A remote control hydraulic clamp device and control method

A technology of remote control type and control device, which is applied to earth-moving drilling, drilling equipment, drill pipe, etc., can solve the problems of operator injury, broken tail rope, high labor intensity, etc., so as to reduce labor intensity and reduce processing costs. Low, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

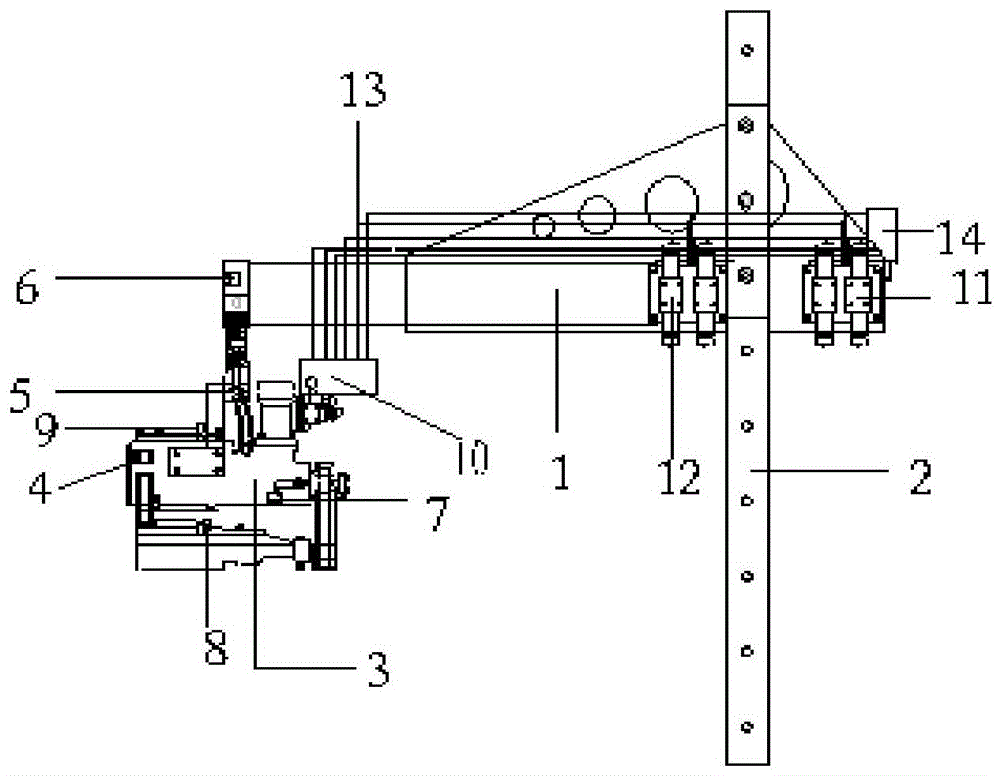

[0031] Embodiment 1: as figure 1 As shown in the figure, a remote-controlled hydraulic tong device, the telescopic push cylinder 1 is integrated and installed in the beam of the height adjustment bracket 2, and the whole is installed on the wellhead workover operation platform with fixing bolts;

[0032] The anti-torque device 5 includes an anti-torque cylinder, an inverted Y-shaped bracket, and a balance beam component. The anti-torque device 5 is connected to the height adjustment bracket 2 with dovetail groove connecting bolts, and is connected to the hydraulic clamp 3 by bolts;

[0033] The automatic gear-shifting valve switch system includes hydraulic tong high and low speed shift control device 7, hydraulic back tong forward and reverse control device 8, hydraulic main tong forward and reverse control device 9; hydraulic tong high and low speed shift control device 7, hydraulic back tong The forward and reverse control device 8 and the forward and reverse control device ...

Embodiment 2

[0036] Embodiment 2: as figure 1 as shown,

[0037] A remote-controlled hydraulic clamp device is composed of four parts: a height adjustment push system, an anti-torque system, an automatic shift valve switch system, and a control system.

[0038] The height adjustment push system consists of a telescopic push cylinder 1 and a height adjustment bracket 2. The telescopic push cylinder 1 is integrated and installed in the beam of the height adjustment bracket 2, and the whole is installed on the wellhead workover operation platform with fixing bolts.

[0039] The anti-torque system includes components such as an anti-torque cylinder, an inverted Y-shaped bracket, and a balance beam. The anti-torque device 5 is connected to the height adjustment bracket 2 with dovetail groove connecting bolts, and is connected to the hydraulic clamp 3 by bolts.

[0040] The automatic shifting valve switch system includes a hydraulic tong high and low speed shift control device 7, a hydraulic ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com