3D printing in-situ repairing system for metal part damage and repairing method thereof

An in-situ repair and 3D printing technology, applied in the field of metal parts repair, can solve problems such as potential safety hazards and high-speed train failures, and achieve the effects of improving repair quality, eliminating internal stress, and eliminating internal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

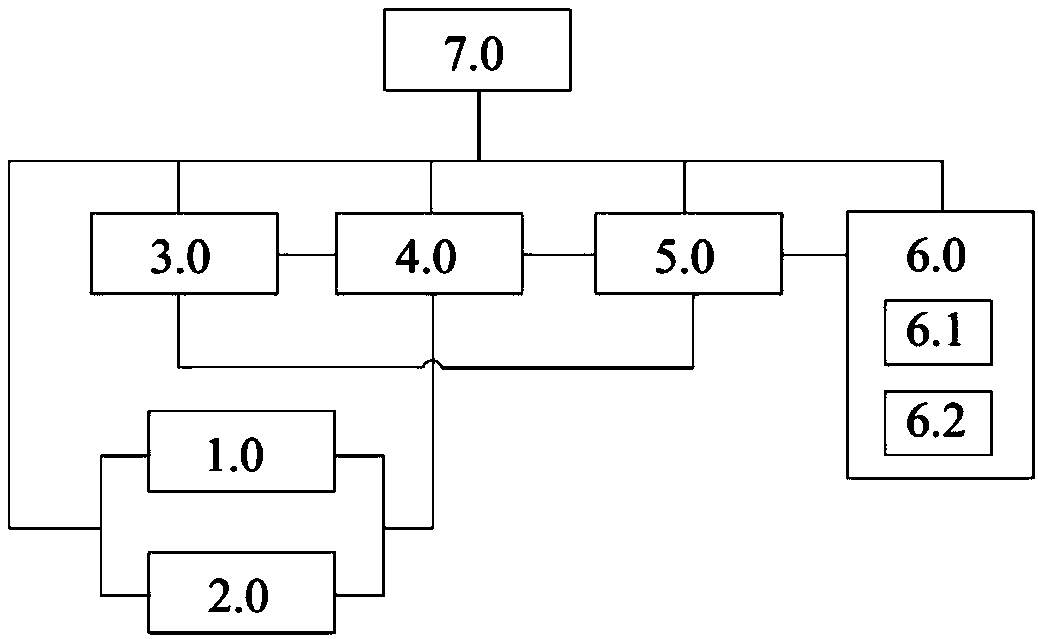

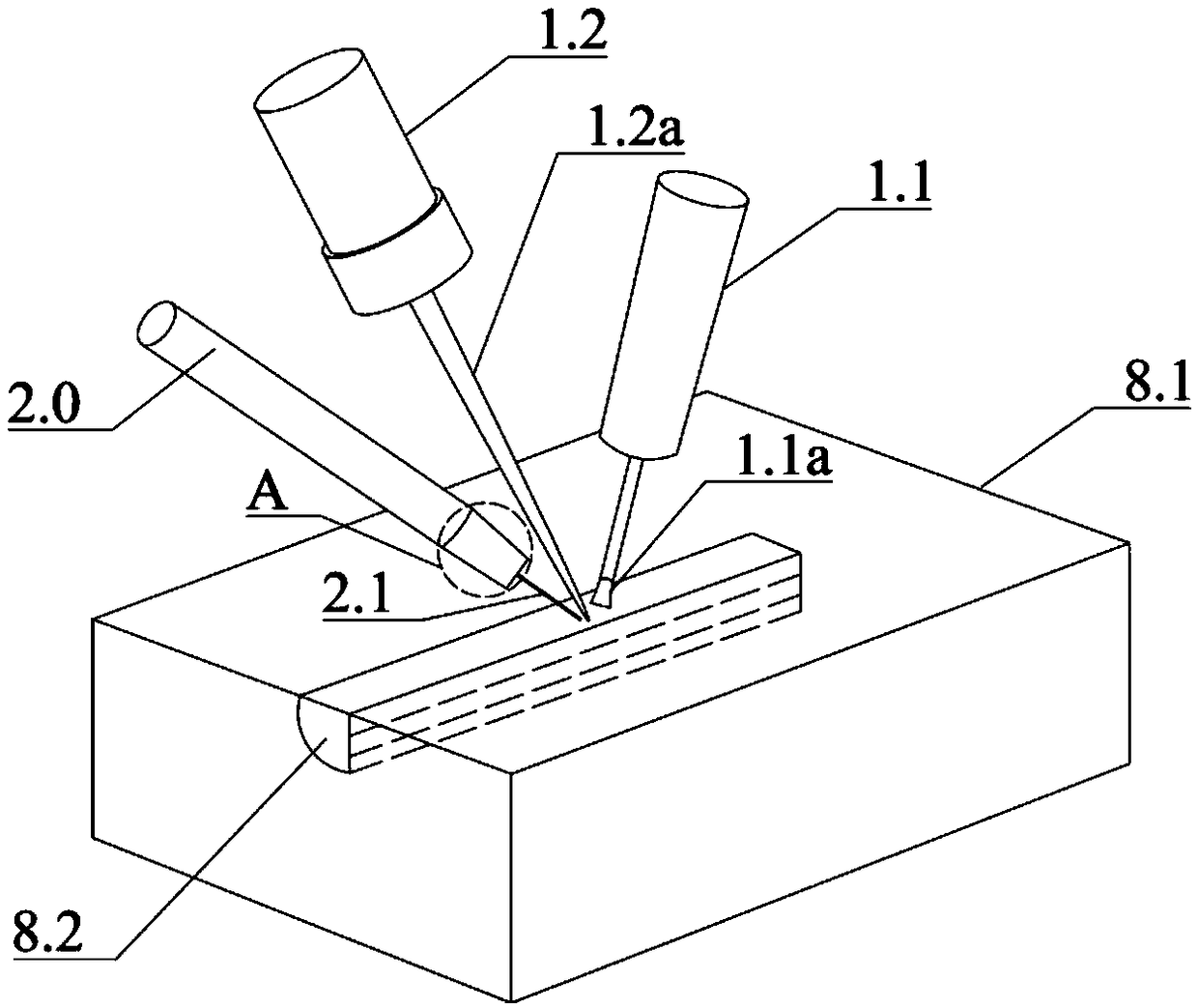

[0056] figure 1 It shows a 3D printing in-situ repair system for damaged metal parts. Its structural features include a mechanical arm, a laser-TIG composite welding gun 1.0 installed at the end of the mechanical arm and a wire feeding device 2.0. The repair system also includes Space scanning camera device 3.0, printing path design device 4.0, interlayer temperature monitoring device 5.0, interlayer quality control device 6.0 and control terminal 7.0;

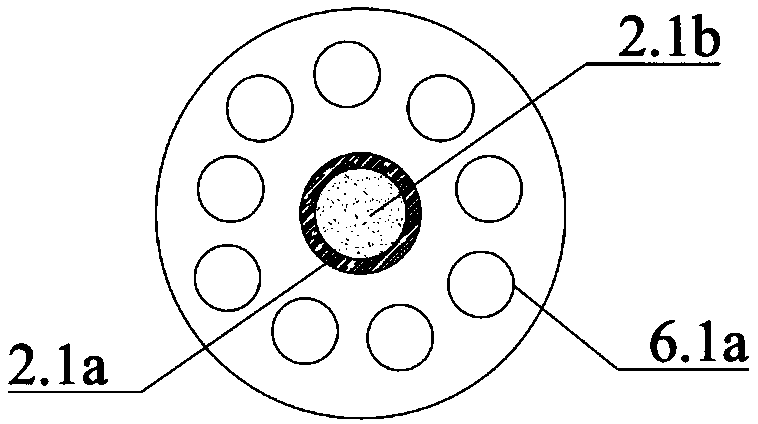

[0057] The wire feeding device 2.0 is equipped with a repairing flux-cored welding wire 2.1, and its specific preparation process is as follows: processing the matrix of the same material as the part to be repaired into a hollow tubular welding wire 2.1a, and filling the prefabricated alloy powder 2.1b tightly to the In the tube core of the hollow tubular welding wire 2.1a, the repairing flux-cored welding wire 2.1 is obtained; the diameter of the repairing flux-cored welding wire 2.1 is 0.8-1.6mm, and the diameter of the tube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com