Surface modified positive electrode material for solid-state lithium battery and preparation method thereof

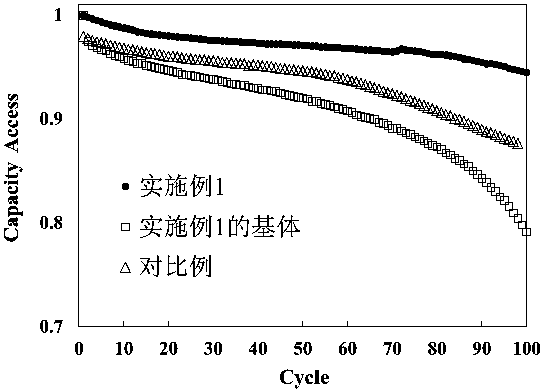

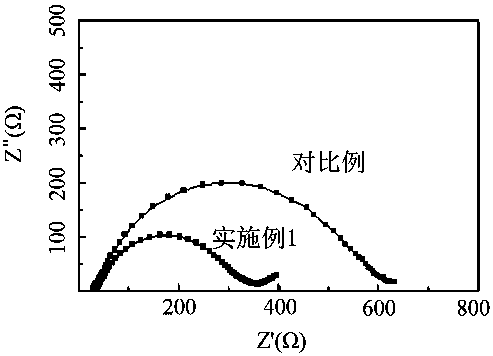

A technology of surface modification and positive electrode material, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of low electronic conductivity, and achieve the effect of alleviating electrode polarization, ensuring charge transfer, and improving electronic conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0041] The solid-state lithium battery assembly process in the following embodiments 1-6 is:

[0042] (1) Preparation of positive electrode sheet: Dissolve PEO, PS, and LiTFSI in acetonitrile at a weight ratio of 2:1 to form a uniform solution, and then add the modified positive electrode material and acetylene black to the above-mentioned The solution is prepared as a slurry. Then, the slurry was coated on a carbon-coated aluminum foil, and vacuum-dried at 60° C. for 10 h to obtain a positive electrode sheet.

[0043] (2) Preparation of solid electrolyte: PEO, LiTFSI, solid electrolyte Li 7 La 3 Zr 2 o 12 The nanoparticles are dissolved in acetonitrile according to the weight ratio of 6:3:1, and the slurry is formed after uniform mixing. The slurry was coated on a polytetrafluoroethylene film, and after drying at 60° C. for 12 hours, the polytetrafluoroethylene film was peeled off to obtain a solid electrolyte.

[0044] (3) Preparation of solid-state lithium battery: Th...

Embodiment 1

[0055] (1) The preparation method of the cathode active material matrix is consistent with that of the comparative example.

[0056] (2) According to the coating Li 3.9 Mg 0.1 Ti 4.9 Zr 0.1 o 12 In the metering ratio of each element, weigh the raw materials lithium acetate, magnesium carbonate, tetrabutyl titanate, zirconium nitrate solution. Dissolve the above raw materials in ethanol solution, add 0.01mol / L citric acid and stir at room temperature, then add ammonia water to the above solution to form a mixed solution with pH=10.

[0057] (3) Add the cathode active material matrix into the above mixed solution, stir at 60°C for 1 hour, and then transfer it to a vacuum drying oven at 100°C to dry completely to obtain a dry powder.

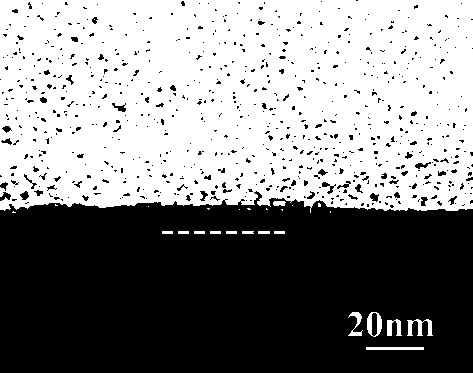

[0058] (4) Sieve the above dry powder, then sinter at 600°C for 5h, after cooling to room temperature, crush and sieve to obtain Li 3.9 Mg 0.1 Ti 4.9 Zr 0.1 o 12 A surface-modified positive electrode material for a coated solid-state li...

Embodiment 2

[0063] (1) The preparation method of the cathode active material matrix is consistent with that of the comparative example.

[0064] (2) According to the coating Li 4 Ti 4.8 Mo 0.2 o 12 In the metering ratio of each element, the raw materials lithium nitrate, titanyl sulfate and ammonium molybdate were weighed. Dissolve the above raw materials in a mixed solution of ethanol and water (ethanol: water = 1: 3), stir at room temperature, and then add triethanolamine to the above solution to form a mixed solution with pH = 9.2.

[0065] (3) Add the positive electrode active material matrix into the above mixed solution, stir at 70°C for 1 hour, and then transfer it to a vacuum drying oven at 120°C for complete drying.

[0066] (4) Sieve the above dried product, then sinter at 700°C for 6h, and after cooling to room temperature, crush and sieve to obtain Li 4 Ti 4.8 Mo 0.2 o 12 A surface-modified positive electrode material for a coated solid-state lithium battery. The thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com