Patents

Literature

273results about How to "Structural damage is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Powder metallurgy preparation method of carbon nanotube reinforced aluminum alloy composite material

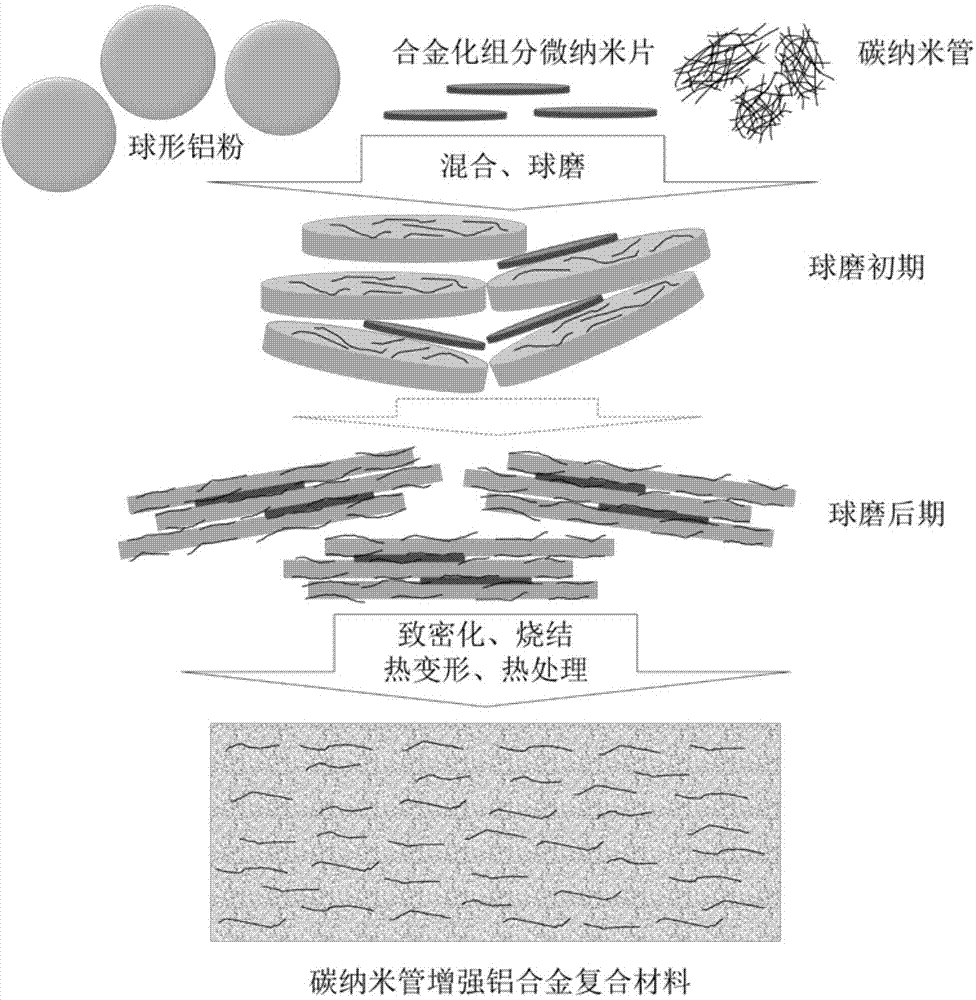

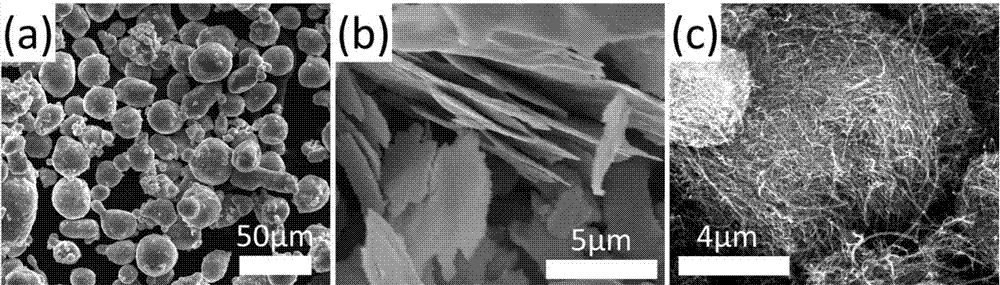

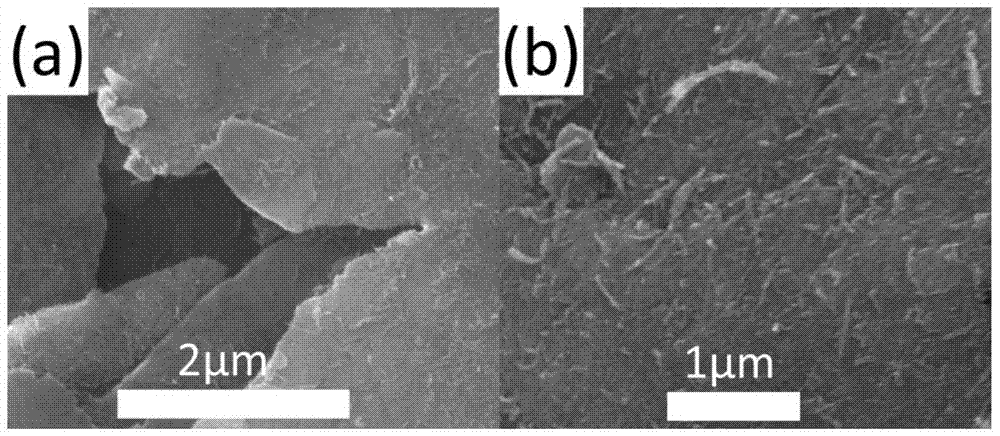

ActiveCN103789564ARapid precipitation strengtheningReliable and efficient processMicro nanoThermal deformation

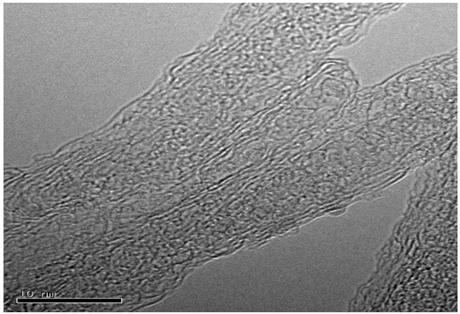

The invention provides a powder metallurgy preparation method of a carbon nanotube reinforced aluminum alloy composite material. The method comprises the following steps: pre-preparing micro-nano flake powder of an alloying component, subsequently ball-milling the powder with a carbon nanotube and spherical pure aluminum powder to prepare flake composite powder, and further performing densifying, sintering, thermal deformation processing and thermal treatment to achieve alloying so as to finally obtain the carbon nanotube reinforced aluminum alloy composite material. Uniform compounding of the matrix aluminum powder, the carbon nanotube and the alloying component can be achieved through limited ball-milling, and meanwhile dangerous elements or uneasy grinding elements such as magnesium and silicon which are high in activity and likely to combust and explode are avoided by adopting the stable and easily ground pre-alloying aluminum powder, so that the security and the reliability are improved; in addition, because of large interlayer boundary and small layer thickness distance, the flake structure is beneficial for uniformly dispersing the alloying component and forming refined dispersed separated phase. The method is beneficial for bringing the effects of composite reinforcement of carbon nanotubes and alloy reinforcement into play to the maximum extent, is energy-saving and time-saving, and is safe and feasible.

Owner:SHANGHAI JIAO TONG UNIV

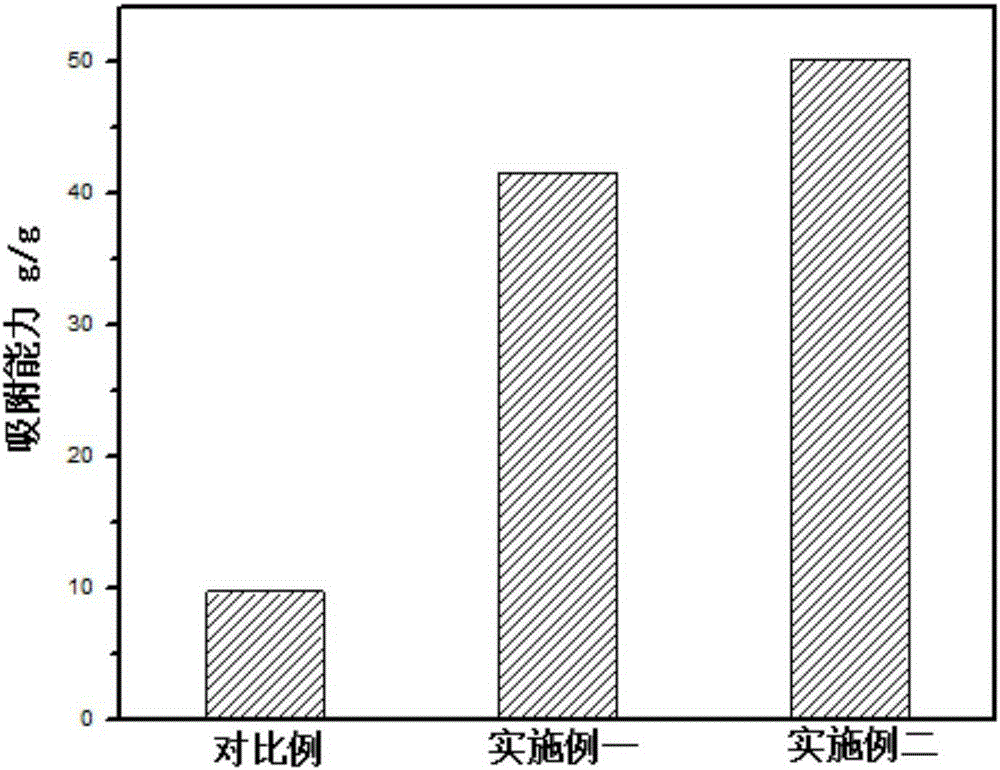

Preparation method of graphene oxide/silicon dioxide hybrid aerogel

A preparation method of graphene oxide / silicon dioxide hybrid aerogel comprises the following steps: A, adding 0.05-0.1 mol of a precursor into 9-18 ml of distilled water and dropwise adding a hydrolyst with its concentration of 0.2-0.6 mol / L into the precursor aqueous solution, wherein molar ratio of the hydrolyst to the precursor is 1:20-1:100; stirring at 20-30 DEG C for 5-8 h; adjusting pH value to 6-7 and stirring for 5-45 min so as to obtain a dispersion containing silicon dioxide microspheres; B, adding water to dilute the silicon dioxide microsphere dispersion by 5-50 times, carrying out iso-volume mixing on the diluted silicon dioxide microsphere dispersion and a graphene oxide dispersion with its concentration being 0.6-2 mg / ml, stirring for 10-30 min, carrying out ultrasonic treatment for 10-30 min so as to obtain graphene oxide / silicon dioxide hybrid aerogel; and C, freezing the hybrid aerogel under liquid nitrogen for 5-10 min, freeze-drying and dewatering to obtain the graphene oxide / silicon dioxide hybrid aerogel. The method is environmentally friendly, and the technology is simple. The prepared hybrid aerogel has advantages of complete gel network structure, high porosity, good adsorptivity, high strength, low density and the like.

Owner:SOUTHWEST JIAOTONG UNIV

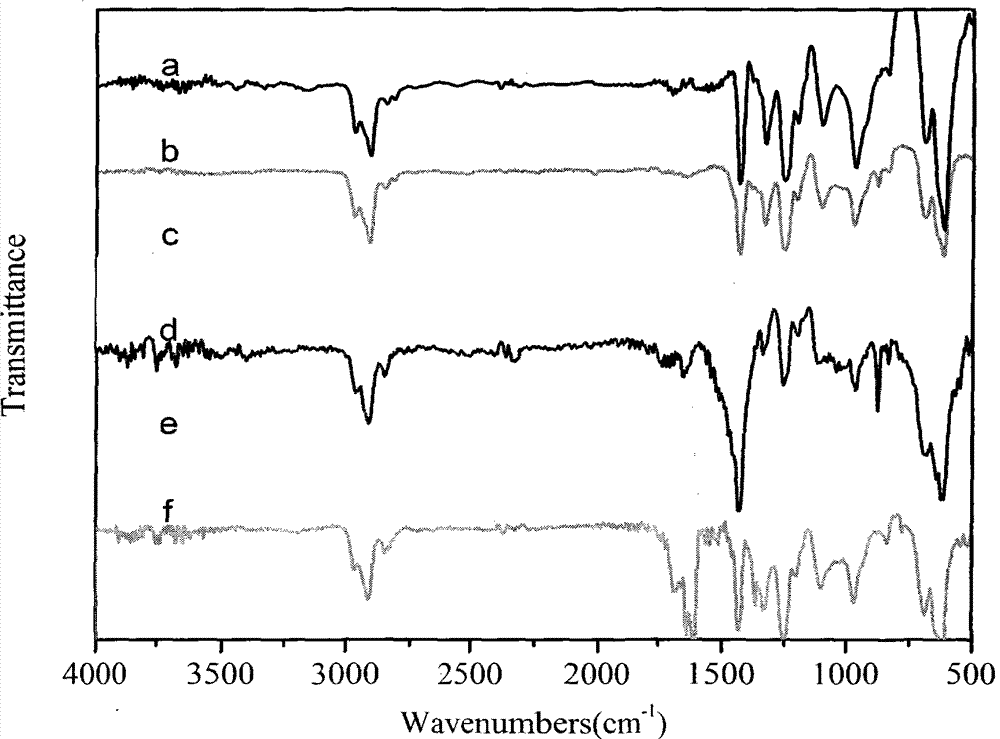

Method for preparing polyamide-amine in-situ intercalation graphene composite material

ActiveCN102390830AStructural damage is smallSolve the problem of not being conductivePolymer scienceOrganic solvent

The invention discloses a method for preparing a polyamide-amine in-situ intercalation graphene composite material. The method comprises the following steps of: (1) dispersing graphite in an imidazole-compound-containing organic solvent with ultrasonic, and centrifuging to obtain multi-layer graphene suspension; and (2) polymerizing to generate polyamide-amine in the multilayer graphene by adopting an in-situ polymerization method to prepare the polyamide-amine in-situ intercalation graphene composite material. According to the method, natural graphite is directly subjected to ultrasonic exfoliation in the organic solvent to obtain single-layer or multi-layer graphene suspension, the original sp2 structure of the graphene is slightly damaged because an oxidation step is not carried out, the polyamide-amine in-situ intercalation graphene composite material is prepared by using an in-situ polymerization method, so that graphene laminas are spread, interlamellar spacings are enlarged, the polyamide-amine on the surface of the graphene functionally prevents agglomeration of the graphene laminas, the graphene laminas are uniformly dispersed, and the product has good stability and is hardly precipitated.

Owner:SOUTH CHINA UNIV OF TECH

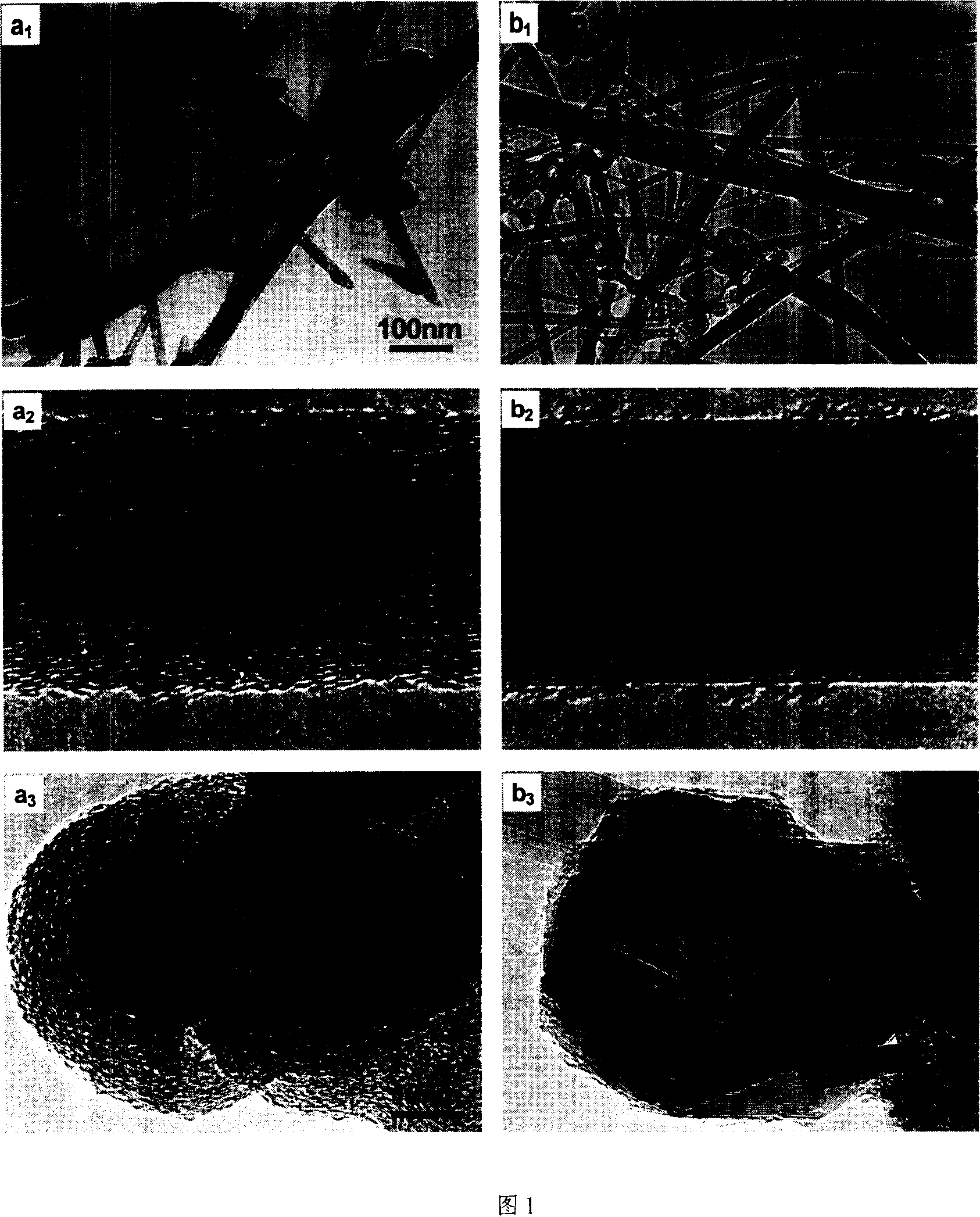

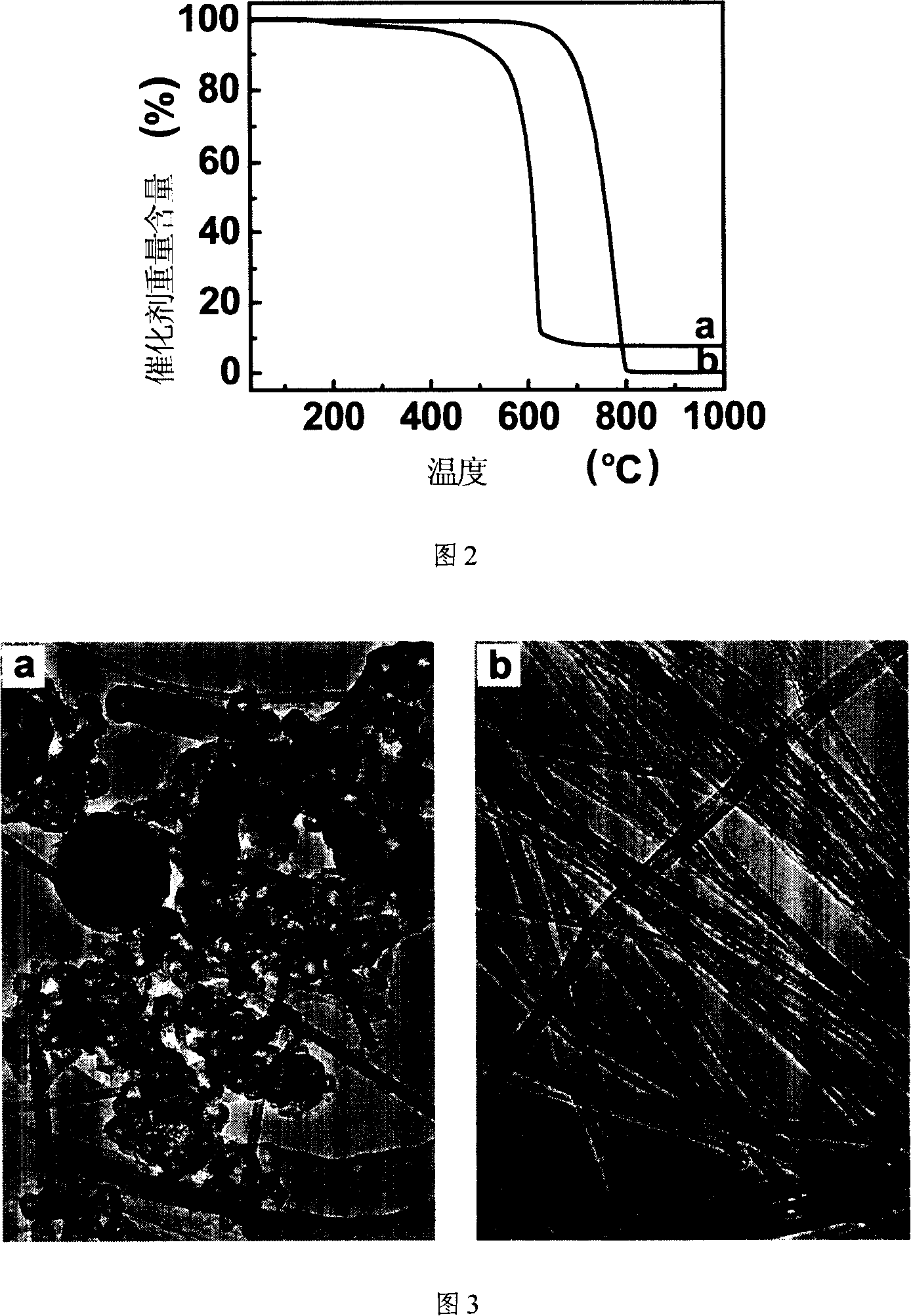

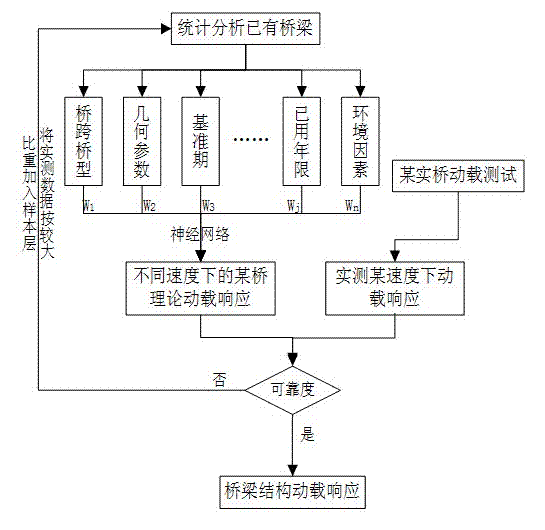

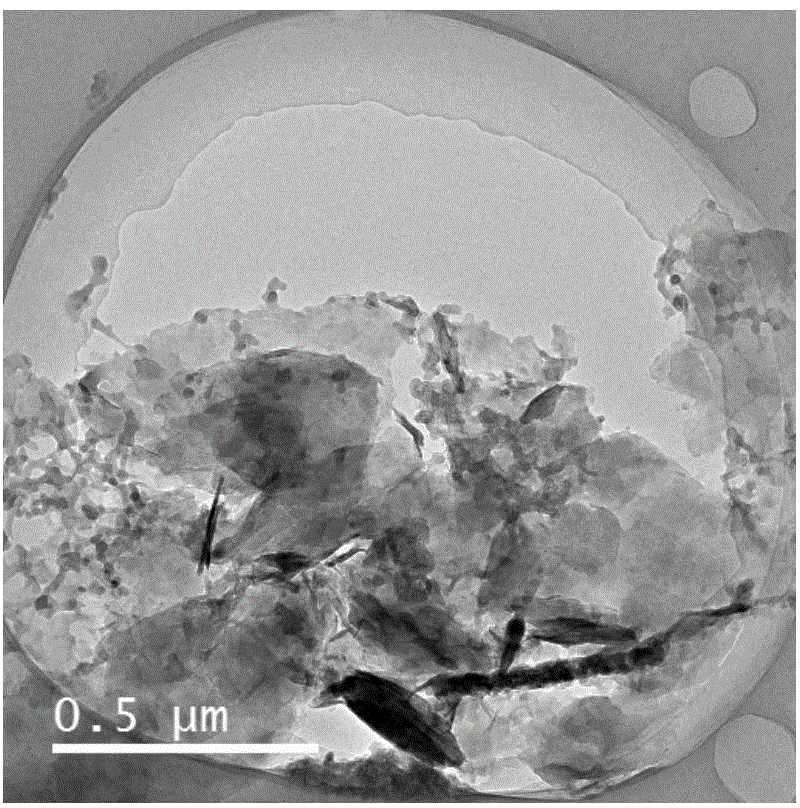

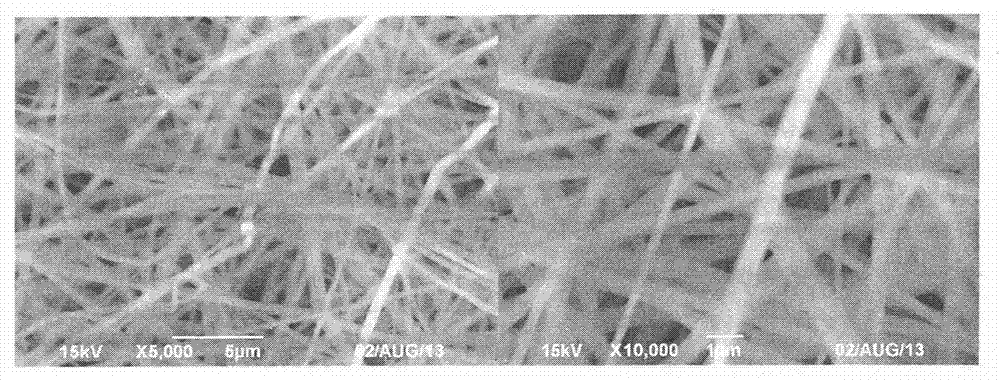

Method for purifying nano carbon fiber of multi-wall carbon nano-tube

InactiveCN101130431AImproves Structural IntegrityImprove the degree of graphitizationPolycrystalline material growthSingle crystal growth detailsFiberPurification methods

The invention discloses a purifying technique of metal catalyst and carbon nanometer particle in the original sample of multi-wall carbon nanometer pipe / nanometer carbon fiber, which comprises the following steps: doing high-temperature graphitizing disposal (1800-3000 deg. c) for original multi-wall carbon nanometer pipe / nanometer carbon fiber to remove high-temperature effumable impurity, for example metal catalyst; eliminating the defect in the multi-wall nanometer carbon pipe; dispersing the graphitized carbon nanometer pipe / nanometer carbon fiber with different carbon structures evenly through dispersant solution under ultrasound; making different carbon structure form discrete phase; filtering to remove discrete carbon nanometer particle in the sample; obtaining high-purity product. The method has advantages of simple operation, high purify, easy manufacturing and so on.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

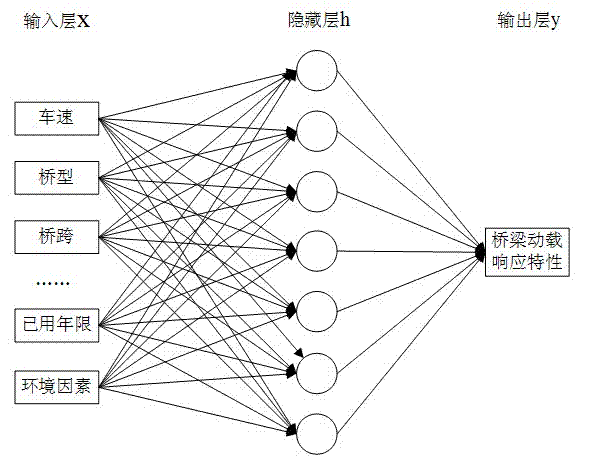

Bridge dynamic load testing method based on neural network technology

InactiveCN102539098AStructural damage is smallImprove analysis efficiencyBiological neural network modelsVibration testingStructural dynamicsDynamic load testing

The invention provides a bridge dynamic load testing method based on neural network technology, which includes conducting statistic analysis on a large amount of existing bridge testing results, determining dynamic load response affecting parameters of a bridge structure, using the affecting parameters as an input layer to construct a neural network model, and deducing structural dynamic load response predicted value; and conducting dynamic load actual measurement on the bridge under single vehicle speed, conducting reliability inspection on neural network theoretical derivation value by using actual measurement value, obtaining dynamic response verified through the actual measurement and characteristics of the bridge structure, and judging actual states and safety performance of the bridge structure according to the dynamic response and the characteristics of the bridge. Due to the fact that the bridge dynamic load testing method combines advantages of a conventional dynamic load testing method and the neural network technology is used to optimize a testing process, bridge dynamic load testing estimation conducted by means of the method greatly reduces structural damage caused by conventional dynamic load testing and improves analysis efficiency and operability on the basis of being capable of guaranteeing accurate and reliable testing results.

Owner:SOUTHEAST UNIV

Bamboo carbon fiber underwear fabric and manufacture method thereof

InactiveCN101532204AFully reflect the decomposition of odorFully reflect the functionWeft knittingYarnFiberTextile technology

The invention relates to a bamboo carbon fiber underwear fabric and a manufacture method thereof, belonging to the technical field of textiles. The bamboo carbon fiber underwear fabric consists of a lining layer and an external layer, and is characterized in that the lining layer consists of bamboo carbon fibers and cotton fibers according to the weight ratio of 15-30:70-85; the external layer consists of cotton fibers, Newdal fibers and polyurethane elastic fibers according to the weight ratio of 43-54:40-54:3-6. The manufacture method comprises that: the bamboo carbon fibers and the cotton fibers, the cotton fibers and the Newdal fibers are respectively spun into Sirospun blended yarns; the Sirospun blended yarns are interwoven with polyurethane elastic fibers to form a knitted underwear fabric; and the knitted underwear fabric forms a final finished product, namely the bamboo carbon fiber underwear fabric through dyeing, drying, sanding and shaping treatment. The fabric and the manufacture method have the advantages that the bamboo carbon fiber underwear fabric not only has good skin-friendly property, low pilling tendency and comfortable elasticity, and has functions of good odor decomposition, smell elimination and the like.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV

Preparation method for modified graphene-loaded titanium dioxide composite photocatalyst

InactiveCN104785235AStructural damage is smallEasy to separatePhysical/chemical process catalystsAir atmosphereSulfate

The invention discloses a preparation method for a modified graphene-loaded titanium dioxide composite photocatalyst. The method comprises the following steps: obtaining a graphene oxide suspension through an improved Hummers method, and adding triethanolamine into the graphene oxide suspension for reacting to obtain a modified graphene oxide suspension liquid; dropwise adding the obtained modified graphene oxide suspension liquid into a sulfuric acid solution in which titanyl sulfate is dissolved; performing ultrasonic auxiliary soaking, and then performing centrifugal separation to obtain a composite photocatalyst precursor; adding the composite photocatalyst precursor into an alkali solution to perform hydrothermal reaction; pre-drying a hydrothermal reaction product, and performing high-temperature calcining and reducing in an air atmosphere to obtain the modified graphene-loaded titanium dioxide composite photocatalyst which is stable in structure, high in specific surface area, high in photocatalytic activity, small in titanium dioxide particle size (about 10 nm), uniform in distribution, and difficult to agglomerate. The method is easy to operate and low in cost, and meets industrial production.

Owner:CENT SOUTH UNIV

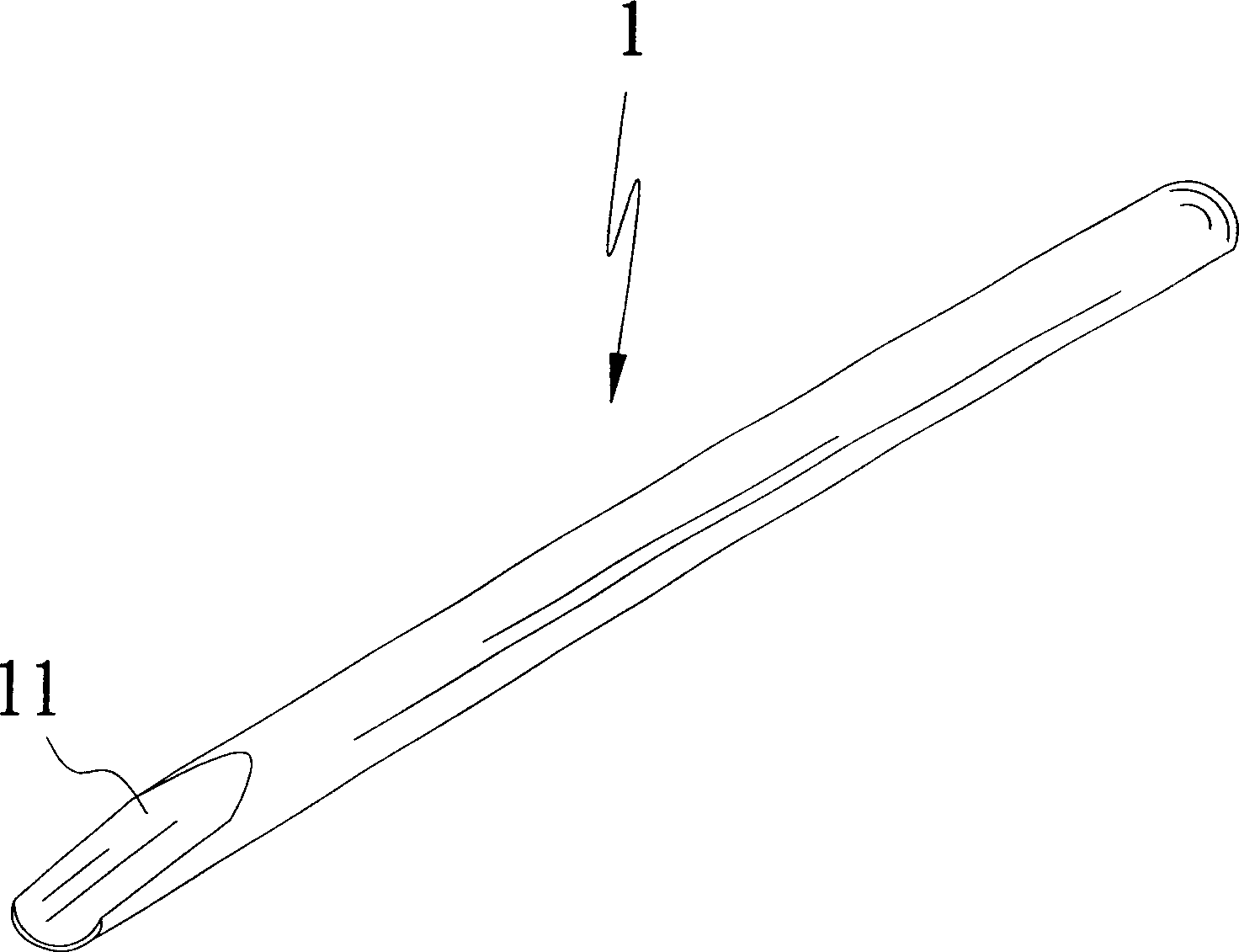

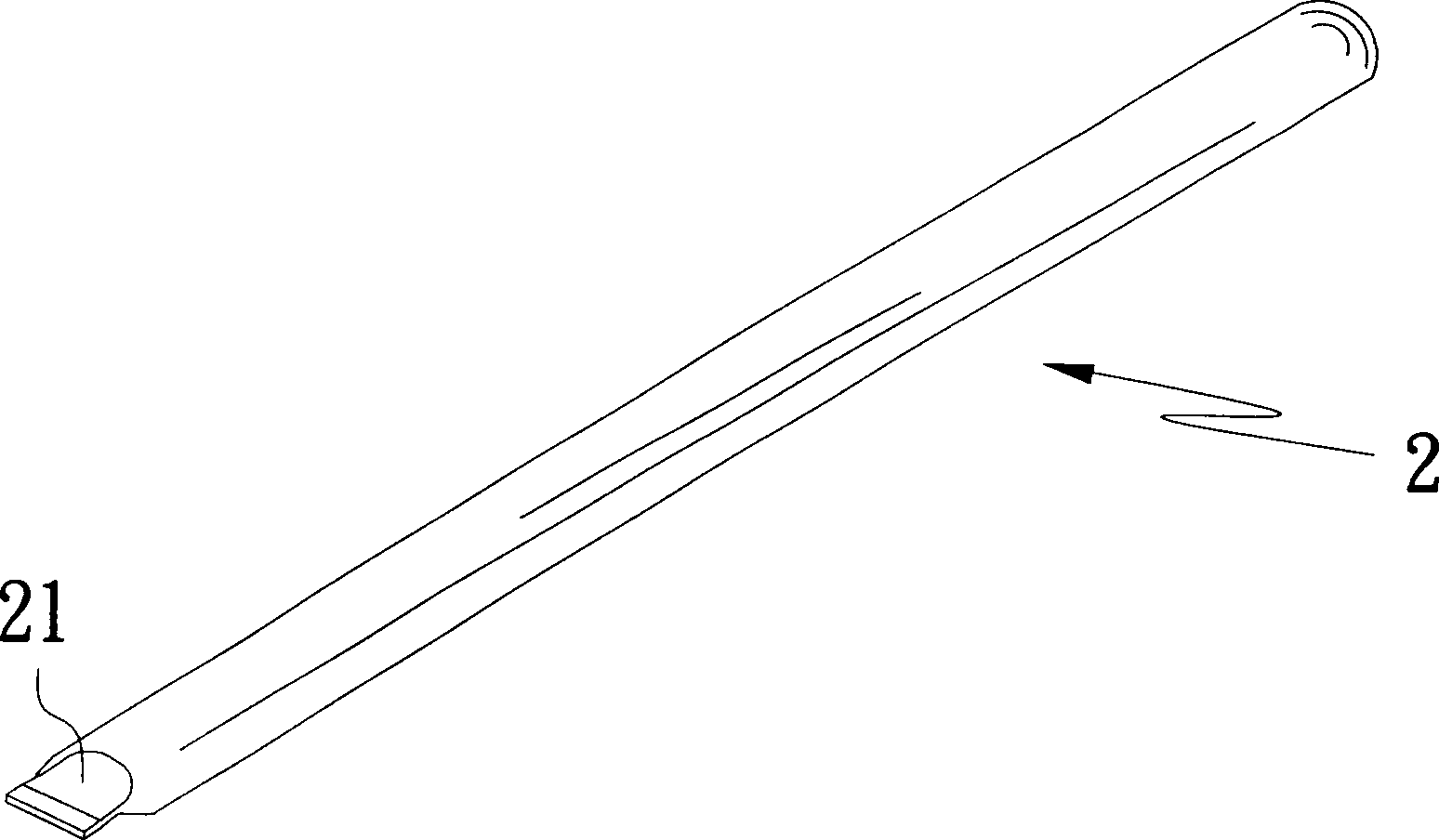

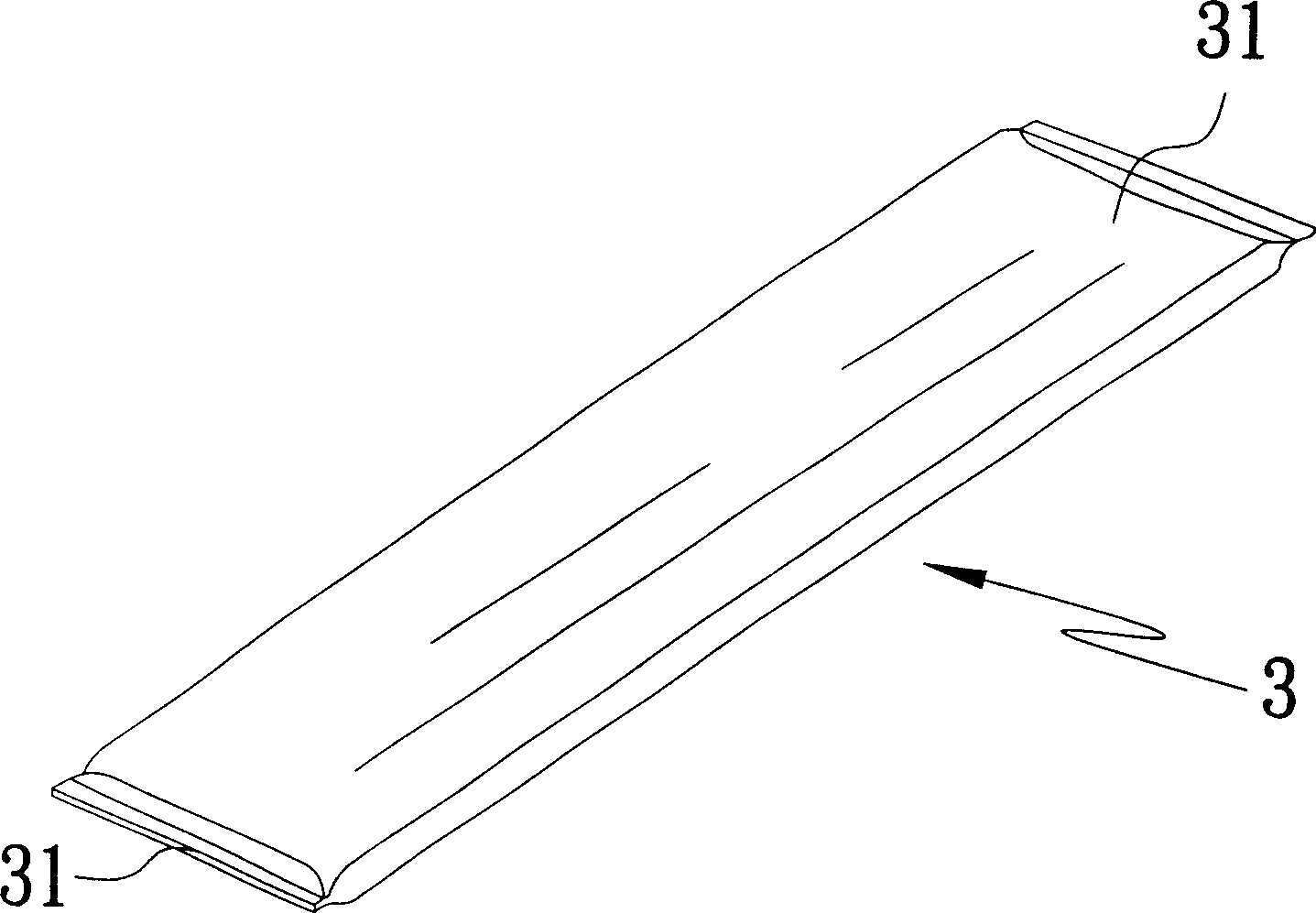

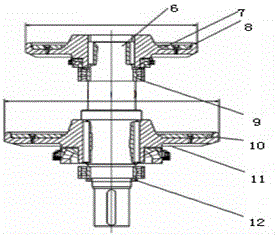

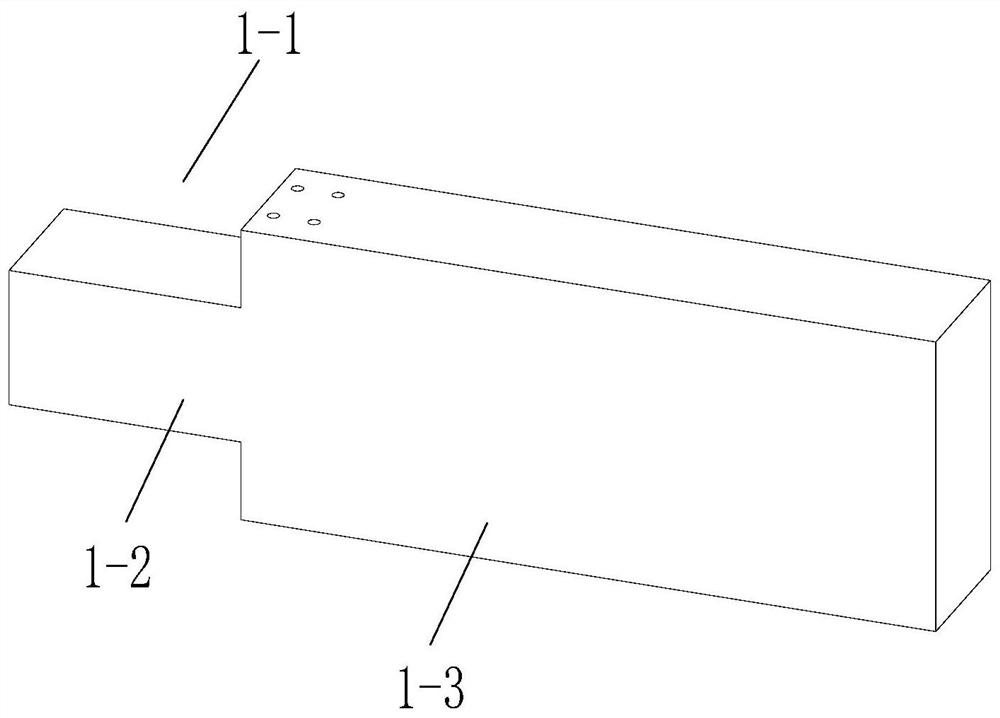

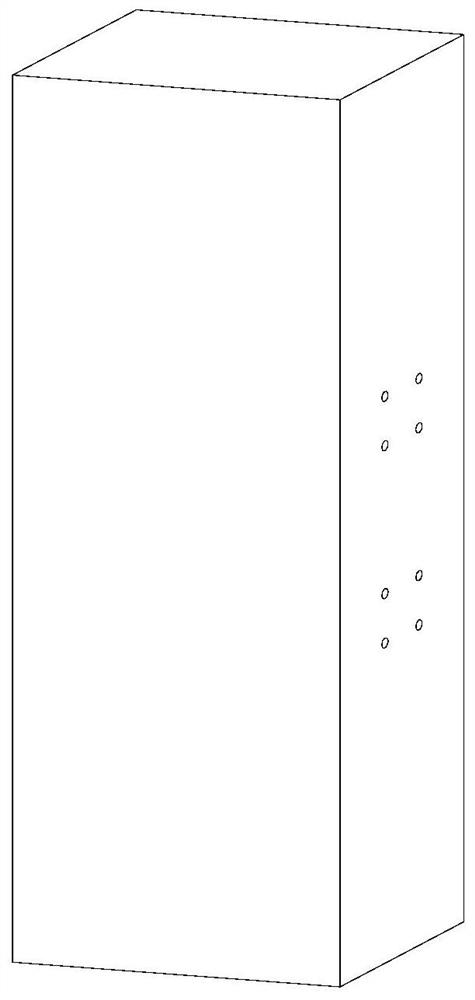

Heat pipe sealing structure, and its pressing method and special mould

InactiveCN1891374AImprove the pressing strengthImprove pressure distributionShaping toolsIndirect heat exchangersStress concentrationHeat conducting

This invention relates to a sealing and stitching method for heat conducting pipes including: providing a die with a first and a second moulds and at least a surface of one is processed with die stamping to form multiple convexes and concaves, putting the open-end of a heat conduction pipe between the two moulds to apply pressure onto the open-end to close it simultaneously when passing through the concaves and convexes and let the extruded metal of the pipe extend to the multiple concaves and convexes to form an embossing closing part at the open-end, the embossing part is set on the special die and the sealing structure.

Owner:郑坚地

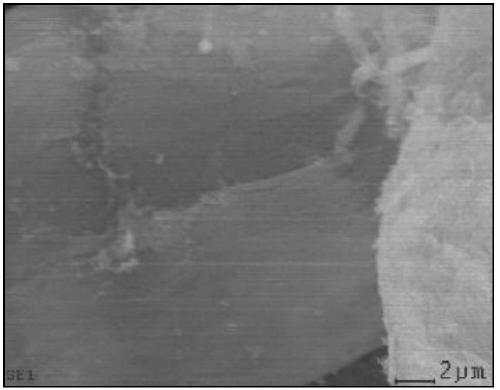

Preparation method of constant-hydrophilic graft-modified chlorinated polymer micro/nano fiber film

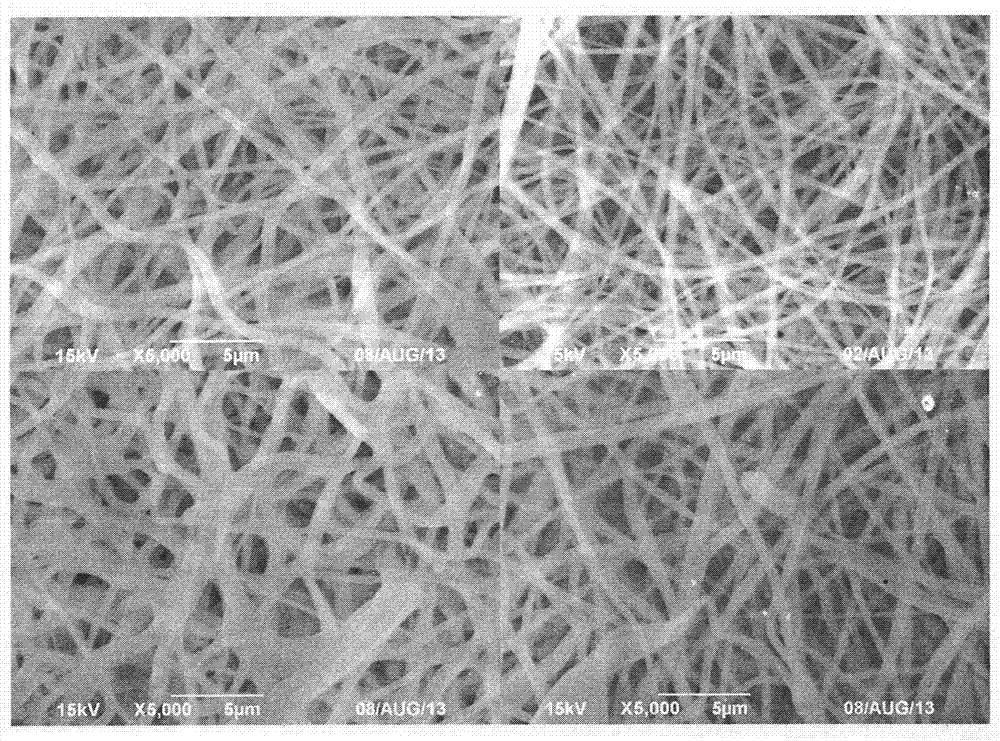

ActiveCN103924384AStructural damage is smallLow application costFibre treatmentNon-woven fabricsFiberHydrophilic monomer

The invention provides a preparation method of a constant-hydrophilic graft-modified chlorinated polymer micro / nano fiber film, and relates to electric-spinning preparation and surface modification of the chlorinated polymer micro / nano fiber film. According to the method for preparing the chlorinated polymer micro / nano fiber film through electrospinning and surface graft polymerization hydrophilic modification, the problems that pressure drop is large, flux is small and the film is prone to contamination during a water system is treated through hydrophobic film material can be solved on the basis of less damages to the film structure. The method includes performing mild dehydrochlorination on chlorinated polymer resin during reflux under the condition of alkaline catalysis, preparing spinning solution, utilizing a self-made electrospinning device, adjusting spinning process parameters, obtaining the micro / nano fiber film with uniform fiber morphology and good mechanical property, then performing surface modification by the method of hydrophilic monomer surface grafting polymerization initiated by azodiisobutyronitrile, and obtaining the chlorinated polymer micro / nano fiber film with high hydrophilicity. The film can be applied to efficient frame-type filtering films.

Owner:SHIHEZI UNIVERSITY

Aluminium nitride and copper mixed nanometer lubricating grease additive and application thereof

The invention relates to preparation of an aluminium nitride and copper mixed nanometer lubricating grease additive and an application thereof, and belongs to the technical field of lubrication. The nanometer lubricating grease additive disclosed by the invention is prepared from nanometer AIN and nanometer Cu in a mixing manner, wherein the particle size ranges of the AIN powder and the Cu powder are 50-200nm. The obtained additive is added to base lubricating grease, so that not only can the anti-wear antifriction performance of the base lubricating grease be improved, but also the base lubricating grease can act on the surface of a friction pair, the roughness of the surface of the friction pair is improved, and a polishing scratch on the surface is repaired, so that the abrasion loss of the friction pair is reduced, the friction pair and the accuracy are effectively ensured, meanwhile, accumulation of heat on the friction surface is reduced, and the service life of the friction pair is prolonged. The test data show that compared with the lubricating grease to which the additive disclosed by the invention is not added, the friction coefficient of the lubricating grease to which the additive disclosed by the invention is added is reduced by 23.6-15.8%, and the friction durability is prolonged by 6-7 times.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Peeling method of layered material and high-quality peeling material obtained by peeling

The invention discloses a peeling method of a layered material and a high-quality peeling material obtained by peeling. The method comprises the following steps: 1) mixing the layered material and anintercalating agent to achieve infiltration of the layered material by the intercalating agent; 2) adding an activating agent to allow the activating agent reacted with the intercalating agent, so that the physical impact of a generated gas flow on the layered material causes the sheet layers of the layered material to peel, thereby resulting in a dispersion solution of a peeling material precursor; and 3) mixing the obtained dispersion solution of the peeling material precursor with a dispersion medium, and performing physical disintegration on the obtained dispersion system so as to obtain adispersion solution of the peeling material. According to the peeling method, the gas flow compact generated by the violent reaction of the intercalating agent and the activating agent which are intercalated on the sheet layer surfaces and at the interlaminations is used to overcome a force between the sheet layers to realize expansion peeling, so that the peeling material with less layer and high quality is obtained; and the process is simple, the production cycle is short, and high efficiency mass production of the peeling material can be realized.

Owner:哈尔滨万鑫石墨谷科技有限公司

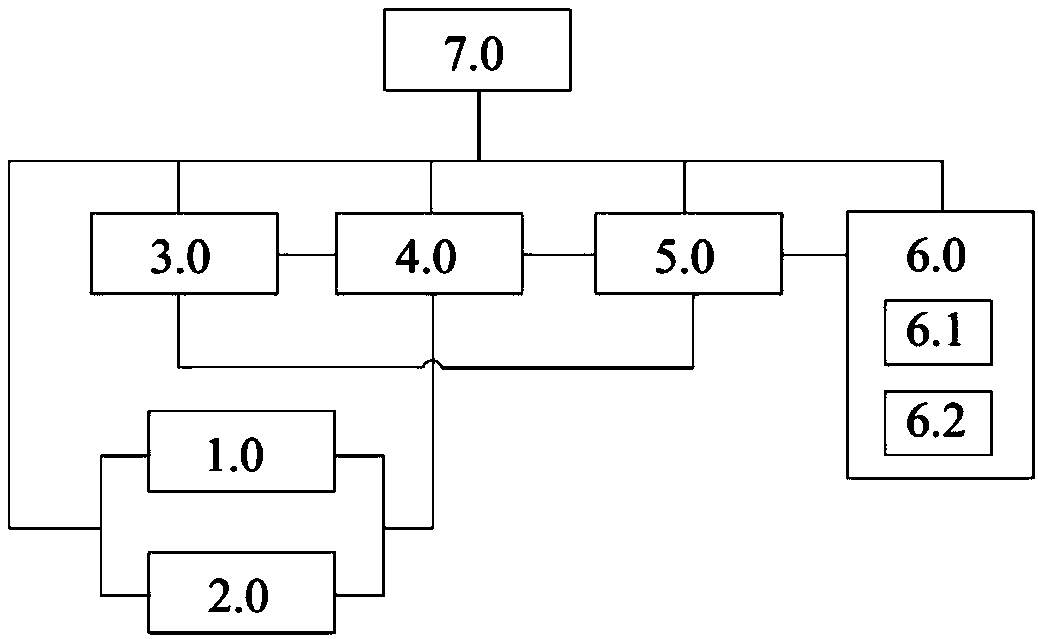

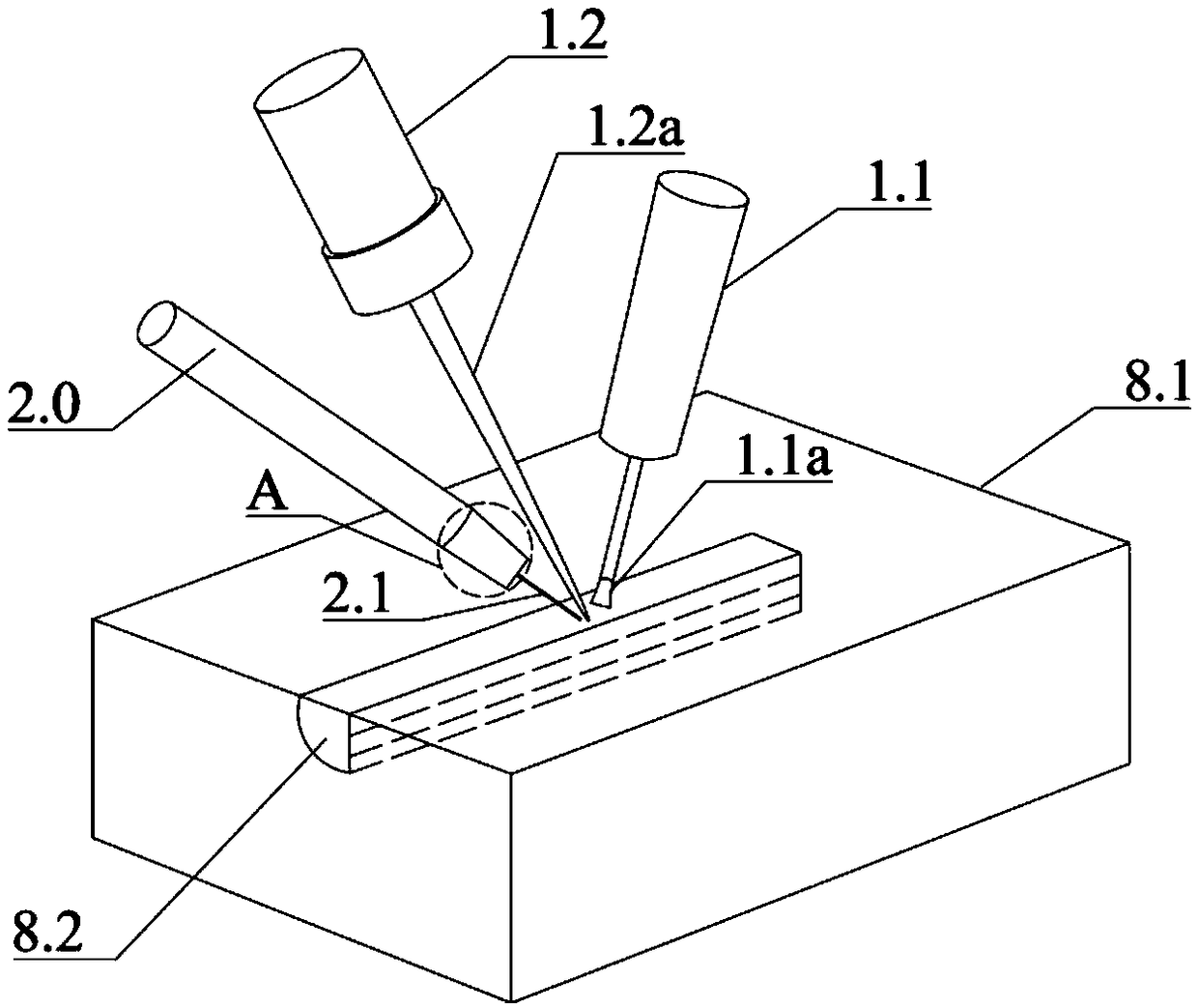

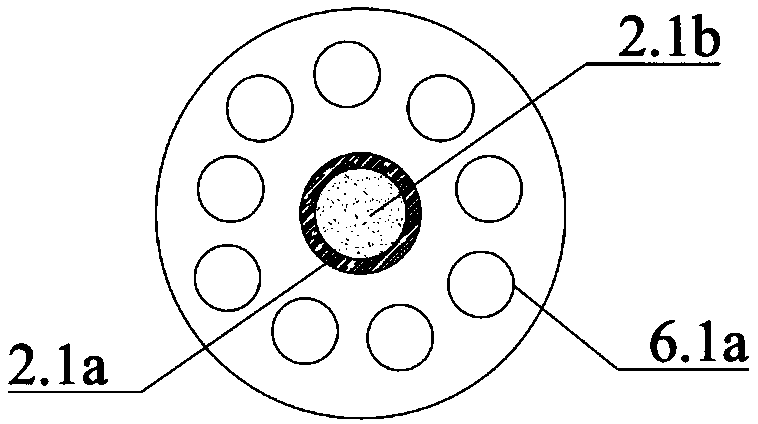

3D printing in-situ repairing system for metal part damage and repairing method thereof

ActiveCN109158599AStructural damage is smallImprove restoration qualityAdditive manufacturing apparatusIncreasing energy efficiencyQuality optimizationEngineering

The invention provides a 3D printing in-situ repairing system for metal part damage and a repairing method thereof. According to the 3D printing in-situ repairing system for metal part damage and therepairing method thereof, rapid in-situ repairment can be carried out on the damage of parts of a high-speed train, the repairing quality is good, and the efficiency is high. The repairing system comprises a mechanical arm, a laser-TIG composite welding gun, a wire feeding device, a space scanning camera shooting device, a printing path design device, an interlayer temperature monitoring device, an interlayer quality control device and a control terminal, wherein the laser-TIG composite welding gun and the wire feeding device are installed at the tail end of the mechanical arm, the space scanning camera shooting device comprises a laser contour scanner for carrying out three-dimensional outline scanning on the defect portions of the parts, the printing path design device is used for acquiring three-dimensional outline data of the defect portions of the parts, setting the layer thickness of a layer to be printed, determining the printing starting point for the layer to be printed and determining the printing path of the layer to be printed, and the interlayer quality control device comprises an interlayer temperature control sub-device and a cladding layer quality optimization sub-device.

Owner:SOUTHWEST JIAOTONG UNIV

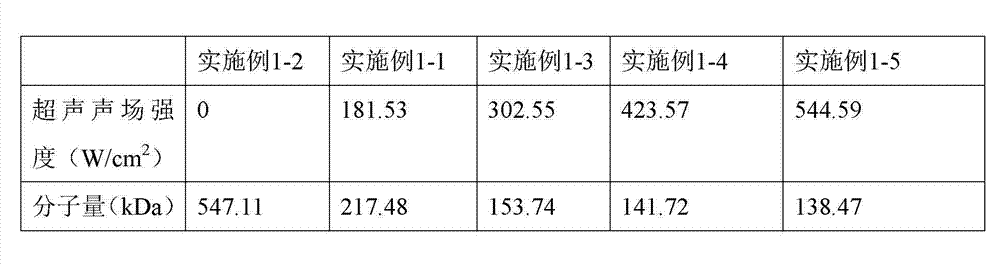

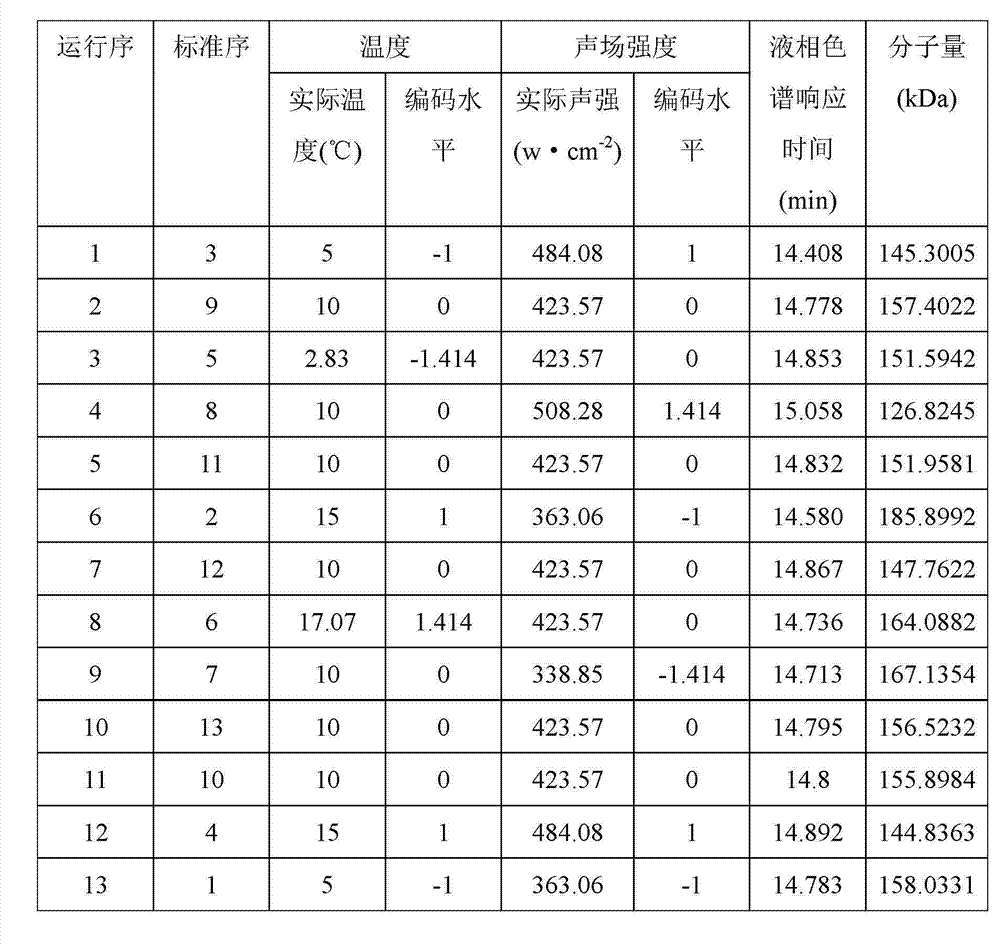

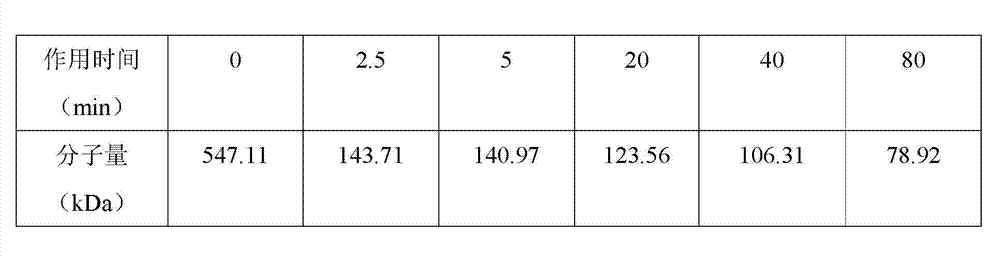

Preparation method of low-molecular-weight sea cucumber fucosan sulfate

The invention discloses a preparation method of low-molecular-weight sea cucumber fucosan sulfate. In the preparation method, a sea cucumber polysaccharide prepared by performing enzymolysis on pulverized sea cucumbers is used as a raw material. The preparation method comprises the following steps: 1) dissolving the sea cucumber polysaccharide in a sodium chloride solution, then adding ethanol, and centrifuging to remove the precipitate, thus obtaining the supernatant; and adding ethanol into the supernatant, centrifuging, dialyzing the obtained precipitate, and performing freeze-drying to obtain sea cucumber fucosan sulfate; 2) dissolving the sea cucumber fucosan sulfate in solvent, and performing ultrasonic treatment at 0-45 DEG C, wherein the treatment time is 10-180 minutes, and the ultrasonic sound field strength is 60-800 W / cm<2>; and 3) dialyzing the treated solution obtained in the step 2), and performing vacuum freeze-drying to obtain the low-molecular-weight sea cucumber fucosan sulfate. According to the invention, an ultrasonic degradation technology is adopted, high-molecular-weight sea cucumber fucosan sulfate can be quickly degraded, the reaction conditions are mild, and the preparation method is green and environment-friendly.

Owner:ZHEJIANG UNIV

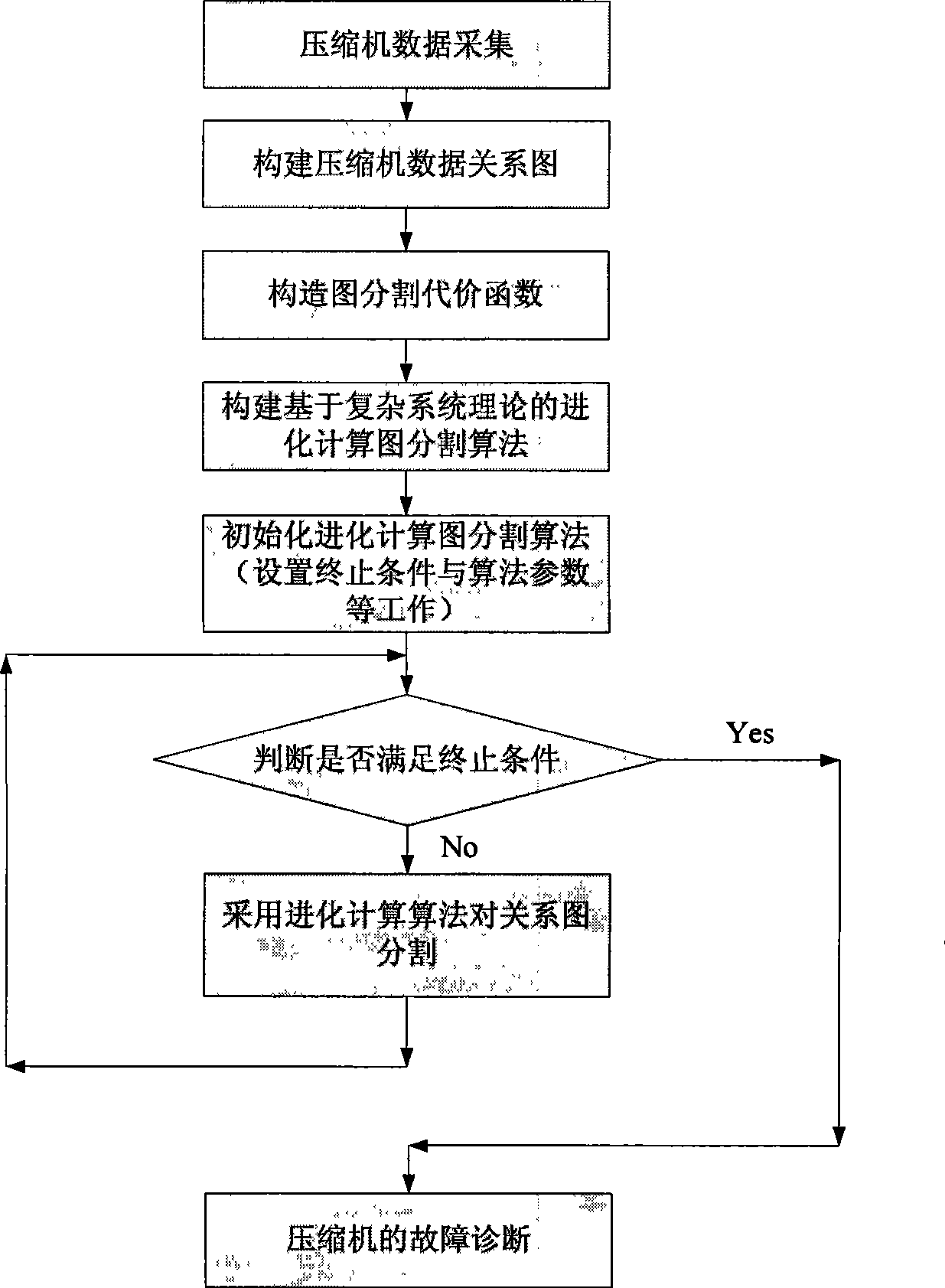

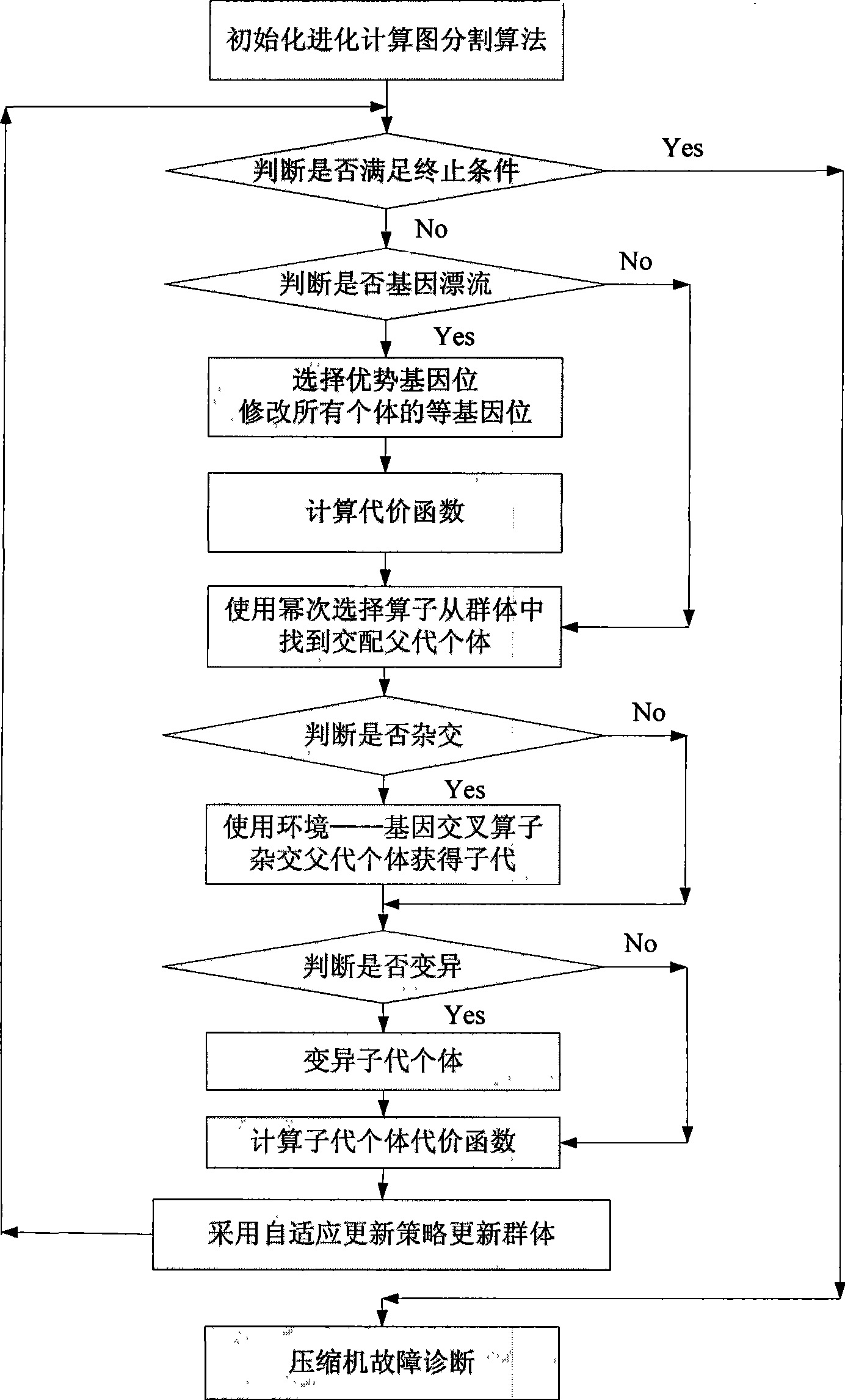

Evolutionary computation-based method for diagnosing compressor fault

InactiveCN101446283AStructural damage is smallLow implementation costPump testingGenetic modelsAlgorithmComplex system

The invention discloses an evolutionary computation-based method for diagnosing compressor fault. The method comprises the following steps: data about the working condition of a compressor is collected and acquired; an observation point is taken as a node, and the correlation between observation points produced by the actual compressor physics; a weighting undirected graph G(V,A) is set up for measured data; the distance between fault data points is gauged by means of a relational graph instead of the traditional Euclidean distance method; the data about the fault of the compressor is converted into a problem with the partitioning of the weighting undirected graph G; the Pareto Principle structural map is adopted for partitioning cost function; an evolutionary calculation chart partitioning computation based on the improvement on the complexity system theory is designed to partitioning the relational graph; and the clustering / classification of the compressor fault data is realized through the optimal computation of the cost function, so that the purpose of fault diagnosis can be achieved.

Owner:XI AN JIAOTONG UNIV

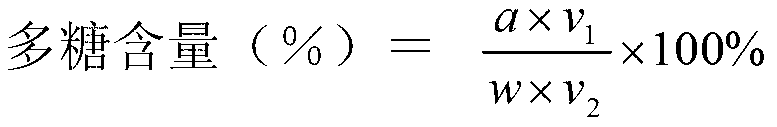

Method for extracting peanut polysaccharide from cold pressed peanut cake

The invention discloses a method for extracting peanut polysaccharide from cold pressed peanut cake. The method comprises the following steps of: (1) adding water into cold pressed peanut cake powder to obtain a peanut cake suspension; (2) adding a neutral protease into the peanut cake suspension to carry out an enzymatic hydrolysis reaction; (3) after the enzymatic hydrolysis reaction is ended, carrying out enzyme inactivation treatment on a reaction liquid obtained by the enzymatic hydrolysis reaction, and then, separating the reaction liquid to obtain protein-removed peanut cake residues; (4) extracting the peanut polysaccharide from the protein-removed peanut cake residues by using hot water to obtain a peanut cake polysaccharide extracting solution, wherein the hot water extraction temperature ranges from 50 DEG C to 90 DEG C; and (5) adding ethanol into the supernatant liquid of the peanut cake polysaccharide extracting solution to carry out sedimentation treatment to obtain a precipitate, i.e., the peanut polysaccharide. The peanut cake is subjected to enzymatic hydrolysis by using an efficient and nontoxic biological enzyme to remove proteins in the peanut cake effectively, so that the purity of the peanut polysaccharide is increased and is as high as 92.87%, and the extracting rate of the peanut polysaccharide is up to 27.04%.

Owner:北京中农探味科技有限公司

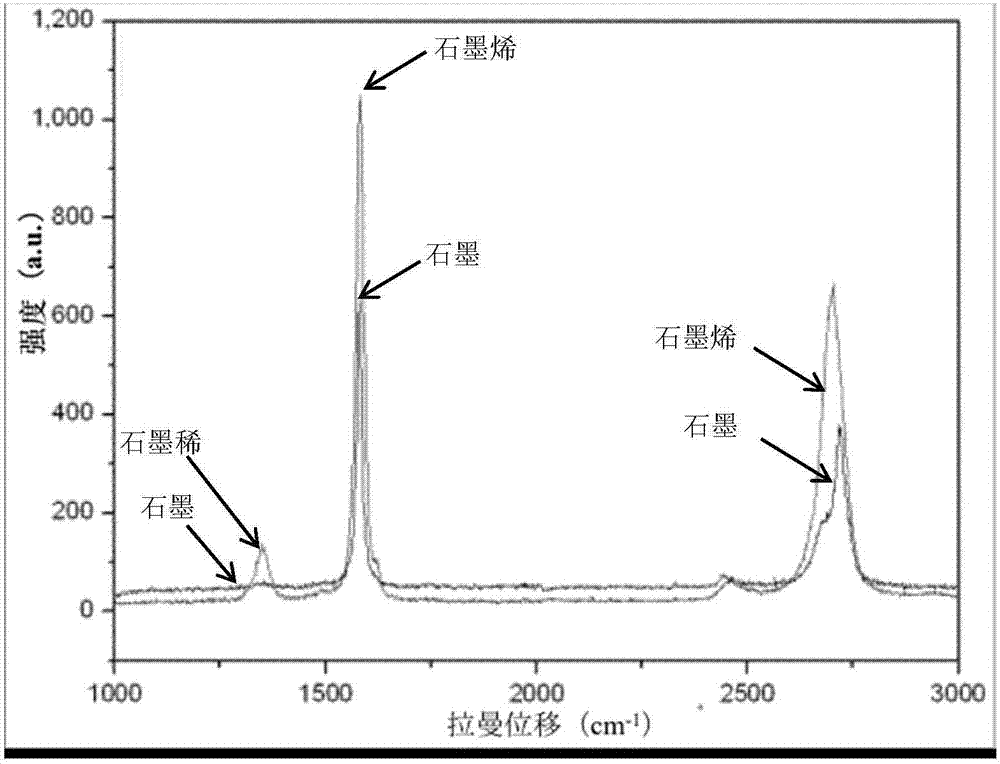

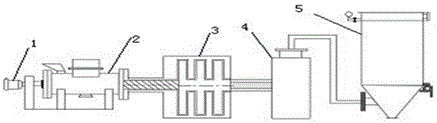

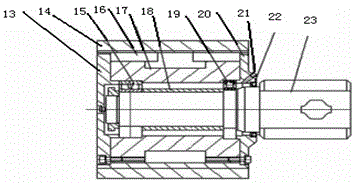

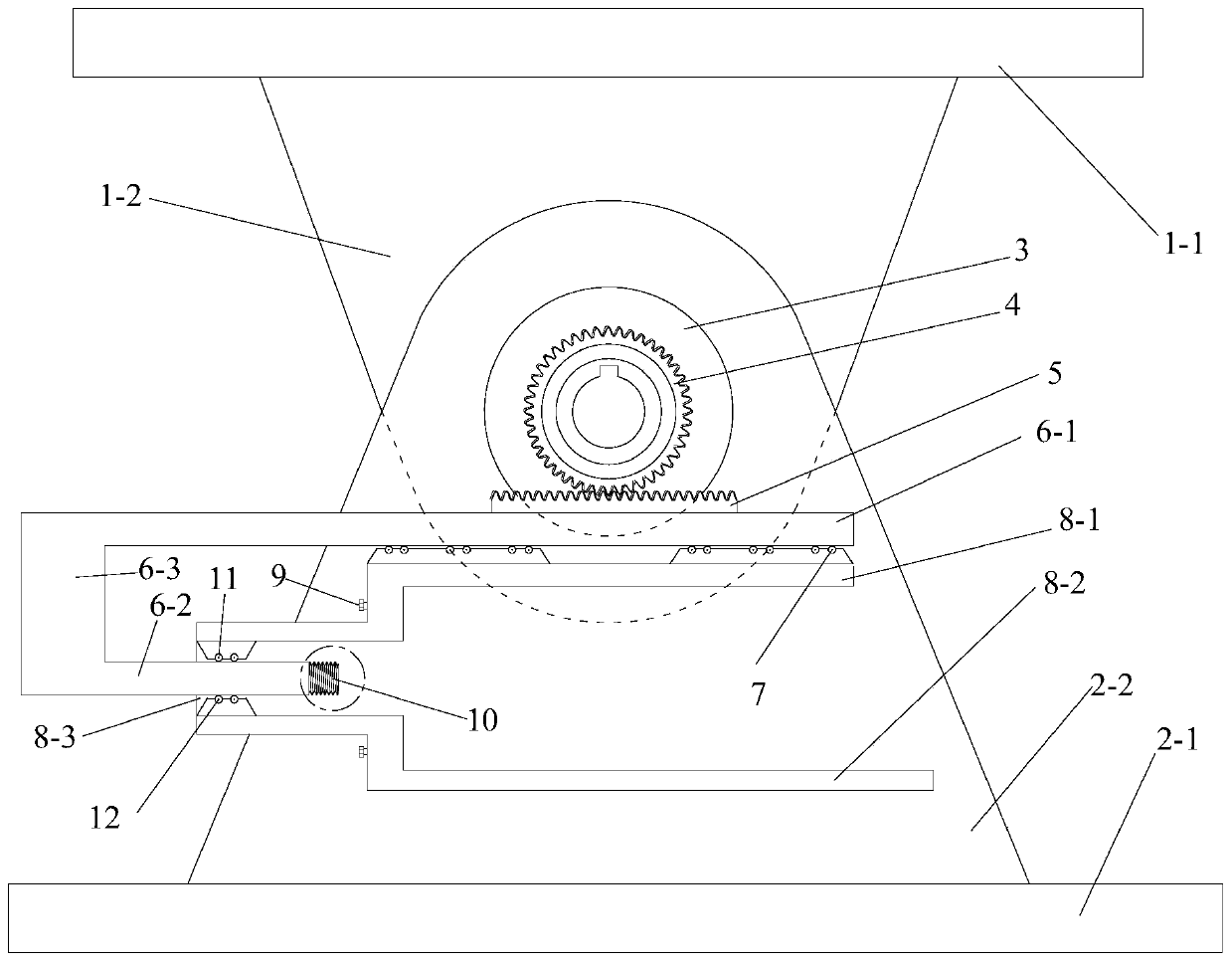

Device for preparing graphene by dry grinding and stripping with and method for production graphene

ActiveCN106744877AStructural damage is smallPrevent aggregate reunionGrapheneCocoaGraphenePolymer science

The invention belongs to the technical field of graphene and provides a device for preparing the graphene by dry grinding and stripping. The device is characterized by comprising a driving unit, a disc rolling unit, a serial disc extruder, a cyclone disperser and a product collector, the disc rolling unit is provided with a grinding disc and a grinding roller, and the serial disc extruder is provided with a fixed disc and a moving disc which are combined dynamically and statically. The primary graphene is prepared by gradual shearing and striping with the disc rolling unit, and the graphene product is obtained by further shearing and stripping with the serial disc extruder. The graphene is prepared by continuous and stable stripping under the dry condition, production efficiency is high, and large-scale production of the graphene is easily realized.

Owner:苏州中野桑拿设备有限公司

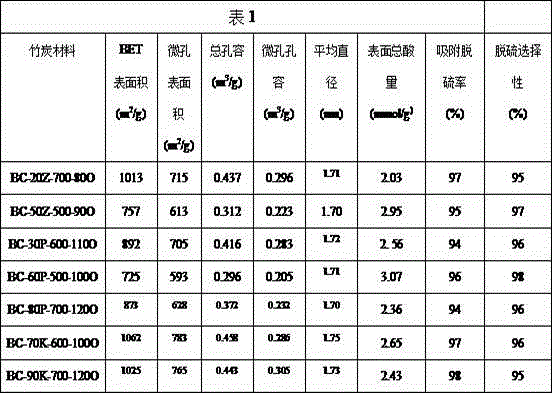

High-selectivity fuel adsorption and desulfurization agent of bamboo source porous biomass carbon

InactiveCN106824068AHigh yieldImprove structural stabilityOther chemical processesHydrocarbon oils refiningPhosphoric acidPotassium hydroxide

The invention discloses a high-selectivity fuel adsorption and desulfurization agent of a bamboo source porous biomass carbon. The high-selectivity fuel adsorption and desulfurization agent is prepared through chemical activation and carbonization and concentrated nitric acid oxidation; and the high-selectivity fuel adsorption and desulfurization agent comprises the steps of carrying out wet impregnation on 20-40mesh bamboo powder by using chemical activator deionized water clear solutions of zinc chloride, phosphoric acid or potassium hydroxide at a room temperature for 12-24 h, putting a product into a vacuum oven of 40-80 DEG C for baking for 6-12 h, treating the product in a quartz glass tube in a tube furnace in a nitrogen atmosphere at 500-700 DEG C for 2-4 h, naturally cooling to a room temperature, washing and pickling by using deionized water, washing until filtrate is neutral and drying in the oven of 110 DEG C for 8-12 h to obtain the bamboo source porous biomass carbon; and treating the bamboo source porous biomass carbon by using 65% nitric acid at 80-120 DEG C for 3-8 h, washing to be neutral by using distilled water and drying in the oven of 110 DEG C for 8-12 h to prepare the material. The high-selectivity fuel adsorption and desulfurization agent is low in cost and small in structure damage after being oxidized by the nitric acid, and is suitable for being used as the high-selectivity fuel adsorption and desulfurization agent; and surface acidic groups are greatly improved.

Owner:HUNAN NORMAL UNIVERSITY

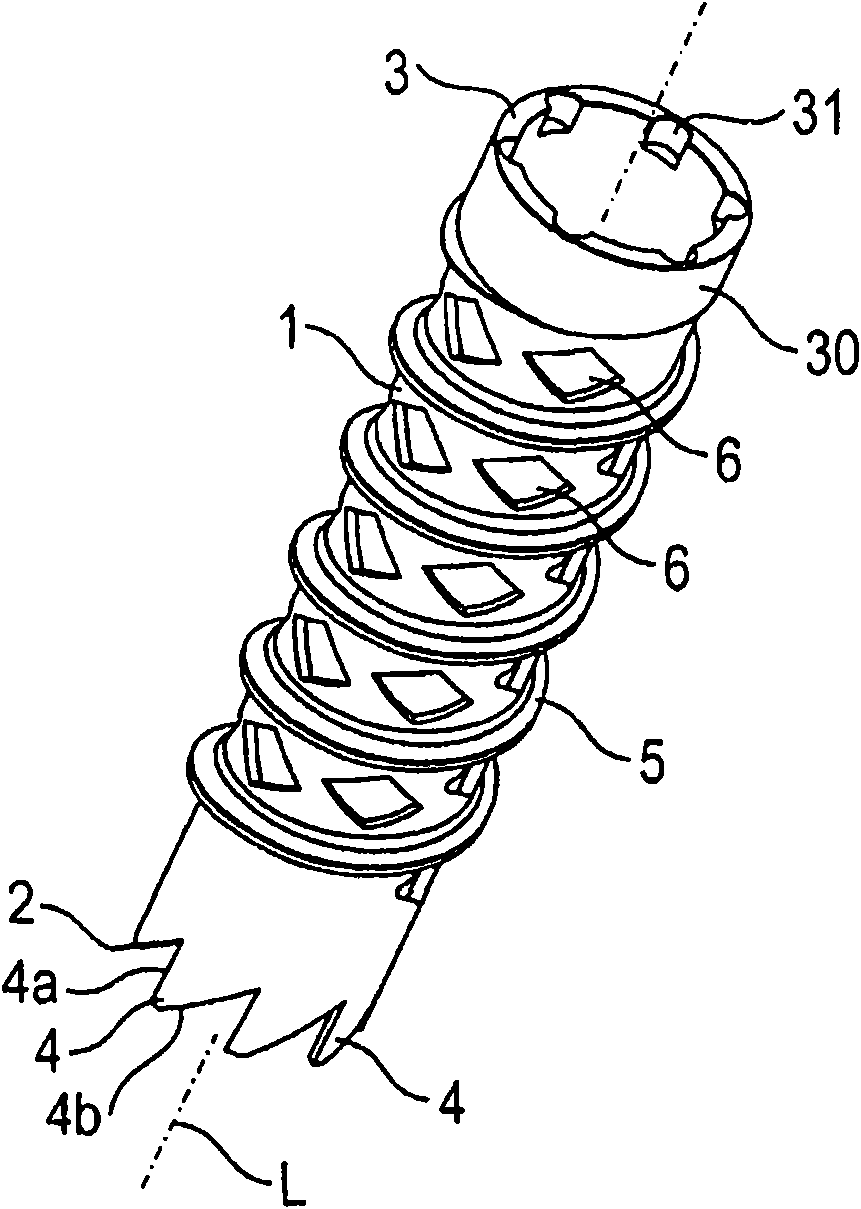

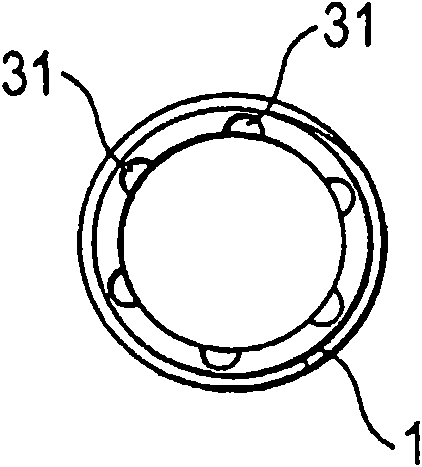

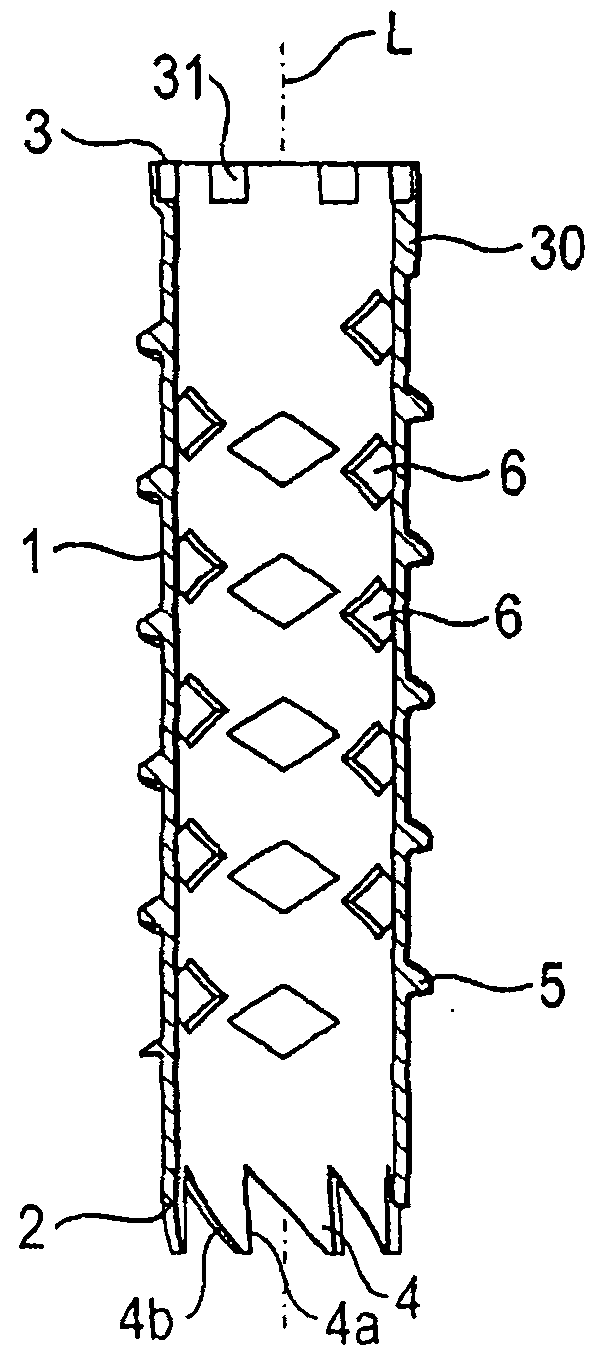

Bone screw

InactiveCN102085114APromotes the healing processShorten the timeFastenersInternal osteosythesisEnthesisEngineering

The present invention provides a bone screw including a tubular body (1) with a bone thread (5) in at least a portion of its outer wall, the tubular body having an open first end (2) and an open second end (3); wherein at the open first end (2) a plurality of cutting teeth (4) is provided and wherein at the second end (3) a structure (31, 310) for engagement with a screwing-in tool (100) is provided. The invention also provides a tool used for being inserted into the bone screw, wherein the tool includes a structure (102, 103) for engagement that join with the structure (31, 310) for engagement of the bone screw to form a guide thread.

Owner:BIEDERMANN TECH GMBH & CO KG

Method for continuously preparing graphene by utilizing ultrasonic wave

The invention provides a method for continuously preparing graphene by utilizing ultrasonic wave. The method is characterized by comprising the following steps: immerging a physical foaming agent into a graphitic layer under high pressure; cracking the graphitic layer by the foaming agent under a heating condition; and ultrasonically cavitating and stripping in a continuous ultrasonic device, thereby realizing the continuous ultrasonic stripping preparation for graphene. Different from the traditional method that the ultrasonic wave is used to damage the graphitic interlayer structure under a liquid phase condition, continuous scaled production is unavailable, and efficiency is low, the method is suitable for large-scale continuous production; the yield of the graphene is increased; the preparation capacity is promoted; the production cost is obviously lowered; the preparation process is nontoxic and harmless; the operation is safe; the process is simple; the after-treatment is simple and easy; and the method is safe and environment-friendly.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

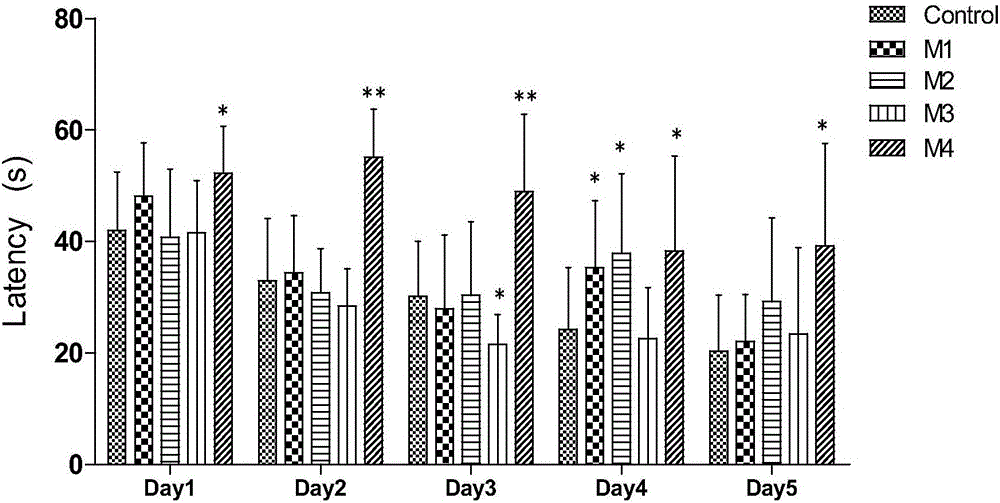

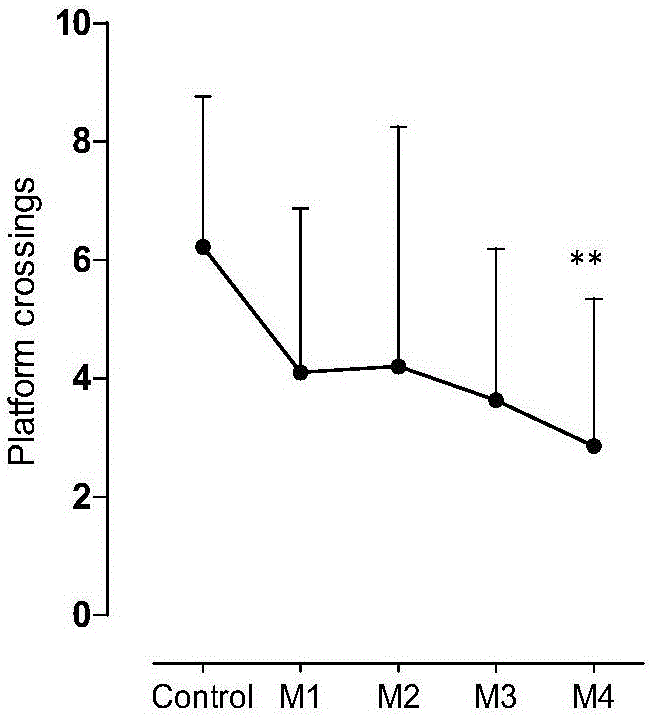

Identification method for urine metabolism marker based on alzheimer disease

The invention relates to an identification method for a urine metabolism marker based on alzheimer disease. The identification method aims at solving the problem that a urine metabolism marker of existing alzheimer disease has not been clarified. The identification method for the urine metabolism marker based on alzheimer disease includes the specific steps that 1, alzheimer rat model is built and evaluated; 2, the intervention effect of Kaixin powder on building different-stage AD fat models is evaluated through the biomarker. The identification method is used for the field of metabolism marker identification.

Owner:王喜军

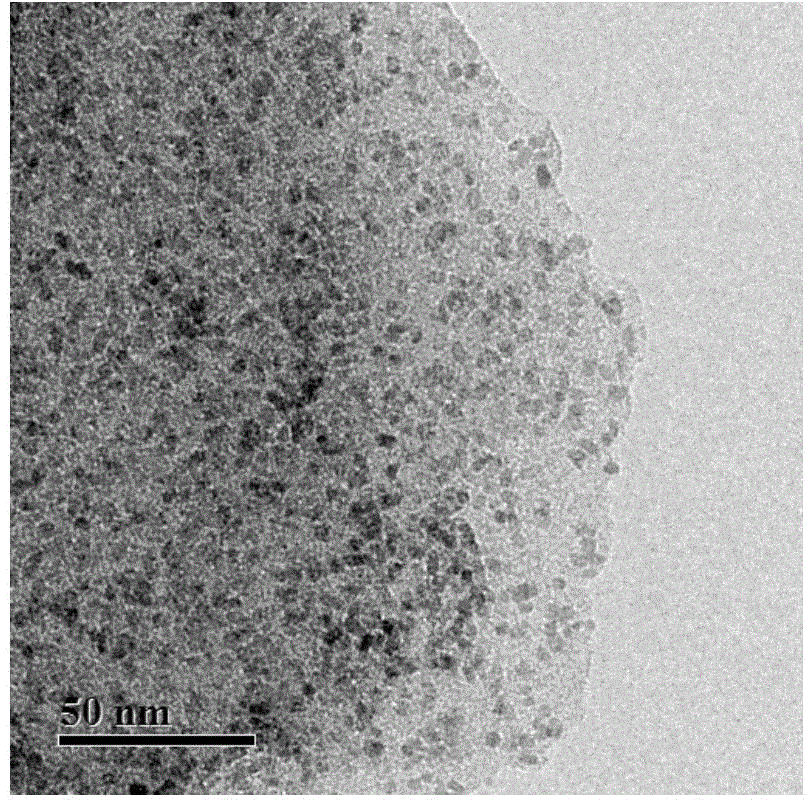

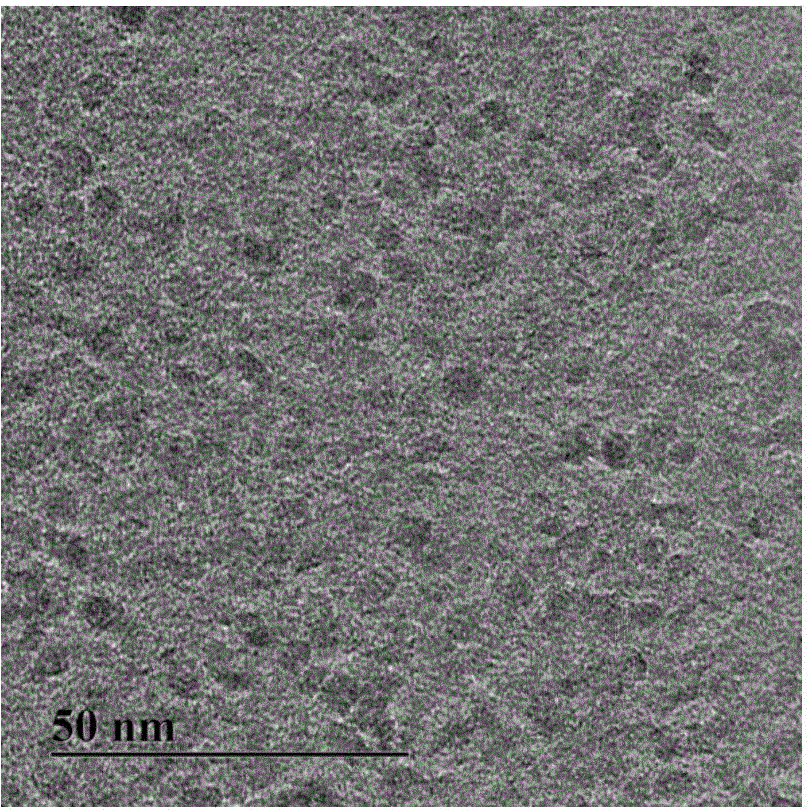

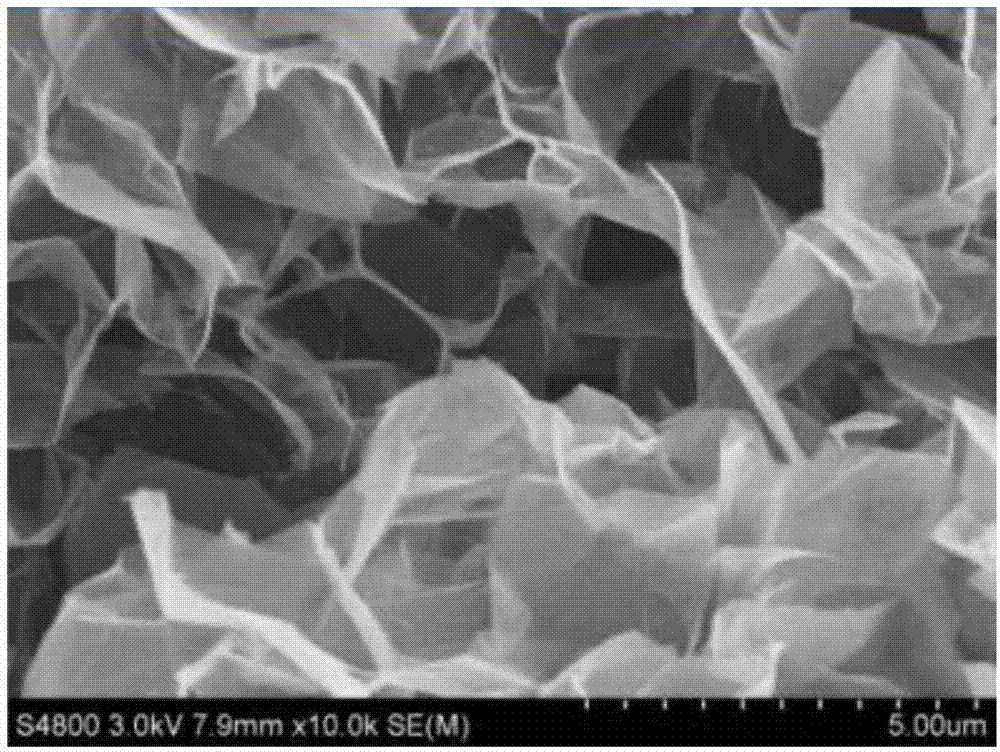

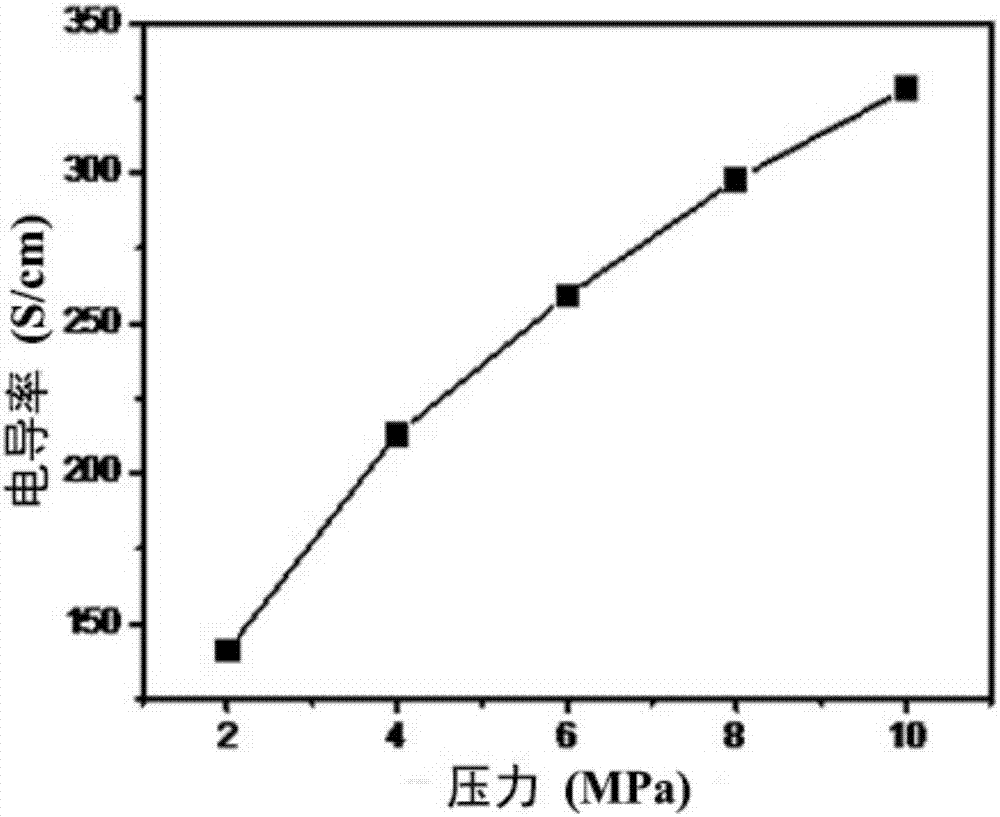

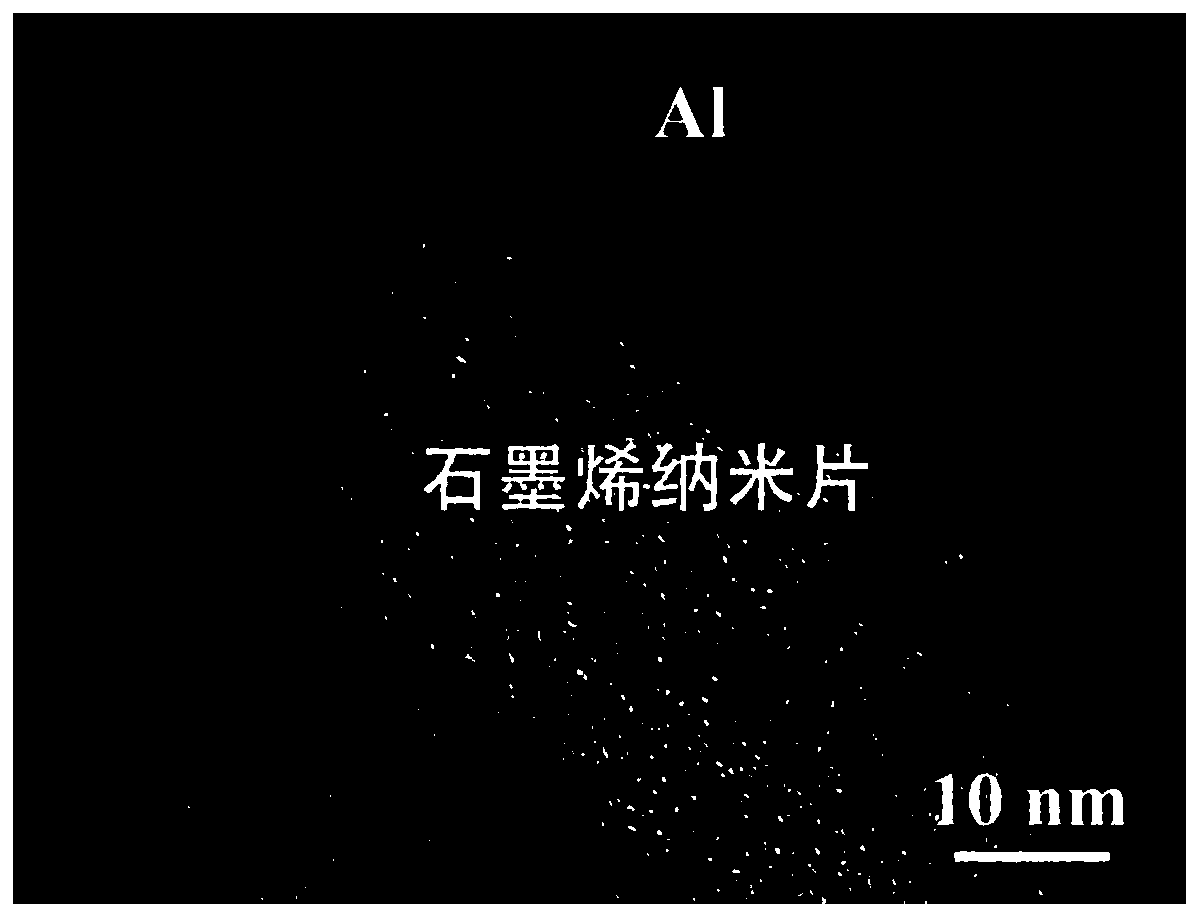

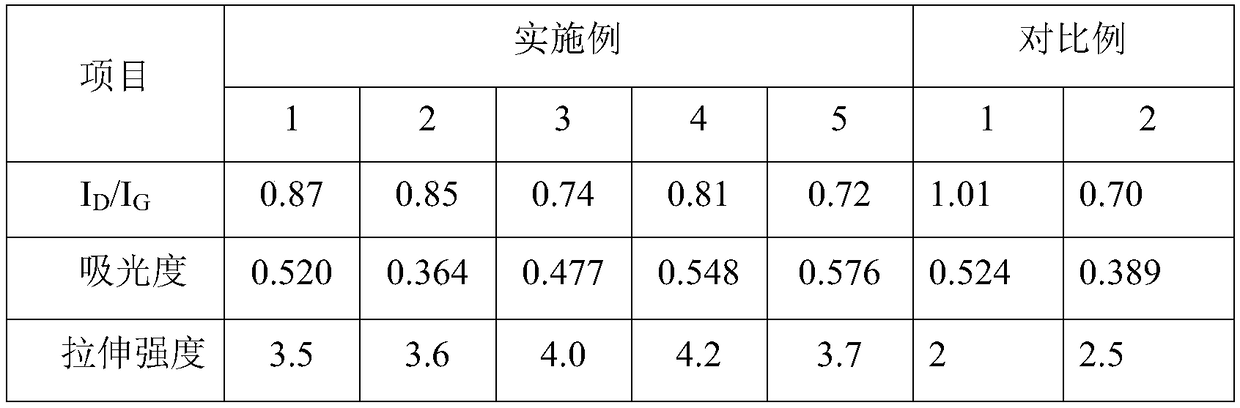

Graphene nanosheet/aluminum composite and preparation method thereof

InactiveCN110578076AAvoid pollutionEvenly dispersedTransportation and packagingMetal-working apparatusAlcoholFiltration

The invention relates to a graphene nanosheet / aluminum composite and a preparation method thereof. The preparation method comprises the following main steps that (1) a graphene nanosheet is dispersedinto an absolute ethyl alcohol solution, and an absolute ethyl alcohol dispersion solution of the graphene nanosheet is prepared; (2) under argon shielding, spherical aluminum powder is converted intosheet aluminum powder through ball grinding; (3) in an argon inflated glove box, the sheet aluminum powder is moved into the absolute ethyl alcohol dispersion solution of the graphene nanosheet, andcomposite slurry of graphene nanosheet / sheet aluminum powder is prepared through mechanical stirring; (4) graphene nanosheet / sheet aluminum powder composite powder is prepared through suction filtration and drying; (5) a graphene nanosheet / aluminum composite blank is prepared through cold pressing and vacuum sintering; and (6) the graphene nanosheet / aluminum composite is prepared through hot extrusion. The preparation process has the advantages that structure damage of the graphene nanosheet is small, dispersion is uniform, and graphene nanosheet-Al interface bonding is good; and the preparedgraphene nanosheet / aluminum composite is high in strength and good in plasticity.

Owner:SHENYANG AEROSPACE UNIVERSITY

Wash-resisting polyamide fabric dyeing process

InactiveCN105019271AGreat dye adhesionLittle structural damageFibre typesDyeing processPolyamidePre treatment

The present invention discloses a wash-resisting polyamide fabric dyeing process comprising the following steps: a) base material dosing; b) cold heaping; c) heating; d) fiber treatment, to be more specific, 30 to 36 parts of a desizing refining agent, 13 to 18 parts of a fiber bulking agent, 15 to 20 parts of a dye leveling agent, 5 to 7 parts of a penetrating agent and 23 to 26 parts of glacial acetic acid are added into a dye vat, the PH value is adjusted, the PH value is maintained at 5.3 to 5.5, and the time is 2-5 hours; e) pretreatment; f) staining, to be more specific, baking soda is added, the PH value is adjusted to 9.5, dye tianlong yellow, tianlong blue and tianlong turquoise blue are added, water and the dyes are mixed into a dye liquid, and the weight ratio of dye tianlong yellow and cloth is 0.05: 1, the weight ratio of dye tianlong blue and cloth is 0.05: 1, and the weight ratio of dye tianlong turquoise blue and cloth is 0.5: 1; and g) color fixing, to be more specific, 5 to 9 parts of a color fixing agent and 3 to 7 parts of glacial acetic acid are added. Through the process, dyes are high in tendency in entering into the fabric, dye adhesion is large, the dyes are low in tendency to fall off by lighting and water washing, and damage to the internal structure of the fabric is small.

Owner:赵仕建

One-way damping hinge device and method for controlling passive vibration of structure by using same

ActiveCN109826480AImproved Vibration Control EfficiencySmooth transmissionProtective buildings/sheltersShock proofingVibration controlControl theory

The invention discloses a one-way damping hinge device, which comprises an upper connecting support, a lower connecting support and a hinge shaft, wherein the hinge shaft is fixedly connected with theupper connecting support; the hinge shaft is rotatably connected with the lower connecting support; a gear rack transmission mechanism, a damper mounting frame and a U-shaped transmission curved rodwhich is fixedly connected with an input rod of a damper are arranged on the lower connecting support; the gear rack transmission mechanism comprises a driving gear and a driven gear rack which are meshed with each other; the driving gear is fixedly connected with the hinge shaft; the driven gear rack is fixedly connected with the U-shaped transmission curved rod; and rollers are arranged betweenthe damper mounting frame and the U-shaped transmission curved rod. In addition, the invention also provides a method for controlling passive vibration of a structure by using the one-way damping hinge device. According to the one-way damping hinge device, the gear transmission principle is utilized, so that the capability of the building structure to resist vibration load can be effectively improved, the vibration control efficiency of the building structure is improved, and a new and effective method is provided for the vibration control of the structure in the field of civil engineering.

Owner:CHANGAN UNIV

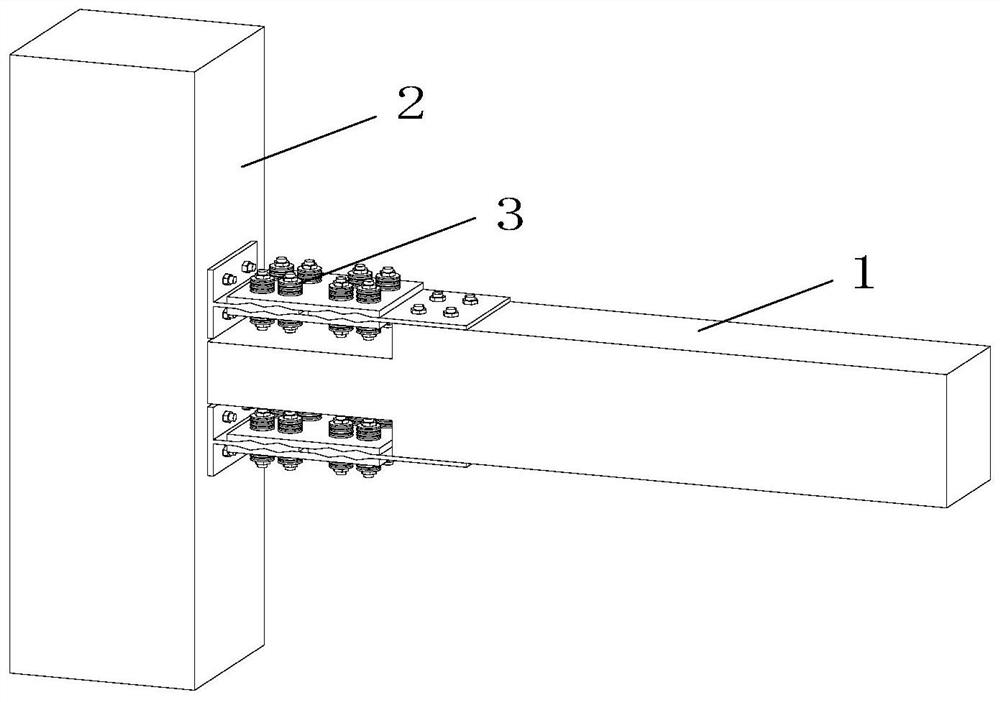

Friction type self-resetting cast-in-place beam column joint

ActiveCN112962807AReduce internal force requirementsLow damage stateProtective buildings/sheltersShock proofingReinforced concrete columnRebar

The invention relates to a friction type self-resetting cast-in-place beam column joint. The friction type self-resetting cast-in-place beam column joint comprises a weakened reinforced concrete beam, a reinforced concrete column and self-resetting friction type connecting pieces; and the weakened reinforced concrete beam and the reinforced concrete column are connected through cast-in-place, and the self-resetting friction type connecting pieces are additionally arranged in two weakened areas on the upper side and the lower side of the end of the weakened reinforced concrete beam. The friction type self-resetting cast-in-place beam column joint has the following beneficial effects that the damage mode of strong column and weak beam is realized by weakening the beam end, the damage is mainly concentrated on the replaceable self-resetting friction type connecting pieces at the beam end, and the internal force requirement of adjacent beam components is reduced; and energy consumption design, resetting design and replaceable design are integrated, the structural energy consumption can be increased through variable friction force, the structural damage can be reduced, self-resetting can be realized by utilizing the elasticity of a disc spring, residual deformation is reduced, periodic replacement of vulnerable components can be realized through full-bolt connection, and post-earthquake repair is facilitated.

Owner:BEIJING JIAOTONG UNIV

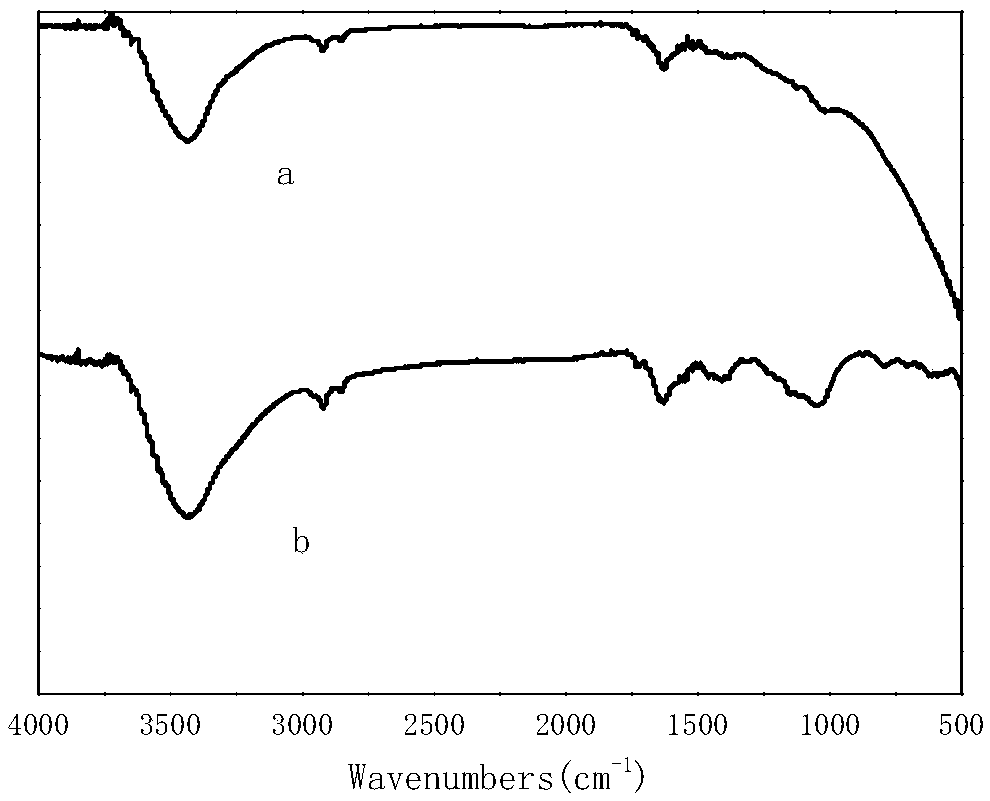

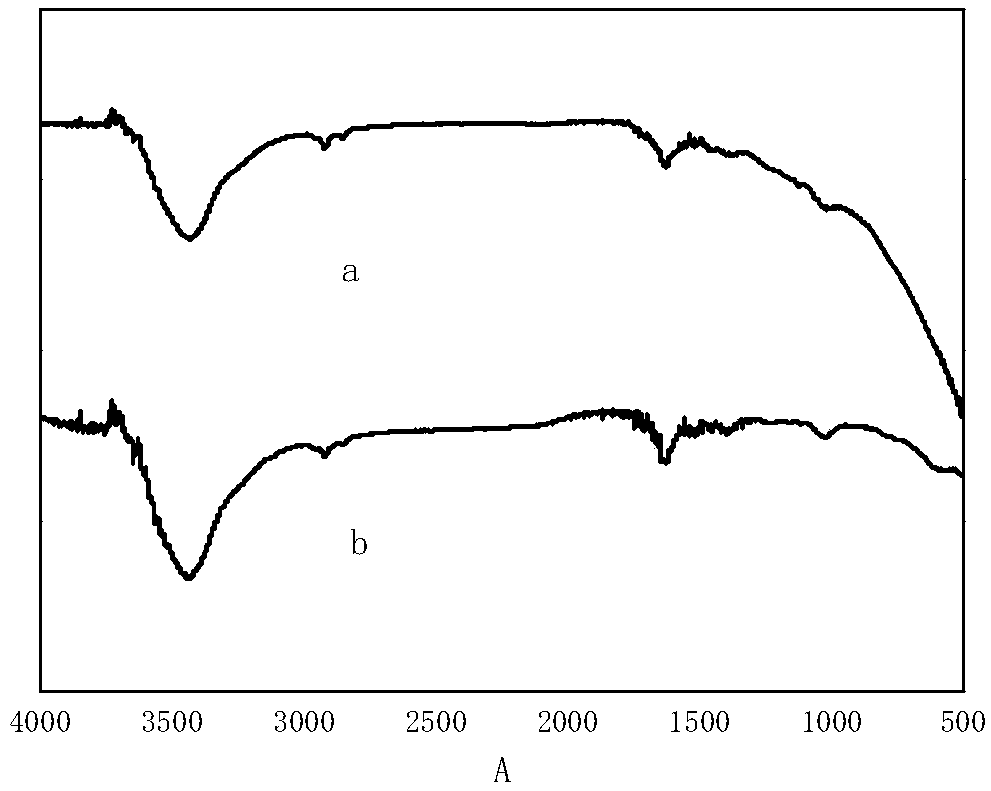

Carbon nanotube surface modification method

ActiveCN109052370AStructural damage is smallAvoid damageCarbon nanotubesOrganic solventFenton reagent

The invention belongs to the field of fine chemical industry, and relates to a carbon nanotube surface modification method. The carbon nanotube surface modification method comprises the following steps: (1) purifying an untreated carbon nanotube by utilizing a fenton reagent; (2) roasting the carbon nanotube treated in step (1) at a high temperature to further complete the purification; (3) covering the surface of the carbon nanotube treated in step (2) by utilizing poly-dopamine; and (4) modifying the carbon nanotube treated in step (3) by virtue of a coupling agent. By adopting the carbon nanotube surface modification method, the surface of the carbon nanotube is covered with the poly-dopamine, and the outer surface of the poly-dopamine is provided with the coupling agent, so that the carbon nanotubes can be stably dispersed in water or an organic solvent. Compared with the prior art, on the basis of not damaging the structure of the carbon nanotube, the dispersion performance is improved; and moreover, the carbon nanotube surface modification method has the advantages of simplicity in operation, no use of toxic reagent, no pollution, good dispersion effect and the like. The method is also suitable for a single-wall carbon nanotube and a multi-wall carbon nanotube.

Owner:CHANGZHOU UNIV

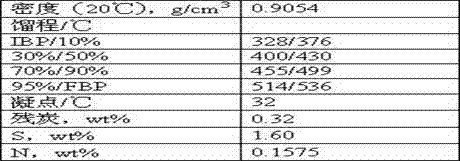

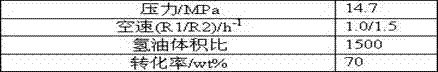

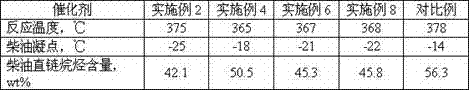

Hydrocracking catalyst for maximum production of low-solidifying point diesel oil and preparation method and application thereof

ActiveCN107344111AGood hydrogenation ring-opening abilityReduce manufacturing costMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveMetal

The invention discloses a hydrocracking catalyst for the maximum production of low-solidifying point diesel oil and a preparation method and an application thereof. The method includes the following content: (1) alumina powder, modified Y-type molecular sieve and modified Beta zeolite powder are uniformly mixed, then added with acid solution, sufficiently ground and then shaped, drying and roasting are then carried out, and thereby a catalyst carrier is obtained; (2) impregnating solution containing an active metal component is used for impregnating the catalyst carrier obtained in step (1), drying and roasting are then carried out, and thereby the hydrocracking catalyst is obtained. Since the catalyst prepared by the method adopts the novel modified molecular sieve, the catalyst has the characteristics of high hydrocracking activity and good isomerizing property, and the solidifying point of obtained hydrocracked diesel oil product is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

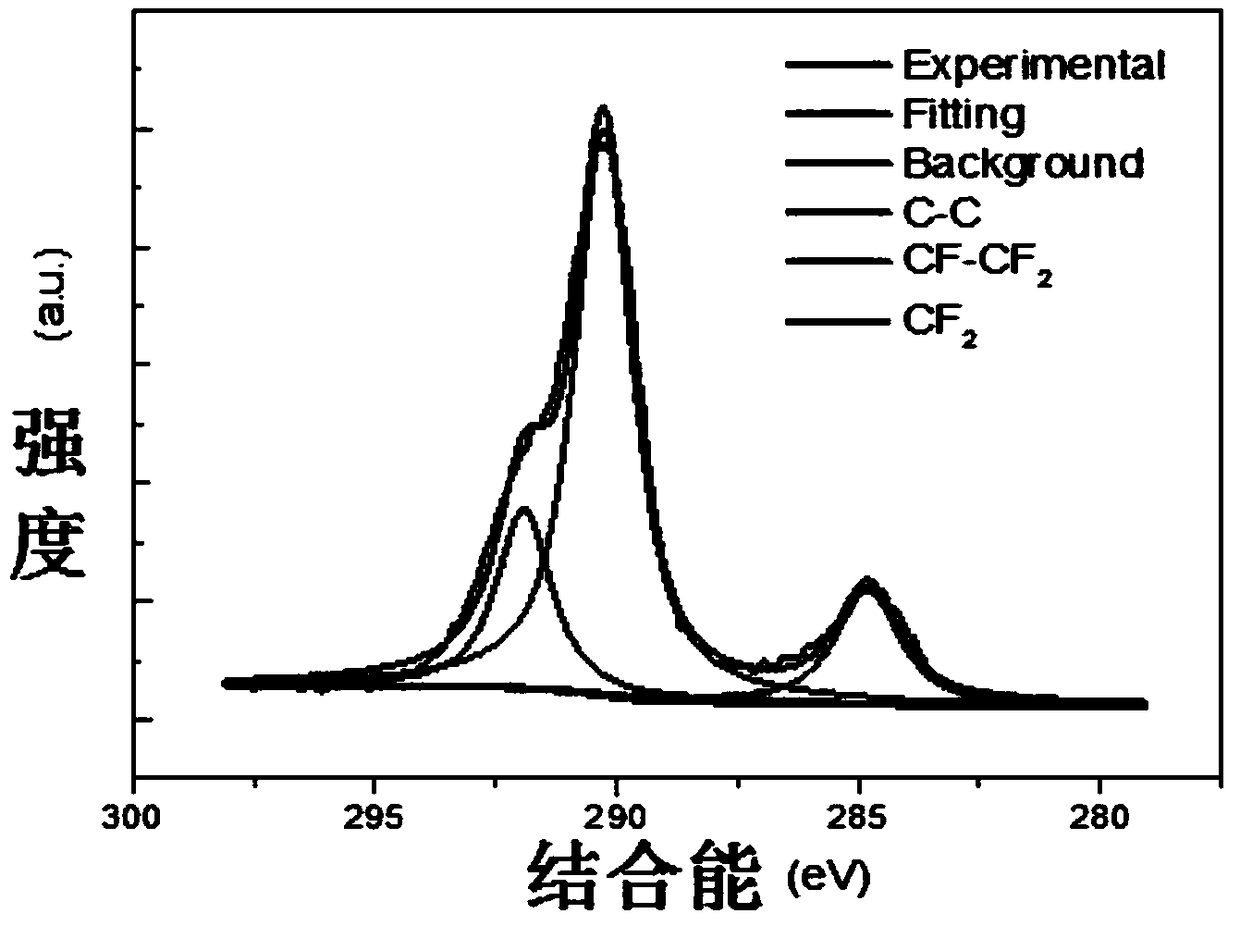

Fluorine-carbon ratio control method for fluorinated carbon nanotubes

InactiveCN108928809AImprove electron conductivityStructural damage is smallCarbon fluoridesSolventChemistry

The invention discloses a fluorine-carbon ratio control method for fluorinated carbon nanotubes. The method includes warming a mixture to perform reaction after uniformly mixing a fluorinated carbon nanotube and a polar solvent; and using the polar solvent to perform replacement on the fluorine in the carbon nanotube so as to make fluorine atoms detached from the carbon tube, or to weaken the acting force between fluorine and carbon so that defluoridation effects can be achieved. Through the selection of different polar solvents, hydrothermal temperatures and hydrothermal time, the method canwell control the defluorination amount of the carbon tube, and therefore, the fluorine-carbon ratio of the fluorinated carbon nanotube can be controlled; the method is simple in operation and high incontrollability; and compared with high temperature annealing treatments, the method can reduce damages to carbon tube structures and keep the excellent performance of the carbon tubes.

Owner:TIANJIN UNIV

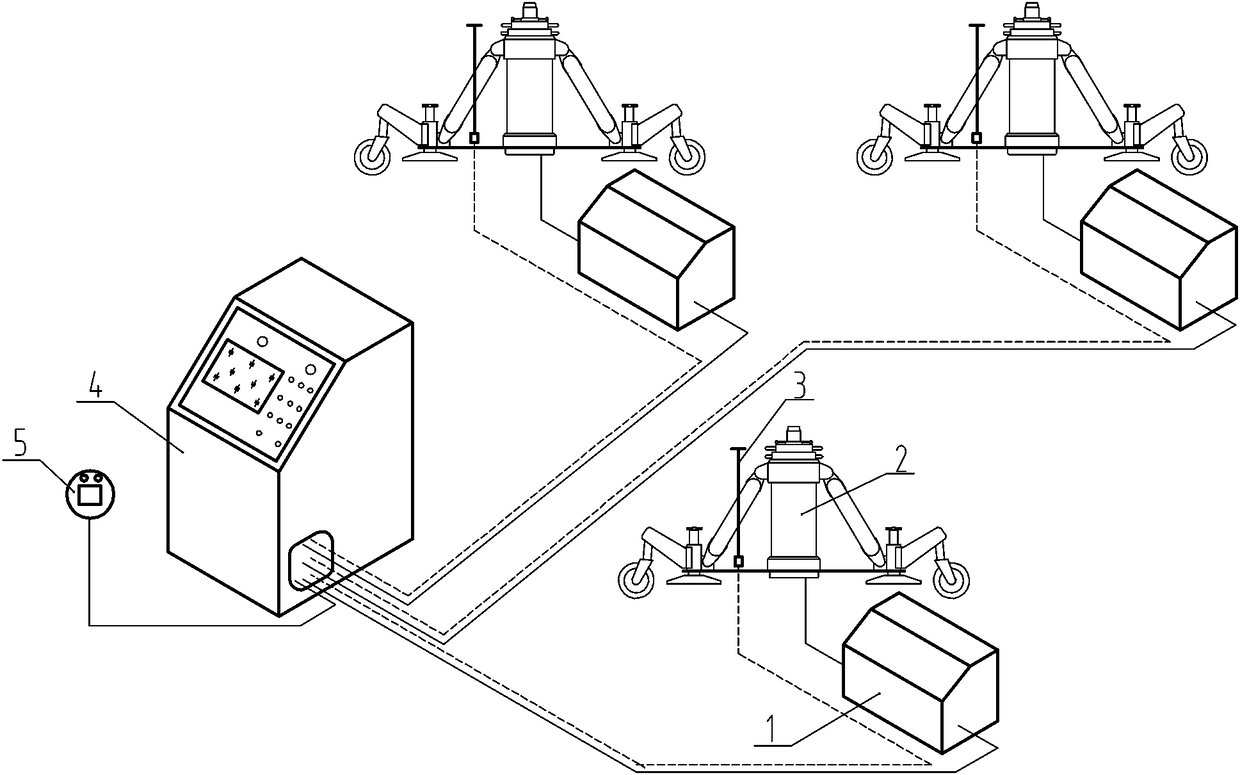

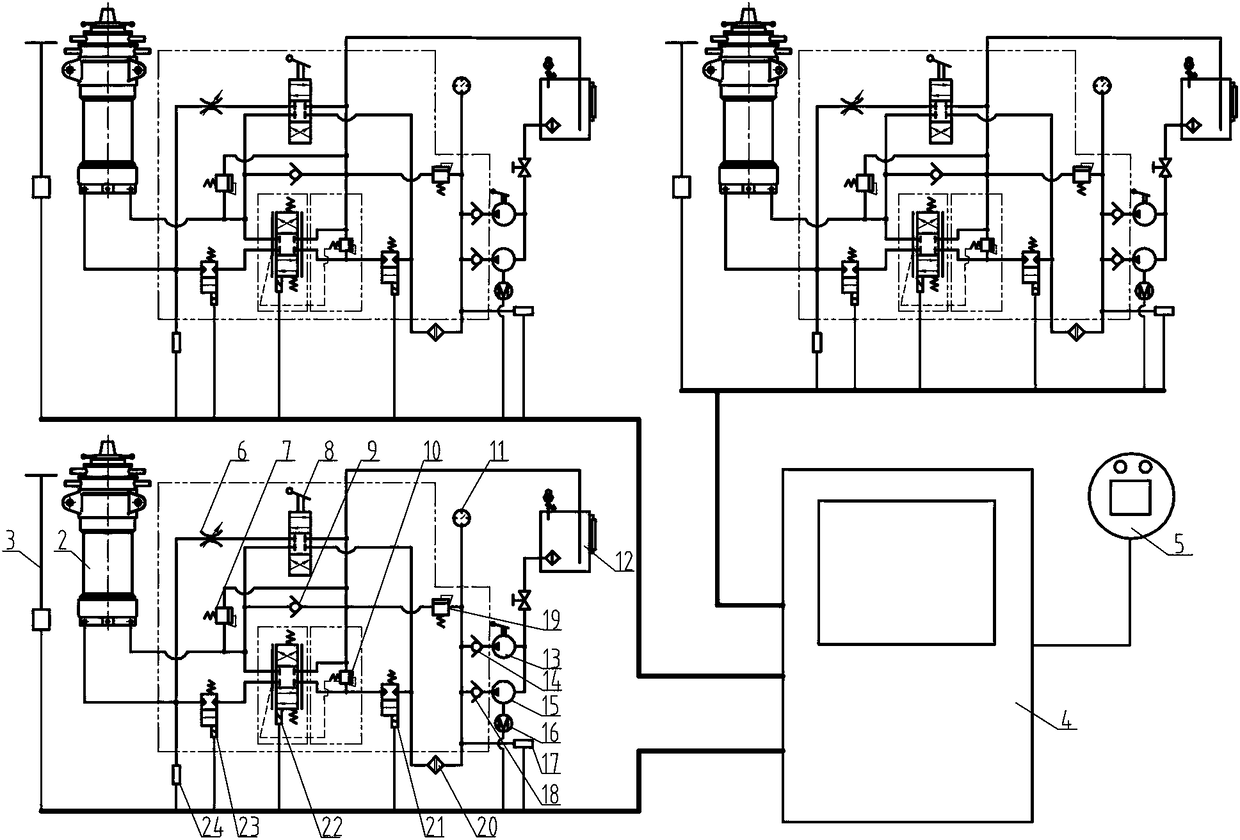

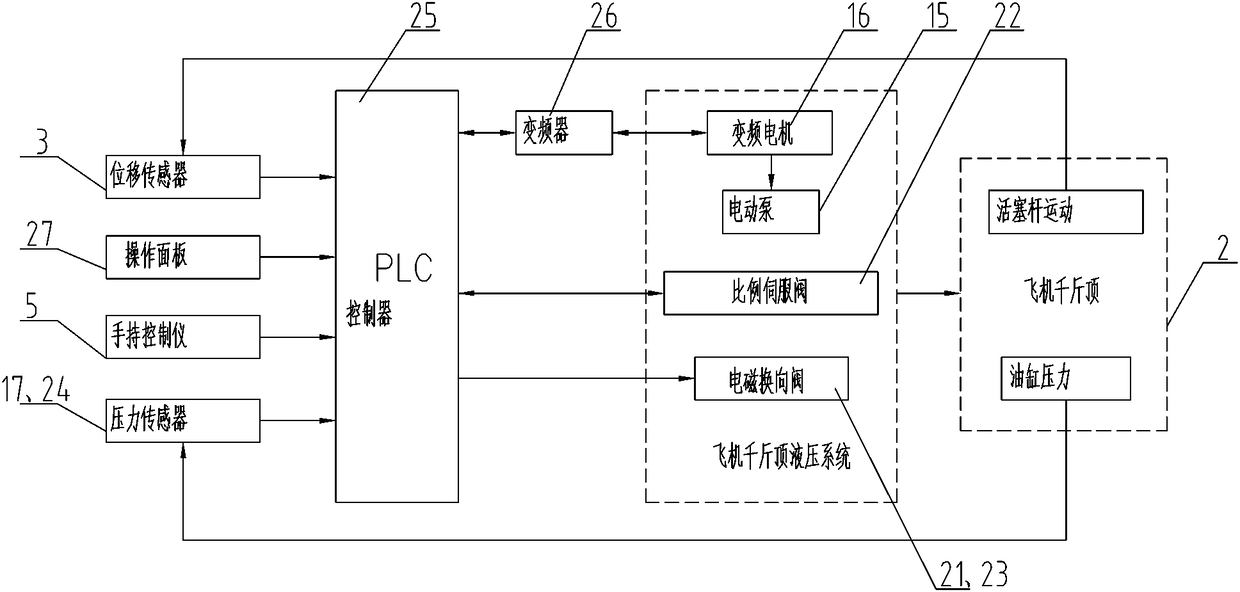

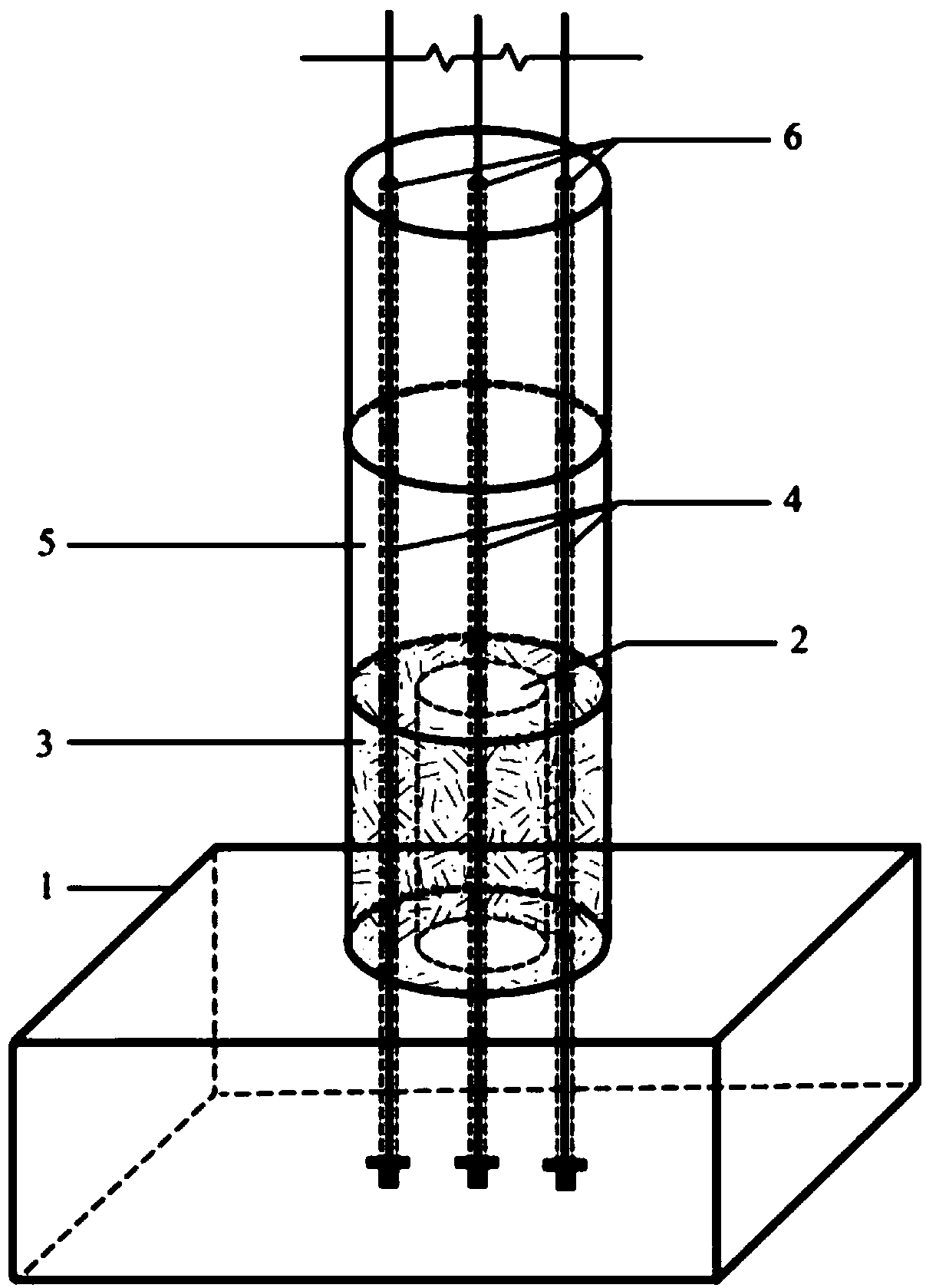

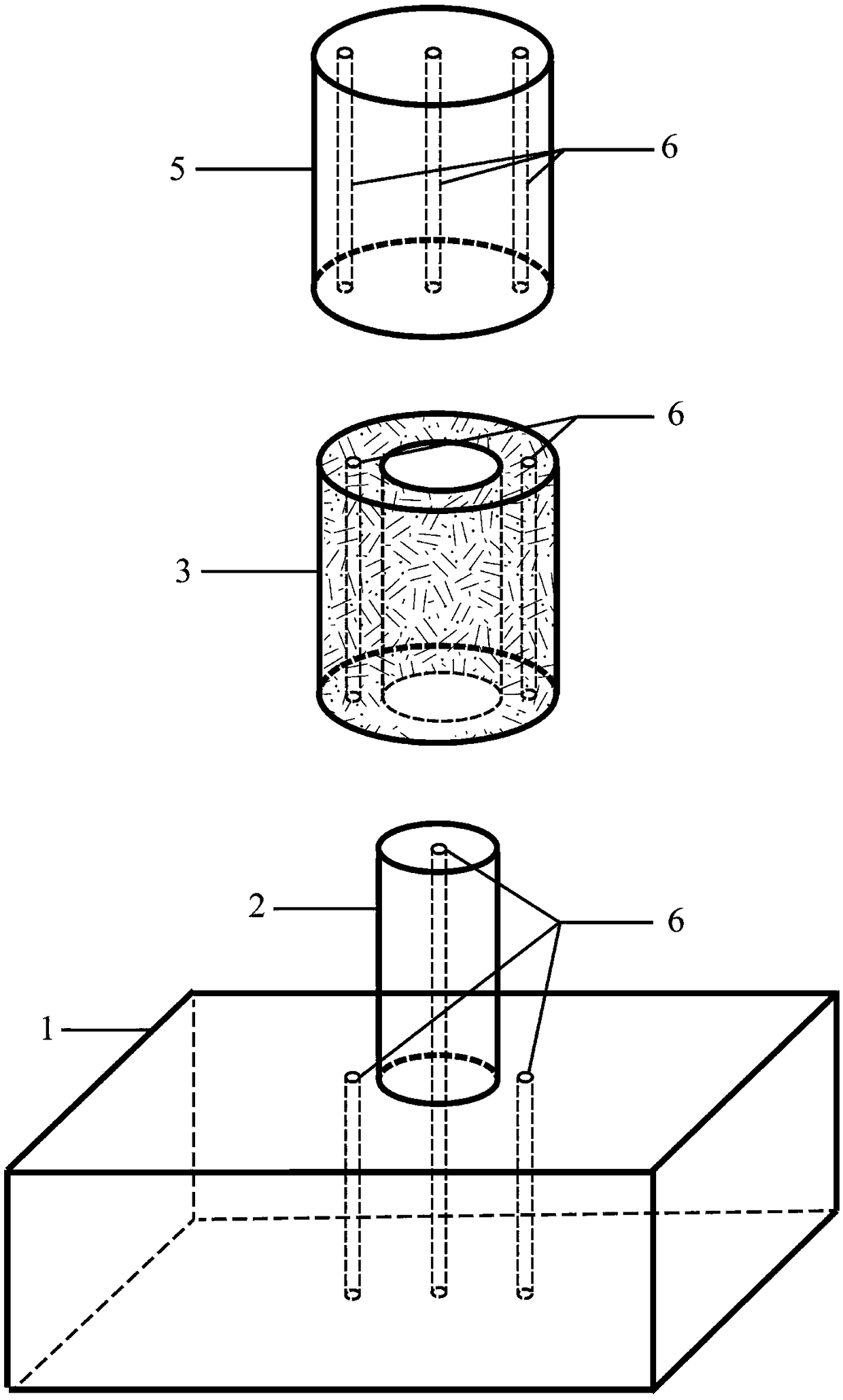

Multi-station synchronous lifting control system and operation method for aircraft takeoff and landing

PendingCN108408637AStructural damage is smallReduce labor intensityFluid-pressure actuator safetyServomotorsControl systemElectrical control

The invention provides a multi-station synchronous lifting control system and an operation method for aircraft takeoff and landing. The multi-station synchronous lifting control system comprises multiple sets of aircraft jacks with independent hydraulic pressure stations, wherein each aircraft jack is provided with a displacement sensor, all the hydraulic pressure stations are connected with an electrical control console through signal cables and control cables separately, and the electrical control console is connected with a handheld control instrument; each independent hydraulic pressure station is connected with the corresponding aircraft jack through a jack hydraulic system, and lifting movement of the aircraft jacks is synchronously controlled; and the jack hydraulic system is connected with an electrical control system, and the movement of the jack hydraulic system is controlled. The control system aims to control aircraft postures, altitude difference changes and the like, control contact force value changes in the aircraft lifting process and reduce the damage of the lifting process to the aircraft structure in the process of using the jacks to lift an aircraft.

Owner:凌云(宜昌)航空装备工程有限公司 +1

Decoloration method for enoxaparin sodium intermediate

ActiveCN103214597AMild conditions for oxidative decolorizationStructural damage is smallHigh concentrationDissolution

The invention discloses a decoloration method for an enoxaparin sodium intermediate. The decoloration method for the enoxaparin sodium intermediate comprises the following operation steps of: (1) dissolving the enoxaparin sodium intermediate by sodium chloride solution to obtain dissolution solution; (2) adding the dissolution solution obtained in the step (1) in hydrogen peroxide solution, and filtering to obtain filtrate; (3) adsorbing the filtrate obtained in the step (2) by macroporous anion exchange resin, sequentially washing by purified water and low-concentration sodium chloride solution, and eluting by high-concentration sodium chloride solution to obtain eluate after the adsorption is complete; and (4) precipitating the eluate obtained in the step (3) by ethanol, dehydrating, and vacuum-drying to obtain the enoxaparin sodium finished product.

Owner:山东万邦赛诺康生化制药股份有限公司

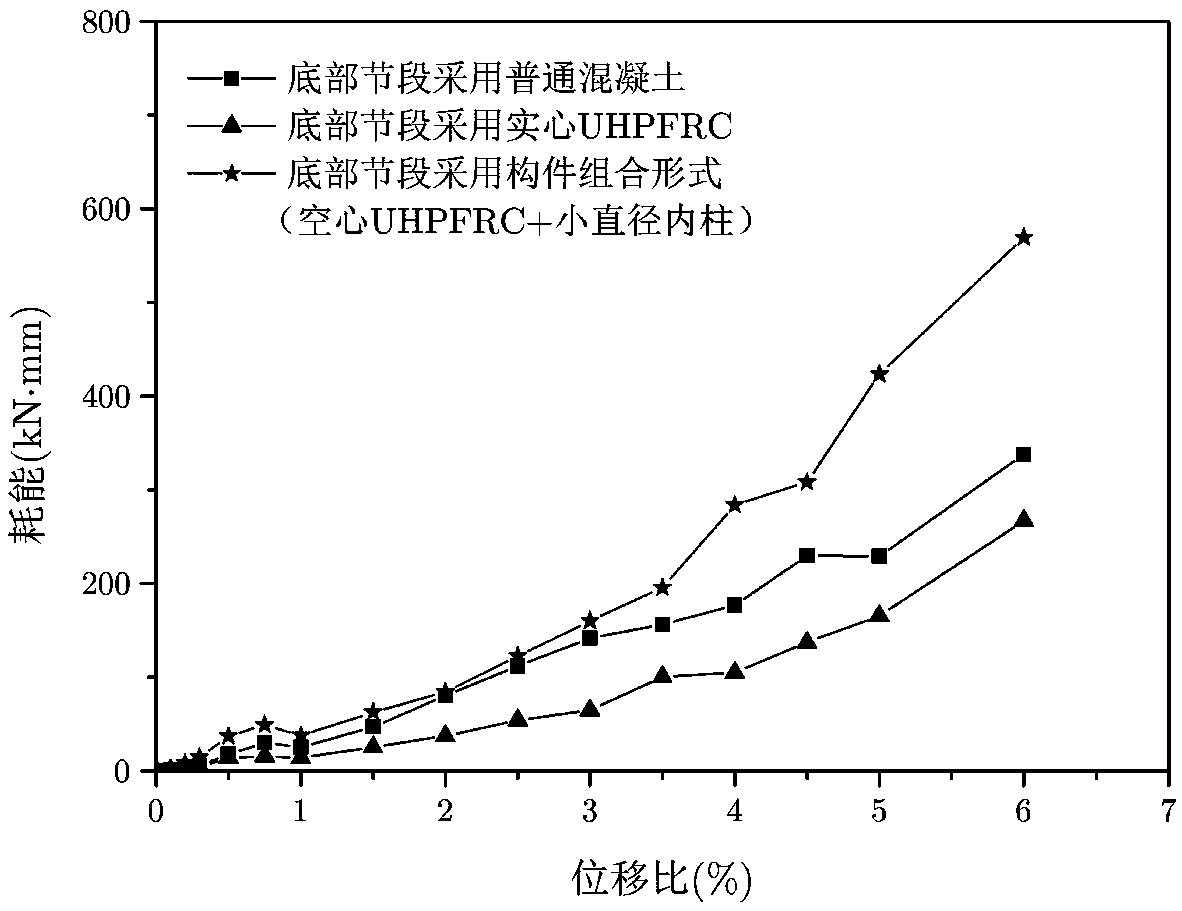

Prefabricated segmental assembling pier in the form of component combination for the bottom segments

InactiveCN109208463AImprove carrying capacityImprove energy consumptionBridge structural detailsBridge erection/assemblyPre stressEngineering

The invention provides a prefabricated segmental assembling pier in the form of component combination for the bottom segments. The prefabricated segmental assembling pier includes a bearing cap, a small-diameter pier column, hollow segmental pier bodies, a prestressed steel bars and a plurality of solid pier bodies. The bearing cap is fixed. The lower end of the small-diameter pier column is fixedwith the bearing cap, the hollow segmental pier bodies are arranged along the circumference of the small-diameter pier column and are fixed with the small diameter pier column. The solid pier bodiesat the lowest end are arranged on the small diameter pier column, and the hollow segment pier bodies, the upper solid pier body is arrange on the lower solid pier body, the prestressed steel bars respectively pass through the solid pier bodies, the hollow segment pier bodies and are fixed on the bearing cap or respectively pass through the solid pier bodies, and the small diameter pier column andare fixed on the bearing cap.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com