Multi-station synchronous lifting control system and operation method for aircraft takeoff and landing

A technology for synchronous lifting and control systems, which is applied in aircraft maintenance, fluid pressure actuation system safety, fluid pressure actuation system components, etc. It can solve the impact of the structure of the load object, uncontrolled variable load hydraulic cylinder, and easy damage to the body structure and other issues to achieve the effect of reducing quantity, reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

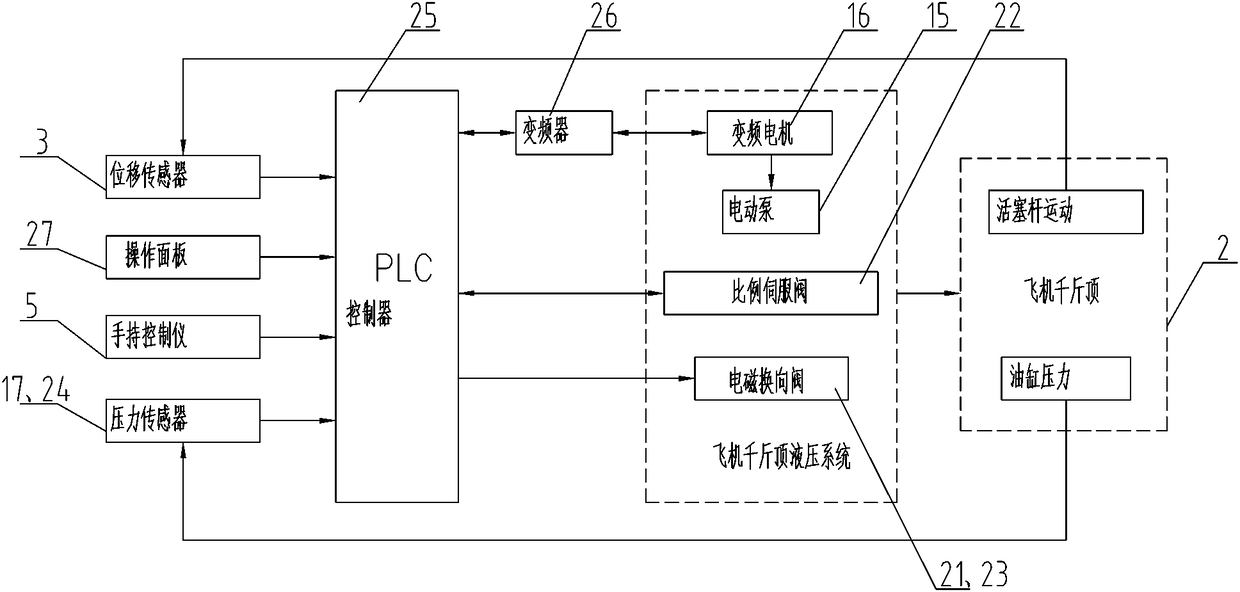

[0071] The control strategy of the multi-station synchronous lifting control system of the present invention includes:

[0072] 1) Overall control strategy

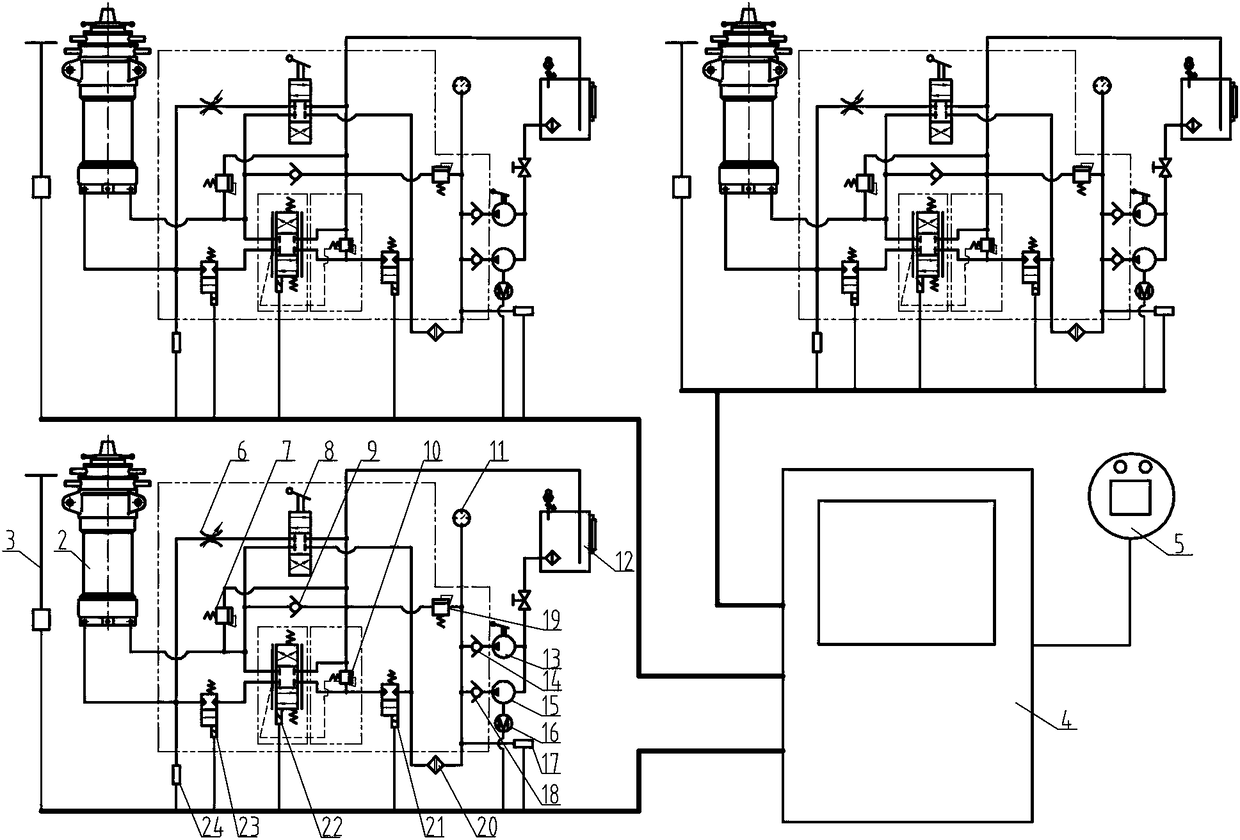

[0073] The system uses a proportional servo valve to adjust the oil supply of the hydraulic system to the jack, thereby controlling the operating speed of the jack. By comparing the position of each jack, calculating and analyzing the adjustment speed of each jack, adjusting the proportional servo valve to adjust the opening of the spool, and adjusting the operating speed of each jack to achieve a synchronous effect.

[0074] The oil pump is used to supply oil during the lifting stage of the jack, and the flow rate is adjusted by the proportional servo. The falling stage relies on the load to compress the jack, the jack returns oil, and the proportional servo valve adjusts the flow of the reverse oil circuit.

[0075] The control system monitors the position, pressure and force of each jack in real time, controls the op...

Embodiment 3

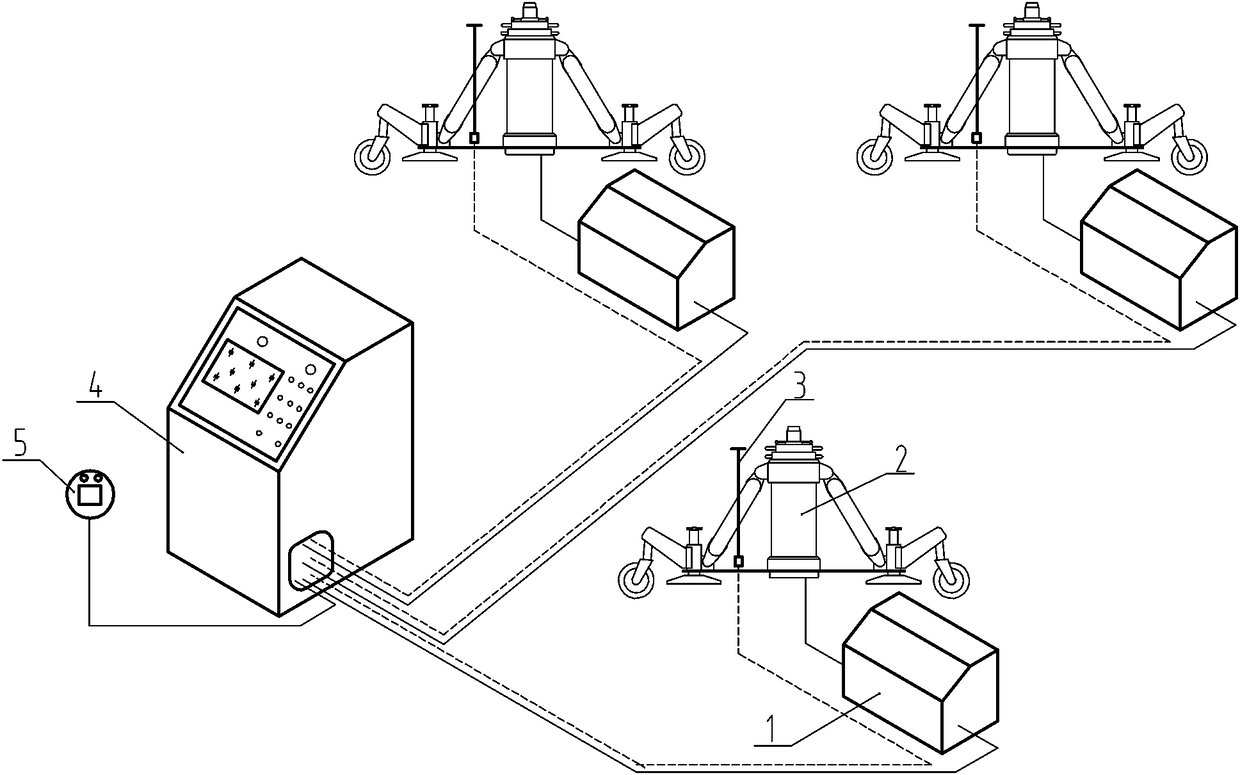

[0097] The operation method of carrying out aircraft jacking by adopting any one of the multi-station synchronous lifting control system includes the following steps:

[0098] S1: Maintenance preparation, make preparations for the aircraft jacking up according to the safety operation regulations;

[0099] S2: In-place operation, put down the wheels of the aircraft jack, push the aircraft jack to the vicinity of the support point of the jack, continuously move the aircraft jack so that the nest is aligned with the support point of the aircraft jack, put away the wheels of the aircraft jack, and place the support plate on the ground, manual or electric operation Lift the aircraft jack until the socket of the aircraft jack is in reliable contact with the supporting point of the aircraft jack and a certain contact force is generated;

[0100] S3: Leveling operation, set the corresponding jacking distance for each aircraft jack according to the leveling needs, start the system, aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com