Wood composite flame retardant and preparation method thereof

A composite flame retardant and wood technology, applied in wood treatment, impregnated wood, wood impregnation, etc., can solve the problems of poor loss resistance and aging resistance, great influence on the mechanical properties of plywood, and insignificant flame retardant effect, etc. Good combustion effect, smoke suppression, friendly environment, good smoke suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

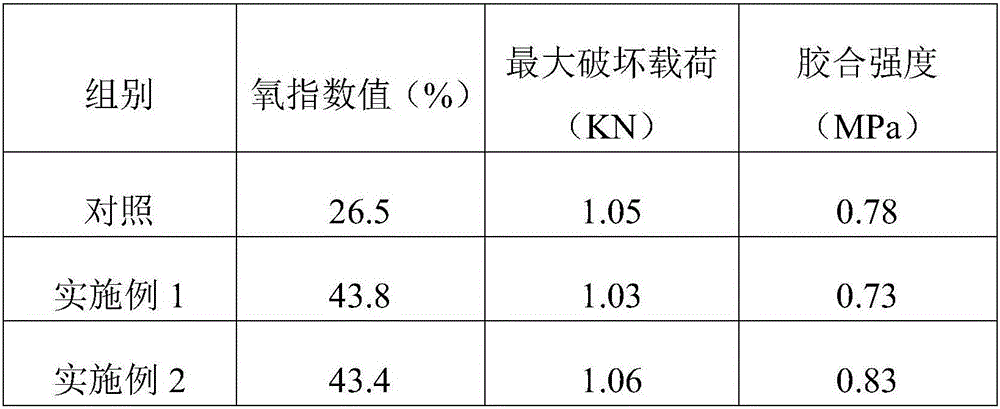

Embodiment 1

[0017] A wood composite flame retardant comprises the following raw materials in parts by weight: 25 parts of melamine, 5 parts of sodium dihydrogen phosphate, 0.1 part of sodium hydroxide, 30 parts of borax and 30 parts of boric acid.

[0018] The preparation method of the wood composite flame retardant comprises the following steps: weighing 25 parts of melamine, 5 parts of sodium dihydrogen phosphate, 0.1 part of sodium hydroxide, 30 parts of borax and 30 parts of boric acid, and adding them into a pulverizer to pulverize to 120 purpose, then mix the components, and finally add water to prepare a wood composite flame retardant solution with a mass concentration of 10%.

[0019] The application of described wood composite flame retardant in the production of flame retardant fiberboard comprises the following production steps:

[0020] (1) Select a veneer with few knots and few defects, clean the surface, dry the veneer to a moisture content of 8%, then put it into a wood com...

Embodiment 2

[0025] A wood composite flame retardant, comprising the following raw materials in parts by weight: 35 parts of melamine, 15 parts of sodium dihydrogen phosphate, 0.5 parts of sodium hydroxide, 40 parts of borax and 40 parts of boric acid.

[0026] The preparation method of the wood composite flame retardant comprises the following steps: weighing 35 parts of melamine, 15 parts of sodium dihydrogen phosphate, 0.5 parts of sodium hydroxide, 40 parts of borax and 40 parts of boric acid, respectively adding them into a pulverizer and pulverizing to 150 parts purpose, then mix the components, and finally add water to prepare a wood composite flame retardant solution with a mass concentration of 15%.

[0027] The application of described wood composite flame retardant in the production of flame retardant fiberboard comprises the following production steps:

[0028] (1) Select a veneer with few knots and few defects, clean the surface, dry the veneer to a moisture content of 10%, an...

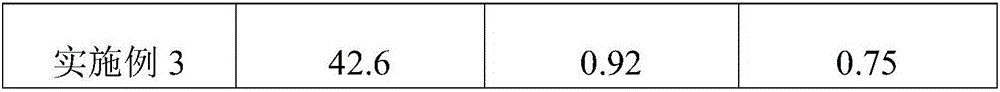

Embodiment 3

[0033] A wood composite flame retardant comprises the following raw materials in parts by weight: 30 parts of melamine, 10 parts of sodium dihydrogen phosphate, 0.3 parts of sodium hydroxide, 35 parts of borax and 35 parts of boric acid.

[0034] The preparation method of the wood composite flame retardant comprises the following steps: weighing 30 parts of melamine, 10 parts of sodium dihydrogen phosphate, 0.3 parts of sodium hydroxide, 35 parts of borax and 35 parts of boric acid, respectively adding them into a pulverizer to crush to 140 purpose, then mix the components, and finally add water to prepare a wood composite flame retardant solution with a mass concentration of 12%.

[0035] The application of described wood composite flame retardant in the production of flame retardant fiberboard comprises the following production steps:

[0036](1) Select a veneer with few knots and few defects, clean the surface, dry the veneer to a moisture content of 9%, and then soak it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com