Resin and plastic belt pulley and its manufacturing method

A manufacturing method and pulley technology, applied in belts, other household appliances, applications, etc., can solve the problems of dimensional stability, poor wear resistance and heat resistance, poor wear resistance, and difficult molding processing, etc., to achieve Ease of recycling, excellent wear resistance, and good dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

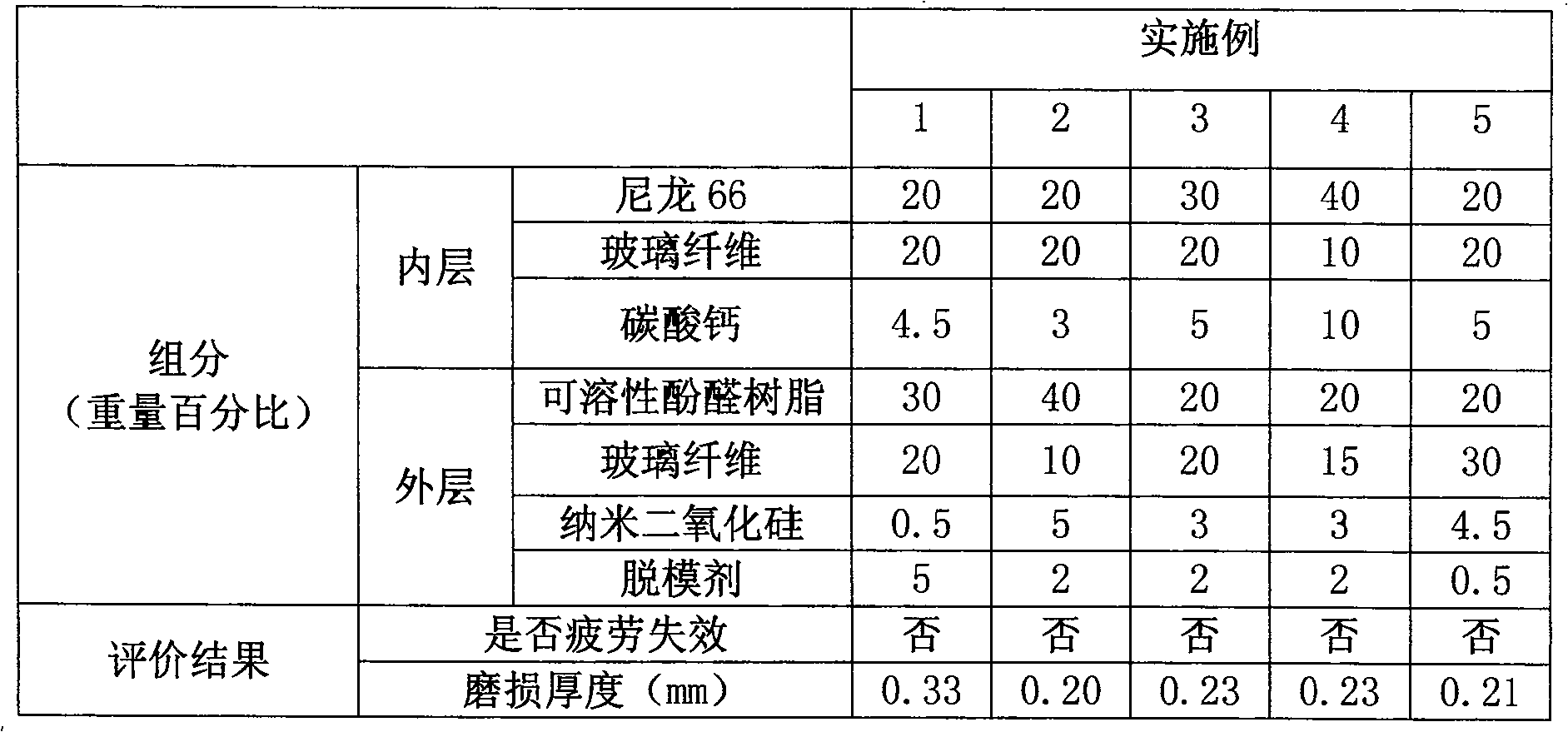

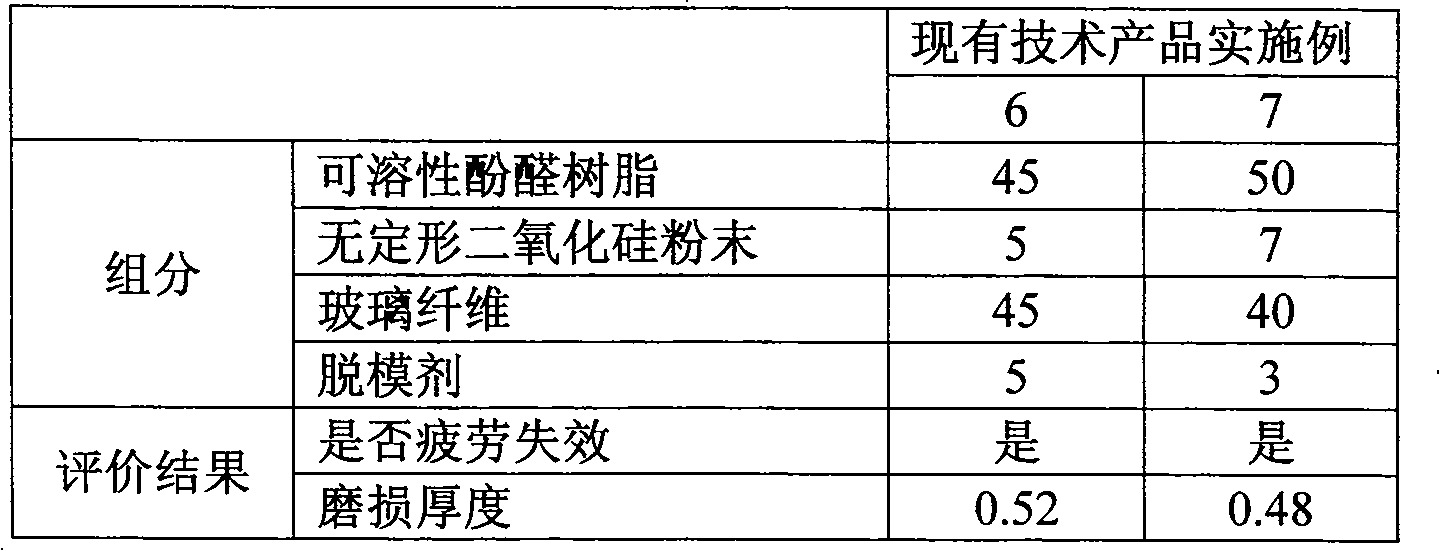

[0018] The following examples are only to further illustrate the present invention in detail, and the present invention should not be limited to the specific and express contents of the following experimental examples without violating the gist of the present invention.

[0019] The double resin plastic pulley in the embodiment that the present invention enumerates comprises inner and outer two layers, wherein,

[0020] Inner layer material: 20-40% by weight of nylon 66, 1-10% by weight of calcium carbonate, and 10-30% by weight of glass fiber.

[0021] Outer layer materials: 20-40% by weight of phenolic resin, 0.5-5% by weight of nano silicon dioxide, 10-30% by weight of glass fiber and 0.5-5% by weight of release agent.

[0022] As the phenolic resin, novolac phenolic resin and / or resole phenolic resin are preferable. (In the embodiment, specify which one is, if both components have, then illustrate their respective proportions)

[0023] During the manufacturing process, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com