Device for preparing graphene by dry grinding and stripping with and method for production graphene

A dry grinding and production method technology, applied in the field of graphene, can solve problems such as graphene lattice defects, reduce graphene size, and graphite lattice damage, achieve easy large-scale production, prevent aggregation and reduce structural damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

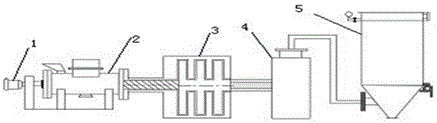

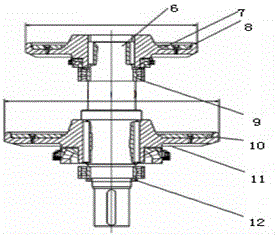

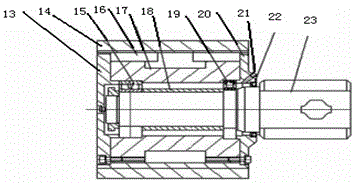

[0034] A device for preparing graphene by dry grinding and stripping, such as figure 1 As shown, it includes drive device (1), disc rolling device (2), tandem disc extruder (3), swirl disperser (4), product collector (5), and the disc The rolling device (2) consists of a main shaft (6), an upper plate (7), an upper liner (8), and a bearing (9); a lower liner (10), a lower plate (11), and a bearing (12). In order to gradually shear and peel off graphite to form sheet-type orientation, slide between layers, and use subsequent deep peeling to prepare graphene, its disc rolling device is provided with a feeding port; wherein the disc rolling device (2 The grinding roller in ) consists of front end cover (13), roller sleeve (14), self-aligning roller bearing (15), flat key (16), roller body (17), spacer sleeve (18), cylindrical roller bearing (19 ), the rear end cover (20), the oil hole bolt (21), the oil seal (22), and the roller shaft (23). Shearing and exfoliating graphite, th...

Embodiment 2

[0036] The present embodiment provides a kind of production method of graphene, and it is the method that adopts the preparation device of the graphene of embodiment 1 to carry out production, and this method comprises the following steps;

[0037] (1) Put graphite and stripping agent into the disc-type rolling device, grind and strip the graphite step by step through the relative movement of the grinding roller and the grinding disc to obtain graphene coarse material, the rotation speed is 500 rpm; the stripping agent is urea, sodium cholate, P-benzenesulfonamide is prepared according to the mass ratio of 1:2:1

[0038] (2) Pass the graphene coarse material obtained in step (1) through a tandem grinding disc extruder, and use the strong shear force generated by the relatively high-speed movement of the dynamic and static grinding discs, dragging shear and exchange to make the graphite layers slide, Graphene is obtained by exfoliating layer by layer at different stages, and th...

Embodiment 3

[0042] The present embodiment provides a kind of production method of graphene, and it is the method that adopts the preparation device of the graphene of embodiment 1 to carry out production, and this method comprises the following steps;

[0043] (1) Put graphite and stripping agent into the disc-type rolling device, grind and strip the graphite step by step through the relative movement of the grinding roller and the grinding disc to obtain graphene coarse material, the rotation speed is 2000 rpm; the stripping agent is urea, sodium cholate, P-benzenesulfonamide is prepared according to the mass ratio of 1:5:3

[0044] (2) Pass the graphene coarse material obtained in step (1) through a tandem grinding disc extruder, and use the strong shear force generated by the relatively high-speed movement of the dynamic and static grinding discs, dragging shear and exchange to make the graphite layers slide, Graphene is obtained by exfoliating layer by layer at different stages, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com