Dynamic load testing testbed for agricultural mechanical rotary cultivation part

An agricultural machinery and dynamic load technology, applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve the problems of poor interchangeability and versatility of working parts, limited torque of test data, and single load test. , to achieve the effect of shortening response time, saving maintenance costs, and improving adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and example the present invention is described in further detail.

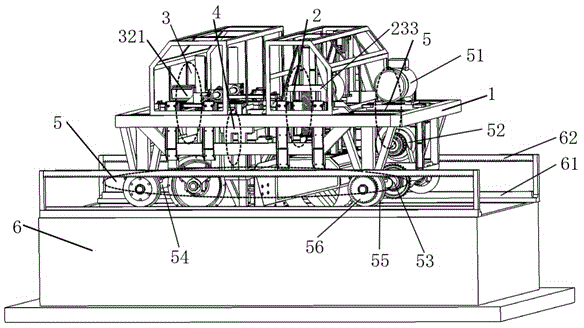

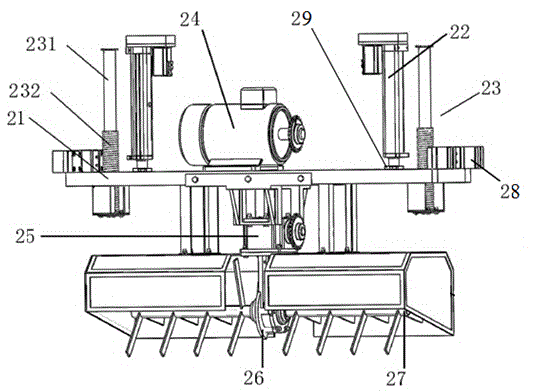

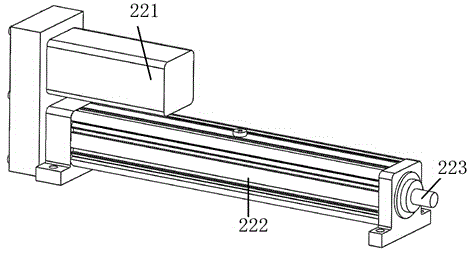

[0039] see figure 1 A test bench for dynamic load testing of agricultural machinery rotary tillage components, including a soil tank 6 and a trolley, the trolley including a trolley frame 1, a rotary tillage system 2, a soil compaction system 3, a soil leveling system 4 and a walking system 5. The rotary tillage system 2 is installed on the trolley frame 1, and the distance between the rotary tillage system 2 and the front end of the trolley frame 1 is smaller than the distance between the rotary tillage system 2 and the rear end of the trolley frame 1. The soil compaction system 3 is installed on the trolley frame 1, and the distance between the soil compaction system 3 and the front end of the trolley frame 1 is greater than the distance between the soil compaction system 3 and the rear end of the trolley frame 1. The soil leveling system 4 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com