Preparation method of low-molecular-weight sea cucumber fucosan sulfate

A technology of fucoidan sulfate and low molecular weight, which is applied in the field of preparation of low molecular weight sea cucumber fucoidan sulfate, can solve the problems of severe molecular structure damage, difficulty in industrialized large-scale production, harsh reaction conditions, etc., and achieve good The ability to scavenge free radicals, good anticoagulant activity, and little damage to the product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0027] Example 1-1. A method for preparing low-molecular-weight sea cucumber fucoidan sulfate, using sea cucumber polysaccharides obtained by enzymatic hydrolysis after pulverizing sea cucumbers as raw materials, and the following steps are carried out in sequence:

[0028] 1) Dissolve sea cucumber polysaccharides in a 3mol / L sodium chloride solution (concentrated saline) to obtain a sea cucumber polysaccharide solution. The mass concentration of sea cucumber polysaccharide in the sea cucumber polysaccharide solution is 1%;

[0029] Add ethanol to the sea cucumber polysaccharide solution until the final concentration of ethanol is 37%. Centrifuge (6000r / min, 15min) to remove the precipitate to obtain the supernatant;

[0030] Add ethanol to the supernatant until the final concentration of ethanol is 75%, centrifuge (6000r / min, 15min), and the resulting precipitate is dialyzed (over a dialysis bag with a molecular weight cut-off of 8000kDa) and freeze-dried (in- After drying at 45°C a...

Embodiment 1-2~1-5

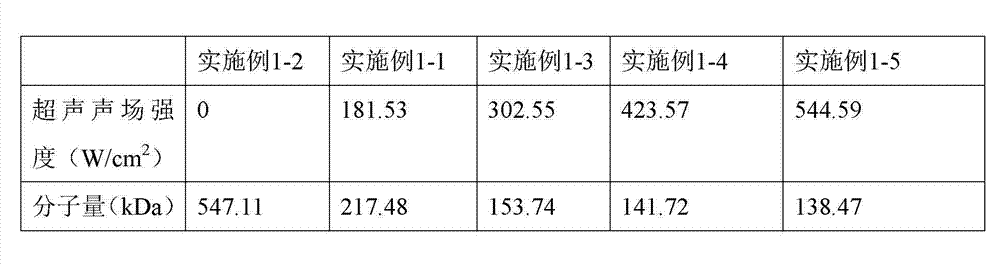

[0035] In order to verify the effect of ultrasonic degradation of different ultrasonic sound field intensity in step 2) on the prepared low-molecular-weight sea cucumber fucoidan sulfate, the ultrasonic sound field intensity in step 2) was changed, and the rest were the same as in Example 1-1 to obtain Examples 1-2 to 1-5; the specific ultrasonic sound field intensity and the corresponding molecular weight of the obtained low molecular weight sea cucumber fucoidan sulfate are shown in Table 1.

[0036] Table 1. Molecular weight of low molecular weight sea cucumber fucoidan sulfate obtained from different ultrasonic sound field intensity

[0037]

[0038] It can be found from Table 1 that the ultrasonic sound field intensity is 181.53-544.59 W / cm 2 After 10 minutes of action, with the increase of ultrasonic sound field intensity, the molecular weight of sea cucumber fucoidan sulfate continued to decrease, focusing on 138.47-217.48kDa. When the ultrasonic sound field intensity was 54...

Embodiment 2-1~2-3

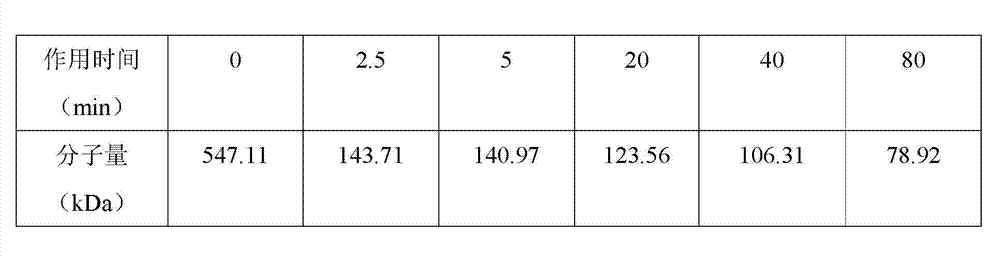

[0040] In order to verify the effect of ultrasonic degradation at different reaction temperatures in step 2) on the prepared low-molecular-weight sea cucumber fucoidan sulfate, the reaction temperature in step 2) of Example 1-4 was changed, and the rest were the same as in Example 1. -4, so as to obtain Examples 2-1~2-3 (that is, the processing time is 10 minutes, the ultrasonic sound field intensity is 423.57 W / cm 2 ); The specific reaction temperature and the corresponding molecular weight of low molecular weight sea cucumber fucoidan sulfate are shown in Table 2.

[0041] Table 2. Molecular weight of low molecular weight sea cucumber fucoidan sulfate obtained at different reaction temperatures

[0042]

[0043] It can be found from Table 2 that when the reaction temperature is 5-45°C, after 10 minutes of ultrasonic action, the degradation trend increases as the temperature decreases. The molecular weight of sea cucumber fucoidan sulfate is concentrated in 139.06-212.97kDa. Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com