A kind of preparation method of graphene quantum dot

A graphene quantum dot and expanded graphite technology, which is applied in the field of preparation of high-quality graphene quantum dots, can solve the problems of harsh preparation conditions, difficult separation and purification, complicated operation, etc., and achieves clear process and principle, simple and controllable operation. , the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment relates to a preparation method of low-temperature expanded graphite, specifically:

[0039] One, prepare the mixed acid of sulfuric acid and nitric acid, control the massfraction of sulfuric acid wherein is 70%, the massfraction of nitric acid is 68%;

[0040] 2. Add natural flake graphite to the mixed acid of sulfuric acid and nitric acid, and drop in potassium permanganate to control the ratio of natural flake graphite, mixed acid of sulfuric acid and nitric acid, and potassium permanganate to be 1g: 3mL: 0.11g, at 80 ℃ for constant temperature water bath reaction;

[0041] 3. Deacidify the reaction solution, wash it with water until the pH value is 6-7, dry it to constant weight, and undergo high-temperature instantaneous expansion treatment at 300-600° C. to obtain low-temperature expanded graphite.

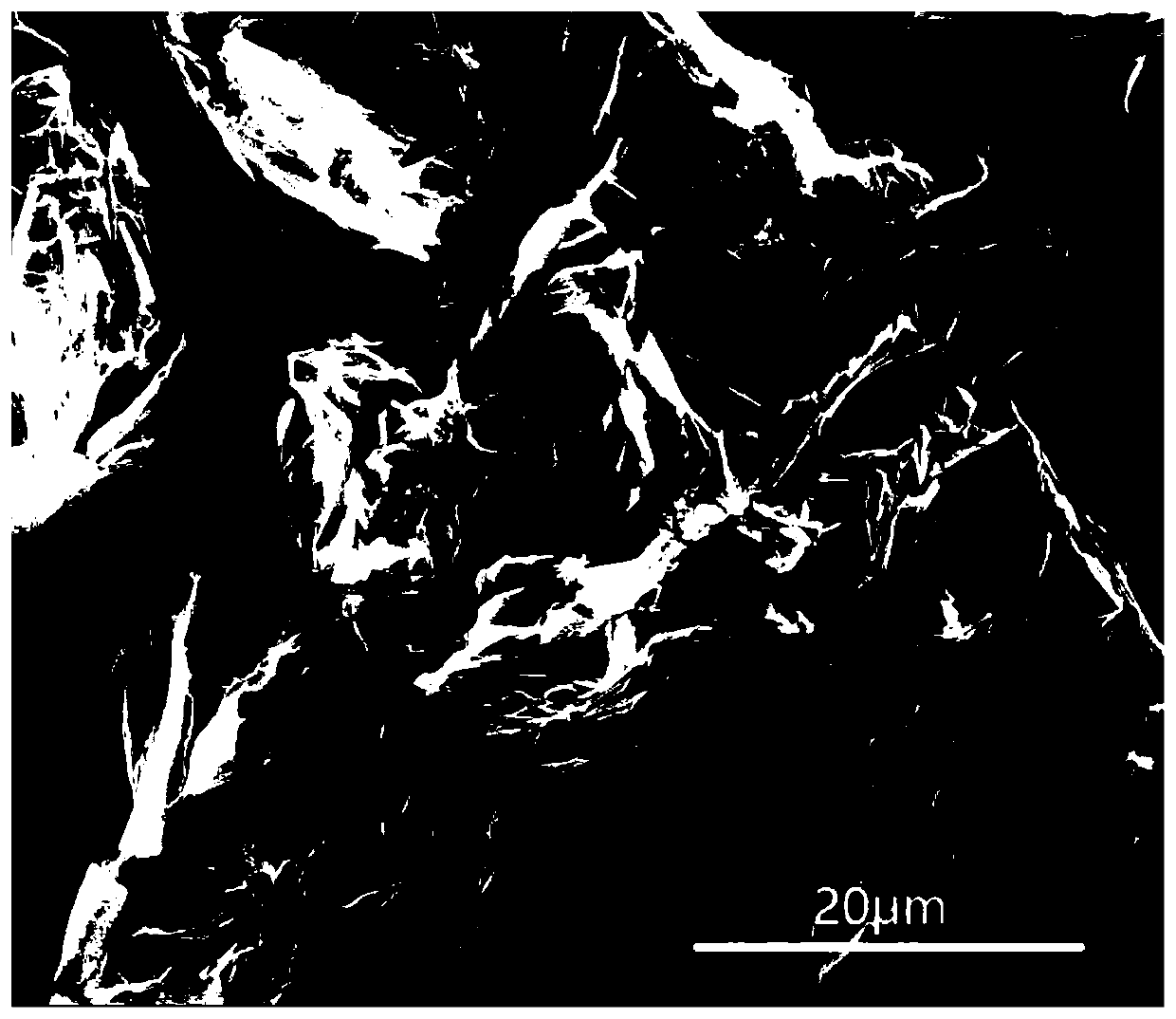

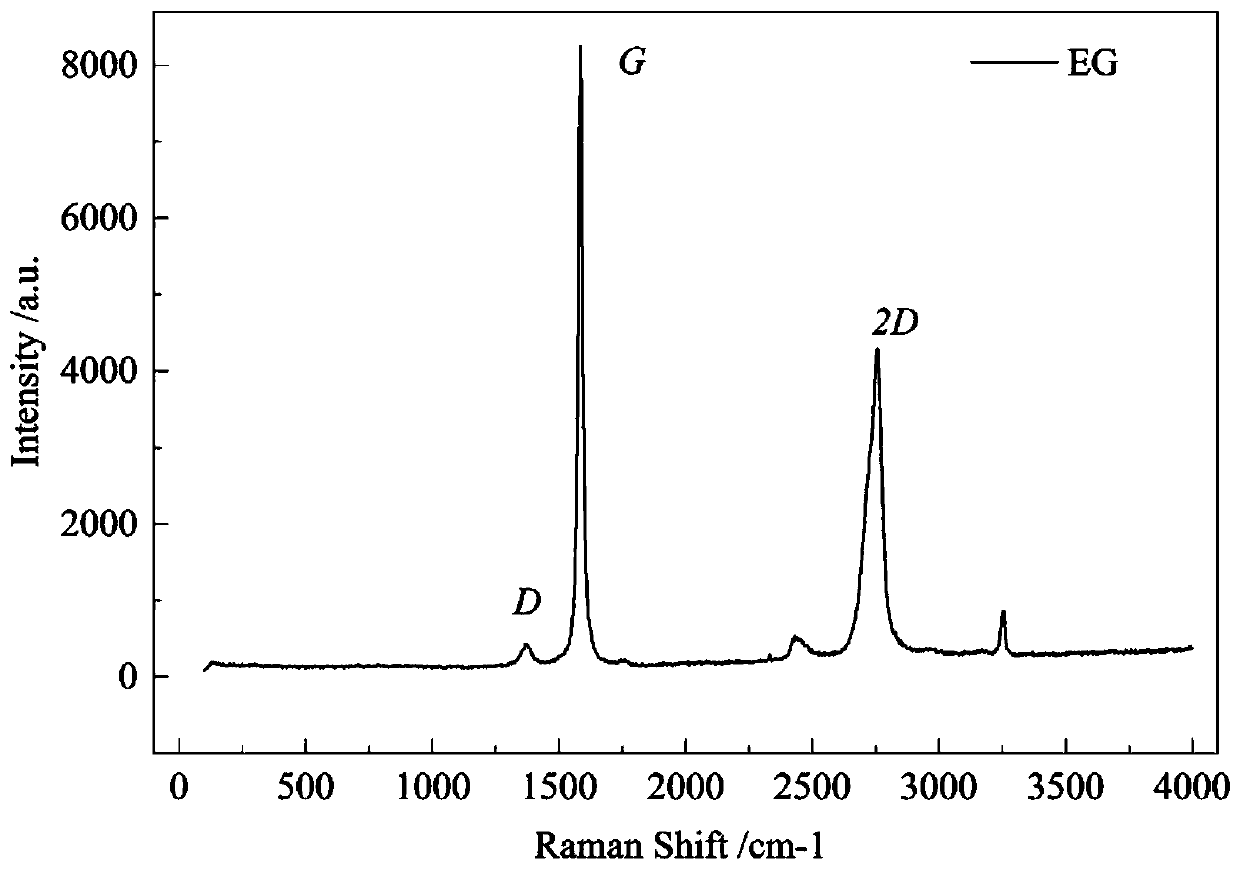

[0042] The TEM and Raman spectrograms of the transmission electron micrographs of the low-temperature expanded graphite prepared in this embodiment a...

Embodiment 2

[0044] The present embodiment relates to a kind of preparation method of graphene quantum dot, specifically:

[0045] One, utilizing the weakly oxidized low-temperature expanded graphite prepared in Example 1;

[0046] 2. Fully mix 40mL of SDS aqueous solution with a concentration of 1.5mg / mL and 20mg of expanded graphite powder, stir evenly, and use a pulsed ultrasonic wave with a power of 800W to conduct controllable ultrasonic treatment on the mixed solution for 4 hours to obtain a dark black solution.

[0047] 3. Separation and purification of the dark black solution after treatment, including high-speed centrifugation (8000rpm, 10min, keep the supernatant), vacuum filtration (Φ0.22μm PTFE filter membrane, keep the filtered solution), deionization Water dialysis treatment (MWCO=8000-14000Da, 24h), that is, a transparent light gray graphene quantum dot solution is prepared.

[0048] The graphene quantum dots prepared by the method have a concentrated size of about 35nm, a co...

Embodiment 3

[0050] The present embodiment relates to a kind of preparation method of graphene quantum dot, specifically:

[0051] One, utilizing the weakly oxidized low-temperature expanded graphite prepared in Example 1;

[0052] 2. Fully mix 40mL of SDS aqueous solution with a concentration of 1.5mg / mL and 20mg of expanded graphite powder, stir evenly, and use a pulsed ultrasonic wave with a power of 1000W to conduct controllable ultrasonic treatment on the mixed solution for 4 hours to obtain a deep black solution.

[0053] 3. Separation and purification of the dark black solution after treatment, including high-speed centrifugation (8000rpm, 10min, keep the supernatant), vacuum filtration (Φ0.22μm PTFE filter membrane, keep the filtered solution), deionization Water dialysis treatment (MWCO=8000-14000Da, 24h), that is, a transparent light gray graphene quantum dot solution is prepared.

[0054] The graphene quantum dots prepared by the method have a concentrated size of about 18 nm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com