Prefabricated segmental assembling pier in the form of component combination for the bottom segments

A combined form and segment technology, used in the erection/assembly of bridges, bridges, bridge construction, etc., to prevent lateral shear displacement, reduce structural damage, and facilitate fabrication and construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

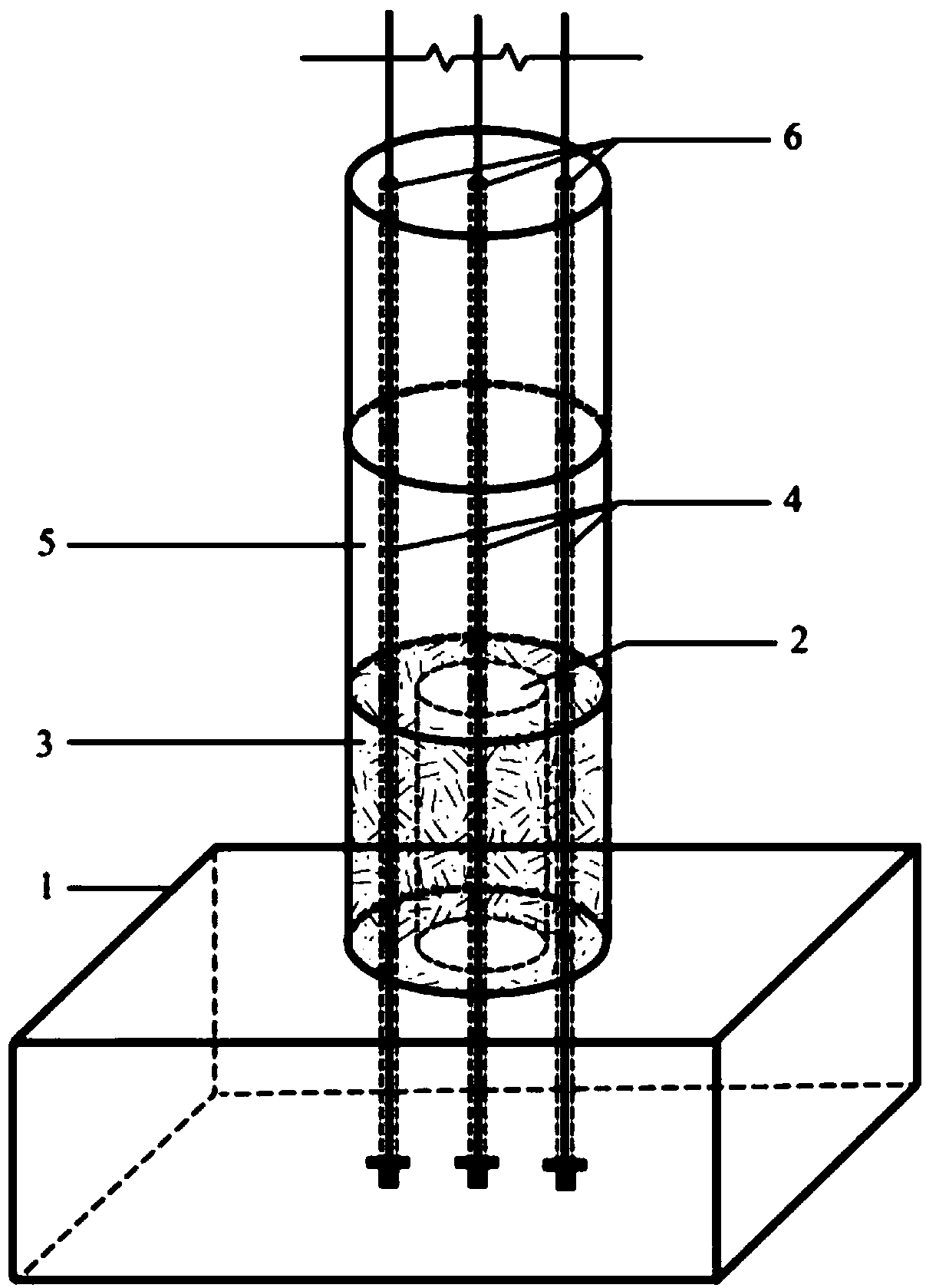

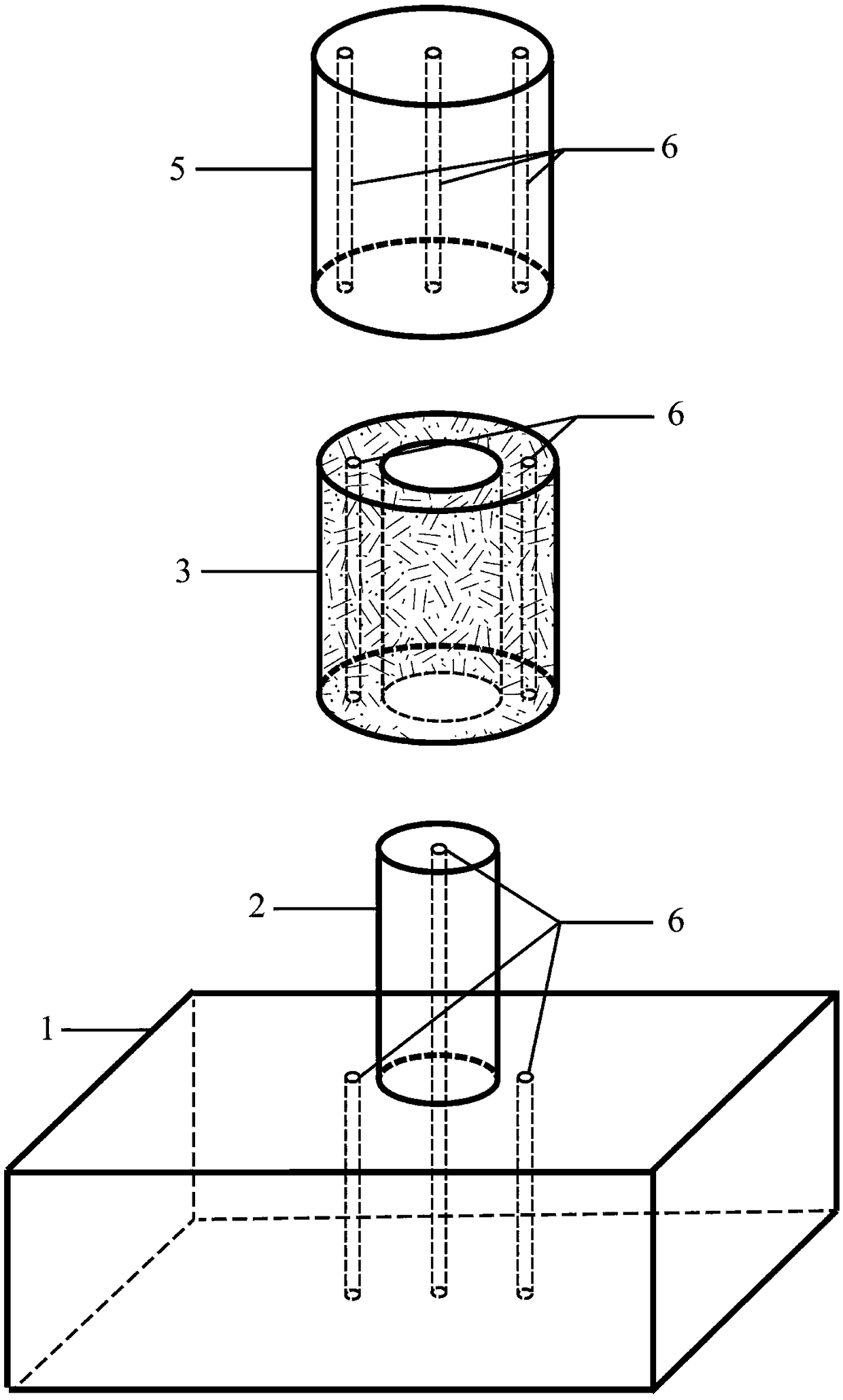

[0014] combine figure 1 , a prefabricated segmental assembled bridge pier in which the bottom segment adopts the form of component combination, mainly including a bearing 1 poured together with a small-diameter pier column 2, a solid pier body, a hollow segmental pier body 3, a steel cage, and a prestressed tendon 4; Reinforcement cages are respectively arranged in each pier column, and the reinforcement cage of pier column 2 poured together with cap 1 extends to the inside of cap 1 and is welded with the steel bars inside cap 1, and the hollow segment pier body 4 and cap 1 The consolidated small-diameter pier columns 2 are bonded by high-strength grouting materials to form the bottom section of the entire pier. Three prestressed tendons 4 are arranged along the diameter direction of the circular cross-section, and the bottom is anchored in the cap 1. All sections They are all connected by four prestressed tendons and assembled into a bridge pier, and the prestressed tendons 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com