Positive electrode active material for all-solid-state lithium ion batteries, positive electrode for all-solid-state lithium ion batteries, all-solid-state lithium ion battery, and method for producing positive electrode active material for all-solid-state lithium ion batteries

A cathode active material, lithium ion battery technology, applied in the direction of active material electrodes, solid electrolytes, lithium batteries, etc., to achieve the effect of improving electronic conductivity and good output characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

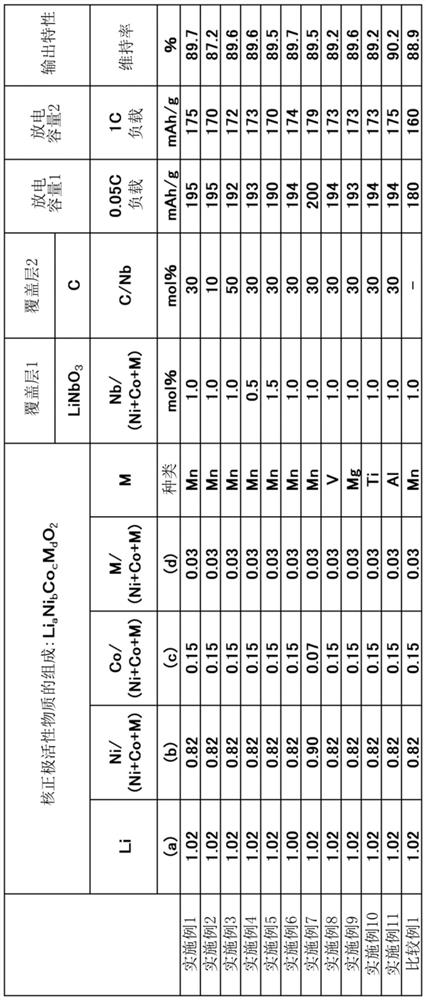

Examples

Embodiment 1

[0043] (1) Manufacturing process of nuclear cathode active material

[0044] Commercially available nickel sulfate, cobalt sulfate, and manganese sulfate are made into an aqueous solution, mixed so that the molar ratio of Ni, Co, and M becomes a specified value, and coprecipitated with an alkali (sodium hydroxide) solution while fully stirring React, filter and wash. The reaction method is carried out according to a conventional method. Thereafter, the coprecipitation reactant was mixed with lithium hydroxide monohydrate so that the molar ratio of Li to the total of Ni, Co, and M (Li / (Ni+Co+M)) became a predetermined value, and the Firing in a roller hearth kiln (firing temperature 720°C, firing time 24 hours), crushing with a roll mill and a pulverizer to obtain a nuclear positive electrode with a particle size D50 of 4.5 μm substance.

[0045] (2) Covering process of nuclear positive electrode active material

[0046] with LiOC 2 h 5 and Nb(OC 2 h 5 ) 5 solution, us...

Embodiment 2

[0048] A positive electrode active material in which the core positive electrode active material was coated with lithium niobate and simple carbon was obtained in the same manner as in Example 1, except that the simple substance of carbon was covered with respect to Nb at 10 mol%.

Embodiment 3

[0050] A positive electrode active material in which the core positive electrode active material was coated with lithium niobate and simple carbon was obtained in the same manner as in Example 1, except that the simple substance of carbon was covered with respect to Nb at 50 mol%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com