A kind of thermoplastic polyether ester elastomer foaming material and preparation method thereof

A technology for thermoplastic polyetherester and foaming materials, which is applied in the field of preparation of thermoplastic polyetherester TPEE elastomer foaming materials, can solve the problems of difficulty in continuous foaming, difficulty in producing foamed materials with stable performance, etc., and achieve excellent appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

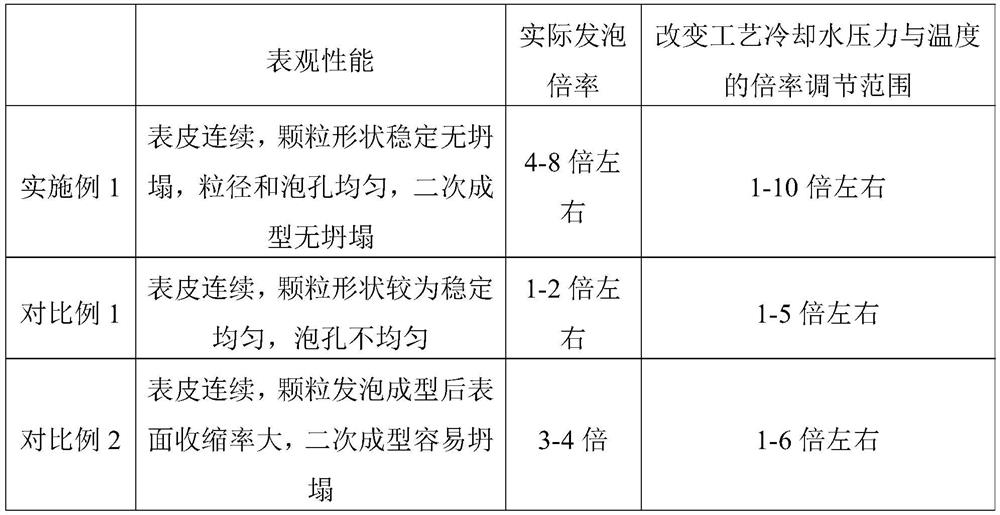

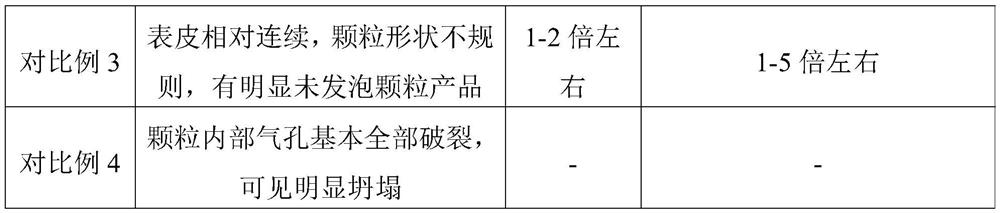

Examples

Embodiment 1

[0039] A thermoplastic polyether ester elastomer foaming material, wherein the necessary raw materials are: 80 parts of polyether ester TPEE, 0.5 parts of nucleating agent, and 1.5 parts of foaming agent. Among them, the melting temperature T of polyether ester TPEE 2 (Test standard ISO11357) and Vicat softening point temperature T 1 (Test standard ISO 306) difference T 2 -T 1 =75°C, tensile strength (test standard ISO 527)=25Mpa, elongation at break (test standard ISO527) is approximately equal to 850%, the nucleating agent is modified nano-calcium carbonate, and the blowing agent is carbon dioxide.

[0040] In this embodiment, the foam material is preferably prepared by underwater pelletizing and foaming, and the specific process is as follows:

[0041] (1): Take polyether ester TPEE and other raw material components other than foaming agent and add them to the twin-screw extruder, control the temperature to the melting temperature of the material, so that the material ca...

Embodiment 2

[0059] A thermoplastic polyether ester elastomer foaming material, wherein the necessary raw materials are: 50 parts of polyether ester TPEE, 0.05 part of nucleating agent, and 0.1 part of foaming agent. Among them, the melting temperature T of polyether ester TPEE 2 (Test standard ISO11357) and Vicat softening point temperature T 1 (Test standard ISO 306) difference T 2 -T 1 It is about 30°C, the tensile strength (test standard ISO 527) is about 30Mpa, the elongation at break (test standard ISO527) is about 600%, the nucleating agent is 2-10um talcum powder, and the foaming agent is nitrogen.

[0060] In this embodiment, the foam material is prepared by underwater granulation and foaming, and the specific process is as follows:

[0061] (1): Take polyether ester TPEE and other raw material components other than the foaming agent and add them to the twin-screw extruder, so that the material is hot-melted under the action of high temperature, high pressure and high mechanica...

Embodiment 3

[0066] A thermoplastic polyether ester elastomer foaming material, wherein the necessary raw materials are: 95 parts of polyether ester TPEE, 0.1 part of nucleating agent, and 5 parts of foaming agent. Among them, the melting temperature T of polyether ester TPEE 2 (Test standard ISO11357) and Vicat softening point temperature T 1 (Test standard ISO 306) difference T2 -T 1 ≥30°C, tensile strength (test standard ISO 527) ≥15Mpa, elongation at break (test standard ISO527) ≥300%, nucleating agent is modified montmorillonite, foaming agent is carbon dioxide and nitrogen by volume ratio 1 :1 mix.

[0067] In this embodiment, the foam material is prepared by underwater granulation and foaming, and the specific process is as follows:

[0068] (1): Take polyether ester TPEE and other raw material components other than the foaming agent and add them to the twin-screw extruder, so that the material is hot-melted under the action of high temperature, high pressure and high mechanical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com