Patents

Literature

59 results about "Fracture load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

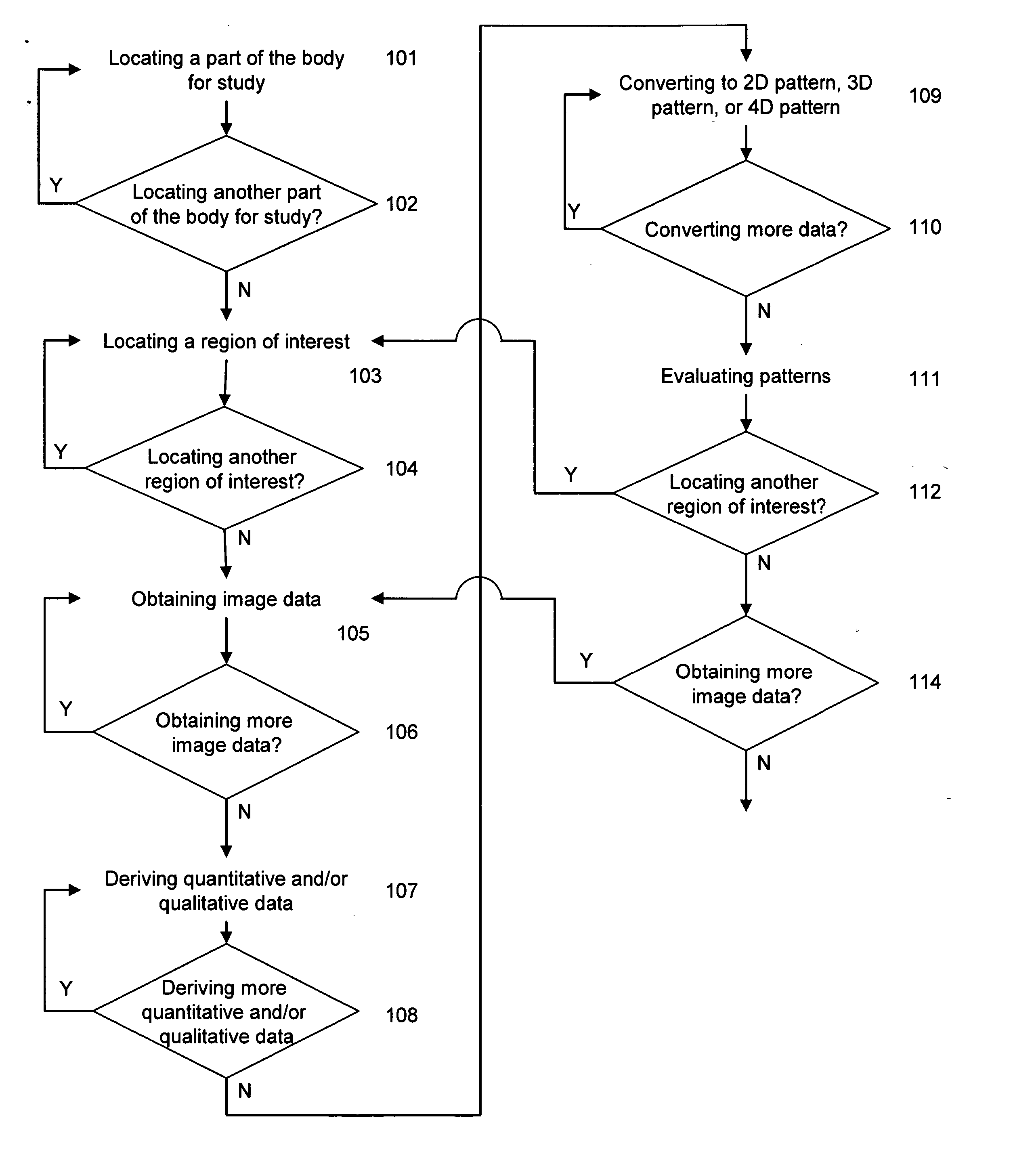

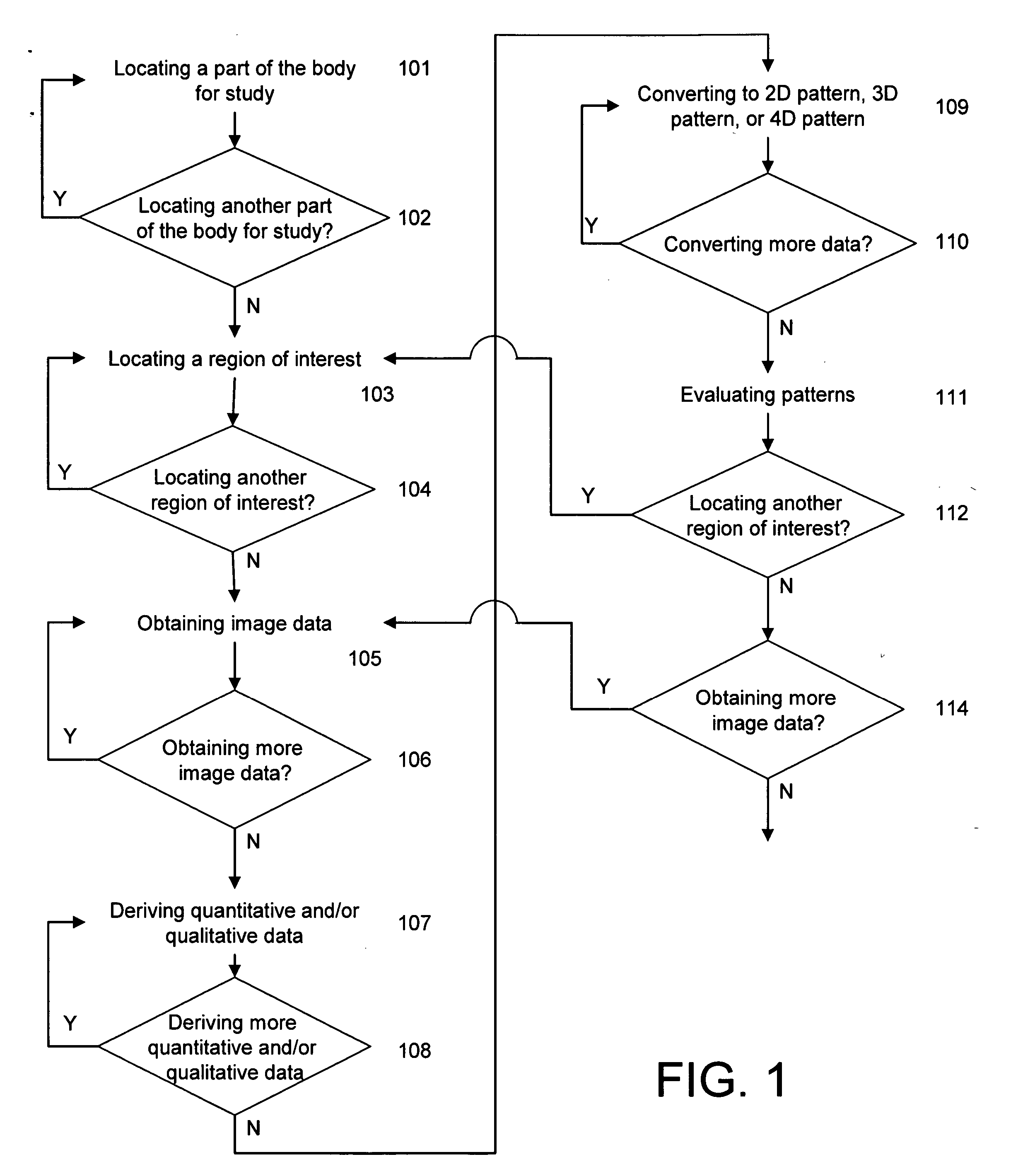

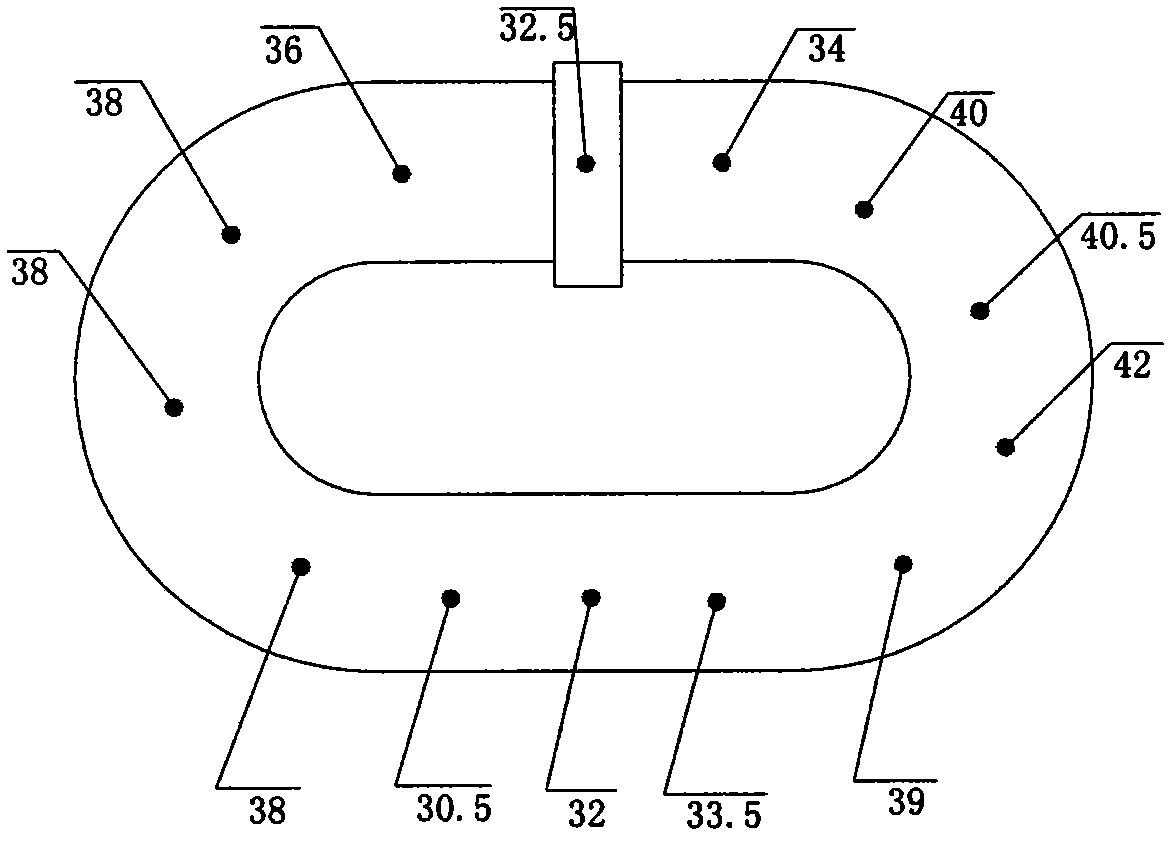

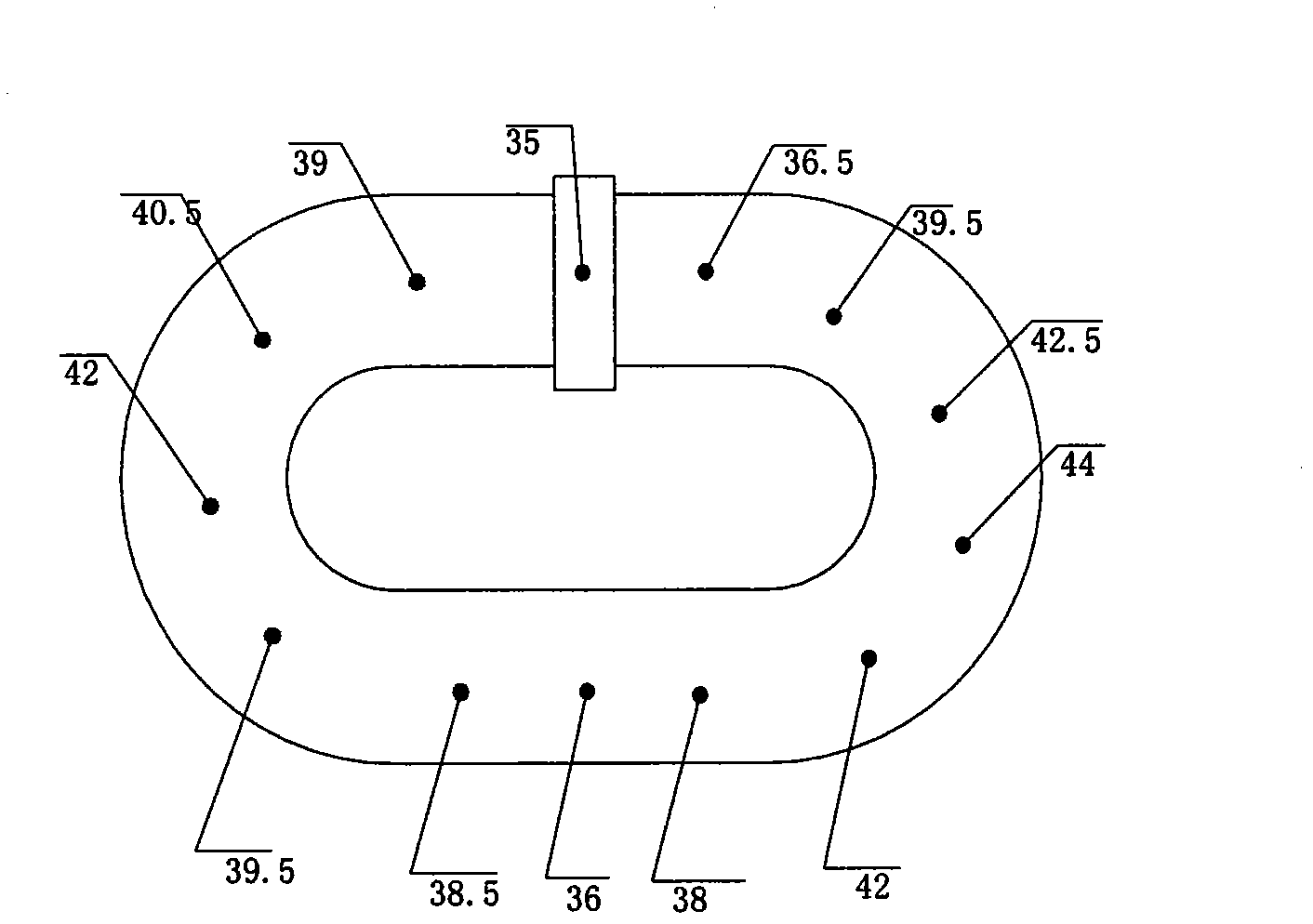

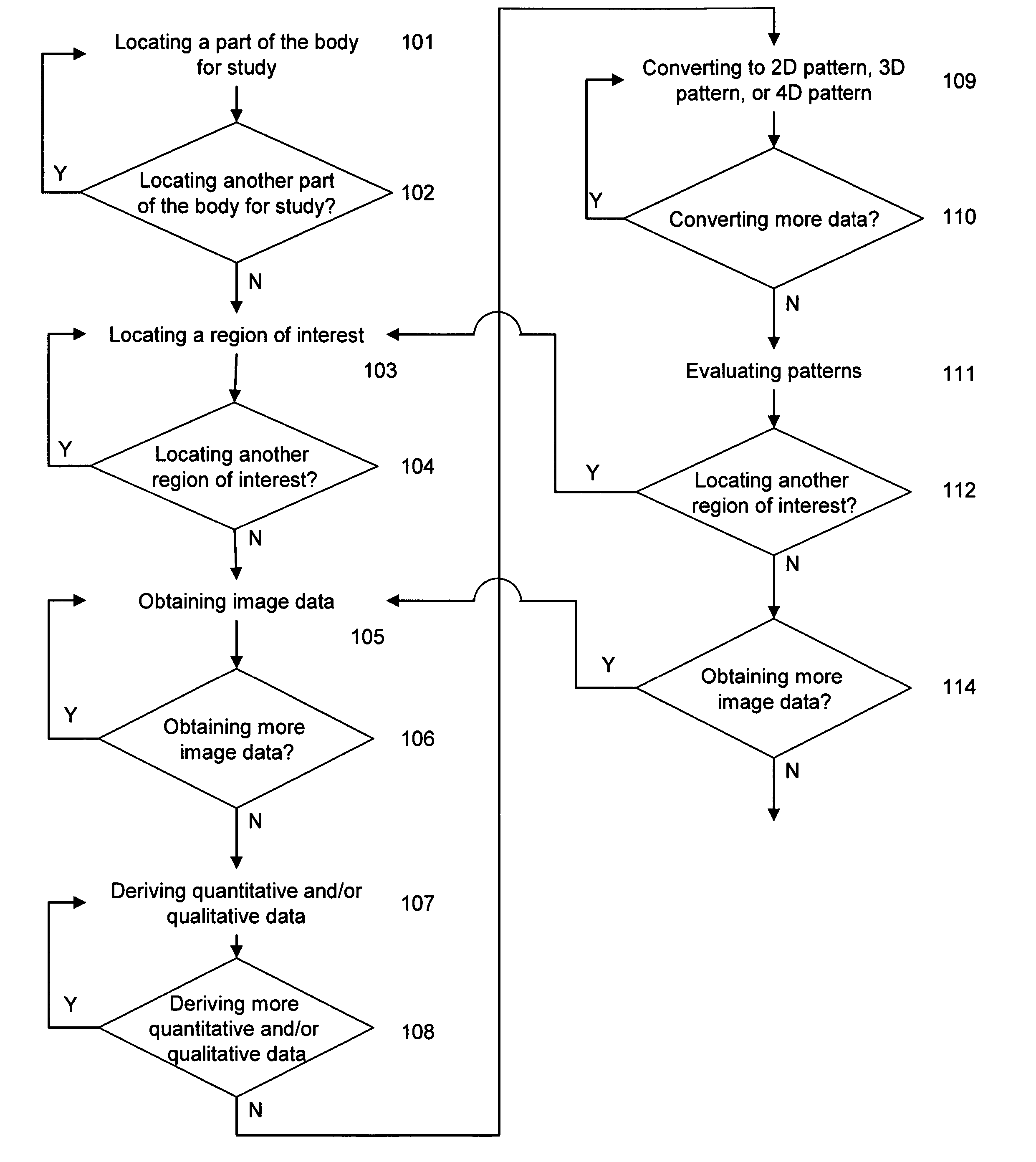

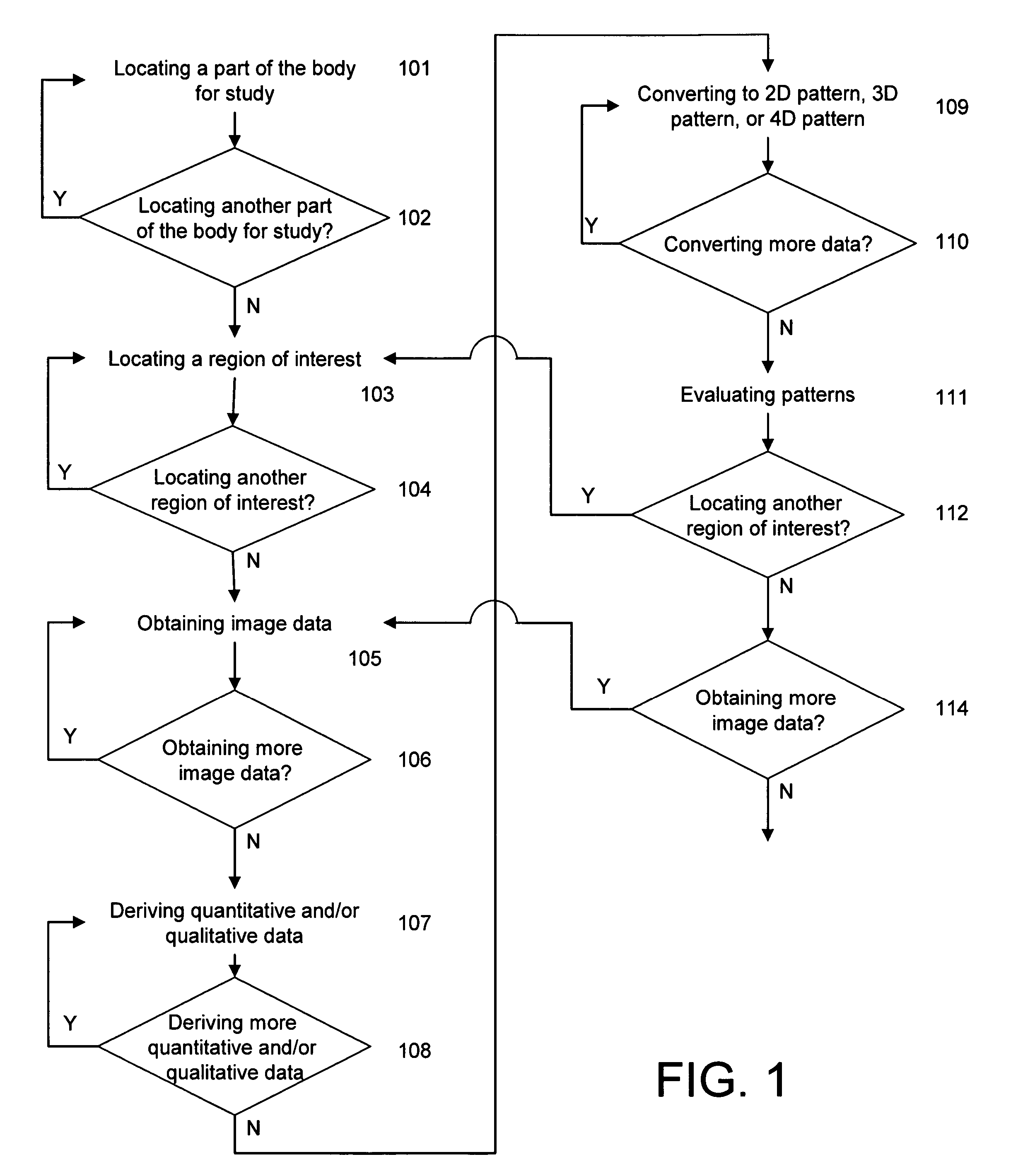

System and method of predicting future fractures

Methods of predicting fracture risk of a patient include: obtaining an image of a bone of the patient; determining one or more bone structure parameters; predicting a fracture line with the bone structure parameter; predicting a fracture load at which a fracture will happen; estimating body habitus of the patient; calculating a peak impact force on the bone when the patient falls; and predicting a fracture risk by calculating the ratio between the peak impact force and the fracture load. Inventive methods also includes determining the effect of a candidate agent on any subject's risk of fracture.

Owner:IMATX

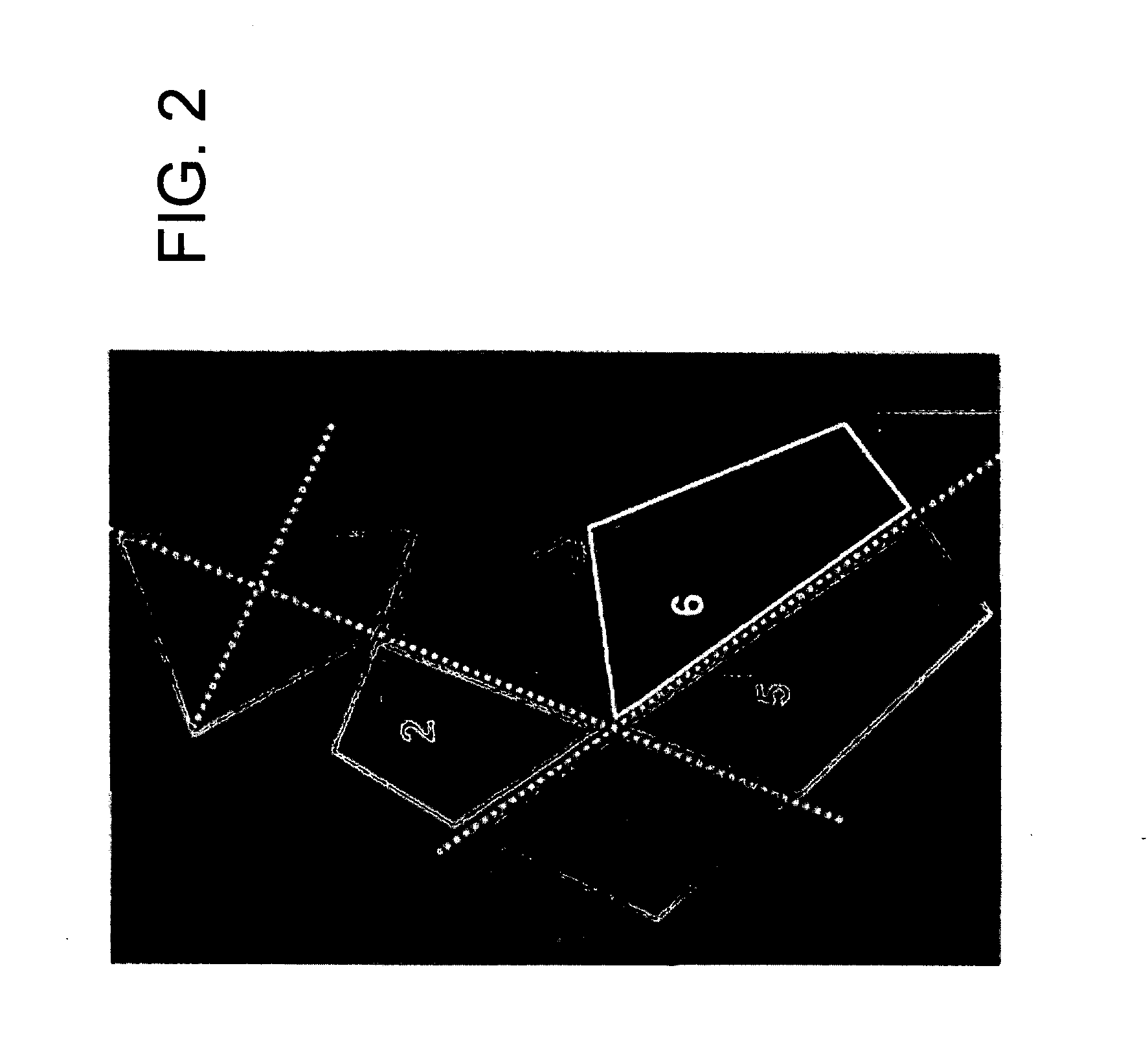

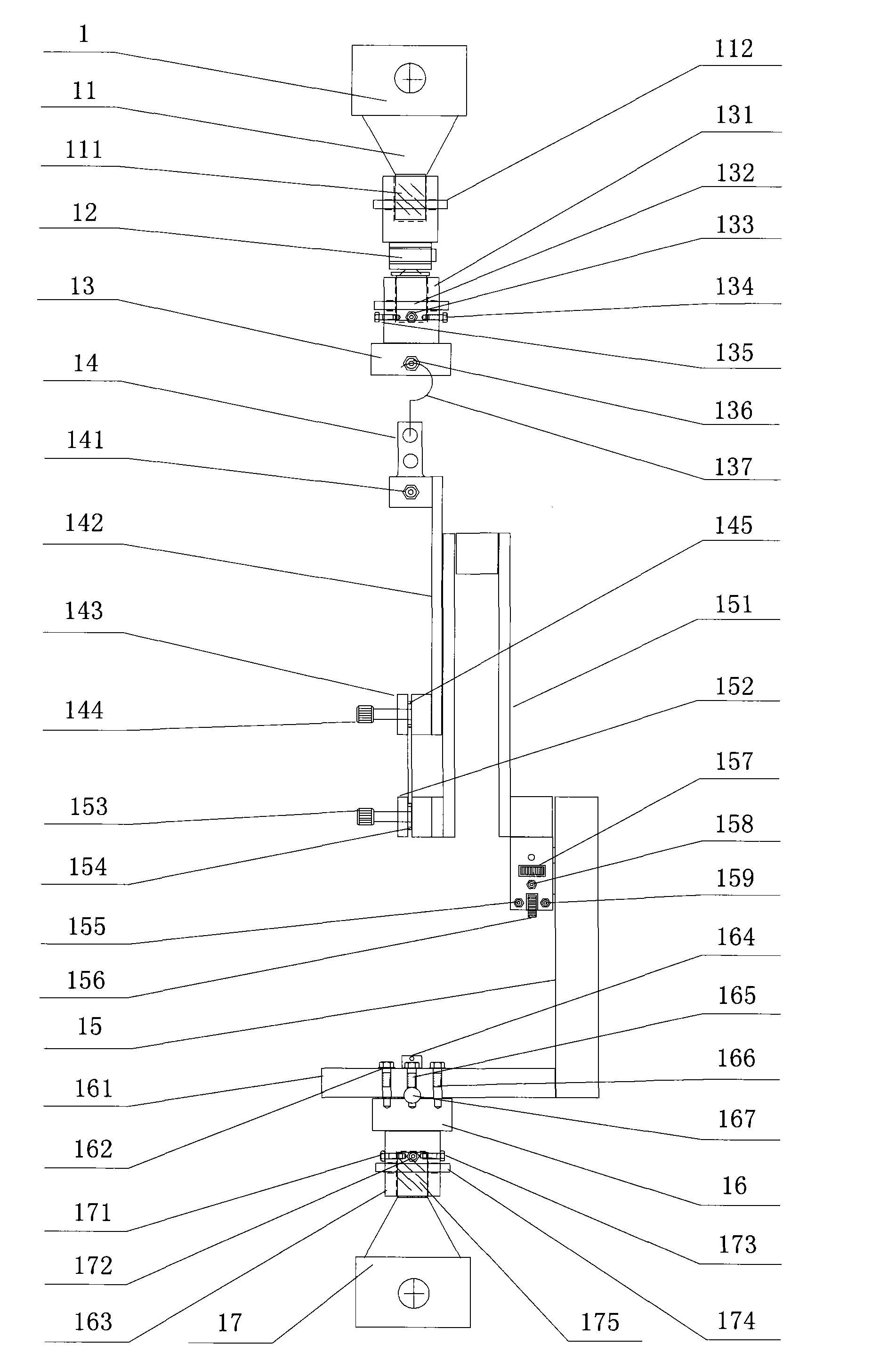

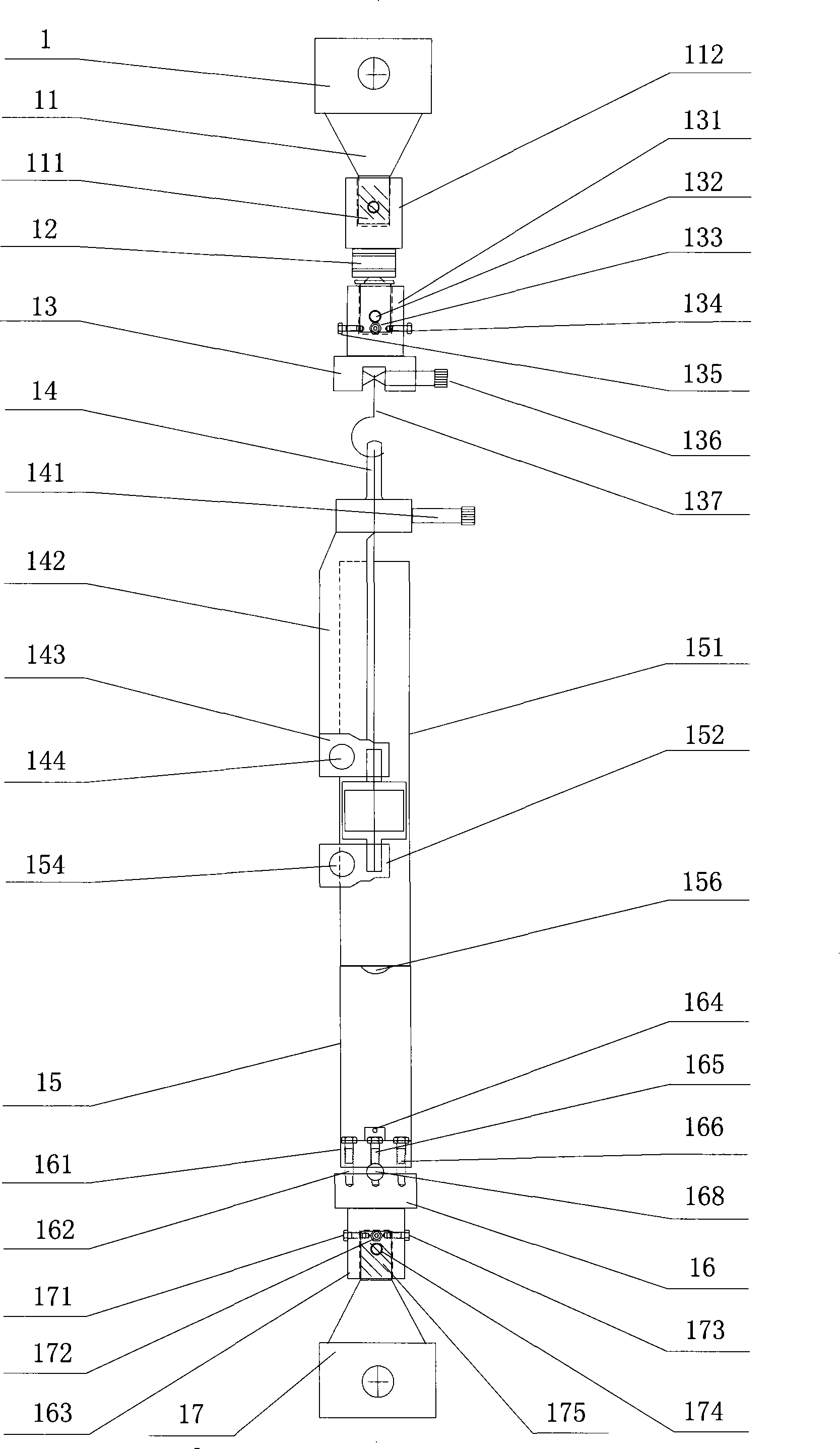

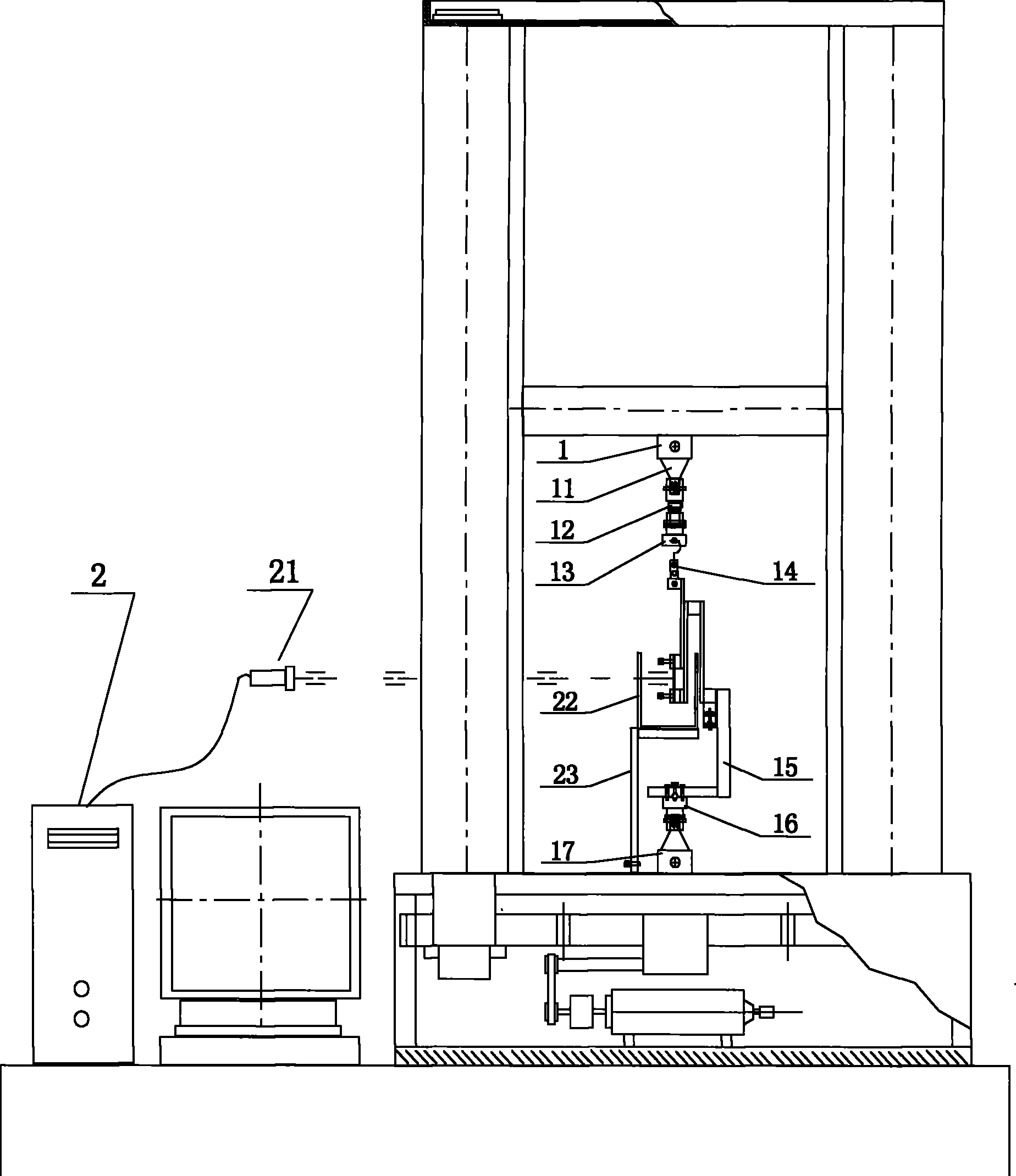

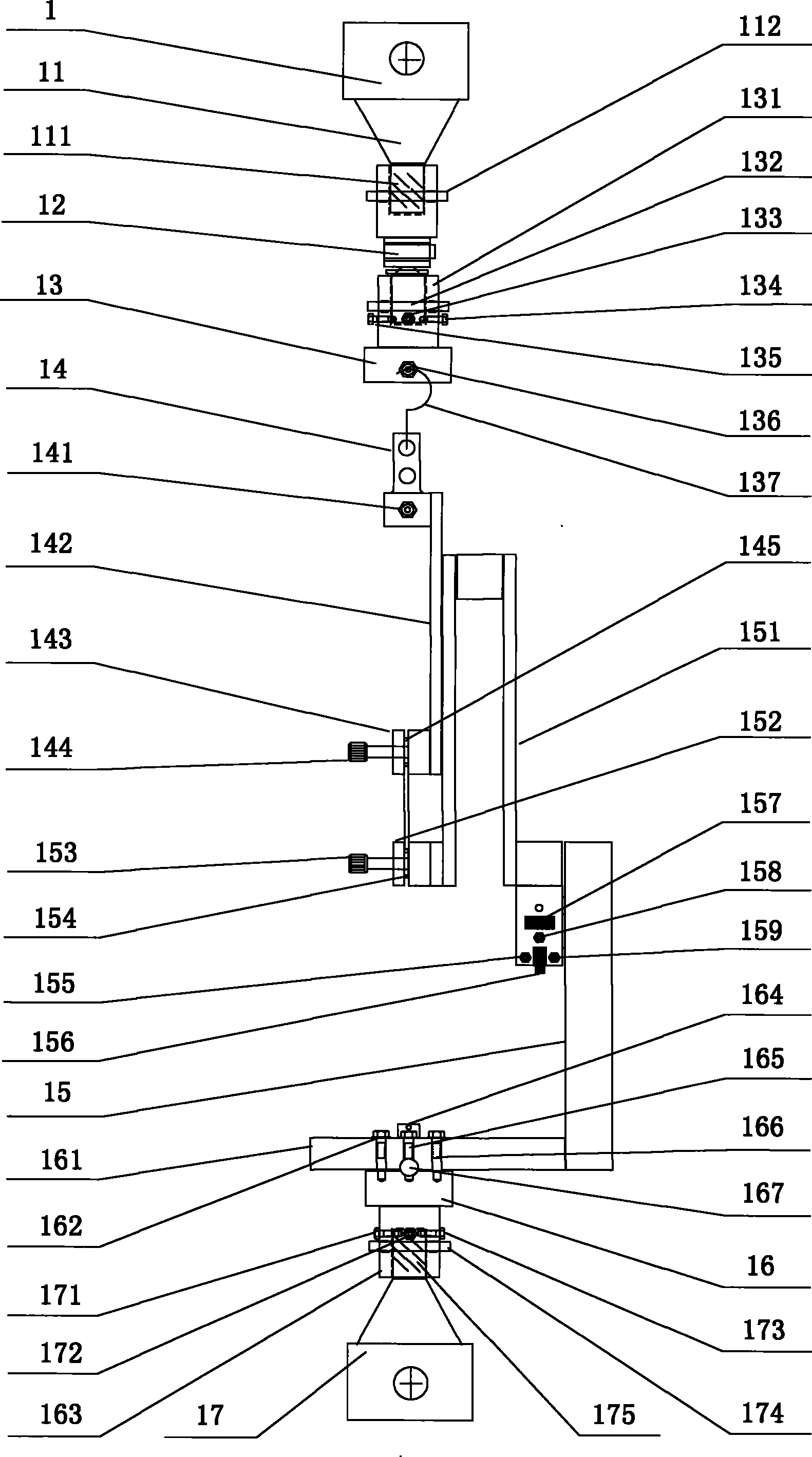

Testing machinery cellfiber clamper and method for measuring tensile strength

InactiveCN101251455AGuaranteed verticalityThe strain value is scientific and accurateMaterial strength using tensile/compressive forcesSingle fibreEngineering

The invention provides a tester single fibre clamp and a tensile strength measuring method relating to a clamp and tensile strength measurement. The invention provides a tester single fibre clamp and a method for measuring the tensile strength of ceramic single fibre. The clamp is provided with an upper collet device of a tester, a load sensor, a tenaculum device, an upper and lower clamping device, a horizontal adjusting device and a lower collet device of the tester. The adjusting clamp in proper alignment measures the load linearity in vertical direction and rectifies the focus of a photoelectric extensometer; the parameters of an measuring program are set; single fibre is put on the centerline of a hole of a square paper frame, then placed in the middle of the upper and lower clamping device; the vertical direction of the single-fibre is adjusted; the edge of the square paper frame is burned off; a strain collecting device is started to trace the edge distance between the upper and the lower paper frames; a tensile program is started up to begin the measurement; the relation between the load and the strain is recorded to obtain a fibre fracture load value and deformation data, thereby measuring a fibre strain value; a diameter value of a fracture is observed and input to the tester in order to acquire the fracture strength of the single fiber.

Owner:XIAMEN UNIV

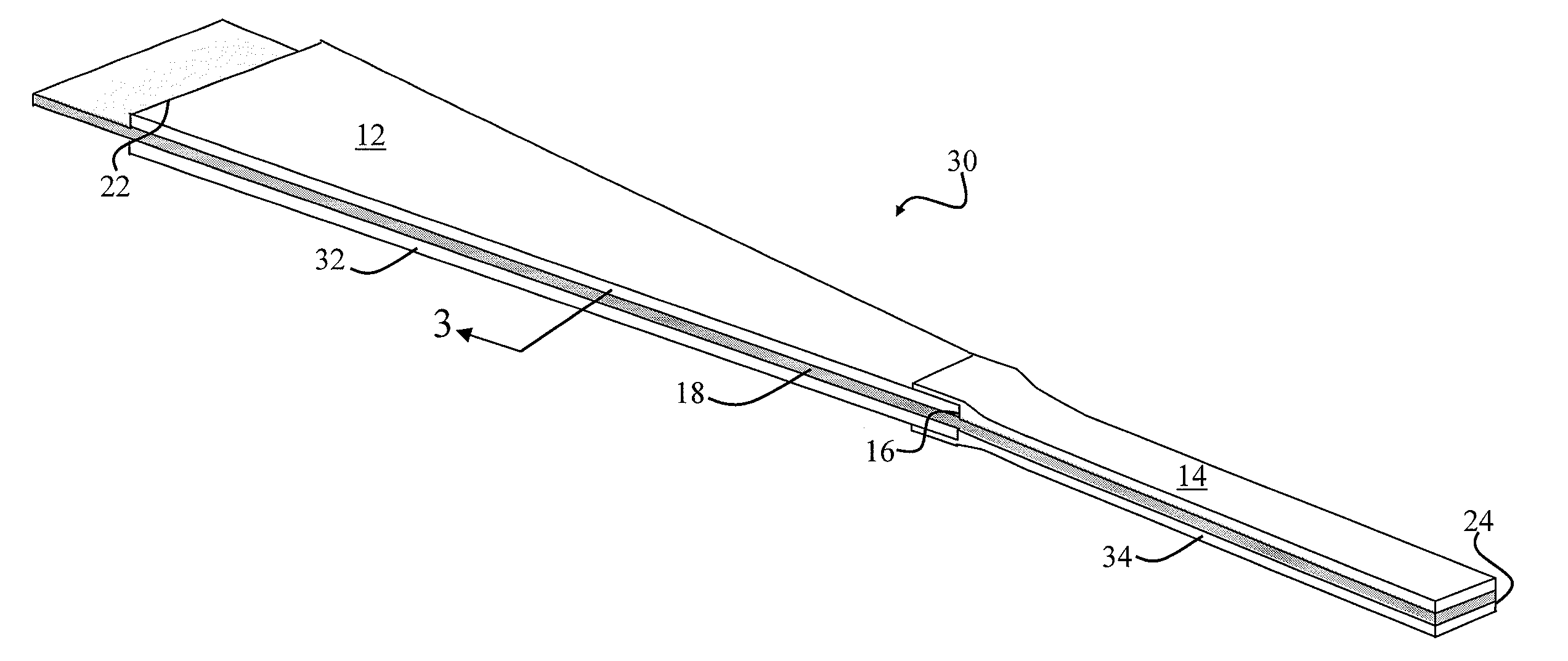

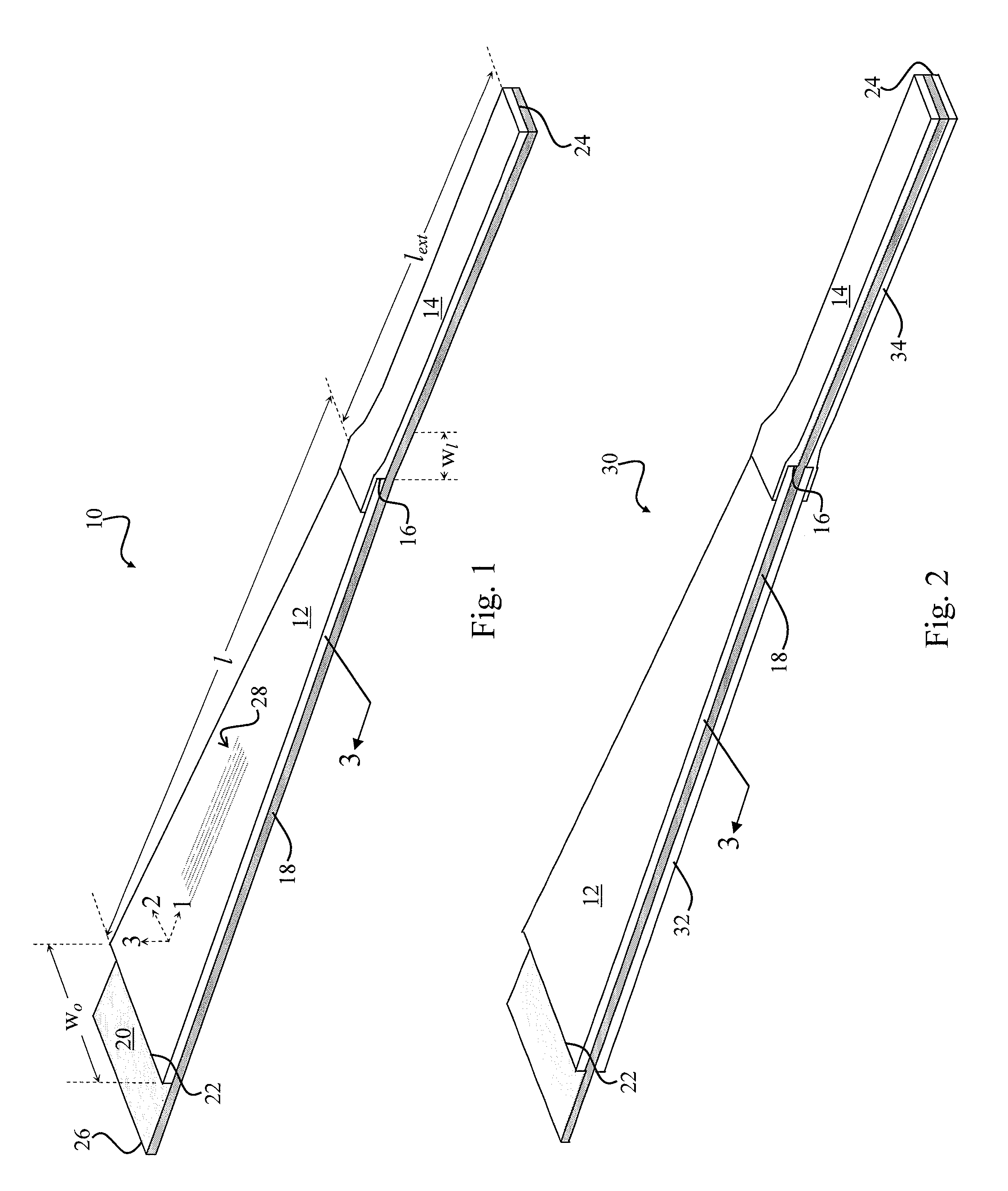

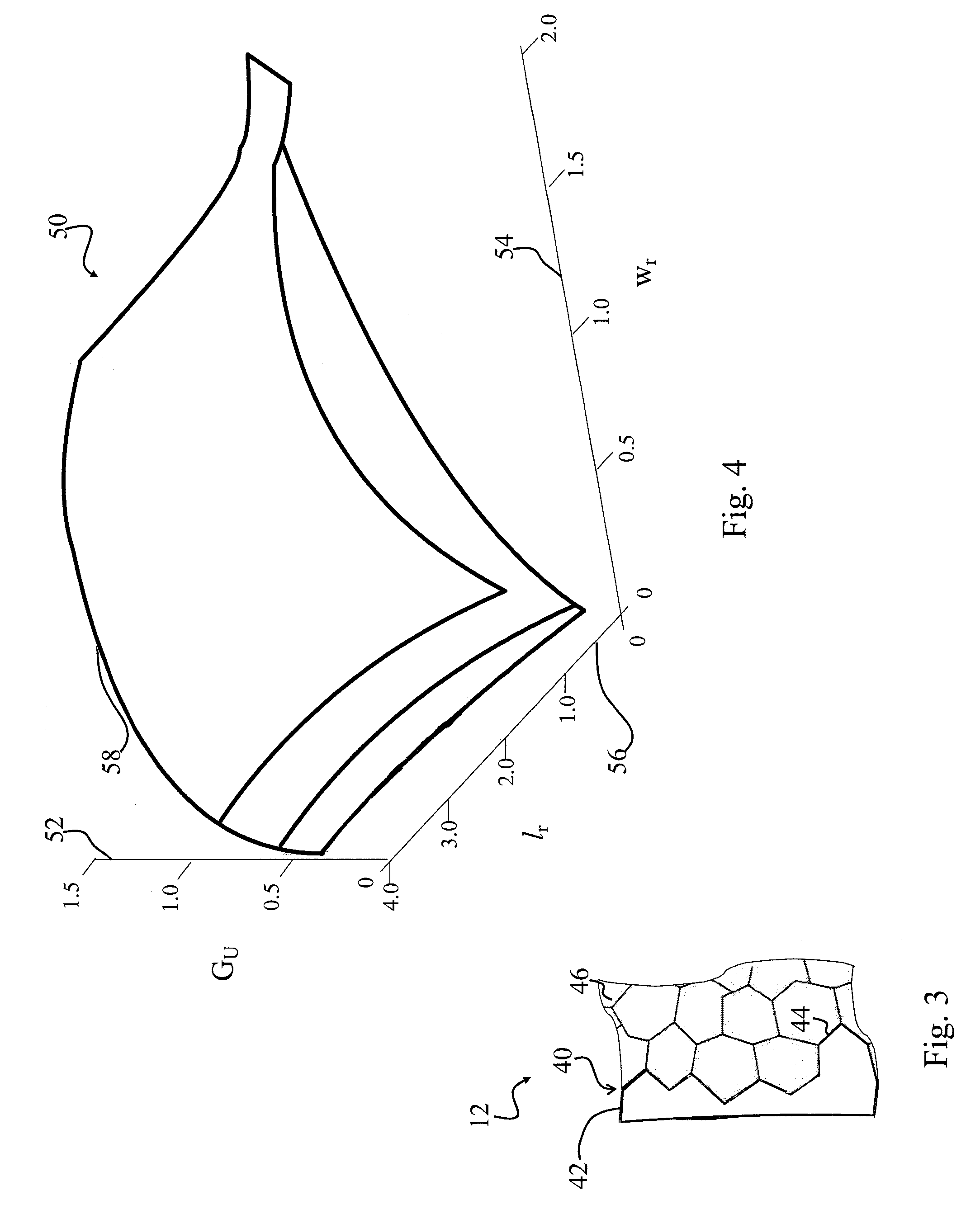

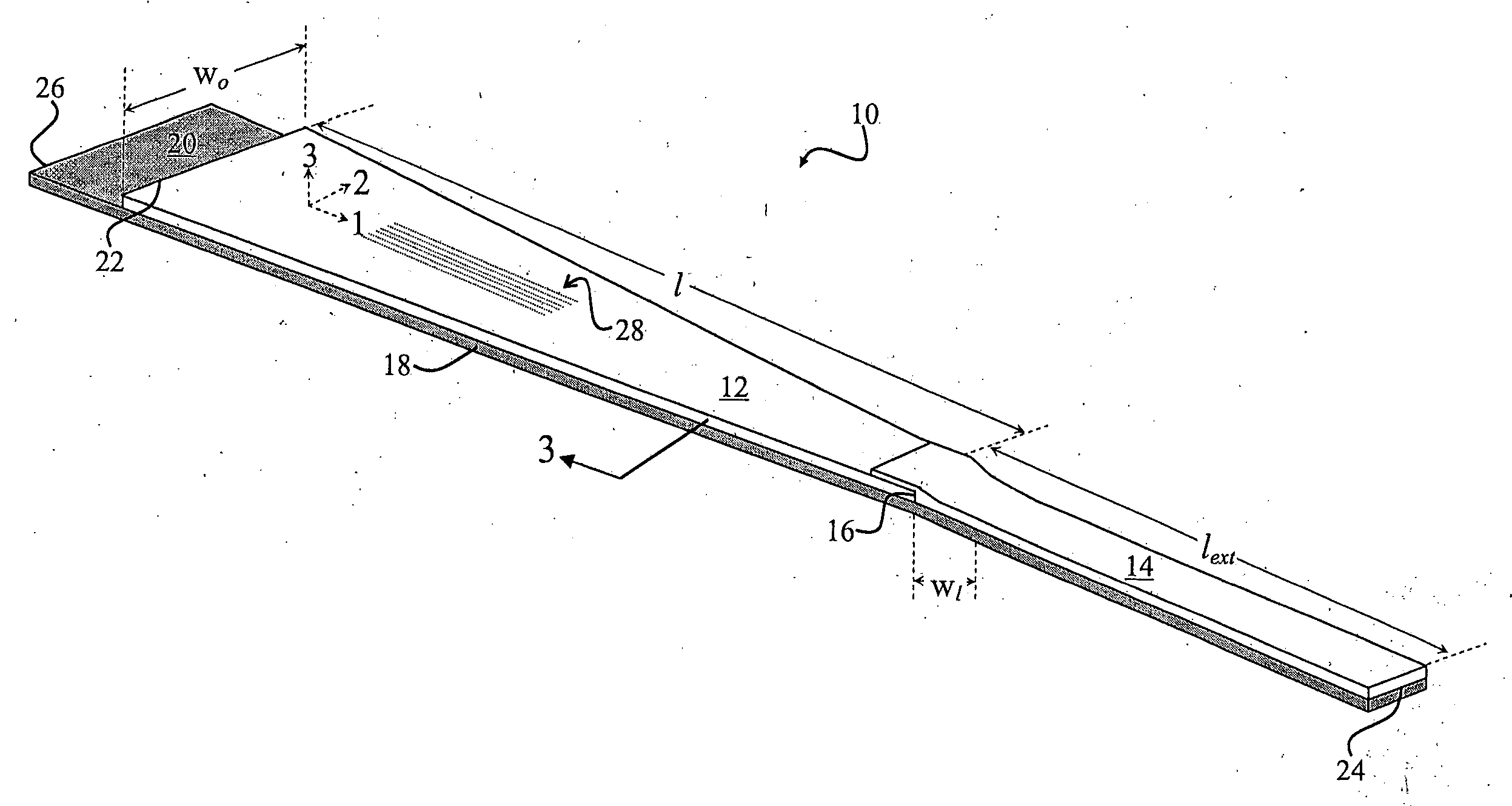

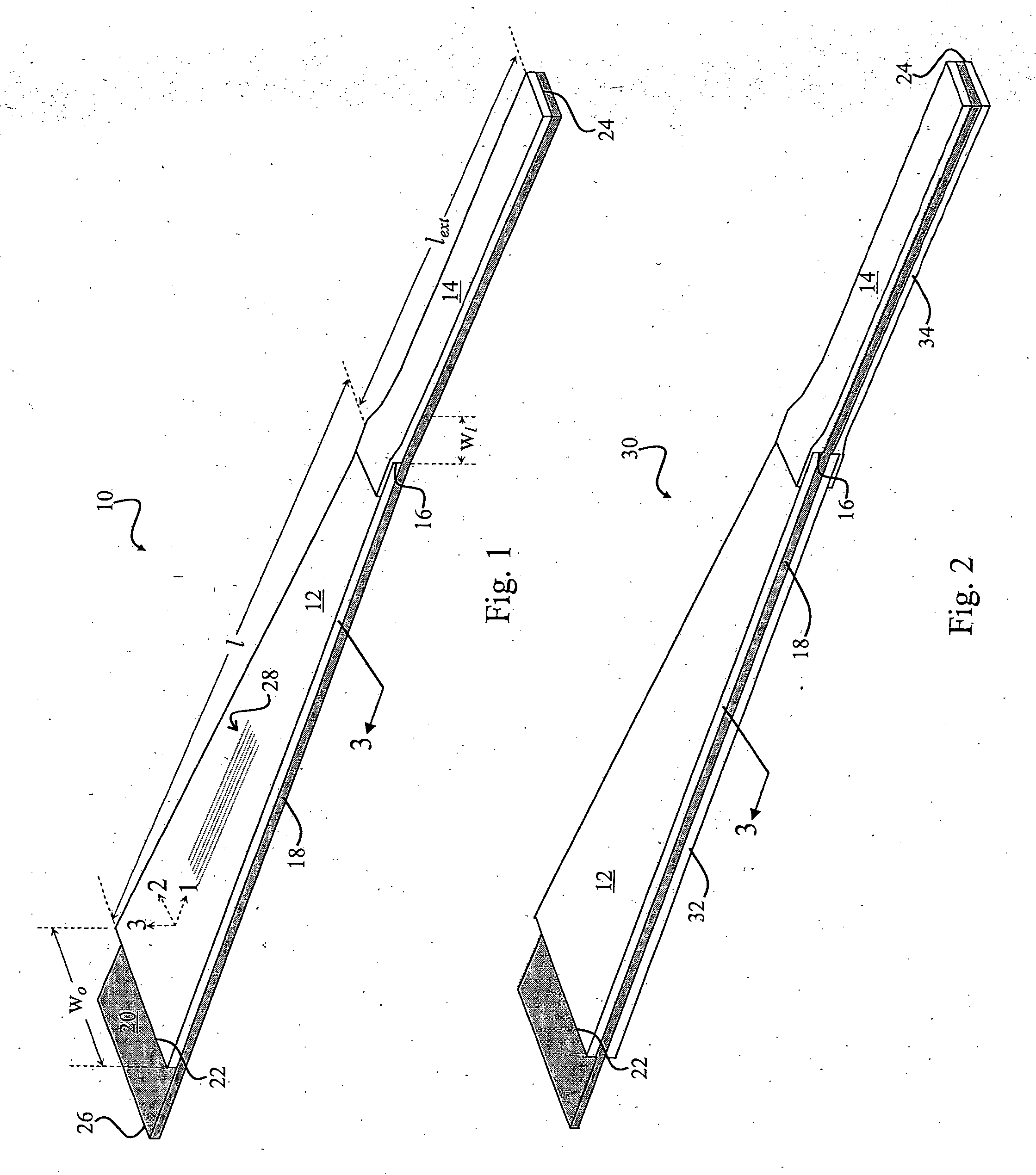

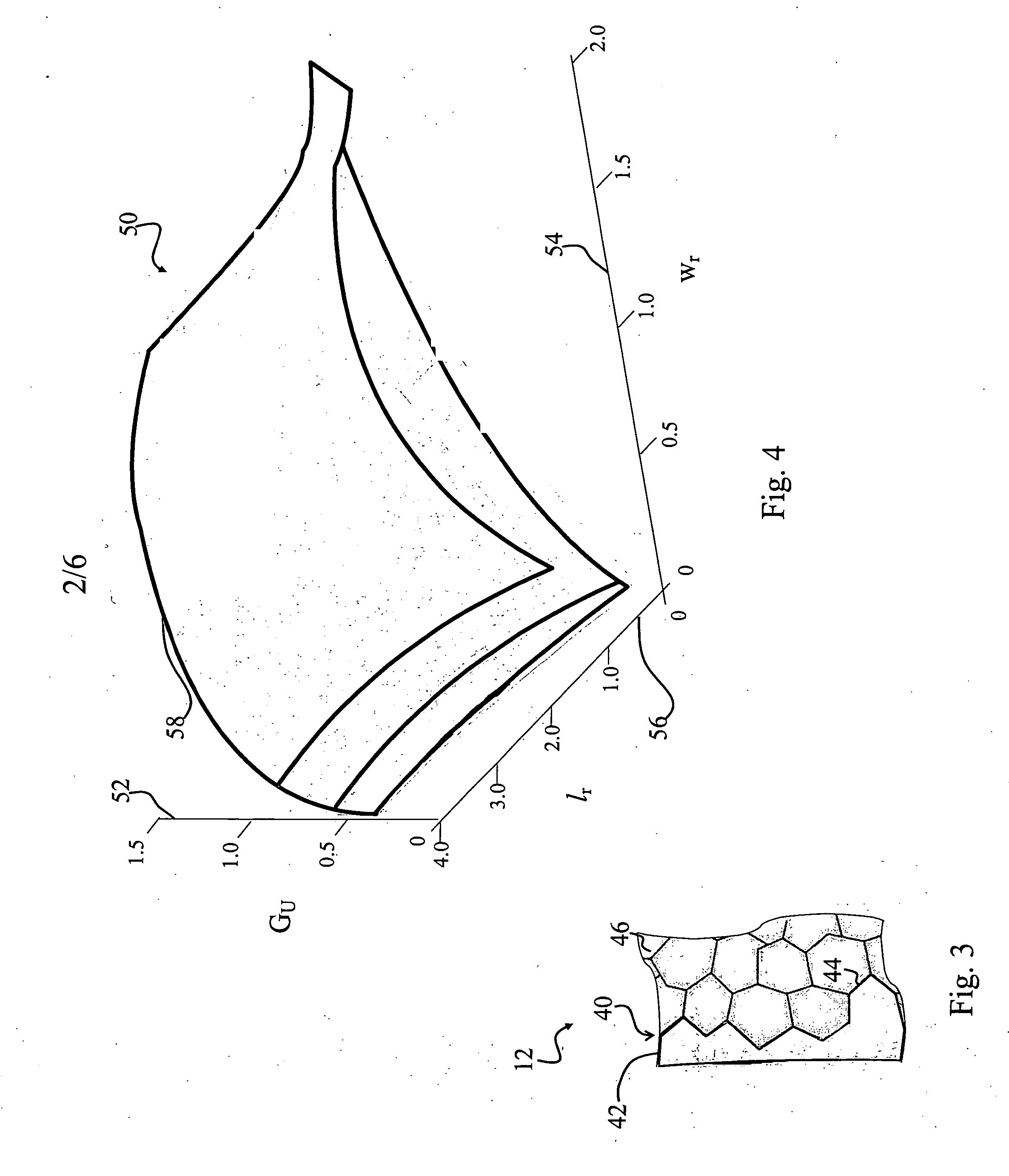

High performance piezoelectric actuator

InactiveUS7368860B2Improvement factorLow fracture toughnessPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device detailsPiezoelectric actuatorsEngineering

A high performance piezoelectric actuator. The actuator includes a piezoelectric material exhibiting a selectively tapered width sufficient to enhance actuator fracture load capabilities. A passive material is disposed on or integrated with the piezoelectric material. A drive system is connected to the piezoelectric material. The drive system is capable of selectively applying an electric field to the piezoelectric material. In specific embodiment, the piezoelectric material includes a curved piezoelectric layer exhibits a default state of compression along a surface of the piezoelectric layer.

Owner:RGT UNIV OF CALIFORNIA

High performance piezoelectric actuator

InactiveUS20060181179A1Improve performanceImprovement factorPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesPiezoelectric actuatorsFracture load

A high performance piezoelectric actuator. The actuator includes a piezoelectric material exhibiting a selectively tapered width sufficient to enhance actuator fracture load capabilities. A passive material is disposed on or integrated with the piezoelectric material. A drive system is connected to the piezoelectric material. The drive system is capable of selectively applying an electric field to the piezoelectric material. In specific embodiment, the piezoelectric material includes a curved piezoelectric layer exhibits a default state of compression along a surface of the piezoelectric layer.

Owner:RGT UNIV OF CALIFORNIA

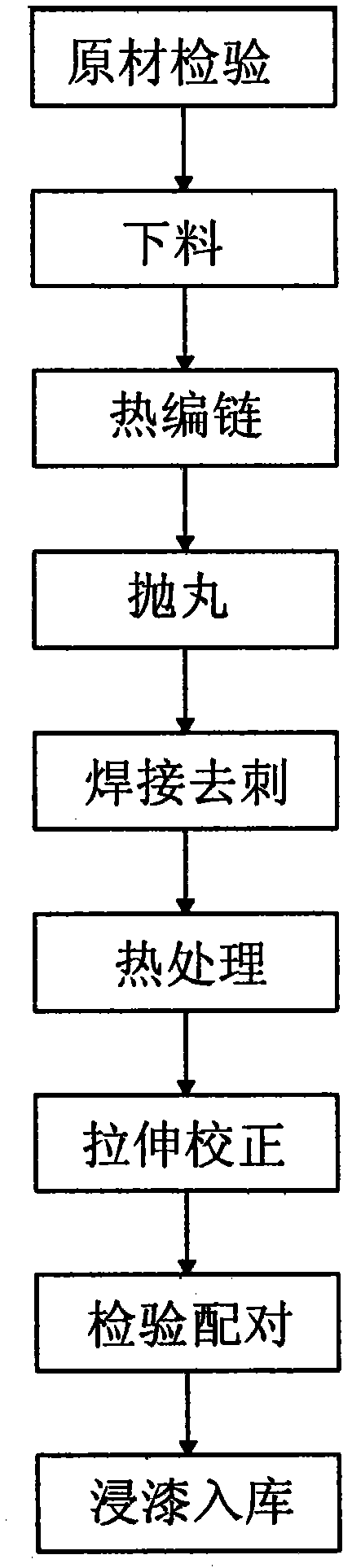

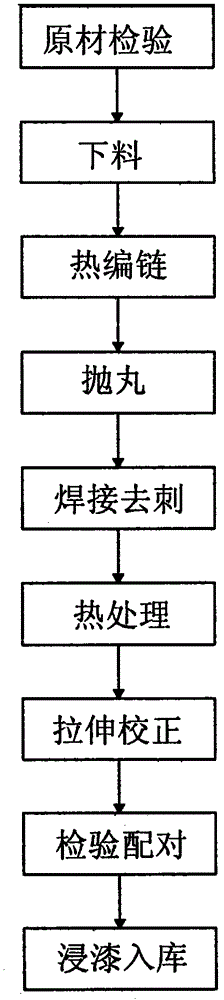

Method for producing round-link chain

The invention discloses a method for producing a round-link chain, which comprises the following steps: A1) raw material selecting: adopting high-quality alloy steel 23MnNiMoCr54; A2) baiting, wherein baiting demands are as follows: being capable of standing, being free from burr and chamfer, and keeping a length error of a bar stock being plus / minus 0.5mm; A3) hotly chaining: bending the bar stock into a chain in a given size under the action of hydraulic power of a chaining machine; A4) ball blast: removing an oxide skin from the surface, preparing for the next process and ensuring the welding quality; A5) welding and removing the burs; A6) heat treatment; A7) stretching and calibrating: once stretching under a stretching load being 80% of a fracture load; and A8) checking, pairing, painting and placing the chain into a storage. By using the method, the efficiency of producing the round-link chain is increased and the cost is lowered. The fracture load, a coefficient of elongation under a test load, a fracture elongation coefficient and a fatigue life of the round-link chain all meet the national standard.

Owner:SHANDONG LIANGDA FASING ROUND LINK CHAINS

System and method of predicting future fractures

Methods of predicting fracture risk of a patient include: obtaining an image of a bone of the patient; determining one or more bone structure parameters; predicting a fracture line with the bone structure parameter; predicting a fracture load at which a fracture will happen; estimating body habitus of the patient; calculating a peak impact force on the bone when the patient falls; and predicting a fracture risk by calculating the ratio between the peak impact force and the fracture load. Inventive methods also includes determining the effect of a candidate agent on any subject's risk of fracture.

Owner:IMATX INC

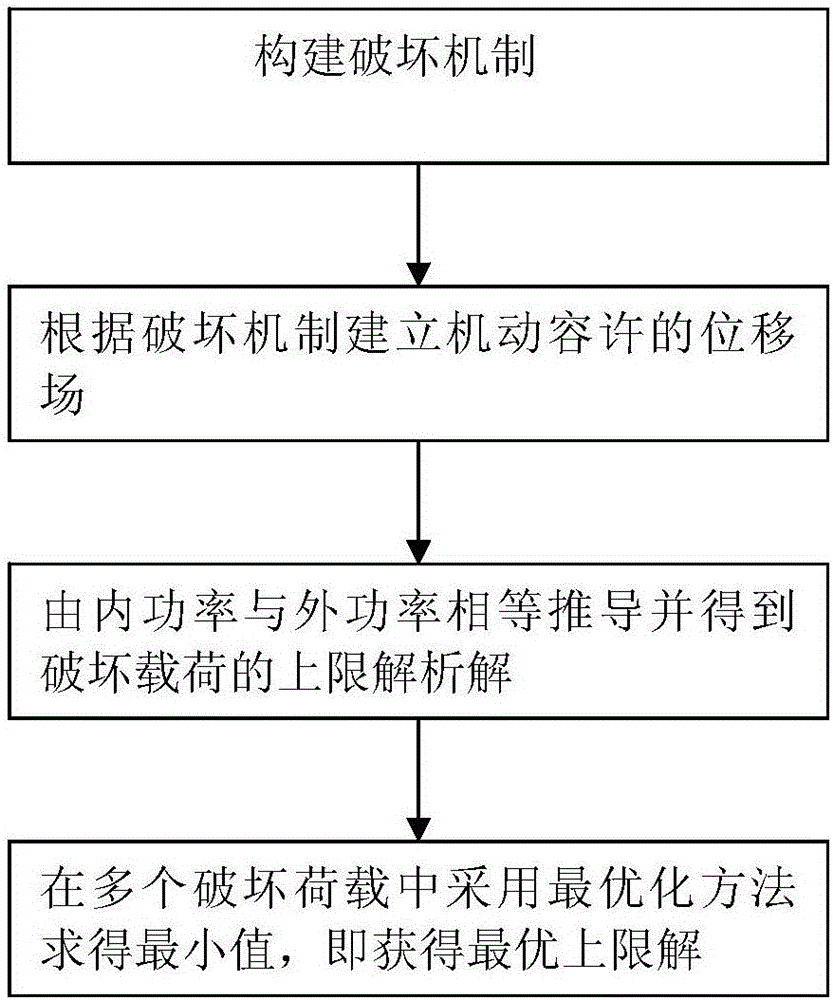

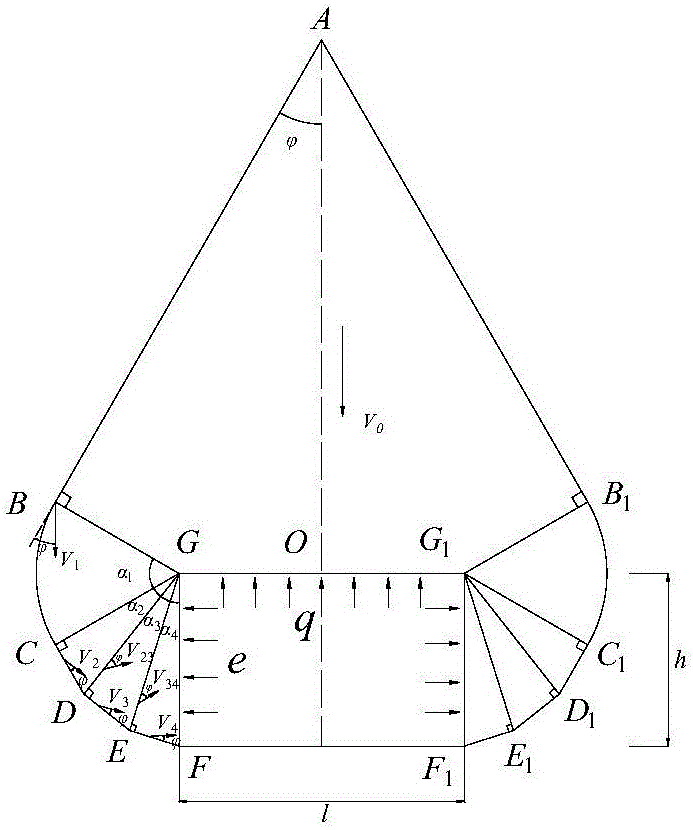

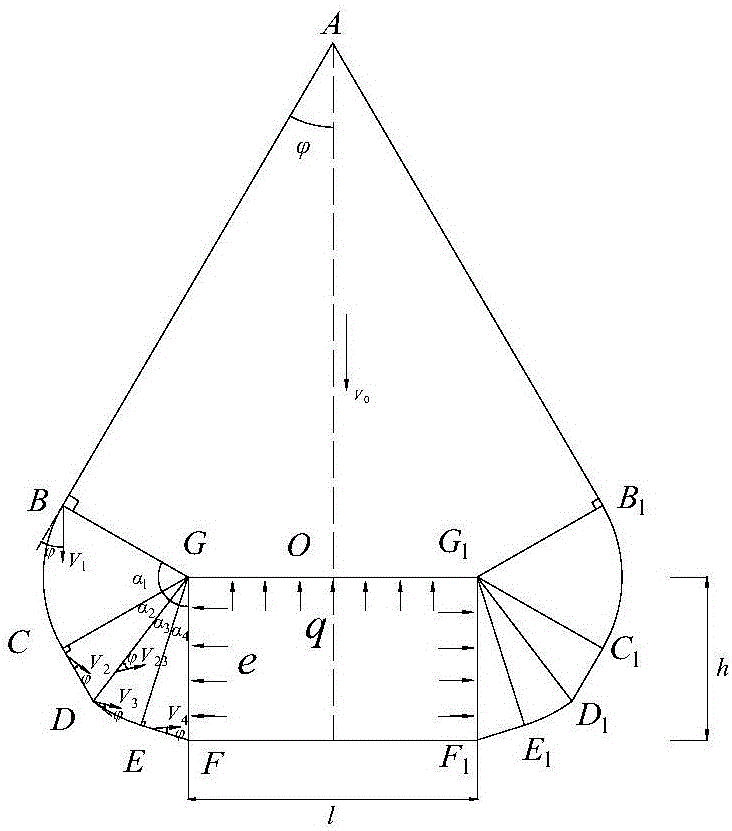

Deep chamber surrounding rock pressure calculating method

InactiveCN106682330AHigh precisionDesign optimisation/simulationSpecial data processing applicationsFracture loadEngineering structures

The invention discloses a deep chamber surrounding rock pressure calculating method. The method comprises the following steps that a kinetically admissible velocity field is built according to the failure mechanism; upper limit analytical solutions of fracture loads are derived and obtained on the basis that internal power is equal to external power; a minimum value is obtained in the plurality of fracture loads, that is the optimal upper limit solution is obtained. The failure mechanism comprising a wedge-shaped collapsing body sliding down, a rotational arc body with the vertex angle as the center of a circle and n translational triangular bodies is provided, then the upper limit analytical solutions of fracture loads are derived and obtained on the basis that the internal power is equal to the external power, the minimum value is obtained in the plurality of fracture loads by means of the optimization method, and the optimal upper limit solution is obtained. The upper limit solution is a strict upper limit value of the surrounding rock pressure, and a theory reference can be provided for supporting designs of the engineering structure.

Owner:HUNAN UNIV OF SCI & TECH

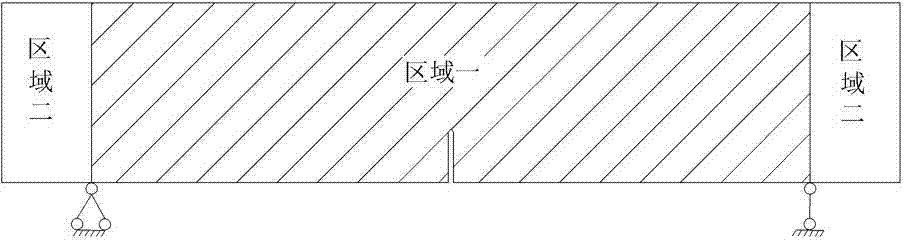

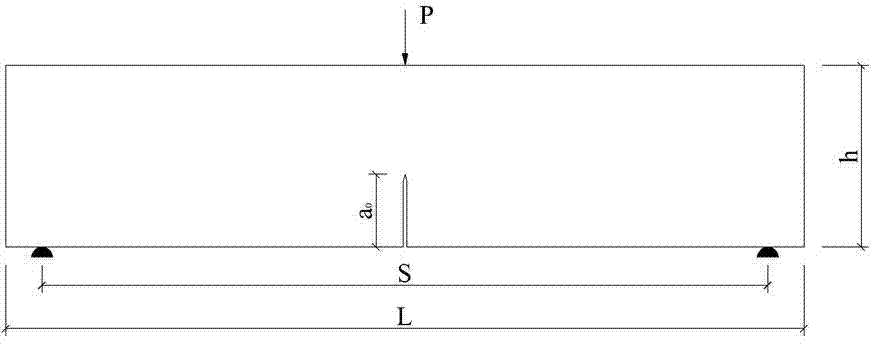

Self-weight influence-free concrete material fracture toughness testing method

ActiveCN103698224AIncreased testable sizeMake up for the inaccurate determination of crack initiation and instability toughness valueMaterial strength using steady bending forcesTest beamEngineering

The present invention relates to a self-weight influence-free concrete material fracture toughness testing method, and belongs to the technical field of physical measurements. The determination method comprises: 1) erecting a test beam on two rolling bearings of the current three-point bending beam test device, and arranging a load measurement device and a strain measurement device on the test beam; 2) measuring the applied maximum load Fmax through the load measurement device, and measuring an initiation fracture load FQ through the strain measurement device; and 3) calculating an unstable toughness and an initiation fracture toughness. With the self-weight influence-free concrete material fracture toughness testing method, influence of the member self-weight on the testing result is eliminated so as to accurately determine the concrete initiation fracture and unstable toughness and meet the initiation fracture and unstable toughness determination requirements of the concrete material (including hydraulic concrete) of the high crack-depth ratio or large size specimen.

Owner:NANJING HYDRAULIC RES INST

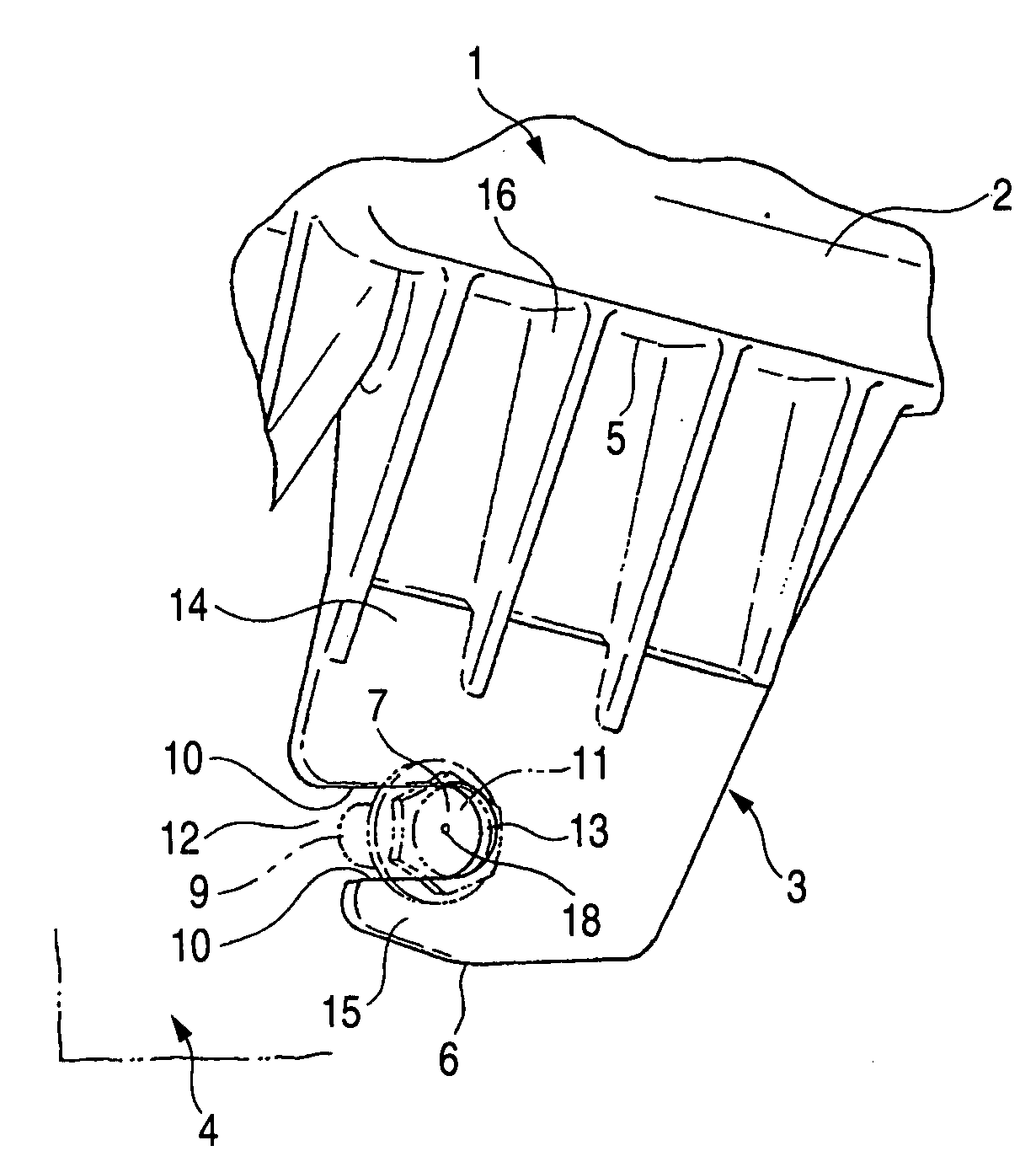

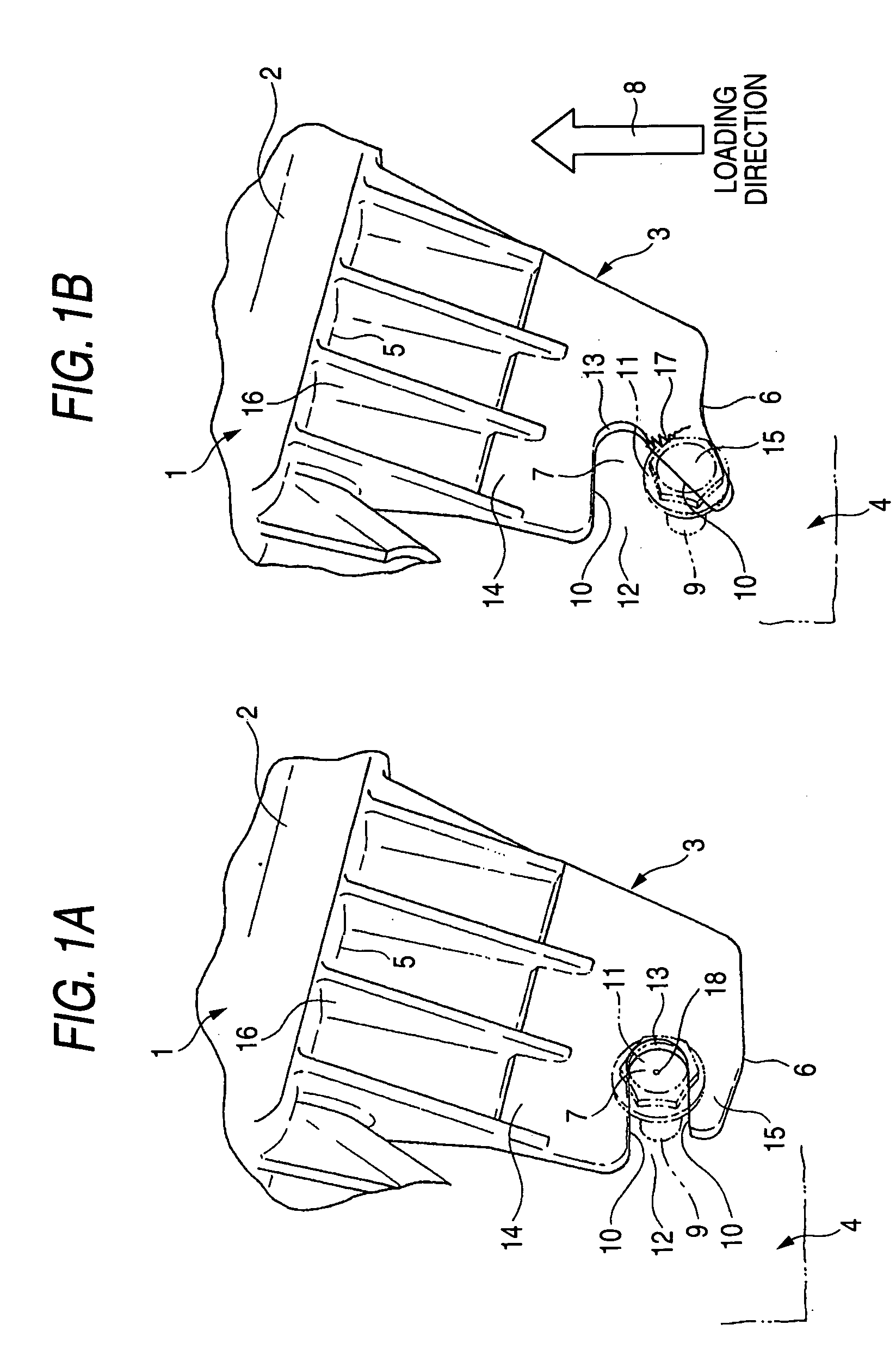

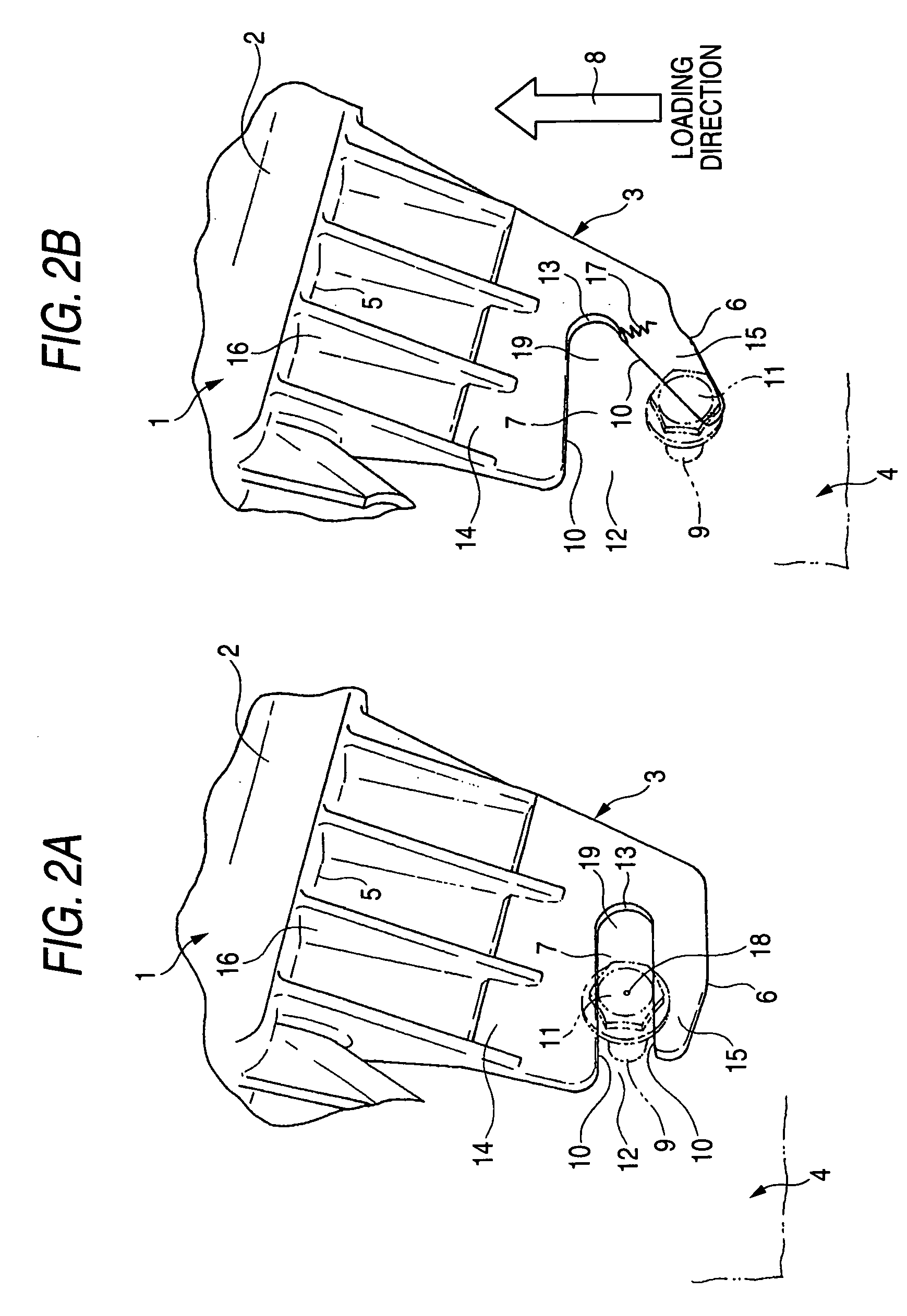

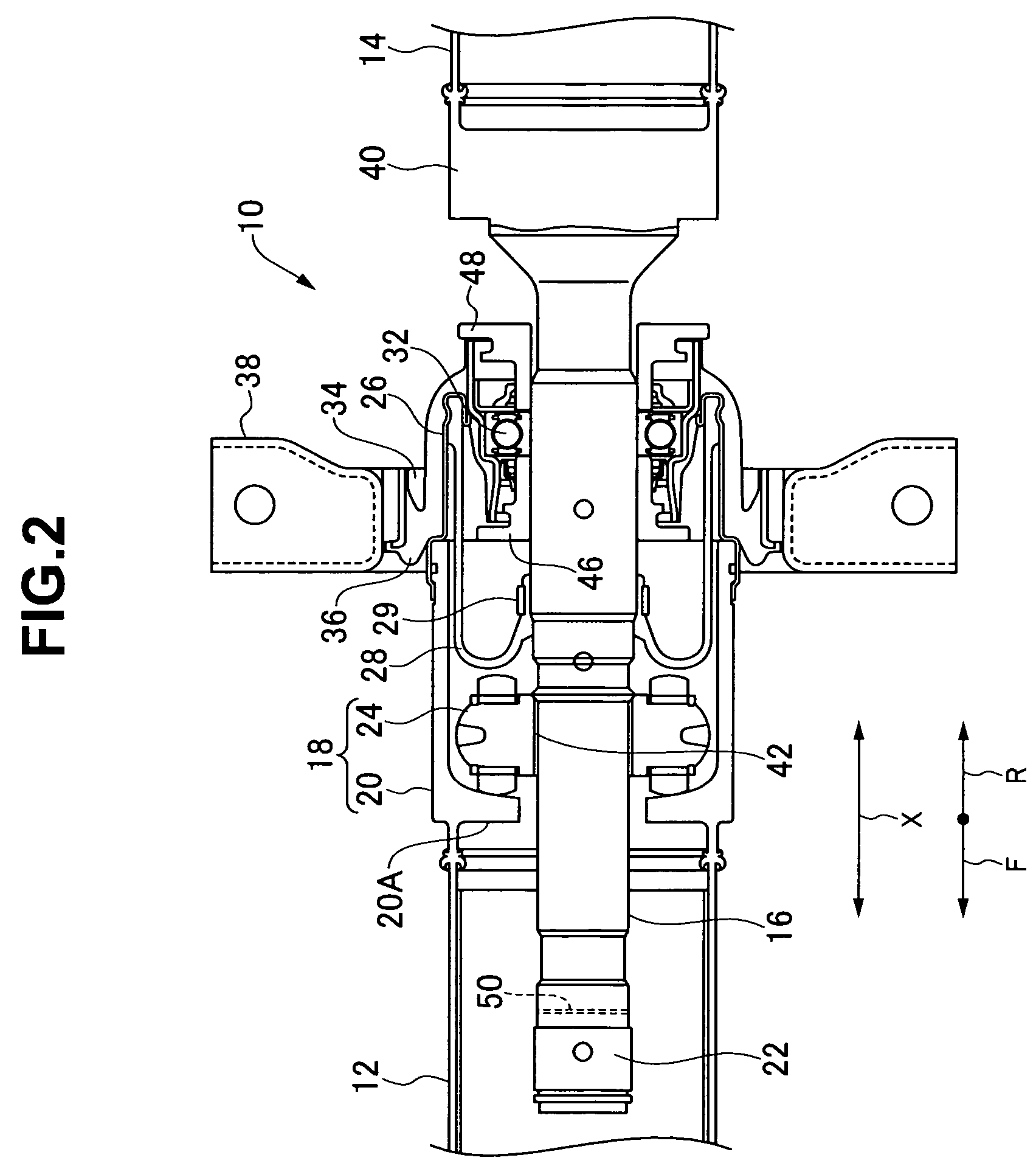

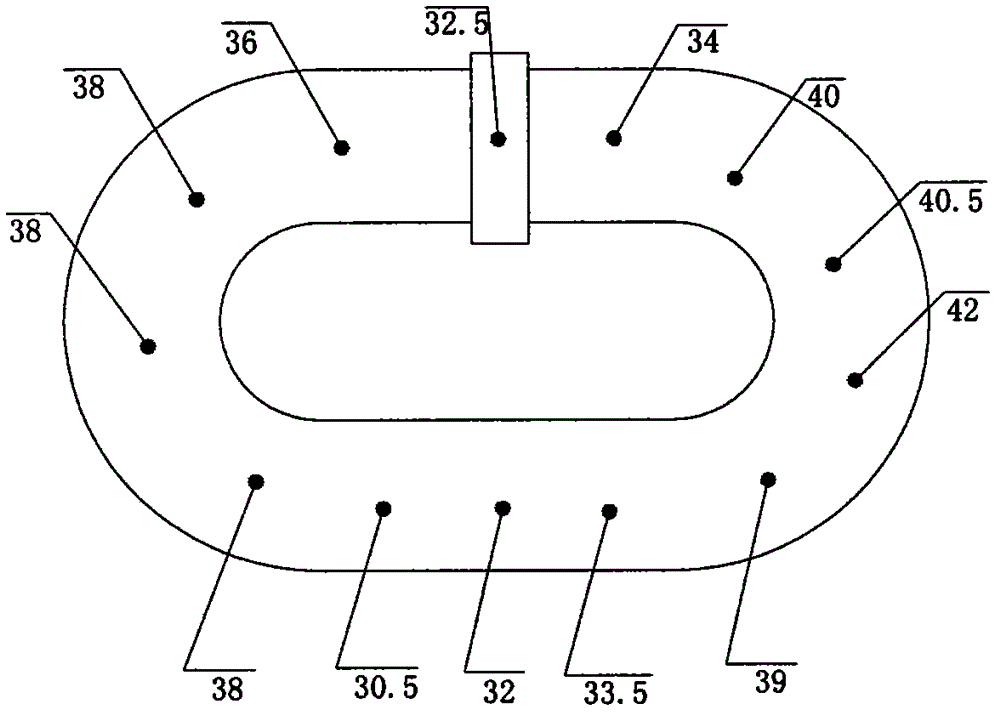

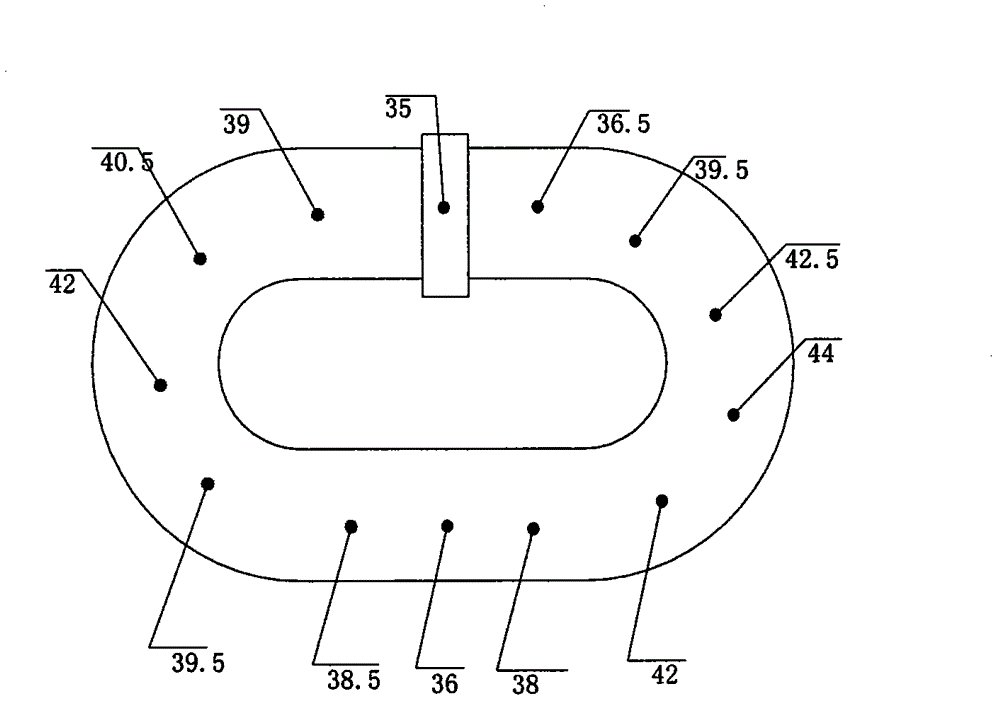

Mounting bracket structure

InactiveUS20060243870A1Easy to installIntuitive effectSubstation/switching arrangement detailsStands/trestlesEngineeringFracture load

Owner:YAZAKI CORP

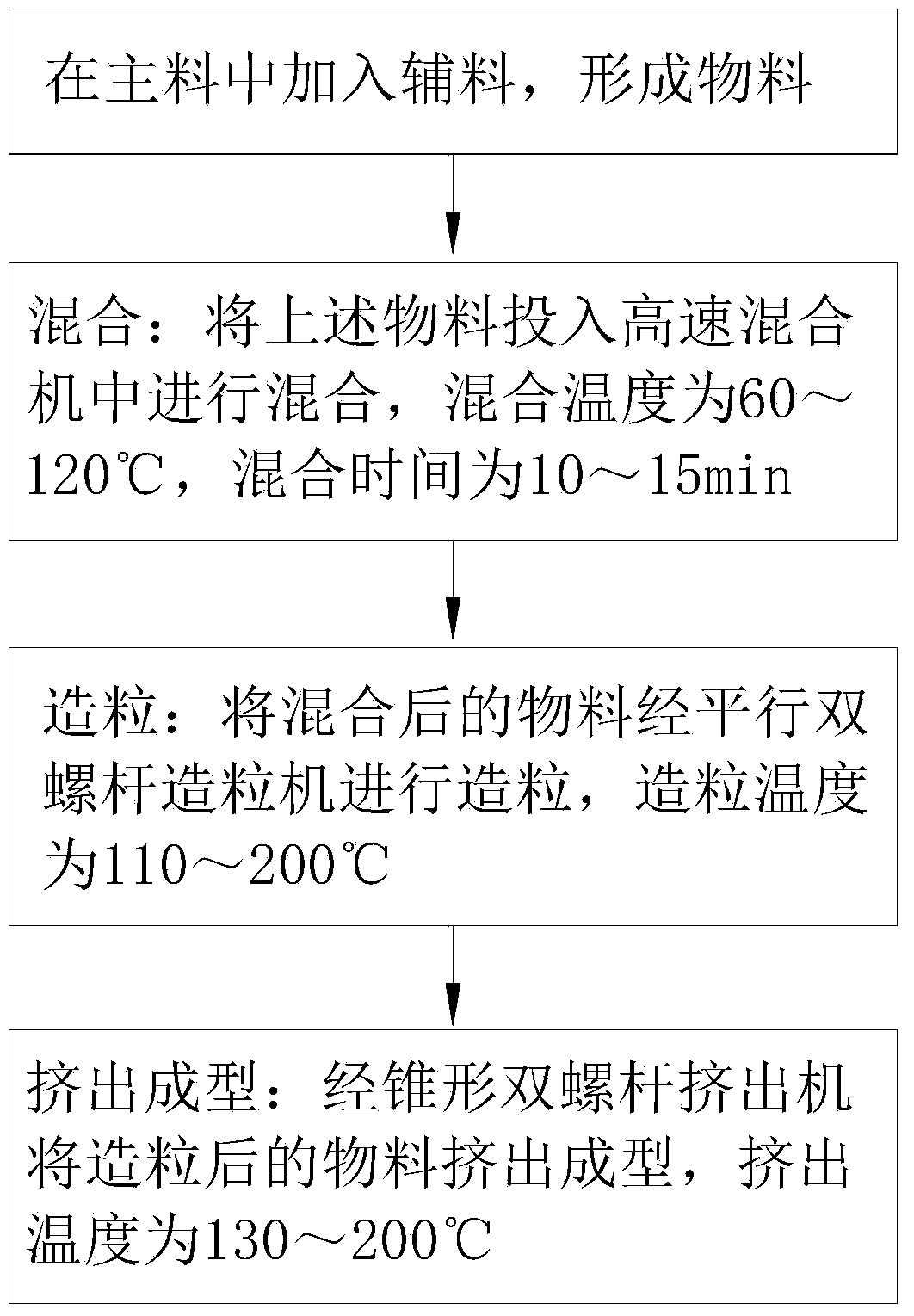

Preparation method of high-strength wood-plastic composite section bar

The invention discloses a preparation method of a high-strength wood-plastic composite section bar, which is processed and formed by taking wood powder or bamboo powder as a primary material and taking polyolefin resin, filler, a coupling agent and a lubricant as auxiliary materials through processes such as mixing, pelletizing and extruding. The method disclosed by the invention improves processing performance and mechanical performance of the wood-plastic composite section bar and improves bending fracture load and bending elasticity modulus of the wood-plastic floors; a product is good in stability, easy to install, free from cracks and warping defect, fireproof, waterproof, mothproof, sun-resistant, ageing-resistant, corrosion-resistant, free from formaldehyde, capable of being 100% recycled, and suitable for the fields such as outdoor landscape architecture and home decoration. Besides, various indexes of the high-strength wood-plastic composite section bar are higher than those in national standard GB / T24508-2009, wherein the bending fracture load is not less than 5000N, and the bending elasticity modulus is not less than 4000MPa.

Owner:HUANGSHAN MEISEN NEW MATERIAL TECH

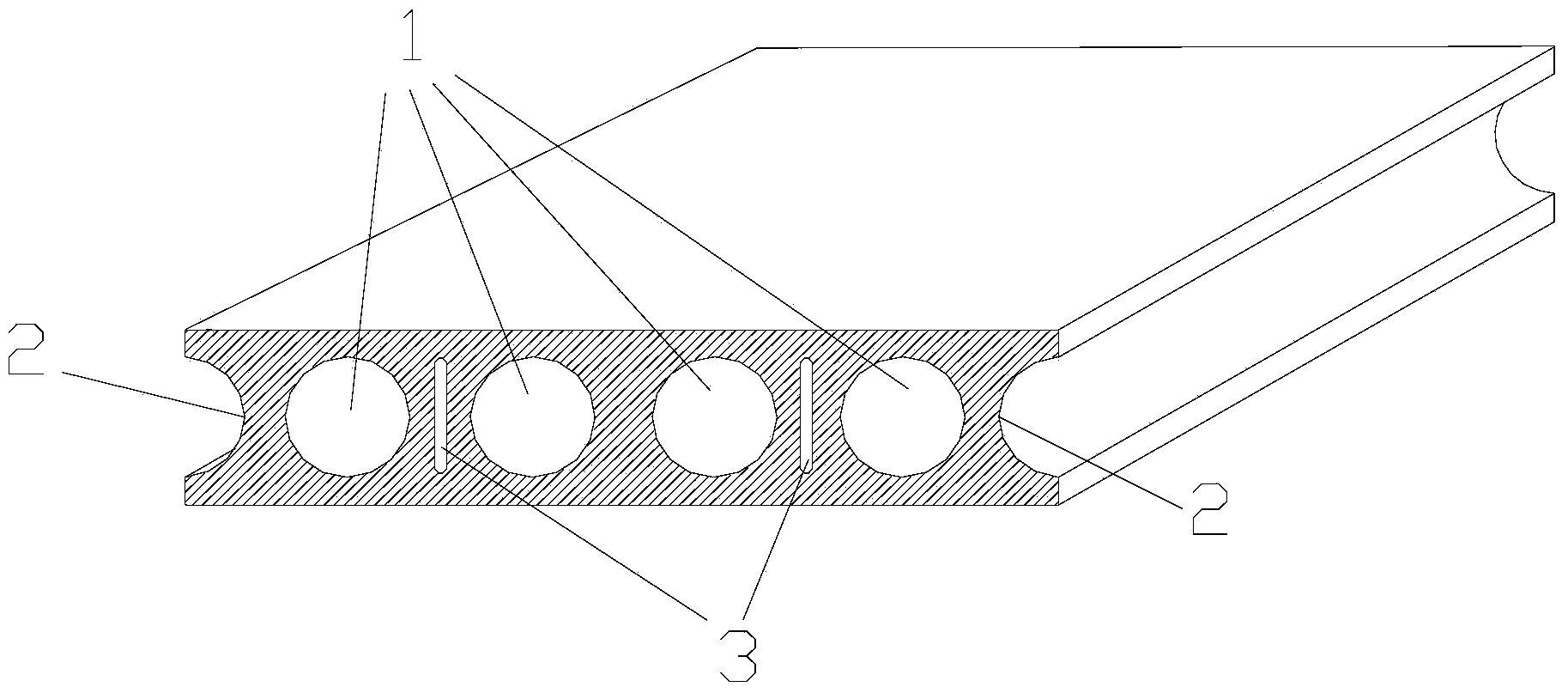

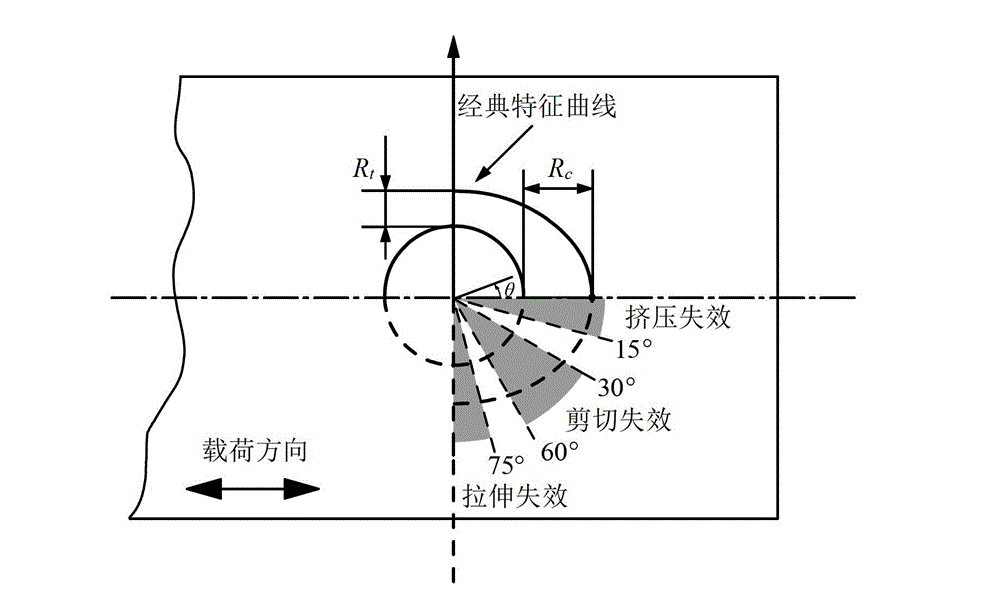

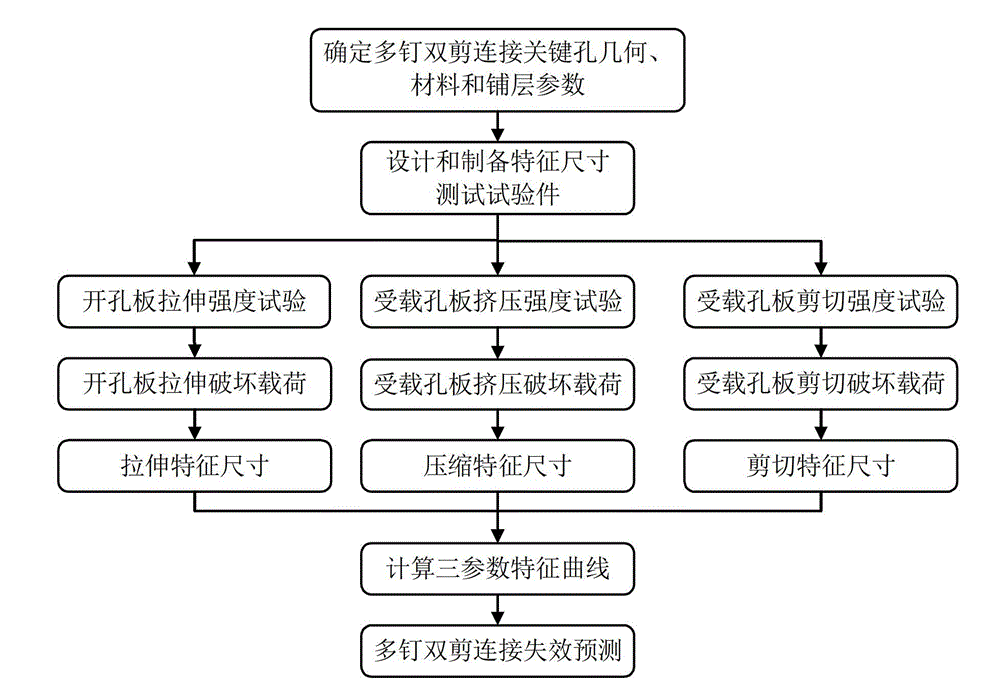

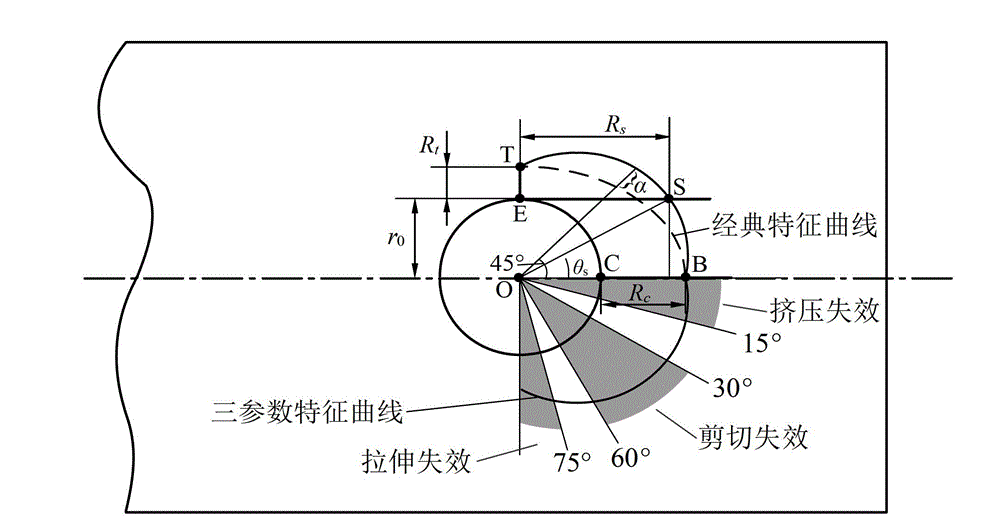

Composite material multi-nail and double-shear connection failure prediction method based on three-parameter characteristic curve

InactiveCN103335886APredict failure modePredicted Failure LoadMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesEngineeringFracture load

The invention provides a composite material multi-nail and double-shear connection failure prediction method based on a three-parameter characteristic curve. The composite material multi-nail and double-shear connection failure prediction method comprises the following steps of: (1) designing and preparing a test piece of a tensile, compression and shear characteristic size test according to parameters of geometry, a material, a laying layer and the like of a multi-nail and double-shear connection key hole of a composite material; (2) carrying out a static-force tensile test to obtain a tensile fracture load of an opening laminated board, an extrusion fracture load of a carrying hole laminated board, and a shearing fracture load of the carrying hole laminated board; (3) calculating tensile, compression and shear characteristic sizes according to the fracture loads; (4) acquiring the three-parameter characteristic curve based on the tensile, compression and shear characteristic sizes, wherein the curve passes through a tensile characteristic point, an extrusion characteristic point and a shearing characteristic point of the key hole; and (5) predicating a failure mode and a fracture load of a multi-nail and double-shear connection structure of the composite material based on the three-parameter characteristic curve. The composite material multi-nail and double-shear connection failure prediction method disclosed by the invention is applicable to multi-nail and double-shear connection failure prediction of the composite material in engineering application, and the failure mode and the fracture load of the connection structure can be accurately predicated by considering the shearing characteristic size.

Owner:BEIHANG UNIV

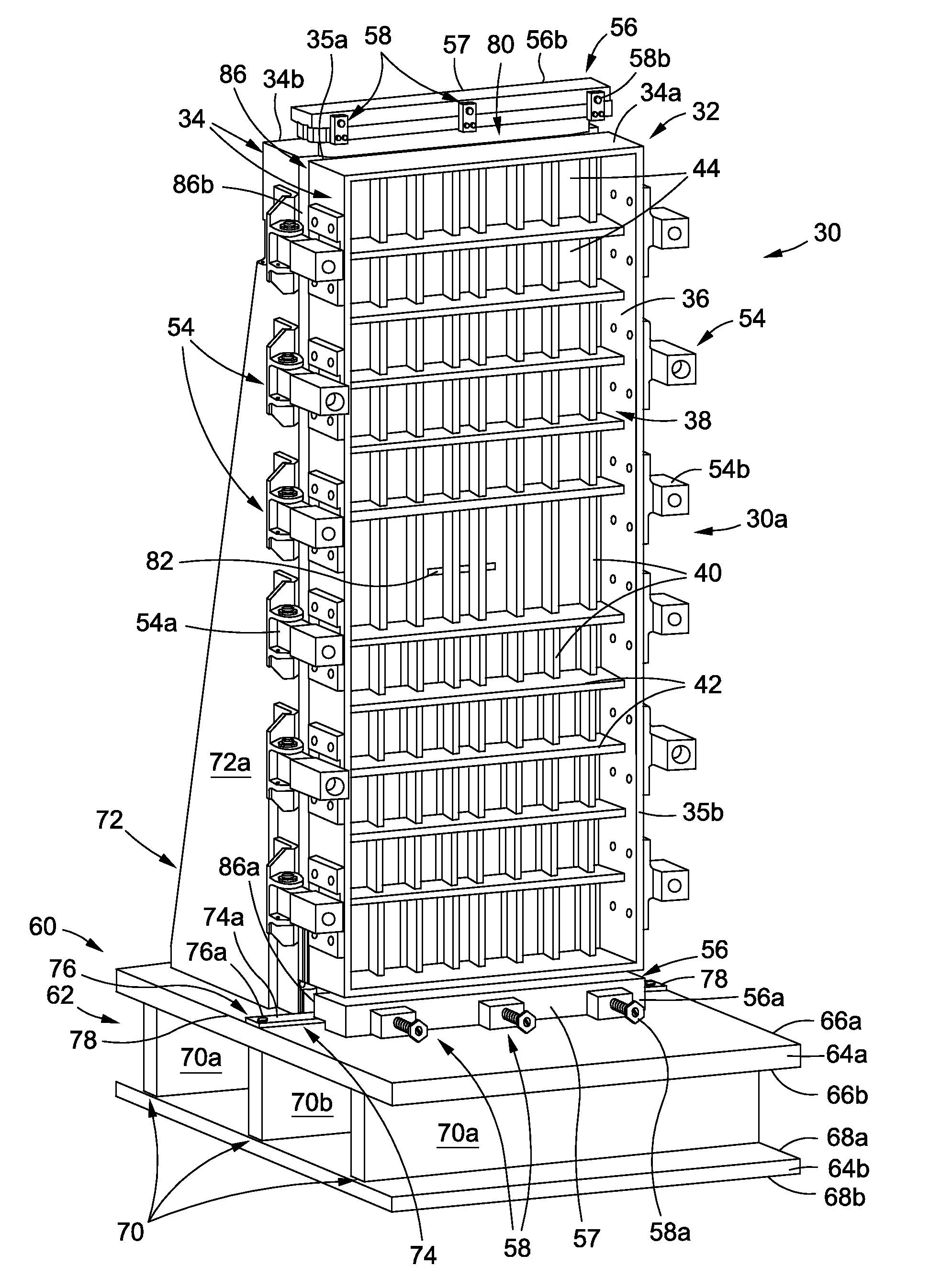

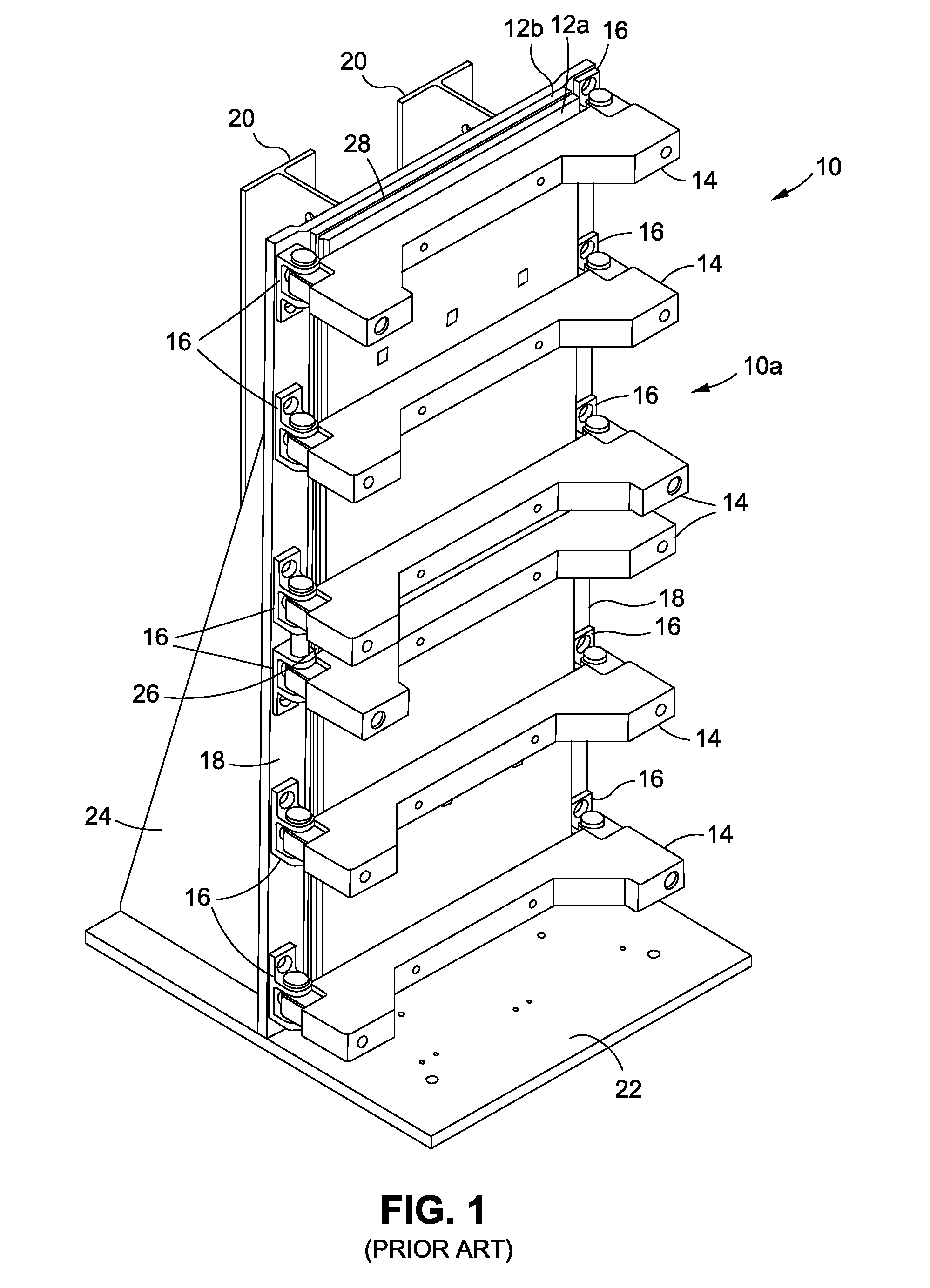

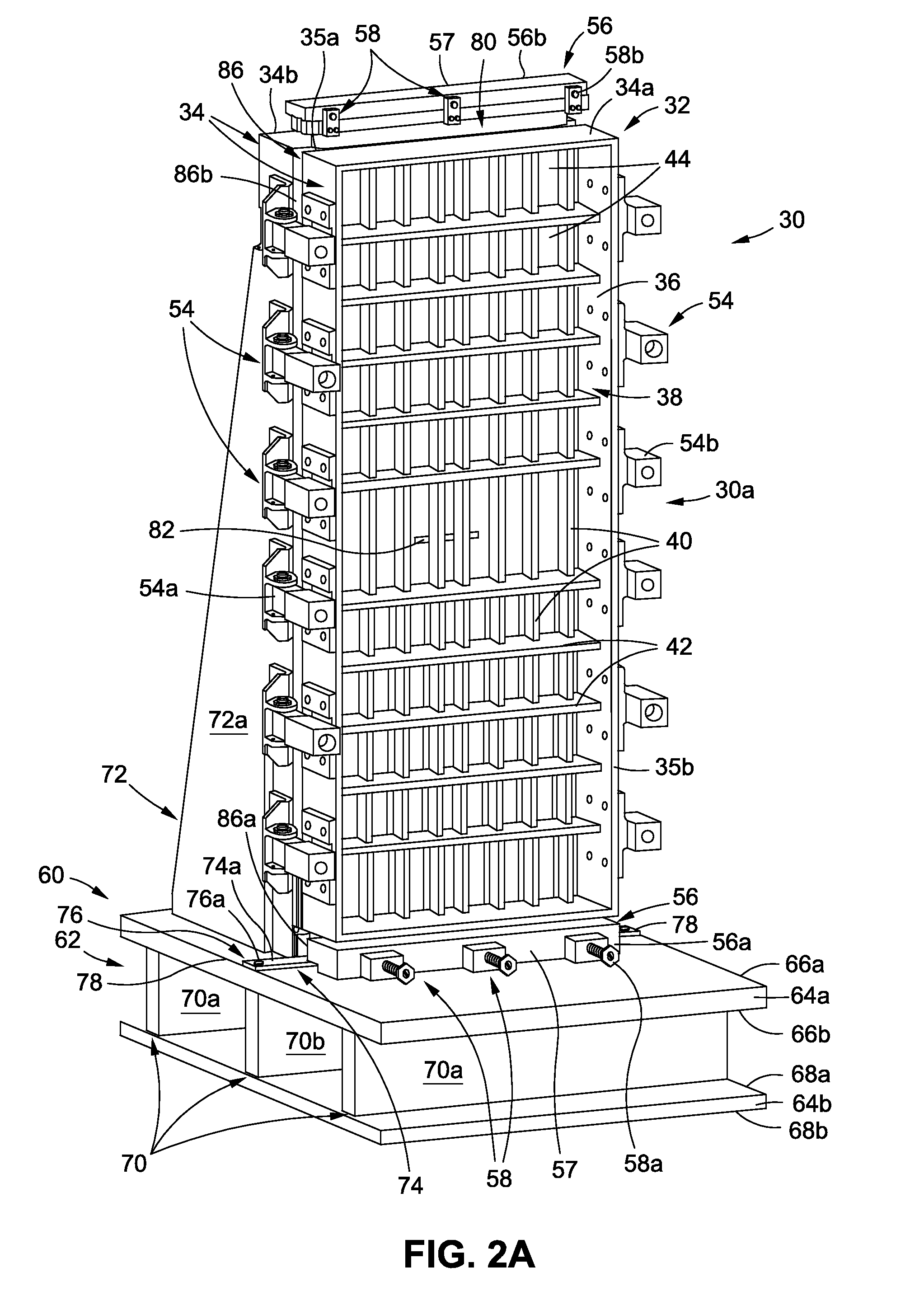

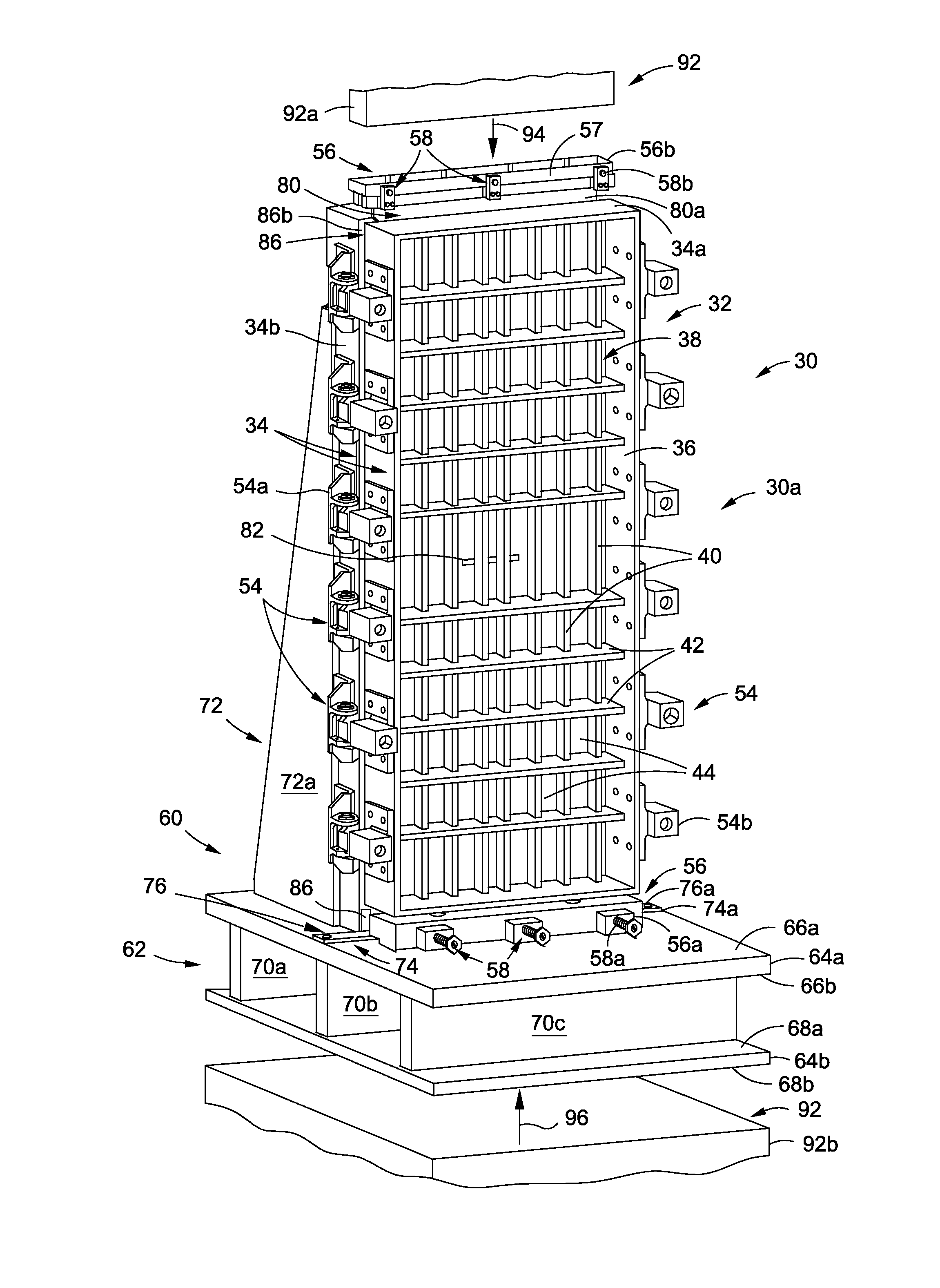

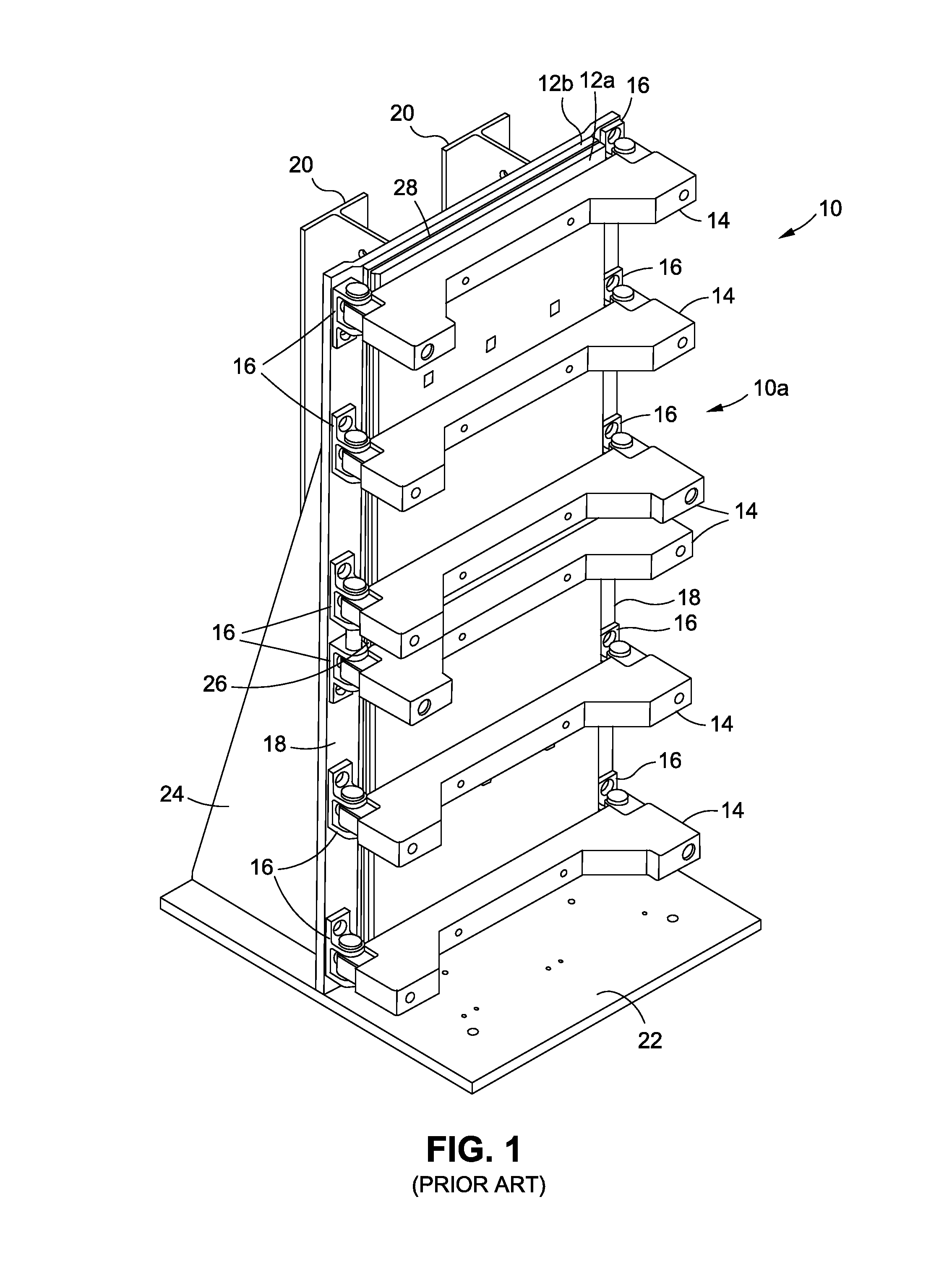

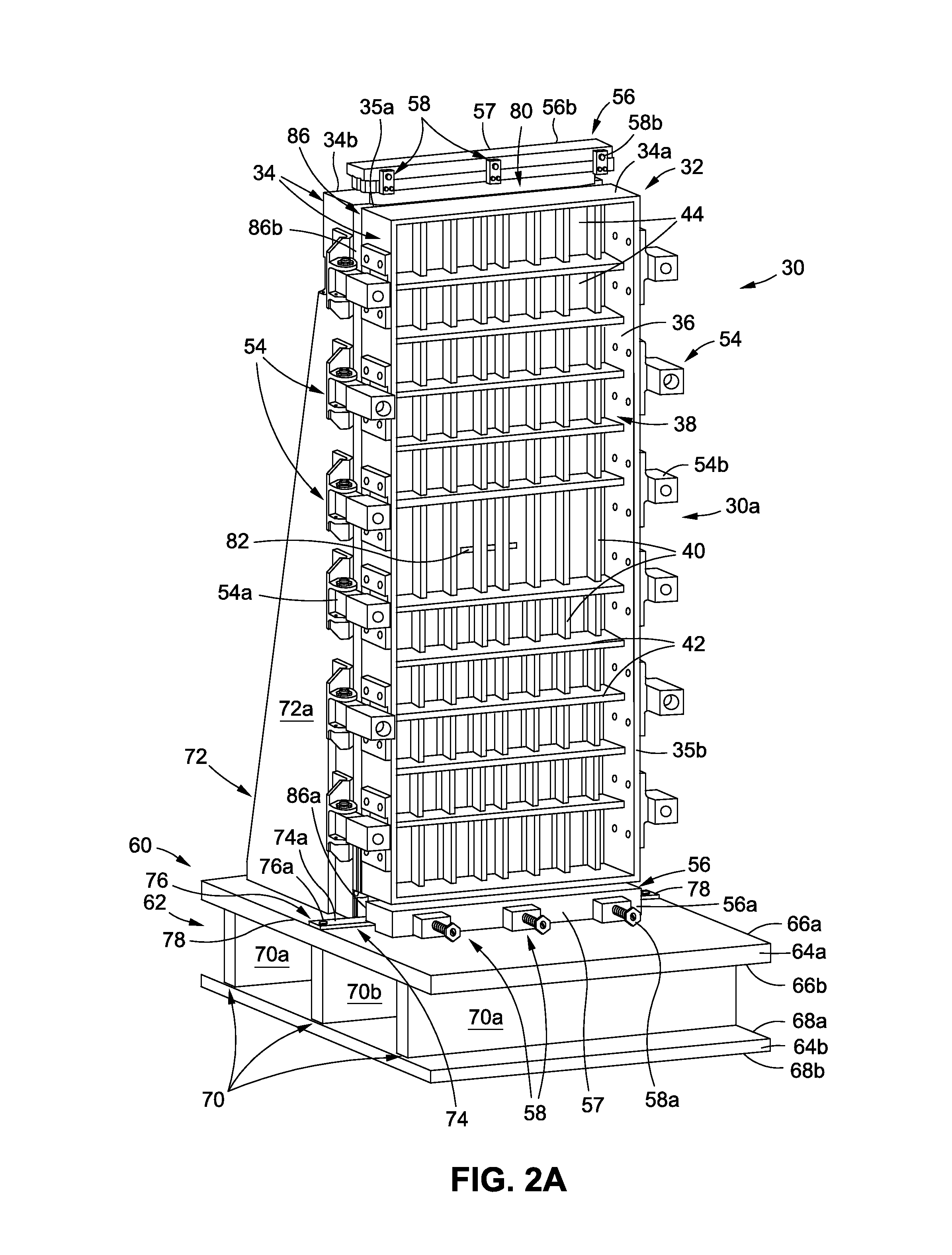

Apparatus, System and Method for Compression Testing of Test Specimens

ActiveUS20150020603A1Satisfies needBig advantageForce measurement by measuring optical property variationMaterial strength using tensile/compressive forcesTest sampleFracture load

There is provided an apparatus for compression testing. The apparatus has a base assembly having an end load element attached to the base assembly, the base assembly being rigid. The apparatus has a support assembly attached to the base assembly, and having a plurality of window portions. The apparatus has a core assembly installed within the support assembly, the core assembly being crushable and configured to protect the support assembly and the base assembly from fracture loads generated during compression testing. The base assembly, the support assembly, and the core assembly together form an apparatus for compression testing of a test specimen having a notch portion. The apparatus is configured for use with an optical strain measurement system. When the test specimen is installed in the support assembly, the test specimen and the notch portion are visible to the optical strain measurement system through the plurality of window portions.

Owner:THE BOEING CO

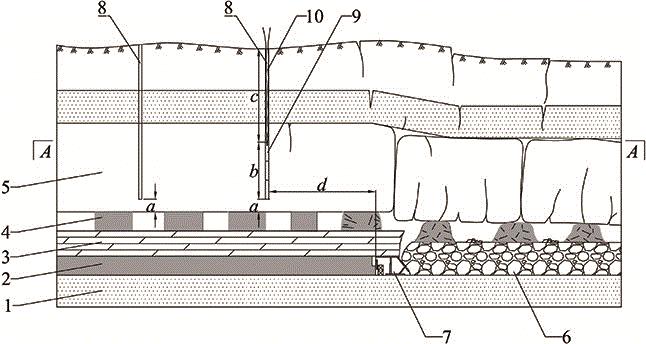

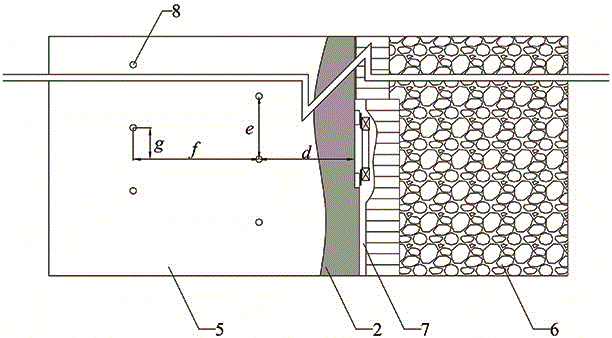

Surface drilling pre-splitting blasting shallow burying method for room type goaf roof

ActiveCN106705773APrevent crushingSafe miningUnderground miningBlastingLongwall miningShortest distance

The invention discloses a surface drilling pre-splitting blasting shallow burying method for a room type goaf roof and belongs to a roof disaster preventing and controlling method for mining of a short distance coal bed below a shallowly-buried goaf. During long wall mining of the short distance coal bed below the shallowly-buried room type goaf, main roof large-area pressure coming happens easily, the yielding damage happens to a small-size coal column under the fracture load of a main roof, a large-size coal column has an elastic kernel and acts the concentrated stress on a lower coal bed work face hydraulic support, and collapse of a work face inner roof, pushing down of a support, hurricane impacting and other disasters are caused. According to the method, drilling pre-splitting blasting of the roof is performed on the ground, the problems that construction is difficult and the effective distance of drilling is short during forced caving of room penetrating type drilling pre-splitting blasting of the goaf are solved, roof large-area pressure coming, roof collapse, pushing down of the support and other disasters can be effectively prevented, and the method is also applicable tomining of lower coal beds of concentrated coal columns of a shallowly-buried long-wall goaf. The method is simple in implementation process, safe and efficient and has wide applicability.

Owner:CHINA UNIV OF MINING & TECH

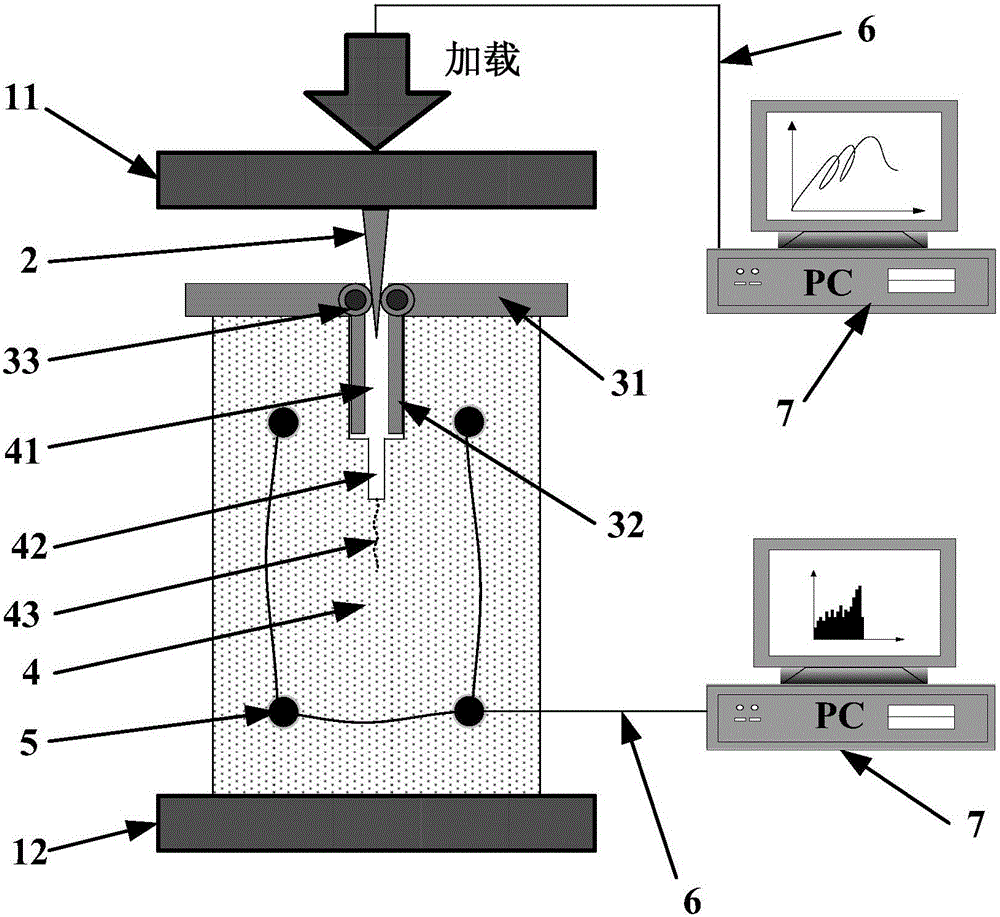

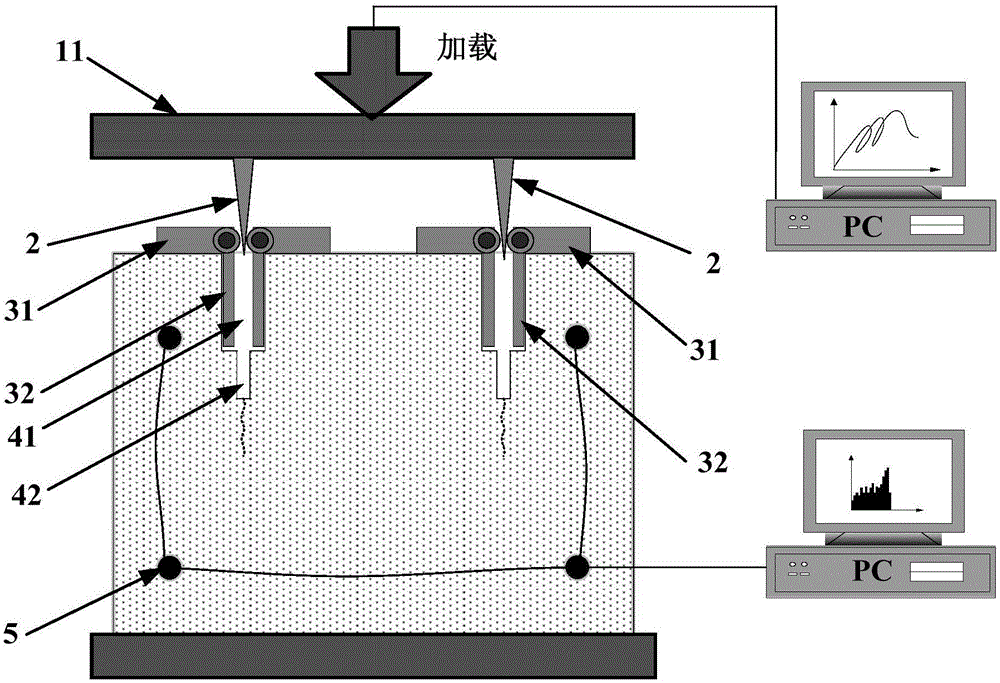

Rock crack propagation simulation testing device and testing method

ActiveCN106053230AEasy to testEasy to makeMaterial strength using tensile/compressive forcesStress conditionsAcoustic emission

The invention discloses a rock crack propagation simulation testing device and testing method. In the rock crack propagation simulation testing device, an extrusion head is fixedly connected to the lower surface of an upper pressure-bearing plate, a rock sample is arranged on the upper surface of a lower pressure-bearing plate, a groove is formed above the rock sample, the rock sample at the bottom of the groove is provided with a precrack, one end of an upper extrusion plate is fixedly connected with one end of a lower extrusion plate, a sliding wheel is hinged to the fixed joint of the upper extrusion plate and the lower extrusion plate, the outer surface of the rock sample is provided with an acoustic emission wave detector, the acoustic emission wave detector is connected with a computer through signals, and a loading end acts on the upper pressure-bearing plate and is connected with the computer through signals. The testing device has the advantages that the rock sample is easy to manufacture, simple in testing and low in testing cost; stable and controllable fracture loads can be applied according to stress conditions of the rock sample, so that the rock sample generates directional cracks, and relations between loads, loading speed and other factors and rock sample crack propagation can be accurately analyzed.

Owner:SHANDONG UNIV OF SCI & TECH

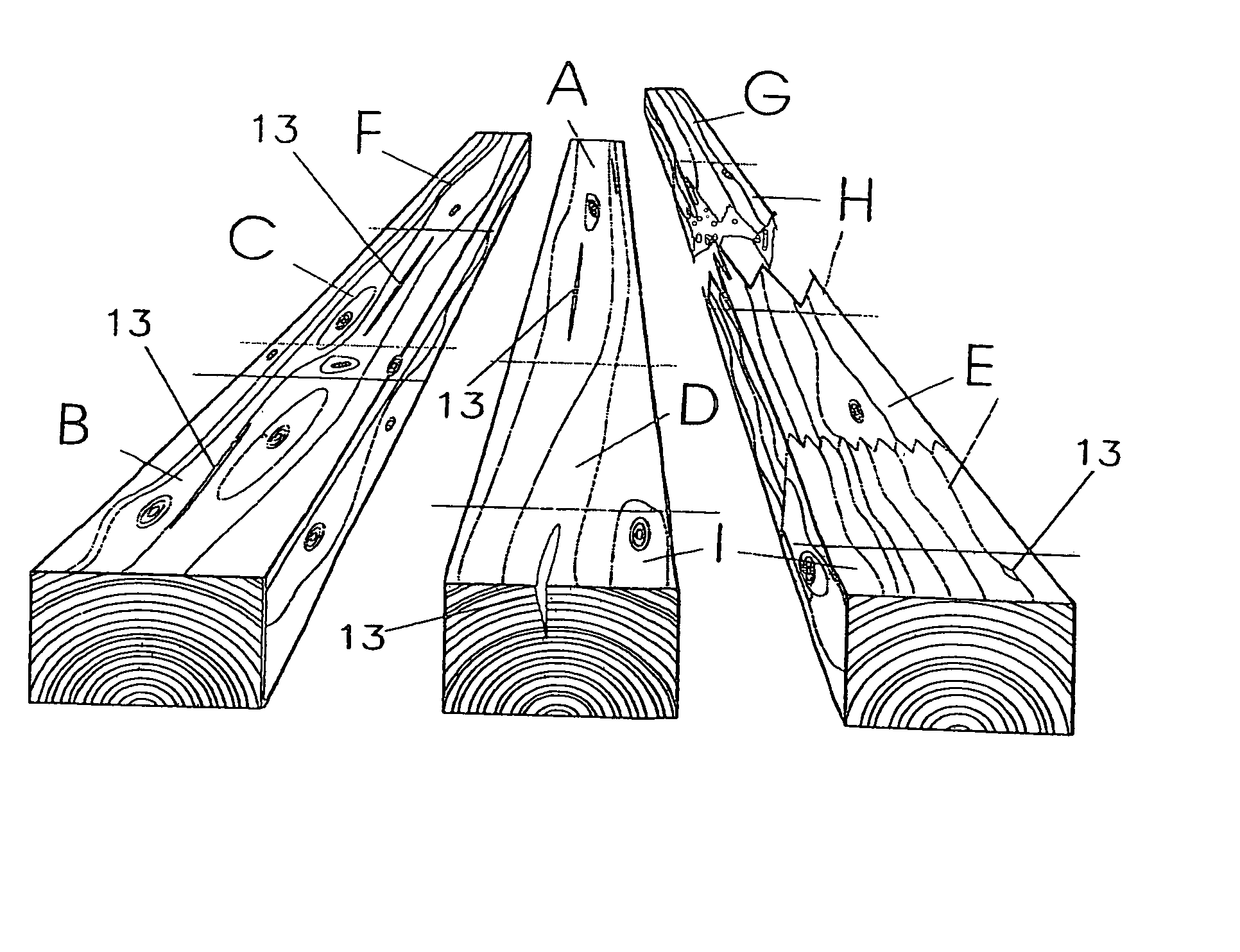

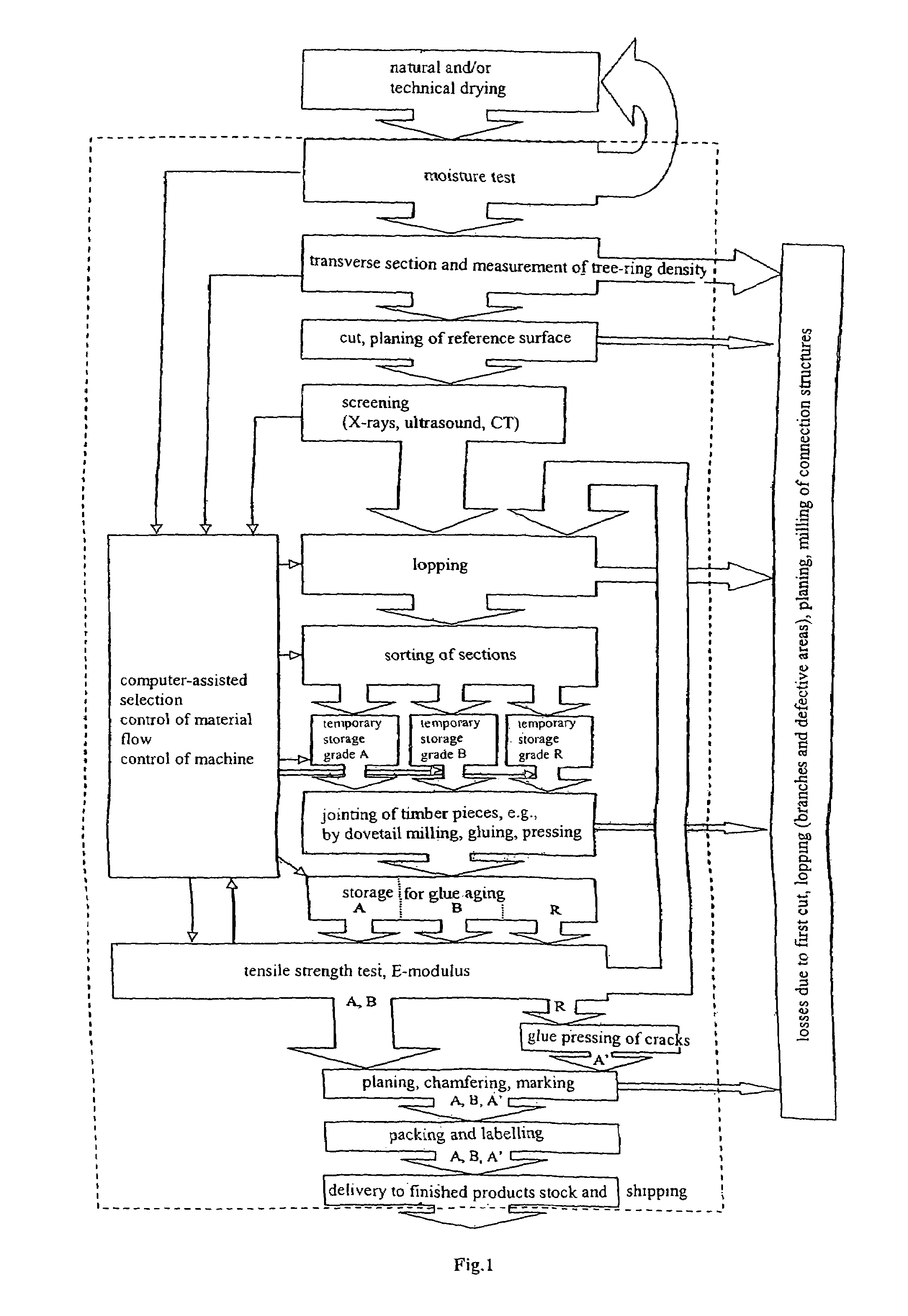

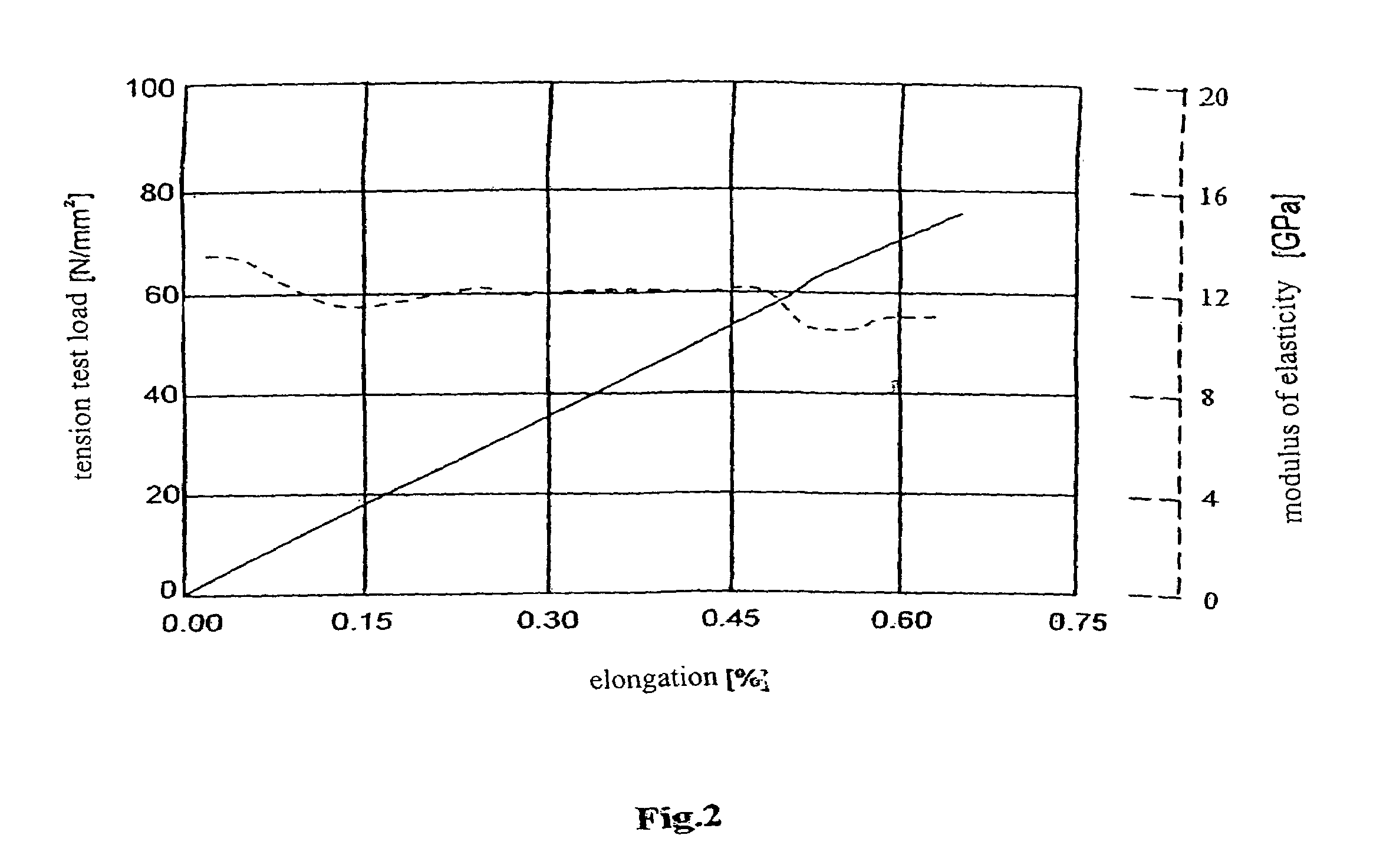

Method for quality assurance of long timber

InactiveUS7418874B2Increase pressureReduce the cross-section surchargesForce measurement by measuring optical property variationWork measurementQuality assuranceStructural engineering

The invention relates to a method for quality assurance in preferably finger-jointed timber (1), produced in series, with a given minimum length (12), characterized in that each piece, produced within the length (12), is loaded with increasing tensile forces at the ends (5) thereof to a threshold value, below the breaking load for a fault-free timber piece, and the length changes (DELTA 1), changing therewith, are determined over a section, or the whole length of the timber piece (1) and used as a quality criterion for the use, or the further processing of the timber piece (1). The invention further relates to a device for carrying out said method.

Owner:HOLZINDUSTRIE LEITINGER GMBH

High-strength reinforced concrete pipe culvert and preparation method thereof

The invention discloses a high-strength reinforced concrete pipe culvert and a preparation method thereof. The preparation method includes the steps that firstly, shell calcined matter is soaked into activation liquid, and then activated shell calcined matter is obtained through filtering, drying and screening; secondly, cement, the activated shell calcined matter, pebbles, sand, coal ash and water are mixed so that concrete can be prepared; thirdly, the concrete is poured into a reinforcement cage, and then the high-strength reinforced concrete pipe culvert is prepared through curing, wherein the activation liquid comprises water, hydrochloric acid, citric acid and potassium chromate. The high-strength reinforced concrete pipe culvert prepared through the method has excellent fracture load and failure load indexes.

Owner:ANHUI YUTE CONCRETE STRUCTURE TECH

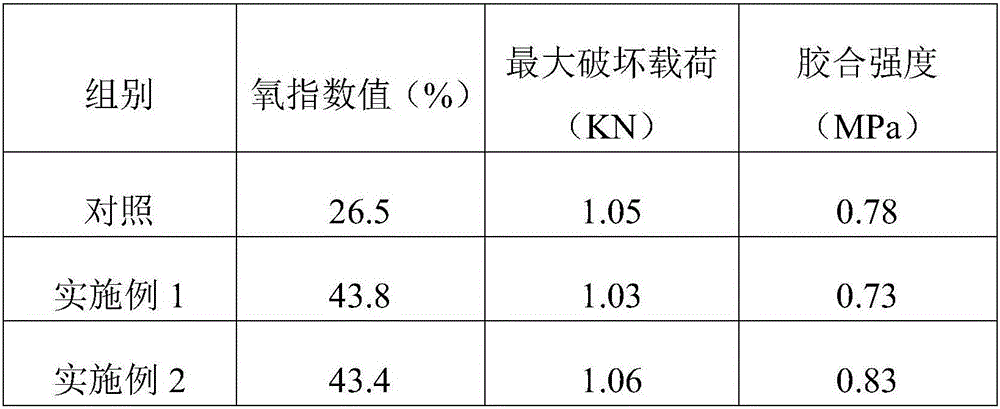

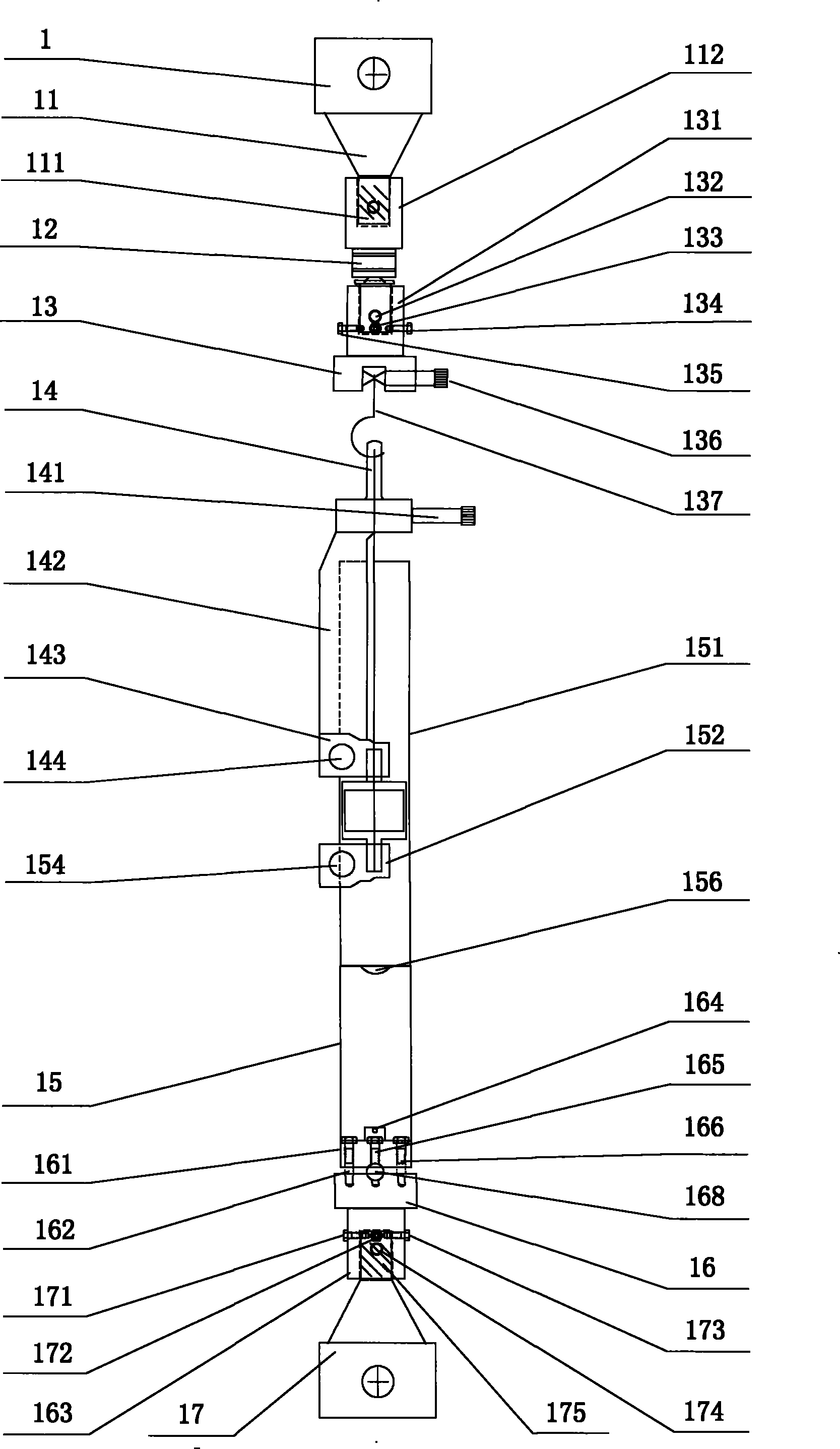

Wood composite flame retardant and preparation method thereof

InactiveCN106553247AImprove flame retardant performanceHigh smoke suppression effectWood treatment detailsWood veneer joiningFireproofingFire retardant

The invention relates to the technical field of wood processing and particularly relates to a wood composite flame retardant and a preparation method thereof, and an application thereof in production of flame retarding plywood. The wood composite flame retardant includes, by weight, 25-35 parts of melamine, 5-15 parts of sodium dihydrogen phosphate, 0.1-0.5 parts of sodium hydroxide, 30-40 parts of borax and 30-40 parts of boric acid. The raw materials of the wood composite flame retardant have synergistic flame retarding effects, so that the flame retardant is good in flame retarding effect, is low-toxicity, has good smoke inhibition property and is environment-friendly, and is also low in cost. The flame retarding plywood produced from the flame retardant is significantly improved in flame retarding performance, which can reach C-level fireproofing grade in national standard. Bonding strength and maximum fracture load of the plywood are approximated to plywood produced without the flame retardant.

Owner:防城港市林木良种繁育中心苗圃

Anti-mold and anti-bacterial paper-surface gypsum board and preparation method thereof

The invention provides an anti-mold and anti-bacterial paper-surface gypsum board and a preparation method thereof. The paper-surface gypsum board comprises a gypsum core and surface protective paperarranged on the surface of the gypsum core; the gypsum core is prepared from the following components: gypsum, a first mold inhibitor, a compound bactericide, a first waterproof agent and a gypsum reinforcer with the mass ratio being 100:(0.001 to 0.045):(0.005 to 0.2):(0.01 to 0.3):(0.01 to 1); and the surface protective paper is prepared from the following components: a second waterproof agent,a second mold inhibitor and a bactericide with the mass ratio being (0.05 to 0.5):(0.05 to 0.5):(0.1 to 1.5). The gypsum core of the anti-mold and anti-bacterial paper-surface gypsum board comprises the specific types of the mold inhibitor, the bactericide and the waterproof agent, the surface protective paper comprises the specified waterproof agent, bactericide and mold inhibitor, under the joint action, the paper-surface gypsum board has the good anti-mold effect, and the gypsum board has no odor and further has the good hardness and fracturing load in the existence of the gypsum reinforcer.

Owner:TAISHAN GYPSUM CO LTD

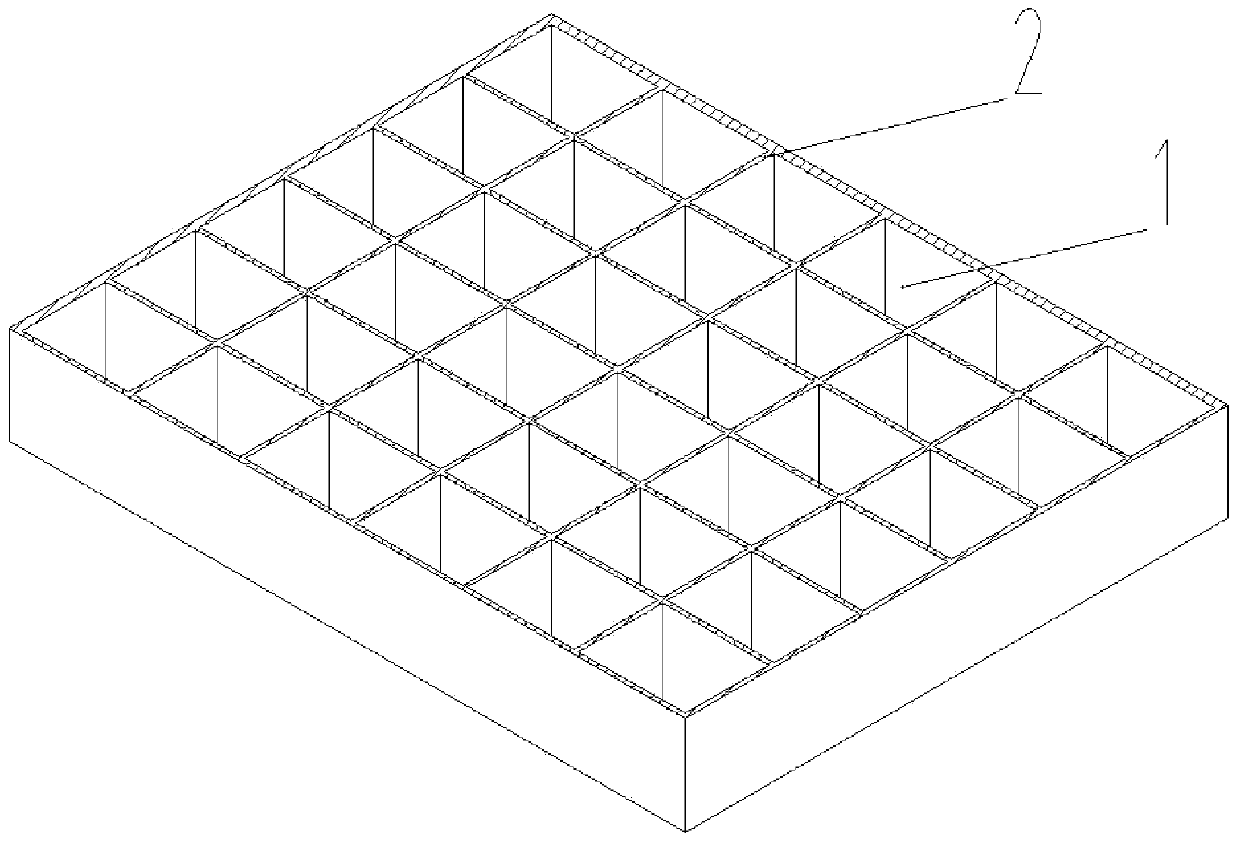

Composite material structural piece and manufacturing method thereof

ActiveCN103696367AImprove lateral strengthImprove carrying capacityBridge structural detailsBridge materialsPolyesterFlexural strength

The invention provides a composite material structural piece which comprises a plurality of core bodies and flexible fiber reinforcing materials, wherein the plurality of core bodies are distributed in a grid-shaped manner; the surfaces of the core bodies are wrapped with the flexible fiber reinforcing materials; the flexible fiber reinforcing materials on the surfaces of adjacent core bodies are connected. The invention further provides a manufacturing method of the composite material structural piece. Experimental result shows that the fracture load of the composite material structural piece which is made from PVC (Polyvinyl Chloride) foam as the core bodies, double-axis fiber cloth as the flexible fiber reinforcing materials and unsaturated polyester and curing agent M50 as gluing resins can be greater than 2.500N, the bending elasticity modulus can be greater than 4,000MPa, and the bending strength can be greater than 45MPa.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

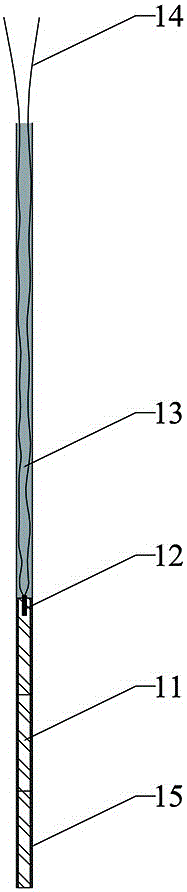

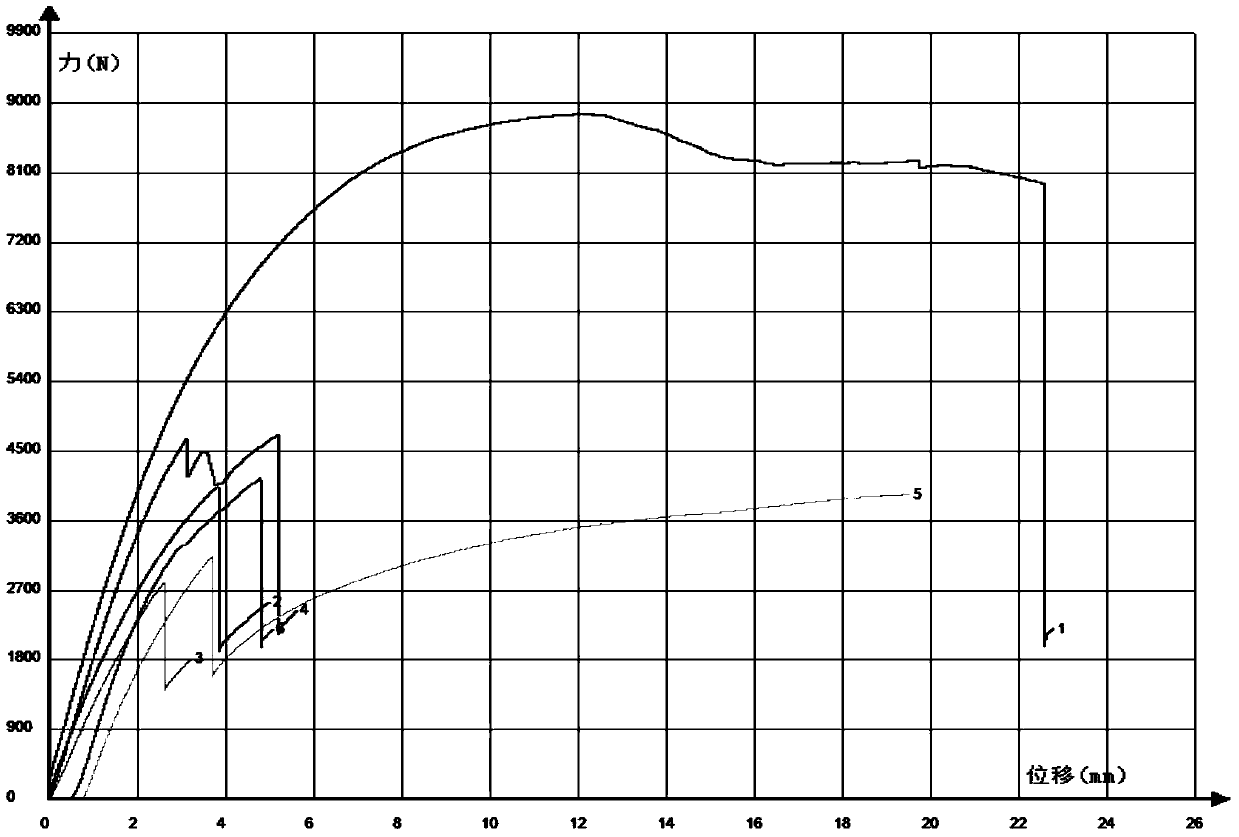

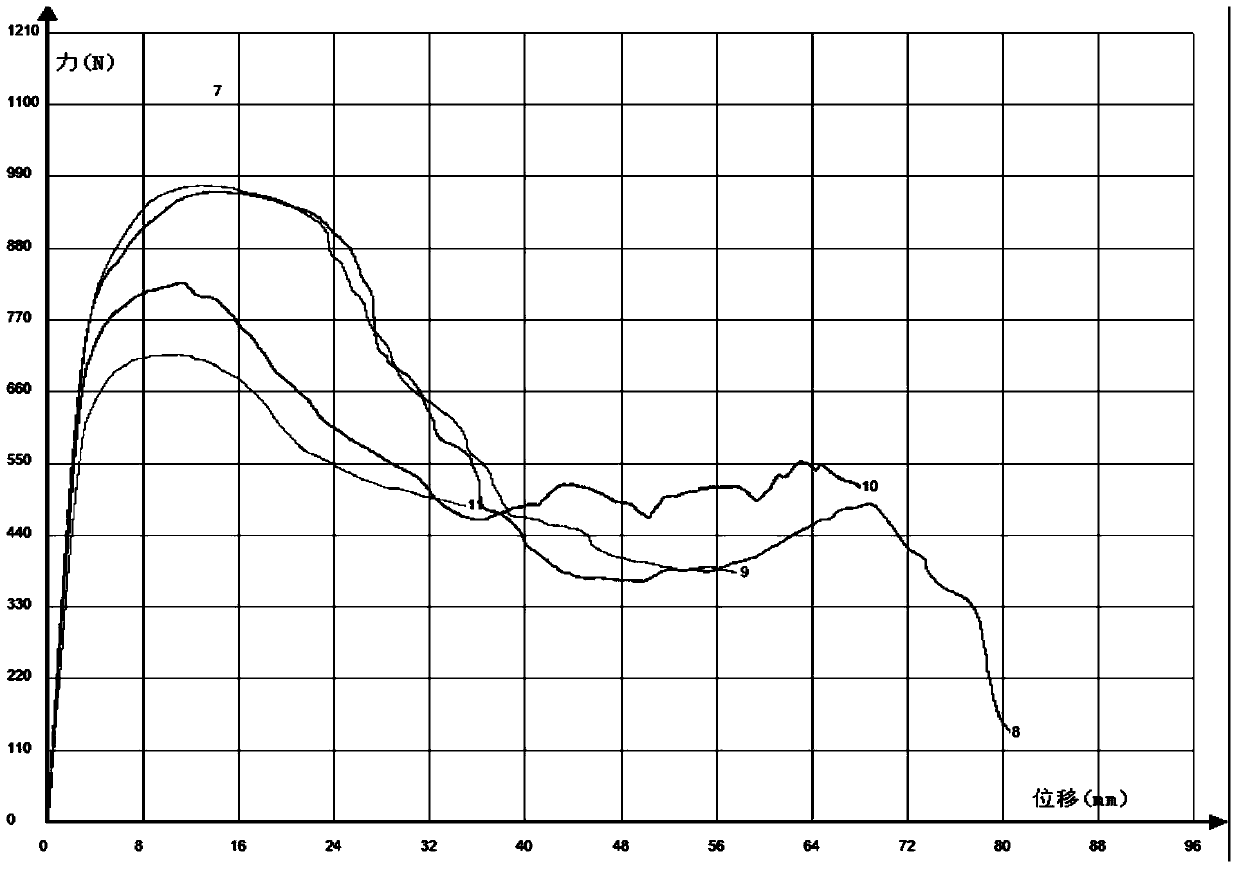

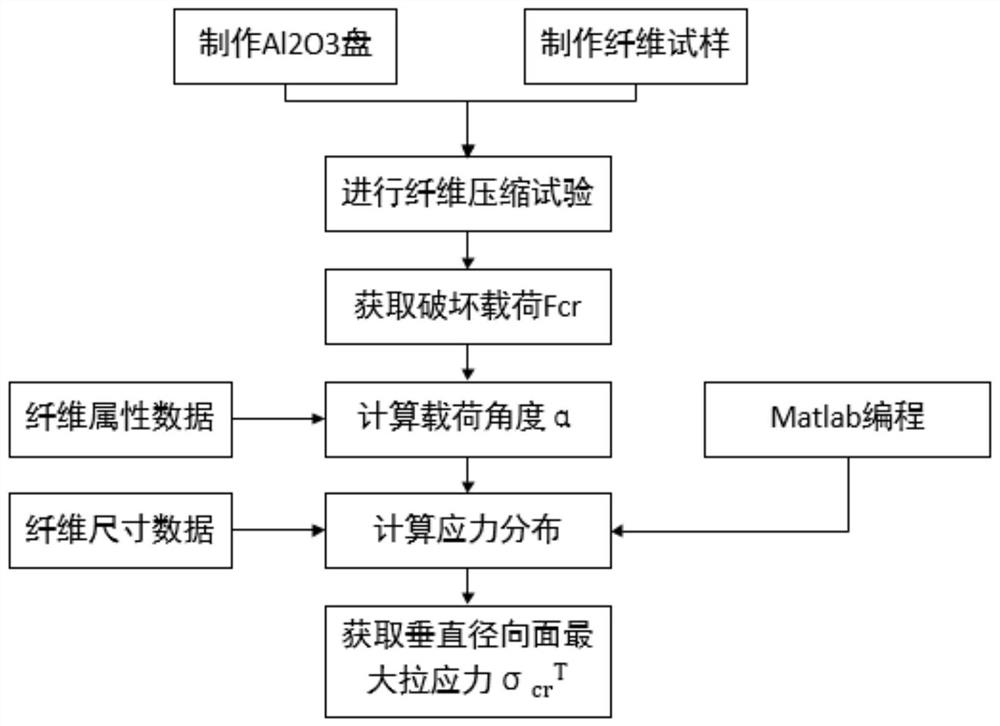

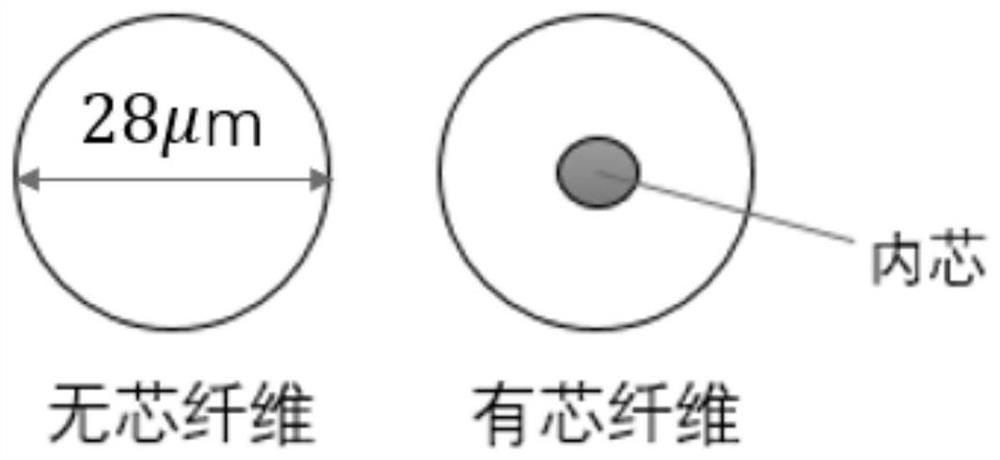

Method for predicting transverse tensile strength of coreless brittle fibers

PendingCN111855401AImprove calculation accuracyEfficient and convenient calculation processPreparing sample for investigationMaterial strength using tensile/compressive forcesFiberElement analysis

The invention provides a method for predicting the transverse tensile strength of coreless brittle fibers. The method comprises the following steps of: step 1, preparing a fiber sample; 2, carrying out a fiber compression test by using a nanoindentor to obtain fracture load data; and 3, calculating a load contact angle according to the fracture load, establishing a fiber compression model, and substituting the fracture load and the load contact angle into the fiber compression model to calculate the stress of the vertical radial surface of a fiber, the stress at the circle center of the vertical radial surface of the fiber being the maximum transverse tensile strength of the fiber sample. The method is high in calculation precision; the influence of the size of a compression contact surface on the internal stress distribution of the fiber is considered; the comparison conformity of a calculation result and a finite element analysis result is high. The calculation process of the methodis efficient and convenient; the transverse tensile strength of the fiber can be calculated only by modifying the contact surface angle and the fracture load, and a series of complex operations such as establishing a model by a finite element method, dividing a load area with a certain angle on a curved surface, applying a constraint load and dividing grids are avoided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

High-strength reinforced concrete pipe culvert and preparation method thereof

The invention discloses a high-strength reinforced concrete pipe culvert and a preparation method thereof. The preparation method includes the steps that firstly, shell calcined matter is soaked into activation liquid, and then activated shell calcined matter is obtained through filtering, drying and screening; secondly, cement, the activated shell calcined matter, pebbles, sand, coal ash and water are mixed so that concrete can be prepared; thirdly, the concrete is poured into a reinforcement cage, and then the high-strength reinforced concrete pipe culvert is prepared through curing, wherein the activation liquid comprises water, hydrochloric acid, sulfurous acid and dimercaprol dimercaptopropanol. The high-strength reinforced concrete pipe culvert prepared through the method has excellent fracture load and failure load indexes.

Owner:ANHUI YUTE CONCRETE STRUCTURE TECH

Apparatus, system and method for compression testing of test specimens

ActiveUS9182330B2Material strength using tensile/compressive forcesOptical apparatus testingFracture loadBiomedical engineering

There is provided an apparatus for compression testing. The apparatus has a base assembly having an end load element attached to the base assembly, the base assembly being rigid. The apparatus has a support assembly attached to the base assembly, and having a plurality of window portions. The apparatus has a core assembly installed within the support assembly, the core assembly being crushable and configured to protect the support assembly and the base assembly from fracture loads generated during compression testing. The base assembly, the support assembly, and the core assembly together form an apparatus for compression testing of a test specimen having a notch portion. The apparatus is configured for use with an optical strain measurement system. When the test specimen is installed in the support assembly, the test specimen and the notch portion are visible to the optical strain measurement system through the plurality of window portions.

Owner:THE BOEING CO

Testing machine cellfiber clamper and method for measuring tensile strength

InactiveCN101251455BGuaranteed verticalityThe strain value is scientific and accurateMaterial strength using tensile/compressive forcesSingle fibreEngineering

The invention provides a tester single fibre clamp and a tensile strength measuring method relating to a clamp and tensile strength measurement. The invention provides a tester single fibre clamp and a method for measuring the tensile strength of ceramic single fibre. The clamp is provided with an upper collet device of a tester, a load sensor, a tenaculum device, an upper and lower clamping device, a horizontal adjusting device and a lower collet device of the tester. The adjusting clamp in proper alignment measures the load linearity in vertical direction and rectifies the focus of a photoelectric extensometer; the parameters of an measuring program are set; single fibre is put on the centerline of a hole of a square paper frame, then placed in the middle of the upper and lower clampingdevice; the vertical direction of the single-fibre is adjusted; the edge of the square paper frame is burned off; a strain collecting device is started to trace the edge distance between the upper and the lower paper frames; a tensile program is started up to begin the measurement; the relation between the load and the strain is recorded to obtain a fibre fracture load value and deformation data,thereby measuring a fibre strain value; a diameter value of a fracture is observed and input to the tester in order to acquire the fracture strength of the single fiber.

Owner:XIAMEN UNIV

Wood flame retardant and application thereof

InactiveCN106553248AImprove flame retardant performanceLow toxicityWood treatment detailsWood veneer joiningFireproofingLow toxicity

The invention relates to the technical field of wood processing and particularly relates to a wood flame retardant and an application thereof. The wood flame retardant includes, by weight, 25-35 parts of melamine, 30-40 parts of boron acid, 10-15 parts of zinc borate, 10-20 parts of zinc sulfate, and 10-15 parts of sodium tripolyphosphate. The raw materials of the wood flame retardant have synergistic flame retarding effects, so that the flame retardant is good in flame retarding effect, is low-toxicity, has good smoke inhibition property and is environment-friendly, and is also low in cost. Flame retarding plywood produced from the flame retardant is significantly improved in flame retarding performance, which can reach C-level fireproofing grade in national standard. Bonding strength and maximum fracture load of the plywood are approximated to plywood produced without the flame retardant.

Owner:防城港市林木良种繁育中心苗圃

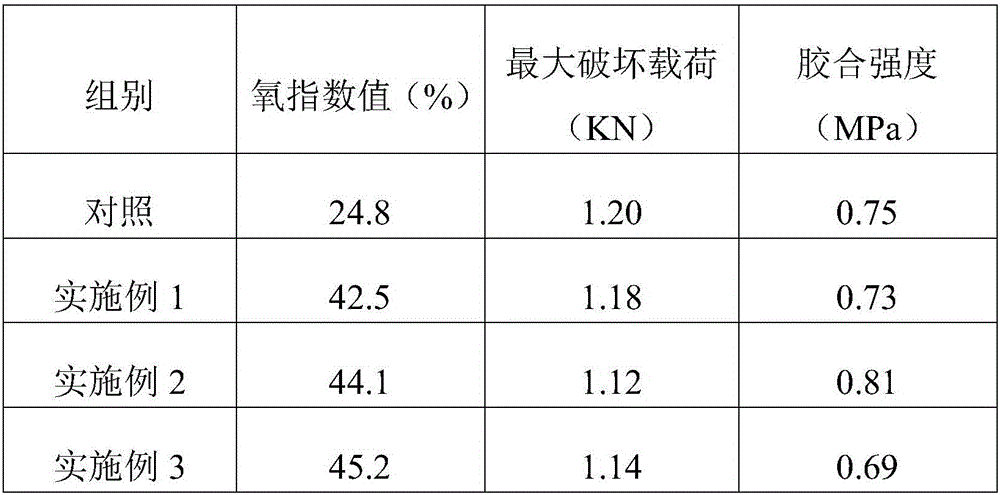

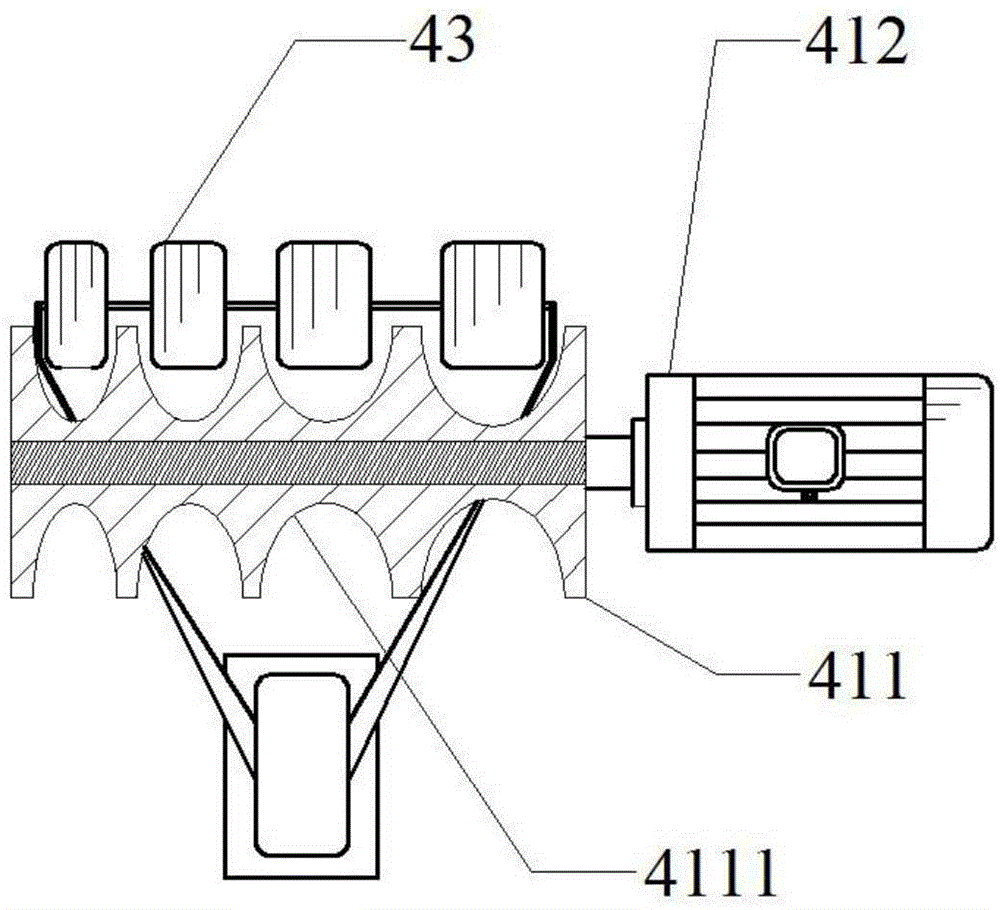

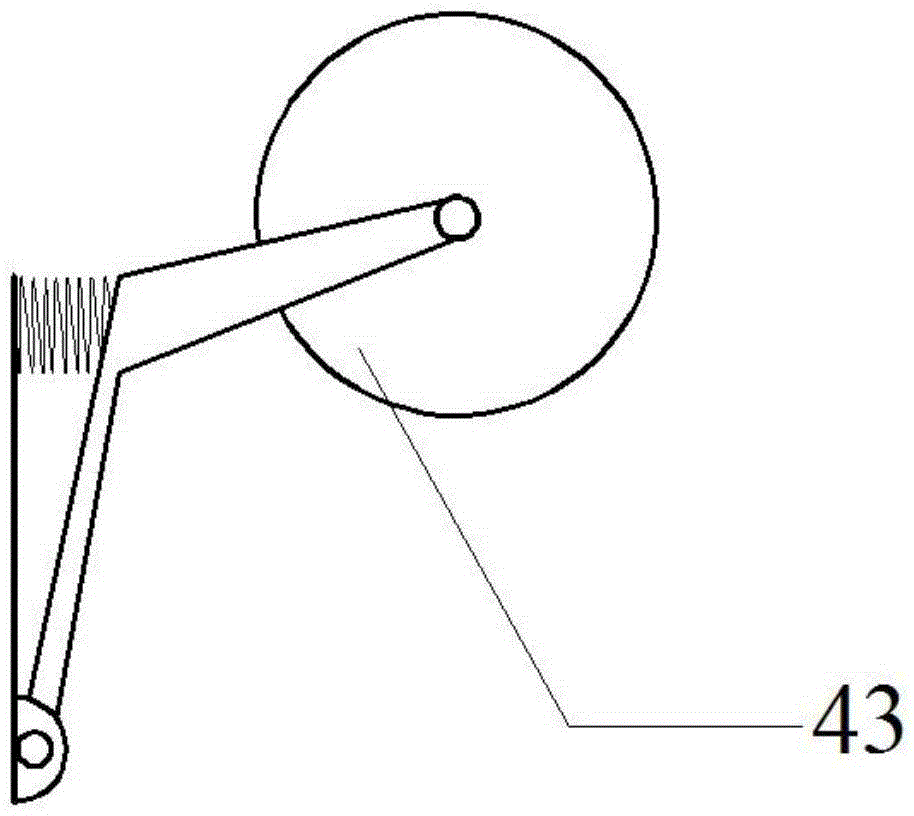

After treatment equipment for ropes

ActiveCN104452380AImprove drying efficiencyIncrease breaking loadRope making machinesMicrowaveAfter treatment

The invention relates to the field of after treatment equipment for ropes, in particular to after treatment equipment for ropes. The equipment comprises a main bracket, a coating mechanism, a drying mechanism, a drafting mechanism and a control box, wherein the main bracket is cuboid, the length of the main bracket is 10500 mm-11500 mm, and the height of the main bracket is 3000 mm-3200 mm; the drying mechanism comprises a microwave heating device and a hot blast box heating device, wherein a plurality of rotating wheels are arranged at the lower end of the microwave heating device and the inner part of the hot blast box heating device, and the rotating wheels are uniformly arrayed in the width direction of the drying mechanism; the drafting mechanism comprises a first drafting mechanism, a second drafting mechanism and compaction wheels, and each drafting mechanism comprises a plurality of traction rollers. The equipment disclosed by the invention uses the microwave heating device and the hot blast box heating device, so that the drying efficiency of the ropes is greatly improved; the drafting mechanism is additionally arranged, so that the fracture load of the ropes can be effectively increased, the layout and the deployment are reasonable, the controllability is strong, and the applicable range is wide.

Owner:QINGDAO HUAKAI OCEAN SCI & TECH

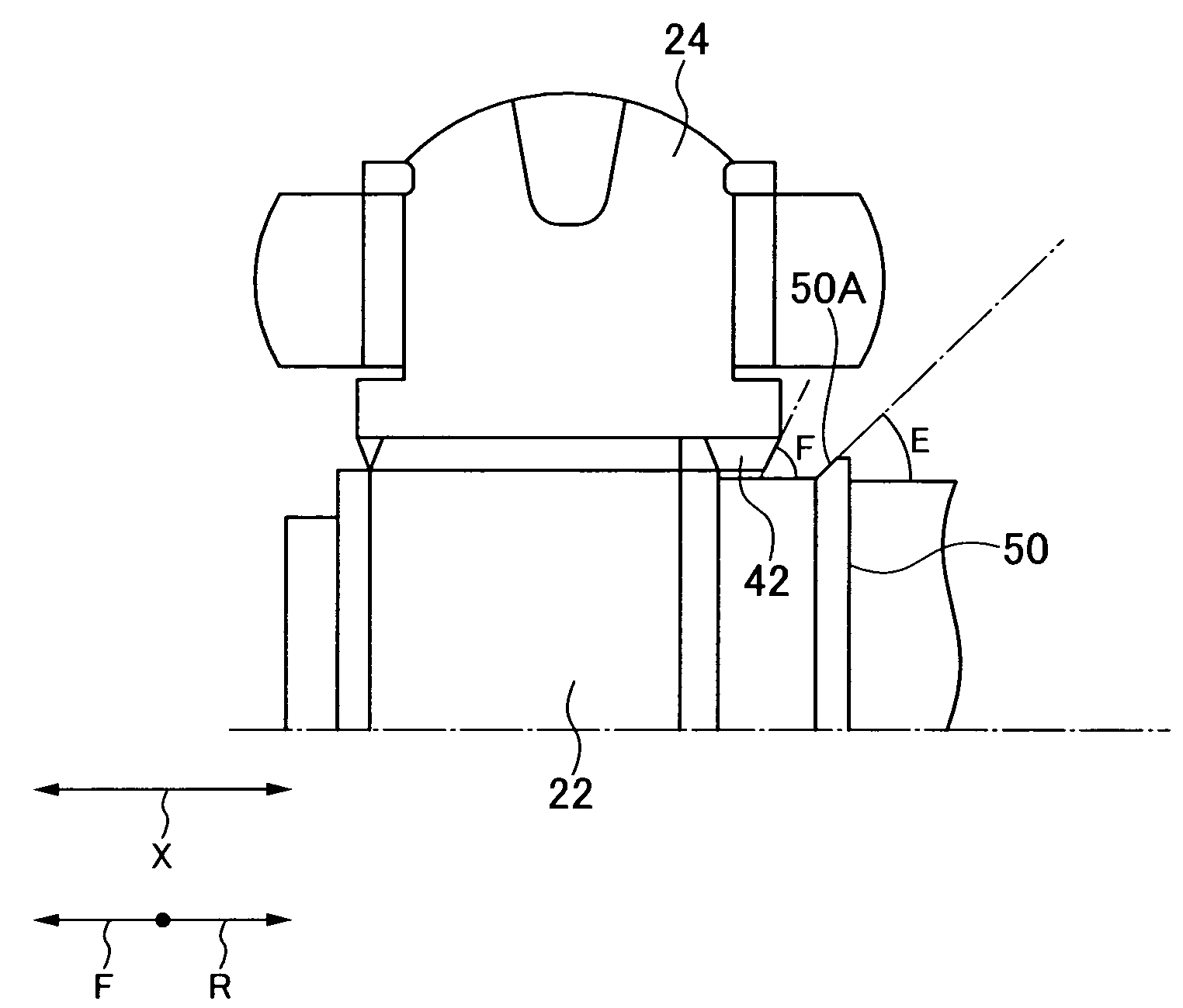

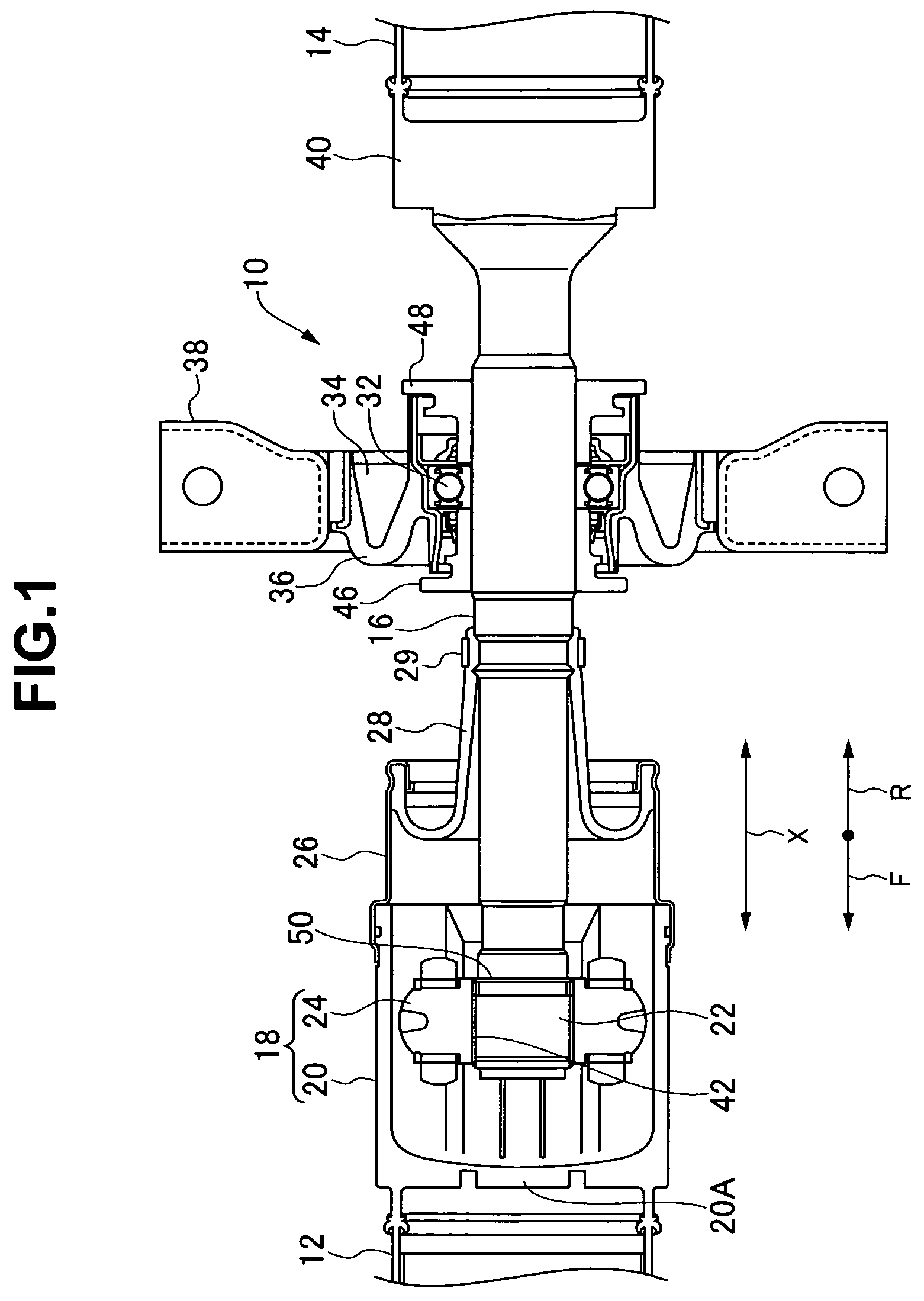

Shock absorbing structure of propeller shaft

InactiveUS7717796B2Crack and fracturePrevent and crack and fracture and likeYielding couplingShaftsStress concentrationPropeller

When an inner ring portion of a tripod is brought into contact with a protruding portion, the inner ring portion is brought into contact with the protruding portion because an outer diameter of the protruding portion is smaller than a diameter of a tilted outer end portion of the inner ring portion. Since the inner ring portion is tilted with respect to an axial direction, the inner ring portion is brought into contact with the protruding portion by a point (a line) not by a surface. If the inner ring portion is brought into contact with the protruding portion by the point, a stress concentration is generated at the point with which the protruding portion is brought into contact, a small impact force overcomes a breaking load of the protruding portion in the stress concentration portion, and the stress concentration portion is easily broken (plastically deformed). Accordingly, it is possible to easily break the protruding portion, and even if there is a dimensional error of the protruding portion or the like, it is possible to make a load breaking the protruding portion approximately constant.

Owner:SHOWA CORP

Method for producing round-link chain

The invention discloses a method for producing a round-link chain, which comprises the following steps: A1) raw material selecting: adopting high-quality alloy steel 23MnNiMoCr54; A2) baiting, wherein baiting demands are as follows: being capable of standing, being free from burr and chamfer, and keeping a length error of a bar stock being plus / minus 0.5mm; A3) hotly chaining: bending the bar stock into a chain in a given size under the action of hydraulic power of a chaining machine; A4) ball blast: removing an oxide skin from the surface, preparing for the next process and ensuring the welding quality; A5) welding and removing the burs; A6) heat treatment; A7) stretching and calibrating: once stretching under a stretching load being 80% of a fracture load; and A8) checking, pairing, painting and placing the chain into a storage. By using the method, the efficiency of producing the round-link chain is increased and the cost is lowered. The fracture load, a coefficient of elongation under a test load, a fracture elongation coefficient and a fatigue life of the round-link chain all meet the national standard.

Owner:SHANDONG LIANGDA FASING ROUND LINK CHAINS

Ecological shell sound-absorbing panel and preparation method thereof

ActiveCN106242481BHigh bending failure loadImprove sound absorptionSolid waste managementCarrageenanSoluble glass

The invention discloses an ecological shell acoustic panel and a preparation method thereof, belonging to the technical field of functional decoration materials for buildings. The ecological shell acoustic panel is prepared from the following raw materials by weight: 30 to 65 parts of blocky shell, 5 to 13 parts of shell powder, 5 to 13 parts of heavy calcium, 1 to 3 parts of sodium hexametaphosphate, 1 to 3 parts of guar gum, 0.5 to 3 parts of carrageenan, 0 to 10 parts of sodium alginate, 0 to 10 parts of water, 10 to 20 parts of paper pulp, 1 to 5 parts of dried Enteromorpha and 1 to 5 parts of a soluble glass adhesive. The ecological shell acoustic panel provided by the invention has high bending fracture load, good sound absorption effect and a noise reduction coefficient of greater than 0.25; the panel does not contain gypsum and is free of the phenomenon of swelling due to water absorption; the main component of the panel is shell, so the panel has excellent air permeability and moisture absorption and releasing performance and good mildew resistance and antibacterial effect and is applicable to a wet environment.

Owner:青岛万源生物科技有限公司

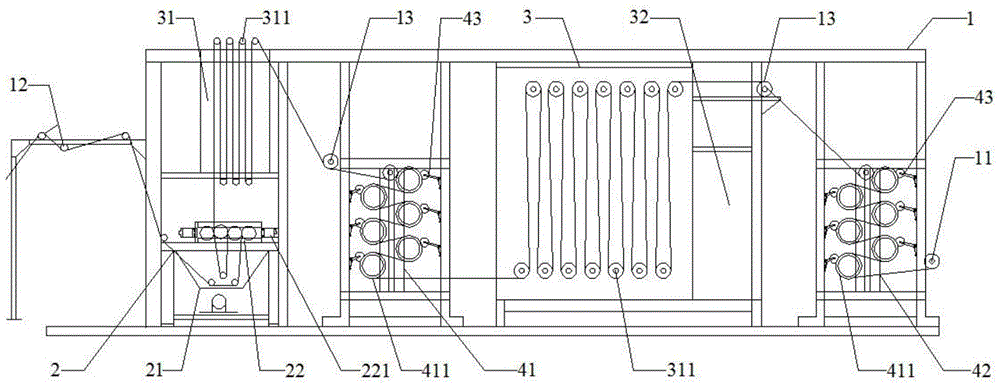

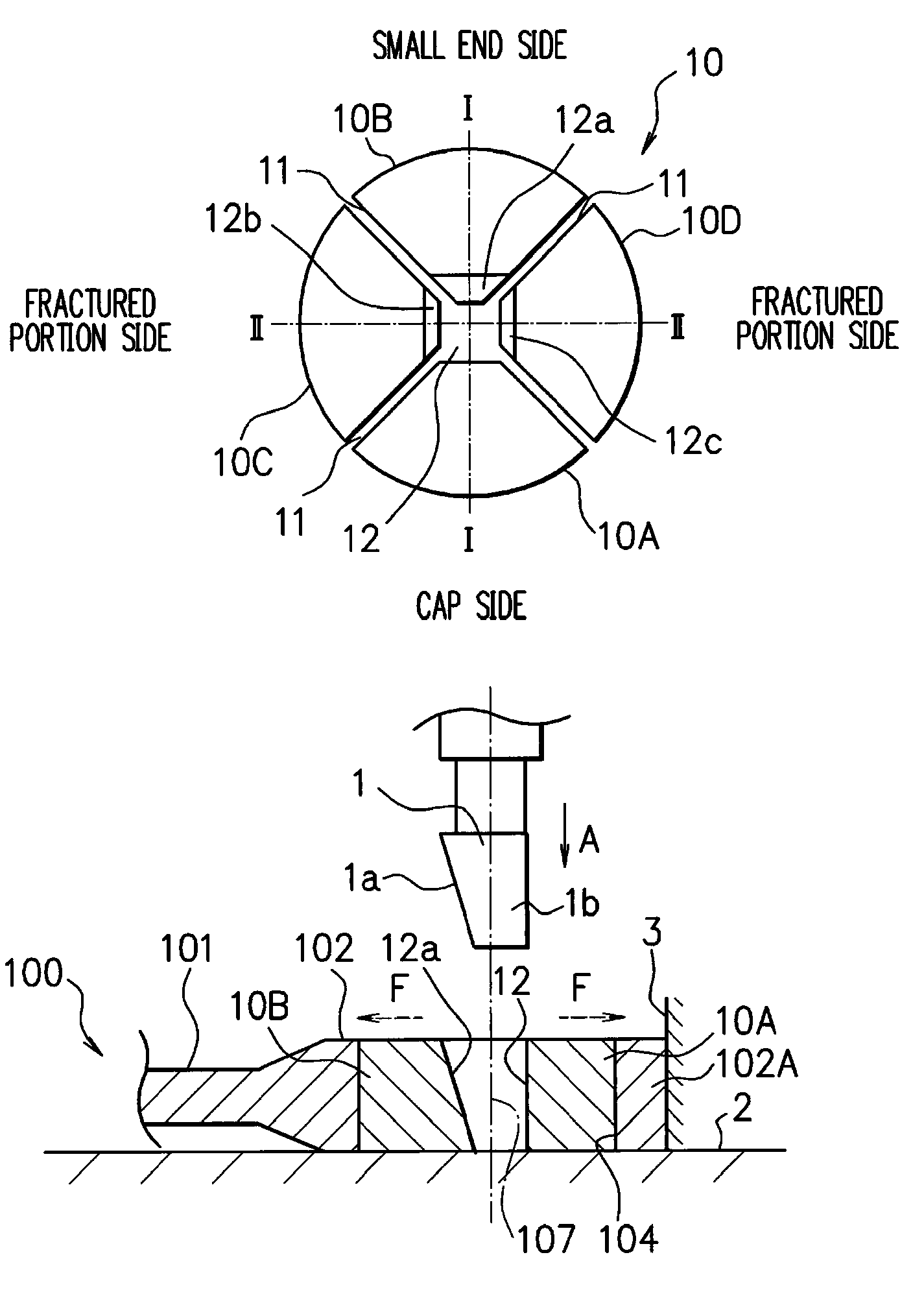

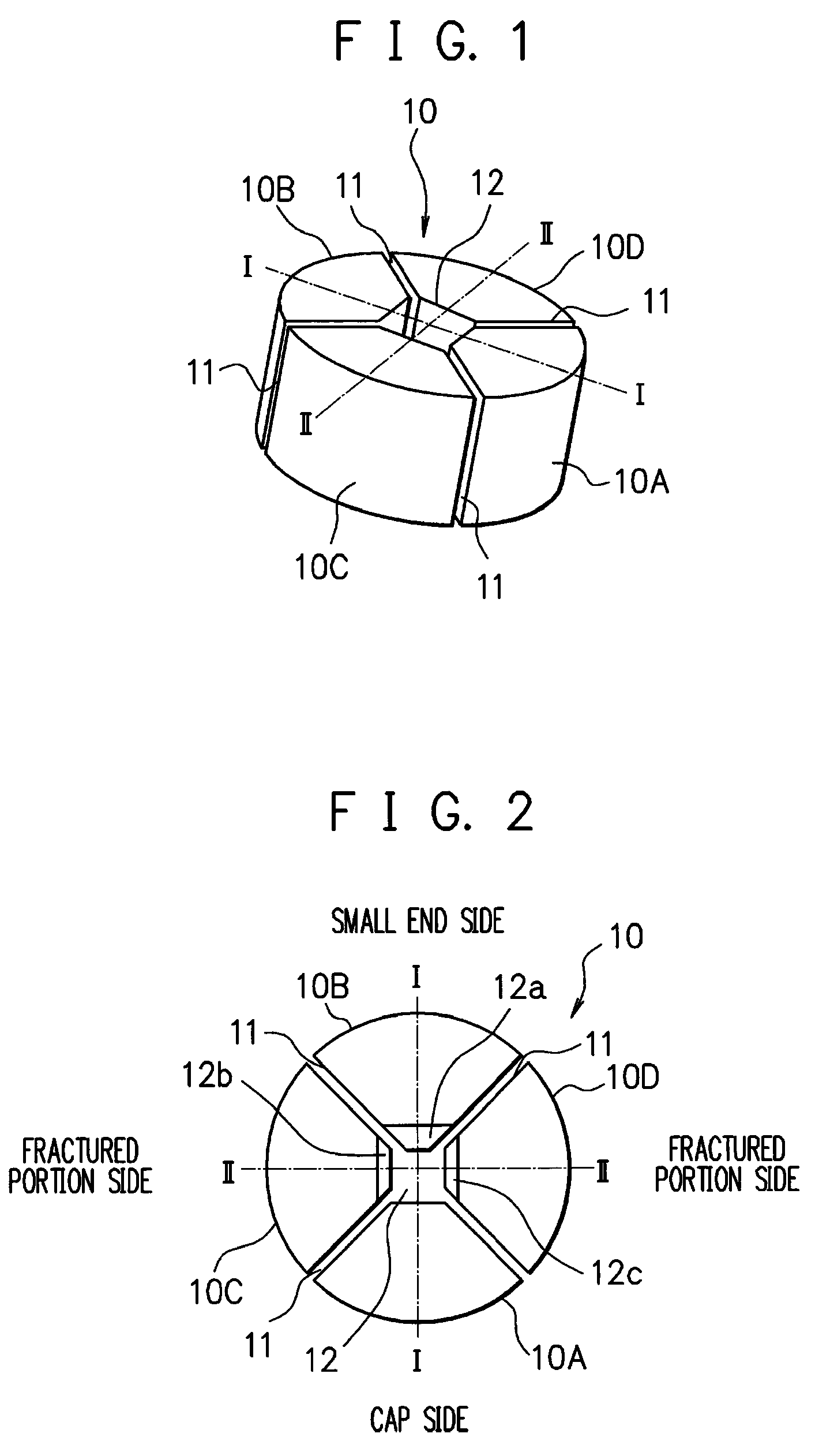

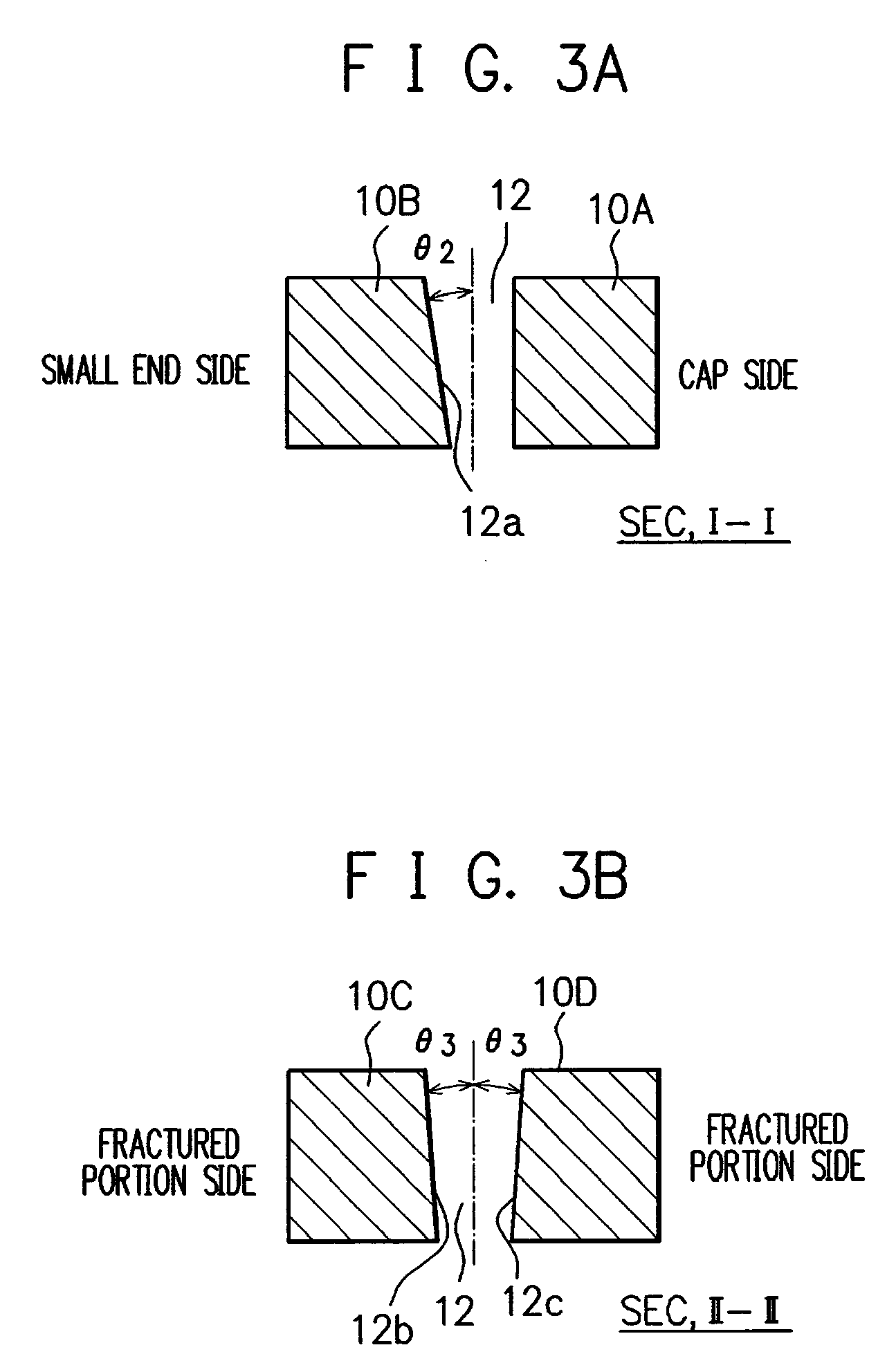

Connecting rod fracture splitting apparatus and fracture splitting method

InactiveUS8657171B2Promote circulationGuaranteed uptimeMetal working apparatusBearingsEngineeringFracture load

A fracture splitting jig is fitted into a crank pin hole of a connecting rod, and a fracture load is applied in a longitudinal direction of the connecting rod via the fracture splitting jig to thereby fracture a big end of the connecting rod. A mandrel as the fracture splitting jig is divided into four parts to be separable from each other in a longitudinal direction of the connecting rod and in a direction orthogonal to the longitudinal direction. When the big end is fractured, a fractured portion thereof is allowed to come in contact with a predetermined portion of the fracture splitting jig.

Owner:SUZUKI MOTOR CORP

Production technique for bar shaped porcelain insulator used for overhead line system of G-series high-speed train

InactiveCN107871567AImprove electromechanical performanceGood antifoulingInsulatorsPass rateNano al2o3

The present invention disclosed a kind of high -speed rail contact network for the production process of stick -shaped porcelain insulator. In the ball milling, the total quality of the raw materials in the ball milling is as follows, and the high aluminum aluminum soil is 30-45 % WT;Yonggaolin 15-20 % WT; Jiangbei clay is 2 to 6 % WT; 3-6 % WT in Kaolin in Guizhou; 1 to 3 % WT in Bi Ji mud; 3 to 5 % WT in Changshi; 0.3 ~ 0.5 % WT of nano alumina powder.The invention has prepared a stick -shaped porcelain insulator for the high -speed rail contact network with excellent mechanical and electrical performance through the selection of the raw material in the formula.; Porcelain inspection, electrical inspection, and glue are high, and the production quality is stable; the product meets the use of 350km / h and above high -speed rail contact network.

Owner:QINGDAO DONGHAO SOFTWARE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com