Bending load test loading device for self-sealing disengagement joint and loading method

A technology of loading device and bending load, applied in the direction of applying stable bending force to test the strength of materials, measuring devices, instruments, etc., can solve the problems of lack of corresponding research on bending fracture performance testing, and achieve simple and convenient installation and operation, strong engineering significance , the effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the object, technical solution and effect of the present invention clearer and clearer, the following examples are given to further describe the present invention in detail. It should be pointed out that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

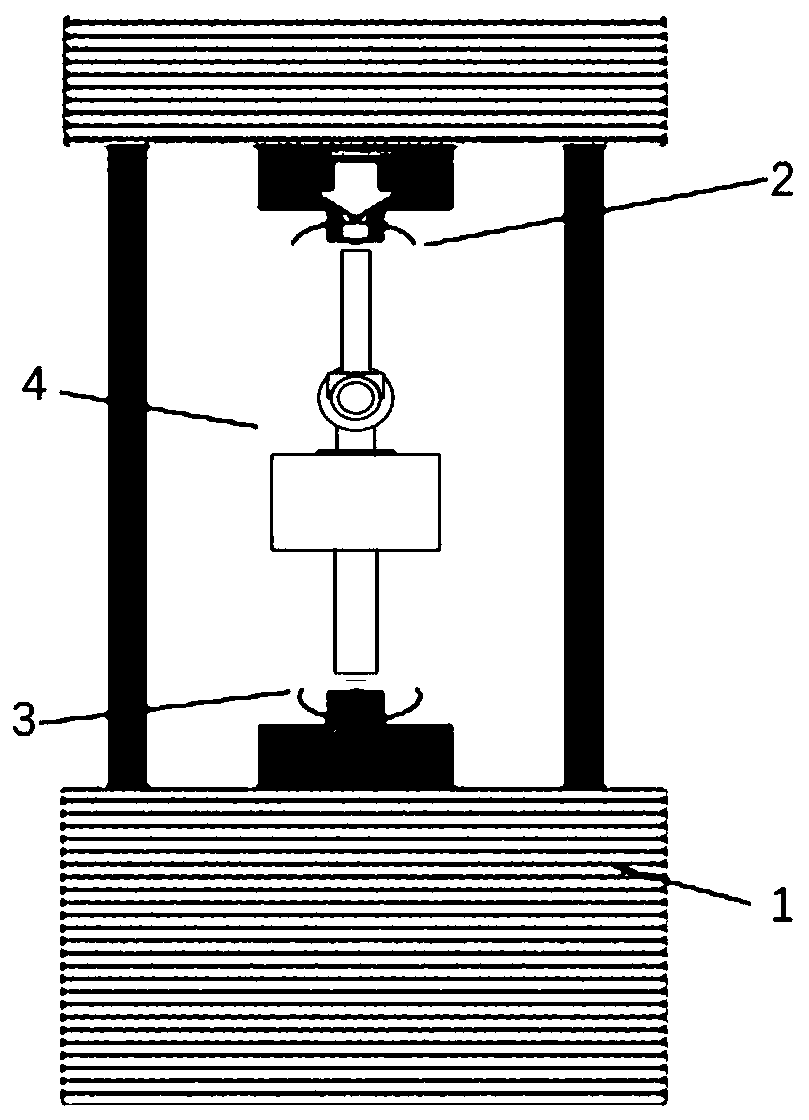

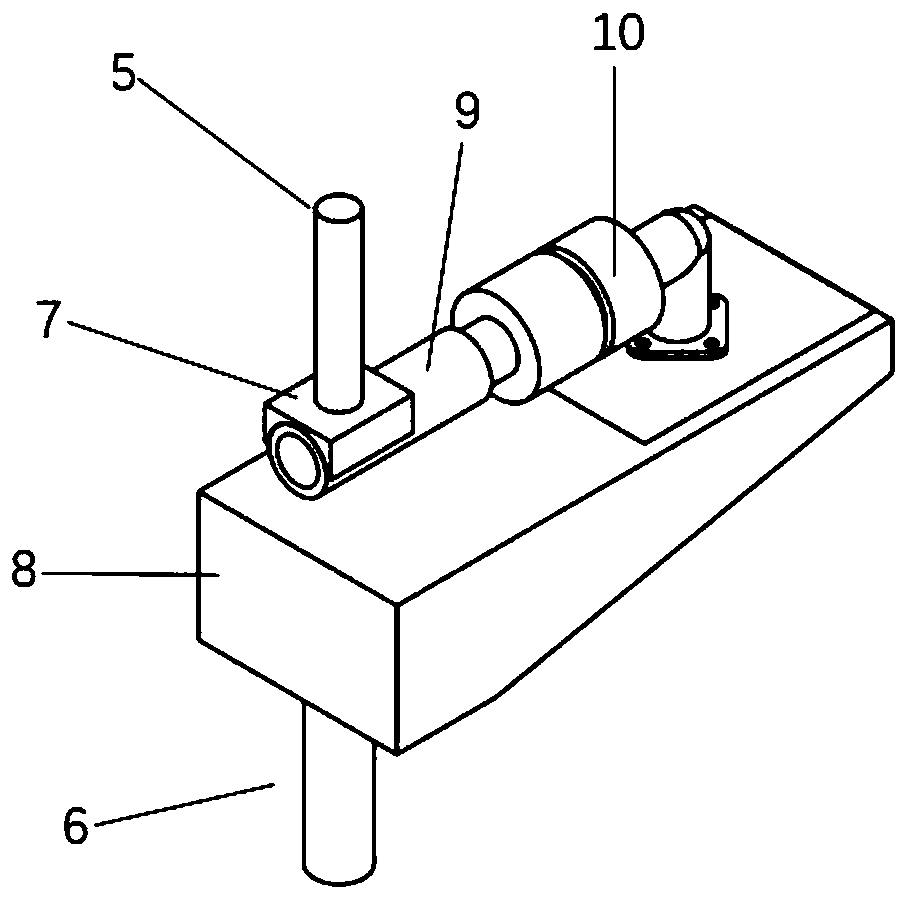

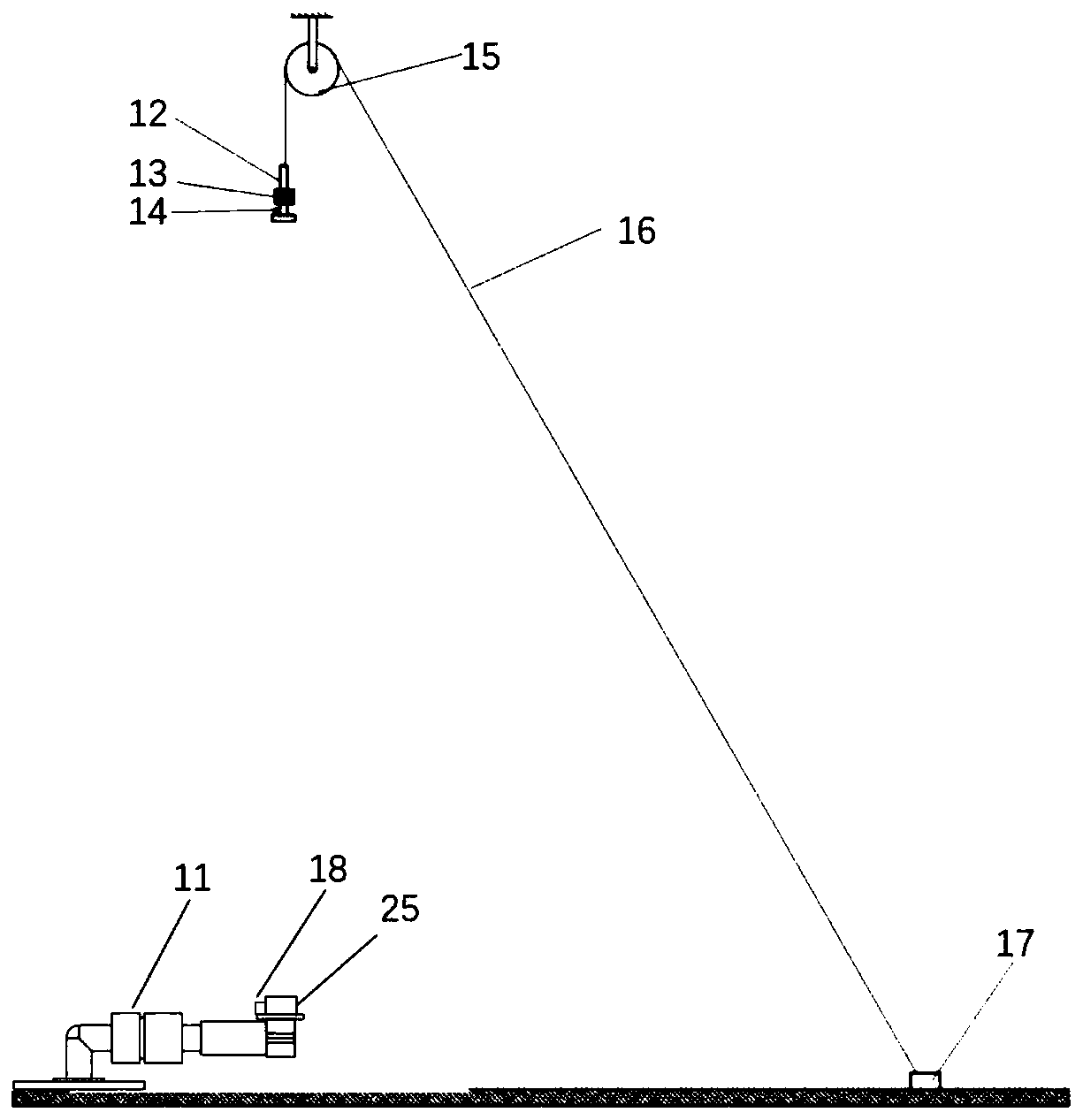

[0048] like figure 1 , figure 2 , Figure 5 As shown, the bending static load loading device is composed of a testing machine 1 and a loading platform 4 of the bending static load loading system, wherein the loading platform 4 is mainly composed of an upper clamping end screw 5, a lower clamping end screw 6, and an upper clamping end base 7 , the lower clamping end base 8, the loading arm 9, and the self-sealing shedding joint 10 are assembled.

[0049] The root of the upper clamping end screw 5 has an external thread that matches the internal thread of the top screw hole of the upper clamping end base 7, and the two are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com