Fluorine-carbon ratio control method for fluorinated carbon nanotubes

A technology of fluorinated carbon nanotubes and fluorocarbon ratio, which is applied in the direction of fluorinated carbon, can solve the problems of high electronic conductivity and difficult precise control, and achieve the effect of high electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

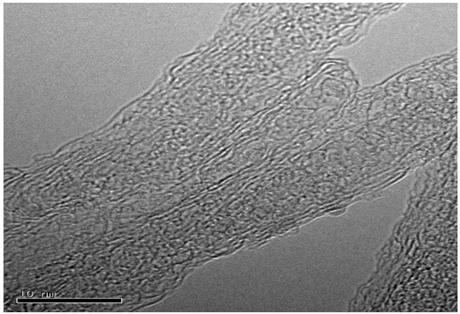

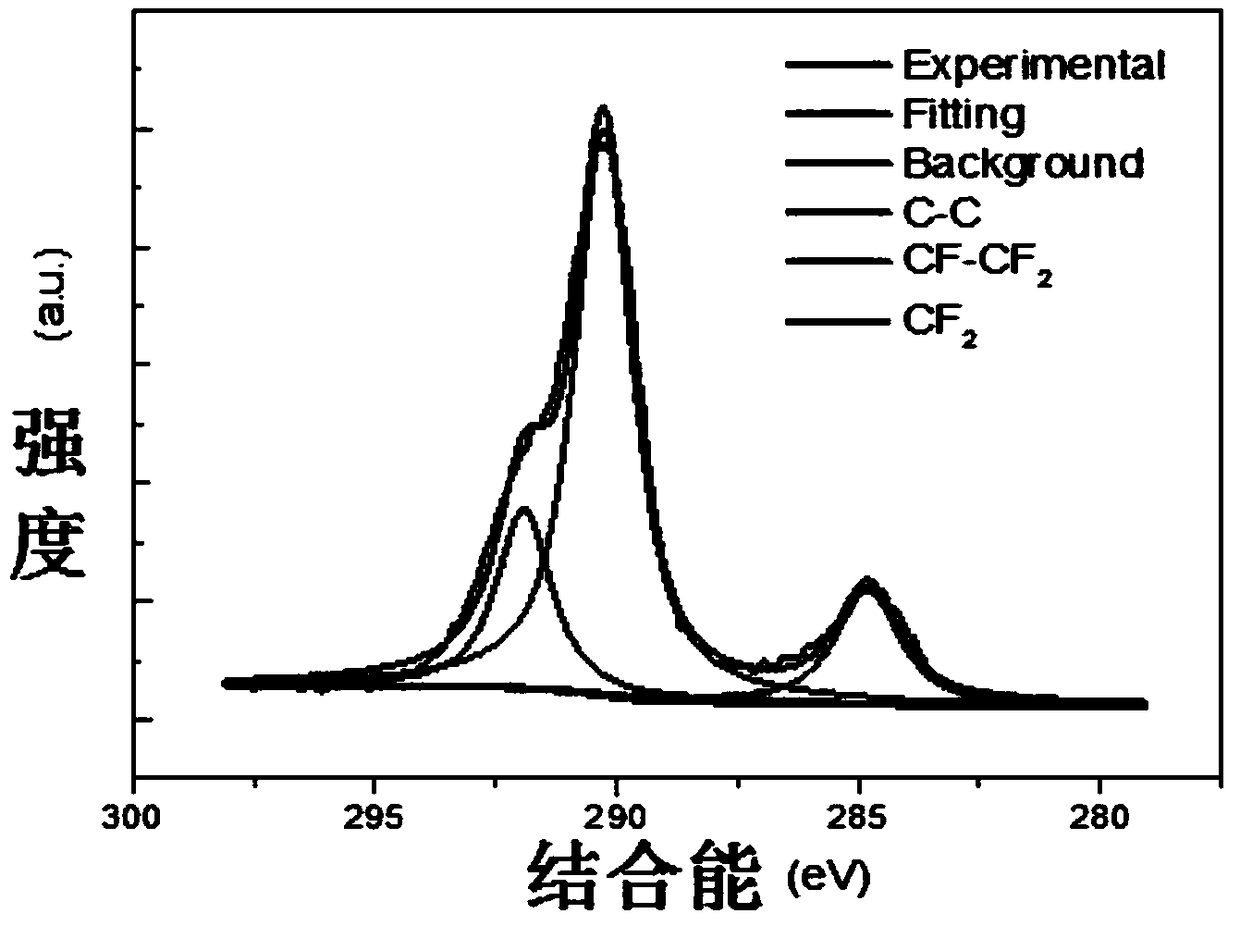

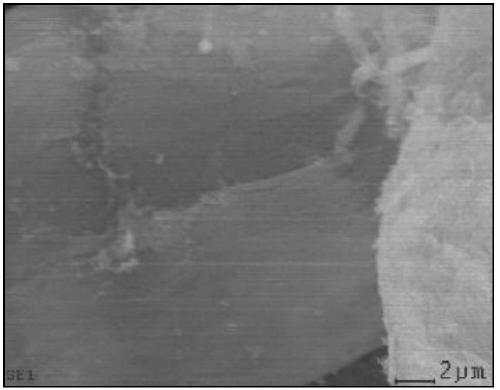

[0020] Mix 60g of fluorinated multi-walled carbon nanotubes and 80mL of isopropanol evenly, sonicate for 1h, then transfer the dispersion to a hydrothermal kettle, raise the temperature to 130°C in a muffle furnace and keep it for 24h; Pour the multi-walled carbon nanotubes into a sand core funnel for suction filtration, wash with deionized water for several times until it is clean, then transfer the filter membrane to a petri dish, place it in a vacuum drying oven, and dry it at 60°C for 24 hours . The fluorine-to-carbon ratio of the fluorinated multi-walled carbon nanotubes was measured to be 0.65.

Embodiment 2

[0022] Mix 80g of fluorinated multi-walled carbon nanotubes and 80mL of tetrahydrofuran evenly, ultrasonicate for 2h, then transfer the dispersion to a hydrothermal kettle, raise the temperature to 150°C in a muffle furnace and keep it for 24h; Wall carbon nanotubes were poured into a sand core funnel for suction filtration, washed with deionized water for several times until clean, then the filter membrane was transferred to a petri dish, placed in a vacuum drying oven, and dried at 60°C for 24 hours. The fluorine-to-carbon ratio of the fluorinated multi-walled carbon nanotubes was measured to be 0.59.

Embodiment 3

[0024] Mix 80g of fluorinated multi-walled carbon nanotubes and 80mL of ethylene glycol evenly, ultrasonicate for 2h, then transfer the dispersion to a hydrothermal kettle, raise the temperature to 150°C in a muffle furnace and keep it for 24h; Pour the multi-walled carbon nanotubes into a sand core funnel for suction filtration, wash with deionized water for several times until it is clean, then transfer the filter membrane to a petri dish, place it in a vacuum drying oven, and dry it at 60°C for 24 hours . The fluorine-to-carbon ratio of the fluorinated multi-walled carbon nanotubes was measured to be 0.76.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com