Preparation method of high-strength wood-plastic composite section bar

A composite profile and high-strength technology, which is applied in the preparation of wood-plastic composite profiles and high-strength wood-plastic composite profiles, can solve the problems of low strength of wood-plastic floors, improve assembly efficiency, save production costs, and improve bending The effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

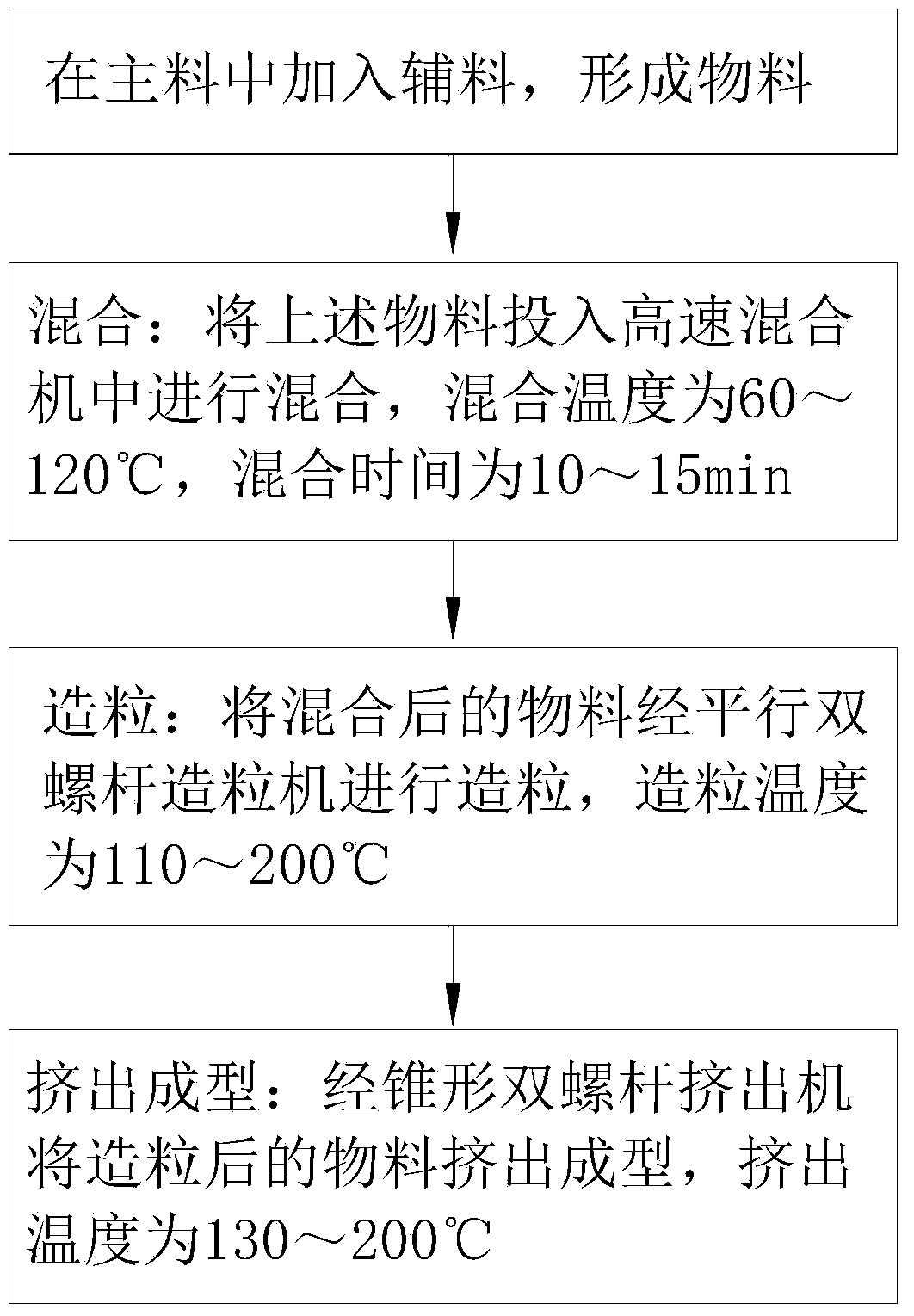

[0026] A method for preparing high-strength wood-plastic composite profiles, using wood powder or bamboo powder as the main material, the particle size of the wood powder or bamboo powder is 80-100 mesh, and it includes the following steps:

[0027] The first step is to add auxiliary materials to the main material to form a material. The material components include: 100-150 parts of wood powder or bamboo powder, 100 parts of polyolefin resin, 5-15 parts of filler, 5 parts of coupling agent ~10 parts, lubricant 10~15 parts. The following optional components can also be added to the material, 1-5 parts of anti-aging agent, 3-5 parts of antibacterial agent, and 1-10 parts of coloring agent.

[0028] The polyolefin resin is one or a combination of PE and PP. In order to further recycle waste plastics and promote recycling of resources, the polyolefin resin can also be recycled PE plastics (PE containing a small amount of PP) or recycled PP plastics.

[0029] The filler is a comb...

Embodiment 1

[0038] Please also refer to Figures 1 to 2 , 100 parts of wood powder (80 mesh), 100 parts of PE plastic, 5 parts of filler, 5 parts of coupling agent, 10 parts of lubricant, 1 part of anti-aging agent, 3 parts of antibacterial agent, 1 part of coloring agent is put into a high-speed mixer for mixing, and then the mixing speed is set to 500 rpm, the mixing temperature is 60°C, and the mixing time is 12 minutes.

[0039]Next, the mixed materials were put into a parallel twin-screw granulator for granulation, the granulation temperature was set at 110° C., and the screw speed was set at 200 rpm.

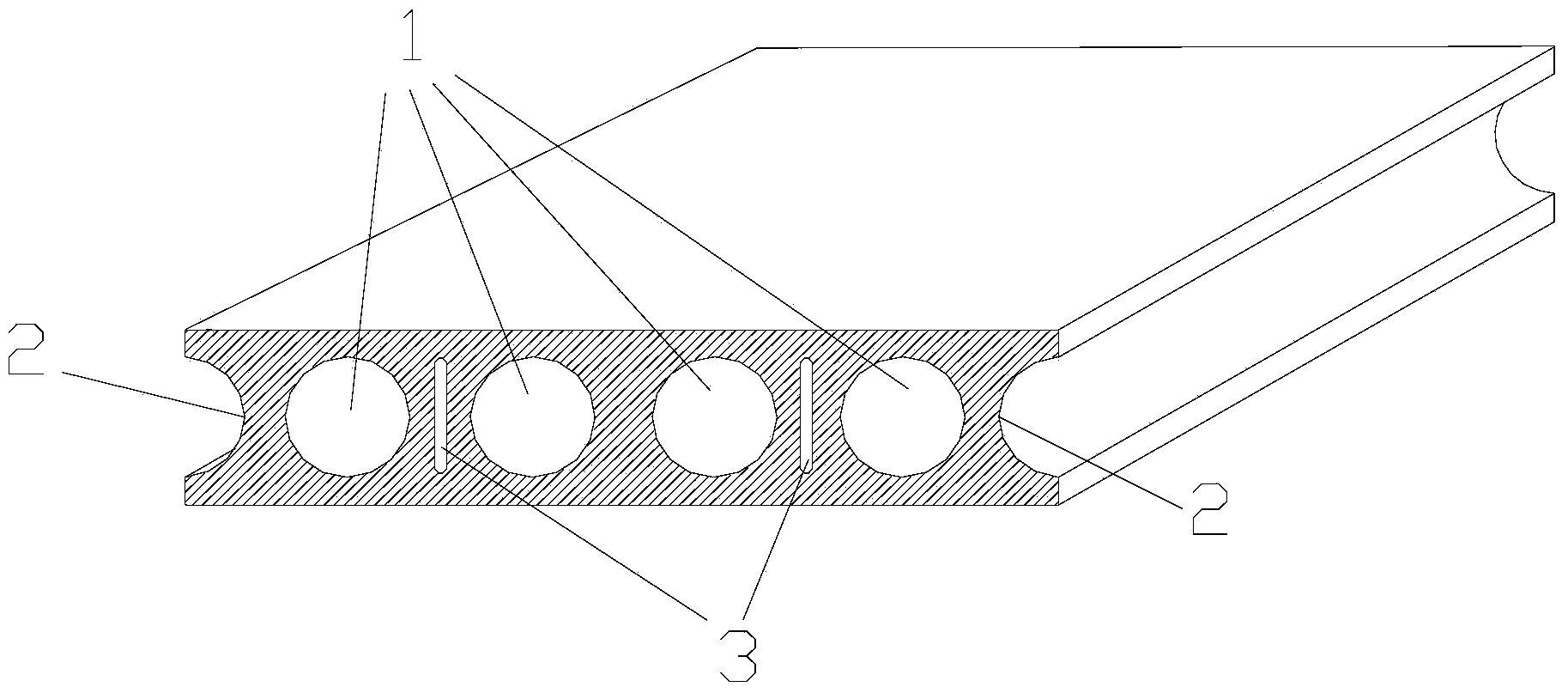

[0040] Then the above-mentioned granulated material is extruded through a conical twin-screw extruder connected to a special die for round-hole profiles. The extrusion temperature is set at 130 ° C. After cooling and shaping, cutting, both sides are made with arc-shaped grooves. In the middle is a substrate with a circular hole structure. Finally, the surface of the above-mentioned ...

Embodiment 2

[0043] 120 parts of bamboo powder (100 mesh), 100 parts of PP plastic, 15 parts of filler, 10 parts of coupling agent, 15 parts of lubricant, 5 parts of anti-aging agent, 5 parts of antibacterial agent, 10 parts 1 part of coloring agent, put them into a high-speed mixer for mixing, and then set the mixing speed to 800 rpm, the mixing temperature to 100°C, and the mixing time to 10 minutes. Next, the mixed materials were put into a parallel twin-screw granulator for granulation, the granulation temperature was set at 200° C., and the screw speed was set at 300 rpm. Then the above-mentioned granulated material is extruded through a conical twin-screw extruder connected to a special die for round-hole profiles. The extrusion temperature is set at 180 ° C. After cooling and shaping, cutting, both sides are made with arc-shaped grooves. In the middle is a substrate with a circular hole structure. Finally, the surface of the above-mentioned substrate is polished, embossed or wire-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Flexural modulus of elasticity | aaaaa | aaaaa |

| Bending failure load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com