Shape processing method for PTFE antenna PCB product without internal positioning narrow edges

A technology of shape processing and PTFE, which is applied in the field of PCB manufacturing, can solve the problems of small size that does not meet the cleaning requirements of finished product cleaning machines, difficult to clean oxides, and low efficiency, so as to meet mass production, ensure product quality, and eliminate The effect of being oversized or undersized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

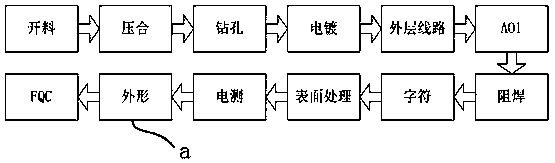

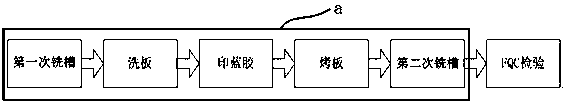

[0026] Such as Figure 1-2 As shown in , the shape processing method a of a narrow-side antenna PCB provided by an embodiment of the present invention can be applied to the existing manufacturing process of a narrow-side antenna PCB, and has wide application and strong versatility. A shape processing method a of a narrow-side antenna PCB, comprising the steps of:

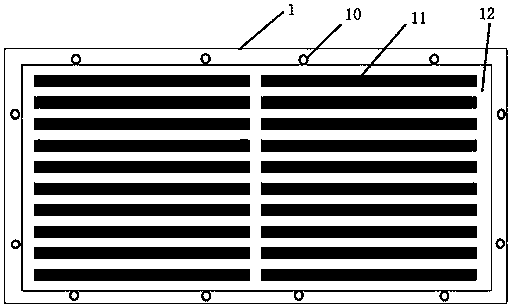

[0027] S1: if image 3 As shown, 20 antenna PCB11 are arranged in a matrix on the large board body 1, and the upper and lower adjacent antenna PCB11 are set as a unit 2. The four sides of the antenna PCB11 are surrounded by the part to be processed 12, and are located near the frame of the large board body 1. Positioning holes 10 are set;

[0028] S2: For the first slot milling, use a CNC machine tool to mill a slot on the part 12 to be processed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com