Field dynamic load testing method for collision resistance and safety of highway corrugated beam barriers

A corrugated beam guardrail and detection method technology, which is applied in the direction of measuring device, impact test, machine/structural component test, etc., can solve the problems of high experiment cost, safety performance evaluation of guardrail, etc., and achieve lower test cost, true results and better detection Easy to operate and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

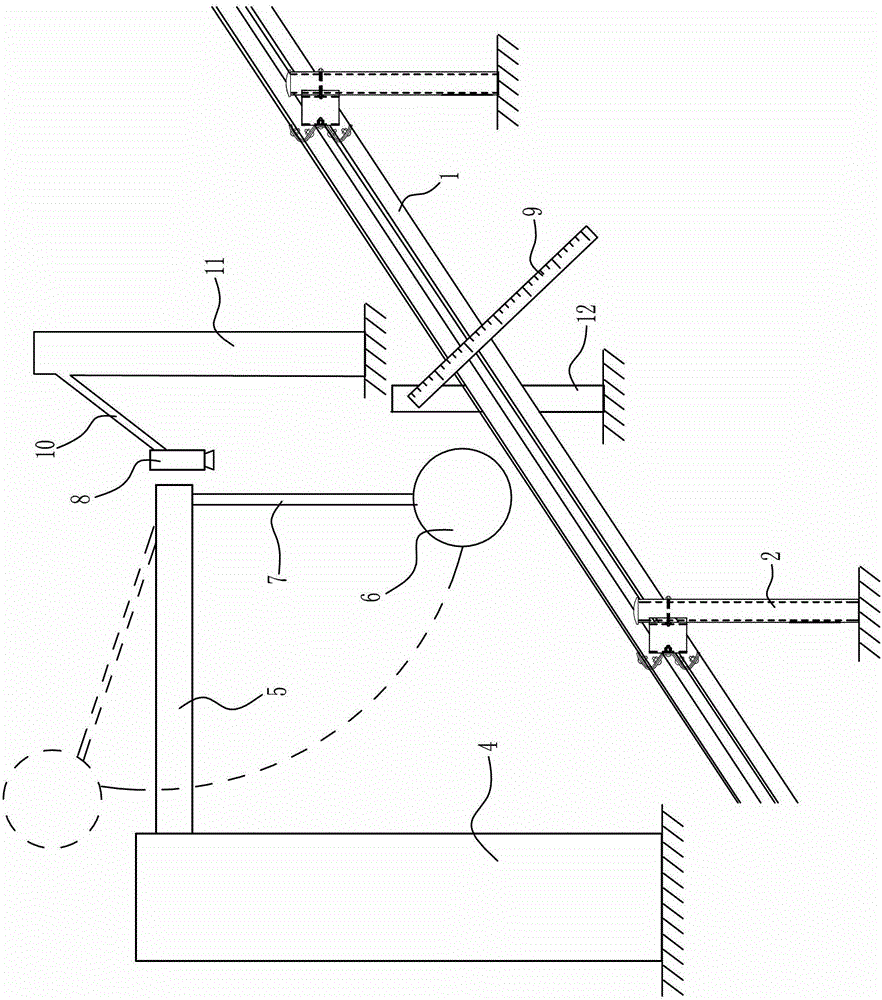

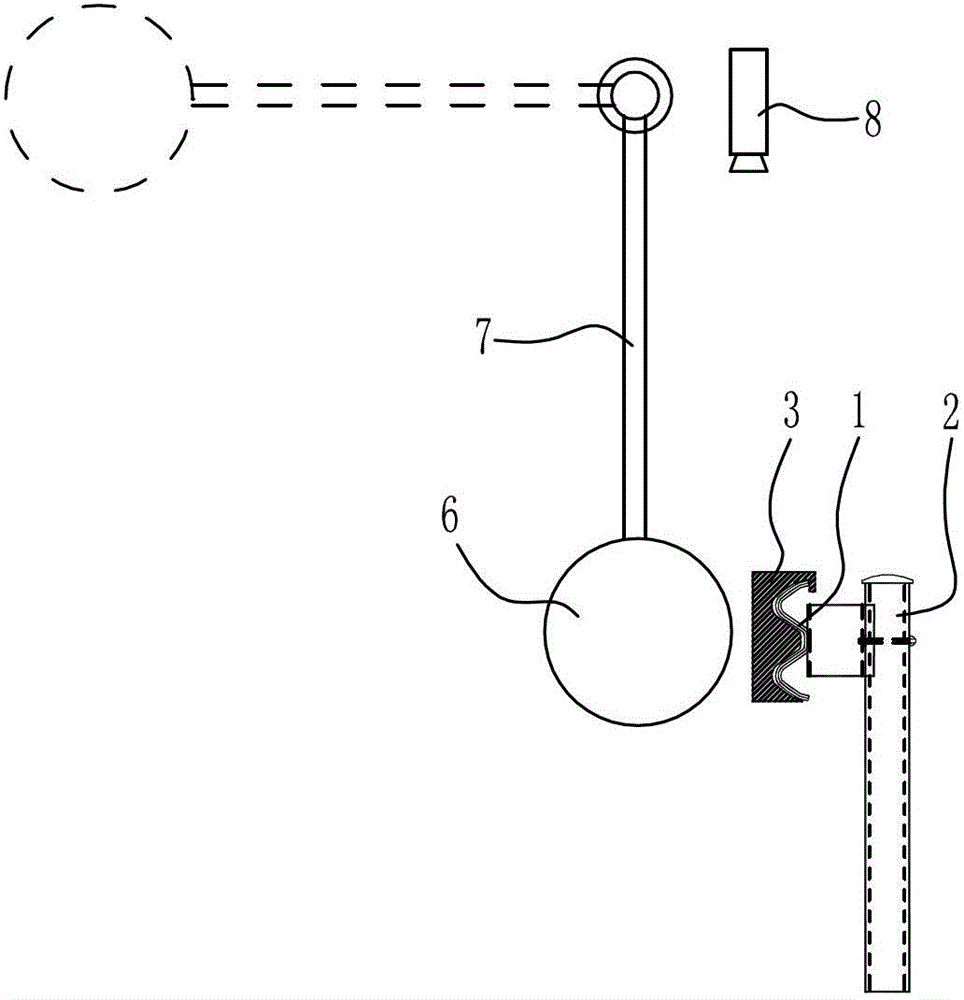

[0028] 1) Select the midpoint of the wave beam guardrail 1 between two adjacent columns 2 as the impact point, and install a steel coupling block 3 at the impact point. The steel coupling block 3 is located inside the wave beam guardrail 1 (facing the road on the side of the side). The steel coupling block 3 is a square structure, and there is a wave-shaped groove on the surface of the steel coupling block 3 facing the wave beam guardrail 1. The shape and size of the wave-shaped groove adapt to the section of the wave beam guardrail 1, and the wave The inner surface of the groove and the steel coupling block 3 is fully fitted. The steel coupling block 3 can be hooked on the corrugated beam guardrail 1 through the hook provided at its upper end, and the steel coupling block 3 can also be snapped on the corrugated beam guardrail 1 through the buckles provided at its upper and lower ends. Of course, as an equivalent replacement, the steel coupling block 3 can also be connected t...

Embodiment 2

[0034] In step 4) of this embodiment, a cast iron block is selected as the heavy object, and the cast iron block hits the steel coupling block 3 under the action of the elastic force of the ejection device. The rest of the steps in this embodiment are the same as those in Embodiment 1, and will not be repeated here. The specific structure of the ejection device can be selected from existing structures according to actual needs, as long as it can provide elastic force to the weight.

Embodiment 3

[0036] In step 4) of this embodiment, the heavy object is a steel column, and the steel column hits the steel coupling block 3 under the action of the traction force of the traction device. The rest of the steps in this embodiment are the same as those in Embodiment 1, and will not be repeated here. The specific structure of the traction device can be selected from existing structures according to actual needs, as long as it can provide traction to the heavy objects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com