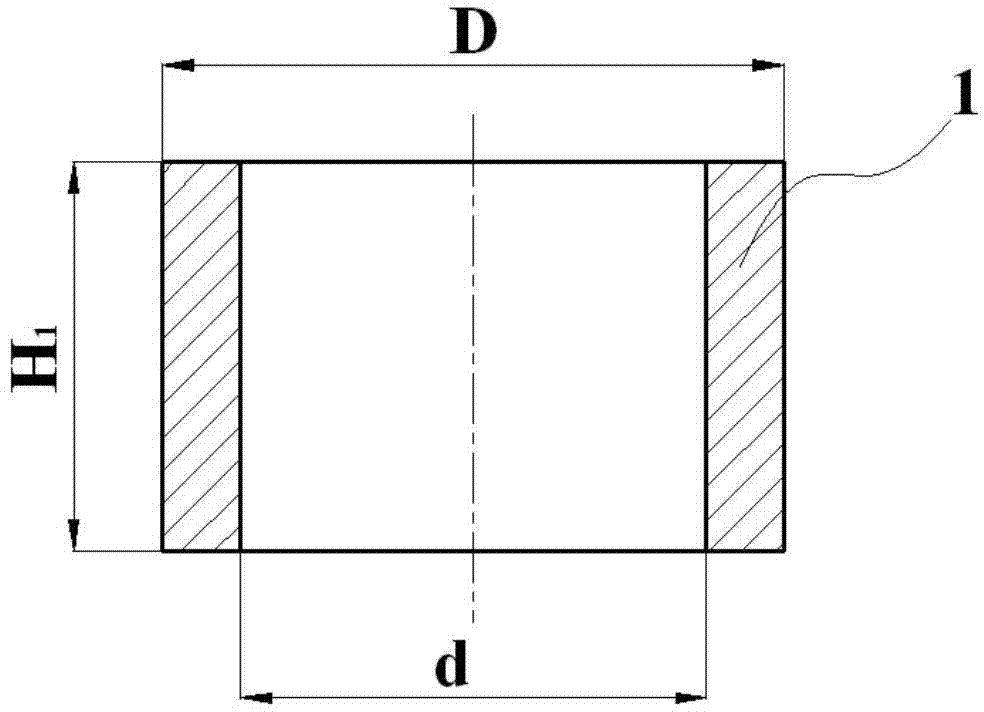

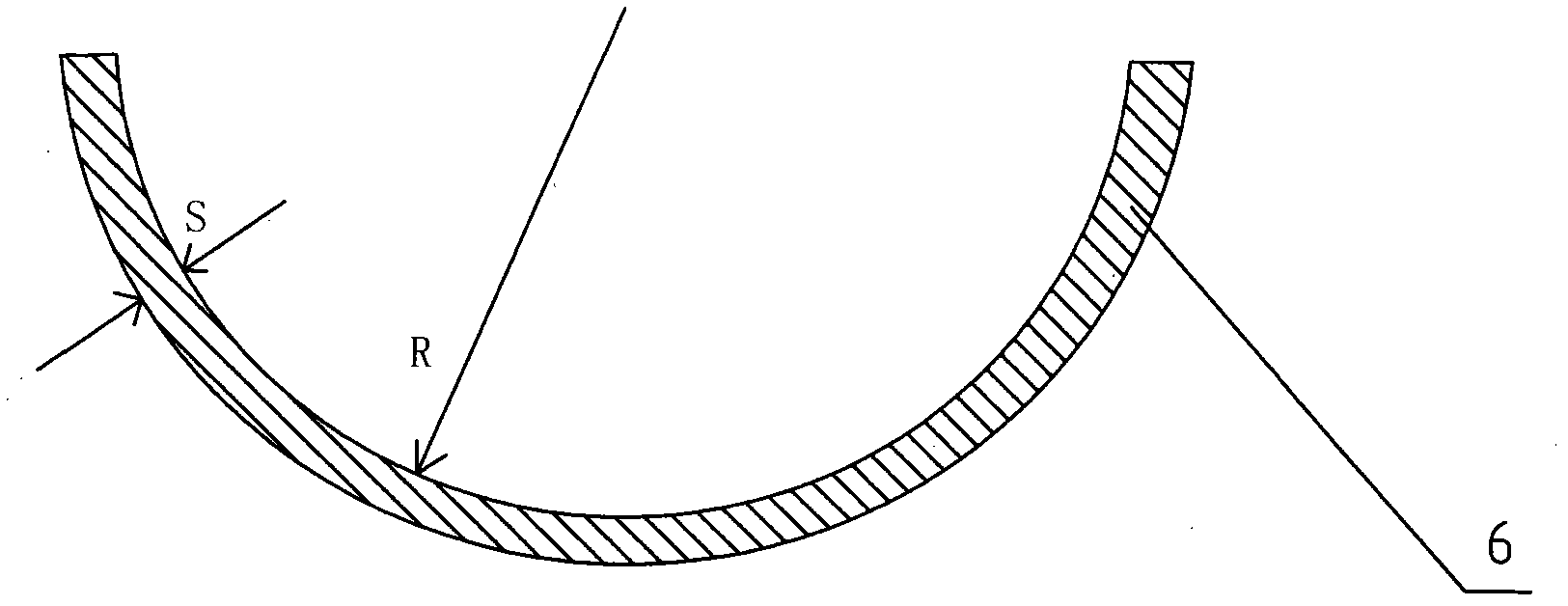

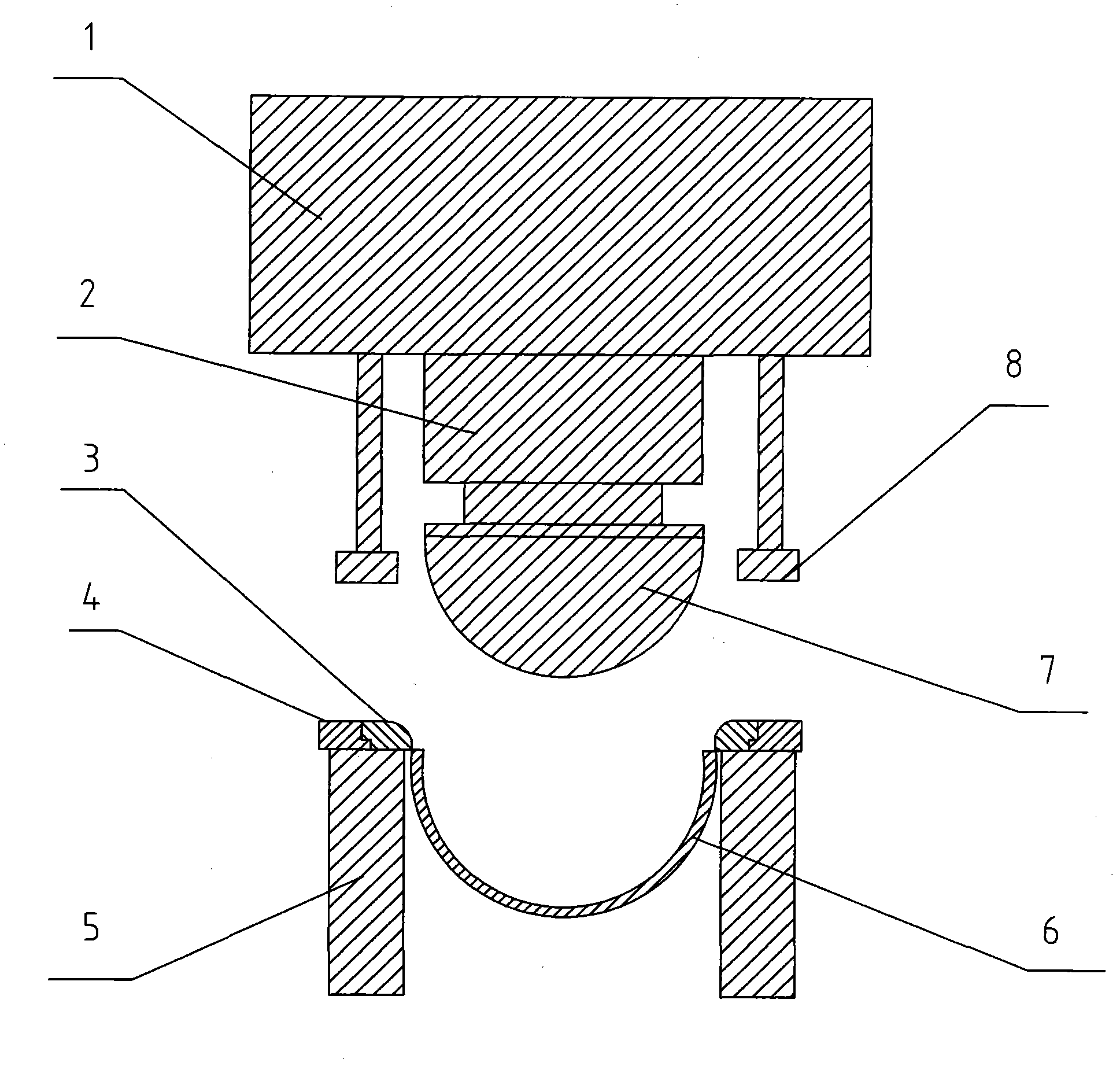

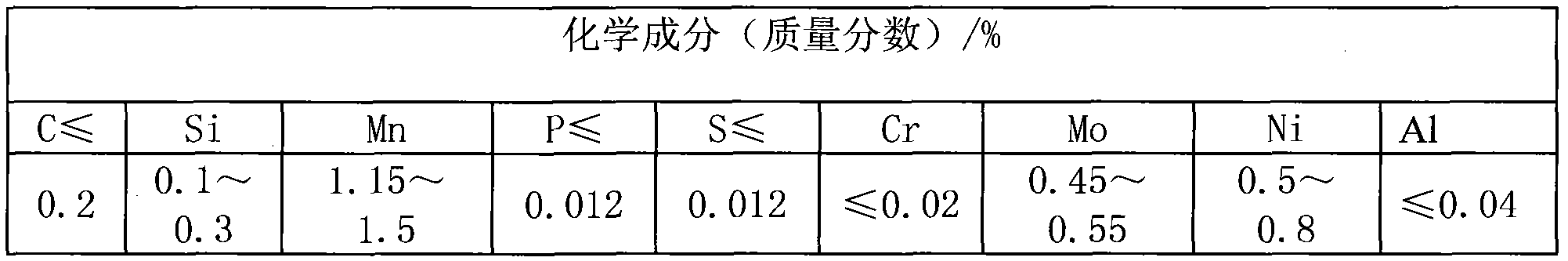

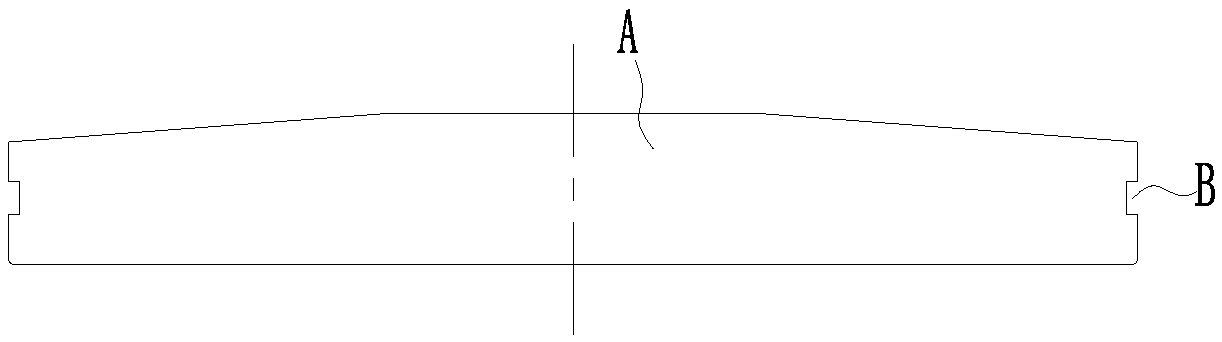

The invention discloses a method for manufacturing an end socket of a voltage stabilizer for nuclear power. The integral end socket is subjected to hot stamping deep drawing by a 16MND5 low-alloy steel plate, and is subjected to heat treatment of normalizing and tempering to form the end socket, which is reliable in quality, accurate in size and high in mechanical property, of the voltage stabilizer for nuclear power. In the method, the weight of the end socket manufactured by the low-alloy steel plate can be reduced by about half compared with that of the end socket manufactured by forging piece materials, the manufacturing period is short and the cost is reduced greatly.

Owner:泰安东润核电装备有限公司

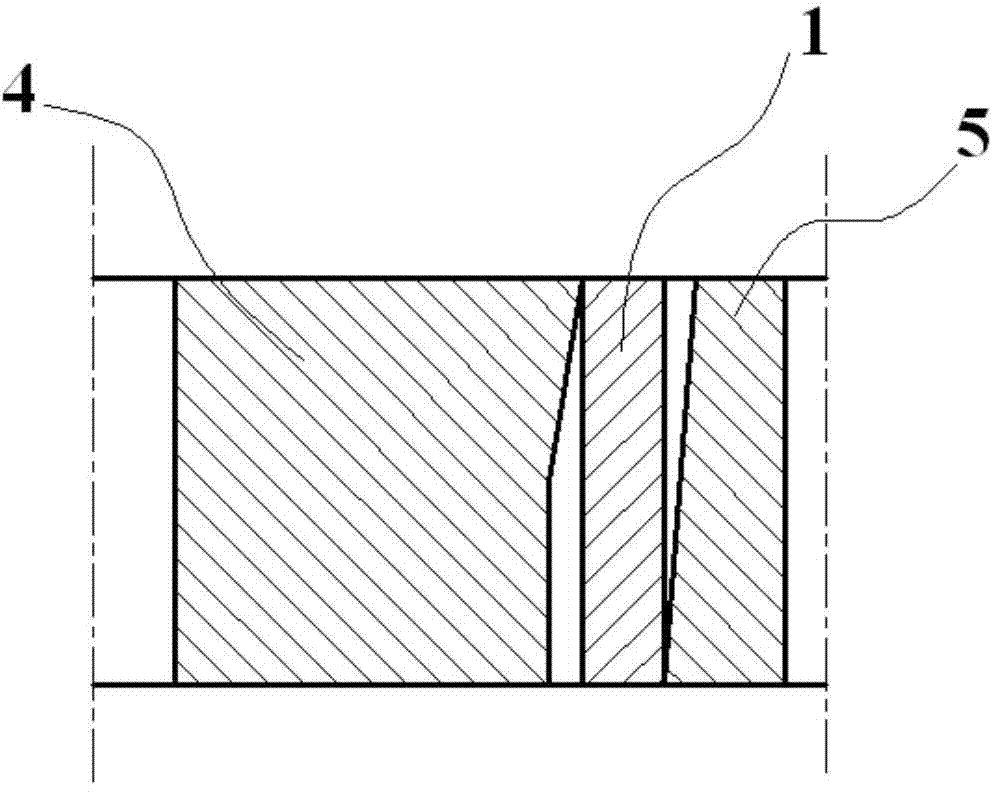

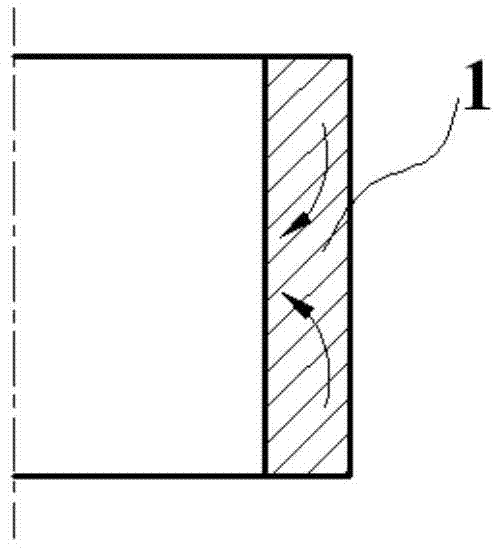

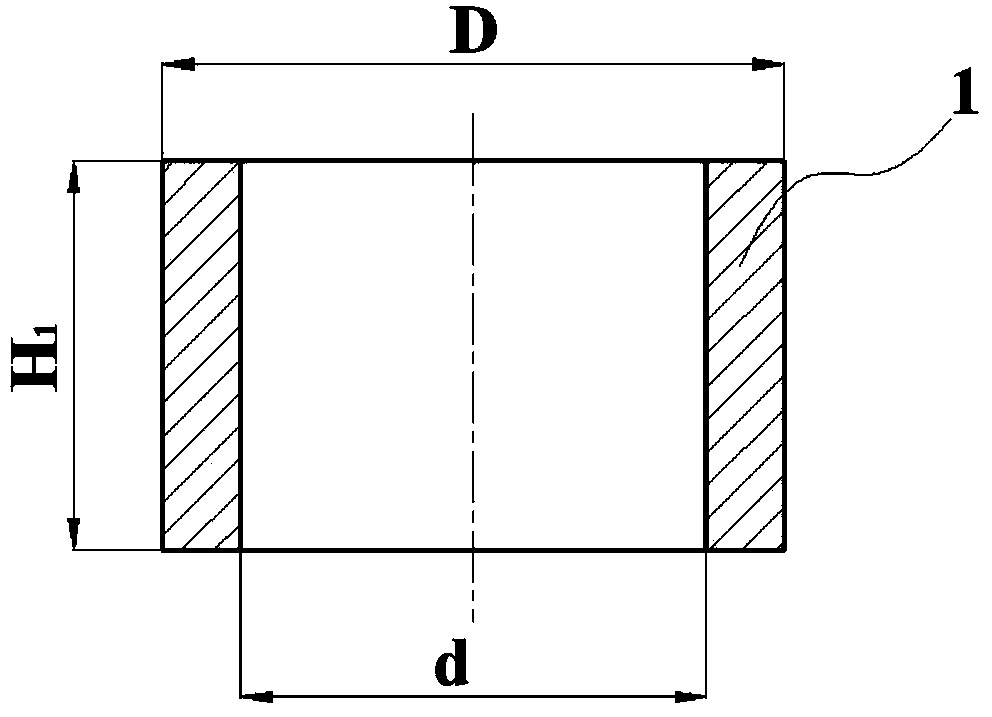

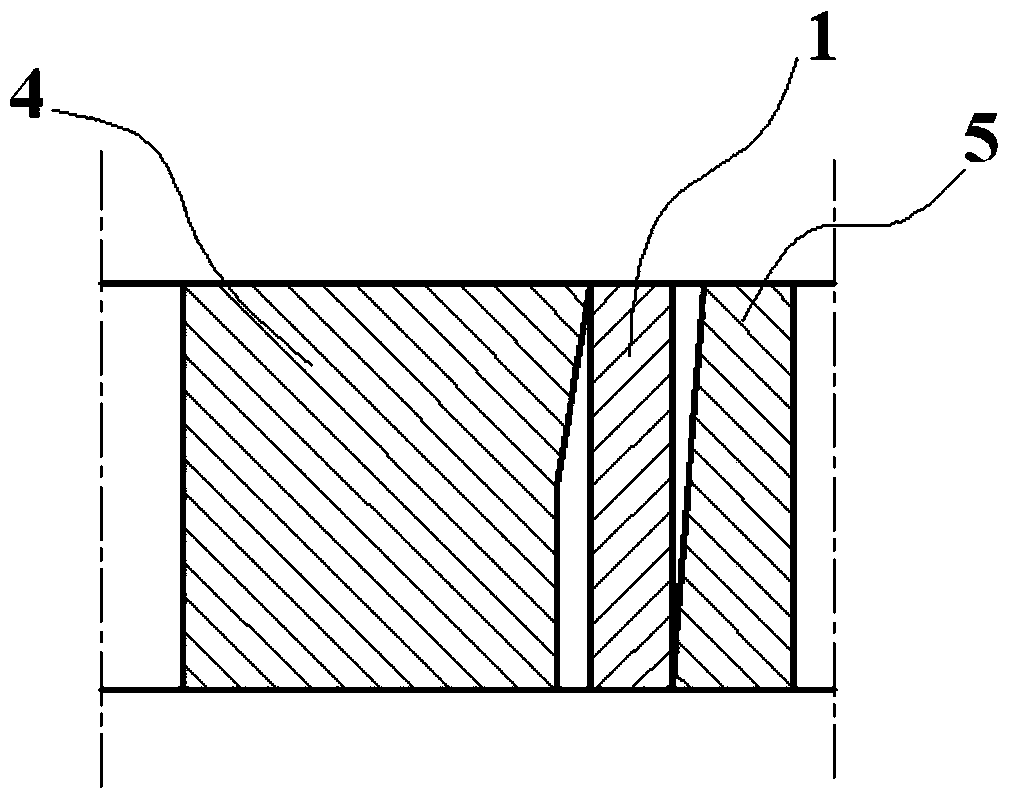

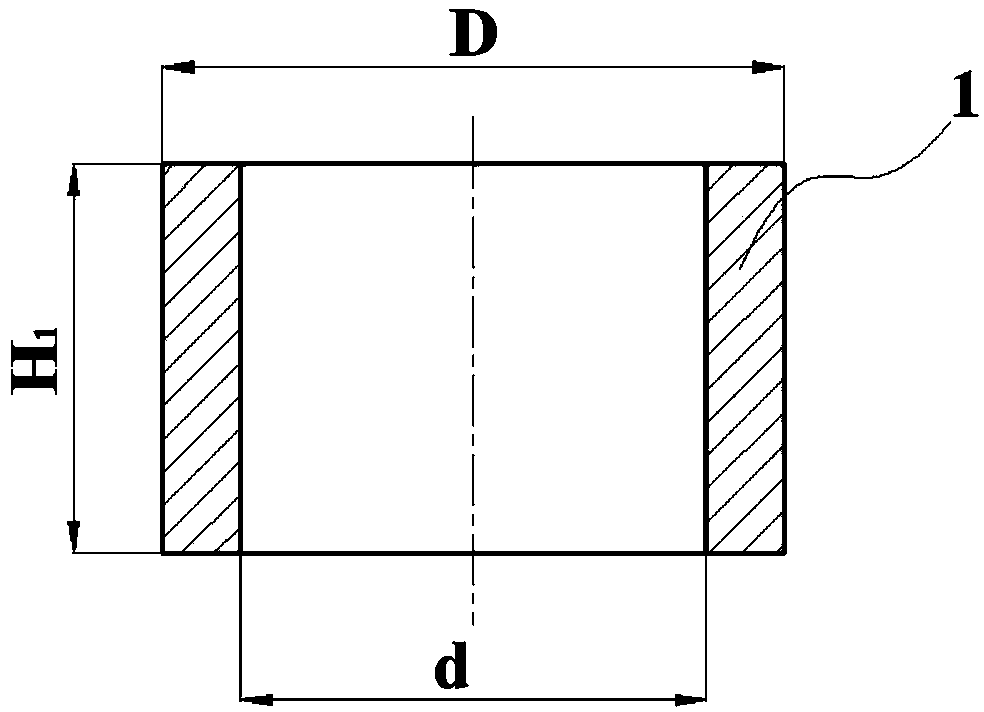

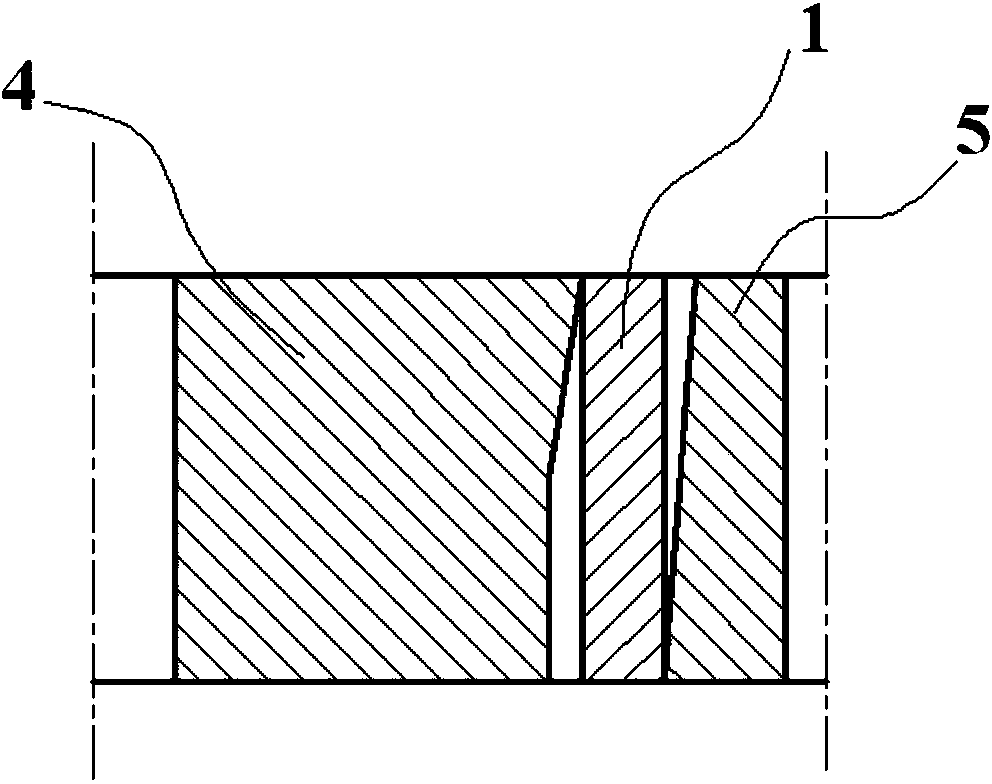

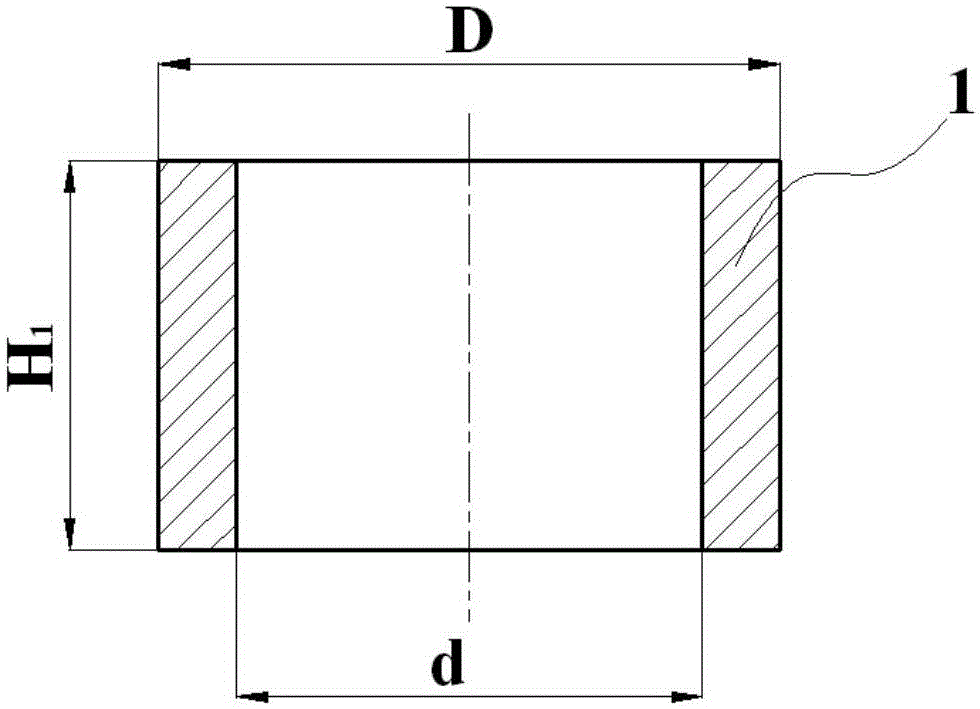

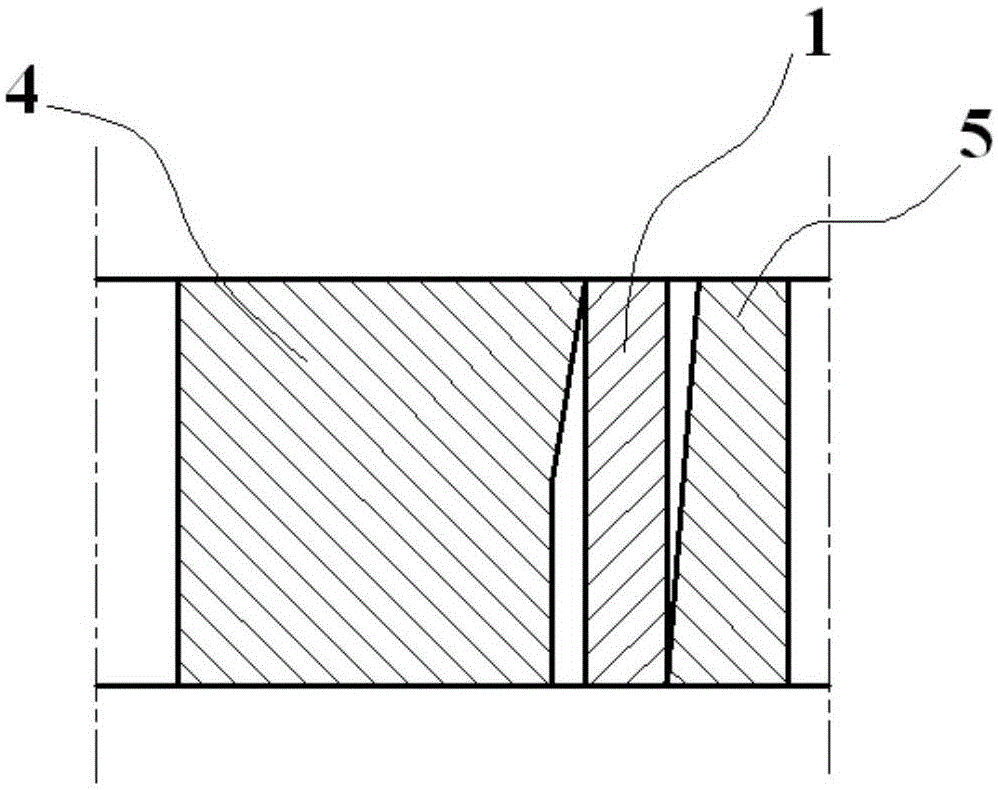

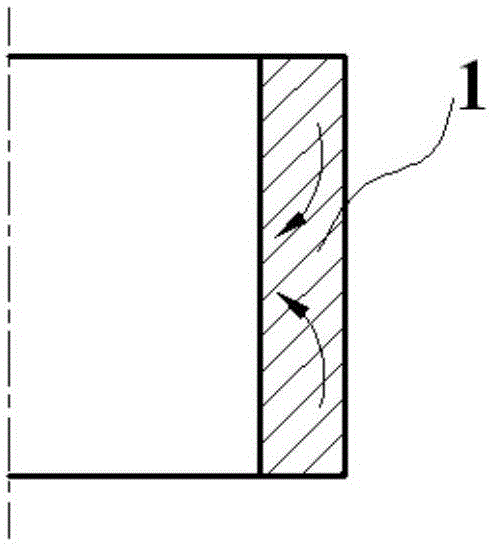

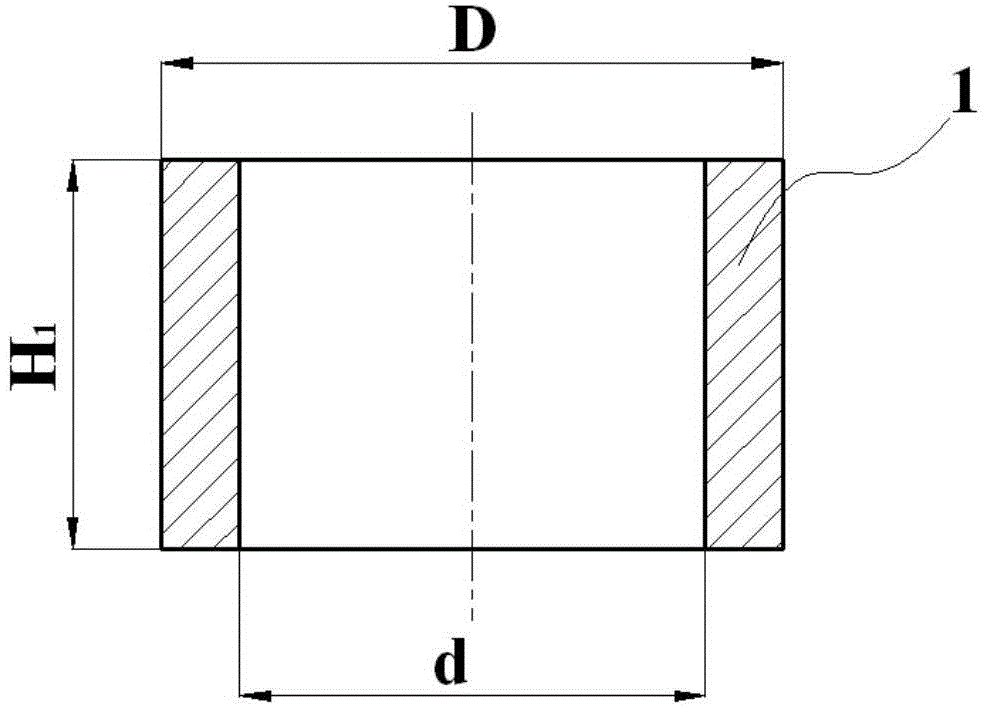

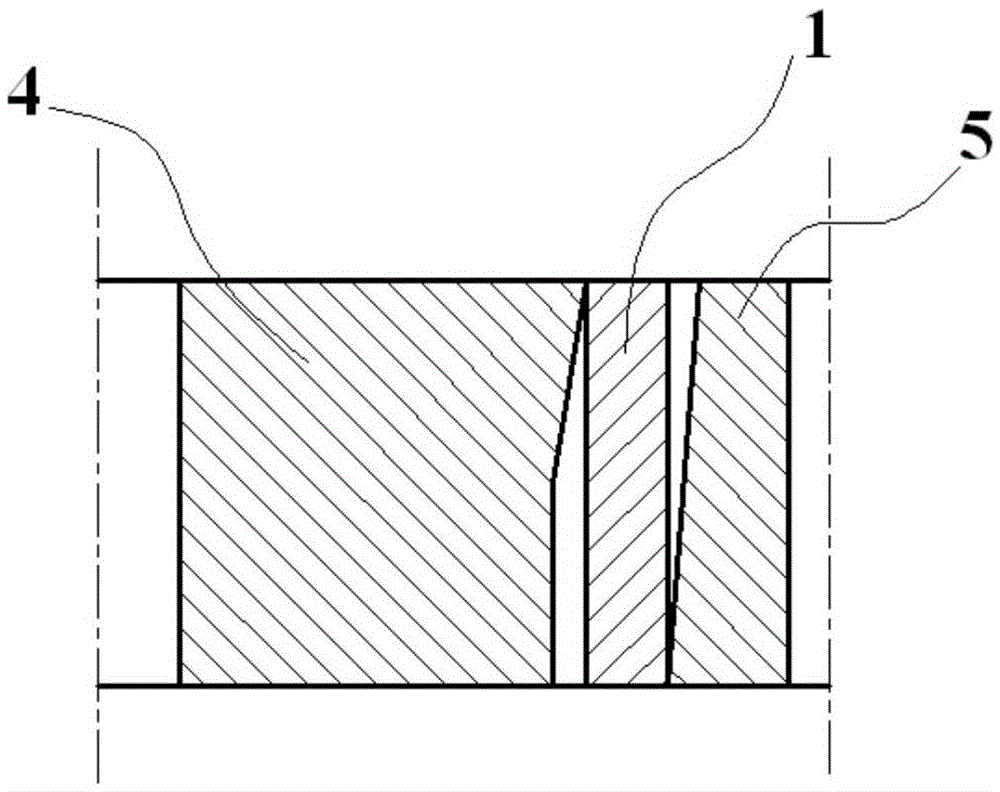

Method for rolling rectangular structural steel ring blank to form irregularly-shaped thin-walled ring part

The invention discloses a method for rolling a rectangular structural steel ring blank to form an irregularly-shaped thin-walled ring part. According to the rolling method, a reasonable core roller feeding mode is provided, and the rectangular structural steel ring blank is inversely designed according to the shape and the size of the irregularly-shaped thin-walled structural steel ring part to realize the rolling of the rectangular structural steel ring blank into the irregularly-shaped thin-walled ring part, so that a rolling process can be continuously and stably implemented; the rolling method is mainly used for the forming of the irregularly-shaped thin-walled structural steel ring part in the fields of aviation, aerospace, industrial machinery and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Method of rolling titanium alloy rectangular ring blanks into special-shaped thin-walled rings

The invention discloses a method of rolling titanium alloy rectangular ring blanks into special-shaped thin-walled rings. A mandrel reasonable feeding manner is provided to achieve a continuous, stable rolling process; titanium alloy rectangular ring blanks are reversely designed according to the shape and size of titanium alloy special-shaped thin-walled rings; accordingly, the titanium alloy rectangular ring blanks are rolled into the special-shaped thin-walled rings. The method is mainly applied to forming the titanium alloy special-shaped thin-walled rings in the fields of aerospace, industrial machinery and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

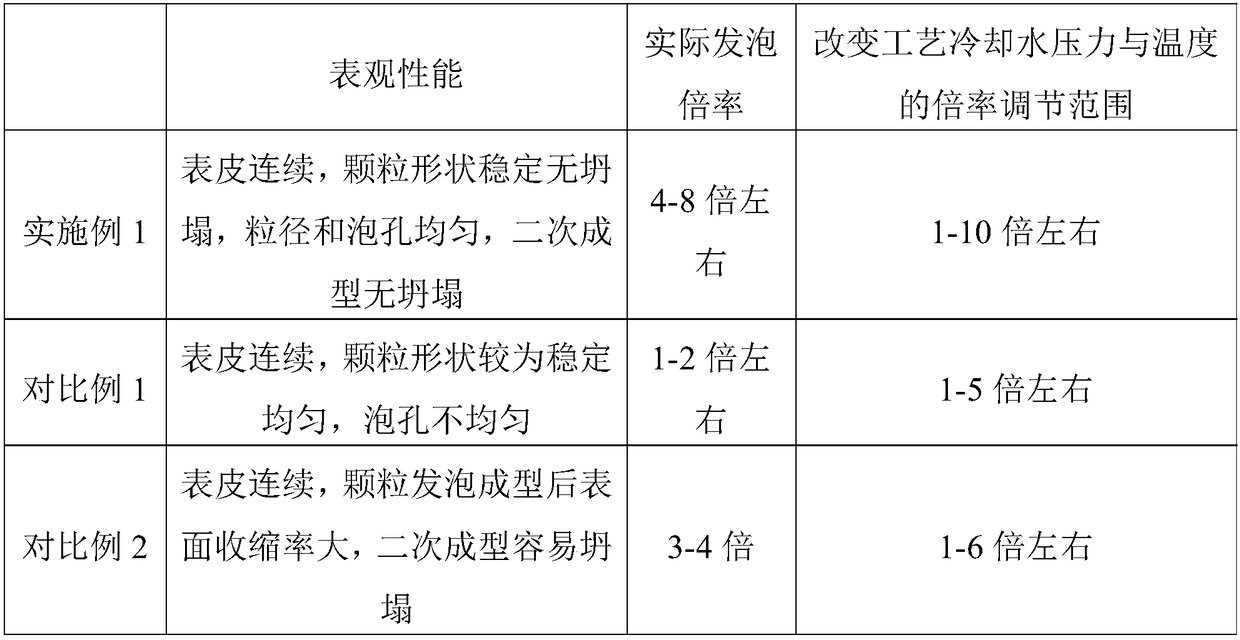

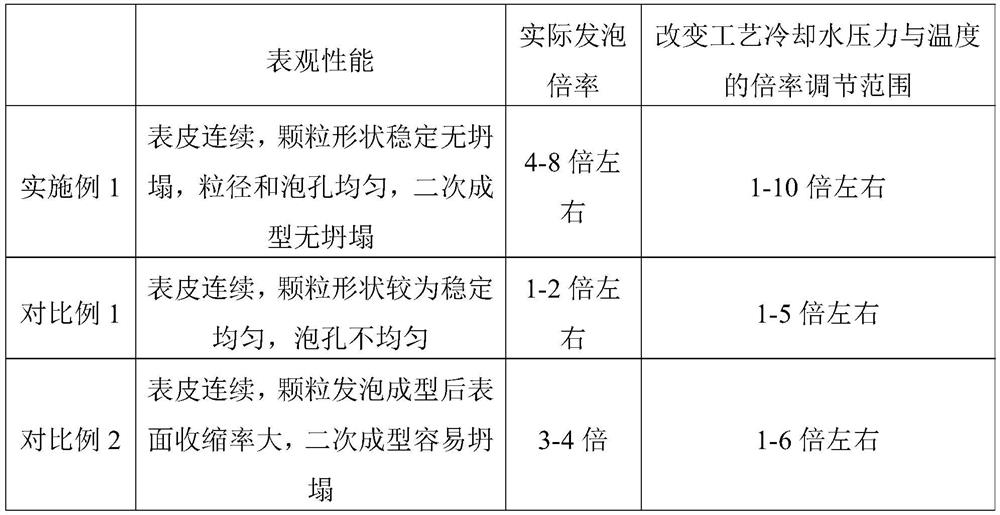

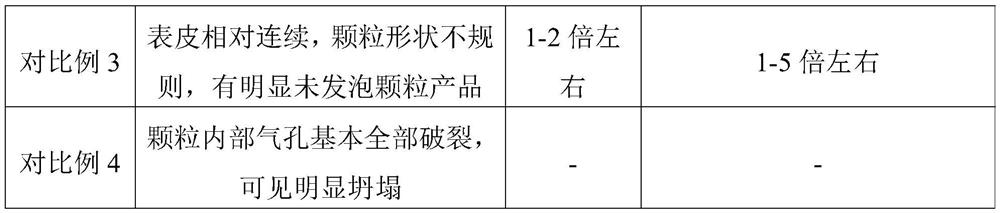

Thermoplastic polyether ester elastomer foaming material and preparation method thereof

The invention relates to a thermoplastic polyether ester elastomer foaming material and a preparation method thereof. The foaming material is prepared from the following raw material components in parts by weight: 50 to 95 parts of polyether ester TPEE (Thermoplastic Polyether Ester Elastomer), 0 to 50 parts of a modified polymer material, 0.05 to 2 parts of a nucleating agent and 0.1 to 5 parts of a foaming agent; when the adding amount of the modified polymer material is 0, the difference (T2-T1) of the melting temperature T2 of the polyether ester TPEE and the Vicat softening point temperature T1 is greater than or equal to 30 DEG C. Compared with the prior art, a continuous foaming formula and a continuous foaming technology of the TPEE are provided, and the problems that the foaming material with stale performance is difficult to prepare by existing TPEE, especially continuous foaming is difficult to realize are solved.

Owner:NANTONG DE NEW MATERIAL CO LTD

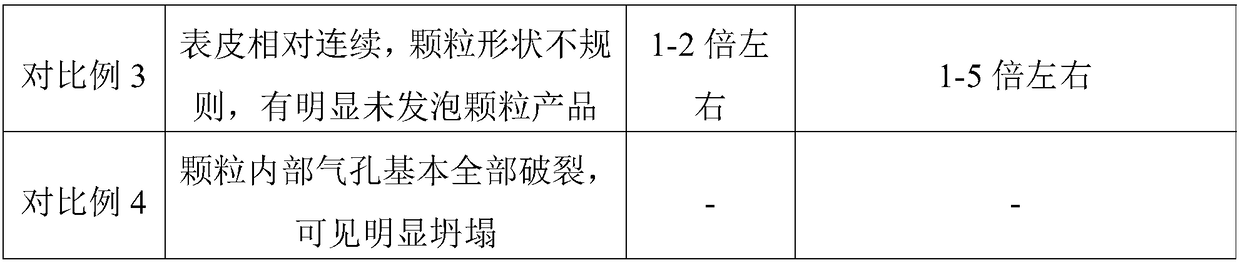

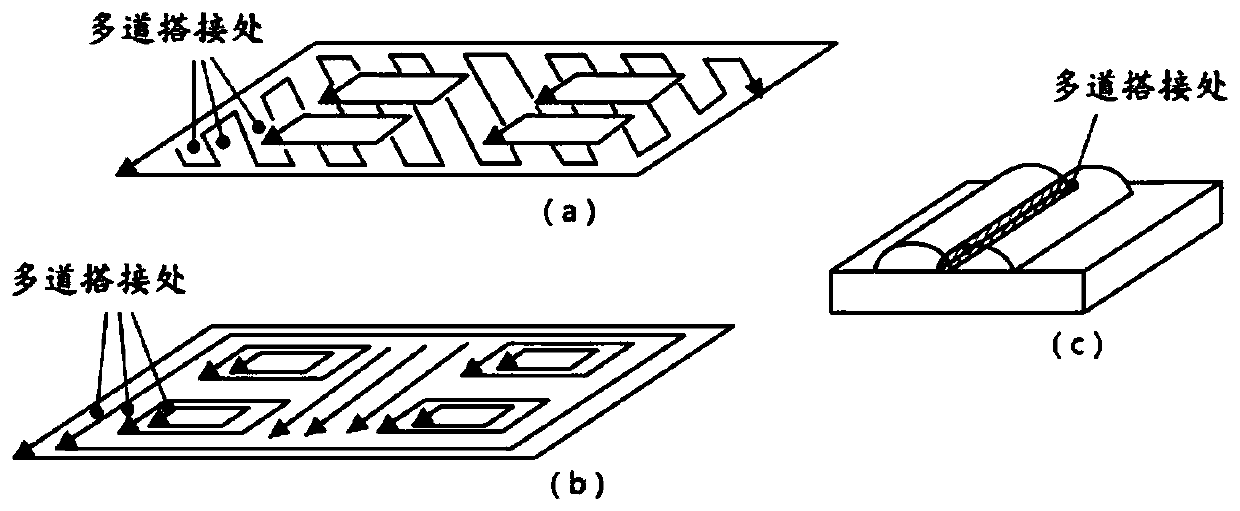

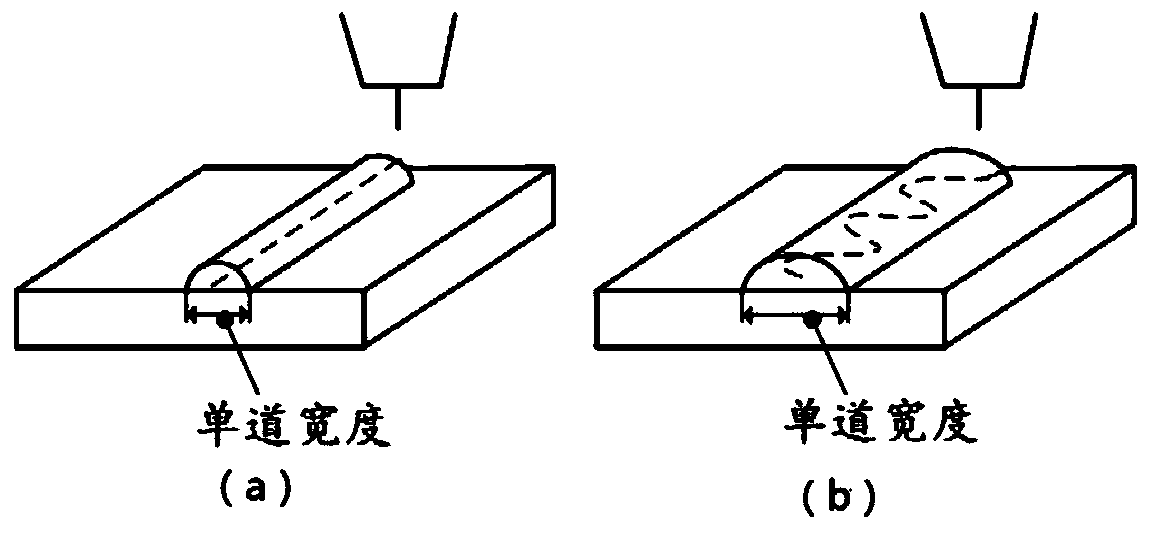

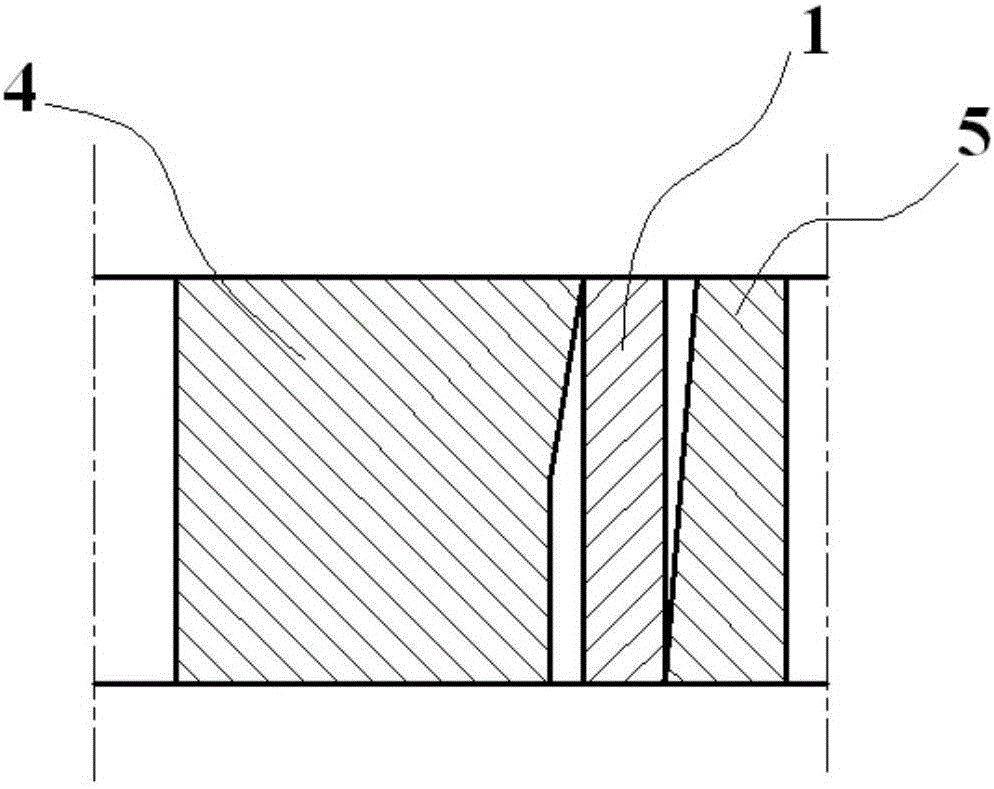

Path planning method of wire arc additive manufacturing without lap joints in layers

ActiveCN111390344ASize qualifiedSufficient machining allowanceAdditive manufacturing apparatusArc welding apparatusLap jointEngineering

The invention provides a path planning method of wire arc additive manufacturing without lap joints in layers, is applicable to a wire arc additive manufacturing process, and can solve the problems ofunstable forming quality due to excessive arc starting points, arc stopping points and multitrack lap joints caused by an existing wire arc additive path planning method, and the frequency reductiondue to large program quantity and the programs need to be uploaded step by step. The method adds a machining allowance to a wire arc additive manufacturing structural member, so that the layered cross-section shape of the wire arc additive manufacturing structural member is simplified into a regular shape with the allowance, a linear feature combination on the layered cross section is extracted onthe basis, a linear path is further formed, and finally, the additive path planning in the cross section is completed by means of the swing filling. The method greatly reduces the number of wire arcadditive manufacturing program statements and arc starting points and arc stopping points, eliminates lap joints between tracks, and helps to improve the wire arc additive manufacturing efficiency andquality.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Method for rolling rectangular die block steel ring blank into abnormal-shaped thin-wall ring member

InactiveCN103658168AGuaranteed final sizeSize qualifiedMetal rolling arrangementsRoll speed control deviceAviationAbnormal shapes

The invention discloses a method for rolling a rectangular die block steel ring blank into an abnormal-shaped thin-wall ring member. With the purpose of continuous and stable operation in a rolling process, a reasonable feeding type of a core roller is provided, the rectangular die block steel ring blank is designed according to the shape and the size of the abnormal-shaped thin-wall ring member in a backward reasoning mode, and therefore the rectangular die block steel ring blank is rolled into the abnormal-shaped thin-wall ring member. The method is mainly used for forming of the abnormal-shaped thin-wall ring member in the fields of aviation, aerospace, industrial machinery and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Production mode of metal ceramic profiles

ActiveCN110586925AAdjust stirring frequencyExtend the mixing timeTransportation and packagingMetal-working apparatusProduct inspectionWet grinding

The invention provides a production mode of metal ceramic profiles. An extrusion production technique comprises the steps of proportioning, wet grinding, mixing (adding of a forming agent), compression moulding, drying, half adding and half testing, sintering and finished product inspection. According to the production mode of the metal ceramic profiles, by changing the proportion of the forming agent, adjusting stirring frequency and prolonging the stirring time, the particle size of stirred materials is moderate, the density is even, the size of finished products is qualified, and deformation is basically avoided.

Owner:自贡鼎力合金材料有限公司

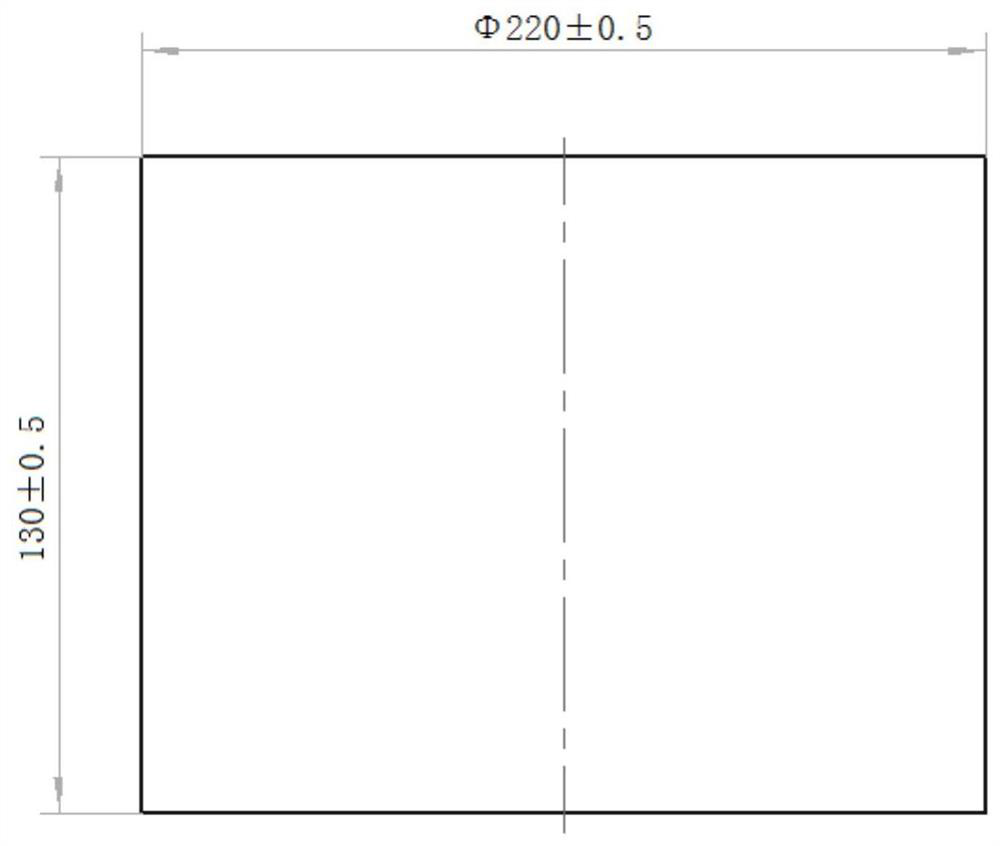

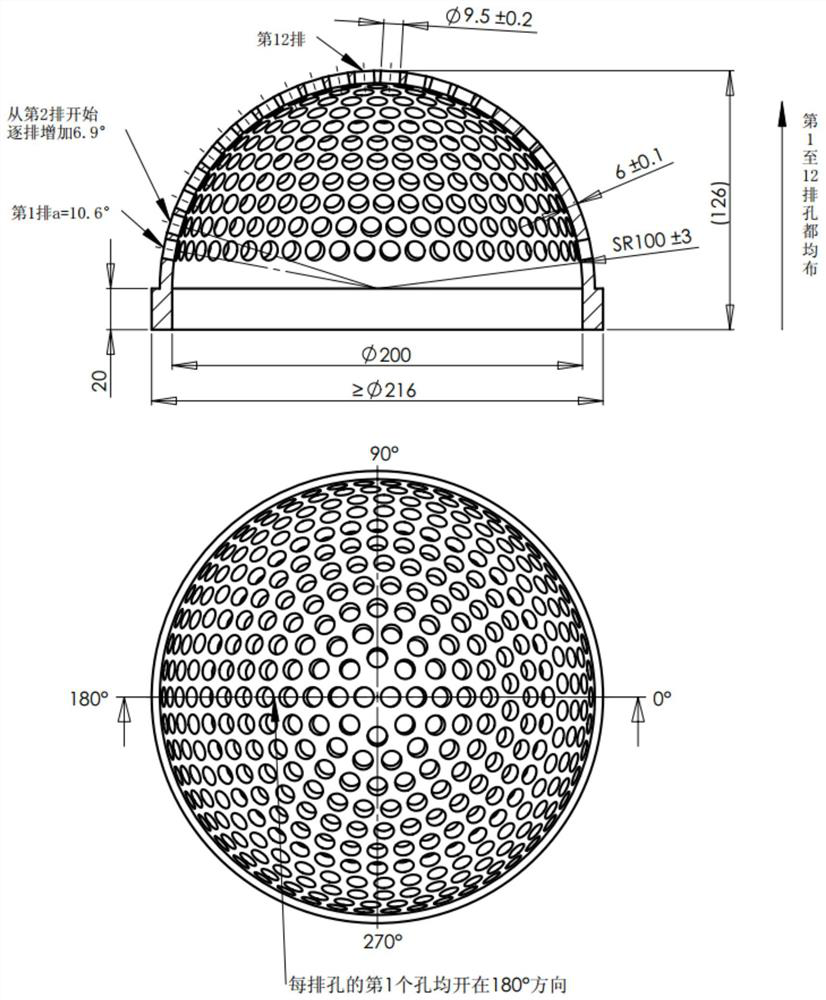

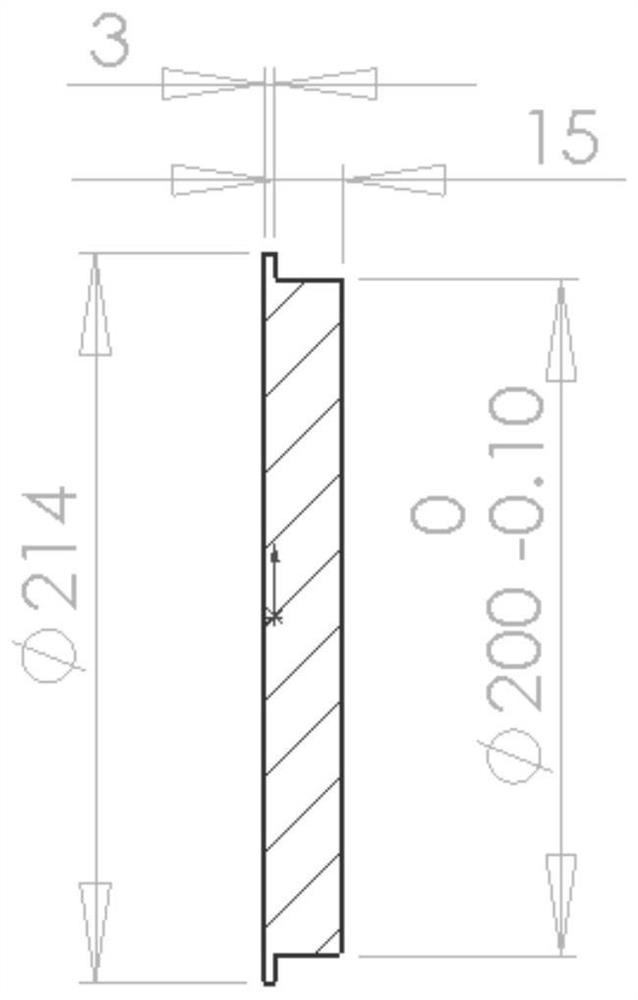

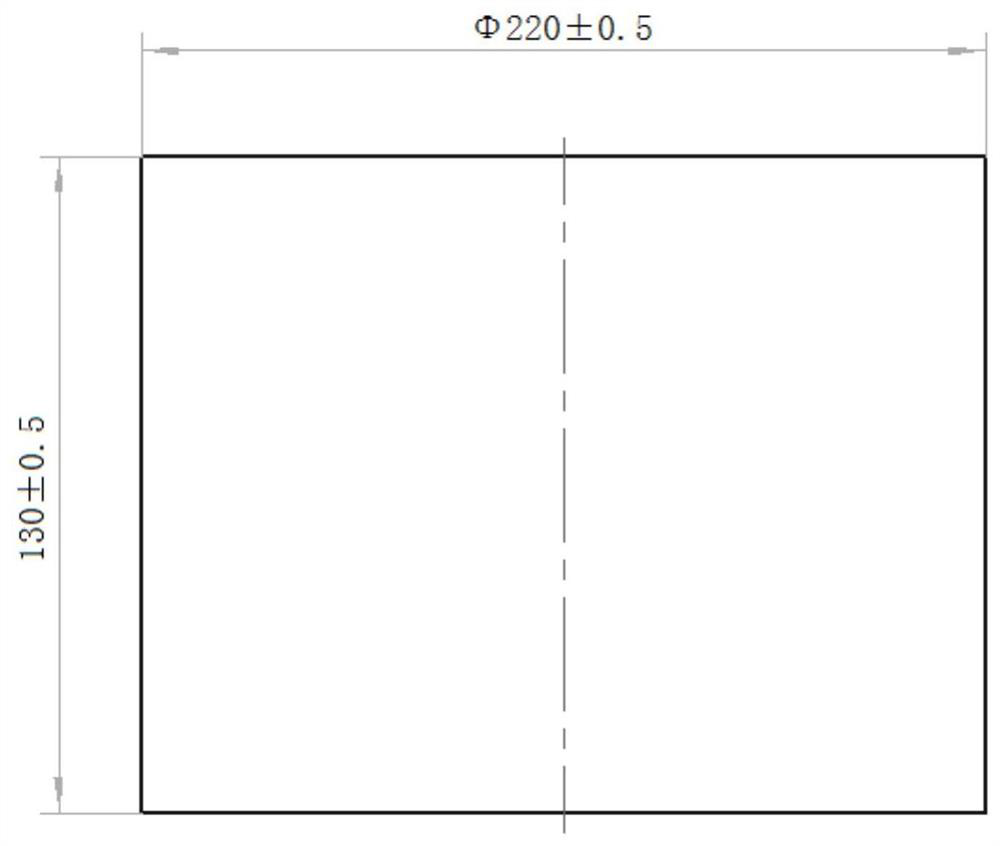

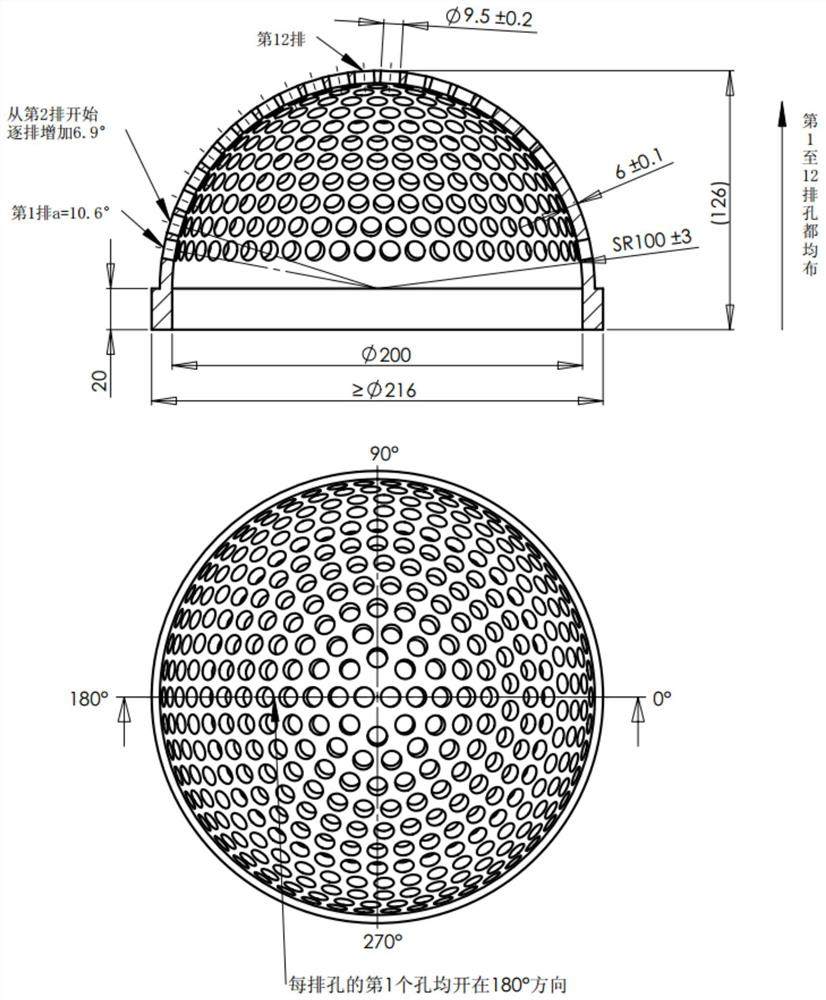

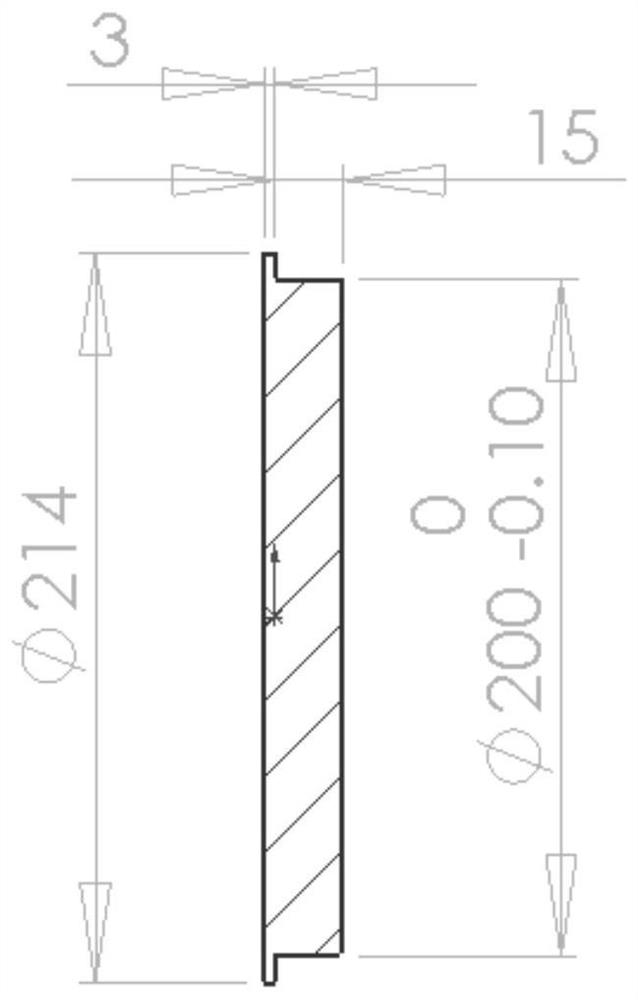

Method of processing fluid distribution housing

The invention discloses a method for processing a fluid distribution housing. The method comprises the steps of turning, finish milling and finish turning. The turning step comprises the following substeps that 1, the axial end face of a cylindrical blank with the length being 130+ / -0.5 and the diameter being 220+ / -0.5 is turned flat; 2, the outer circle of the blank is turned; 3, an auxiliary hole that has the diameter of 50 and the depth of 48 is drilled in the axial direction, an inner hole is bored, and an inner spherical surface is turned; 4, turning around is performed, a tool body and the inner spherical surface are assembled, the outer circle is clamped from the outer diameter position with the diameter being greater than or equal to 2-16 and corrected, and an end surface is turnedflat; and 5, an outer spherical surface is turned to keep the wall thickness size ta 6+ / -0.1 and the total height at 126, and then flash burrs are removed. The finish milling step comprises the following substeps that the outer circle with the diameter of 216 is clamped and supported by the tool body, 366 holes with the diameter of 9.5+ / -0.2are drilled, and then 3 auxiliary holes with the diameter of 10+ / -0.2 are drilled. The finish turning step comprises the following substeps that 1, the outer circle with the diameter of 216 is clamped, and the outer circle, the end face and the 3 auxiliaryholes with the diameter of 10+ / -0.1 serve as benchmarks to correct a workpiece; and 2, reserved process chucks with the size of 20 for clamping are removed by turning.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

A method of processing a fluid distribution casing

The invention discloses a processing method for a fluid distribution cover, which includes the steps of turning, fine milling, and finishing turning; the turning steps are as follows: step 1, a cylindrical blank with a length of 130±0.5 and a diameter of 220±0.5 is flattened by turning The axial end face can be exposed; Step 2, turning the outer circle of the blank; Step 3, drilling a φ50 process hole along the axial direction, with a depth of 48, and boring the inner hole; turning the inner spherical surface; Step 4, turning around, using the tooling body and the inner spherical surface Assembling, clamping and correcting the outer circle from the outer diameter of diameter ≥ φ216, turning the end surface flat; Step 5, turning the outer spherical surface, ensuring the wall thickness 6 ± 0.1 and the total height 126; then remove the flash and burrs; the steps of fine milling are as follows : Clamp the outer circle of ≥φ216, and the tooling body supports it; drill 366-φ9.5±0.2 holes, and then drill 3-φ10±0.2 process holes. The steps of finishing turning are as follows: Step 1, clamping ≥φ216 outer circle Circle, the outer circle, end face and 3‑Φ10±0.1 process hole are used as the reference to correct the workpiece: Step 2, turn off the process chuck with a reserved size of 20 for clamping, and the unit of size is mm.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

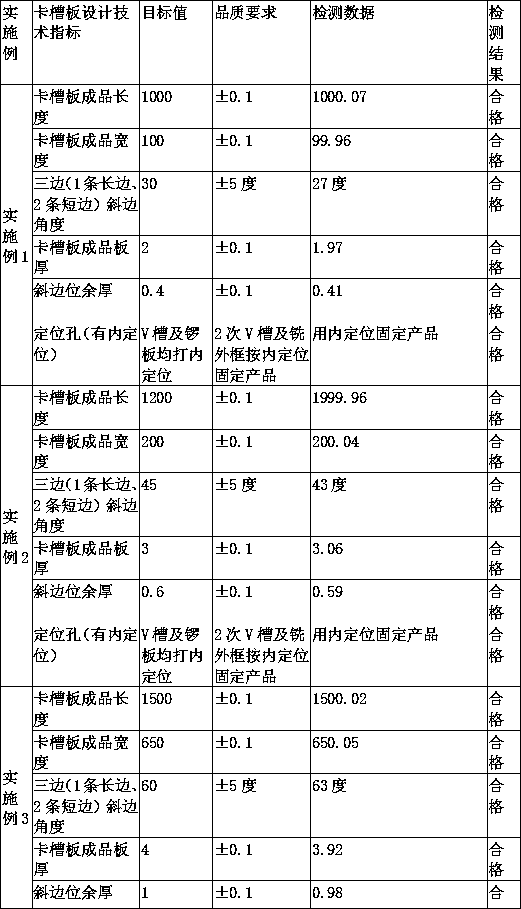

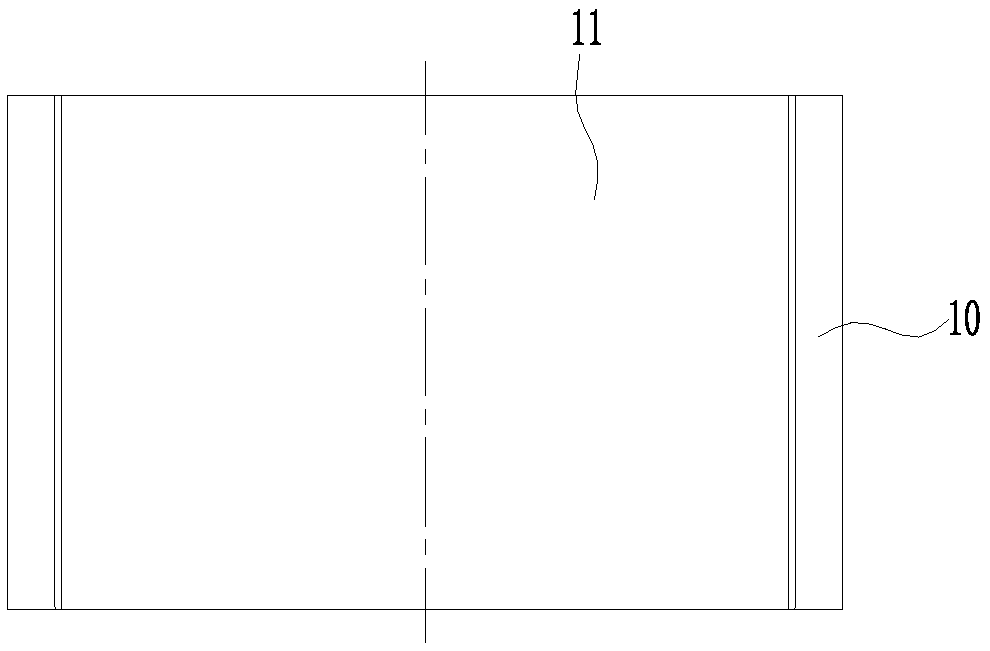

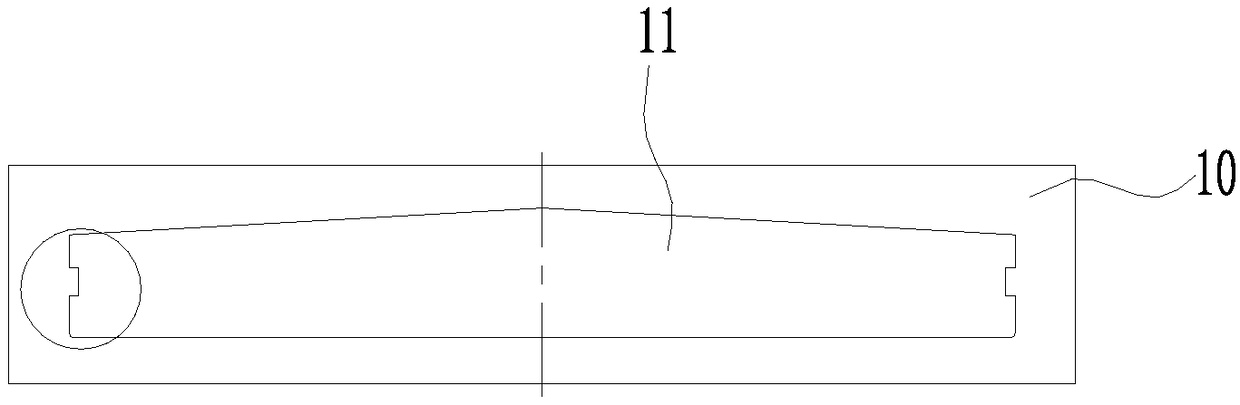

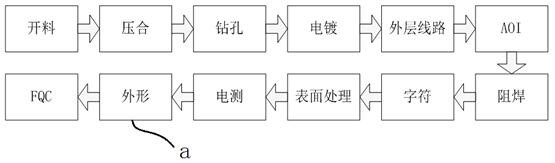

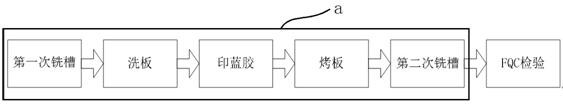

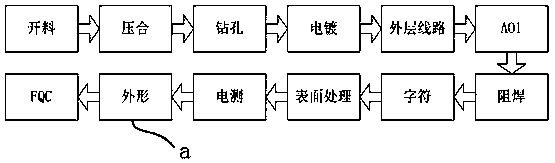

Forming processing method of PCB with ultra-long card groove

ActiveCN110785011AIncrease productivityOptimize process flowInsulating layers/substrates workingTechnology developmentForm processing

The invention provides a forming processing method of a PCB with an ultra-long card groove. The method comprises the steps that S1 V-CUT machine-CNC forming processing is carried out; S2 the processing data of an ultra-long plate card groove plate are designed; S3 the ultra-long card groove plate is processed; and S4 the size and quality of the ultra-long plate card groove plate are detected. According to the invention, the method starts with the technological capabilities of products and equipment; through deeper technological development of the technological capabilities of numerical controlmachine tool equipment, a special ultra-long card plate printed circuit board bevel processing process is designed to ensure that products can be fast and safely produced in batch; the product quality is improved; and the technical problems that a manual beveling machine is slow in efficiency, poor in quality, and has serious safety risks and a conventional beveling machine cannot produce ultra-long card plates are solved.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH +2

Precision grinding and polishing method based on gyroscope cavity of passive laser gyroscope

ActiveCN112338792AEasy to grind and polishDetermine machining allowanceLapping machinesGrinding feed controlPhysicsGrinding

The invention provides a precision grinding and polishing method based on a gyroscope cavity of a passive laser gyroscope. According to the precision grinding and polishing method, on one hand, the process steps of measuring, grinding, finishing, polishing and repeated measuring are combined, on the other hand, in order to solve the problems of clamping and polishing caused by the ultrahigh vertical surface of the cavity, in the process steps, the cavity can be properly inclined so as to be easier to grind and polish, finally, it is guaranteed that the linear dimension and the angular dimension of the cavity can be qualified at the same time, the included angle between adjacent patch surfaces, the perpendicularity angle error between the patch surfaces and the reference surface and the linear dimension are considered to reach the design indexes together, the problems that grinding is excessive, and the size and the angle are out of tolerance in a common method can be solved, it is guaranteed that the surface defect grade and the surface shape precision of the patch surfaces can reach the standard, and the popularization value of patch surface machining of the large-size gyroscope cavity is achieved.

Owner:TIANJIN JINHANG INST OF TECH PHYSICS

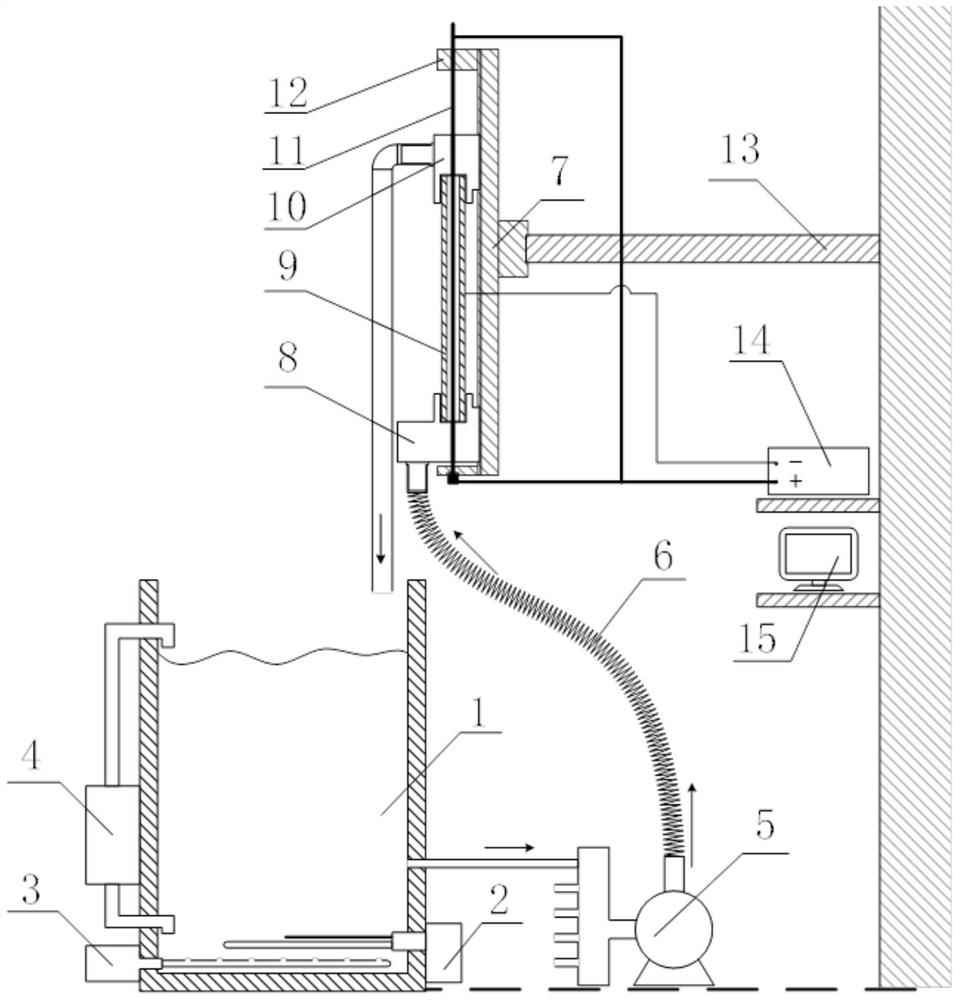

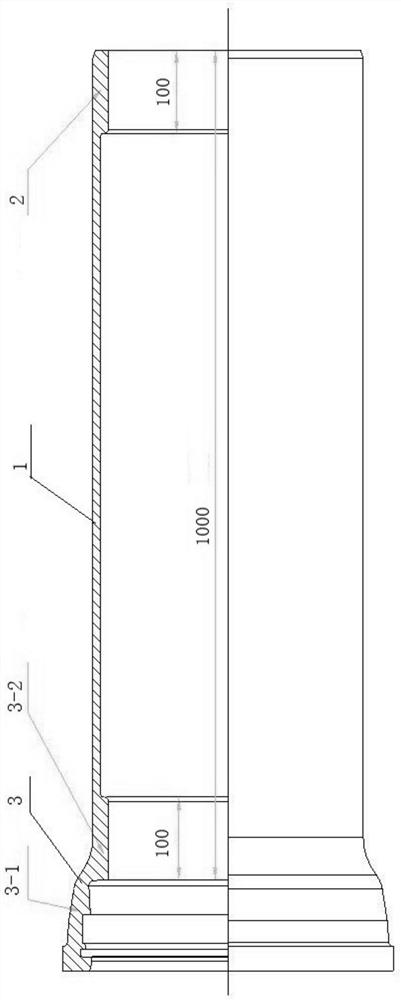

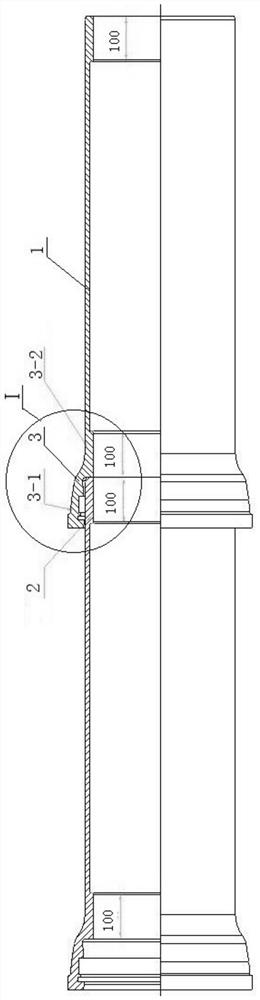

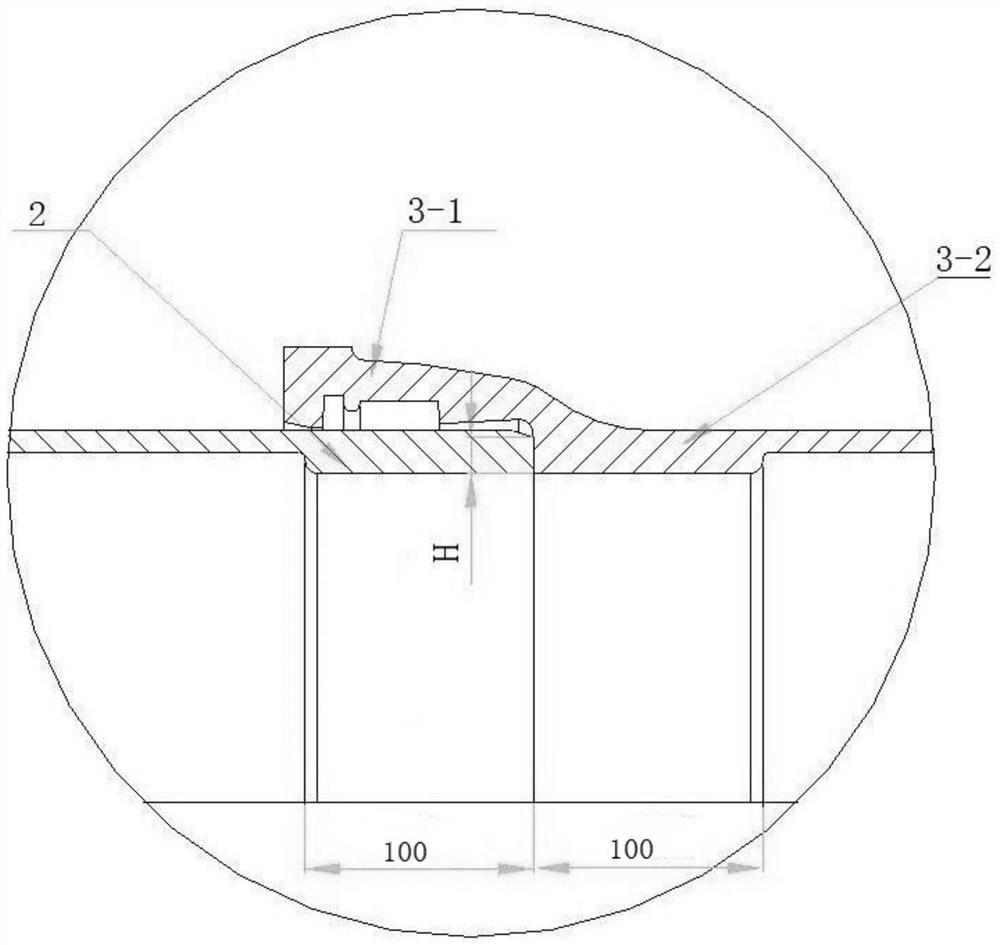

An automatic continuous flow electroplating device and method for the inner wall of a pipe fitting

Owner:UNIV OF SCI & TECH BEIJING

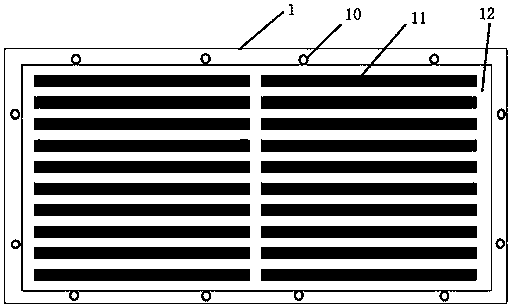

Internally acting type ductile iron jacking pipe for integral trenchless pipeline construction

InactiveCN111637277ASize qualifiedReduce manufacturing costPipe laying and repairFoundry mouldsMaterial consumptionDuctile iron

The invention provides an internally acting type ductile iron jacking pipe for integral trenchless pipeline construction. One end of a cylinder section is connected with a spigot section, and the other end of the cylinder section is connected with a socket section; and a socket seal section is connected with a socket push section. According to the use requirements and manufacturing process of theinternally acting type micro jacking pipe, by reducing the inner diameters of small sections of the socket section and the socket section, the wall thickness of the part of a pipe body is increased tomeet the requirements of transmitting the pushing force. Through the thickening of the tail ends of the spigot section and the socket section, the compression stress of the spigot section is reducedby more than half; the jacking pipe is produced by adopting an integral casting method; and no additional flanges and reinforcing ribs are required, which reduces the material consumption and bondingworkload of the jacking pipe, reduces the production cost, and improves the production efficiency. The internally acting type ductile iron jacking pipe reduces the inner diameters of the small sections of the spigot section and the socket section, increases the wall thickness of the part of the pipe body, and meets the requirements of transmitting the pushing force. The jacking pipe is produced byadopting the integral casting method, which reduces the weight and the difficulty of production. The internally acting type ductile iron jacking pipe is used in the field of trenchless construction in water delivery projects.

Owner:LIAONING EVER FOUNDRY CO LTD

Method for manufacturing end socket of voltage stabilizer for nuclear power

ActiveCN102248362BSize qualifiedQualified shapeFurnace typesHeat treatment furnacesHot stampingNuclear power

The invention discloses a method for manufacturing an end socket of a voltage stabilizer for nuclear power. The integral end socket is subjected to hot stamping deep drawing by a 16MND5 low-alloy steel plate, and is subjected to heat treatment of normalizing and tempering to form the end socket, which is reliable in quality, accurate in size and high in mechanical property, of the voltage stabilizer for nuclear power. In the method, the weight of the end socket manufactured by the low-alloy steel plate can be reduced by about half compared with that of the end socket manufactured by forging piece materials, the manufacturing period is short and the cost is reduced greatly.

Owner:泰安东润核电装备有限公司

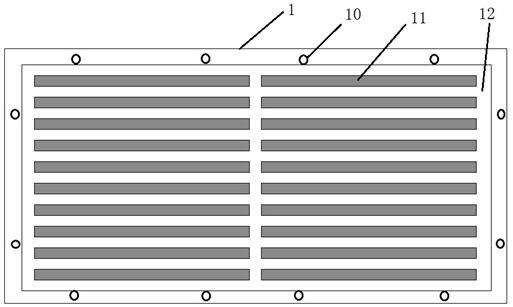

Magnetic steel inspection tool

Owner:ANHUI WANNAN ELECTRIC MACHINE

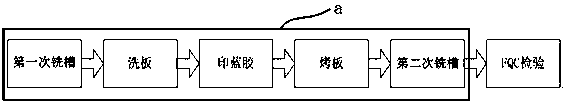

A method for processing the shape of a pcb product with a narrow edge ptfe antenna without internal positioning

ActiveCN109842991BGuarantee product qualitySize qualifiedPrinted circuit manufactureMechanical engineeringElectrical and Electronics engineering

The invention discloses a shape processing method for a narrow-side PTFE antenna PCB product without internal positioning, which is suitable for an ultra-narrow antenna PCB made of PTFE materials, and can ensure that the antenna PCB board is qualified in size after shape processing, and has no oxide and burr defects. Guarantee product quality and eliminate defects of oversized or undersized dimensions due to shape processing.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH +2

Composite material radome arc flange interface hole machining clamp and machining method

The invention discloses a composite radome arc-shaped flange interface hole machining clamp and method. The composite radome arc-shaped flange interface hole machining clamp comprises a drilling clamp and a special countersinking tool. The drilling clamp is composed of a positioning plate used for positioning during drilling and a drilling sleeve used for position guiding in the drilling process, the thickness of the positioning plate is 3 mm, an antenna housing is arranged on the top of the positioning plate, and the appearance of the positioning plate is matched with an oval pit in the bottom of the antenna housing. A drilled hole is positioned and guided through the drilling clamp, accurate drilling is conducted on an arc-shaped flange interface of the radome according to the required position, then the guide part of the special countersinking tool is inserted into the drilled hole, the countersinking tool guide column part is used for limiting and guiding, and the countersinking tool body blade part is used for countersinking. The machined hole is accurate in position and qualified in size, a special drilling tool does not need to be customized, the cost is saved, meanwhile, the task progress can be better guaranteed, and the method is easy to master, high in operability and wide in application range.

Owner:浙江微控智造有限公司 +1

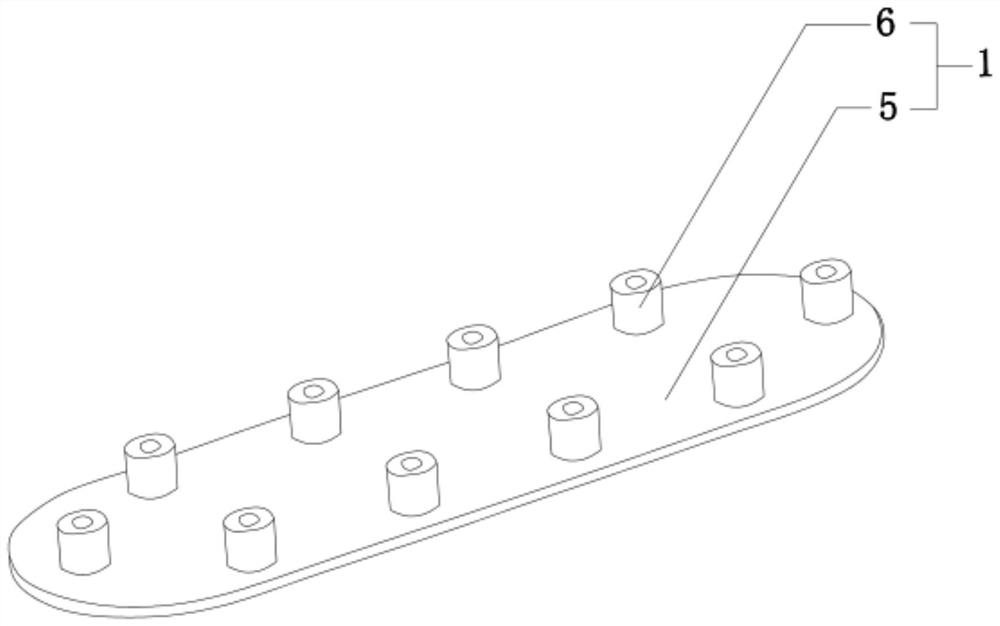

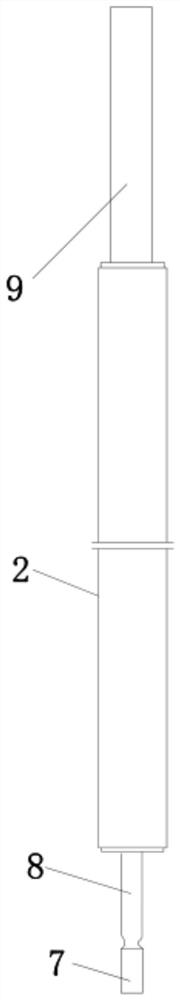

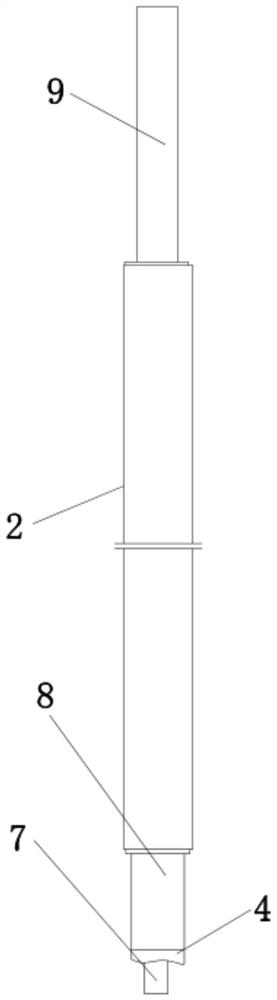

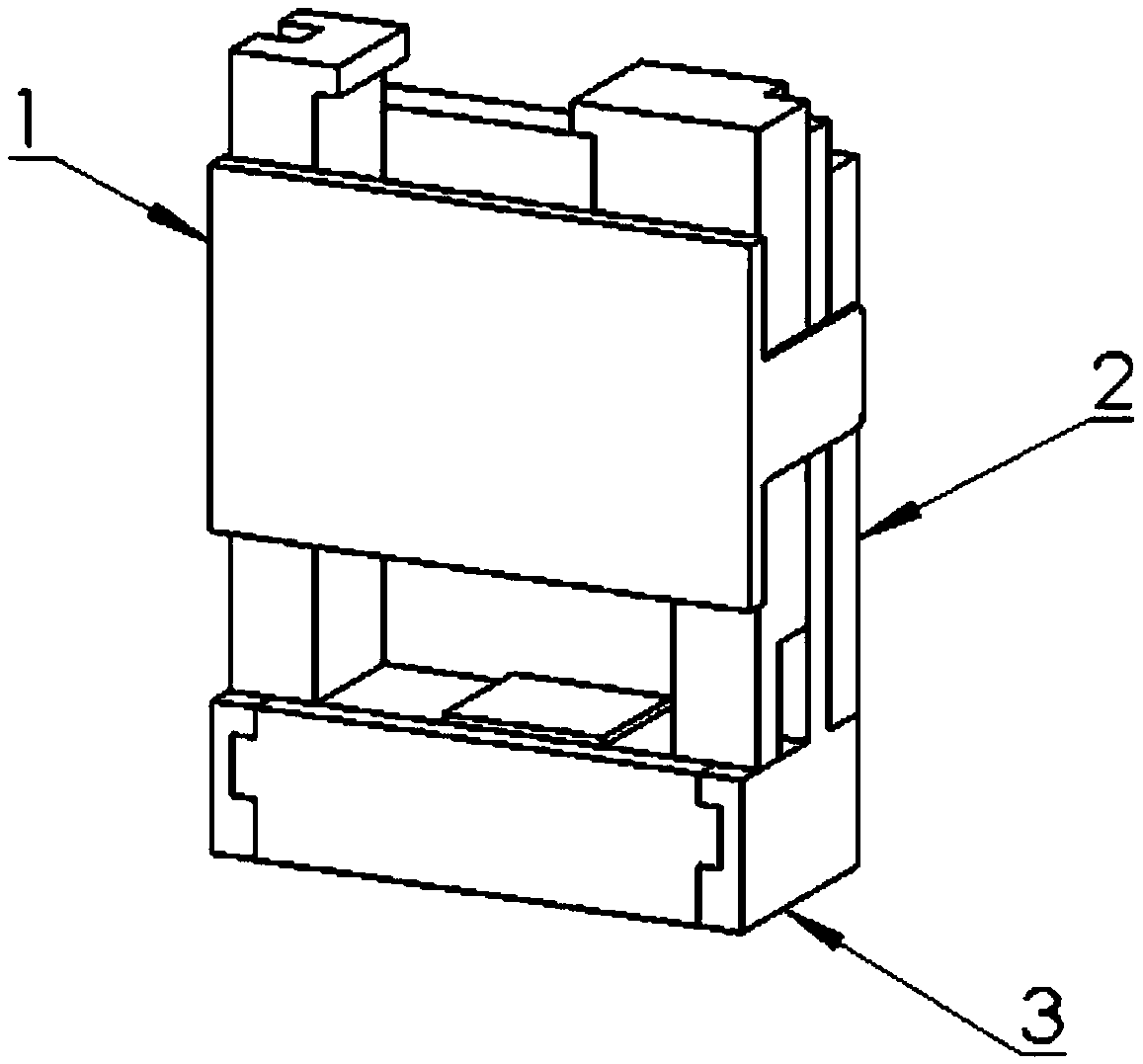

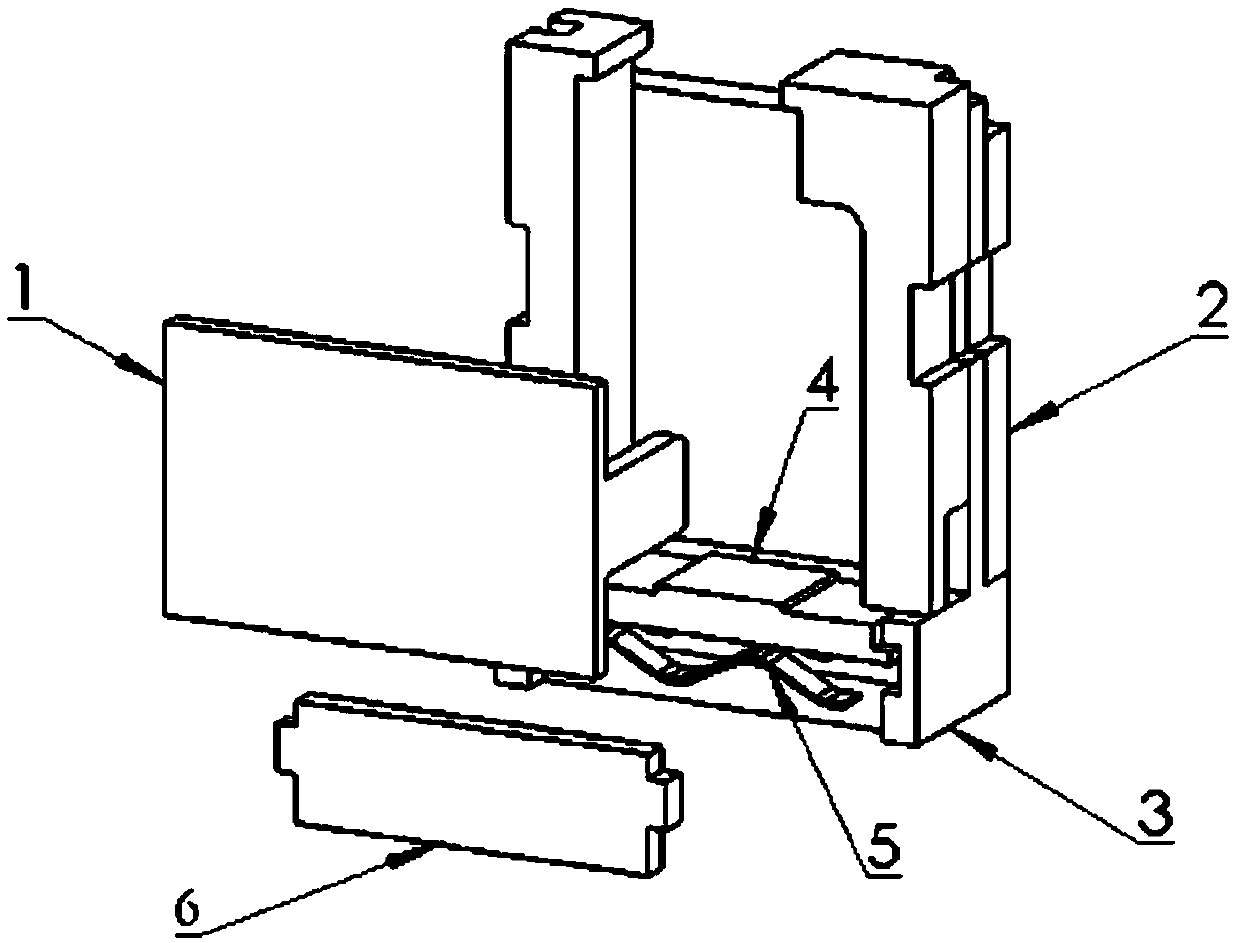

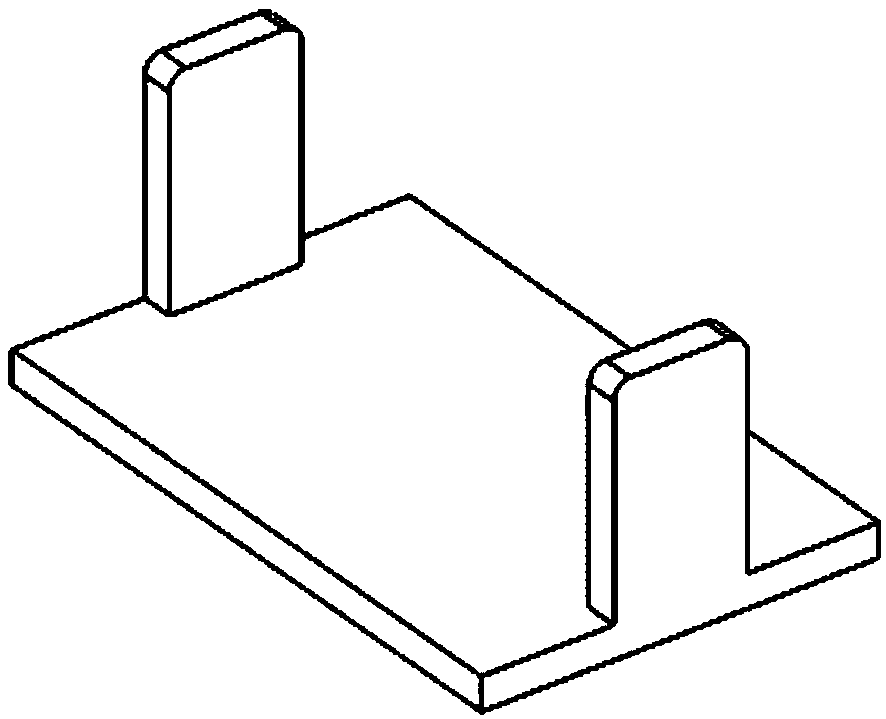

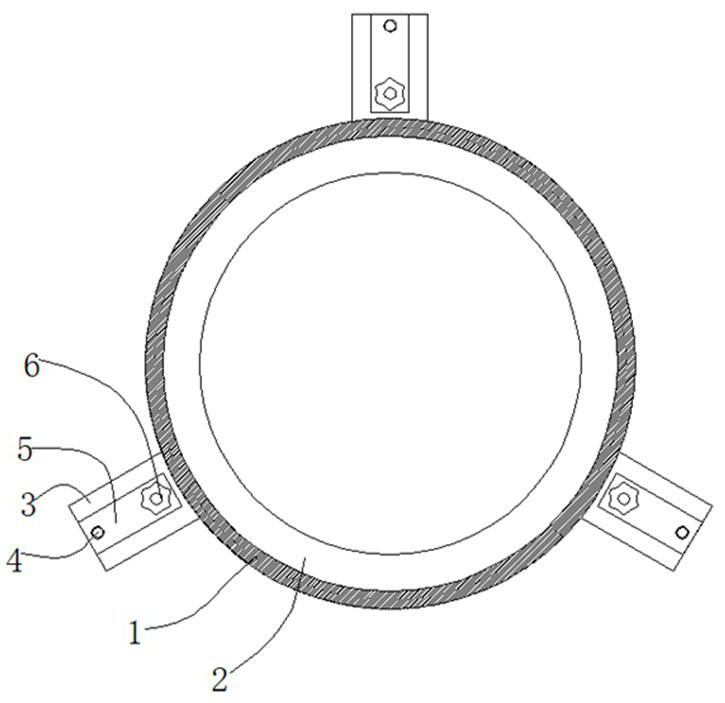

A small clamping tool with fast fixing function

ActiveCN107871645BQuick fixSimplify the assembly processEmergency protective device manufactureAviationLocked plate

The invention relates to a small clamping tool with a fast fixing function. The tool is applied to assembly of an expansion screw part of a circuit breaker product for aviation, fast fixing of the part is achieved and a platform is provided for subsequent assembly of the expansion screw part. The tool mainly comprises a hoop (1), a fixed seat (2), a base (3), a limiting plate (4), a leaf spring (5) and a locking plate (6). The clamping tool is applied to assembly of the expansion screw part of the circuit breaker product and plays limiting and fixing roles in the expansion screw part, and thecondition that the assembly dimension of the expansion screw part meets the requirements is ensured.

Owner:天津航空机电有限公司

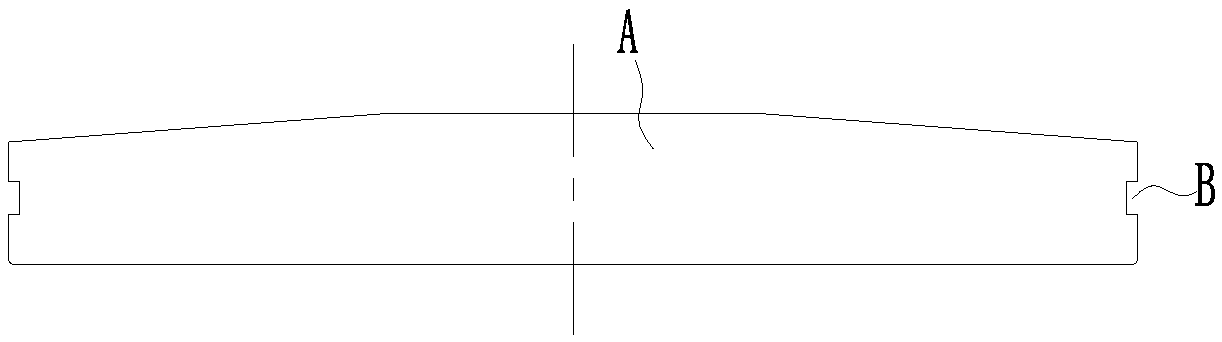

Magnetic steel inspection tool

The invention aims to provide a detection tool for checking the size of magnetic steel. The detection tool comprises a body,wherein a V notch is formed on the body,and the cross section of the V notchis the same as that of the punching groove. Through the simulation of the punching groove type,the magnetic steel A to be detected is a sub-block,and the detection tool is a mother block,and the magnetic steel A to be detected can pass through the V notch on the body and has no obvious clearance,and the size of the magnetic steel A to be detected is qualified.

Owner:ANHUI WANNAN ELECTRIC MACHINE

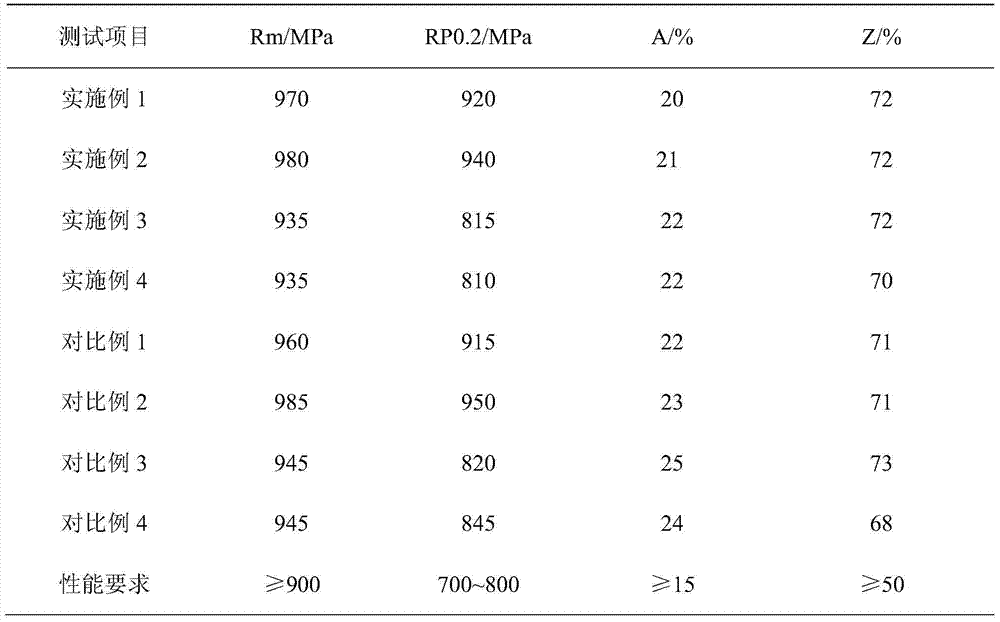

A heat treatment method for precipitation hardened blade steel

The invention discloses a heat treatment method for precipitation hardening vane steel, which comprises the following steps: (1) carrying out intermediate-temperature heating on the precipitation hardening vane steel at the temperature of 800-950 DEG C, and preserving heat for 1-3h; (2) after being discharged, putting the precipitation hardening vane steel onto a die for thermal calibration; and (3) carrying out aging treatment and discharging for air cooling. The heat treatment method can get rid of solution treatment, and can carry out optimizing processing on temperature and time for intermediate-temperature heating and aging treatment, thus effectively solving the problem of large deformation caused by secondary solution heat treatment; and a forged piece obtained by adopting the heat treatment method is small in deformation, qualified in dimension and excellent in performance.

Owner:WUXI TURBINE BLADE

Method for Rolling and Forming Titanium Alloy Rectangular Ring Blank into Irregular Thin-walled Ring

Owner:GUIZHOU ANDA AVIATION FORGING

Method for Rolling and Forming Stainless Steel Rectangular Ring Blank into Special-shaped Thin-walled Ring

ActiveCN103706737BGuaranteed biteGuaranteed final sizeRoll speed control deviceMetallurgyFeeding mode

The invention discloses a method for forming a special-shaped thin-wall ring from a stainless steel rectangular ring blank by rolling. In order to enable the rolling process to be continuously and stably performed, the invention discloses a reasonable feeding mode for a core roll, and moreover, the stainless steel rectangular ring blank is designed in a backstepping manner according to the shape and dimensions of the stainless steel special-shaped thin-wall ring, thus realizing forming for the special-shaped thin-wall ring from the stainless steel rectangular ring blank by rolling. The rolling method is mainly used for forming stainless steel special-shaped thin-wall rings in the fields of aviation, aerospace, industrial machinery and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

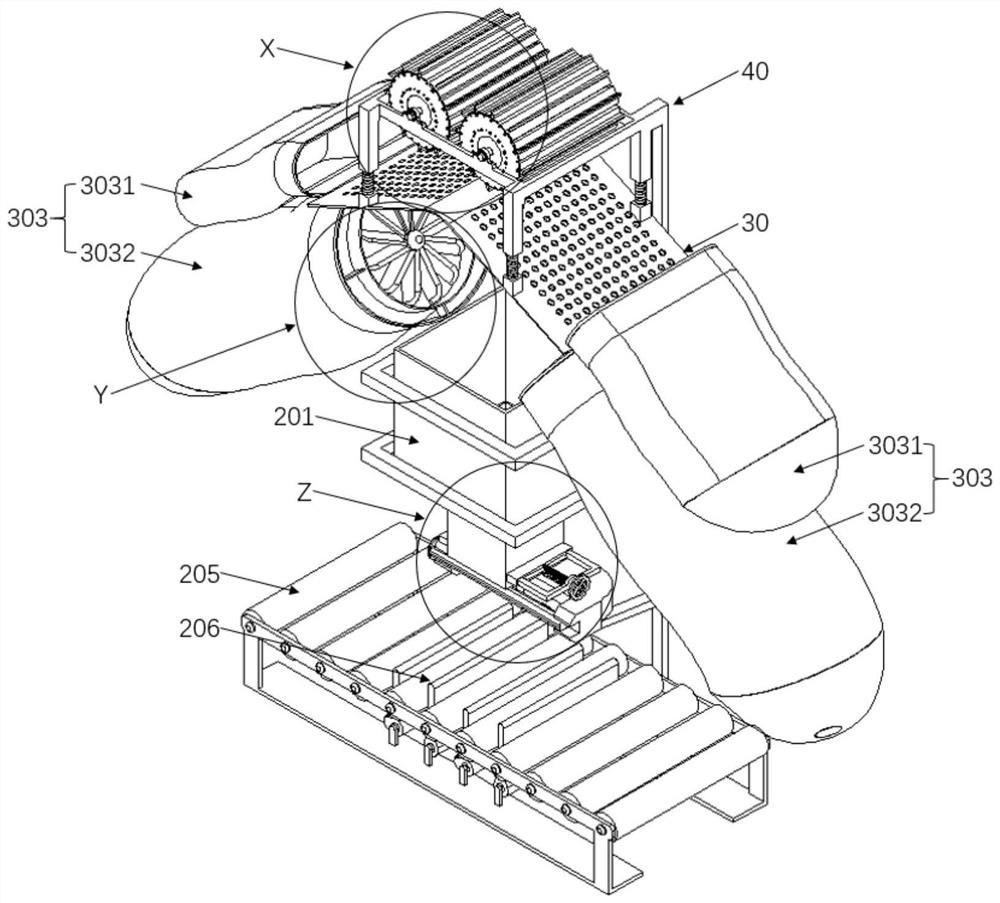

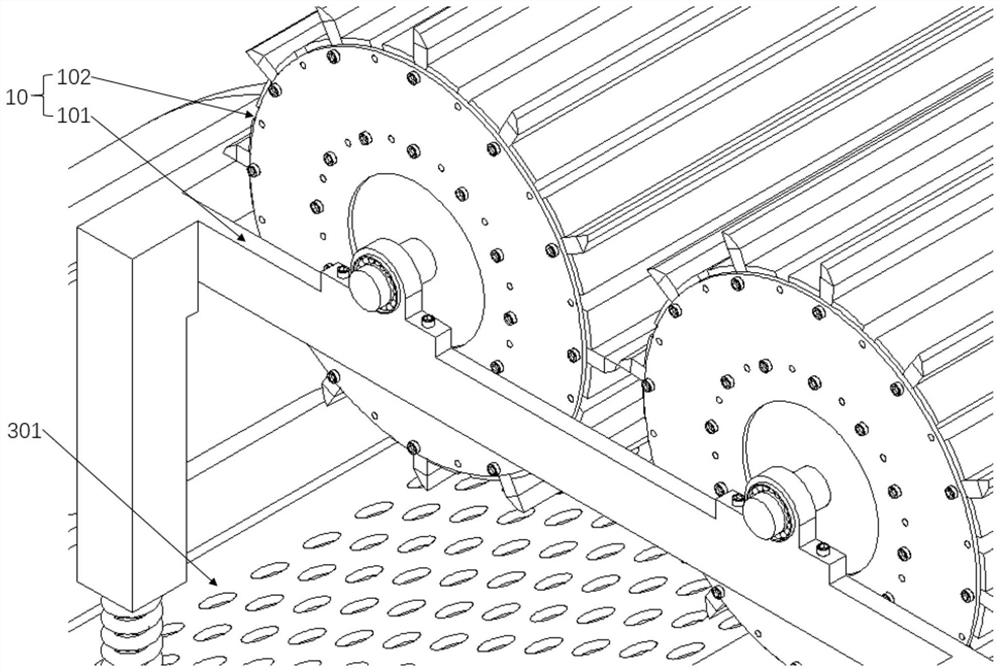

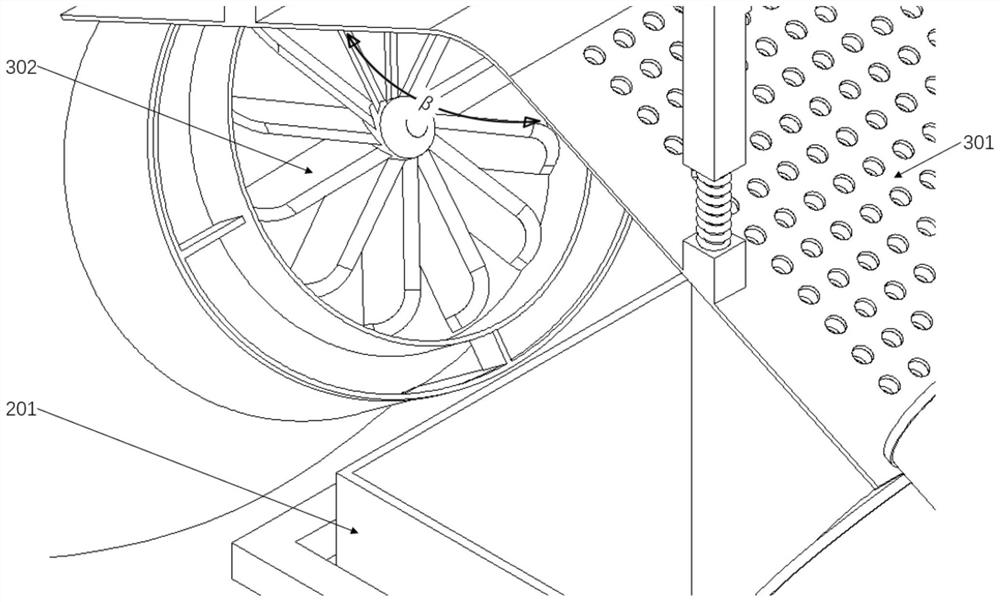

A masterbatch cutting and packaging device

ActiveCN113478675BImprove smooth performanceEasy to replacePackaging machinesMasterbatchProcess engineering

The invention discloses a master batch dicing and packing device, belonging to the technical field of master batch production equipment, comprising a dicing mechanism and a packing mechanism. It includes a roller, a knife slot is arranged on the roller, and ≥15 knife bodies with blades are arranged in the knife slot; a particle screening mechanism is arranged between the pelletizing mechanism and the packing mechanism; The particle screening mechanism includes a screen, a fan and a particle collection bag, and the screen is provided with a vibration device; the packaging mechanism includes a funnel with a discharge port at the bottom, and a packaging bag sealing machine is provided below the discharge port. A conveying wheel is arranged below the discharge port, and a shaking device is arranged on the conveying wheel; the hob of the device of the present invention is easy to maintain and replace, has traction capability, has fast dicing speed and high quality, and can perform different screening of large and small particles. And synchronous drying and cooling, high efficiency of packaging bags, small footprint and convenient operation.

Owner:常州富桐纤维新材料有限公司

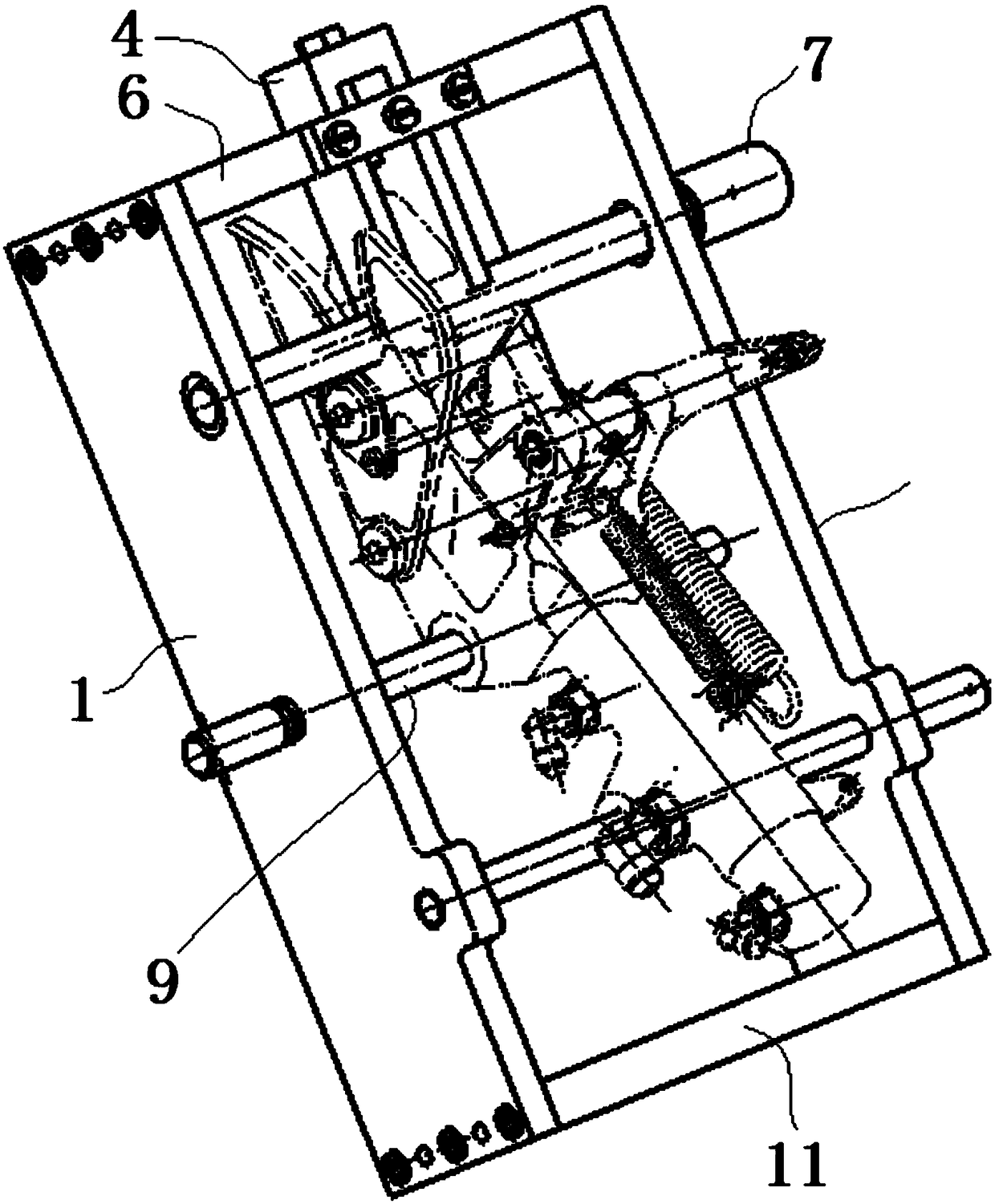

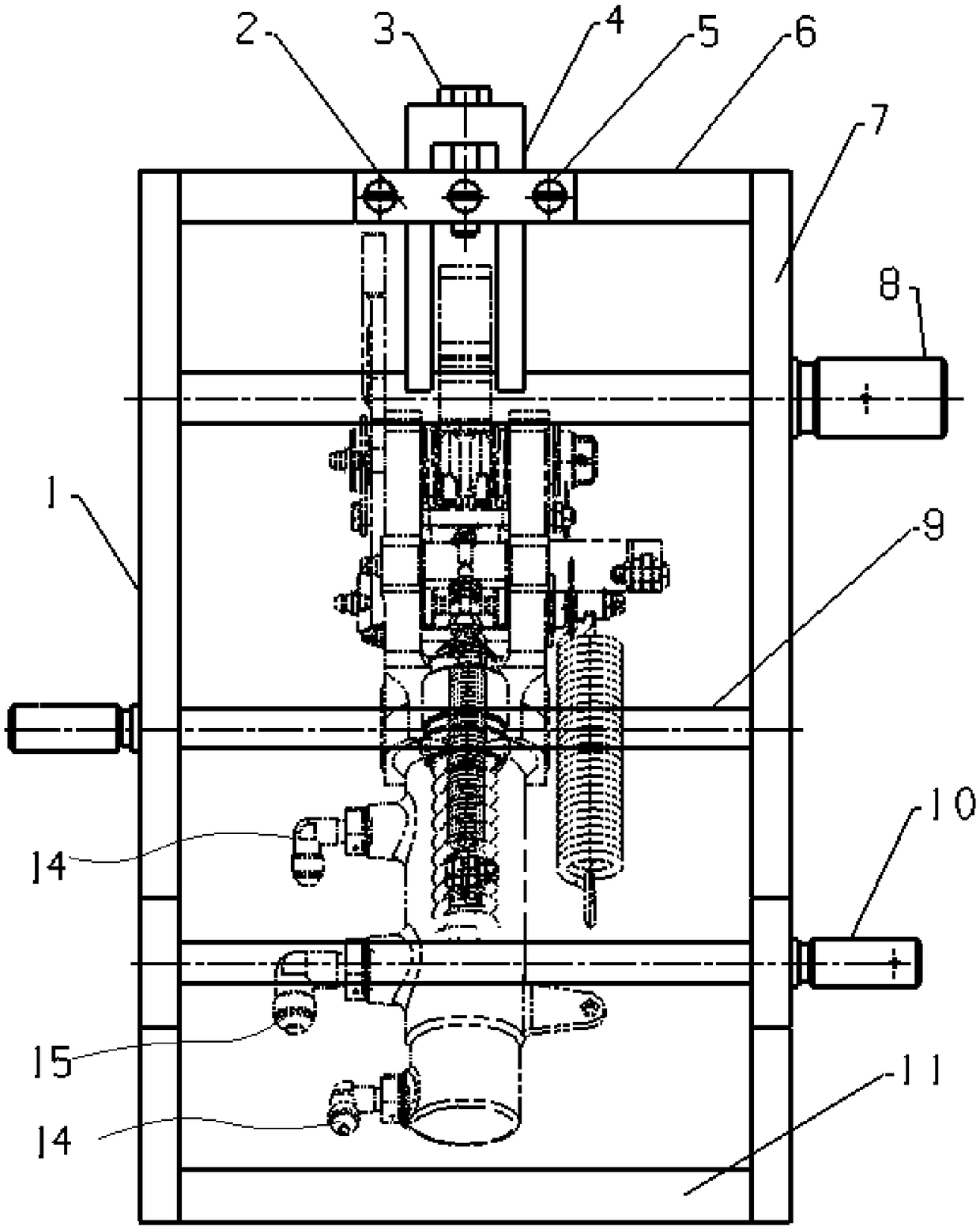

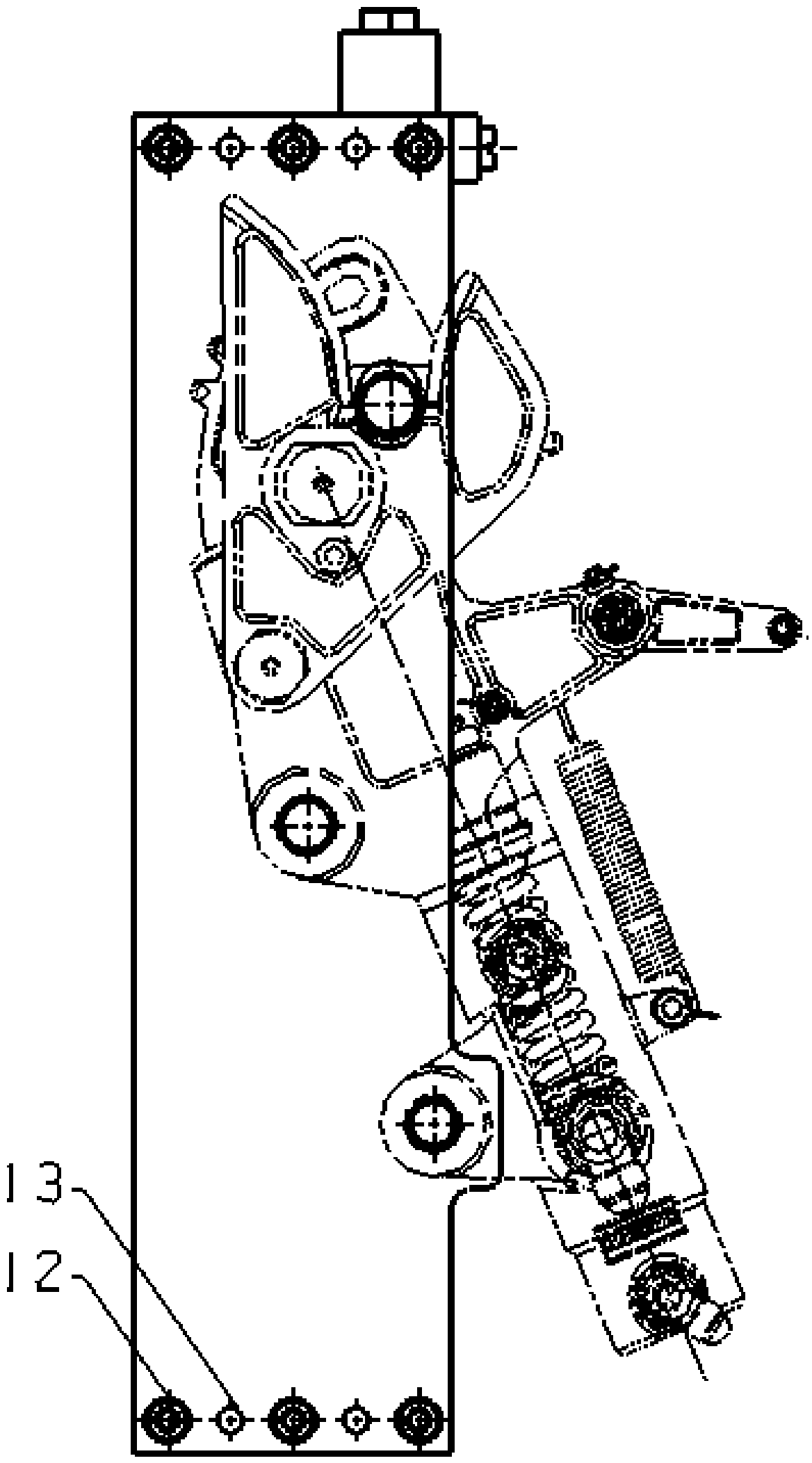

An uplock gap detection device and a detection assembly method

ActiveCN106370072BSize qualifiedGuarantee product qualityMechanical clearance measurementsMechanical engineeringGap detection

The invention discloses an upper lock gap detection device and a detection assembly method. The upper lock gap detection device comprises a support framework and a clamp body arranged on a work bench and used for fixing an upper lock. The bottom end of the support framework has a positioning surface positioned on the work bench; the top end of the support framework is provided with a fork shape member capable of moving up and down with respect to the support framework; the fork shape member is used for carrying out press adjustment on a lock hook of the upper lock; and the support framework is provided with a plurality of plug pins arranged transversely for press positioning of the upper lock after being assembled. The gap detection device can be used for a plurality of gap detection and dimension guarantee of the upper lock; and through reasonable process arrangement, the quality of the product is ensured, and meanwhile, higher production efficiency is also ensured.

Owner:LANDING GEAR ADVANCED MFG

Metal flange plastic lining layer machining process

PendingCN112706226ASize qualifiedThe process method is simpleMetal working apparatusComposite materialEngineering

The invention provides a metal flange plastic lining layer machining process. The metal flange plastic lining layer machining process comprises the following steps of 1, naturally placing a flange subjected to plastic lining to wait for cooling of a plastic lining layer; 2, cutting off redundant lining plastic corners obtained after flange face demolding through a saber saw; 3, sleeving the plastic-lined flange with a fixed mold, and clamping and fixing the fixed mold and the plastic-lined flange; and 4, cutting along the fixed mold through an engraving machine, and after cutting is completed, detaching the fixed mold. According to the metal flange plastic lining layer machining process, the process method is simple and convenient to operate, complex mechanical equipment does not need to be used, the practicability is higher, the purpose of assisting in cutting the flange plastic lining layer is achieved, and the flat flange plastic lining layer can be machined conveniently.

Owner:粤海滚塑科技(中山)有限公司

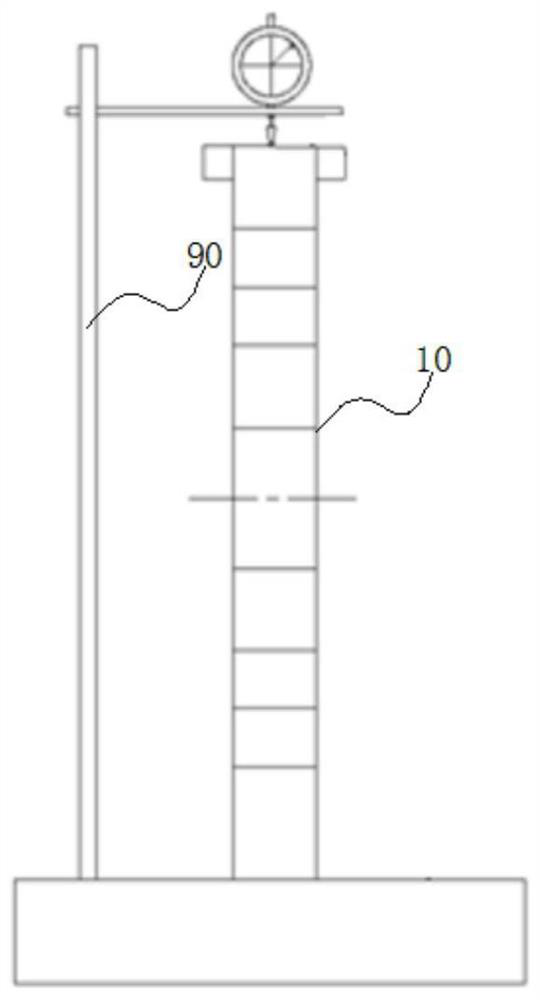

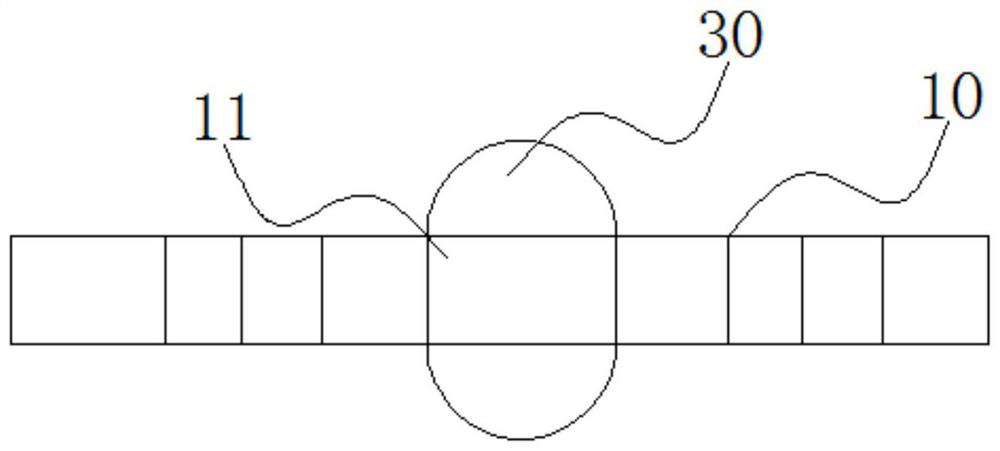

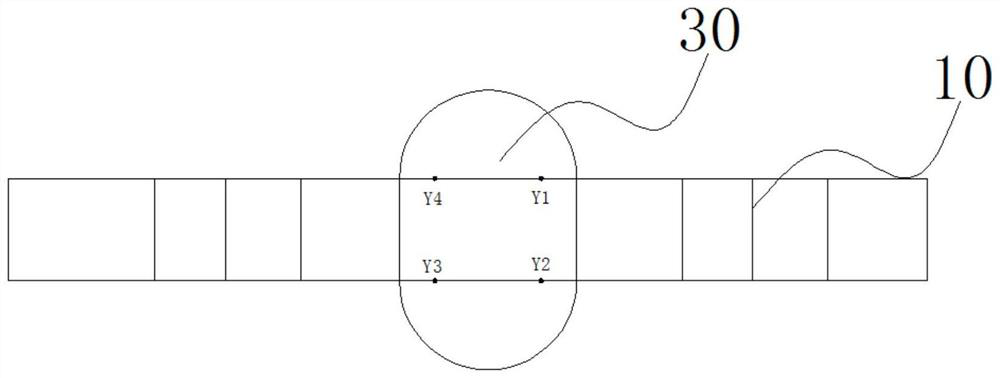

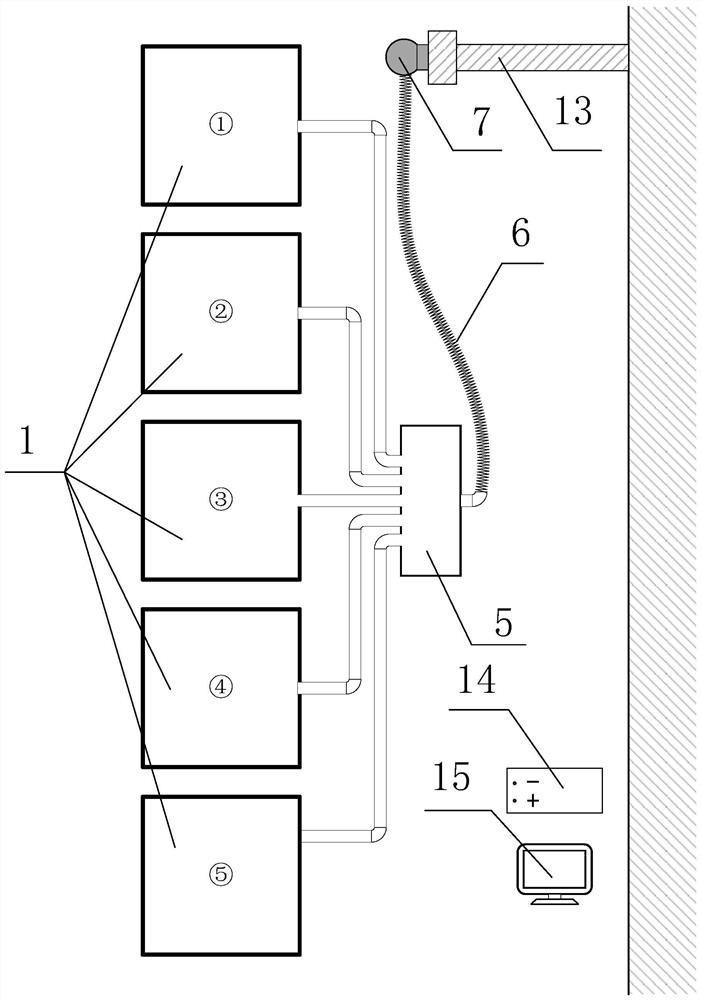

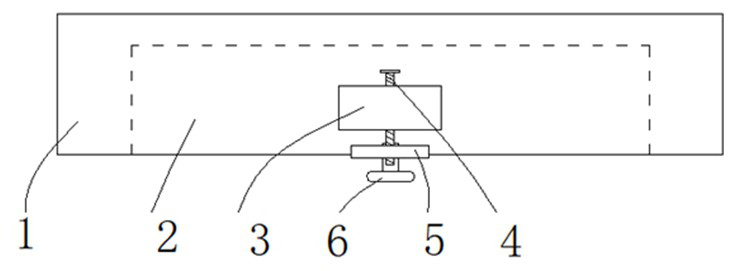

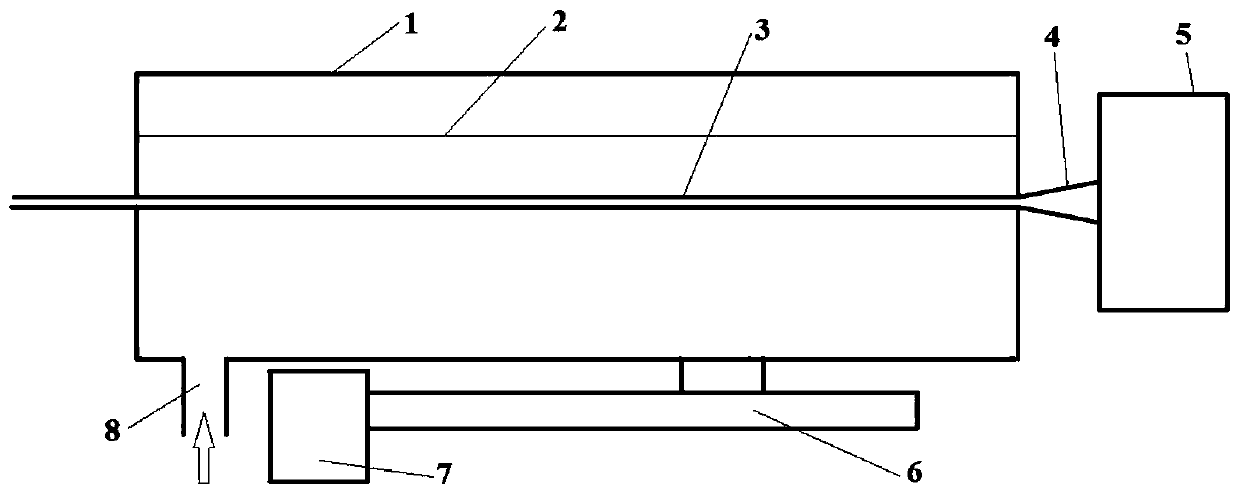

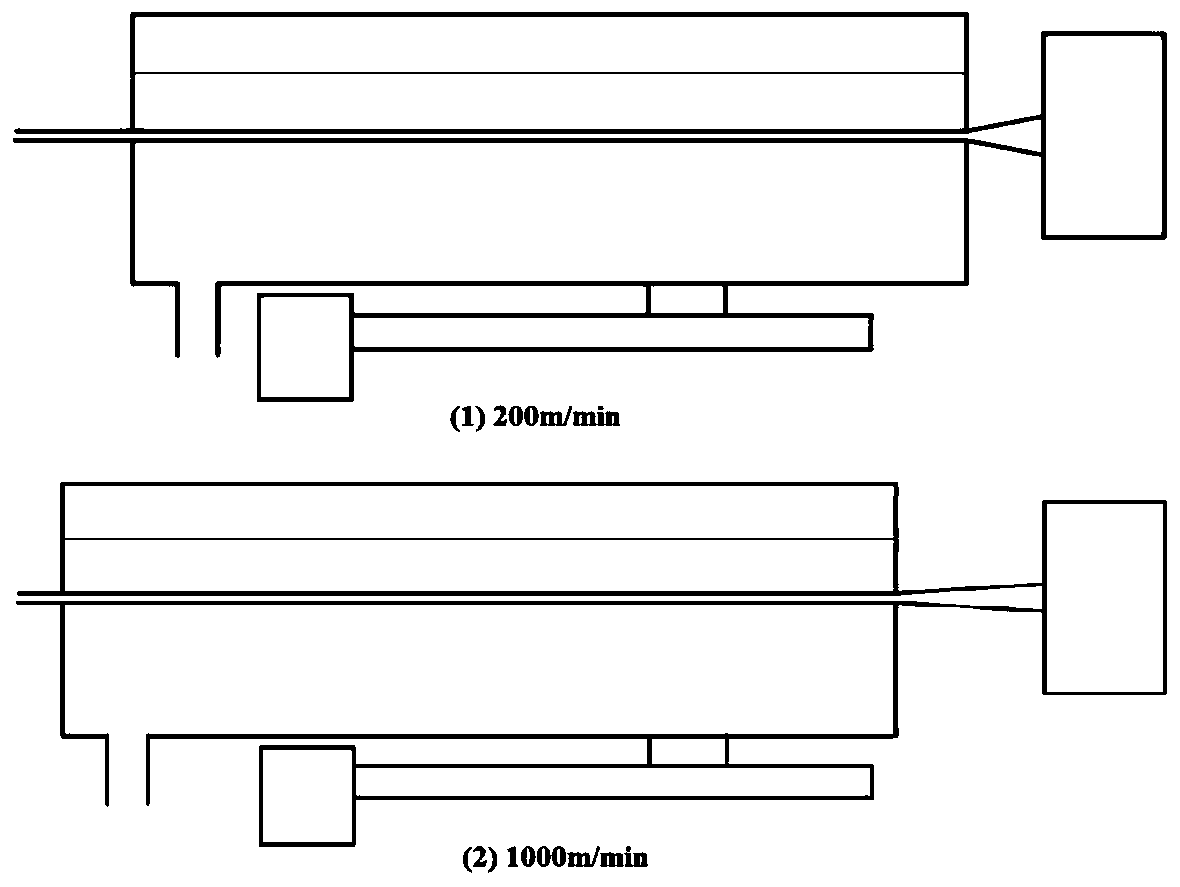

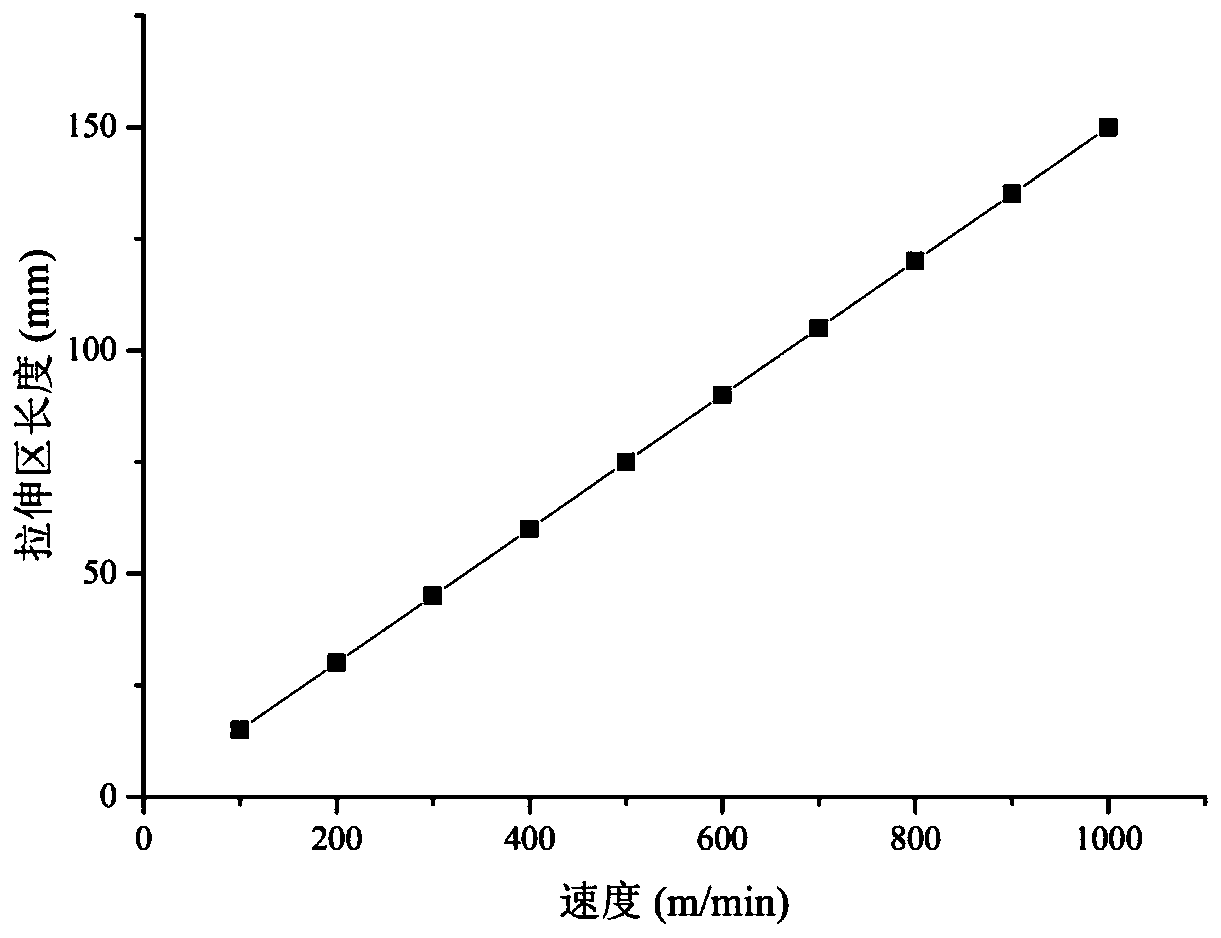

Adaptive cooling device and method for high-speed manufacturing of optical fiber loose tube

The invention discloses an adaptive cooling device for manufacturing a fiber loose tube at a high speed, the adaptive cooling device comprises a water tank, a water volume control unit, a position adjusting unit and a controller; the water tank is used for cooling and shaping the fiber loose tube, and the internal cooling water in the water tank in real time immerses the fiber loose tube; the water volume control unit is used to control the water volume of the water tank to in real time ensure that the cooling water in the water tank can immerse the fiber loose tube; the position adjusting unit is used to adjust the distance between the water tank and an extruder head, thereby adjusting the water inlet surface of a stretching zone to precisely control the cooling and shaping size of the fiber loose tube; the controller is used to control the water volume control unit and the position adjusting unit to work. The present invention also provides an adaptive cooling method for manufacturing the fiber loose tube at the high speed. The adaptive cooling device can precisely control the cooling and shaping size of the fiber loose tube and ensures the dimensional stability of the fiber loose tube in the speed increasing stage.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Shape processing method for PTFE antenna PCB product without internal positioning narrow edges

ActiveCN109842991AGood Dimensional AccuracyProcessing technology is less difficultPrinted circuit manufactureEngineeringOxide

The invention discloses a shape processing method for a PTFE antenna PCB product without internal positioning narrow edges. The shape processing method is suitable for an ultra-narrow antenna PCB madeof a PTFE-based material, can ensure that the antenna PCB is qualified in size, has no oxides and no burr defects after the shape processing, guarantees product quality and eradicates the defects oftoo large or too small size caused by shape processing.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH +2

Method for Rolling and Forming Aluminum Alloy Rectangular Ring Blank into Irregular Thin-walled Ring

Owner:GUIZHOU ANDA AVIATION FORGING

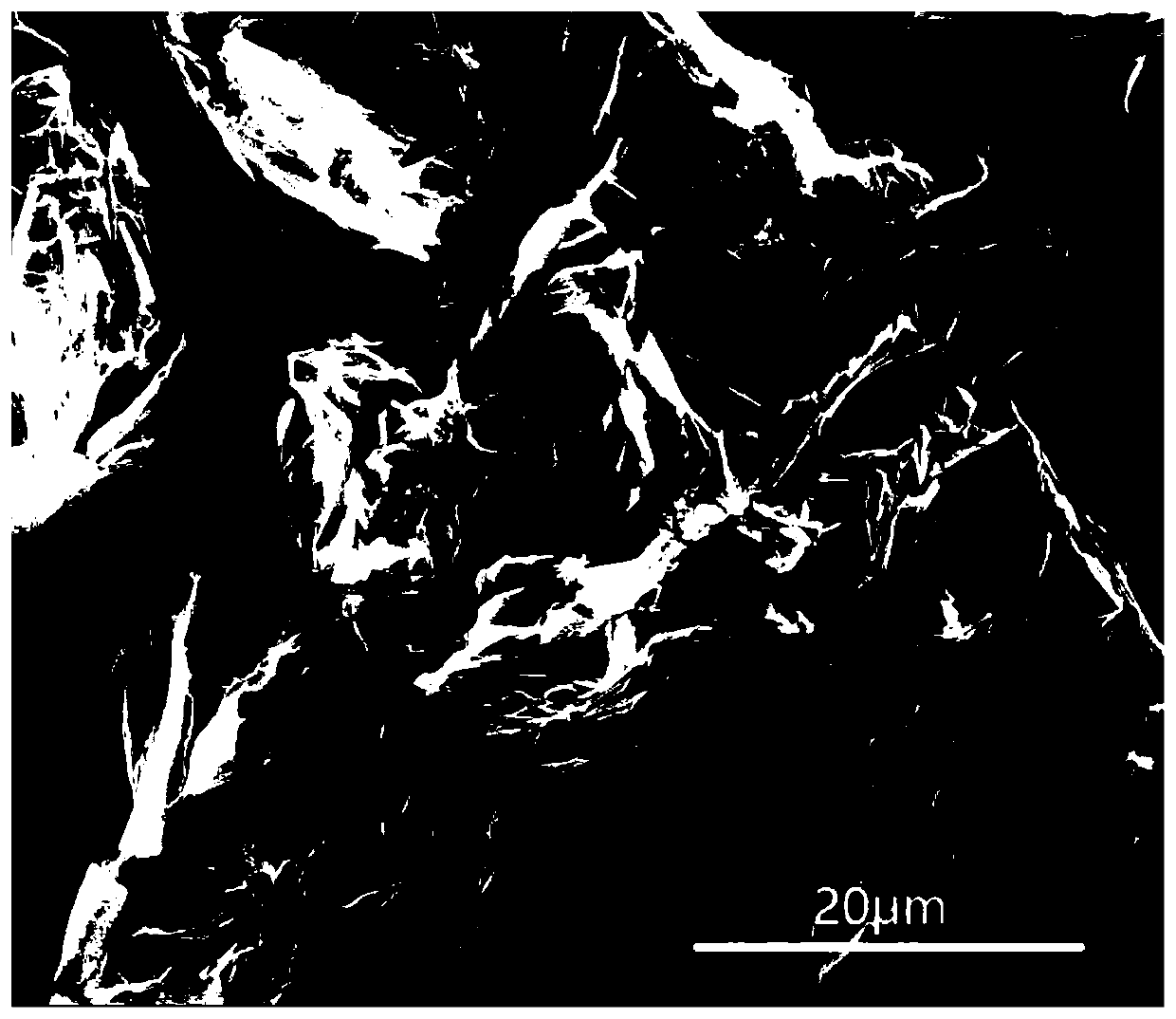

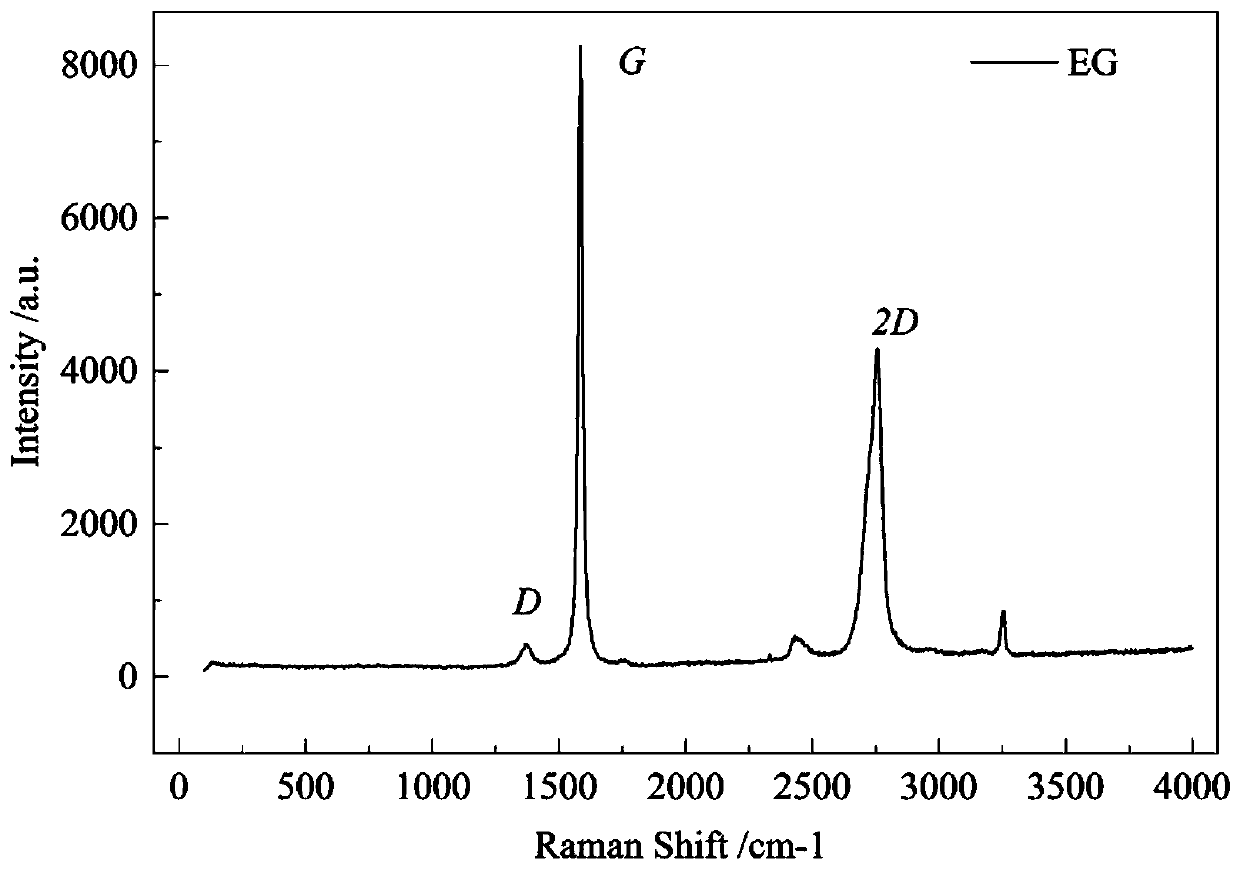

A kind of preparation method of graphene quantum dot

The invention provides a preparation method for a graphene quantum dot. The preparation method comprises the following steps: preparing low-temperature expanded graphite; dispersing the low-temperature expanded graphite in a sodium dodecyl sulfate aqueous solution, carrying out ultrasonic treatment and centrifuging treatment, and subjecting a supernatant to filtering so as to obtain a transparentlight-black solution; and subjecting the transparent light-black solution to dialysis in deionized water, and removing impurities which are soluble in sodium dodecyl sulfate so as to obtain a transparent light-gray graphene quantum dot solution. The preparation method for the graphene quantum dot provided by the invention has the advantages of clear process and principle, simple and controllable operation, economy, high efficiency, sustainability, high product yield and high product quality through intercalation-stripping-dispersion treatment to an expanded graphene raw material by combinationof high-power ultrasonic wave in an SDS solution.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

A kind of thermoplastic polyether ester elastomer foaming material and preparation method thereof

The invention relates to a thermoplastic polyether ester elastomer foaming material and a preparation method thereof. The foaming material is prepared from the following raw material components in parts by weight: 50 to 95 parts of polyether ester TPEE (Thermoplastic Polyether Ester Elastomer), 0 to 50 parts of a modified polymer material, 0.05 to 2 parts of a nucleating agent and 0.1 to 5 parts of a foaming agent; when the adding amount of the modified polymer material is 0, the difference (T2-T1) of the melting temperature T2 of the polyether ester TPEE and the Vicat softening point temperature T1 is greater than or equal to 30 DEG C. Compared with the prior art, a continuous foaming formula and a continuous foaming technology of the TPEE are provided, and the problems that the foaming material with stale performance is difficult to prepare by existing TPEE, especially continuous foaming is difficult to realize are solved.

Owner:NANTONG DE NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com