Preparation method of iron ion doped TiO2 nanotube array photocatalyst

A nanotube array, photocatalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, catalyst carriers, etc., can solve the problems of poor visible light catalysis effect and high energy consumption, and achieve improved The effect of photocatalytic reaction activity, low energy consumption, and enhanced electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

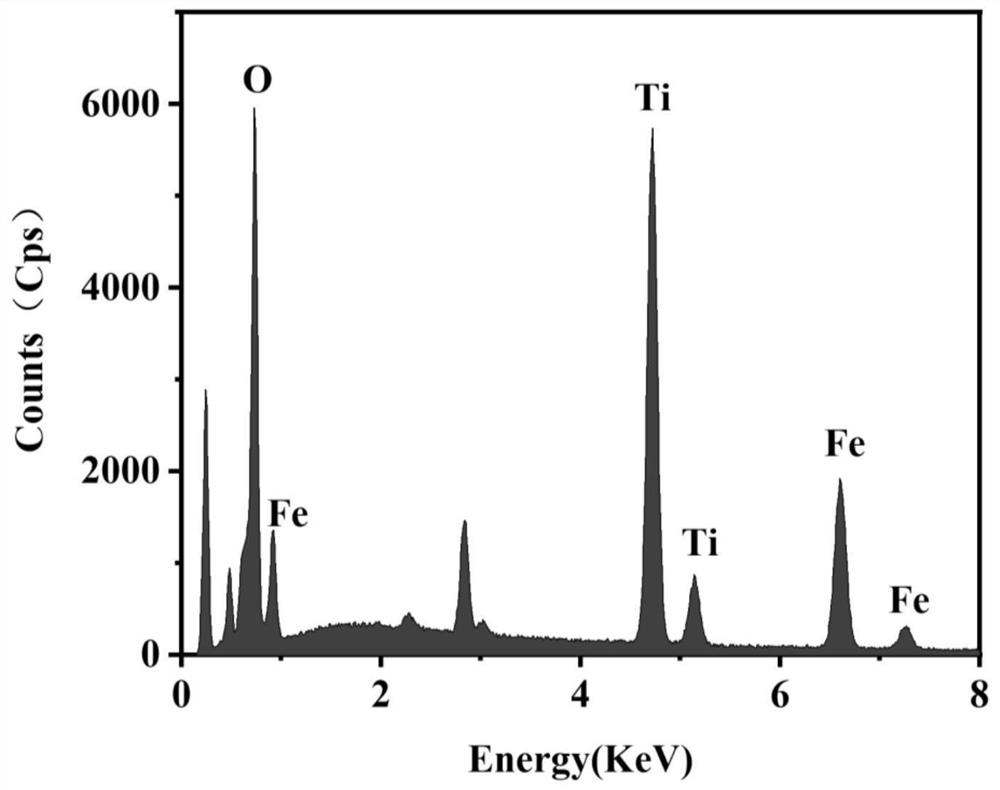

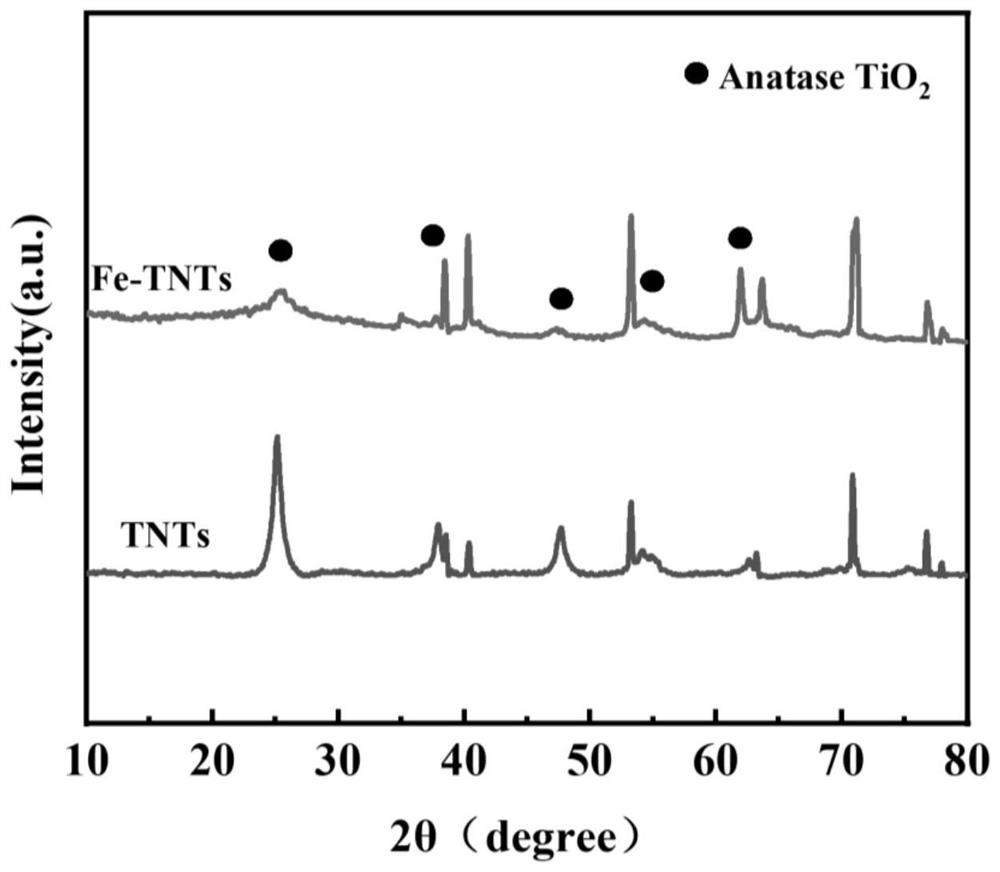

[0050] Example 1: Iron ion doped TiO 2 The preparation method of nanotube array photocatalyst comprises the following steps:

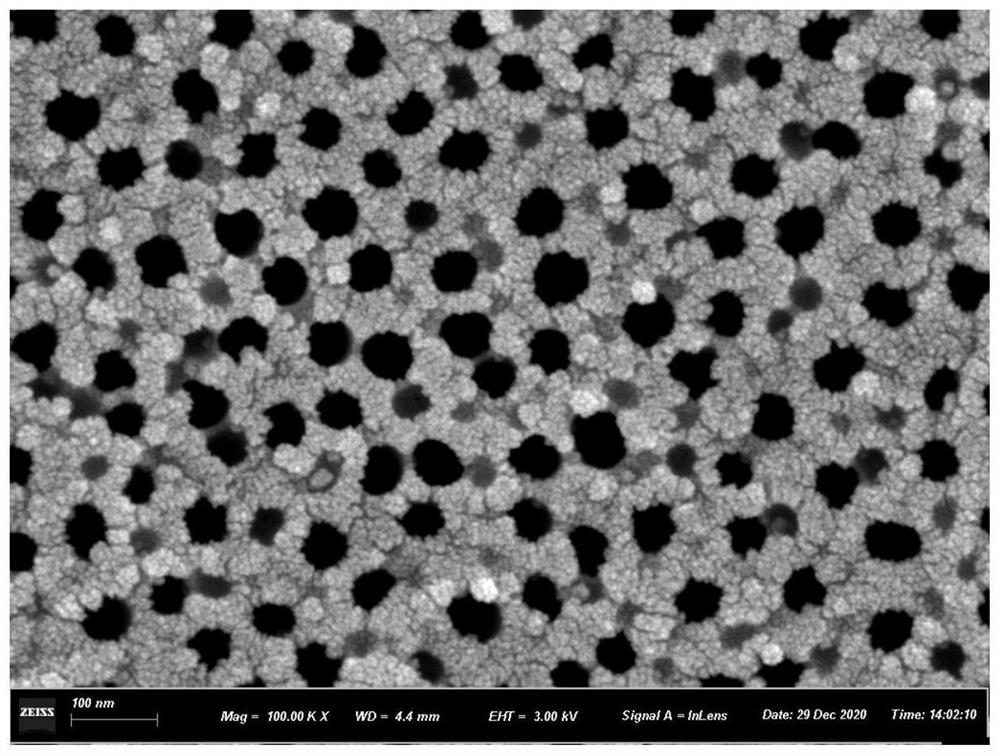

[0051] S1, TiO 2 Fabrication of nanotube arrays

[0052] Preparation of Amorphous TiO by Electrochemical Anodic Oxidation 2 Nanotube arrays, specifically as follows:

[0053] S11, the high-purity titanium sheet 22 with a purity of 99.99% treated by the chemical polishing solution is ultrasonically cleaned in acetone, absolute ethanol and deionized water for 15 minutes by an ultrasonic cleaning device, and dried for use;

[0054] S12, using 0.4wt% ammonium fluoride as a solute, and a mixture of glycerol and deionized water with a volume ratio of 98:2 as a solvent to prepare an organic fluorine-containing electrolyte;

[0055] S13, under the condition of 55V DC voltage, the titanium sheet 22 after cleaning and drying is used as the anode, the platinum electrode with the same area as the titanium sheet 22 is used as the cathode, and the organic fluori...

Embodiment 2

[0082] Example 2: Iron ion doping TiO 2 The difference between the preparation method of the nanotube array photocatalyst and Example 1 is that it comprises the following steps:

[0083] S1, TiO 2 Fabrication of nanotube arrays

[0084] Preparation of Amorphous TiO by Electrochemical Anodic Oxidation 2 Nanotube arrays, specifically as follows:

[0085] S11, the high-purity titanium sheet 22 with a purity of 99.7% treated by the chemical polishing solution is ultrasonically cleaned in acetone, absolute ethanol and deionized water for 5 minutes by an ultrasonic cleaning device, and dried for use;

[0086] S12, using 0.2wt% sodium fluoride as a solute, and a mixture of ethylene glycol and deionized water with a volume ratio of 98:2 as a solvent to prepare an organic fluorine-containing electrolyte;

[0087] S13. Under the condition of 50V DC voltage, the cleaned and dried titanium sheet 22 is used as the anode, the platinum electrode with the same area as the titanium sheet 2...

Embodiment 3

[0095] Example 3: Iron ion doped TiO 2 The difference between the preparation method of the nanotube array photocatalyst and Example 1 is that it comprises the following steps:

[0096] S1, TiO 2 Fabrication of nanotube arrays

[0097] Preparation of Amorphous TiO by Electrochemical Anodic Oxidation 2 Nanotube arrays, specifically as follows:

[0098] S11. The high-purity titanium sheet 22 with a purity of 99.999% treated by the chemical polishing solution is ultrasonically cleaned in acetone, absolute ethanol and deionized water for 25 minutes by an ultrasonic cleaning device, and dried for use;

[0099] S12, using 0.5wt% ammonium fluoride as a solute, and a mixture of glycerol and deionized water with a volume ratio of 98:2 as a solvent to prepare an organic fluorine-containing electrolyte;

[0100] S13. Under the condition of 60V DC voltage, the cleaned and dried titanium sheet 22 is used as the anode, the platinum electrode with the same area as the titanium sheet 22 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com