Non-contact type bridge structure performance and safety rapid test and evaluation system and method

A bridge structure and evaluation system technology, applied in the testing of machines/structural components, elastic testing, measuring devices, etc., can solve problems such as complex line layout and difficult bridges, improve reliability and accuracy, and improve testing Efficiency, solve the effect of inaccurate test positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

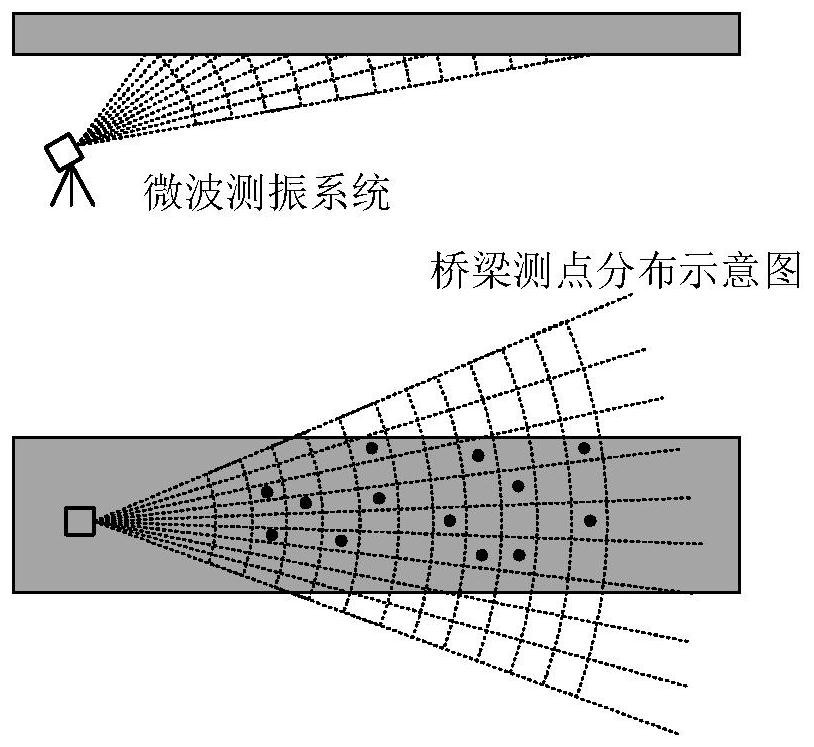

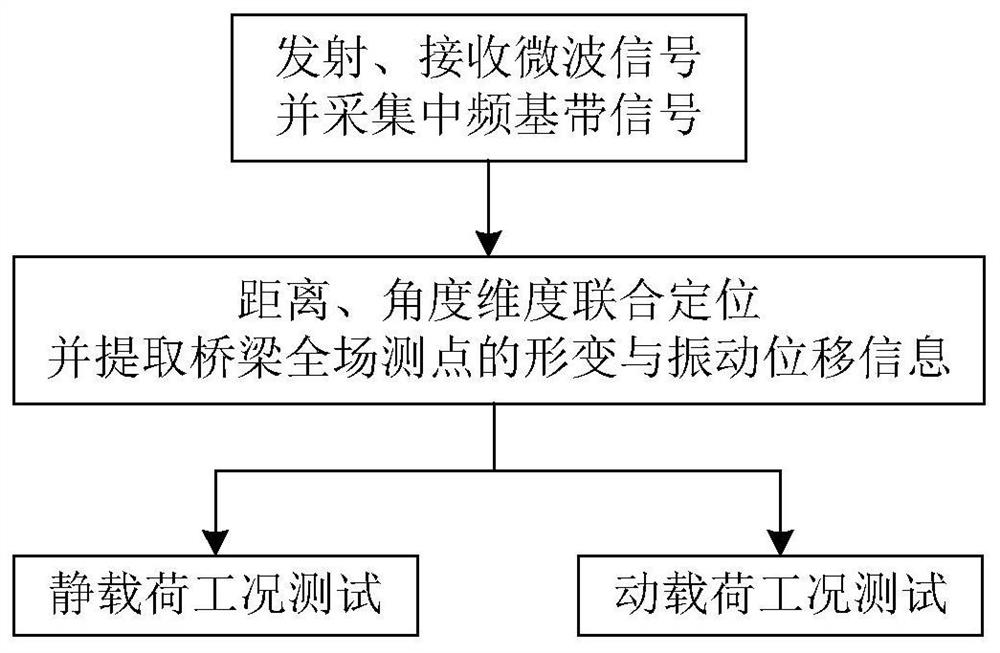

[0033] Such as figure 2 As shown, this embodiment relates to a rapid test and evaluation method for bridge structure performance and safety based on microwave perception, including the following steps:

[0034] Step 1. Install and adjust the transmission beam of the microwave sensing system to cover the bridge structure to be tested, control the repeated transmission of linear frequency modulation continuous wave microwave signals, and receive the reflected signal of the bridge structure to be tested at the same time, and collect multi-channel intermediate frequency baseband signals.

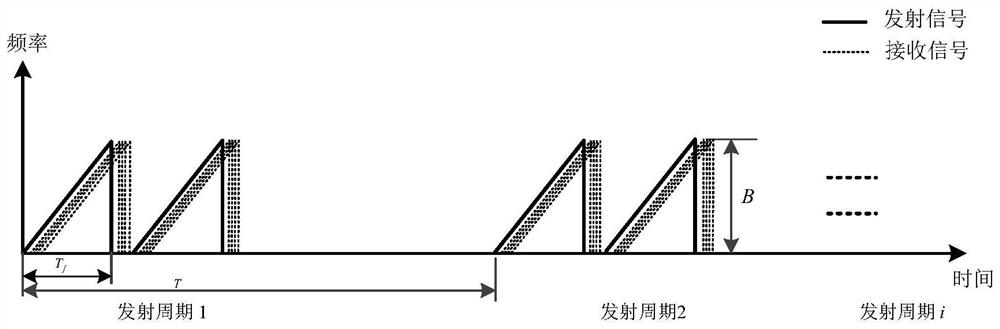

[0035] Such as image 3 As shown, it is a schematic diagram of the instantaneous frequency of microwave radar signals received by four receiving antennas when two transmitting antennas transmit in time-sharing, and the signal transmitting period is T f , the sweep period is T, the bandwidth is B, and the received signal is the time delay of the transmitted signal.

[0036] Step 2: Carry out j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com