After treatment equipment for ropes

A post-finishing and equipment technology, applied in the field of post-processing equipment for ropes, can solve the problems that the finishing equipment does not have rope performance, the rope drying efficiency is low, and the rope is optimized for processing, so as to achieve uniform stress, reasonable layout and configuration, and improve drying. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

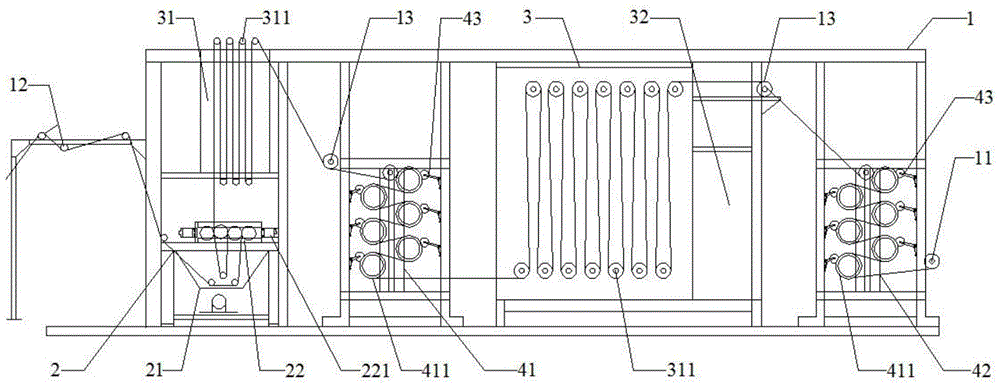

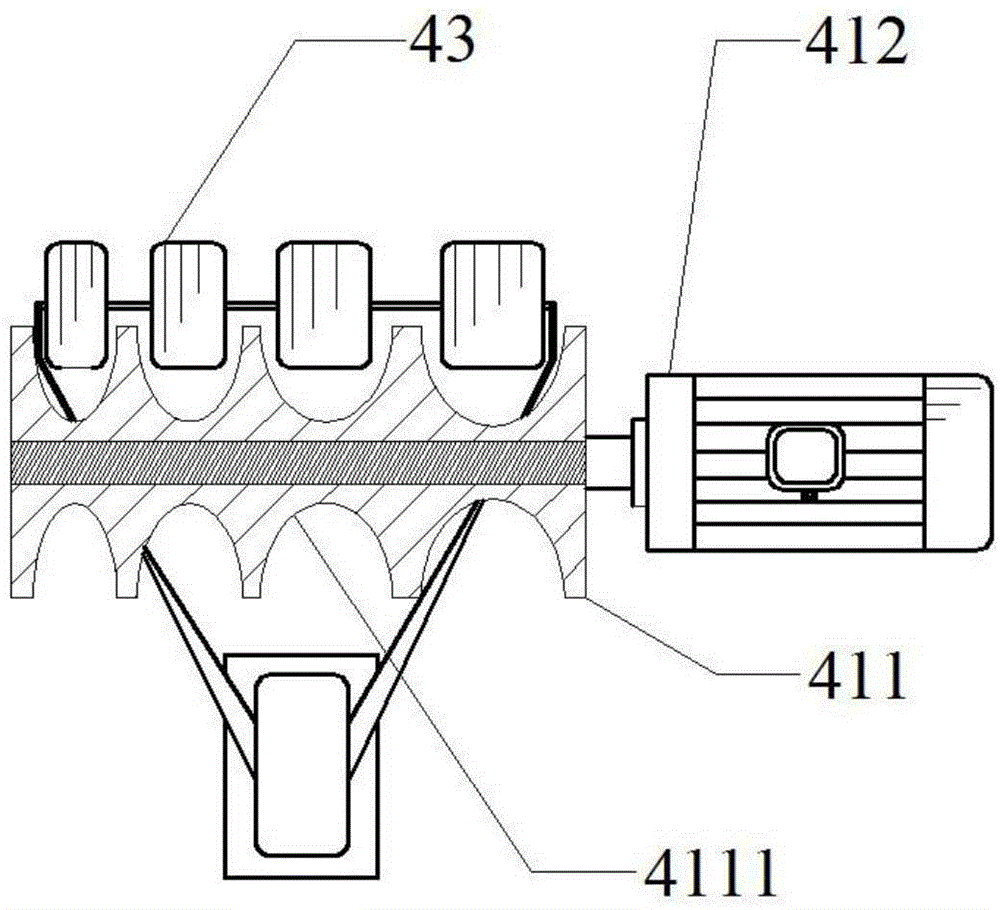

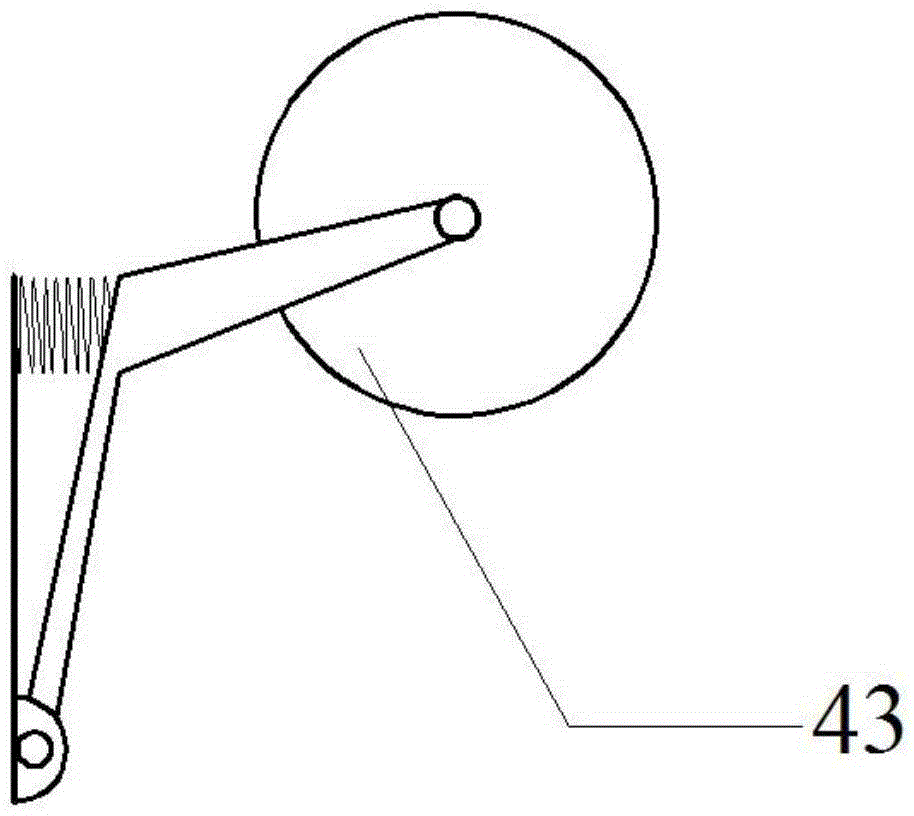

[0019] A kind of rope finishing equipment, such as figure 1 , 2 As shown, a cable finishing equipment includes a main support 1, a coating mechanism 2, a drying mechanism 3, a drafting mechanism 4, and a control box 5. The coating mechanism 2 can color, coat, and dry the cables. Mechanism 3 is used for drying the rope, and the drafting mechanism 4 is used for stretching and pulling the rope, which can increase the breaking load of the rope. The main support 1 is in the shape of a cuboid, and the length of the main support 1 is 10500mm~11500mm, the height of the main support 1 is 3000mm~3200mm, the drying mechanism 3 includes a microwave heating device 31 and a hot air box heating device 32, the microwave heating device 31 is used to pre-dry the rope, and the generated microwave can be quickly Enter the inside of the rope, and dry the rope from the inside to the outside. The hot air box heating device 32 is used to perform final drying treatment on the rope. The lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com