Boring elastic modulus instrument with flexible carrying plate

A bearing plate, elastic modulus instrument technology, applied in earth-moving drilling, wellbore/well components, etc., can solve the problems of large difference in elastic modulus, inconsistent assumptions, small elastic modulus of rock mass, etc., and achieve the distribution of loading stress. Uniform, accurate measurement results, accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

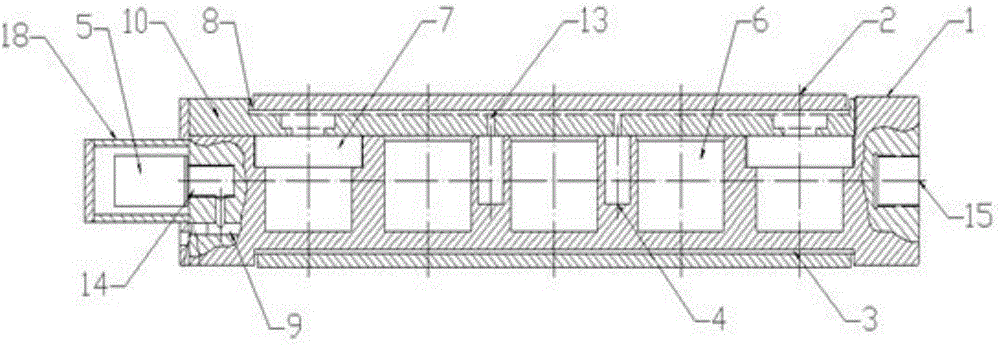

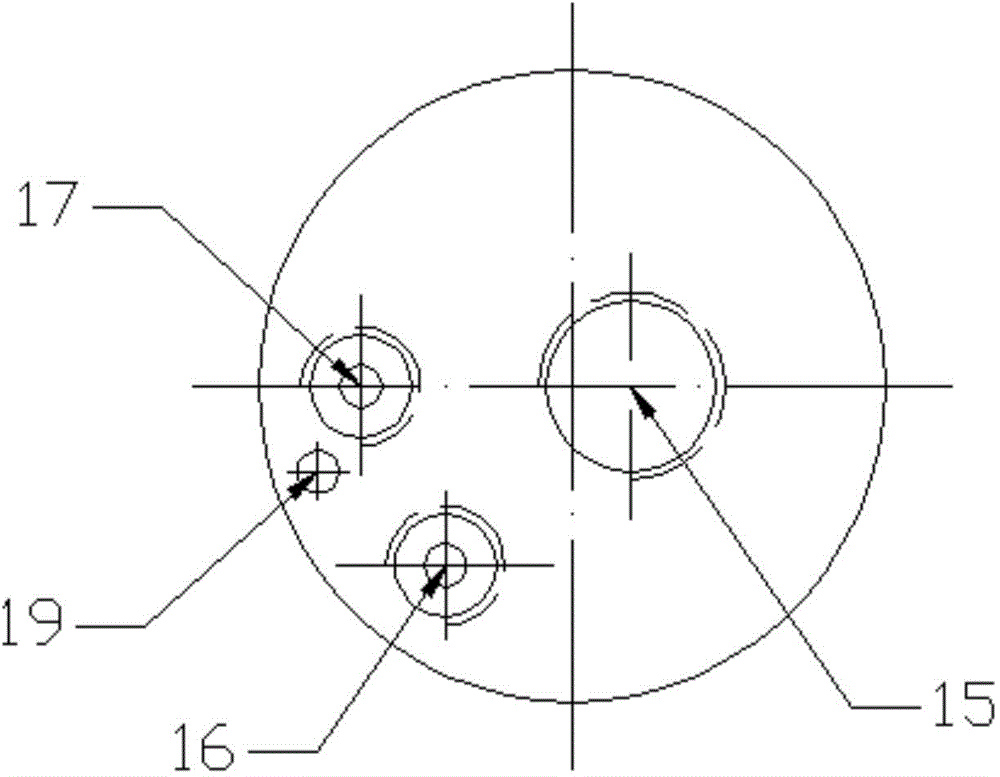

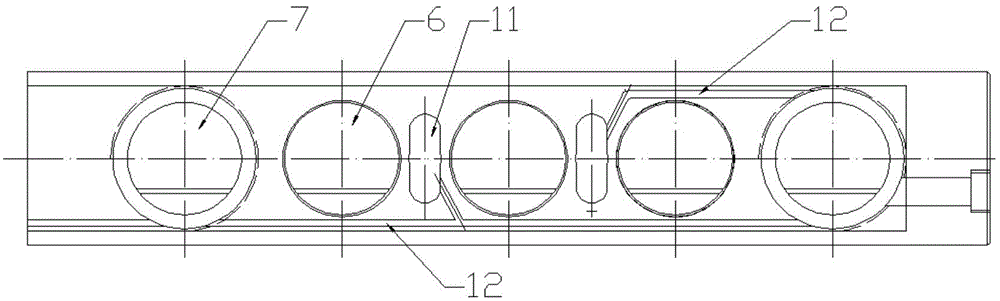

[0028] The system mainly includes a hydraulic loading device 1 , a flexible bearing plate 2 , an adjusting gasket 3 , a displacement sensor 4 , a pressure sensor 5 and a pressure transmission block 10 . Specific embodiments: first, the displacement sensor 4 is installed in the displacement sensor groove 11 reserved by the hydraulic loading device 1, the signal line is pulled out from the wire slot 12, and the measuring end connected to the signal line is pre-installed from the middle of the pressure transmission block 10. Pass through the reserved through hole 13, and fix it on the upper part of the pressure transmission block 10 to ensure that the displacement sensor can move up and down along with the pressure transmission block 10; 7 are connected to ensure that the pressure transmission block and the piston can advance and retreat at the same time. At the same time, an adjusting gasket 3 can be installed on the upper part of the pressure transmission block to adapt to diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com