Internally acting type ductile iron jacking pipe for integral trenchless pipeline construction

A pipeline construction, trenchless technology, applied in the direction of pipeline laying and maintenance, pipe/pipe joint/pipe fittings, casting, etc. It can achieve the effect of realizing mass production, improving the qualified rate of one-time hydraulic pressure, and saving the investment cost of mold and tooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

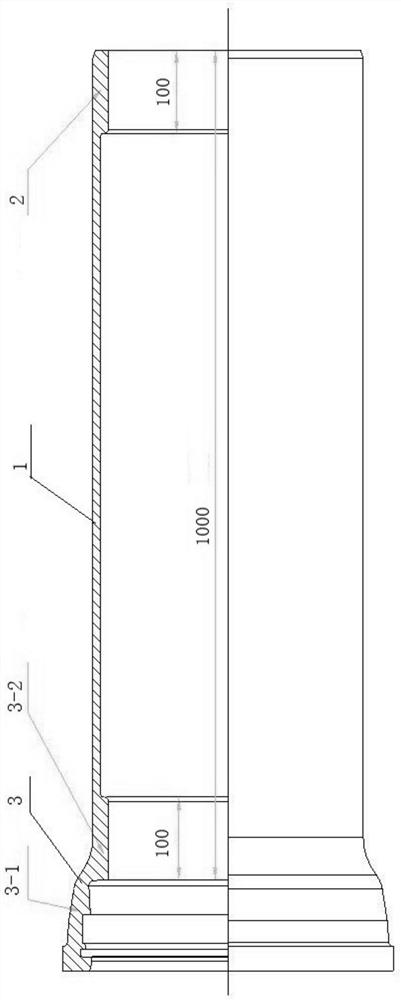

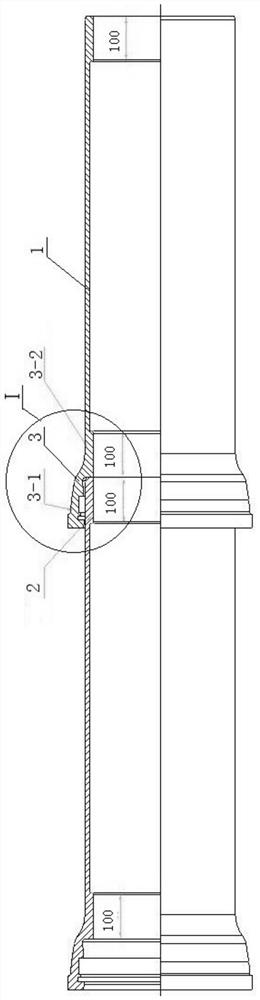

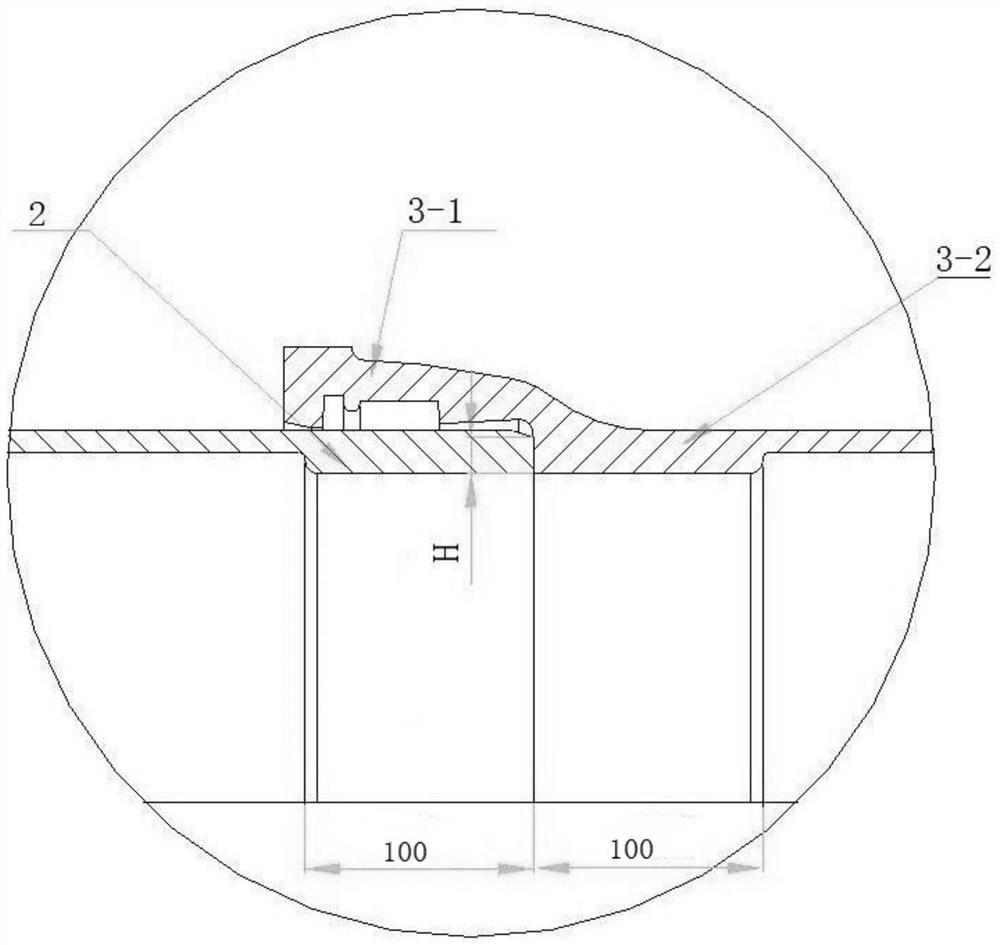

[0042] Casting DN1200, length 3 meters, ductile iron pipe jacking method for internal-action integral trenchless pipeline construction is as follows:

[0043] (1) First cut and bond the pipe body to a length of 3 meters according to the requirements, and then bond the DN1200 socket and DN1200 socket in order;

[0044] (2) Evenly brush the outside of the bonded casting with refractory paint, and send it to the drying room for drying;

[0045] (3) Bond the dried lost foam and the sprue and put them together in the negative pressure sand box; the negative pressure sand box is equipped with a vacuum tube, and the control valve is adjusted when the vacuum pump is working to control the negative pressure;

[0046] (4) Fill dry sand and vibrate, and then vacuumize after coating; the process of filling dry sand is to fill sand while vibrating, after the sand box is filled, cover the upper surface with a plastic film to seal, and vacuum to compact the molding sand;

[0047] (5) Inject...

Embodiment 2

[0051] Casting DN1400, length 3 meters, ductile iron pipe jacking method for internal action integral trenchless pipeline construction is as follows:

[0052] (1) First cut and bond the pipe body with a length of 3 meters according to the requirements, and then bond the DN1400 socket and DN1400 socket in order;

[0053] (2) Evenly brush the outside of the bonded casting with refractory paint, and send it to the drying room for drying;

[0054] (3) Bond the dried lost foam and the sprue and put them together in the negative pressure sand box; the negative pressure sand box is equipped with a vacuum tube, and the control valve is adjusted when the vacuum pump is working to control the negative pressure;

[0055] (4) Fill dry sand and vibrate, and then vacuumize after coating; the process of filling dry sand is to fill sand while vibrating, after the sand box is filled, cover the upper surface with a plastic film to seal, and vacuum to compact the molding sand;

[0056] (5) Inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com