Patents

Literature

53 results about "Dynamic load testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dynamic load testing (or dynamic loading) is a method to assess a pile's bearing capacity by applying a dynamic load to the pile head (a falling mass) while recording acceleration and strain on the pile head. Dynamic load testing is a high strain dynamic test which can be applied after pile installation for concrete piles. For steel or timber piles, dynamic load testing can be done during installation or after installation.

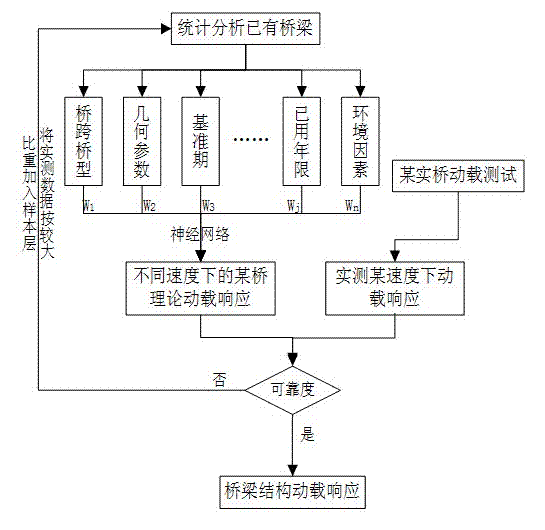

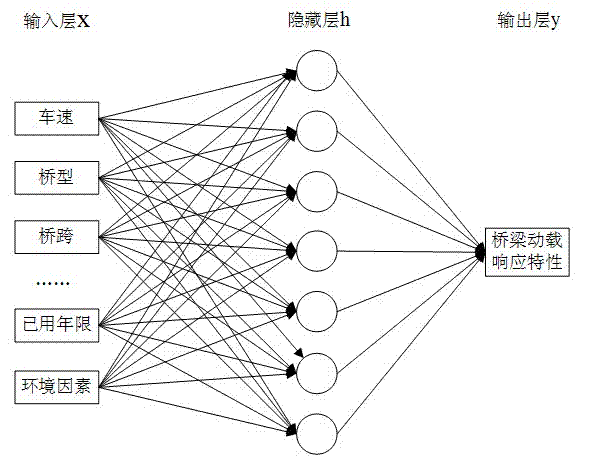

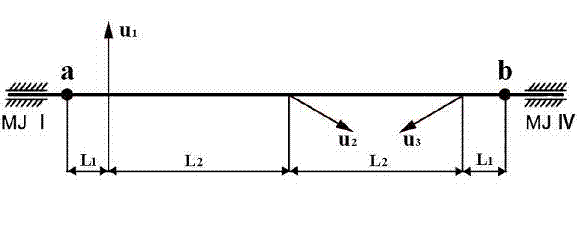

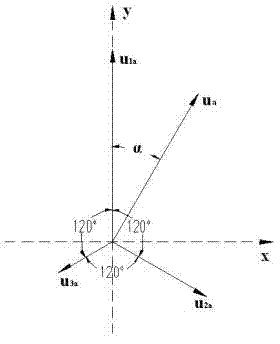

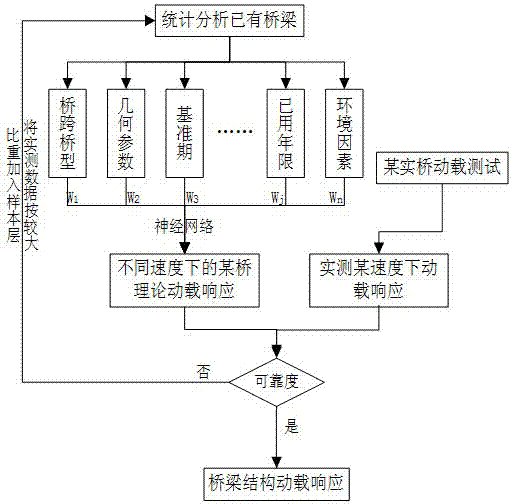

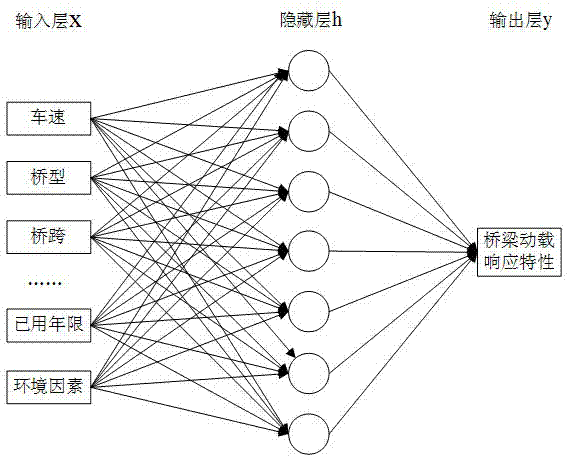

Bridge dynamic load testing method based on neural network technology

InactiveCN102539098AStructural damage is smallImprove analysis efficiencyBiological neural network modelsVibration testingStructural dynamicsDynamic load testing

The invention provides a bridge dynamic load testing method based on neural network technology, which includes conducting statistic analysis on a large amount of existing bridge testing results, determining dynamic load response affecting parameters of a bridge structure, using the affecting parameters as an input layer to construct a neural network model, and deducing structural dynamic load response predicted value; and conducting dynamic load actual measurement on the bridge under single vehicle speed, conducting reliability inspection on neural network theoretical derivation value by using actual measurement value, obtaining dynamic response verified through the actual measurement and characteristics of the bridge structure, and judging actual states and safety performance of the bridge structure according to the dynamic response and the characteristics of the bridge. Due to the fact that the bridge dynamic load testing method combines advantages of a conventional dynamic load testing method and the neural network technology is used to optimize a testing process, bridge dynamic load testing estimation conducted by means of the method greatly reduces structural damage caused by conventional dynamic load testing and improves analysis efficiency and operability on the basis of being capable of guaranteeing accurate and reliable testing results.

Owner:SOUTHEAST UNIV

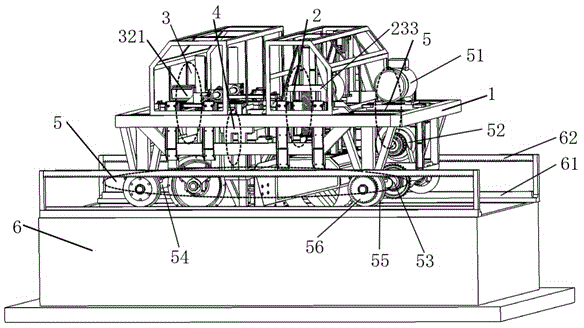

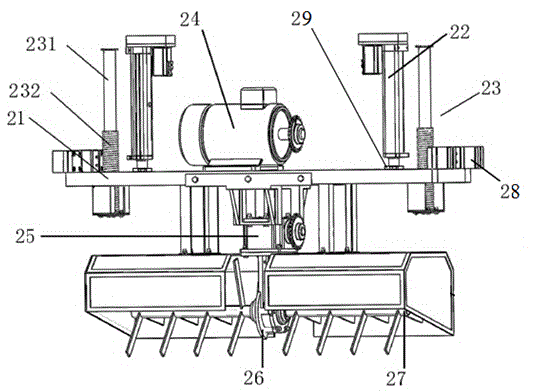

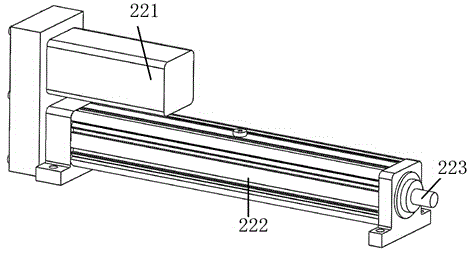

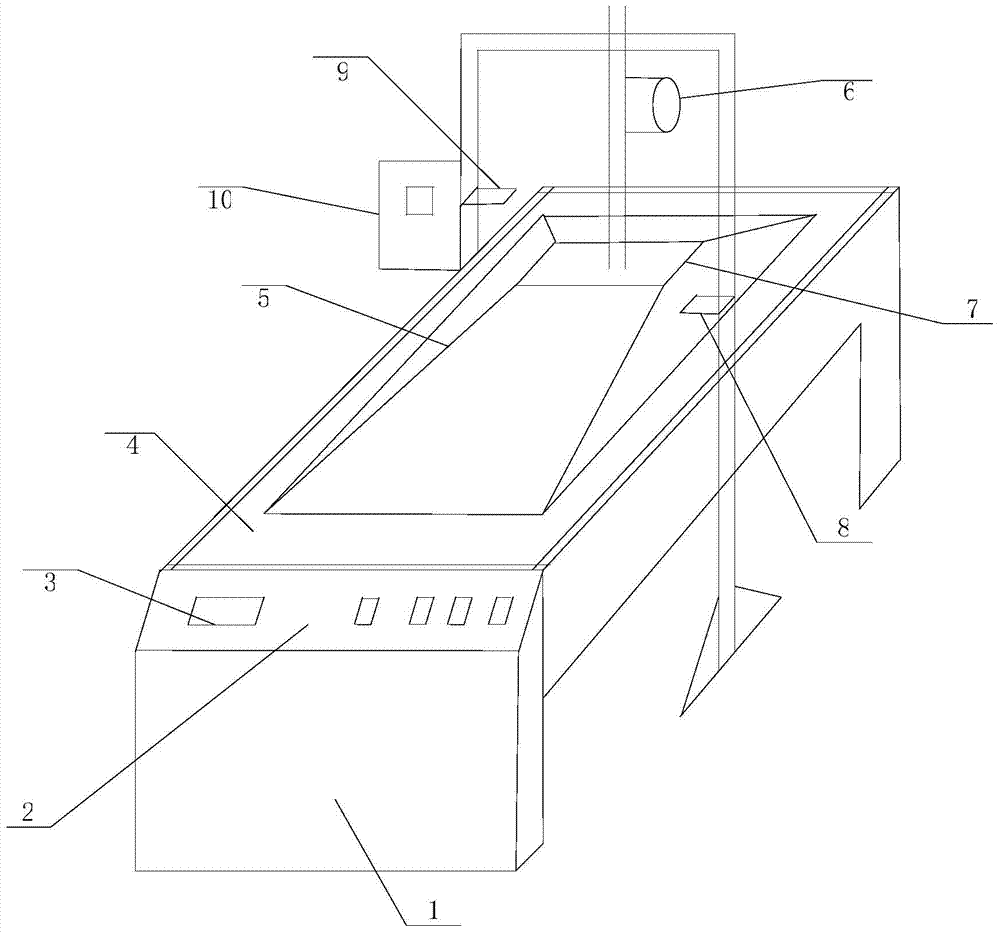

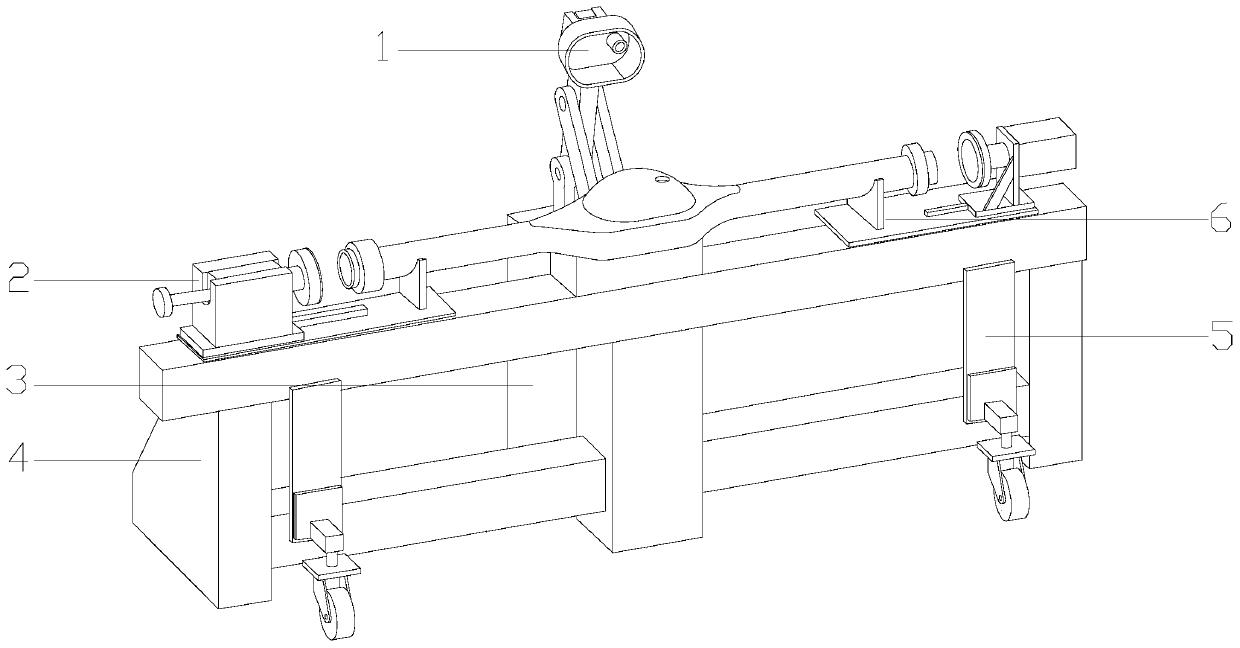

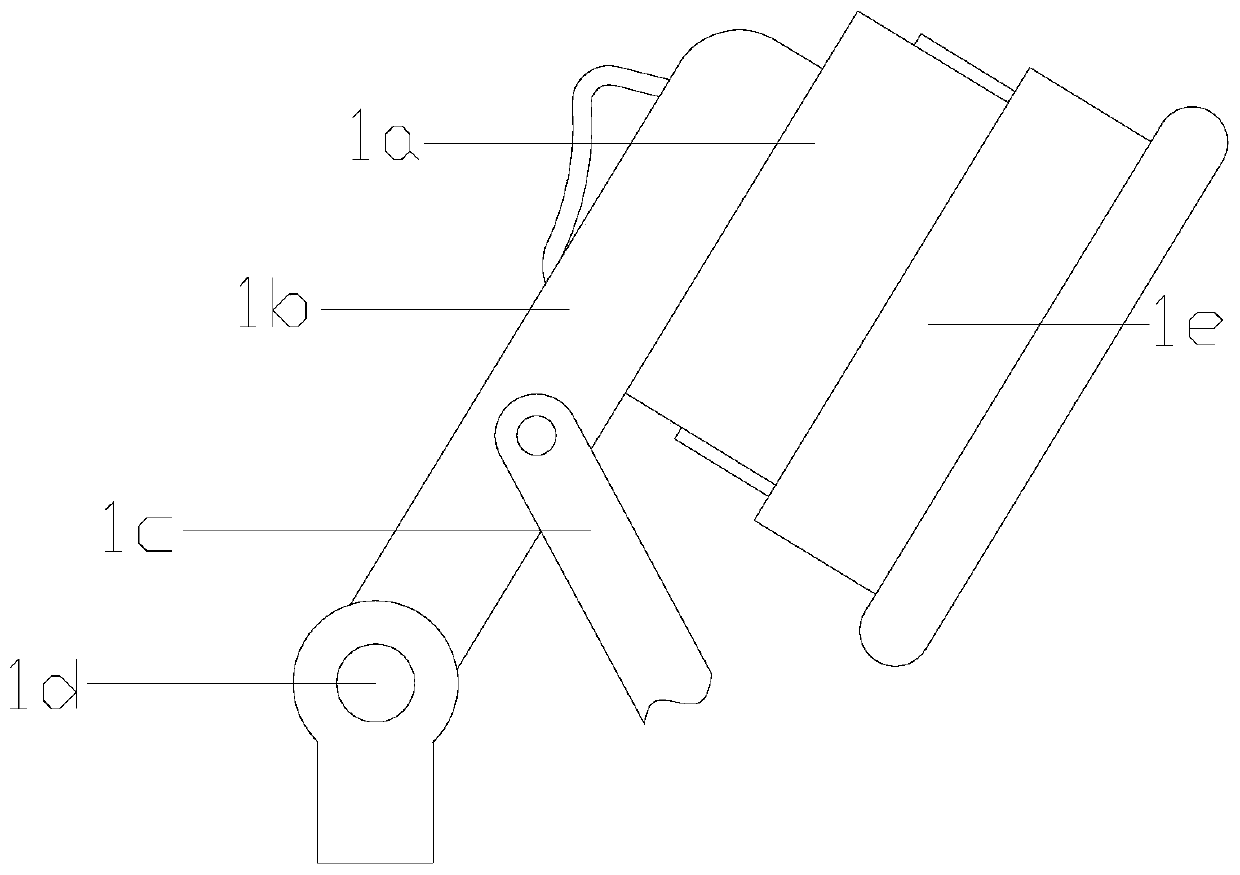

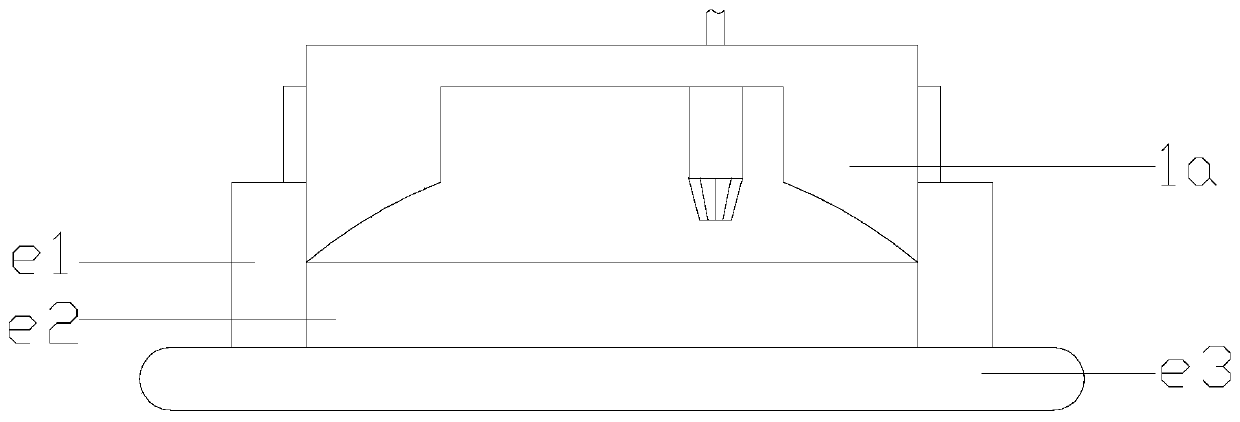

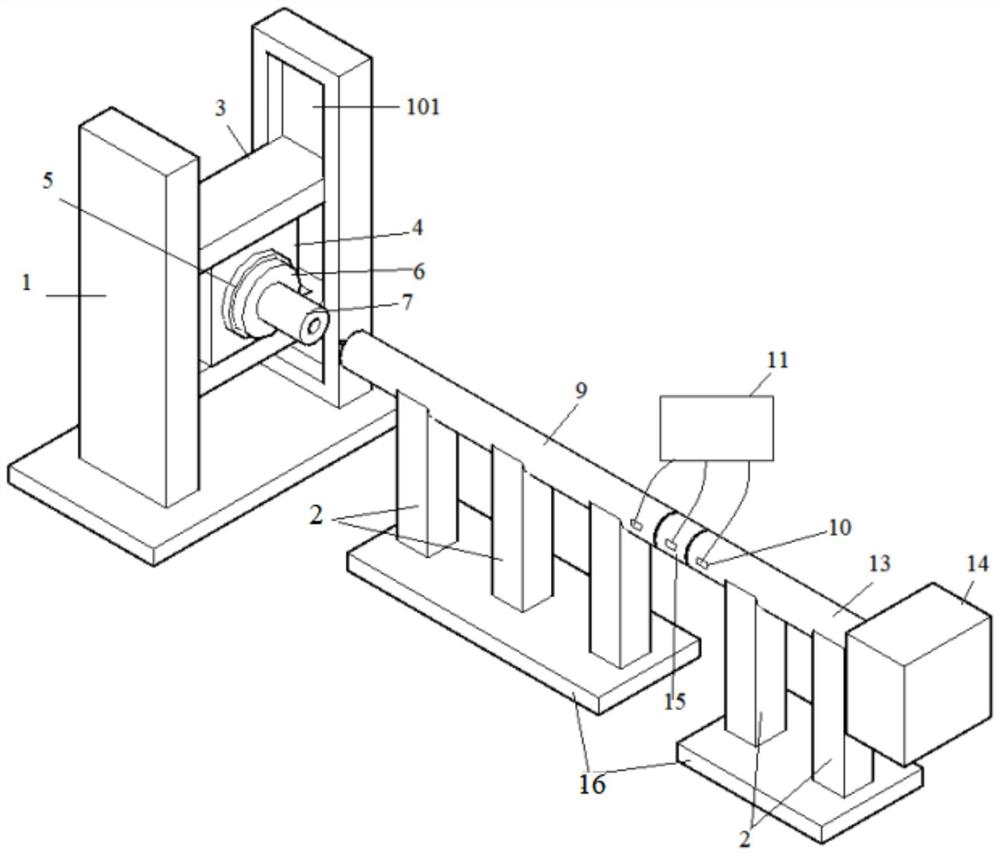

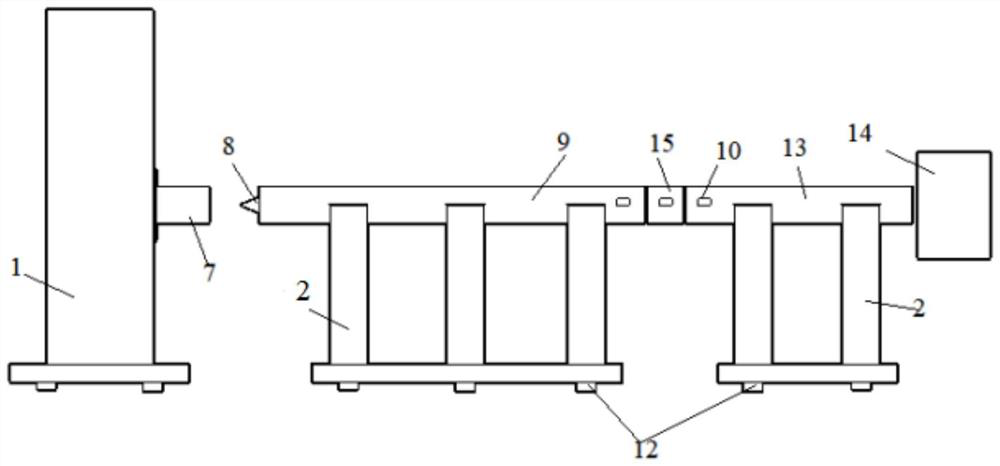

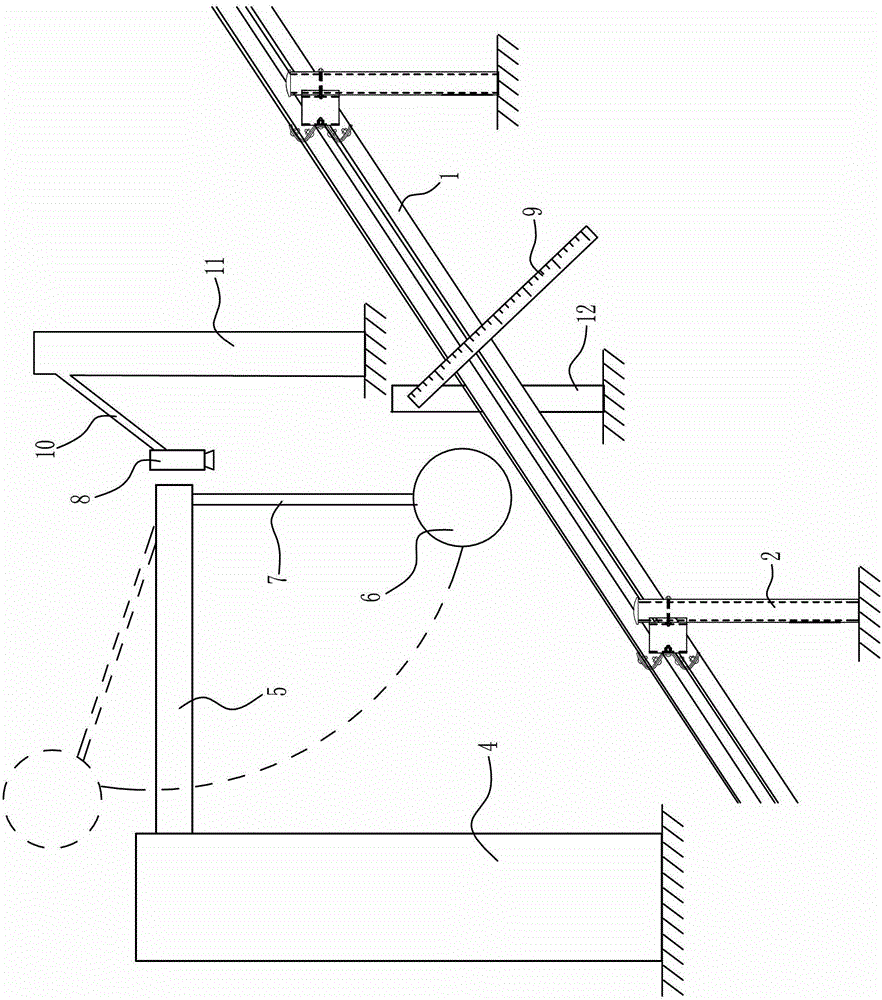

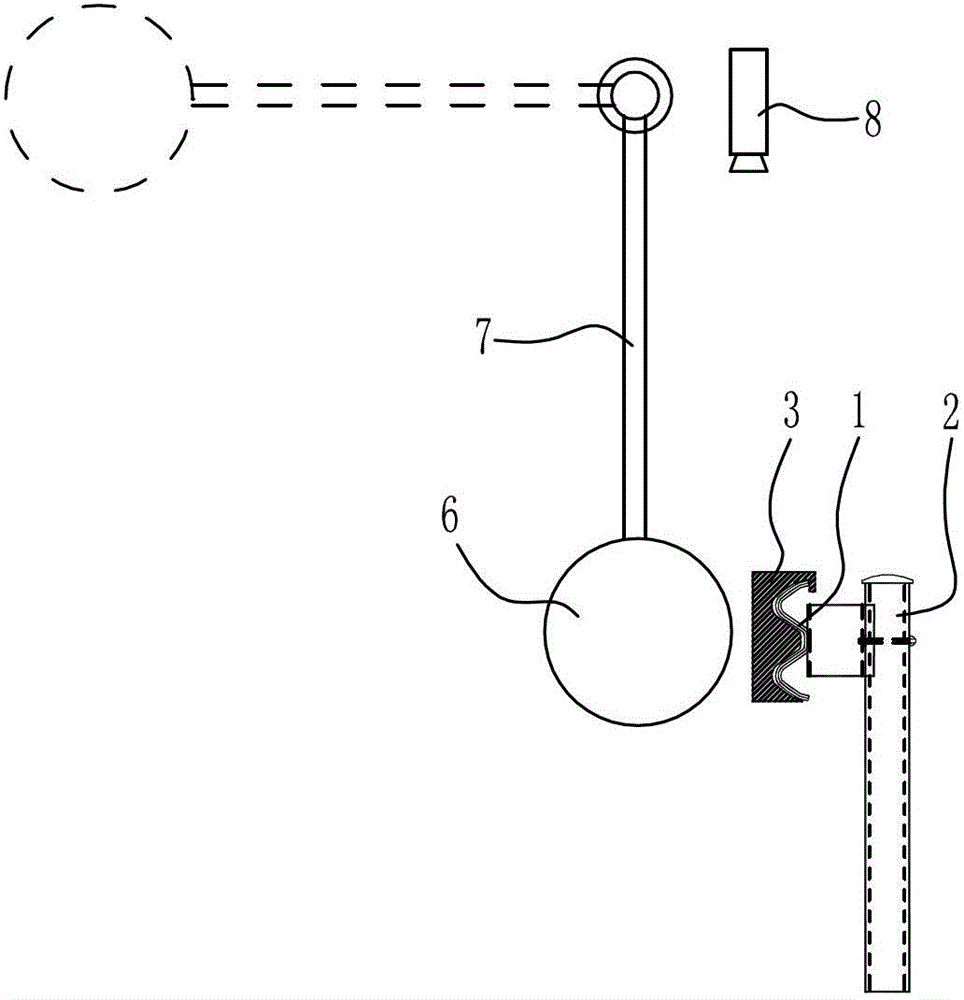

Dynamic load testing testbed for agricultural mechanical rotary cultivation part

InactiveCN104568421AUnaffected by external climateUnconditionalMachine part testingDesign improvementDynamic load testing

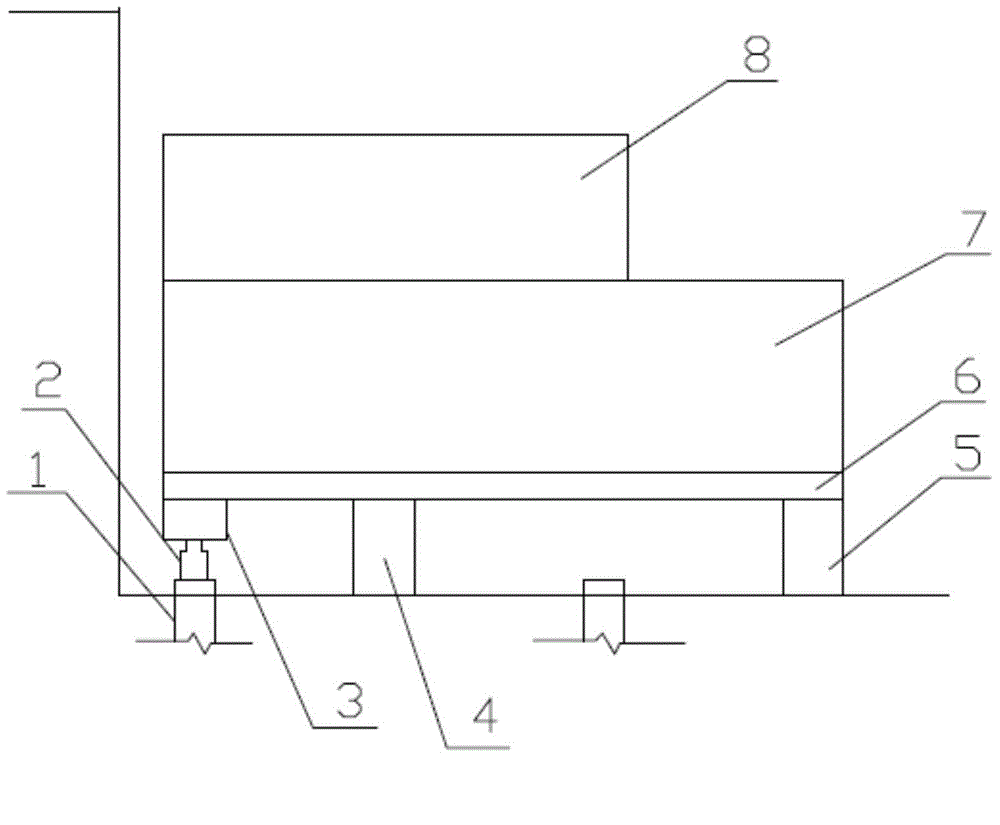

The invention discloses a dynamic load testing testbed for an agricultural mechanical rotary cultivation part. The dynamic load testing testbed comprises a soil groove and a trolley, wherein the trolley comprises a trolley rack, a rotary cultivation system, a soil compaction system, a soil leveling system and a walking system, the rotary cultivation system is installed at the front end of the trolley rack, the soil compaction system is installed at the rear end of the trolley rack, the soil leveling system is installed on the trolley rack and located between the rotary cultivation system and the soil compaction system, and the walking system is installed on the trolley rack. The testbed represents operation of the rotary cultivation part based on the soil groove and tests dynamic load of the rotary cultivation part. The dynamic load testing testbed has the advantages that the dynamic load testing testbed is not limited by seasons and farming seasons, can conduct real-time recovery processing on soil according to different demands, is good in testing repeatability, is not influenced by outside climate and natural conditions and the like, and can provide data support for theoretical research and design improvement of coil cultivation parts on the basis that a large number of resources are saved.

Owner:CHONGQING UNIV OF TECH

Method and apparatus for automatic load testing using bi-directional testing

ActiveUS7353714B2Reduce riskDetailed analysisFoundation testingForce measurementDynamic load testingAutomatic testing

The subject invention pertains to a method and apparatus for testing the static load-bearing capacity of a pile. In an embodiment, one or more load devices for applying a test load can be disposed within a pile such that a pile element can be above the load device, and a pile element can be below the load device. Upon applying a test load, the pile element above the load device and the pile element below the load device tend to separate. The test loads applied to the pile can be controlled in response to the magnitude of the test load, the combined settlement rate of the pile elements, the displacement of the pile elements, and the compression of the pile elements. A test regime can continue until a programmed regime is completed or a fail-safe trigger event occurs.

Owner:HEWLETT PACKARD DEV CO LP +1

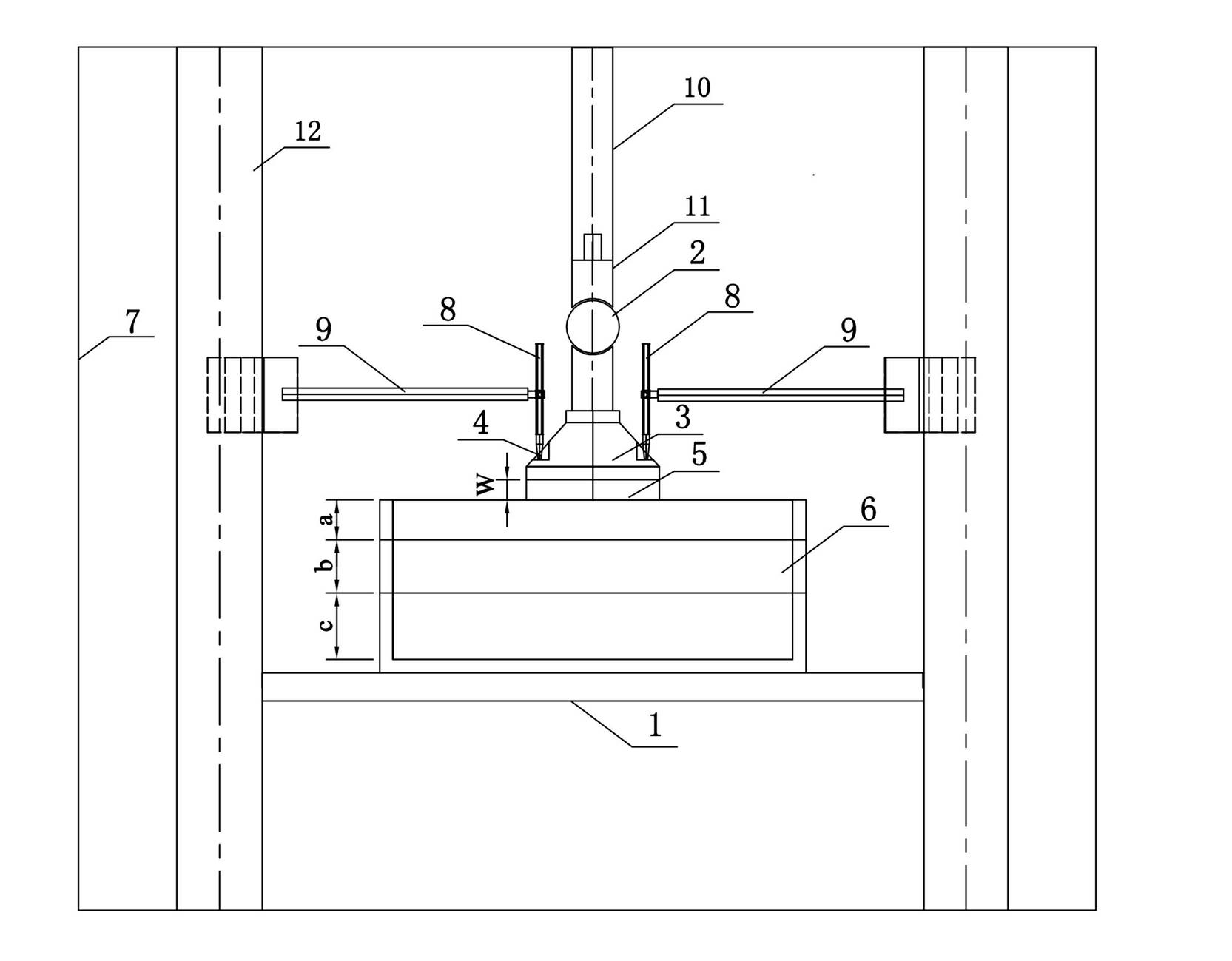

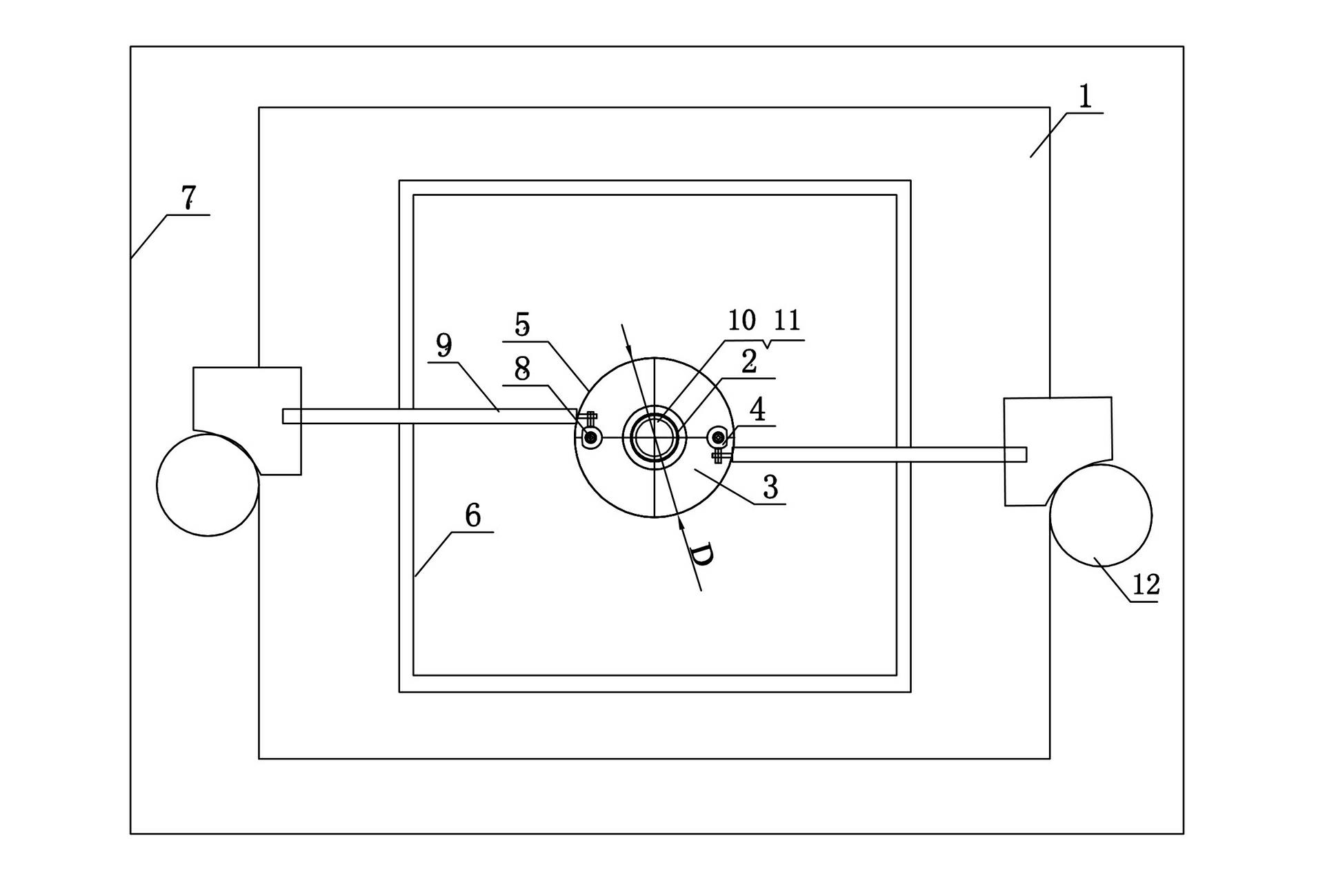

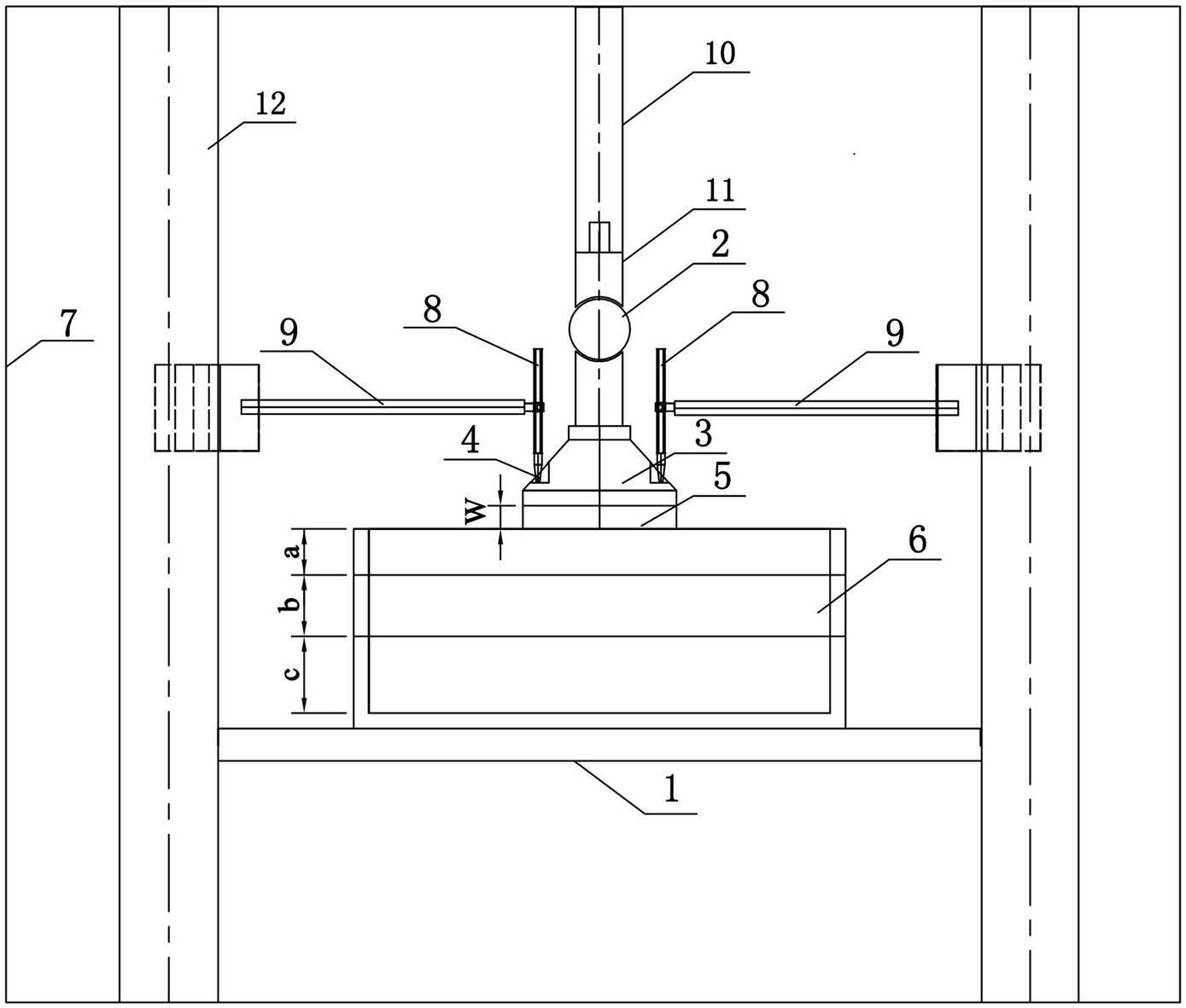

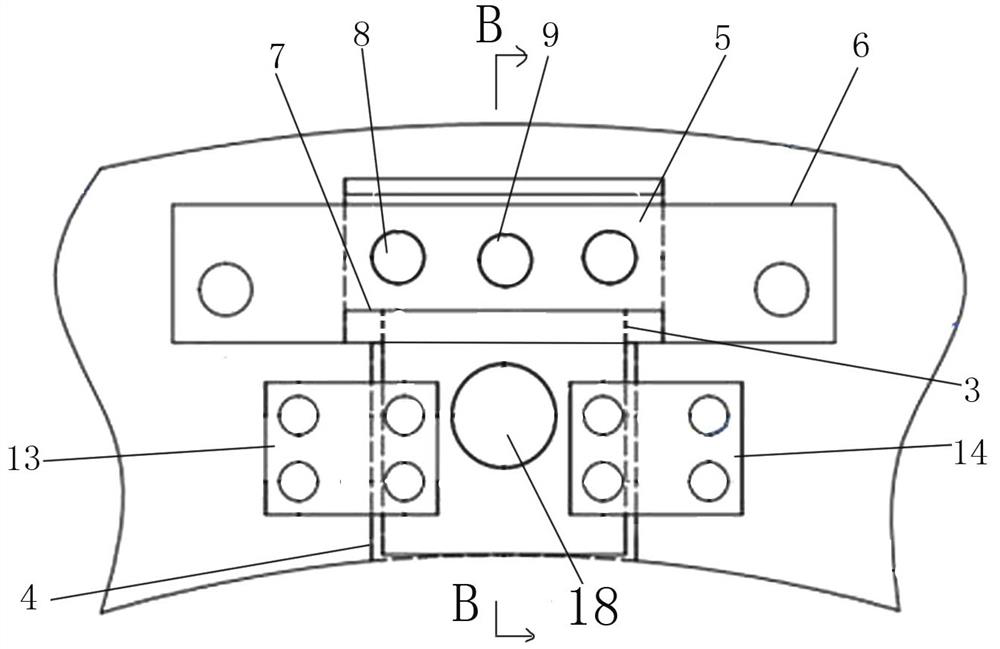

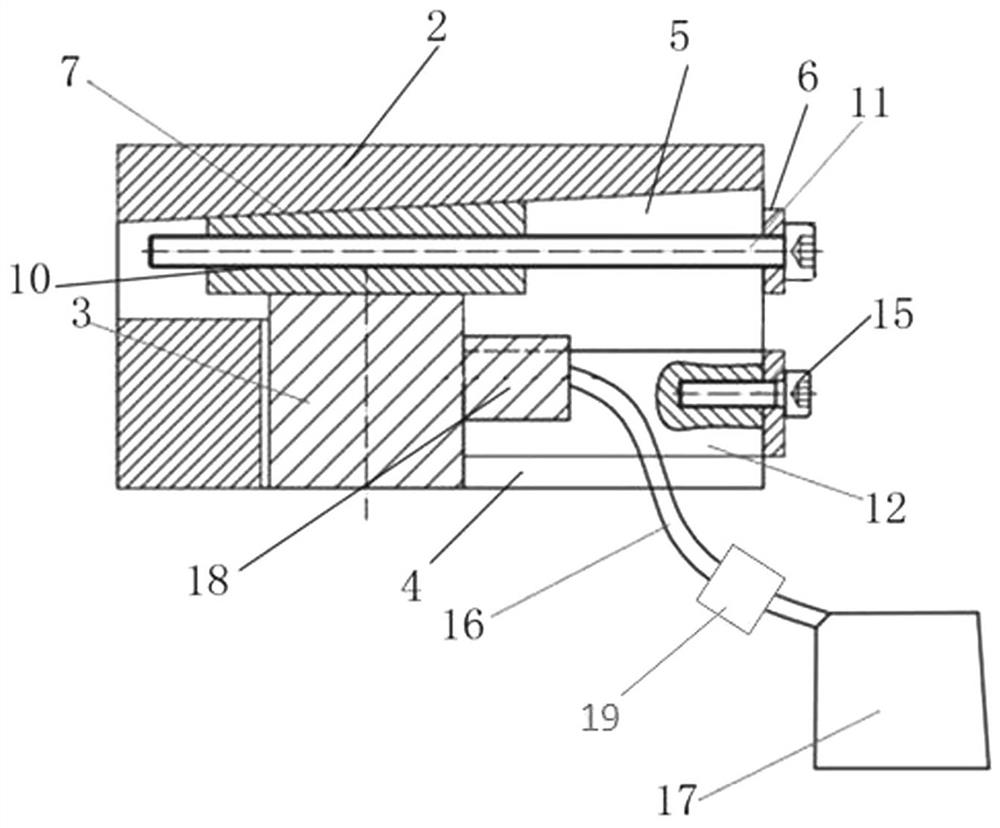

Circulating single shaft dynamic load testing device with function of simulating tire load

ActiveCN102494962AEasy to shapeImprove compactionMaterial strength using repeated/pulsating forcesDynamic load testingClassical mechanics

The utility model discloses a circulating single shaft dynamic load testing device with function of simulating tire load, which includes an environmental box (7), wherein a test mold (6) is arranged in the environmental box (7); a test loading device is correspondingly arranged above the test mold (6); the test loading device includes a loading bar (10), a pressure head (3) connected to the end part of the loading bar (10) and a displacement sensing device mounted on the pressure head (3). The invention has the advantages of simple structure, stable working performance, high precision and convenience for use and operation.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Load pressure simulation device for photovoltaic component

ActiveCN103616291AMaterial strength using tensile/compressive forcesDynamic load testingElectric machinery

The invention discloses a load pressure simulation device for a photovoltaic component. The load pressure simulation device comprises a static mechanical load device and a dynamic mechanical load device, wherein the static mechanical load device and the dynamic mechanical load device are arranged in a case (1); during the static load test, an intelligent digital instrument (3) is used for automatically inflating and deflating an air bag (4) to simulate static load pressure; during the dynamic load test, the dynamic load device is transferred onto the static load device, and the photovoltaic component to be tested is fixed on a lifting table (5) and is electrified; when the air bag (4) is inflated to corresponding pressure, the weight of a sand bag arranged on a back plate of the photovoltaic component can be calculated according to the area of the photovoltaic component, so that a motor rotates to drive the lifting table (5) to move up and down to be in full contact with the surface of the air bag (4), and thus a requirement on the test of simulating the dynamic load is met.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

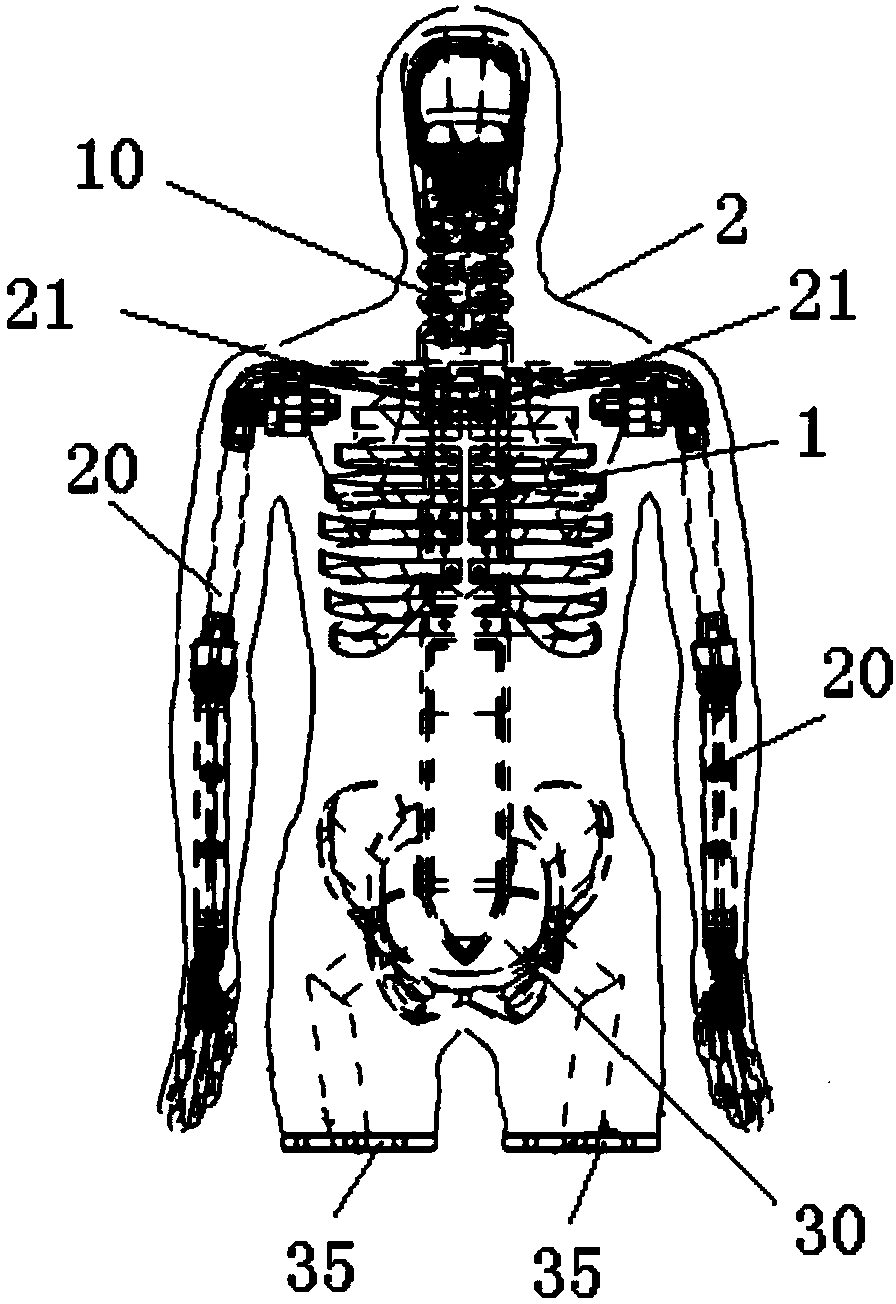

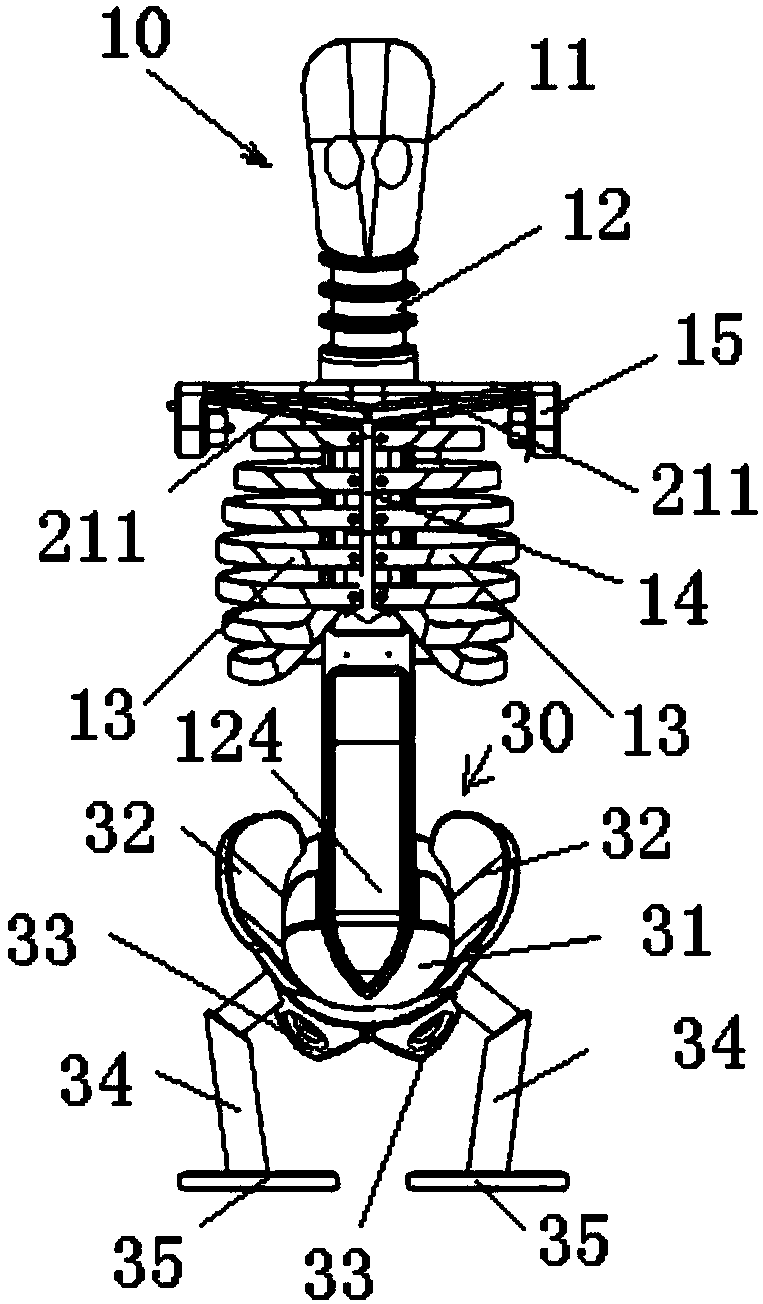

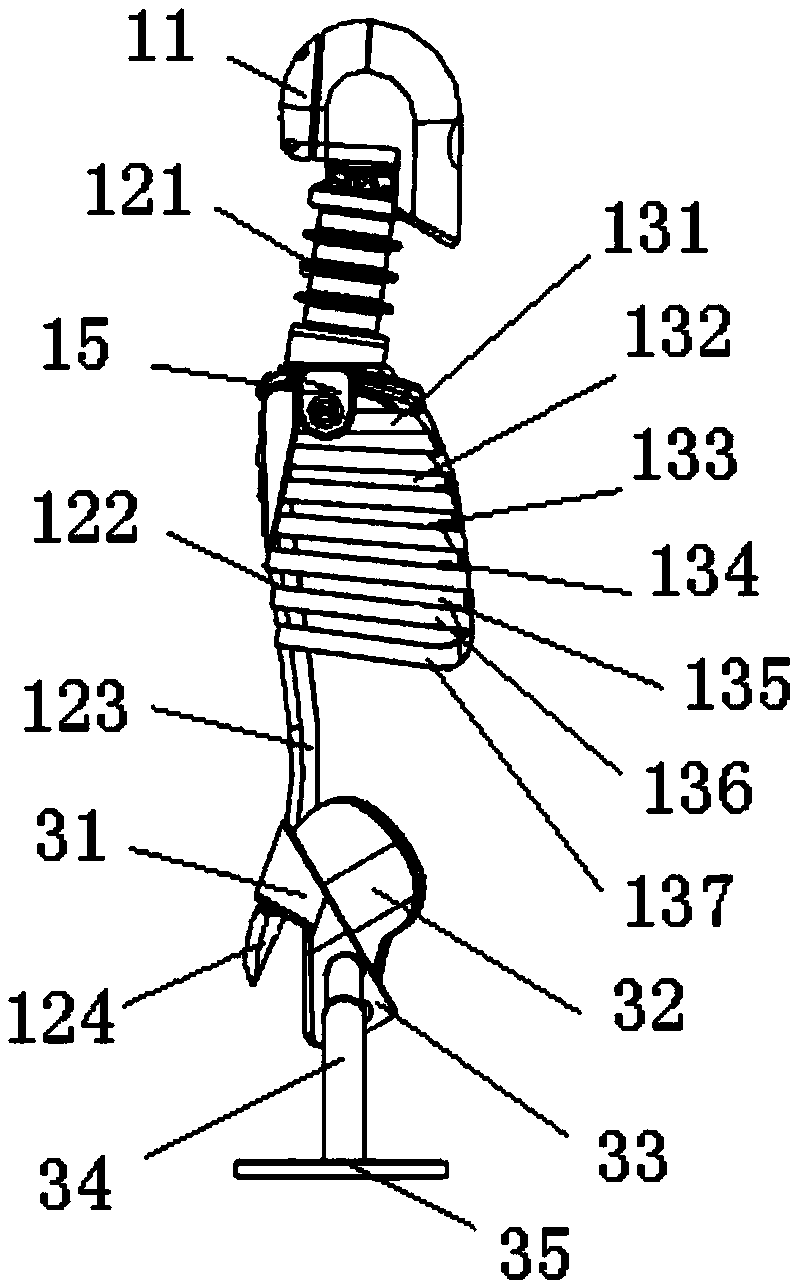

Dummy for simulation trunk load testing

ActiveCN104299501AReflect the characteristics of changes in biomechanical parametersEducational modelsClavicleLoad testing

The invention relates to a dummy for simulation trunk load testing. The dummy is characterized by comprising simulation skeletons and simulation soft tissues; the simulation skeletons include an axial skeleton, two symmetrically-arranged upper limbs and a lower limb; the axial skeleton comprises a skull, a spinal column, ribs, sternums and neck, shoulder and chest connecting pieces; the spinal column comprises a spinal column neck segment, a spinal column chest segment, a spinal column waist segment and a spinal column sacral segment; the ribs include two symmetrically-arranged first ribs, two symmetrically-arranged second ribs, two symmetrically-arranged third ribs, two symmetrically-arranged fourth ribs, two symmetrically-arranged fifth ribs, two symmetrically-arranged sixth ribs and two symmetrically-arranged seventh ribs; each upper limb comprises an upper limb girdle, humerus, radioulna, carpometacarpus, phalanxes, an adduction and abduction shaft, an elbow shaft and a wrist shaft; each upper limb girdle comprises a clavicle, a shoulder blade and a spina scapulae; each phalanx comprises a first phalanx body, a second phalanx body, a third phalanx body, a fourth phalanx body and a fifth phalanx body; the lower limb comprises a sacrum, two symmetrically-arranged hip bones, two closed holes, two thighbones and two installation fixing pieces; the simulation soft tissues comprise a head, a neck, a trunk, upper segments of thighs, the left upper limb and the right upper limb, and the head, the neck, the trunk and the upper segments of the thighs are wholly poured, curved and molded through silicone rubber. The dummy can be widely applied to various static or dynamic load testing processes.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

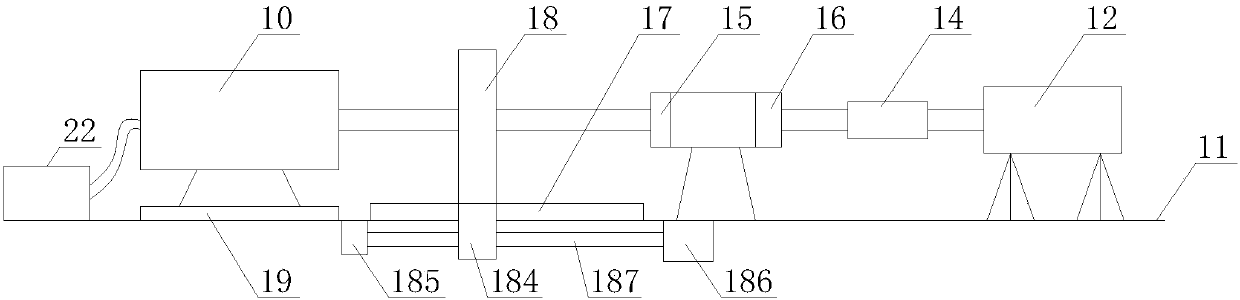

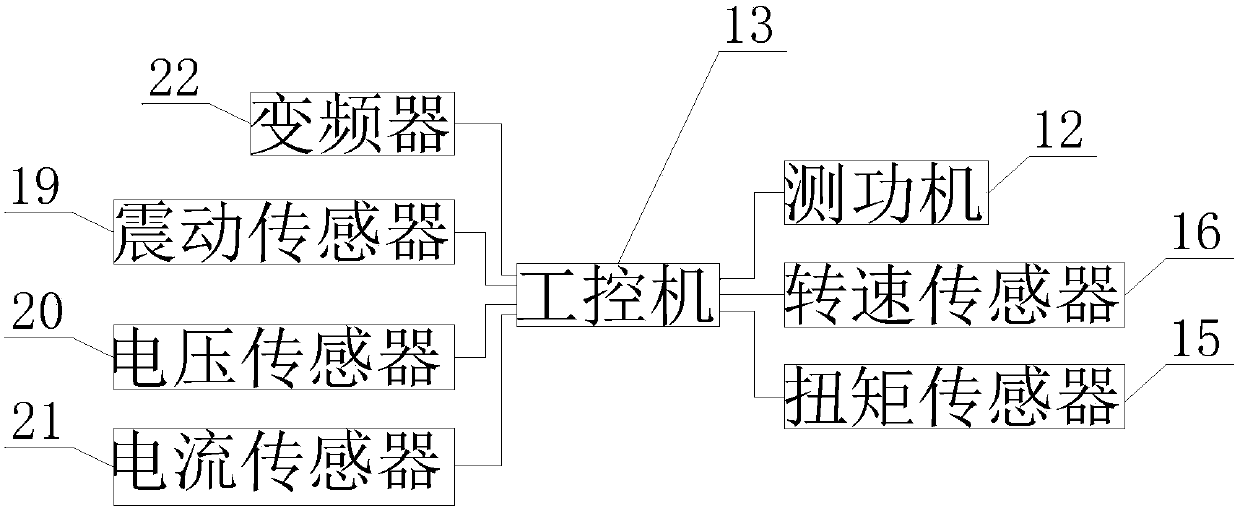

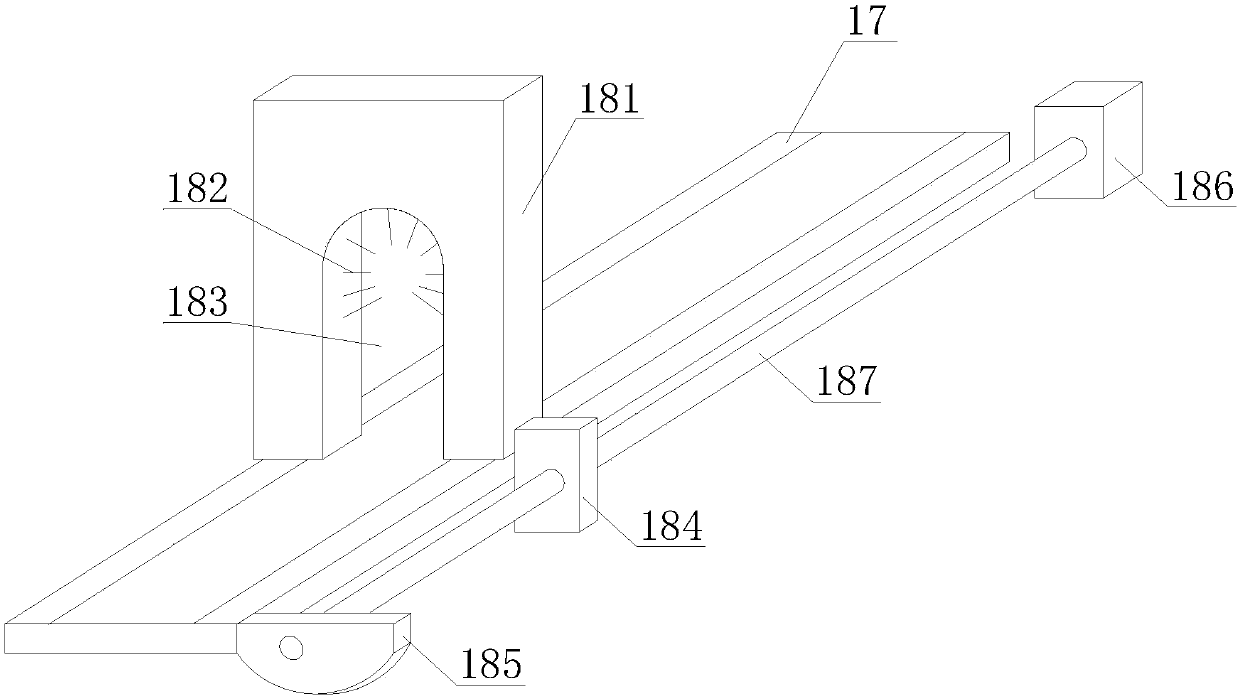

Dynamic testing and analysis system of motor

The invention, which relates to the motor field, discloses a dynamic testing and analysis system of a motor. The system is composed of a to-be-tested motor and a workbench; and the to-be-tested motoris installed on the workbench. The system also includes an industrial personal computer; and a dynamometer is also fixed on the workbench. A coupler is connected between the to-be-tested motor and thedynamometer; and a torque sensor and a rotation speed sensor are connected between the coupler and the to-be-tested motor and are connected with the industrial personal computer. Besides, a track isalso fixed on the workbench; a coaxial amplitude detector for detecting a vibration amplitude of an output shaft of the to-be-tested motor is installed on the track and is connected with the industrial personal computer; and the coaxial amplitude detector includes a detection sliding block and a flexible detection probe. According to the invention, the coaxial amplitude detector is used for detecting the amplitude offset value of rotation of the output shaft of the to-be-tested motor to detect the coaxiality of the output shaft of the to-be-tested motor; and when the coaxial amplitude detectorslides on the track, the coaxial amplitude detector is capable of detecting the whole output shaft of the to-be-tested motor.

Owner:HANGZHOU WEIHENG TECH

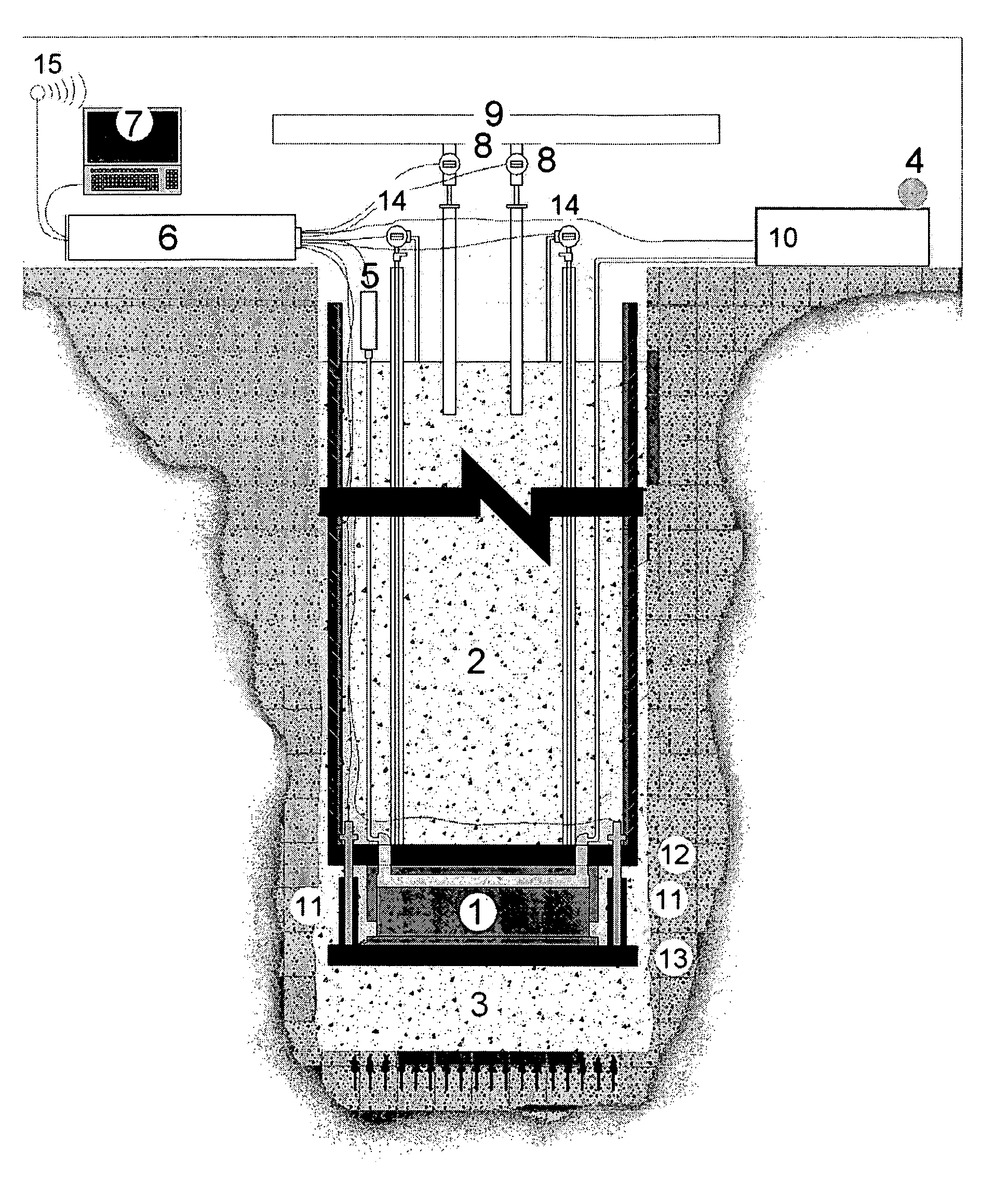

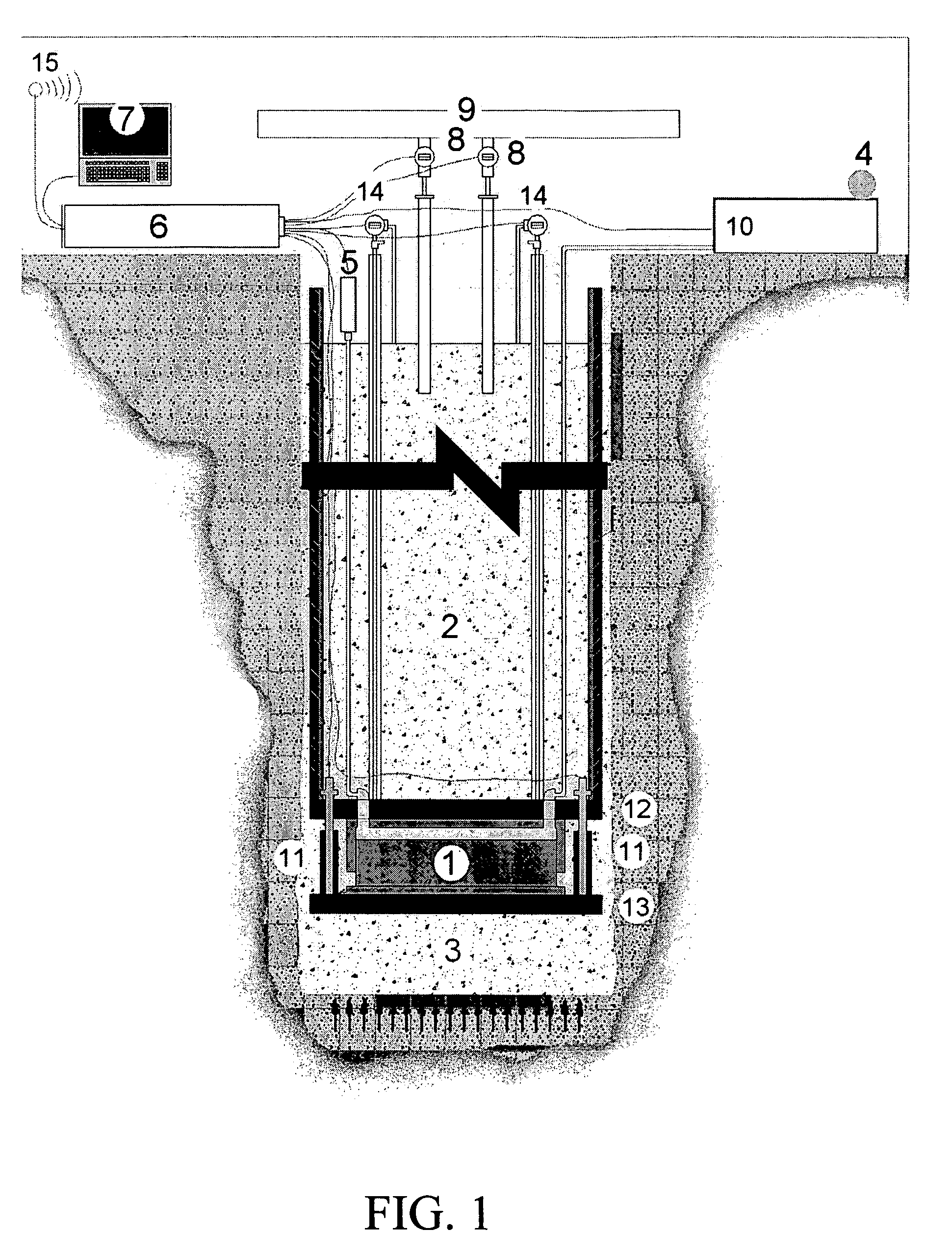

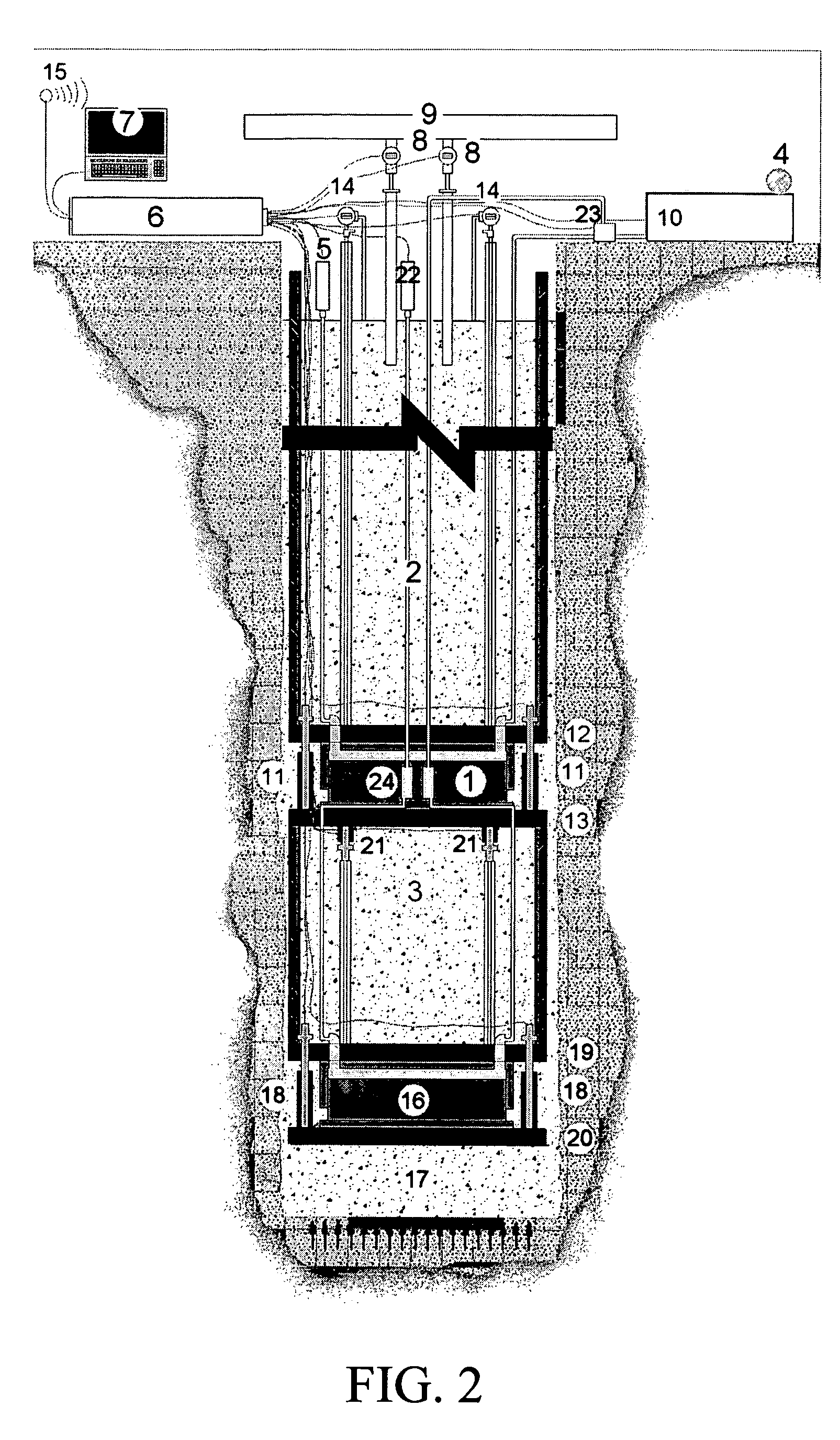

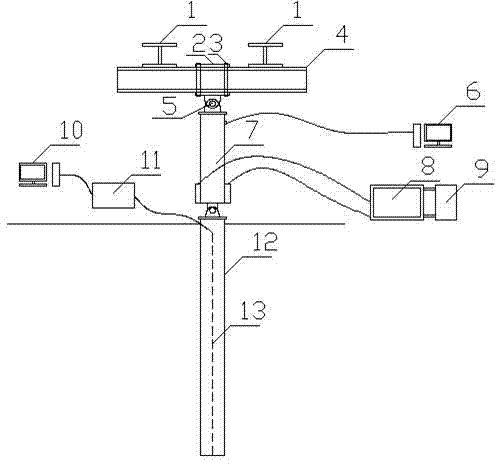

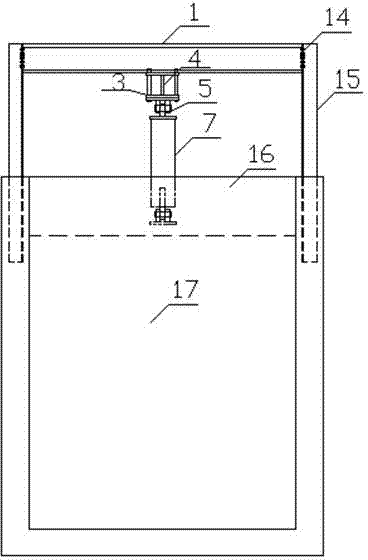

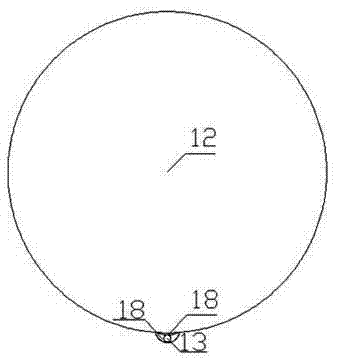

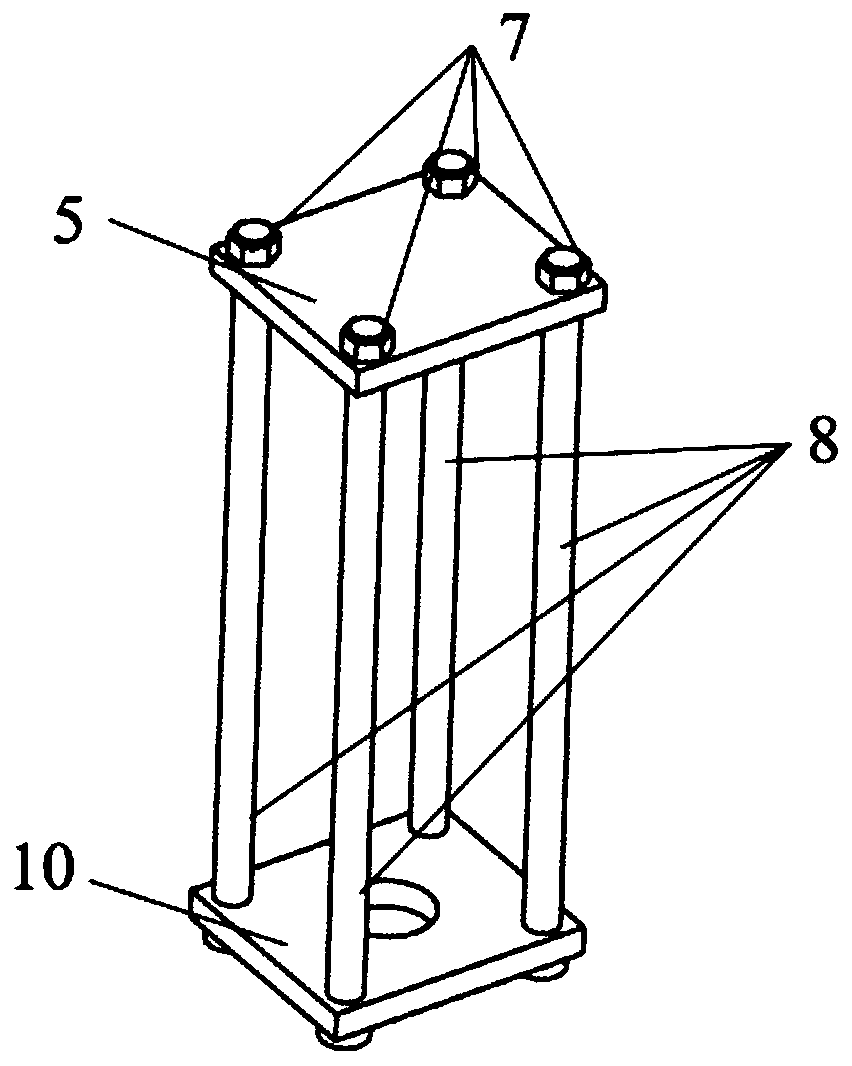

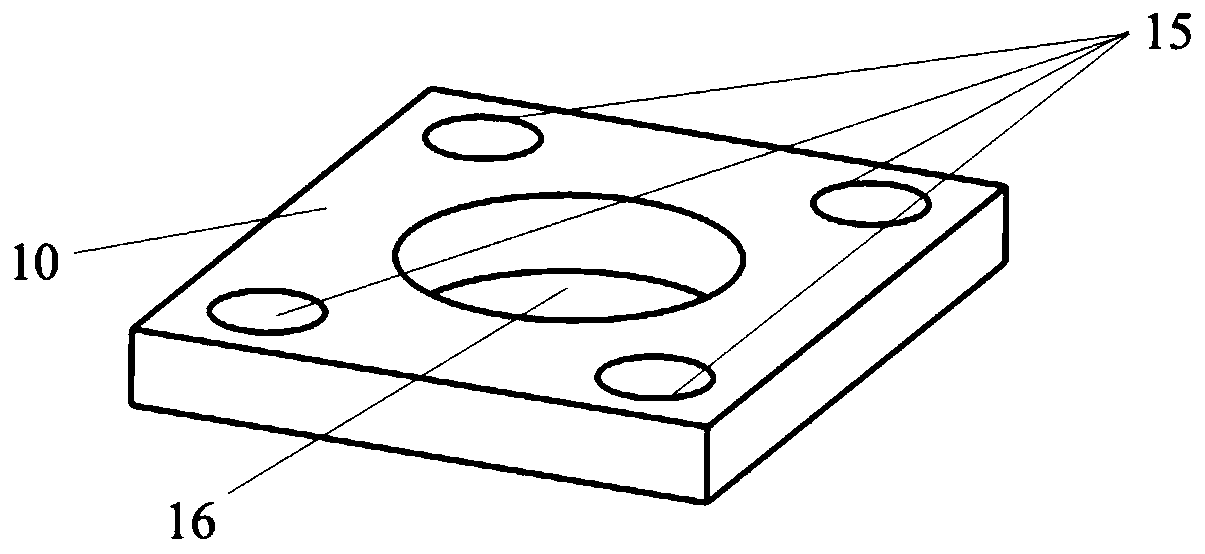

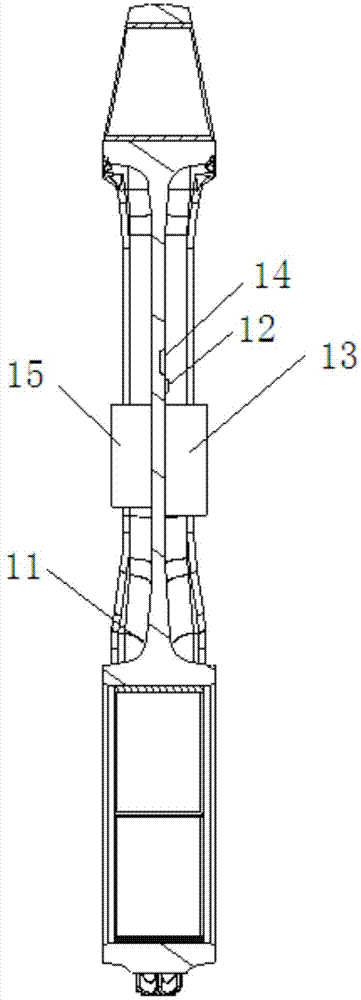

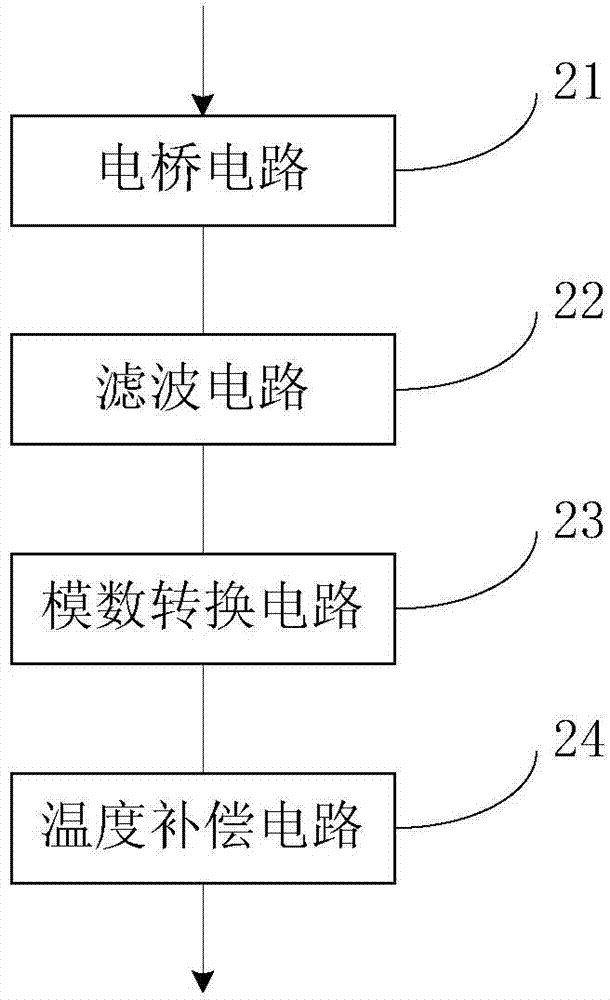

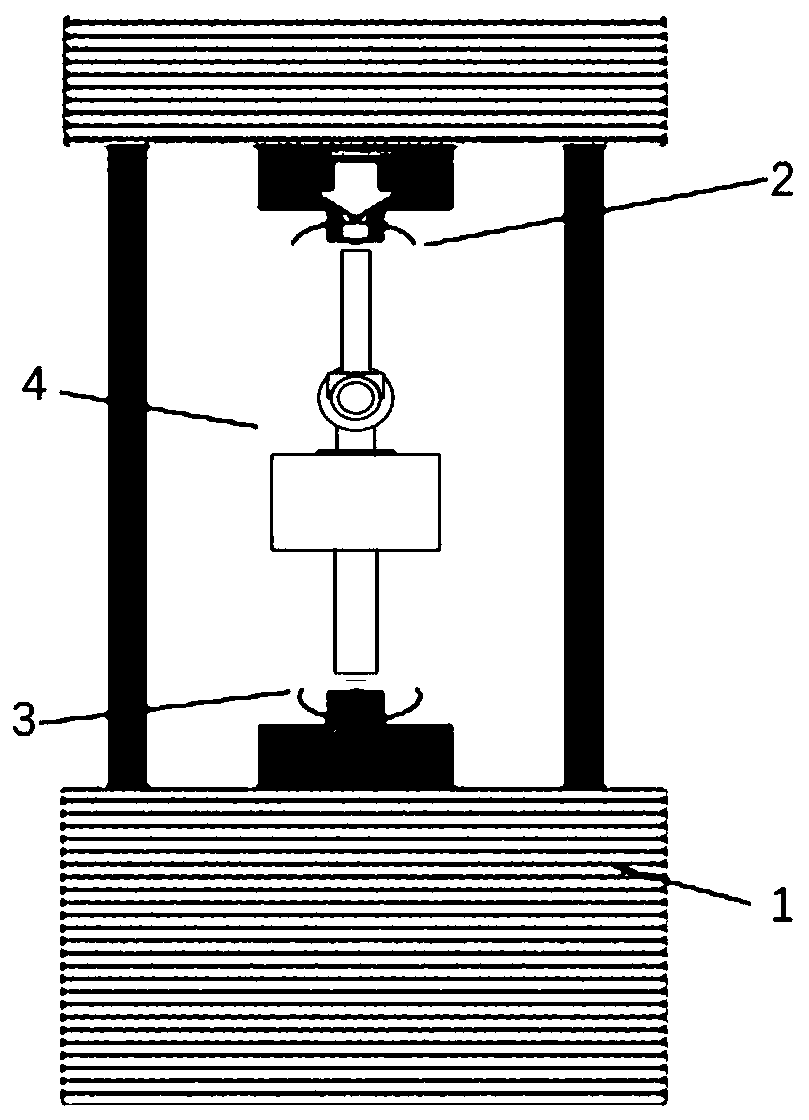

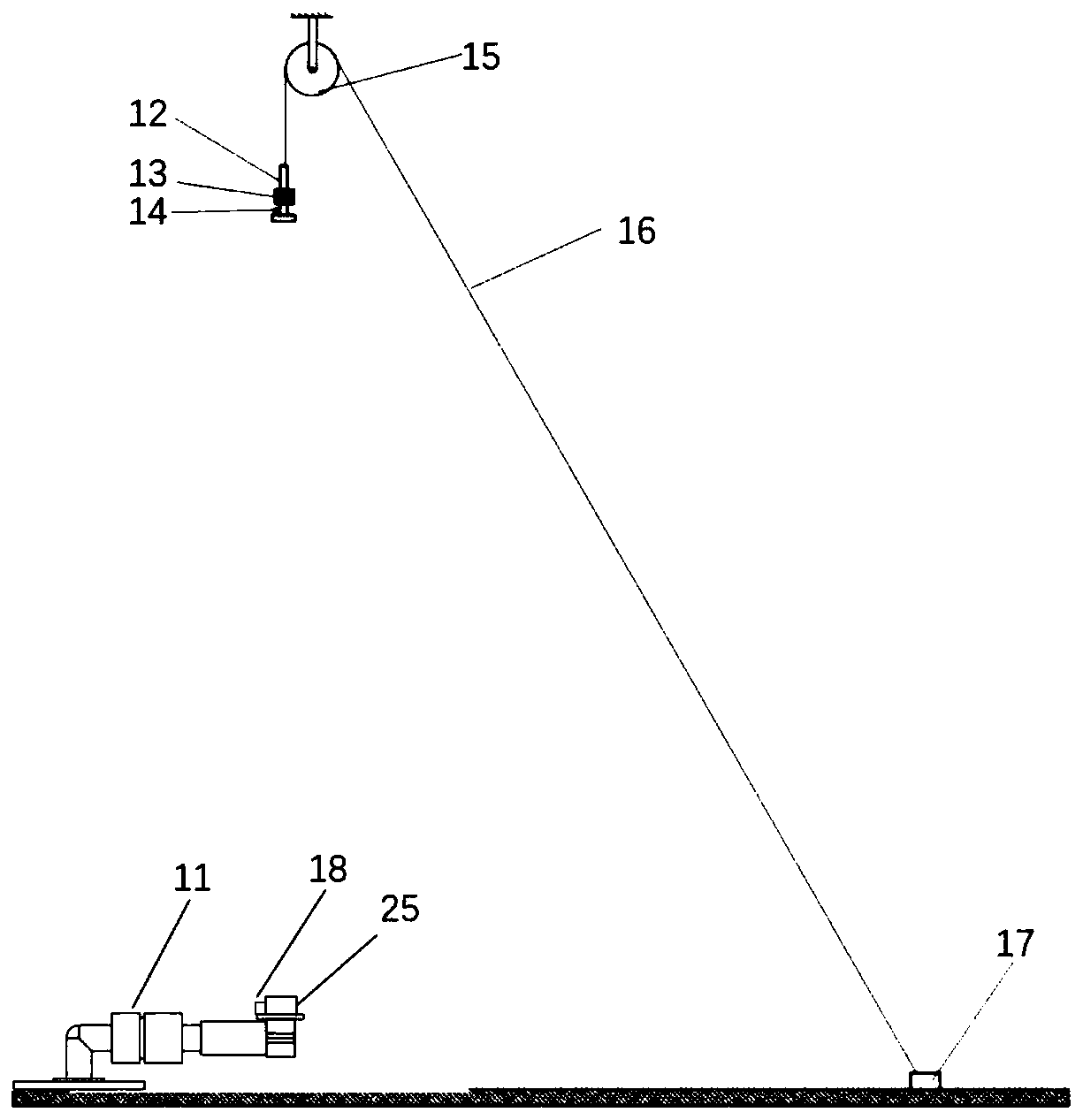

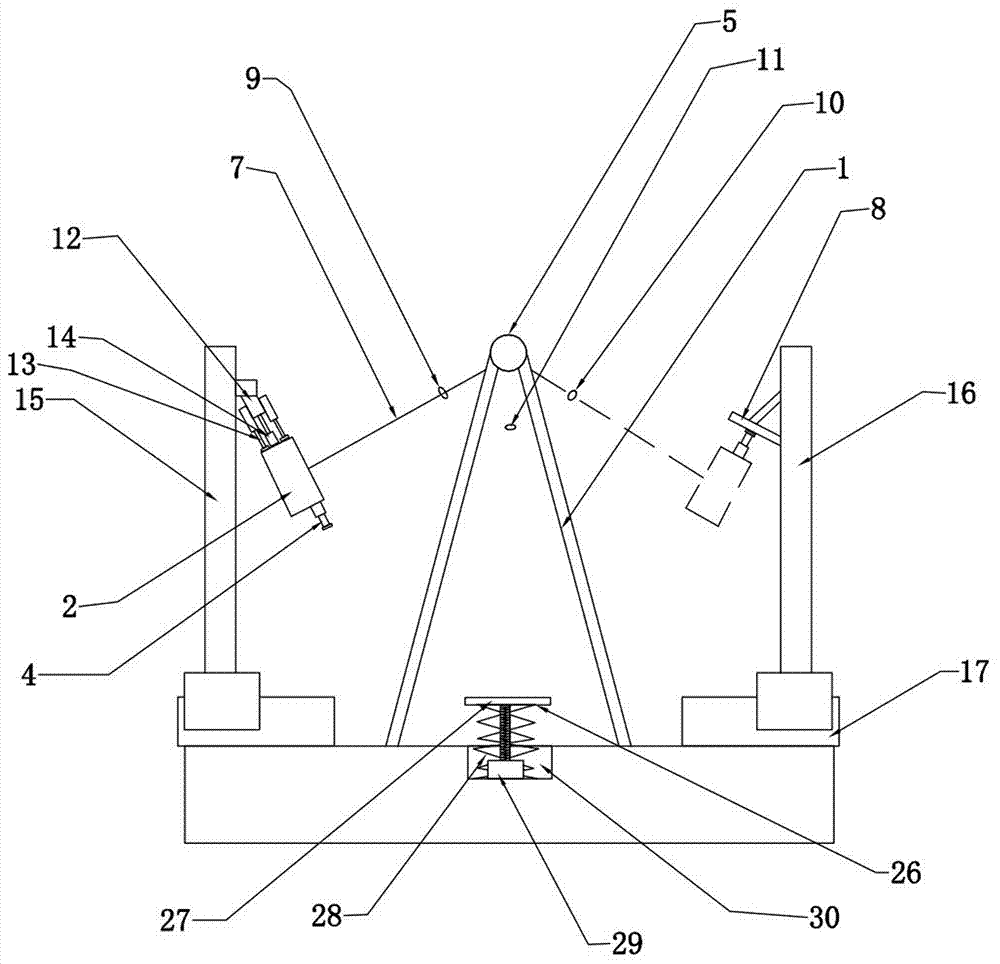

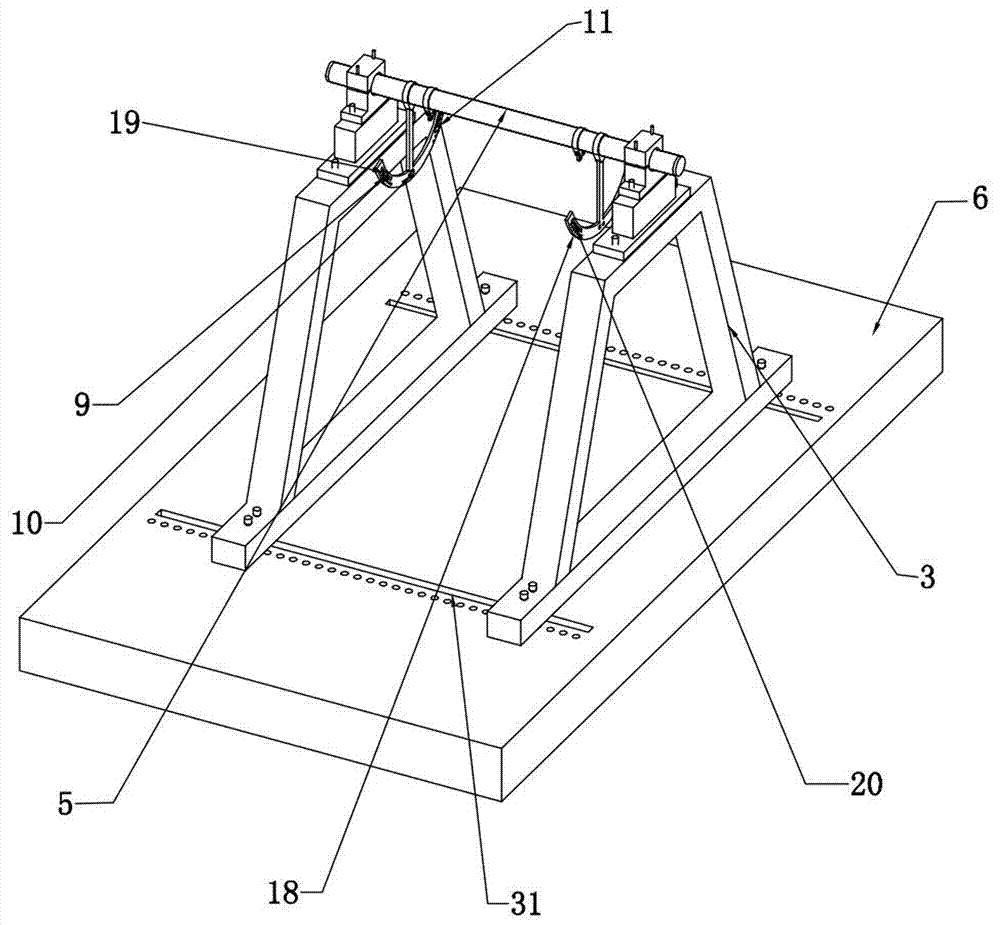

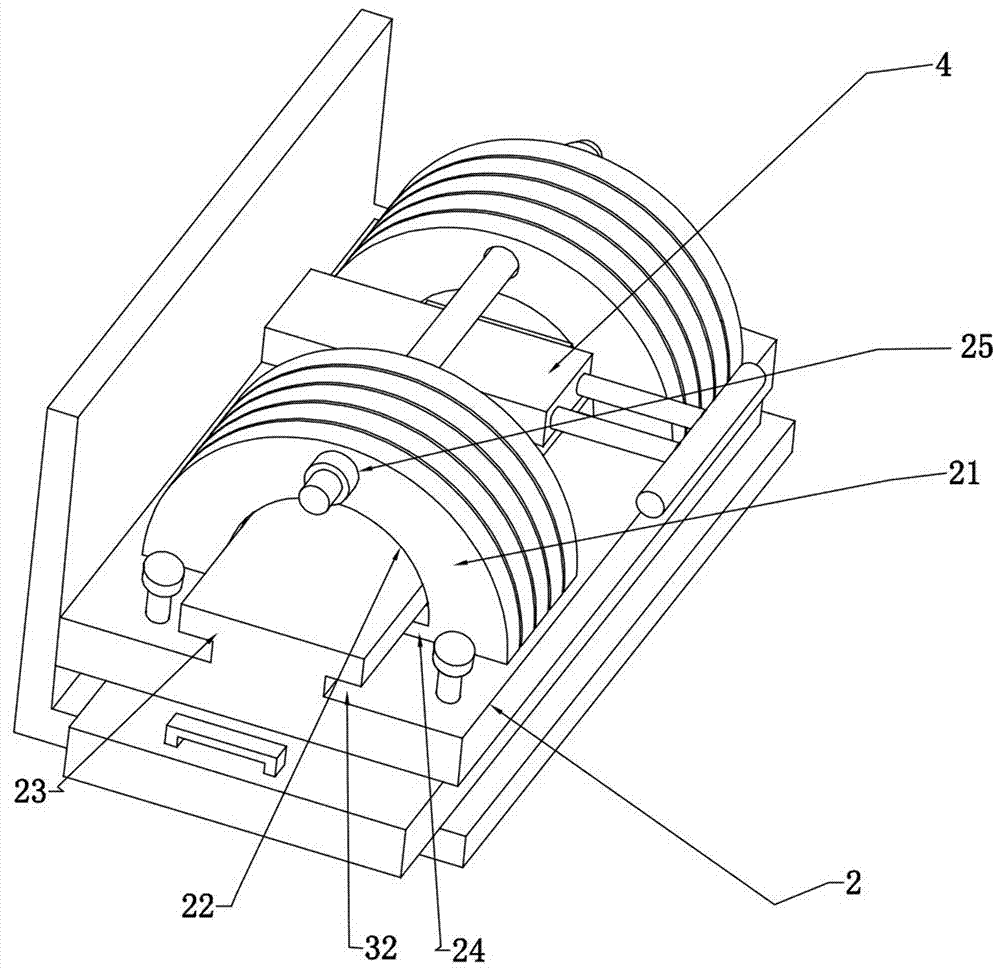

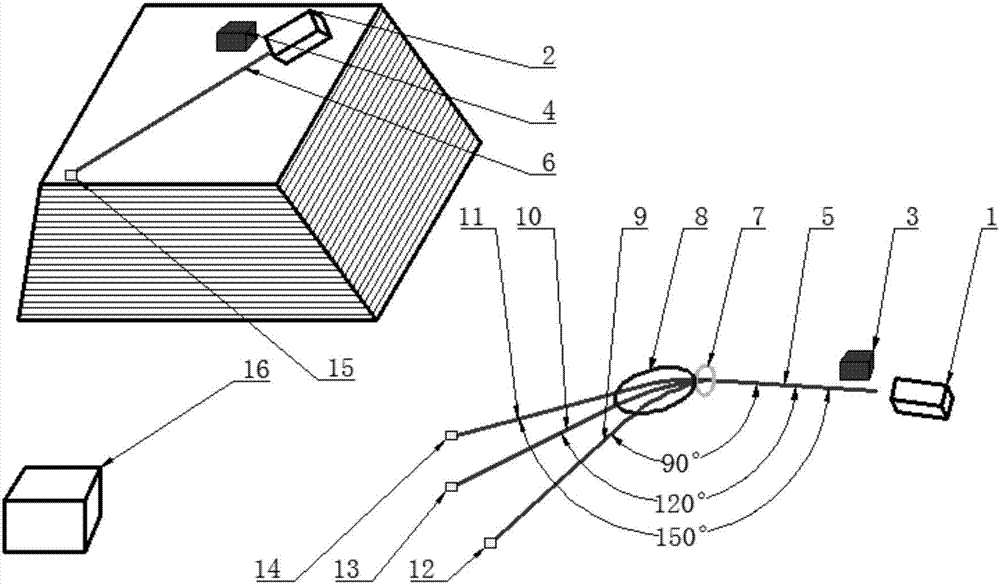

Pile foundation dynamic load testing system based on optical fiber grating and testing method of pile foundation dynamic load testing system

ActiveCN103882893AMonitor stress and strainImprove stabilityFoundation testingDynamic load testingGrating

The invention discloses a pile foundation dynamic load testing system based on an optical fiber grating and a testing method of the pile foundation dynamic load testing system. The testing system comprises a counterforce frame device, a power loading device, a soil containing tank and a monitoring device. The testing method includes the steps that various vibration waves are simulated through the set of power loading device and exerted on a foundation pile, and stress strain deformation conditions of the foundation pile are detected through the sensing optical fiber grating arranged in the foundation pile. The counterforce frame device and the soil containing tank are cast together to ensure that counterforce is transmitted stably and reliably; the power loading device can accurately control loading wave forms and loads in the power testing process; the monitoring device is high in response speed and can achieve remote monitor, and the sensing optical fiber grating has little influence on a pile body.

Owner:HOHAI UNIV

Crankshaft dynamic balance testing and calibration method

ActiveCN104502023AEasy to installReasonable structureStatic/dynamic balance measurementBalancing machineDynamic load testing

The invention relates to a crankshaft dynamic balance testing and calibration method, which comprises the following steps of firstly, equivalently converting amount of unbalance of a crankshaft pin of a crankshaft to amount of unbalance, at some angle, on main journals at two ends of the crankshaft; secondly, manufacturing equivalent mass blocks according to the dimension of the crankshaft, installing the equivalent mass blocks on the main journals at two ends of the crankshaft, compensating self-unbalance of the crankshaft, and realizing basic dynamic balance of crankshaft mass; finally, carrying out crankshaft dynamic balance testing and calibration on a balance machine. According to the crankshaft dynamic balance testing and calibration method, the equivalent mass blocks are installed on the main journals at two ends and are reasonable in structure, and convenient and reliable to install. The crankshaft dynamic balance testing and calibration method can effectively avoid collision caused when an equivalent ring is installed on the crankshaft pin, is high in use safety, simple and convenient to operate, accurate to control and high in detection efficiency, and is an ideal crankshaft dynamic balance testing and calibration method.

Owner:TIANRUN IND TECH CO LTD

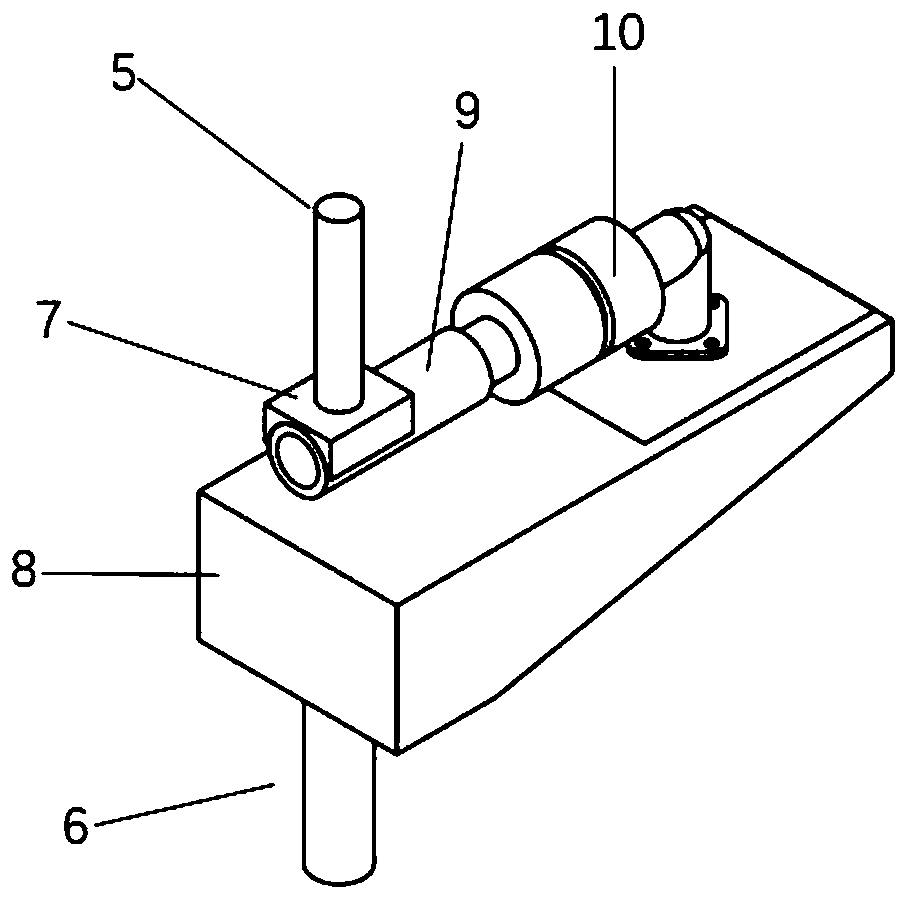

Dynamic load test bed for shaft coupler

InactiveCN102175451AReduce testing costsMachine gearing/transmission testingDynamic load testingReduction drive

The invention provides a dynamic load test bed for a shaft coupler, which comprises a load motor, an output reducer, a shaft coupler to be tested, an input reducer, an electric motor, an equipment base, a pressure sensor, a traveling motor, a traveling mechanism, a revolution speed sensor, an installing bracket of the revolution speed sensor, another pressure sensor, a slide rail of a translating pair, an output flange and an input flange. The revolution speed sensor and the another pressure sensor are linked with a data acquisition device; and the conditions of working, wearing and damaging of components of the shaft coupler under different revolution speeds and torques can be obtained by processing and analyzing the acquired data. The dynamic load test bed for the shaft coupler provided by the invention is mainly used for overall integrated dynamic load test of the shaft coupler; the conditions of working, wearing and damaging of components of the shaft coupler under different revolution speeds and torques can be obtained by simulating the actual working conditions through the dynamic load test bed for the shaft coupler; in addition, the dump energy is recycled to the power grid after the test, thus the test cost is lowered.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Loading device and method for stretch dynamic load test of self-sealing type shedding joint

ActiveCN110095357ARealize tensile dynamic load testSimple structureStrength propertiesVariable thicknessDynamic load testing

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

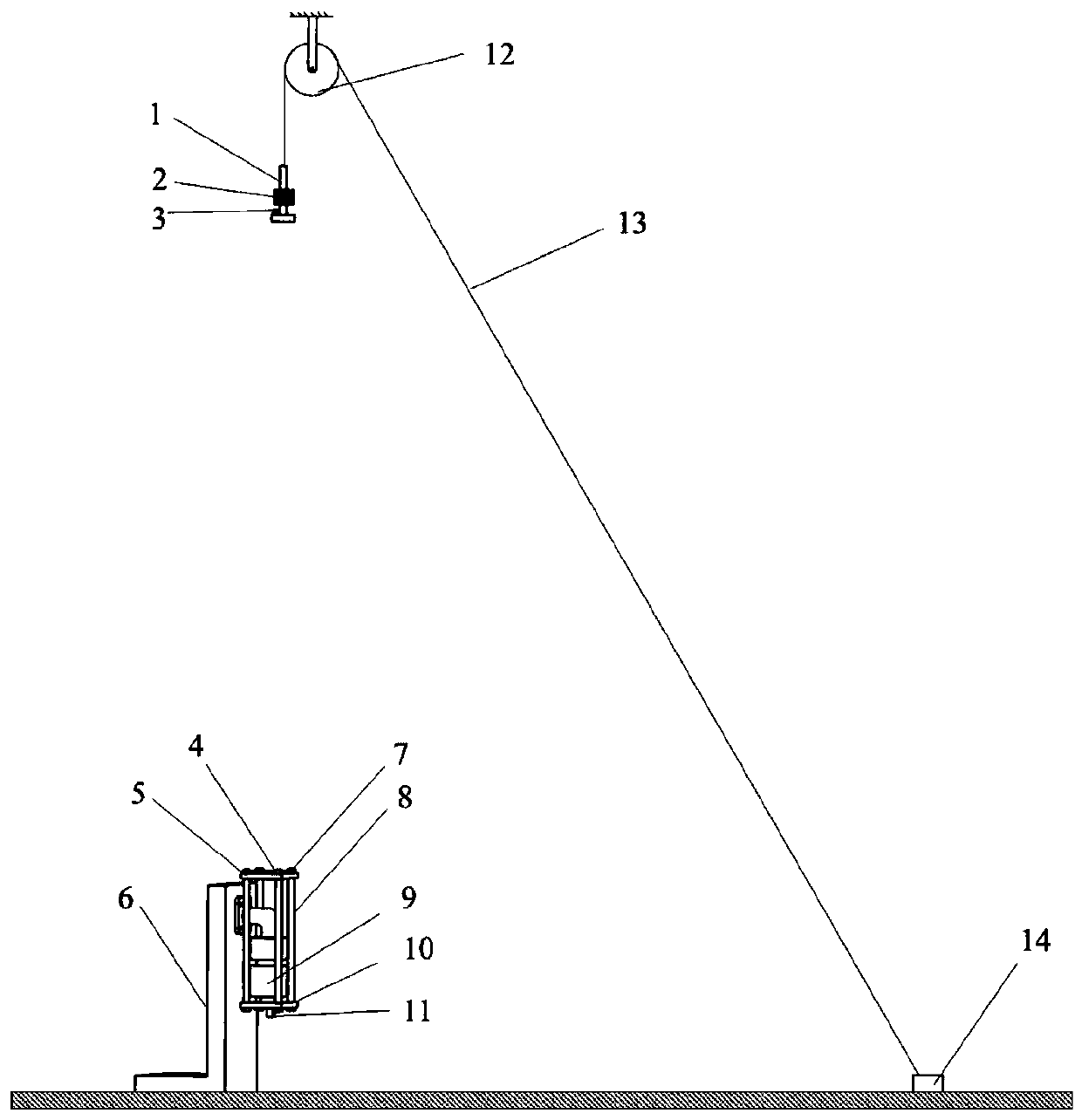

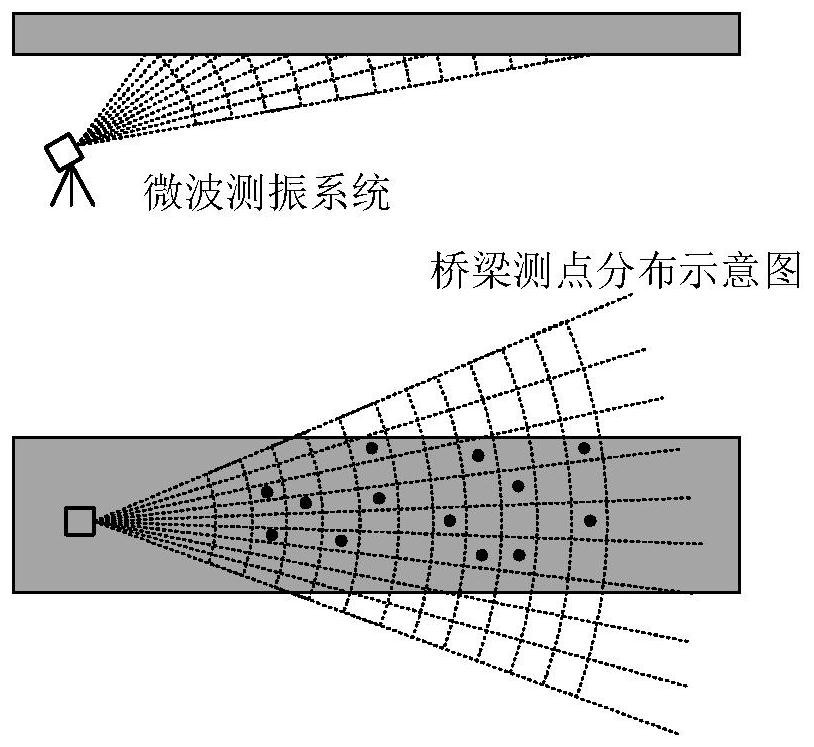

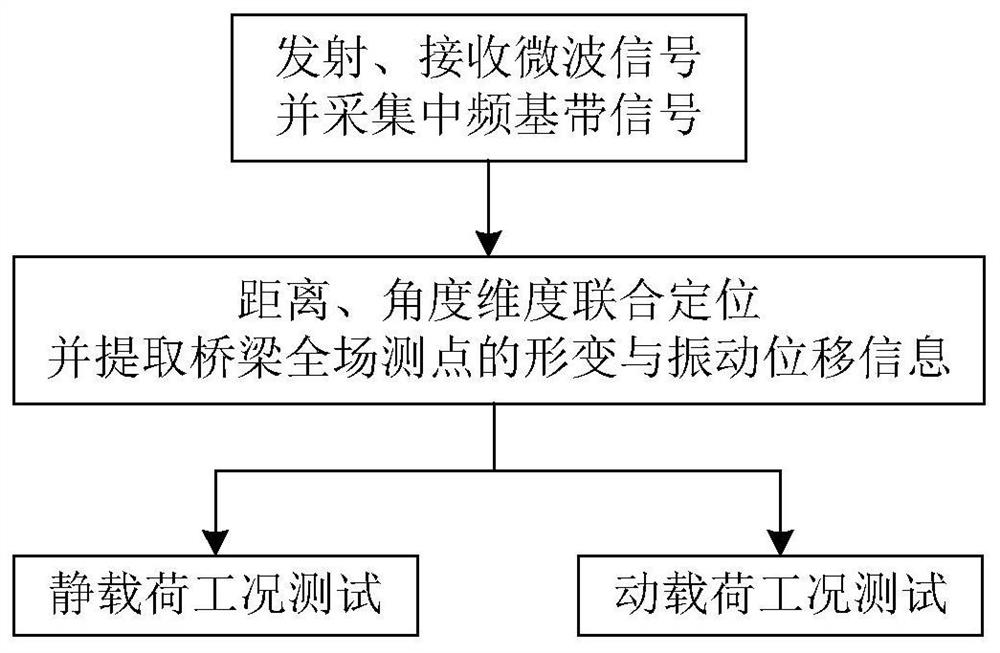

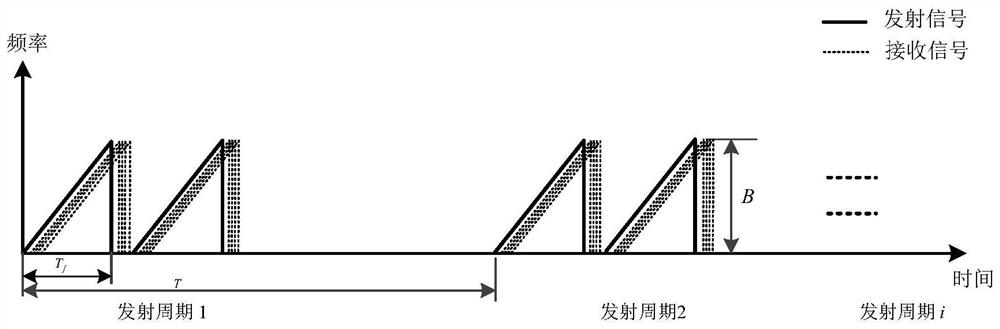

Non-contact type bridge structure performance and safety rapid test and evaluation system and method

ActiveCN112747877ASolve the problem that the whole field measurement cannot be realizedSolve the inaccurate test positioningElasticity measurementTime domainVibration measurement

The invention discloses a non-contact type bridge structure performance and safety rapid test and evaluation system and method. The non-contact type bridge structure performance and safety rapid test and evaluation method comprises the steps of: enabling a transmitting beam of a microwave vibration measurement system to cover a to-be-tested bridge structure, controlling the repeated transmission of a linear frequency modulation continuous wave microwave signal, and collecting a multi-channel intermediate frequency baseband signal; then carrying out combined positioning of the distance and angle dimensions of whole-field measurement points of the tested bridge structure according to the multi-channel intermediate-frequency baseband signal, and extracting to obtain the deformation and vibration time domain information of the multiple measurement points; verifying whether a bridge structure meets design and safety specification requirements or not according to multi-measuring-point deformation information of the tested bridge structure under the static load or dynamic load test working condition, and identifying modal parameters according to deformation and vibration information of full-field measuring points of the tested bridge structure under excitation; and according to the deformation quantity and the modal parameters, carrying out rapid test and evaluation on the performance and safety of the tested bridge structure. The non-contact type bridge structure performance and safety rapid test and evaluation system and the method are used for carrying out distance and angle combined dimension positioning and measurement on the bridge structure, and realize rapid testing and evaluation of structural performance and safety.

Owner:SHANGHAI JIAO TONG UNIV

Foundation pile static load testing and pile press method for buttress outer eccentricity heap loading method

ActiveCN104532884ASolve the problem of static load test to detect bearing capacityShorten the construction periodFoundation testingBulkheads/pilesButtressDynamic load testing

The invention discloses a foundation pile static load testing and pile press method for a buttress outer eccentricity heap loading method. According to the method, jacks are arranged on foundation piles in place, proper main beams are selected to be arranged on the jacks, buttresses are arranged in the direction parallel to the main beams, secondary beams are arranged on the buttresses and placed on the unified plane uniformly and symmetrically, heap loading materials are hoisted onto the secondary beams, and oil is supplied to the jacks for carrying out static load testing or pile press construction. The method which is convenient and fast to use and practical is provided for carrying out pile press treatment and bearing capacity static load testing on side piles or engineering piles close to the edge of a foundation pit.

Owner:ZHENGZHOU UNIV

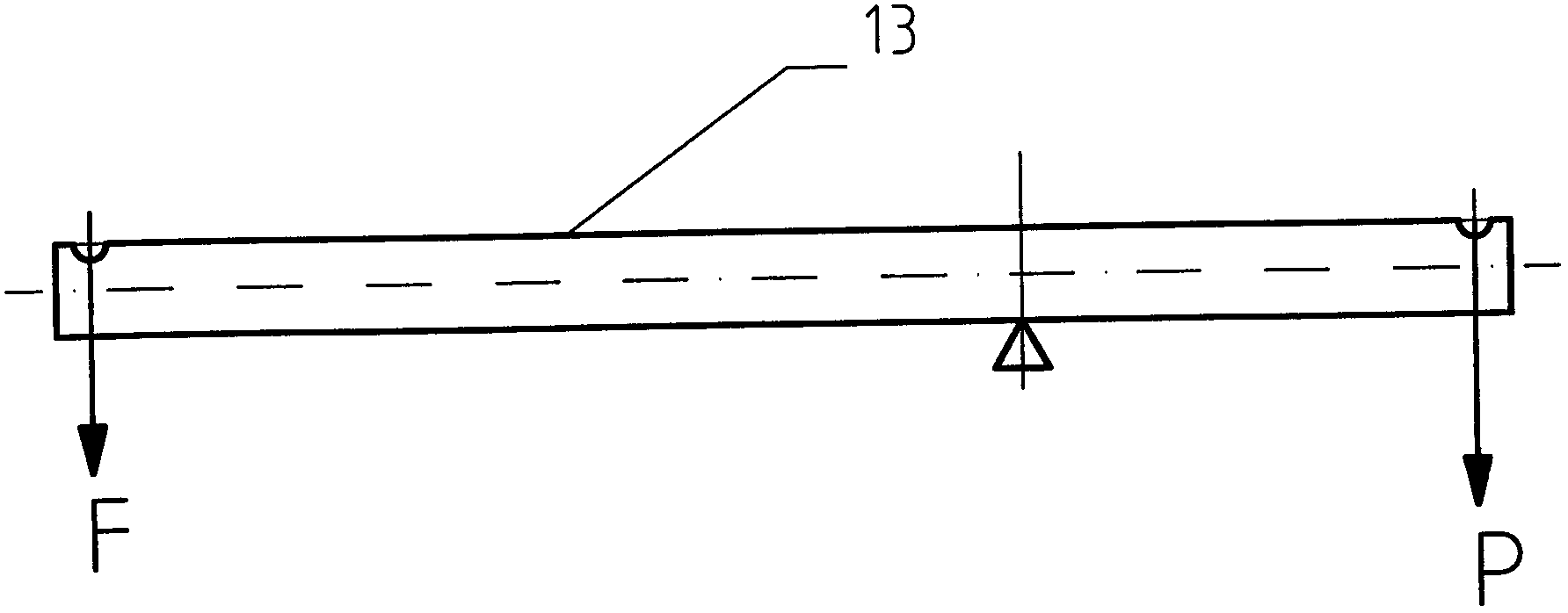

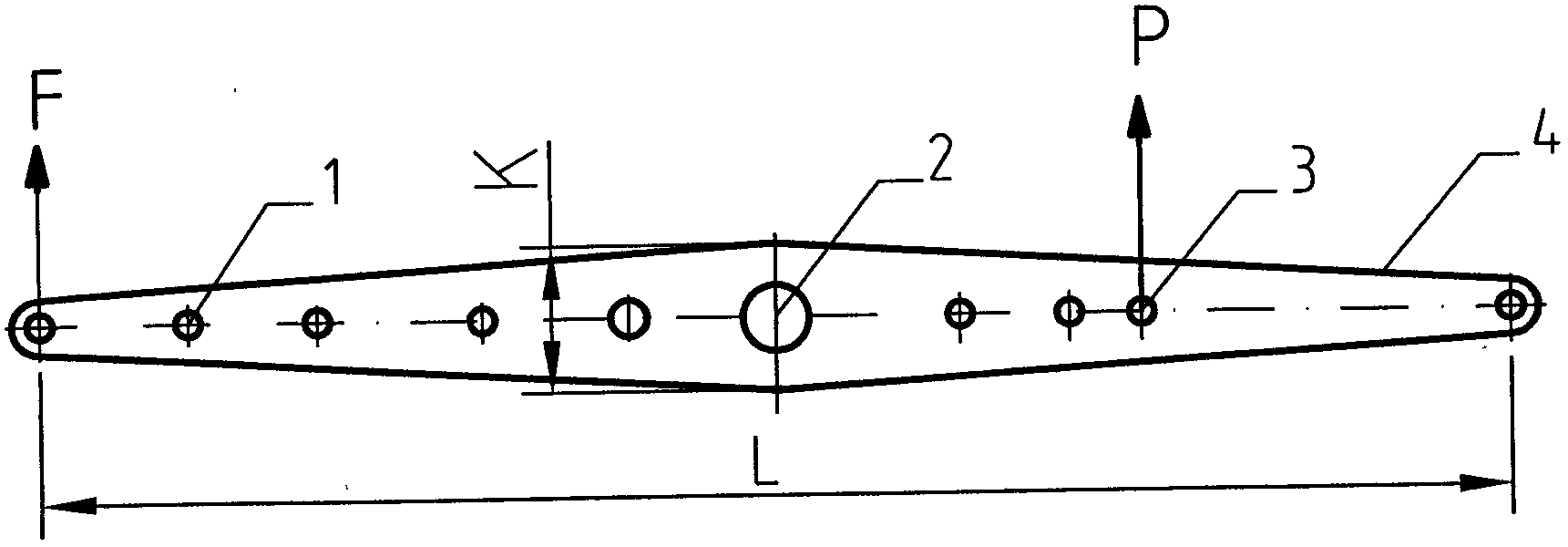

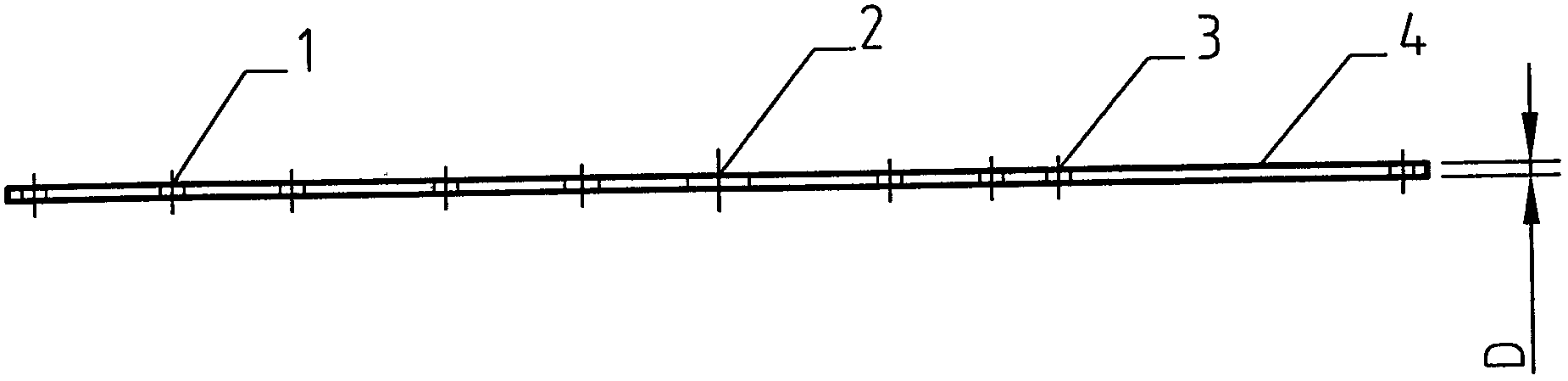

Lever used in leveraged adjustable load dynamic test bench

InactiveCN104075899ASolve the real problemEasy to processStructural/machines measurementDynamic load testingEngineering

The invention discloses a lever used in leveraged adjustable load dynamic test bench, belongingto the technical field of components on dynamic load testing equipment. A lever force arm side is provided with a force arm side mounting hole. A lever heavy arm side is provided with a heavy arm side mounting hole. A lever supporting point hole is opened between the lever force arm side and the lever heavy arm side, and is assembled with other components into a complete load adjustable test bench, so that the test bench can solve the problem of a conventional test bench, and the lever is simple to process. The lever structure helps to achieve an adjustable leverage point and an adjustable gravity force applying position, and has the advantages that the force direction and the gravity force applied direction are upward, and the force applied on the upper surface of the support point is downward.

Owner:北京起重工具厂

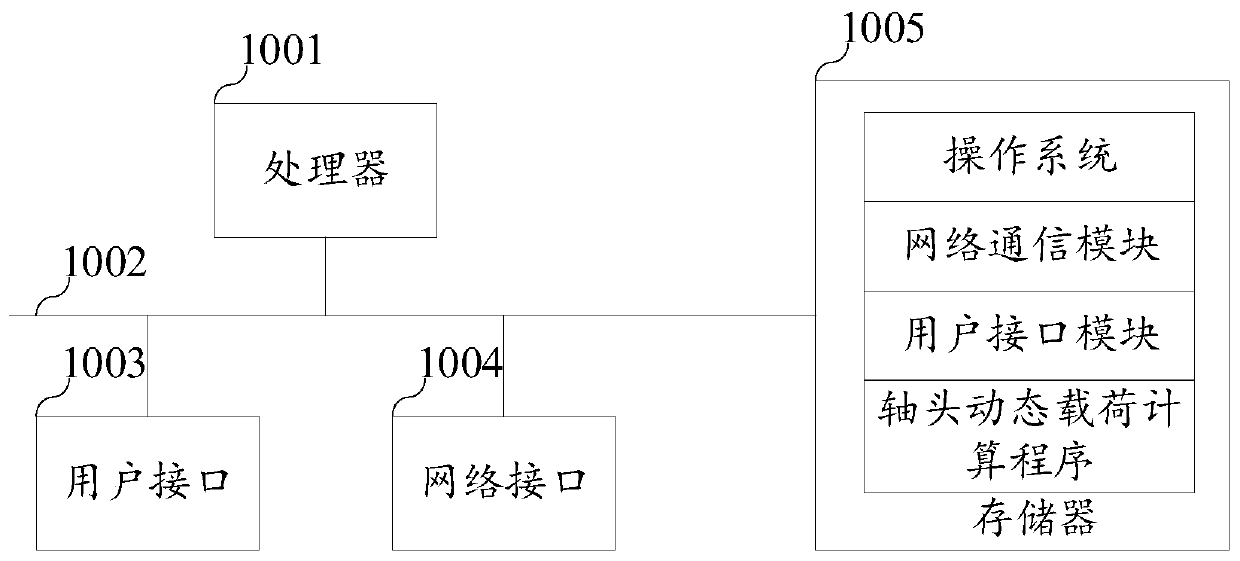

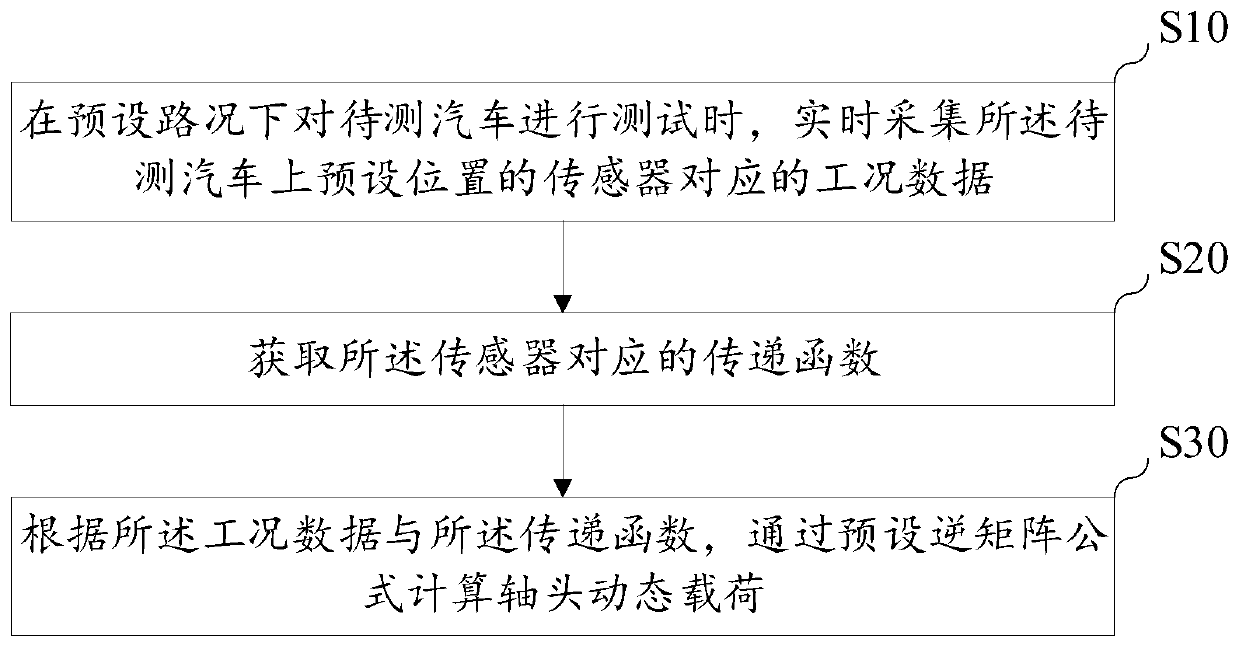

Shaft head dynamic load calculation method and device, equipment and storage medium

ActiveCN110411757ATroubleshooting Dynamic Load MeasurementsLow costVehicle steering/rolling behaviourDynamic load testingEngineering

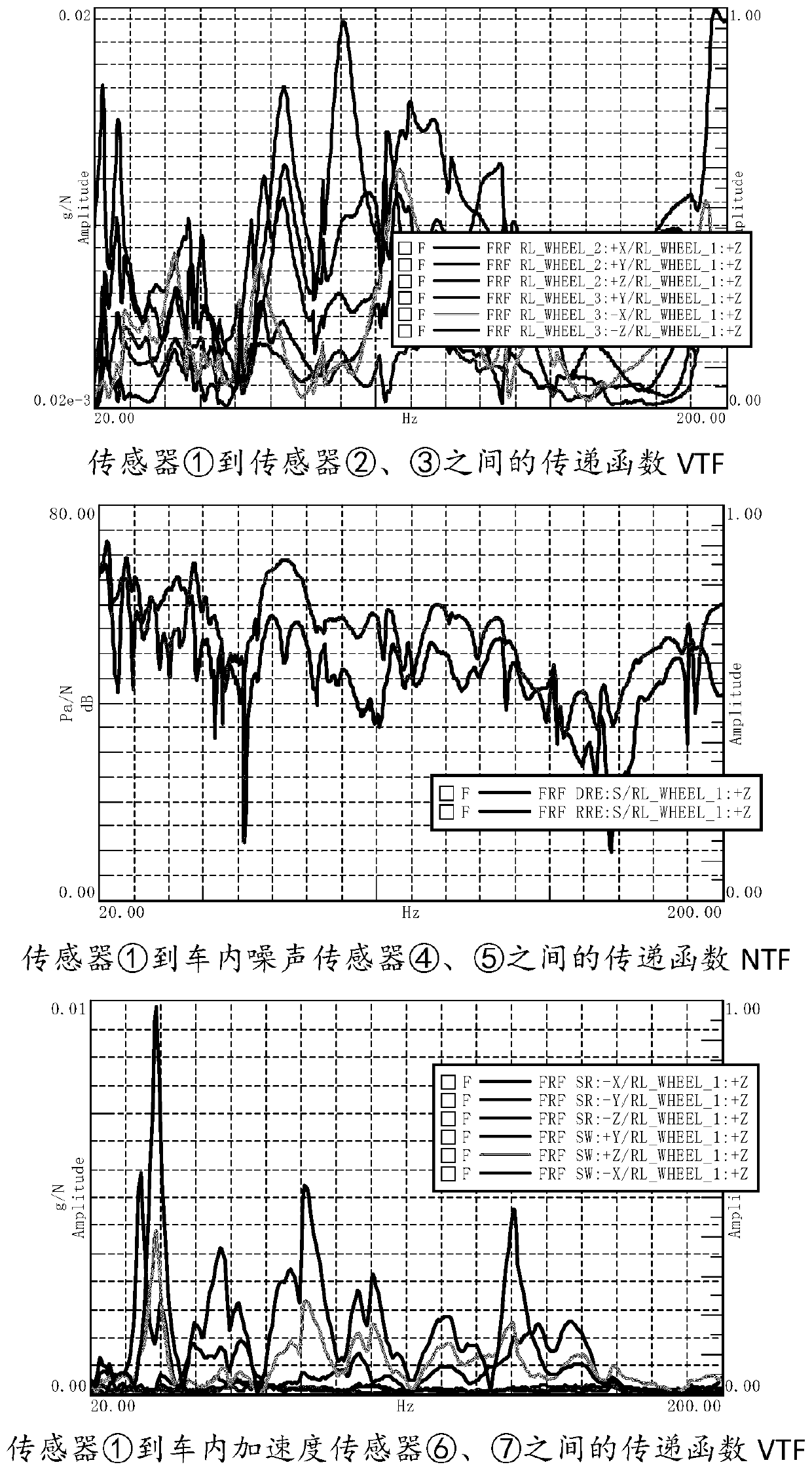

The invention belongs to the technical field of shaft head dynamic load testing, and discloses a shaft head dynamic load calculation method and device, equipment and a storage medium. The method includes the steps of during test of a car to be tested under a preset road condition, acquiring working condition data corresponding to a sensor at a preset position on the car to be tested in real time;acquiring a transfer function corresponding to the sensor; and according to the working condition data and the transfer function, calculating a dynamic load of a shaft head by means of a preset inverse matrix formula. In the above manner, when the dynamic load of the shaft head is measured, the time period is reduced, so that the cost is reduced and the efficiency is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

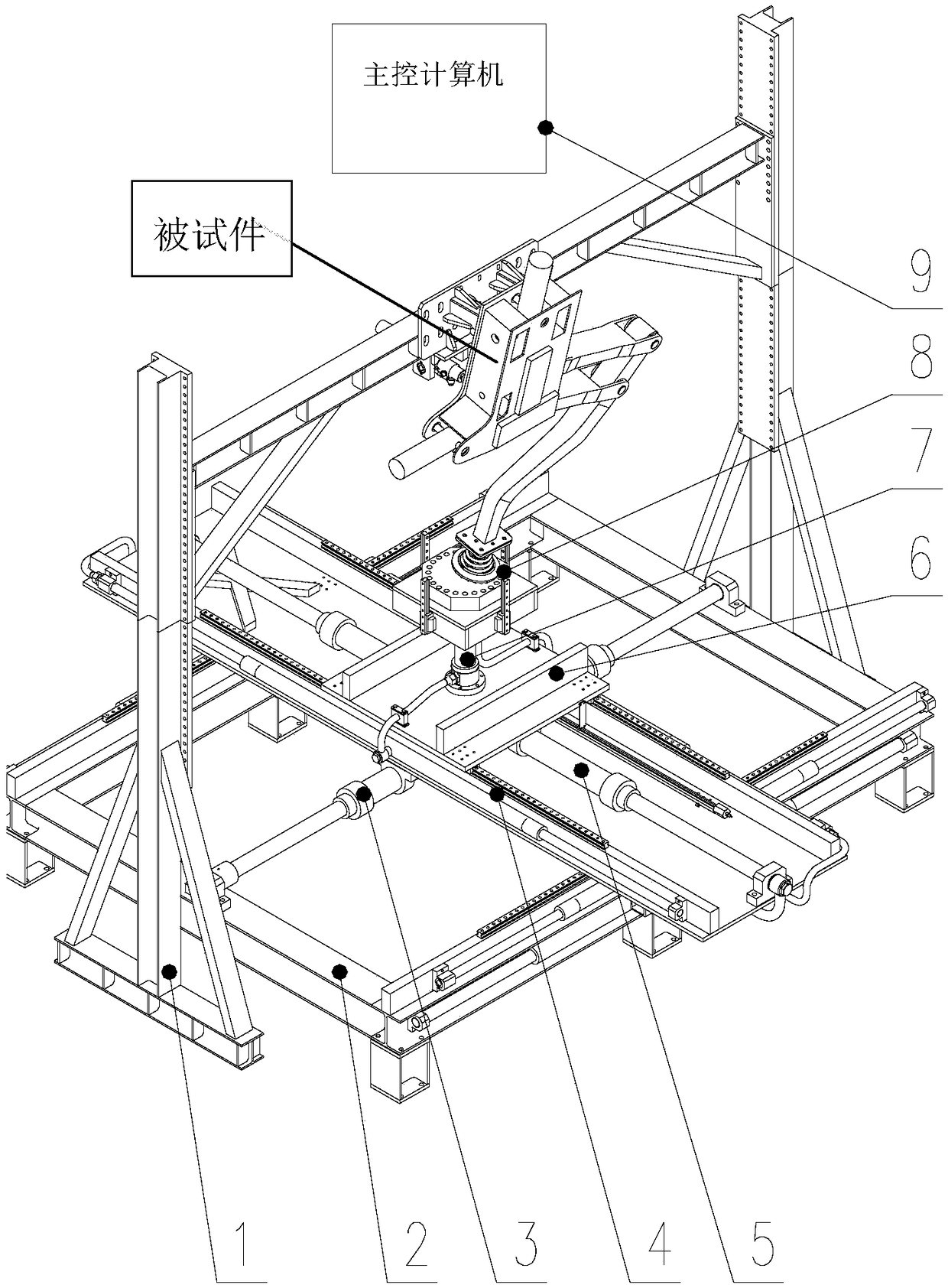

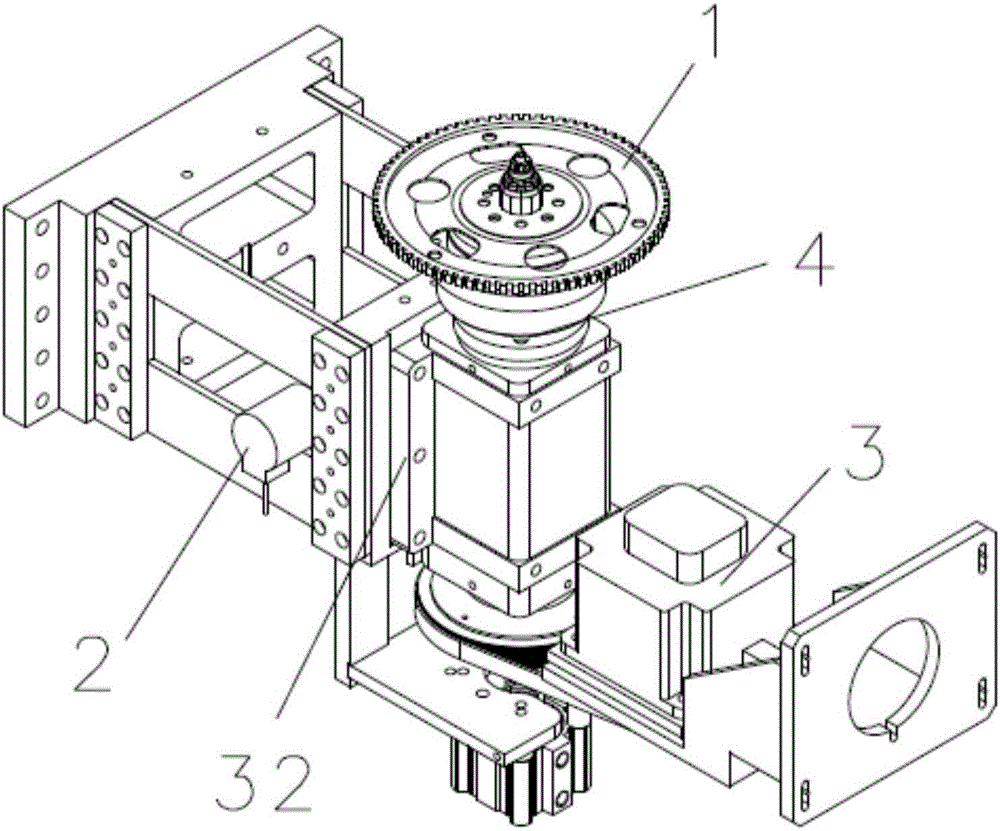

Multi-stage three-degree-of-freedom test bench for single leg of robot foot

The invention discloses a layered three-degree-of-freedom test bench for a single leg of a robot foot, in order to meet the requirements of the single leg performance test of the robot foot. The upperpart of the single leg of the robot foot to be tested is fixed on a height-adjustable gantry and the lower end contacts a ground simulation module. Through a multi-stage loading device, the active loading and passive loading test of three-degree-of-freedom in which the single leg is contacting with different grounds can be realized, so as to test the performance index of the single leg of the robot foot contacting with different grounds. The multi-stage three-degree-of-freedom test bench for the single leg of the robot foot, which is capable of realizing the active and passive loading of thesingle leg of the robot foot in three degrees of freedom and different grounds so as to effectively test various indexes of the performance of the single leg, can be applied to the performance test ofthe single leg of the robot foot.

Owner:内蒙古第一机械集团股份有限公司

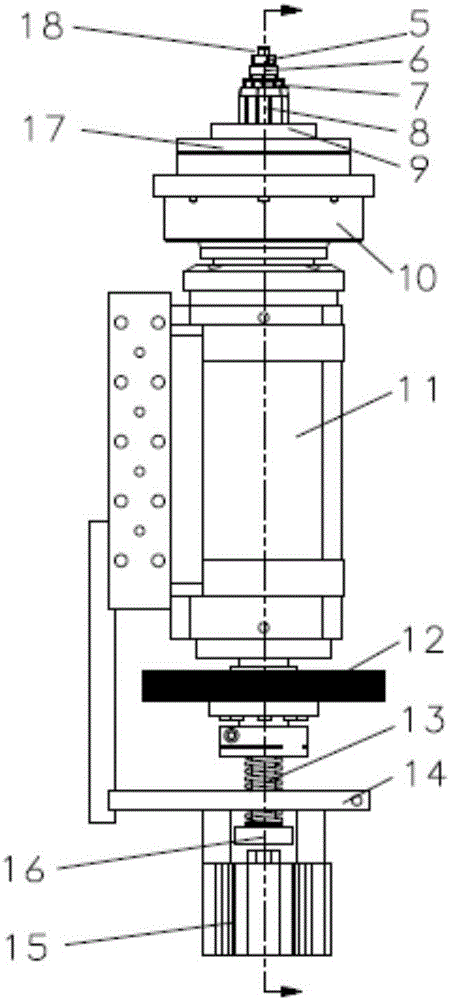

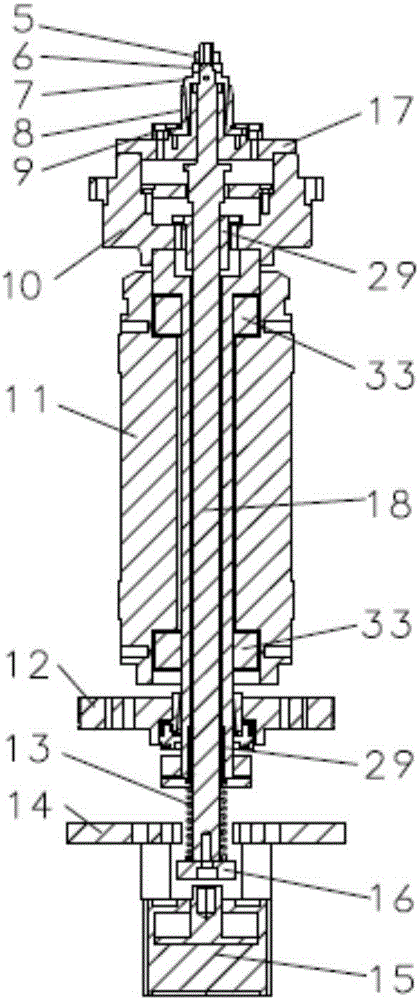

Automatic clamping device for testing dynamic balance of flexible flywheel

ActiveCN106197850AAvoid deformationProtection Runout ToleranceStatic/dynamic balance measurementDynamic load testingDynamic balance

The invention discloses an automatic clamping device for testing the dynamic balance of a flexible flywheel. The device is fixedly installed on a vibrating body of a universal hard supporting balance testing machine, and the flexible flywheel is installed at the top of the device and is clamped by the device. The device is connected with a driving part, and a rotating shaft in the device is driven by the driving part to speed up for dynamic balance testing. The device comprises a rotating main shaft seat, a pull rod, and a rotating main shaft. The rotating main shaft seat is fixed on a rack of the vibrating body, and the pull rod is disposed in a central hole of the rotating main shaft in a sleeved manner through a linear bearing. The rotating main shaft is disposed in the rotating main shaft seat in a sleeved manner through a bearing. The device applies a radial clamping force to the flexible flywheel through radial deformation, effectively avoids the bigger deformation of the flexible flywheel in the axial direction, protects the run-out tolerance of an end face of the flexible flywheel, and improves the dynamic balance testing precision.

Owner:杭州集智机电股份有限公司

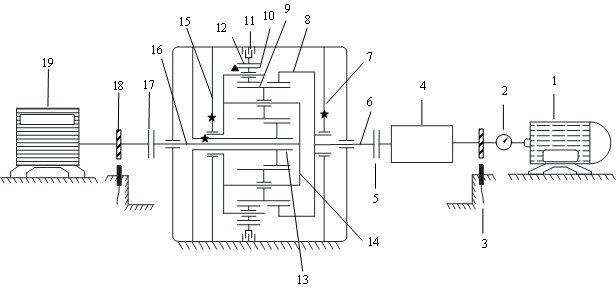

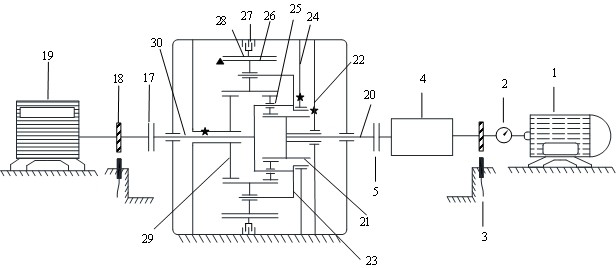

Dynamic load testing method for compound planetary gear transmission mechanism with wet-type gear shifting element

ActiveCN111811814AMeet vibration test requirementsSolve Mesh Shock Vibration Testing ProblemsMachine part testingDynamic load testingGear drive

The invention discloses a dynamic load test method for a compound planetary gear transmission mechanism with a wet-type gear shifting element. The method specifically comprises the steps of: arranginga three-way acceleration sensor on a bearing member in the compound planetary gear transmission mechanism, and arranging a strain test device on a non-bearing member; performing a vibration test on the compound planetary gear transmission mechanism under a stable working condition; carrying out no-load vibration test on the composite planetary gear transmission mechanism under an unstable workingcondition; carrying out a loading vibration test on the compound planetary gear transmission mechanism under an unstable working condition; and carrying out data processing on the obtained three-wayacceleration data and strain data through a signal analysis software system, and analyzing the dynamic load characteristics of the compound planetary gear transmission mechanism based on the processeddata. Vibration data of internal components of the compound planetary gear transmission mechanism with the wet-type gear shifting element can be accurately and reliably measured, and dynamic load characteristic analysis is carried out through a signal acquisition and signal analysis system.

Owner:BEIHANG UNIV

Air pressure dynamic load testing system capable of achieving end face self-cleaning for driving axle assembly

InactiveCN111069104AImprove accuracyEffectively clean upCleaning using toolsFluid-tightness measurement using fluid/vacuumDynamic load testingAir pump

The invention discloses an air pressure dynamic load testing system capable of achieving end face self-cleaning for a driving axle assembly. The air pressure dynamic load testing system structurally comprises an air inflation device, a driving axle sealing device, a driving air pump, an equipment supporting frame, a moving wheel stand and a driving axle fixing frame, the equipment supporting frameis horizontally mounted on the ground, the moving wheel stand and the equipment supporting frame are fixed together through bolts, and the driving axle fixing frame is horizontally mounted at the left end and the right end of the upper surface of the equipment supporting frame. The air pressure dynamic load testing system is provided with a first cleaning device and a second cleaning device, thuswhen an air inflation sealing head is attached to a driving axle housing, dust particles on the junction of the end face of the driving axle housing and the air inflation sealing head can be effectively cleared away, the situations that due to chippings, gaps exist in a detection head and the surface of a driving axle, and leakage occurs during air inflation of the axle housing are avoided, and the accuracy of the air tightness detection result of the driving axle housing is effectively improved.

Owner:南安新笙活商贸有限公司

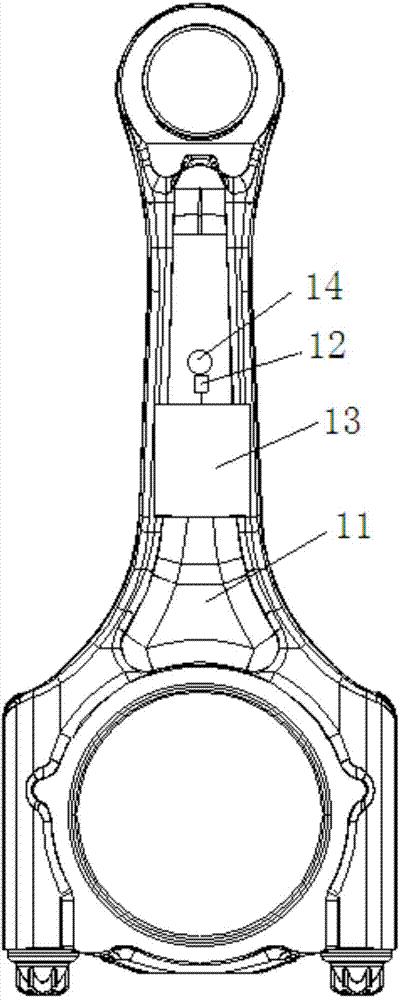

Dynamic load testing device for connecting rod

ActiveCN104849030AExact load spectrumSimple structureMachine part testingDynamic load testingEngineering

The invention relates to a dynamic load testing device for a connecting rod. The dynamic load testing device includes a foil gauge arranged on the to-be-tested connecting rod; and a data collecting unit arranged on the to-be-tested connecting rod and used for collecting strain signals sent by the foil gauge. Therefore, the working dynamic load of the connecting rod when an engine is working can be collected in real time, so that an accurate load spectrum can be provided for connecting rod design, connecting rod simulation calculation and fatigue reliability testing. Besides, the dynamic load testing device is simple in structure, high in precision and low in cost.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

Indoor damage evaluation method under action of cement improved sand rolling load

ActiveCN108007761AEasy to operateEvaluation index sciencePreparing sample for investigationStrength propertiesLoss rateDynamic load testing

The invention provides an indoor damage evaluation method under the action of a cement improved sand rolling load. The indoor damage evaluation method comprises the following steps: confirming a cement content for a sand sample to be improved according to project requirements, acquiring the maximum dry density, the optimal water content and expected compression density of cement improved sand according to compacting experiments, taking a test sample, and performing static strength testing; performing dynamic load testing according to rolling loads, observing the development trend of an axial accumulation plastic strain of the test sample along with vibration times, and performing static shearing on an undamaged test sample; finally according to the deformation development trend of the testsample, and the loss rates of the static shearing strength of the test sample before and after the action of a dynamic load, evaluating the damage degree of the cement improved sand. By adopting themethod, a dynamic rolling load of a road roller is applied to the test sample, the static rolling load can represent a stress state of cement improved sand roadbed packing on a construction site in the layered rolling process, the damage degree of the cement improved sand is evaluated through double indexes, namely deformation and strength of the test sample, the evaluation principles are scientific, test instructions are common instruments, extra processing transformation is avoided, and the test cost is low.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Hopkinson dynamic experiment device for exciting controllable waveform by hydraulic servo testing machine

PendingCN114577640ASolve technical problemsRealize specific waveform excitation importNuclear energy generationStrength propertiesDynamic load testingClassical mechanics

The invention provides a Hopkinson dynamic experiment device with controllable waveform excited by a hydraulic servo testing machine, which comprises a hydraulic servo dynamic load testing machine, a position adjusting mechanism, a Hopkinson incident bar, a Hopkinson transmission bar and a dynamic strain gauge, and is characterized in that a loading disc of the testing machine is arranged in the position adjusting mechanism, and a loading impact shaft is arranged on the loading disc; one end of the Hopkinson incident bar is connected to the loading impact shaft, an experimental sample is mounted between the Hopkinson transmission bar and the Hopkinson incident bar, strain gauges are arranged on the outer walls of the Hopkinson transmission bar, the Hopkinson incident bar and the experimental sample, the dynamic strain gauge is connected with the strain gauges, and the dynamic strain gauge is connected with the Hopkinson transmission bar and the Hopkinson incident bar. According to the method, specific waveform excitation and introduction are realized, stress wave propagation and action processes are truly reduced by virtue of the advantages of a transmission system of the Hopkinson bar, residual wave reflection and oscillation effects are effectively avoided, a relation between stress waves and impact energy is established, and waveform inversion is performed on a fracture behavior of an experimental sample under the action of dynamic impact.

Owner:CHINA COAL RES INST

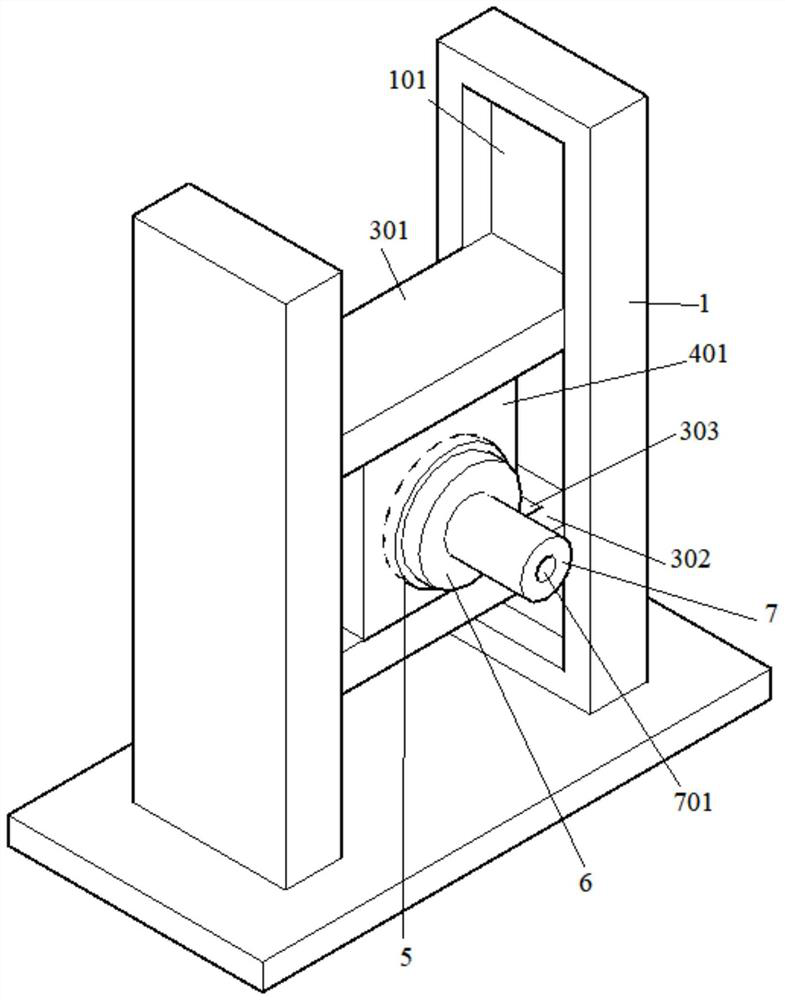

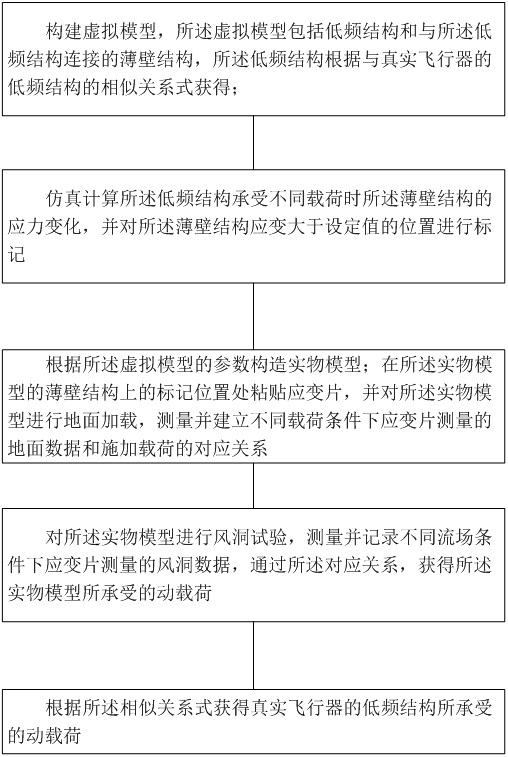

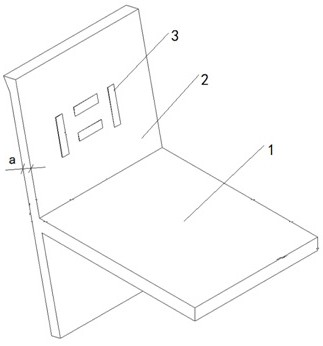

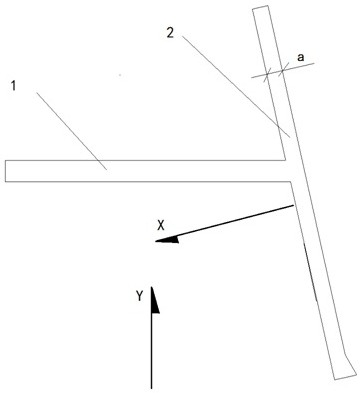

Dynamic load testing method for wind tunnel with large incidence angle and low frequency structure

ActiveCN113504025ALarge strainReduce experiment costAerodynamic testingAircraft components testingDynamic load testingFlight vehicle

The invention discloses a large-angle-of-attack low-frequency structure wind tunnel dynamic load test method. The method comprises steps of a virtual model being constructed, the virtual model comprising a low-frequency structure and a thin-wall structure which are connected with each other, and the low-frequency structure being obtained according to a similar relational expression with a low-frequency structure of a real aircraft; simulating and calculating the stress change of the thin-wall structure when the low-frequency structure bears different loads, and marking the position where the strain of the thin-wall structure is greater than a set value; constructing a physical model according to the parameters of the virtual model; pasting a strain gauge at a mark position on the thin-wall structure of the physical model, carrying out ground loading on the physical model, and measuring and establishing a corresponding relation between ground data measured by the strain gauge and an applied load under different load conditions; performing a wind tunnel test on the physical model, measuring and recording wind tunnel data measured by the strain gauges under different flow field conditions, and obtaining a dynamic load borne by the physical model through a corresponding relation; and obtaining the dynamic load borne by the low-frequency structure of the real aircraft according to the similarity relational expression.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Field dynamic load testing method for collision resistance and safety of highway corrugated beam barriers

ActiveCN102879169BLow implementation costEasy to operateShock testingManagement unitDynamic load testing

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

Bending load test loading device for self-sealing disengagement joint and loading method

ActiveCN110686984AEasy to processReduce mistakesMaterial strength using steady bending forcesDynamic load testingClassical mechanics

The invention relates to a dynamic load and static load testing device and method for the bending performance of an emergency disconnecting device, and belongs to the field of mechanical property testing. The bending static load testing device comprises a testing machine, an upper clamping end screw, a lower clamping end screw, an upper clamping end base, a lower clamping end base, a loading forcearm and a self-sealing disengagement joint. The bending dynamic load testing device comprises a loading force arm, an upper half, a lower half, a self-sealing disengagement joint, a rigid base, a dynamic load loading platform, a drop hammer, an adjusting mass block, an acceleration sensor, a positioning pulley, a flexible rope, a pressing block, a dynamic load sensor and a buffer pad. The deviceis simple, reliable and convenient to operate, is improved compared with the existing testing device which only tests the bending load, comprehensively considers the factors such as the loading rate,the dynamic load acting time, the clamp speed variation and the load size, meets the related requirements of the testing standard, and has important engineering significance in the aspect of determining the bending breaking load of the self-sealing disengagement joint.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Swing dynamic load testing machine

PendingCN107356423AReverse thrust will not be lostCalculations are reasonableMachine part testingDynamic load testingControl engineering

The invention discloses a swinging dynamic load testing machine. The swinging dynamic load testing machine comprises a swing bracket, a load assembly and a first air cylinder which is mounted on the load assembly; the upper end of the swing bracket is provided with a cross beam; a test piece is hinged to the cross beam; the test piece comprises a swinging arm and a seat plate; the load assembly is mounted on the seat plate; one side of the swing bracket is provided with a baffle which can abut against the piston rod of the first air cylinder so that the piston rod of the first air cylinder can obtain a force; the swing bracket is provided with position sensors; the position sensors comprise a first sensor, a second sensor and a third sensor, wherein the first sensor and the second sensor are respectively arranged at two ends of the moving track of the test piece, and the third sensor is arranged between the first sensor and the second sensor; the mounting height of the first sensor is larger than the height of the second sensor; the first sensor is used for detecting the swinging amplitude of a swing; the second sensor is used for triggering the movement of the first air cylinder, so that the first air cylinder can apply a pushing force to the swing timely when the swinging amplitude of the swing is smaller than a certain range after energy is lost; and the third sensor is used for calculating the number of the times of the swinging of the test piece.

Owner:QUALITY INSPECTING CENT OF PUMP & VALVE PROD OF ZHEJIANG PROVINCE +1

Bridge dynamic load testing method based on neural network technology

InactiveCN102539098BStructural damage is smallImprove analysis efficiencyBiological neural network modelsVibration testingStructural dynamicsDynamic load testing

The invention provides a bridge dynamic load testing method based on neural network technology, which includes conducting statistic analysis on a large amount of existing bridge testing results, determining dynamic load response affecting parameters of a bridge structure, using the affecting parameters as an input layer to construct a neural network model, and deducing structural dynamic load response predicted value; and conducting dynamic load actual measurement on the bridge under single vehicle speed, conducting reliability inspection on neural network theoretical derivation value by using actual measurement value, obtaining dynamic response verified through the actual measurement and characteristics of the bridge structure, and judging actual states and safety performance of the bridge structure according to the dynamic response and the characteristics of the bridge. Due to the fact that the bridge dynamic load testing method combines advantages of a conventional dynamic load testing method and the neural network technology is used to optimize a testing process, bridge dynamic load testing estimation conducted by means of the method greatly reduces structural damage caused by conventional dynamic load testing and improves analysis efficiency and operability on the basis of being capable of guaranteeing accurate and reliable testing results.

Owner:SOUTHEAST UNIV

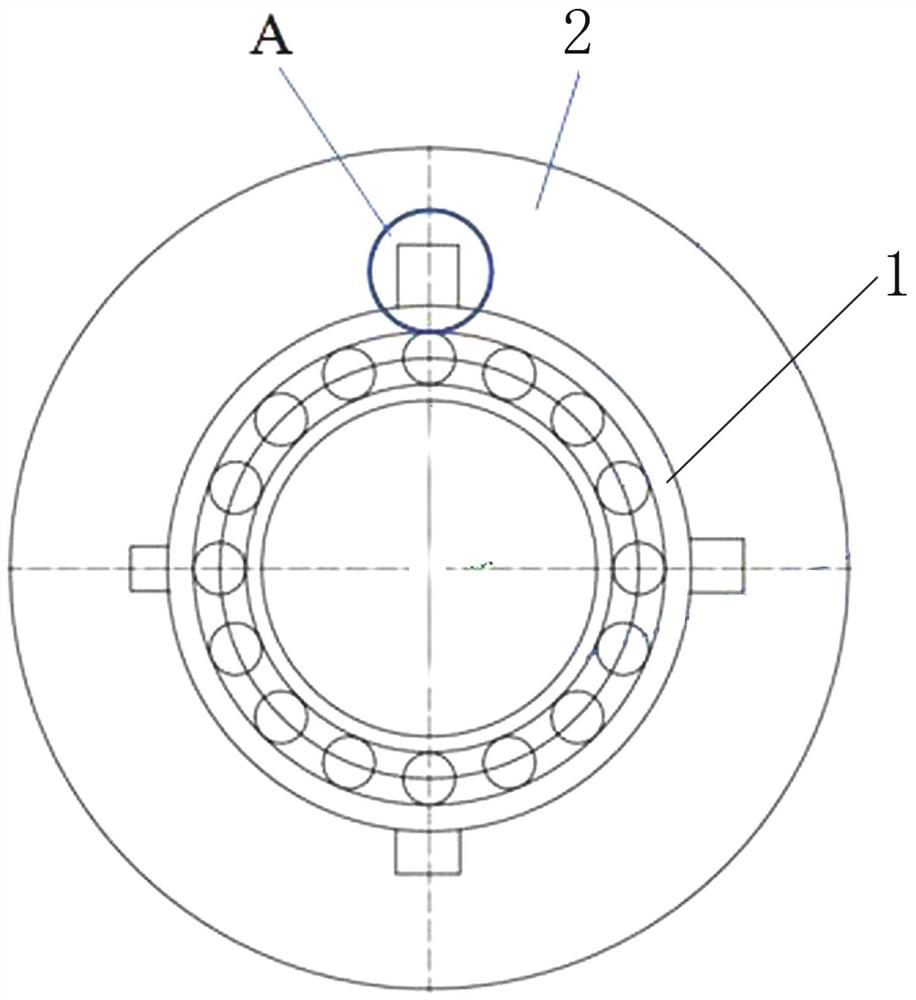

Motor bearing random dynamic load testing device and testing method

PendingCN114354190AResolving inaccurate measurementsAvoid situations where data cannot be detectedMachine bearings testingApparatus for force/torque/work measurementDynamic load testingElectric machine

The invention relates to a motor bearing, in particular to a motor bearing random dynamic load, and specifically relates to a motor bearing random dynamic load testing device and a testing method. In order to solve the problem that a random dynamic load test device and a test method of a motor bearing in the prior art are easy to cause inaccurate random dynamic load test of the motor bearing, the invention provides a novel random dynamic load test device of the motor bearing, which comprises a bearing bush provided with four positioning holes and an adjusting through hole, a dynamometer fixing assembly is arranged in each positioning hole; a dynamometer adjusting assembly is arranged in each adjusting through hole and comprises an adjusting block, the adjusting block is located between the upper end face of the piezoelectric dynamometer and the side wall of the upper portion of the adjusting through hole, and the face, making contact with the adjusting through hole, of the adjusting block is an inclined face. According to the testing device, the piezoelectric dynamometer can be in direct contact with the outer ring of the motor bearing, and the pretightening force can be adjusted through the inclined surface on the adjusting block, so that the testing result is more accurate.

Owner:CRRC YONGJI ELECTRIC CO LTD

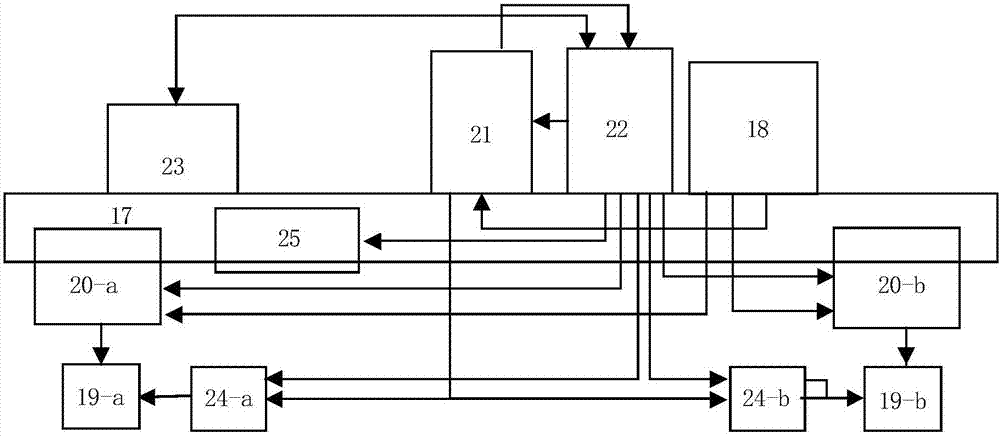

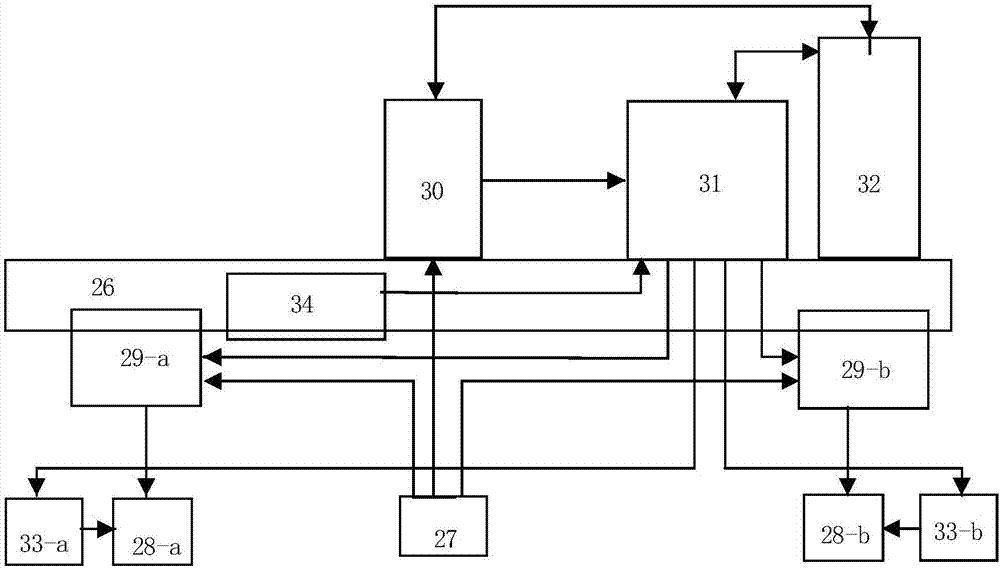

Rail vehicle dynamic-to-dynamic testing system and method

ActiveCN107290162AEasy to controlThe control module is easy to generate and controlRailway vehicle testingVehicle dynamicsDynamic load testing

The present invention relates to a rail vehicle dynamic-to-dynamic testing system and a method. The testing system includes a ground control subsystem, a plurality of testing vehicles, and test lines corresponding to the testing vehicles. Each testing vehicle operates in a corresponding testing line. The ground control subsystem is connected to the testing vehicles in different testing lines respectively, wherein each testing vehicle is provided with a vehicle control module, which receives signals from another testing vehicle and generates corresponding control commands to control the running of the vehicle itself. The testing lines comprise a plurality of line support modules connected in sequence. Compared with the prior art, the system and the method of the present invention has the advantages of performing coordinated testing on different rail vehicles, generating control commands by the vehicle's own control module, designing line support modules that facilitate line construction, and simulating a system more realistically.

Owner:TONGJI UNIV

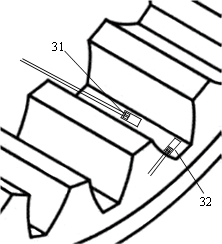

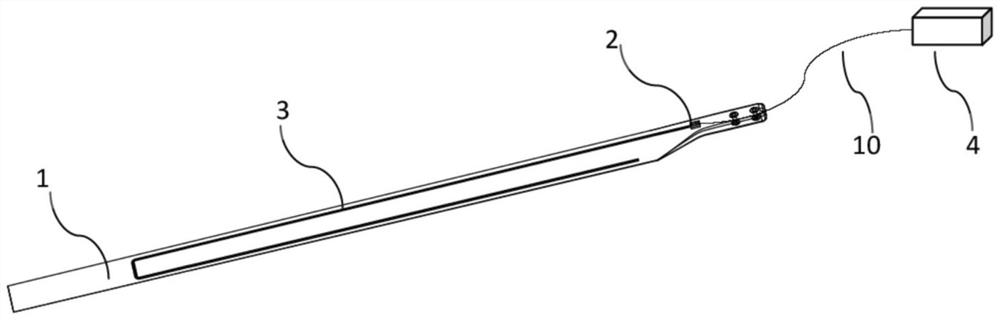

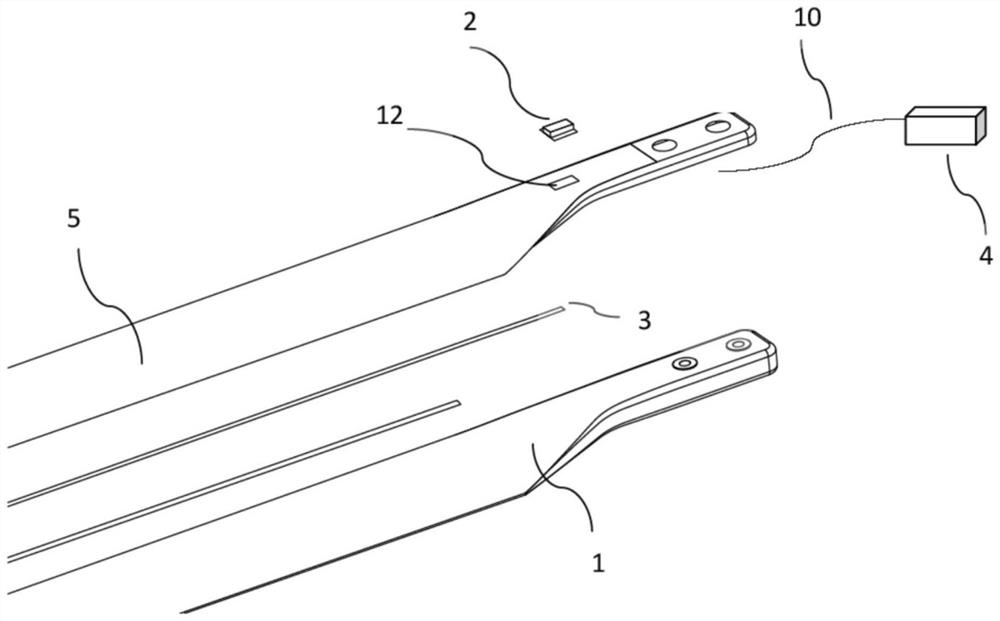

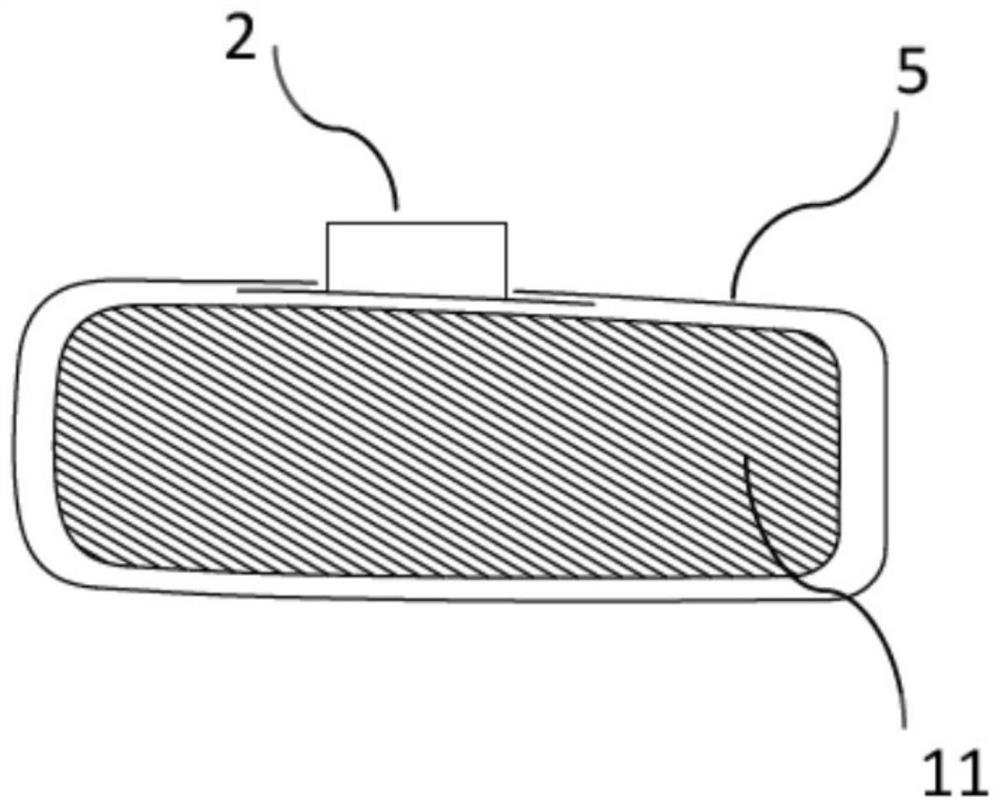

Connection method of transmission interface of embedded sensor for rotor blade and rotor blade

ActiveCN111731503AFirmly connectedEasy maintenanceMachine part testingForce measurement by measuring optical property variationFiberDynamic load testing

The embodiment of the invention discloses a connection method of a transmission interface of an embedded sensor for a rotor blade and the rotor blade, which relate to the technical field of rotor blade dynamic load test, and can improve the reliability of the transmission interface of a fiber bragg grating sensor data signal embedded in the rotor blade. The method comprises the steps that S1, a transmission interface box (2) is installed at the root of a rotor blade (1), and a bottom surface extension edge (6) of the transmission interface box is embedded into the lower surface of a surface layer skin (5) of the rotor blade (1); S2, a tail fiber of a fiber grating sensor (3) embedded in the rotor blade (1) is connected with a connecting fiber (10) of external fiber grating demodulator equipment through a transmission interface box (2), and the transmission interface box (2) serves as a junction box; and S3, the rotor blade (1) provided with the transmission interface box (2) is heated,molded and cured. The method is suitable for reinforcing the sensor transmission interface in the rotor blade dynamic load test.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com