Patents

Literature

56results about How to "Increase breaking load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modification technique of synthetic resin impregnated timber

InactiveCN101352860AShort reaction timeIncrease productivityWood treatment detailsPressure impregnationChemistryPhenols

The invention relates to a technique for modifying synthetic resin impregnation wood and includes the following steps: 1. Preparation of impregnation solutions: liquid alkali is added into phenol at temperature of 42 to 45 DEG C and formaldehyde is added in succession at temperature of 65 to 80 DEG C, the mixture is kept for 3 to 4 hours at temperature of 70 to 85 DEG C and discharging is done after the temperature is reduced to less than 25 DEG C; 2. Impregnation: wood is added into an autoclave, and the vacuum is pumped in the pressure of 0.050 to 0.085Mpa, and the working solution of the impregnation solution is pumped in and pressure is added for 50 to 60 minutes in the condition of 0.7 to 0.9Mpa; 3. Solidification: the wood is placed into a baking oven, and the temperature rises to 90 DEG C after 3 to 4 hours and the wood is baked for 3 to 4 hours at temperature of 90 to 95 DEG C. The impregnation solution of the invention shortens the reaction time in synthesis process, improves the production efficiency, is stable in product quality and has good strengthening performance and processability; in the impregnation technique, the method for first reducing pressure and then increasing pressure is adopted, which causes the infiltration capacity of the synthetic resin to reach a stable amount and solves the problem of quality differences of the modified wood caused by different adsorption amounts of resin; compared with the solidification at temperature of 90 to 95 DEG C, the solidification at temperature of 100 to 105 DEG C causes the failure load and bending strength to increase, the wood not to embrittle and the processability to be good.

Owner:辽宁精化科技有限公司

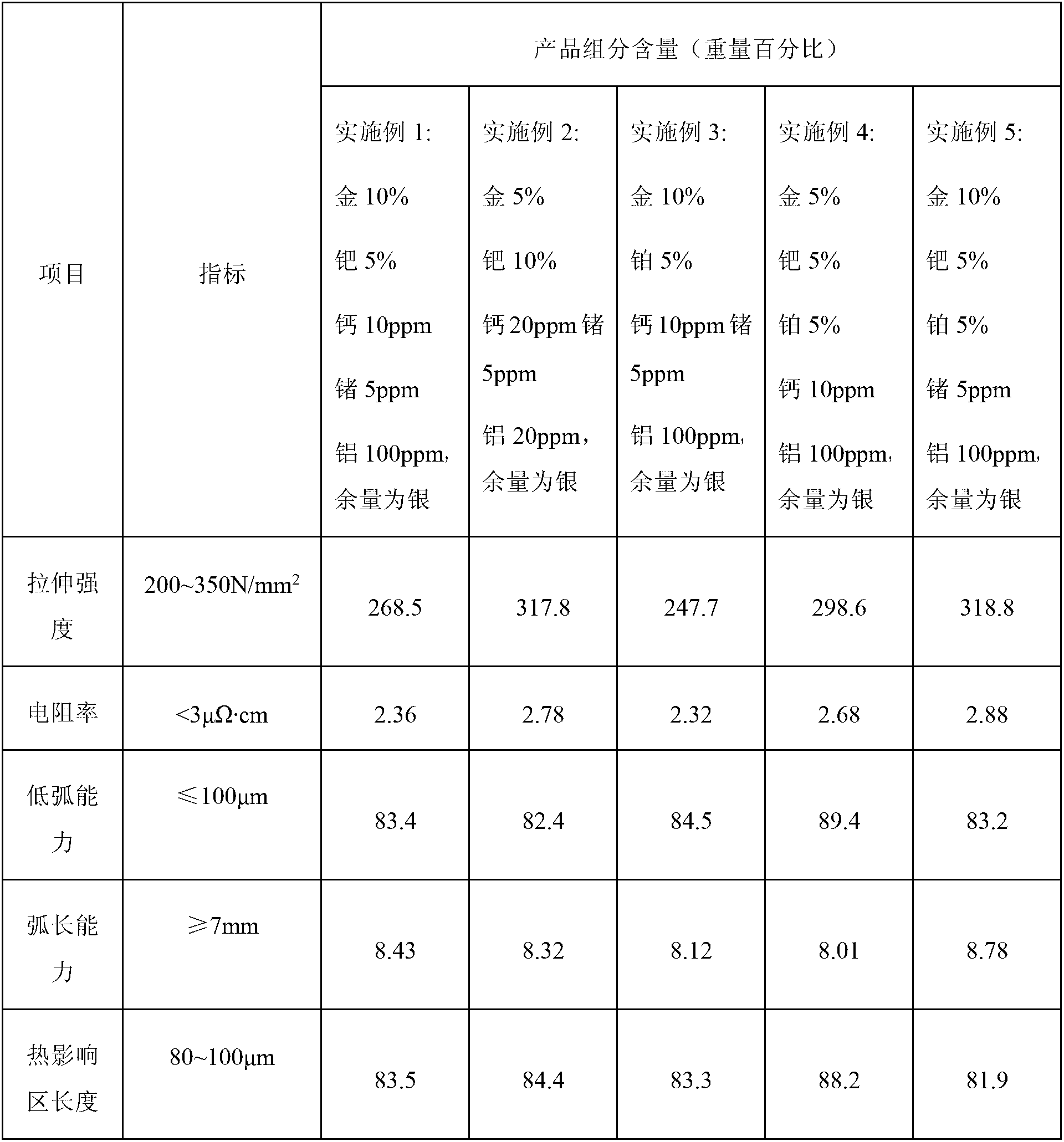

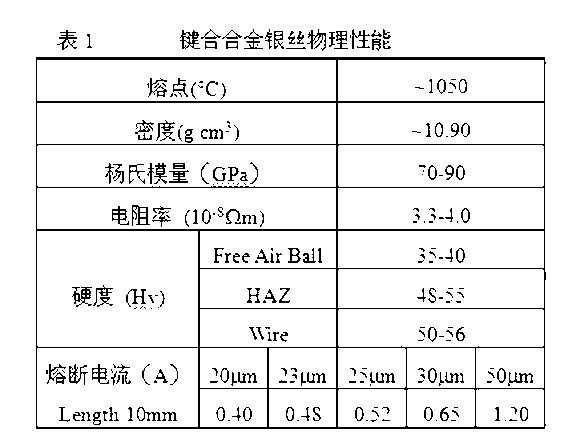

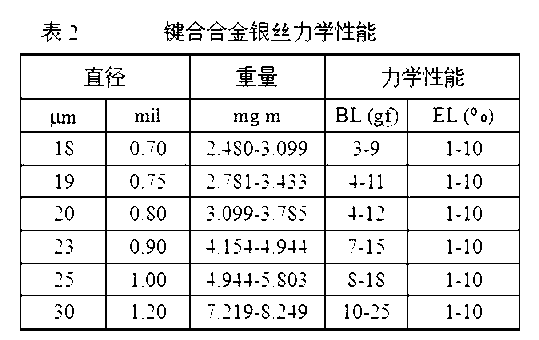

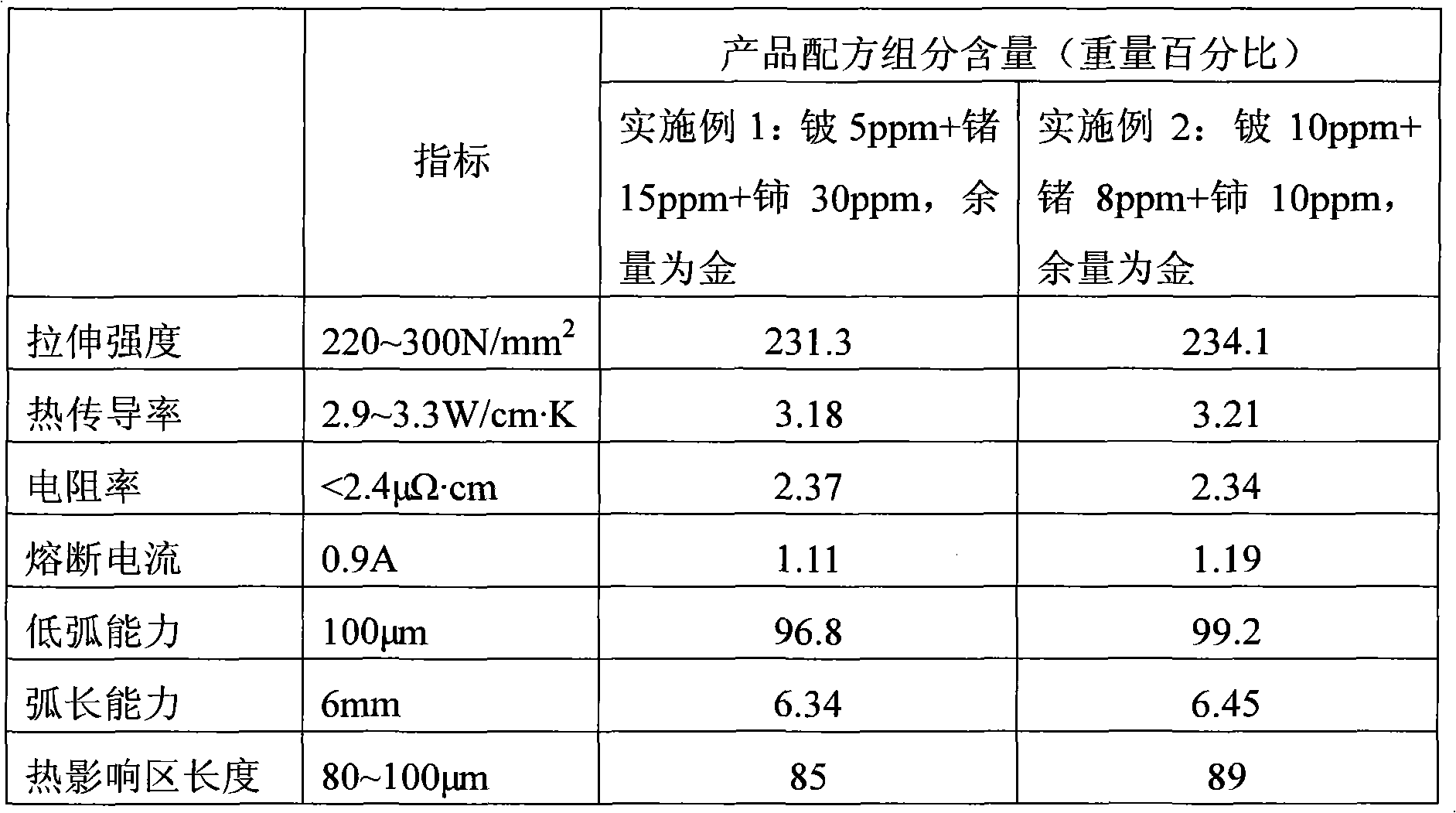

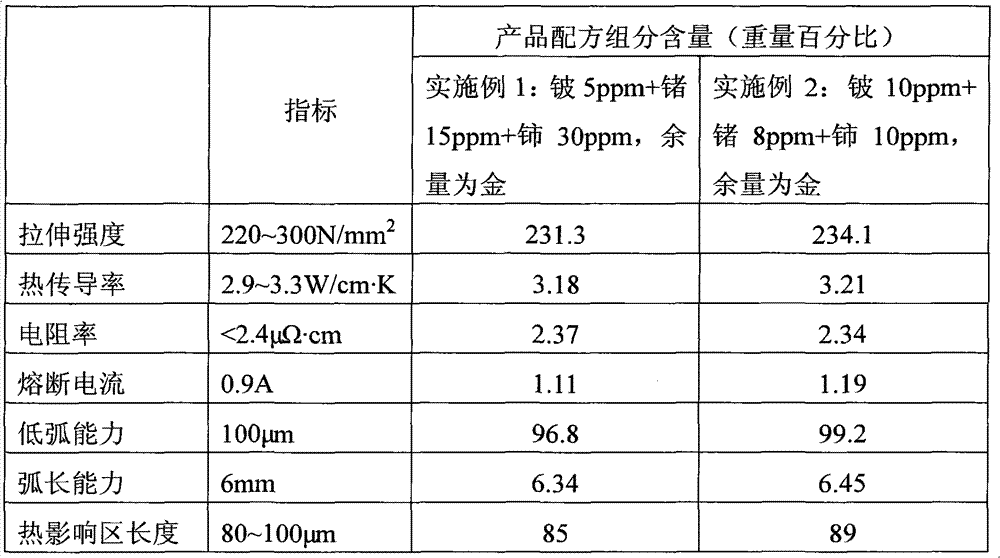

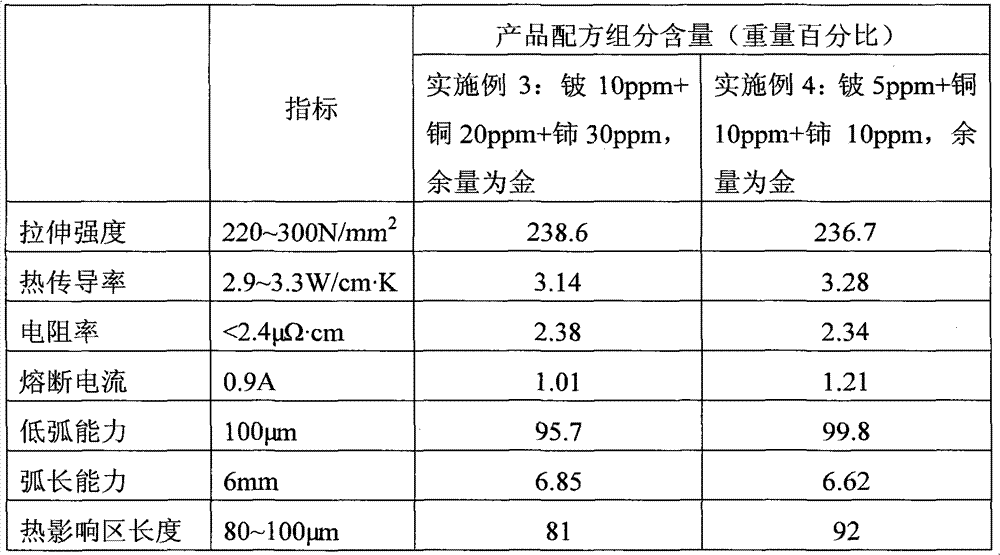

High-end packaging silver alloy bonding wire and method for manufacturing same

ActiveCN102912176AGood ball formingHigh strengthSolid-state devicesSemiconductor/solid-state device manufacturingPlatinumAlloy

The invention discloses a high-end packaging silver alloy bonding wire. The high-end packaging silver alloy bonding wire is characterized by comprising 0.0001%-20% of gold, optional one or more than one of 0.0001%-20% of palladium, 0.0001%-20% of platinum, 0.0001%-0.015% of germanium, 0.0001%-0.015% of calcium and 0.0001%-1% of aluminum, and the balance silver. The invention further discloses a method for manufacturing the high-end packaging silver alloy bonding wire. The high-end packaging silver alloy bonding wire has the advantages of high strength and low hardness and long-arc degree.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

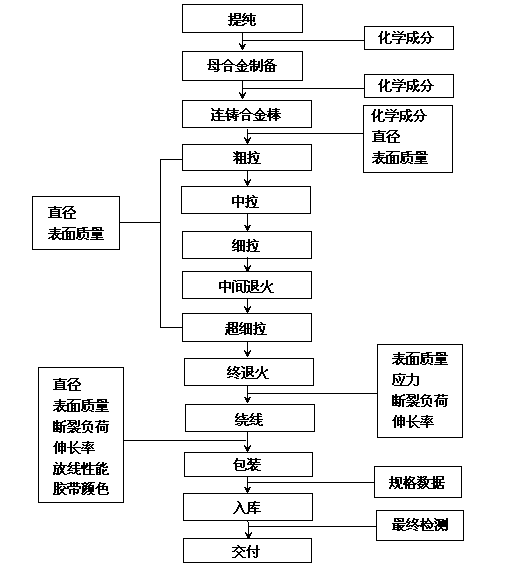

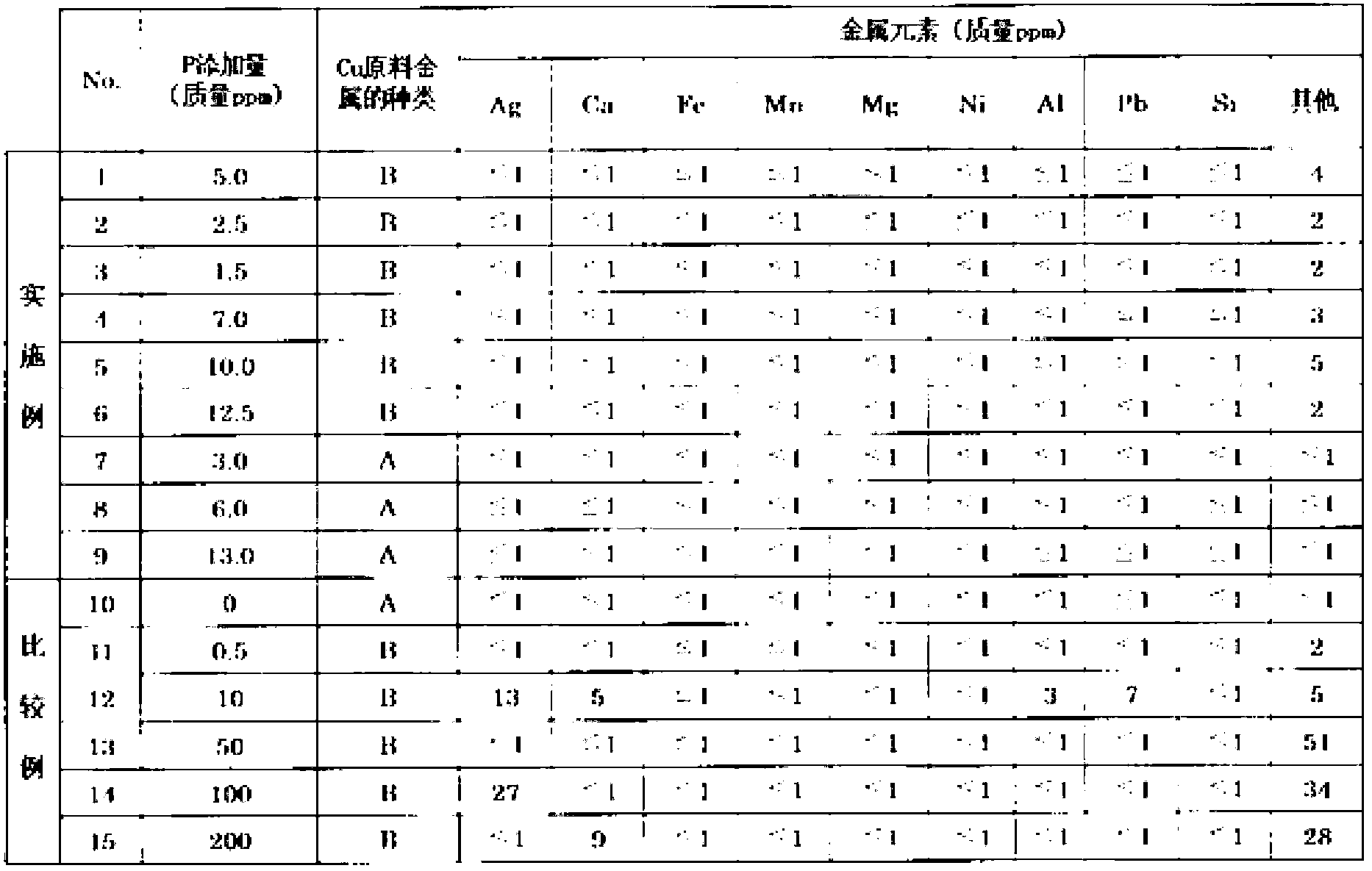

Bonding alloy filamentary silver and preparation method thereof

ActiveCN103194637AImprove conductivityAntioxidantSolid-state devicesSemiconductor devicesCeriumSemiconductor package

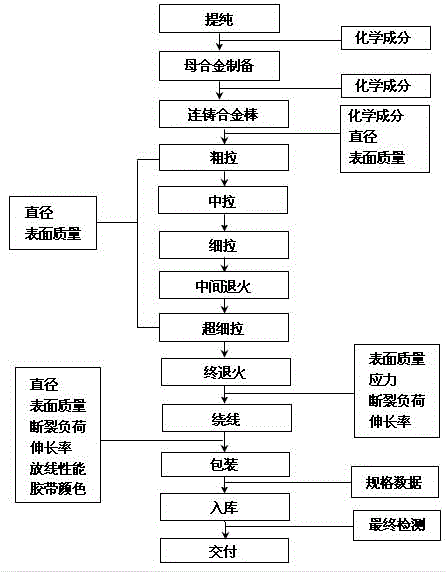

The invention relates to bonding alloy filamentary silver and a preparation method thereof, and belongs to the technical field of processing of a bonding wire. The bonding alloy filamentary silver comprises the following metal materials by mass ratio: less than 90wt% of silver, 3.0-10.0wt% of gold, and 3.0-8.0wt% of palladium; and the bonding alloy filamentary silver also comprises at least two of following metals of 10-100ppm of calcium, 4-10ppm of beryllium, 10-100ppm of cerium, and 50-500ppm of copper. The preparation method comprises the steps of 1) preparing materials; 2) smelting mother alloy; 3) continuously casting an alloy rod; 4) roughly working, intermediately drawing, and finely drawing; 5) carrying out middle annealing; 6) ultra-finely drawing; 7) finally annealing; 8) winding; and 9) packaging. The technology disclosed by the invention is specified and reasonable in design, and simple and convenient to operate; the obtained product is strong in electrical conductivity, has certain inoxidizability, good plasticity, high rupturing load, good elongation and low cost, can meet the demands of the semiconductor encapsulation industry and a light-emitting diode (LED) illumination technology on performance of the bonding alloy filamentary silver, and can be used as a substitute for a bonding alloy wire.

Owner:烟台招金励福贵金属股份有限公司

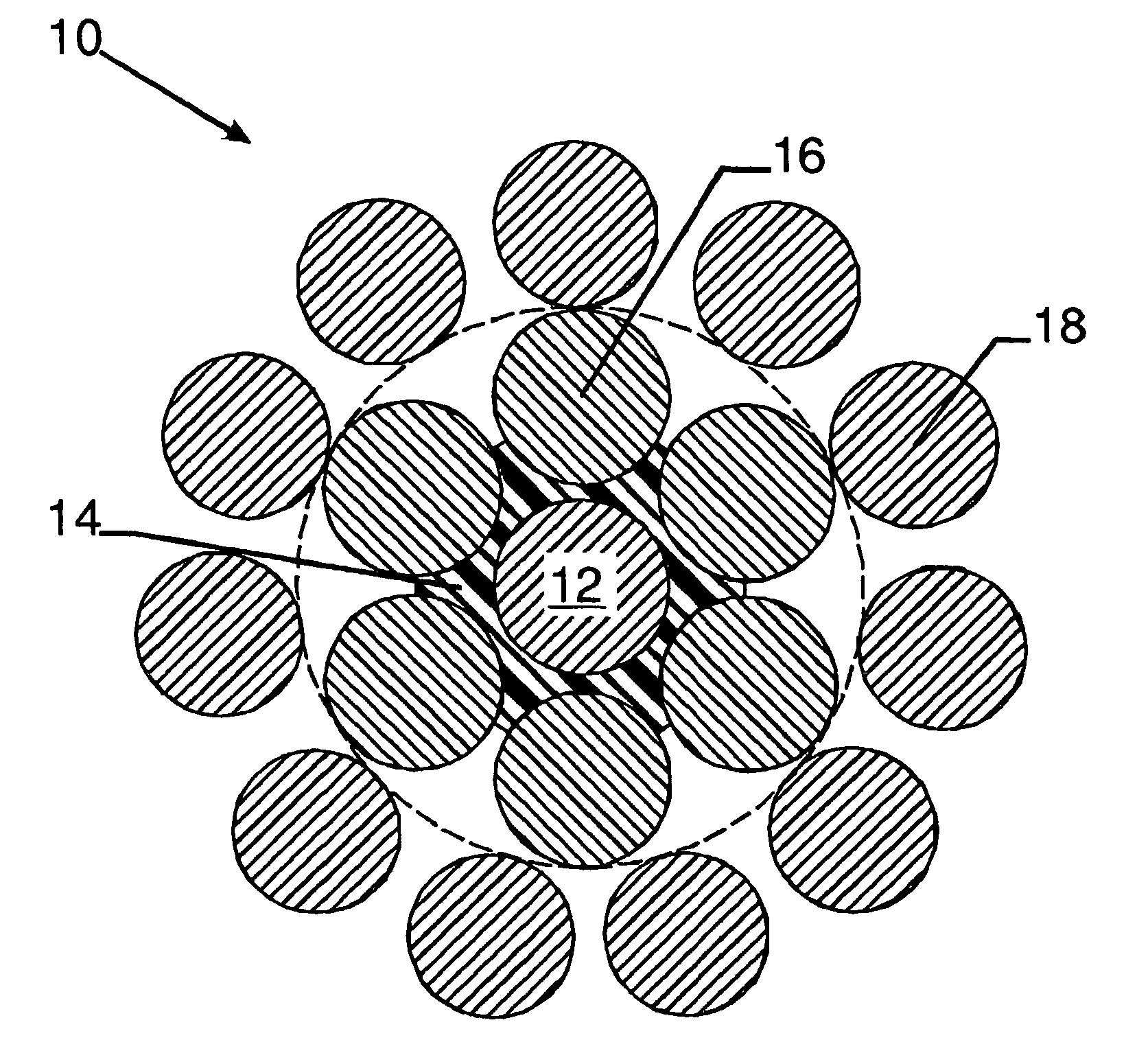

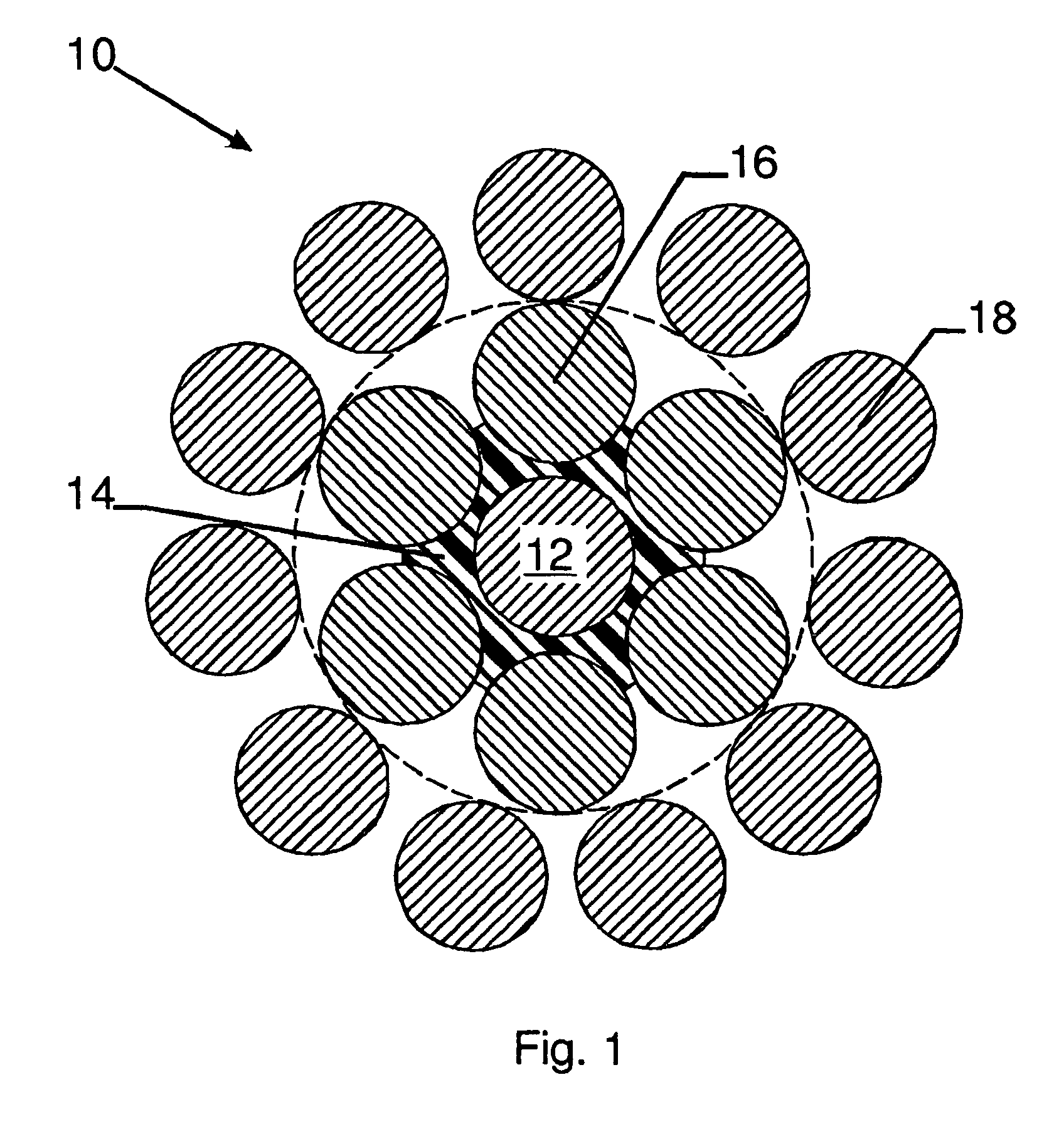

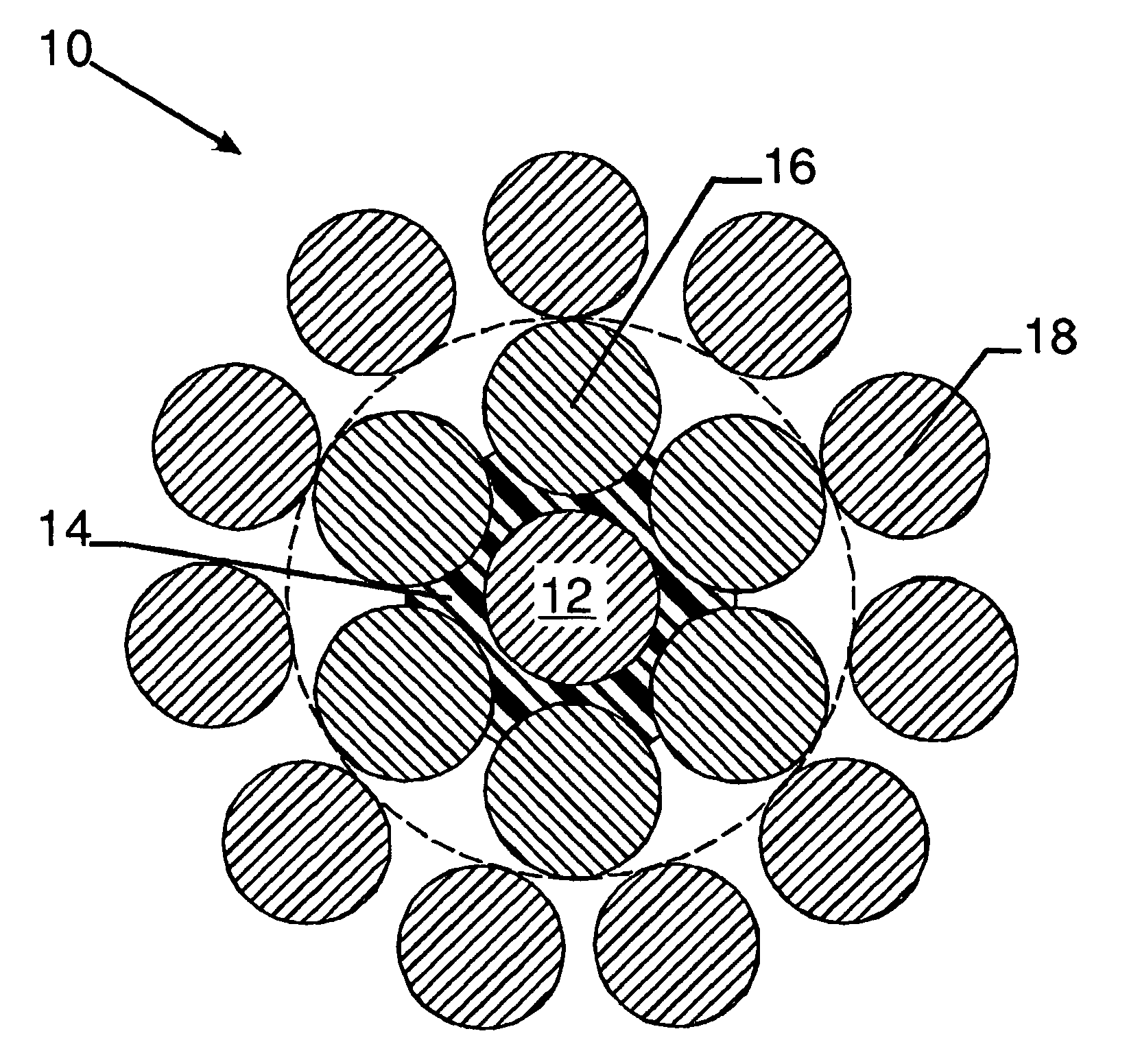

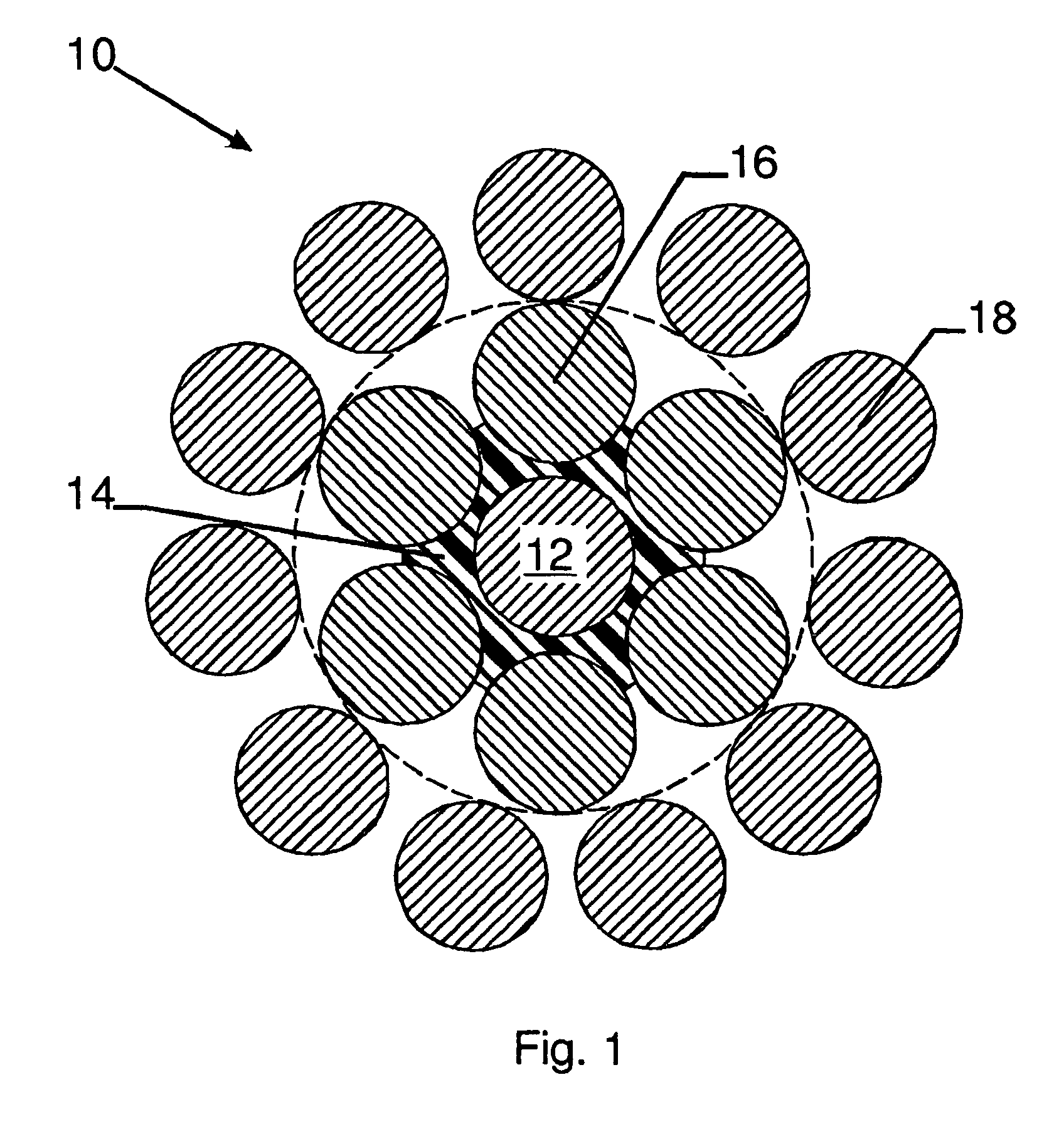

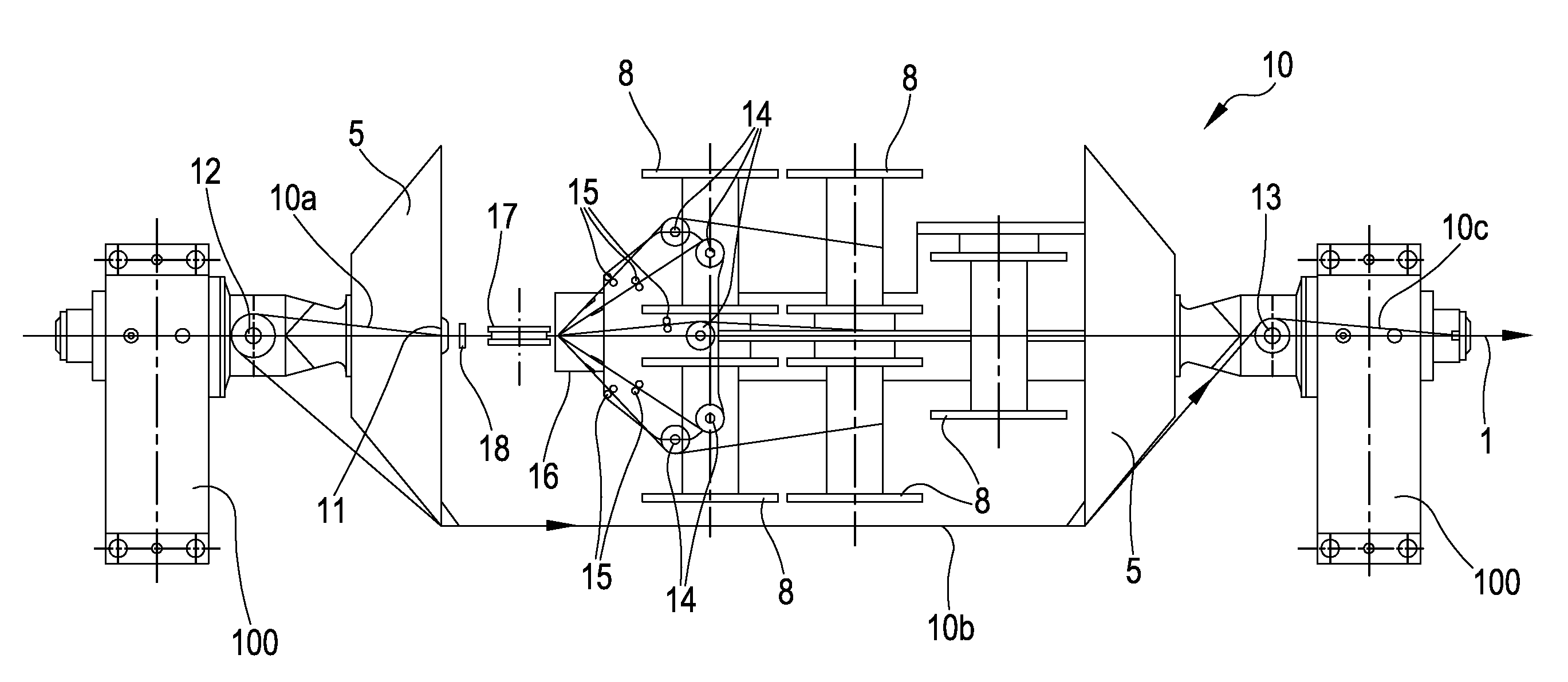

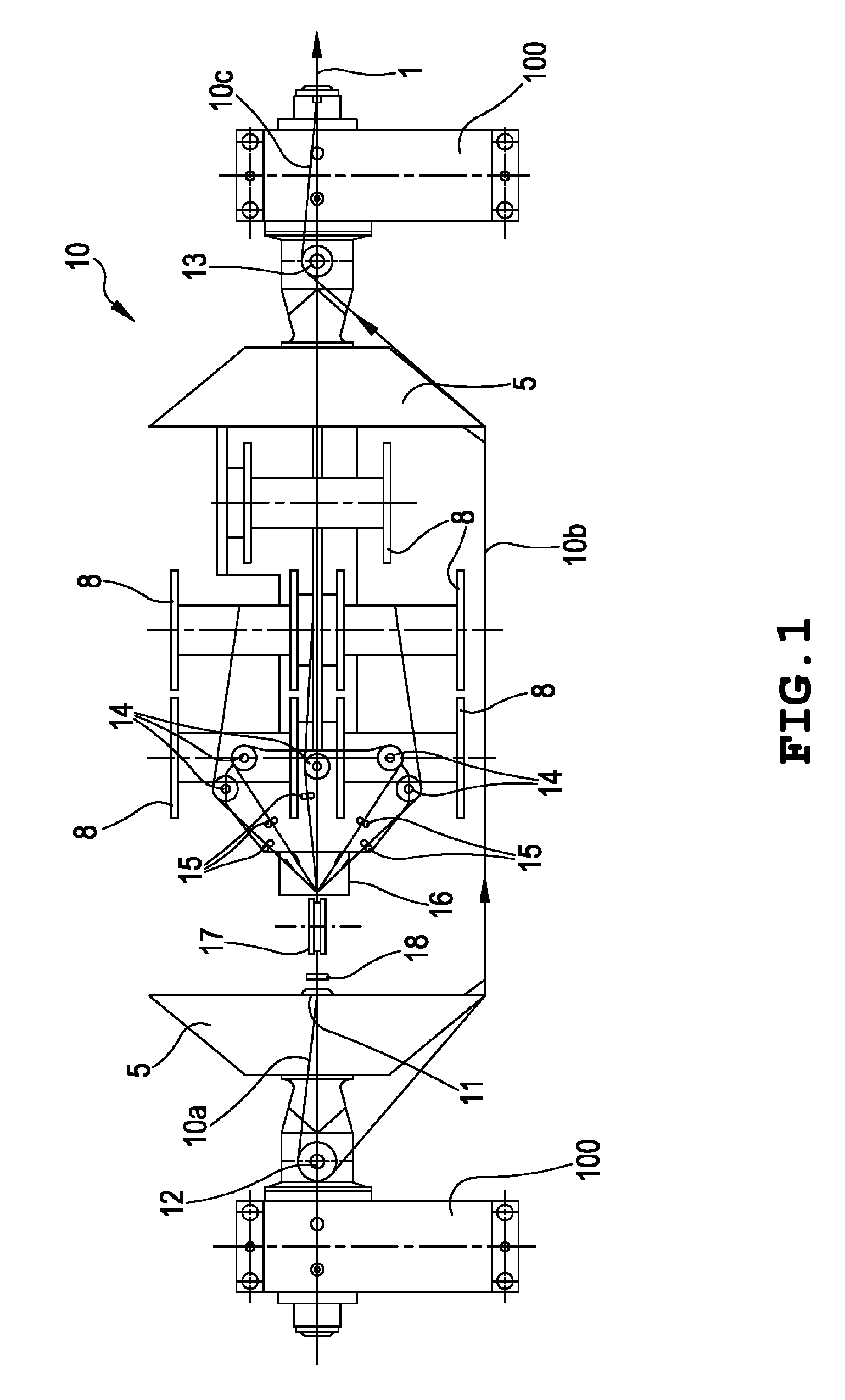

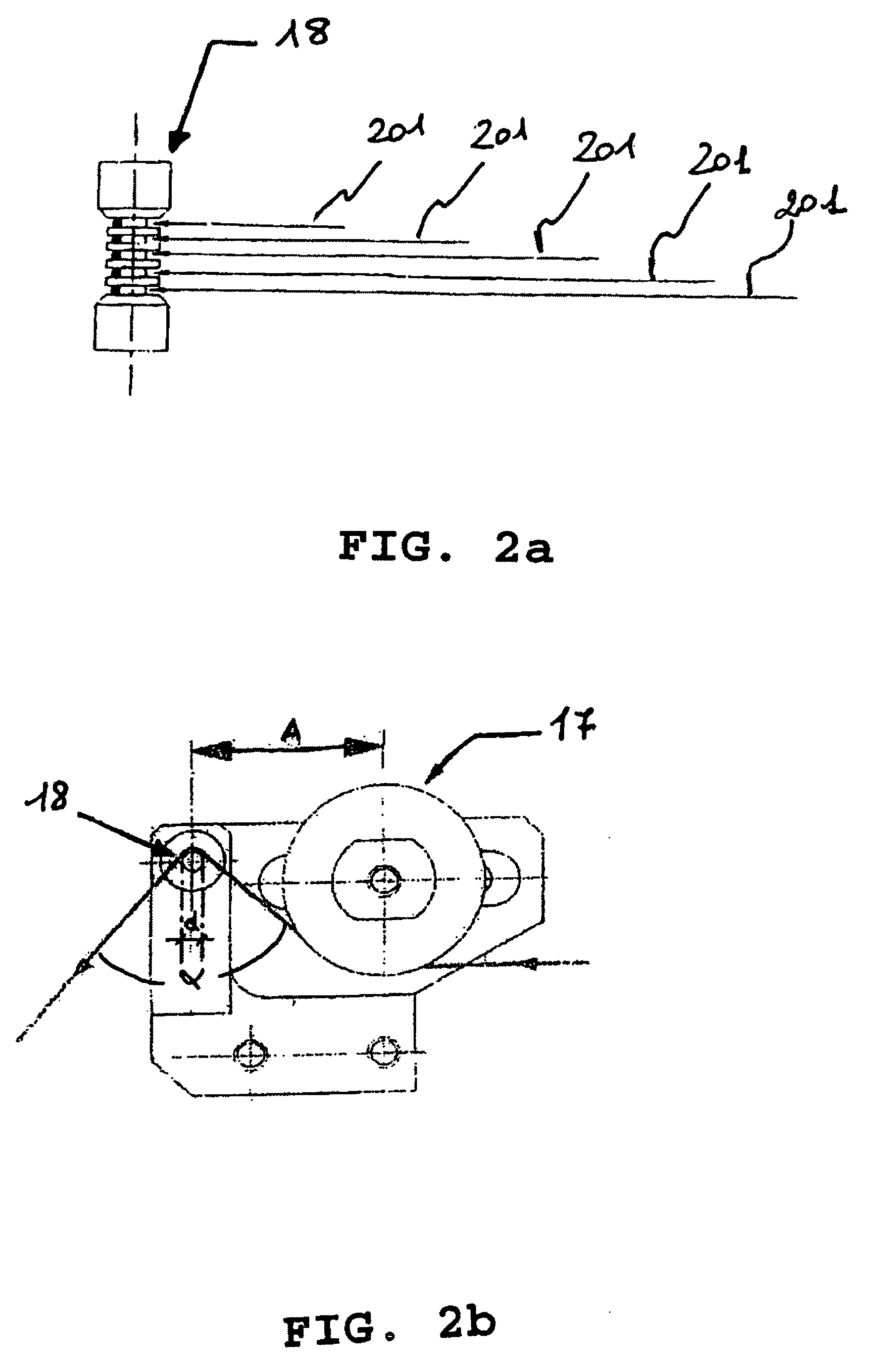

Open layered steel cord with high breaking load

InactiveUS20060191619A1Low tensile strengthReduce controlSpecial tyresPneumatic tyre reinforcementsElastomerMetallurgy

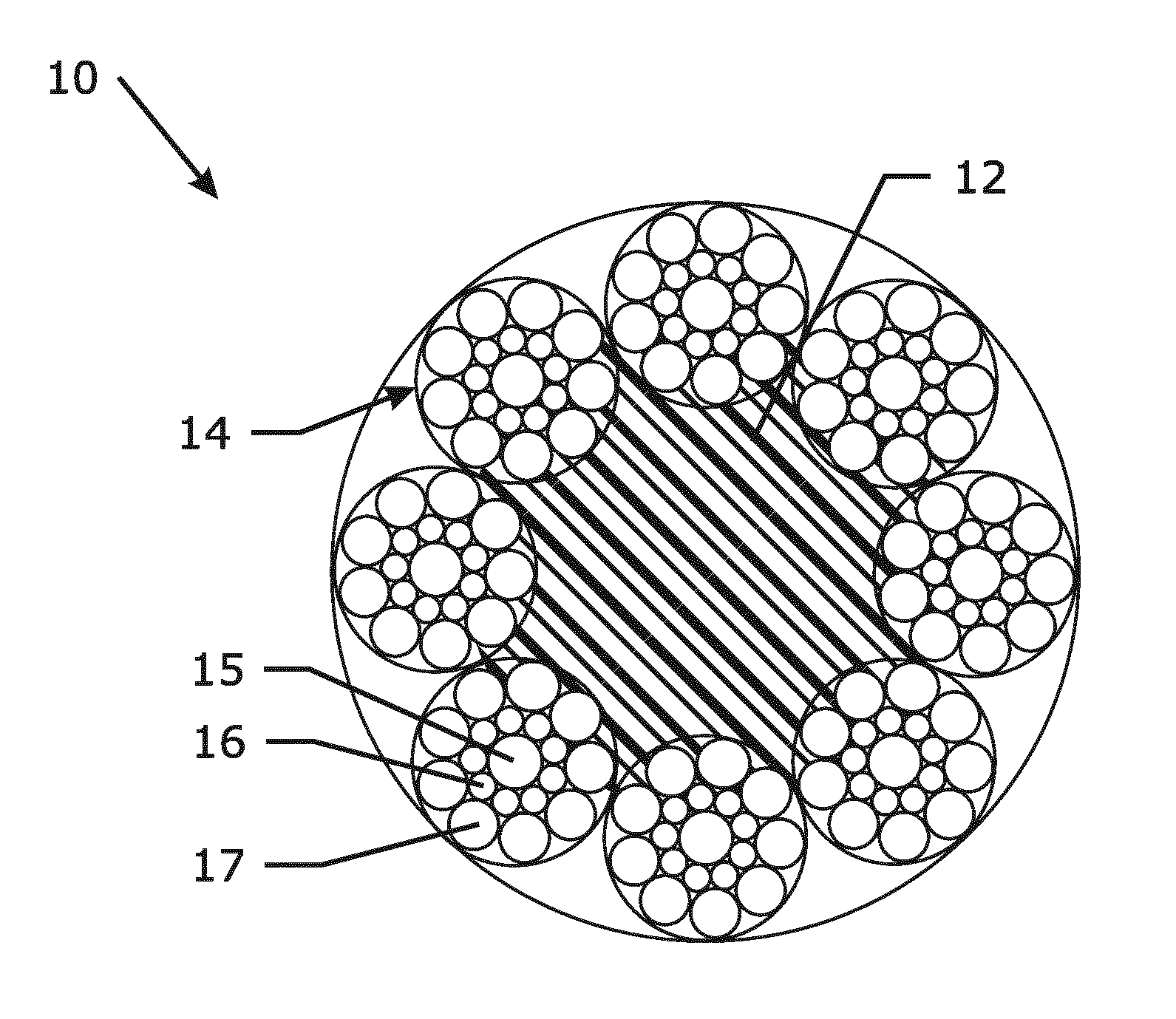

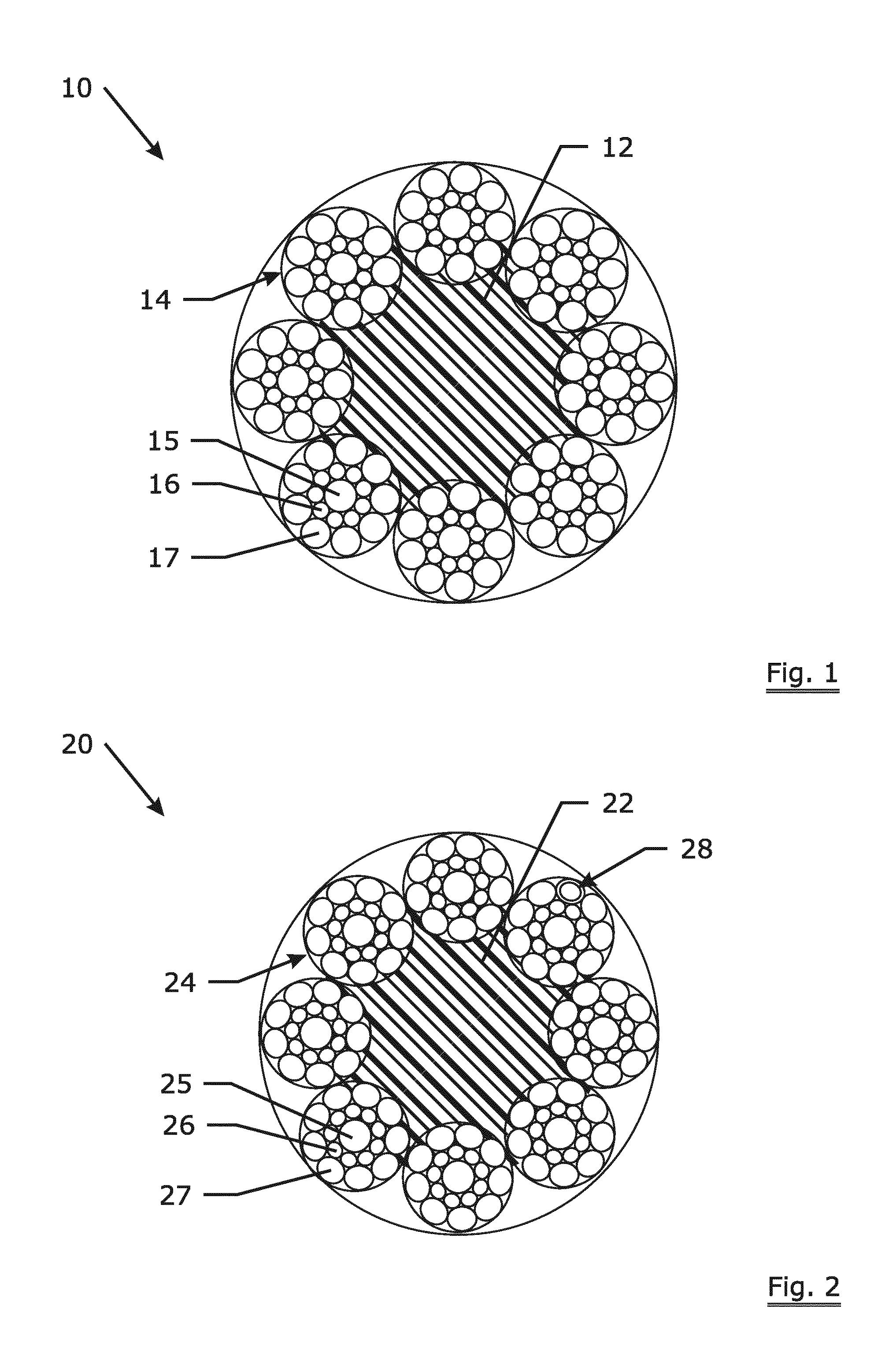

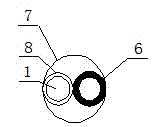

A steel cord (10) adapted for the reinforcement of elastomers comprises: a core steel filament (12) with a core steel filament diameter dc and coated with a polymer (14); six intermediate steel filaments (16) with an intermediate steel filament diameter di smaller than or equal to the core steel filament diameter dc; these intermediate steel filaments (16) are twisted around the core steel filament (12); ten or eleven outer steel filaments (18) with an outer steel filament diameter do smaller than or equal to the intermediate steel filament diameter dl; these outer steel filaments (18) are twisted around the intermediate steel filaments (16), the outer steel filaments (18) are preformed in order to allow rubber penetration inside the core (10). The core steel filament (12), the intermediate steel filaments (16) and the outer steel filaments (18) all have a tensile strength at least 2600 MPa. The cord (10) has an outer diameter D according to following formula: D≦dc+2×di+2×do+0.1 wherein all diameters are expressed in millimeter (mm).

Owner:NV BEKAERT SA

Open layered steel cord with high breaking load

InactiveUS7228681B2Increase breaking loadImprove fatigue resistancePneumatic tyre reinforcementsCoatingsElastomerUltimate tensile strength

A steel cord adapted for the reinforcement of elastomers includes: a core steel filament with a diameter dc and coated with a polymer, six intermediate steel filaments with a diameter di smaller than or equal to dc, the intermediate steel filaments being twisted around the core steel filament, ten to eleven outer steel filaments with a diameter do, smaller than or equal to di wherein these outer steel filaments are twisted around the intermediate steel filaments, and the outer steel filaments are preformed in order to allow rubber penetration inside the cord. The core steel filament, the intermediate steel filaments, and the outer steel filaments all have a tensile strength of at least 2600 MPa. The cord has an outer diameter D according to the following formula: D≦dc+2×di+2×do+0.1 mm, wherein all diameters are expressed in millimeters (mm).

Owner:NV BEKAERT SA

Gold bonding wire and preparation method thereof

ActiveCN102127663AHigh strengthSmall arcSemiconductor/solid-state device detailsSolid-state devicesElectrolysisIngot casting

The invention provides a gold bonding wire. The gold bonding wire comprises the following materials in percentage by weight: 0.0005 to 0.001 percent of beryllium, 0.0008 to 0.002 percent of copper or germanium, 0.001 to 0.003 percent of cerium and the balance of gold, wherein the purity of the gold is more than or equal to 99.996 weight percent. The invention also provides a preparation method of the gold bonding wire. The preparation method comprises the following steps of: electrorefining high-purity gold with purity of 99.999 weight percent by using gold with purity of 99.99 weight percent; smelting the high-purity gold; performing ingot casting to form a gold plate; rolling the gold plate to be a thin gold sheet; manufacturing an intermediate alloy; performing vertical smelting; drawing the wire; annealing; winding; and performing vacuum packaging. The gold bonding wire has the characteristics of high strength and low long radian, the yield of products is high, and the winding length of a reeling shaft is large.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

Process for modifying synthetic resin impregnated wood

InactiveCN101879729AInhibit aggregationIncrease elasticityPressure impregnationWood impregnation detailsPolymer scienceSynthetic resin

The invention relates to a process for modifying synthetic resin impregnated wood, comprising the following steps of: preparing 100 parts by mass of impregnation working solution including 10-20 parts of 100 percent phenolic resin liquid, 0.5-1.5 parts of carbomite and the balance of water; impregnating: adding wood into a high pressure autoclave, evacuating at 0.050-0.085MPa for 20-30min, sucking the impregnation working liquid and pressurizing at 0.7-0.9 MPa for 50-60min; and curing: placing the wood into a drying oven, raising the temperature to 90 DEG C within 3-4h, and drying at 90-95 DEG C for 3-4h. Special resorcin-formalin with the optical density of 1.280-1.330 is detected by using 10 percent of resorcin-formalin, carbamide (NH2)2CO, carbamide and free formaldehyde are added to generate urea resin to lower the residual quantity of formaldehyde and be beneficial to preventing phenolic resin from further polymerizing in storage, thereby being beneficial to absorbing; while the urea resin is elastic resin which can increase the elasticity of wood, damage load and increase the bending strength, therefore, the wood is not fragile and has good processabilitly, and the application range of modified wood is widened.

Owner:辽宁精化科技有限公司

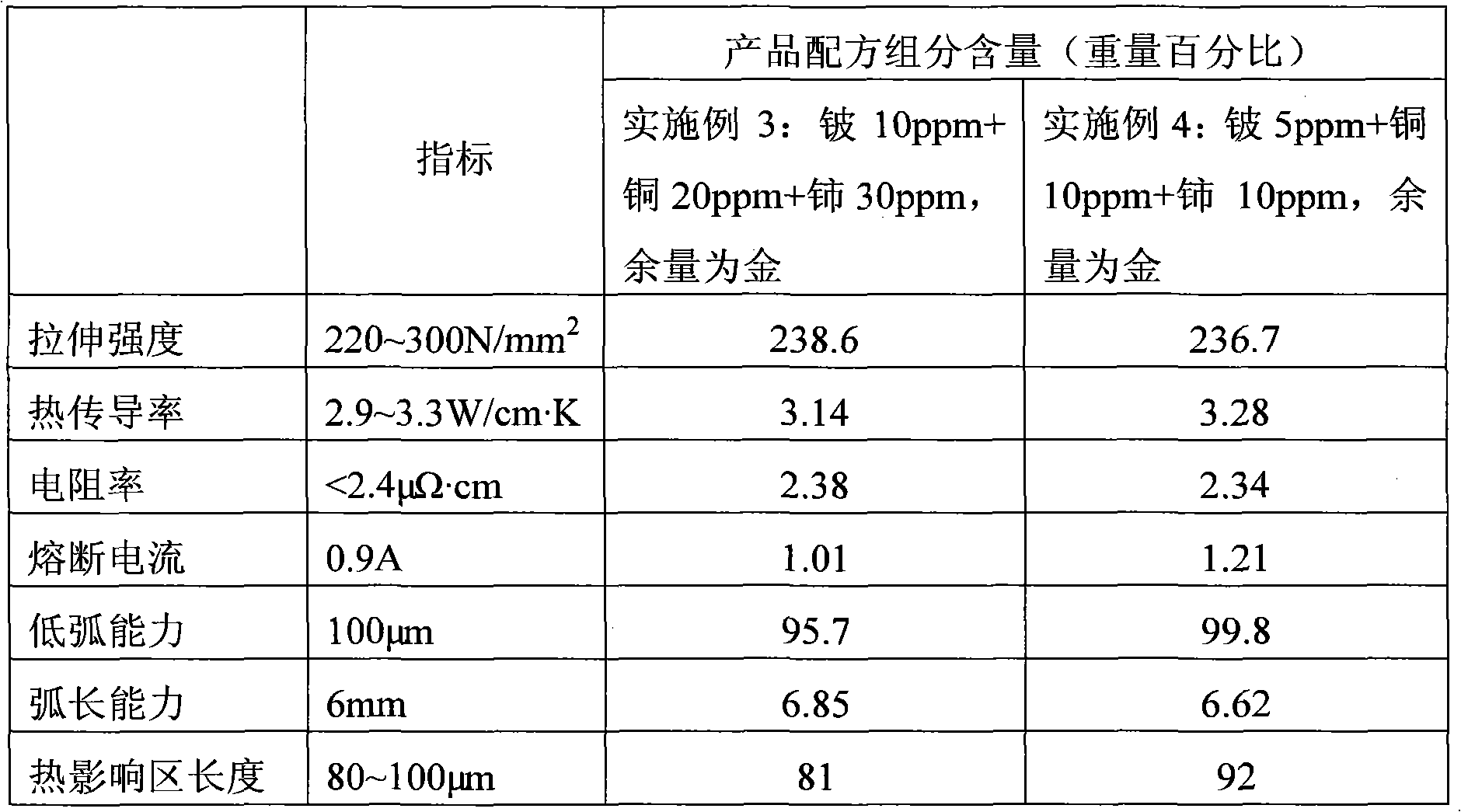

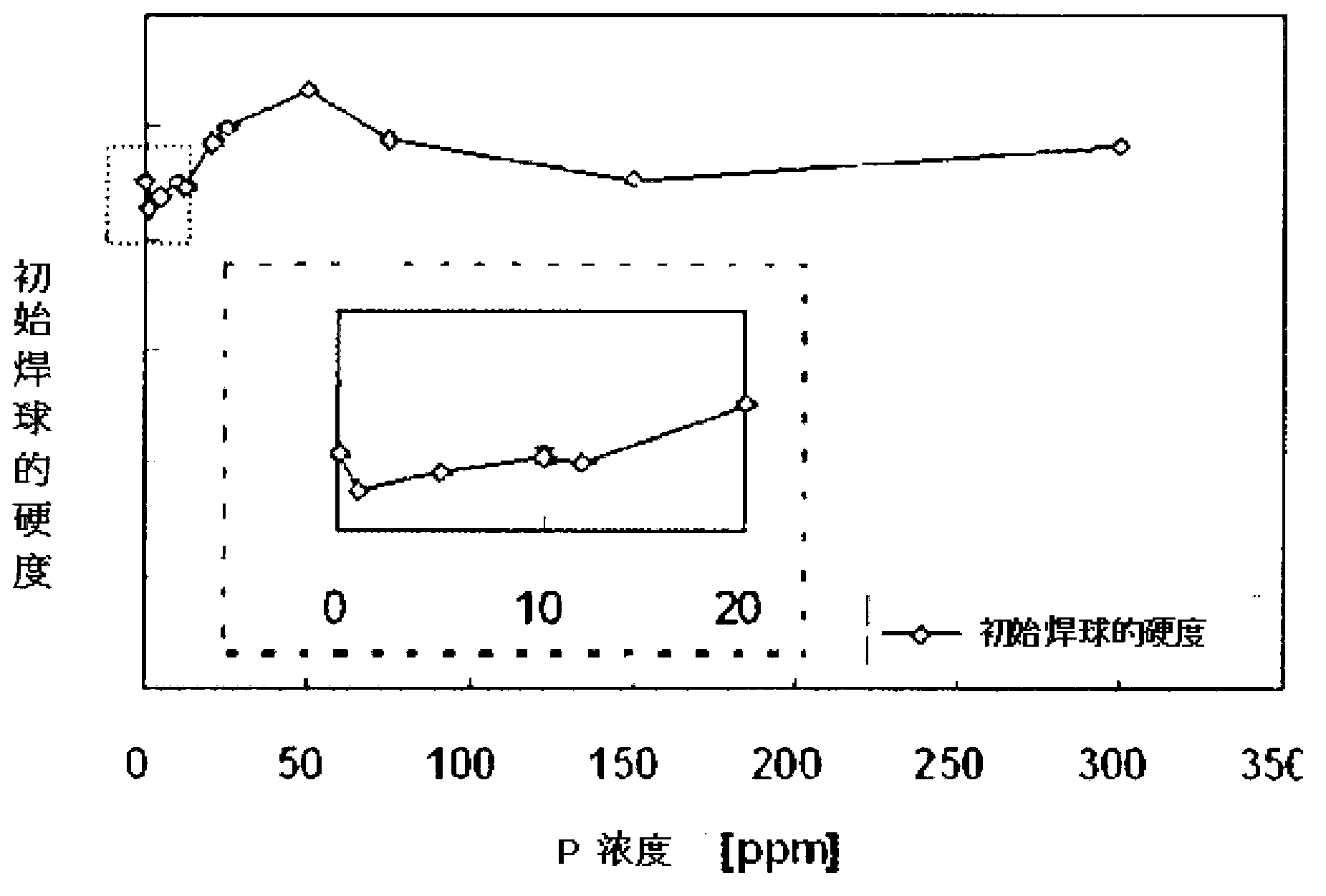

High-purity Cu bonding wire

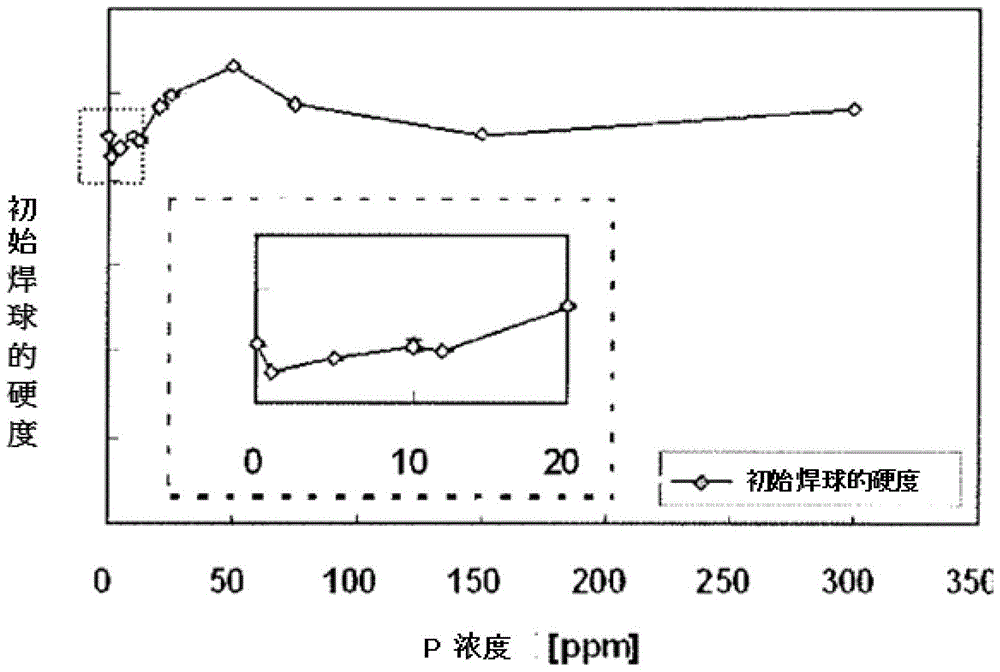

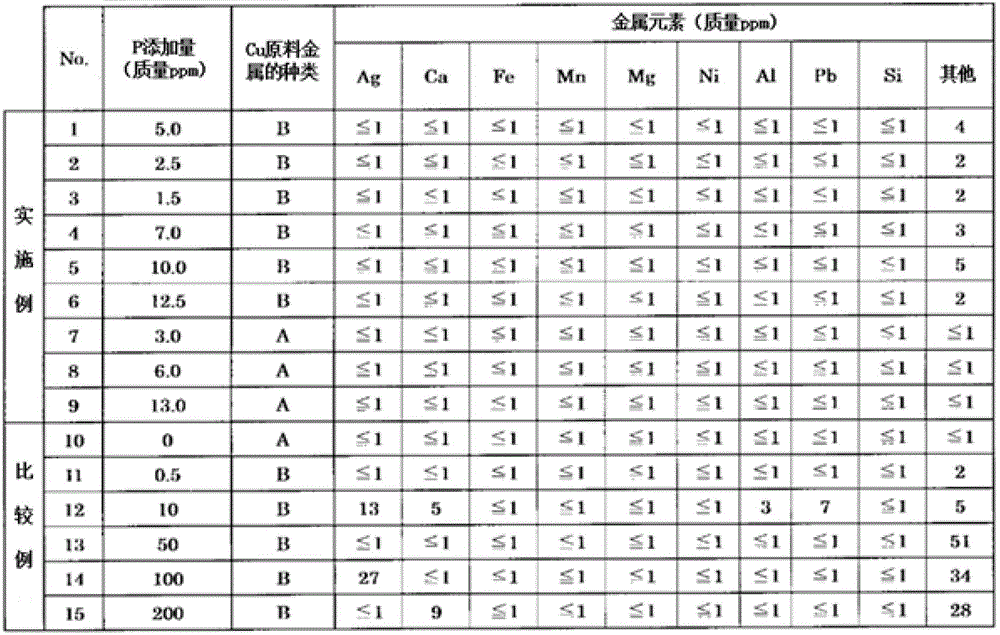

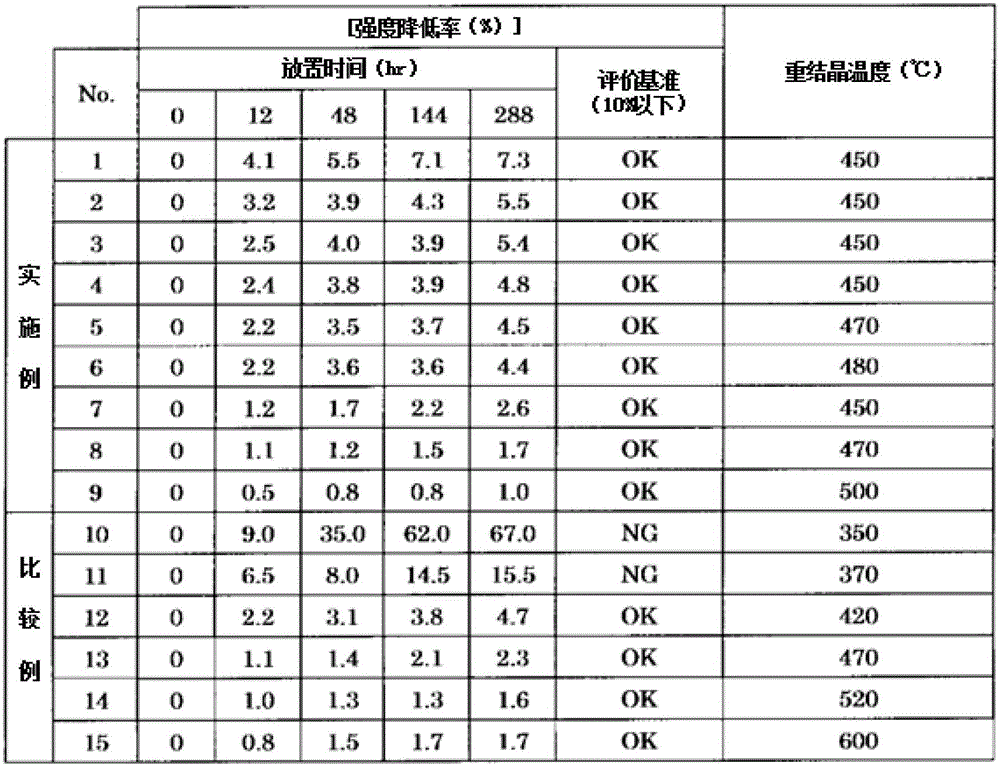

InactiveCN102859672AAvoid damageIncrease breaking loadSolid-state devicesSemiconductor/solid-state device manufacturingHardnessBall bonding

Provided is a ball bonding wire of a high-purity copper alloy, the wire having a high recrystallization temperature and being easily produced through wiredrawing with a die at room temperature. The ball bonding wire has a low initial ball hardness and causes no breakage of IC chips. Phosphorus (P) is added in an amount as slight as 0.5-15 mass ppm to high-purity copper having a purity of 99.9985 mass% or higher to thereby produce a copper alloy which has a higher recrystallization temperature than high-purity copper having a purity of 99.9999 mass% or higher and which has a lowered initial ball hardness in ball bonding. Those characteristics are thus achieved. Alternatively, phosphorus (P) is added in an amount as slight as 0.5-15 mass ppm to high-purity copper having a purity of 99.9985 mass% or higher, and the total amount of any other impurities contained in the copper is reduced to a value lower than the phosphorus (P) content. Those characteristics are thereby achieved.

Owner:TANAKA DENSHI KOGYO KK

Compacted hybrid elevator rope

InactiveUS20130227926A1Reduce stretchIncrease breaking loadElevatorsCoatingsLinear densityEngineering

Owner:BRIDON INT LTD

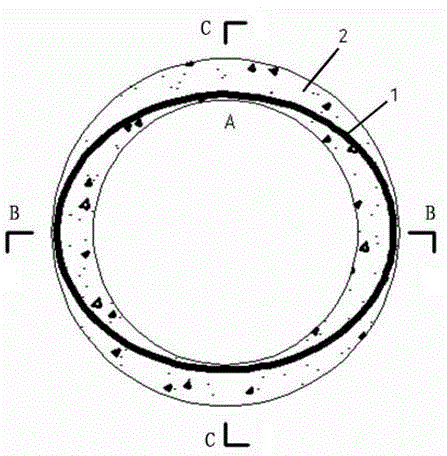

Novel reinforced bar type ultra-high-performance concrete pipeline and preparing method thereof

InactiveCN104832720AEfficient use ofIncrease breaking loadShaping reinforcementsRigid pipesArchitectural engineeringRebar

The invention discloses a preparing method of a novel reinforced bar type ultra-high-performance concrete pipeline. An adopted pipeline forming mold comprises a steel outer mold and an inner mold. The method comprises the following steps that (1) a steel bar framework is welded, a longitudinal bar of the framework is unchanged, and an annular bar is processed into an oval shape; (2) the mold is assembled, a steel bar framework is fixed, a pumping machine is connected with the mold, and the sealing performance is checked; (3) an ultra-high-performance concrete mixture is prepared; (4) the ultra-high-performance concrete mixture is added into the pumping machine, and a pumping jacking process is adopted for forming a pipeline; (5) after the pumping is completed, a closed grouting opening of the mold is sealed in time; (6) a pipeline with the mold is subjected to integral maintenance; (7) the mold is dismounted; (8) hydrothermal maintenance or natural maintenance is carried out after the pipeline mold dismounting. The invention also discloses the novel reinforced bar type ultra-high-performance concrete pipeline. The pipeline annular bar prepared by the method provided by the invention is in an oval shape, so that the strength of a reinforced bar is effectively utilized, and the pipeline strength is improved.

Owner:SOUTH CHINA UNIV OF TECH

Raw material formula and method for manufacturing high-alumina porcelain insulator

The invention relates to a raw material formula and method for manufacturing a high-alumina porcelain insulator, and belongs to the technical field of electric porcelain. The formula comprises bauxite, kaolinite, feldspar, mullite, illite, clay, Zuoyun soil, nacrite, garnet and white carbon black, and the high-alumina porcelain insulator is prepared by a sintering process comprising the followingsteps: using a plurality of raw materials and adding a small amount of garnet, white carbon black and methyl silicone resin, grinding into powder with two different particle sizes in the preparation process, mixing, heating in stages, cooling and heating again. And the obtained porcelain insulator has excellent mechanical properties and meets the requirements of the field of electroceramics at present.

Owner:江西省萍乡市宇翔电瓷制造有限公司

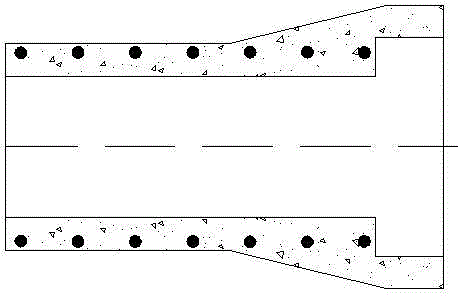

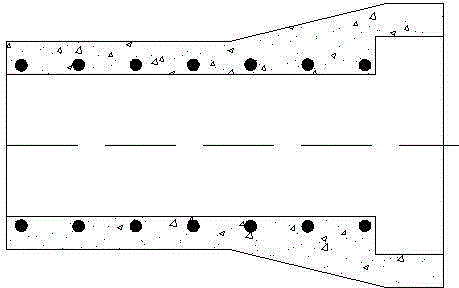

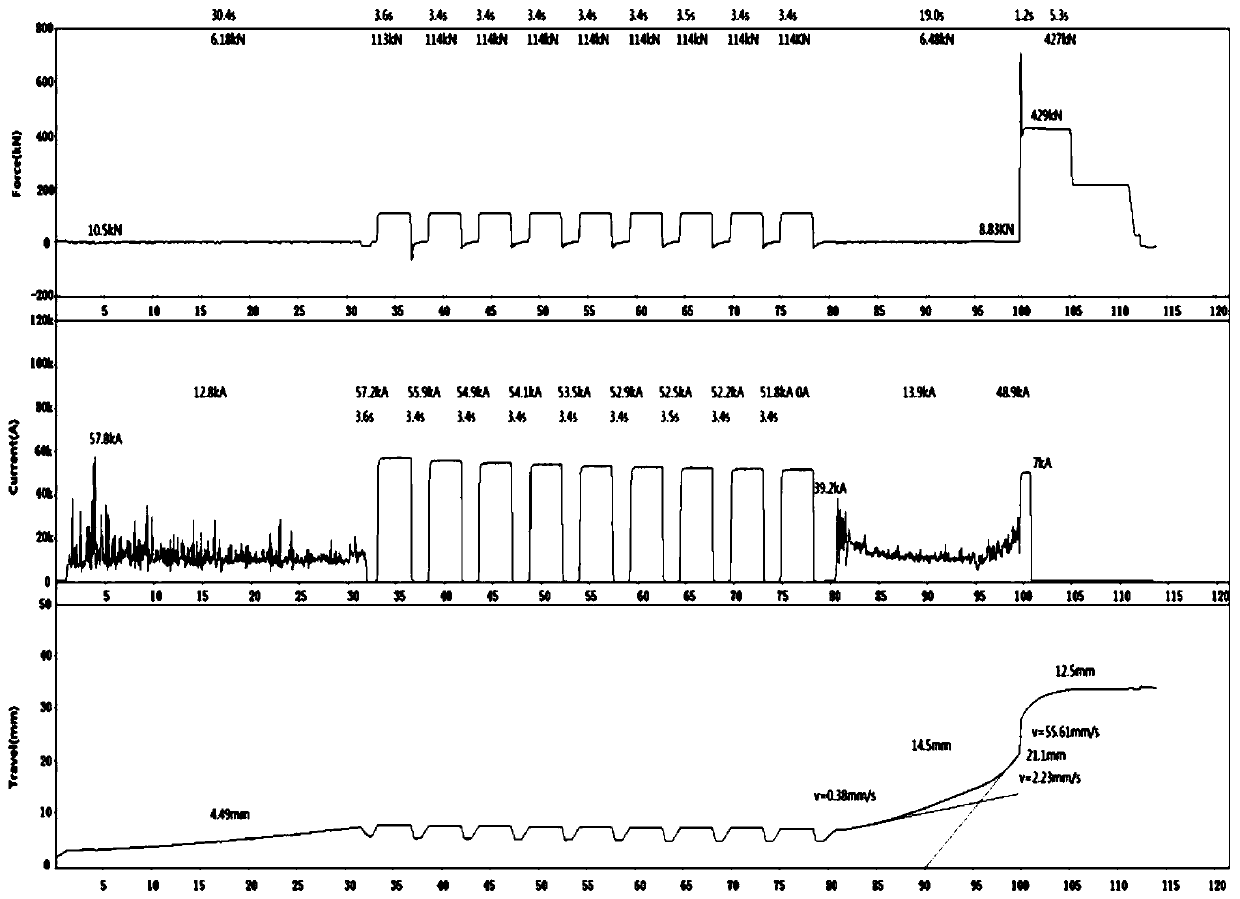

Welding process of alloy steel and trough type steel rail

ActiveCN110102864AStress reliefEnhanced breaking loadResistance welding apparatusUpset forgingAlloy steel

The invention relates to the technical field of tracked trolley bus frog welding, in particular to a welding process of alloy steel and a trough type steel rail. According to the welding process of the alloy steel and the trough type steel rail, the alloy steel and the trough type steel rail are welded together through a flash welding method; the welding process comprises a flash levelling stage,a preheating stage, a burning stage, an upset forging stage and a postheating stage; the total duration time of the welding process is 114s to 115s; the upset forging amount of the welding process is12mm to 12.8mm; and the total consumption amount of the steel rail of the welding process is 30 to 31.8mm. According to the welding process of the alloy steel and the trough type steel rail provided by the invention, the flash welding of the alloy steel and the trough type steel rail is realized successfully, the mechanical property of a formed welding joint is good, and the welding quality is stable.

Owner:CNR BEIJING RAIL EQUIP +1

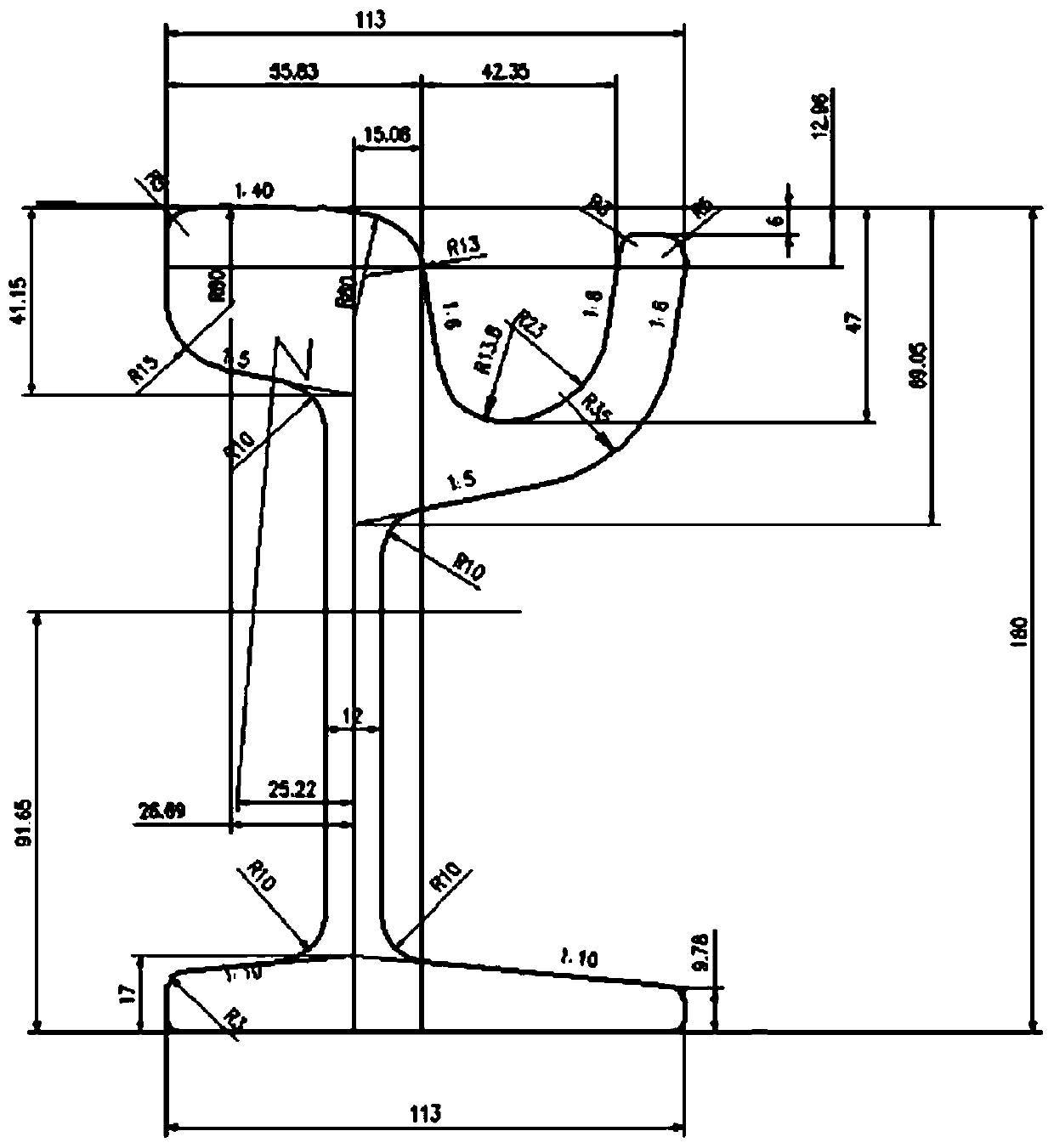

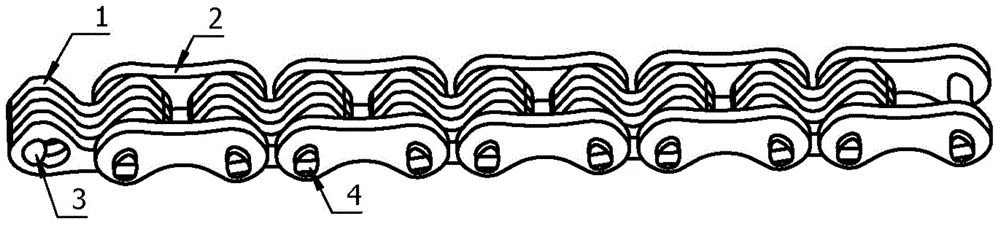

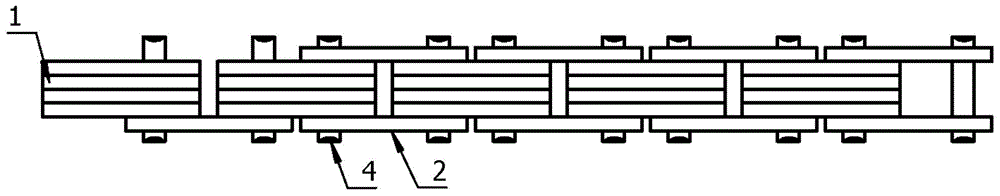

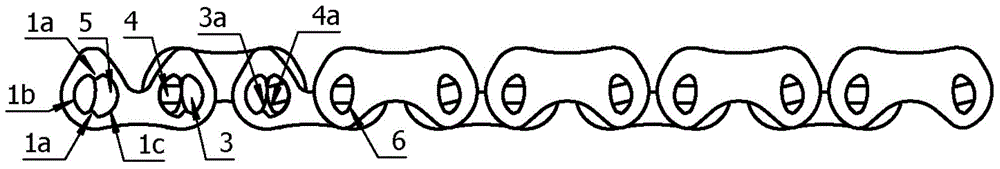

Tooth-shaped chain

InactiveCN103557270AReduce shockReduce vibrationChain linksDriving chainsInterference fitFriction loss

The invention provides a tooth-shaped chain which comprises inner chain plates, outer chain plates, short pin shafts and long pin shafts, wherein the inner chain plate holes formed in the inner chain plates are circular holes or non-circular profile holes; a pair of tooth-shaped bulges is formed in each inner chain plate hole; the inner chain plate holes are divided into outer side slots and inner side hole grooves through the bulges; the short pin shafts are axially positioned through the bulges and the outer side slots, and are fixed together with the inner chain plates in an interference fit manner; multiple inner chain plates are overlapped to form an inner link; the long pin shafts penetrate through the inner side hole grooves of the inner chain plates and are riveted together with the two outer chain plates tightly to form an outer link; the short pin shafts of the inner link is in contact with the long pin shafts of the outer link through arc working surfaces to form a rotation pair which can rotate within a certain range. According to the tooth-shaped chain provided by the invention, the structural constraints of the conventional tooth-shaped chain and Hy-Vo tooth-shaped chain are broken through, the friction loss and impact vibration between the pin shafts and chain plates are reduced by changing the assembling mode of the pin shafts and the arrangement mode of the inner chain plates, and the mechanized and scale production of high-speed tooth-shaped chains is achieved.

Owner:金雁冰 +1

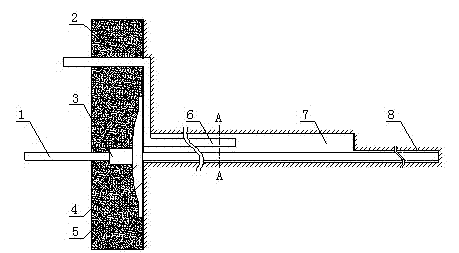

Metal cord and process for manufacturing a metal cord

ActiveUS7975463B2High elongationImproved elastomeric material penetrationRope making machinesYarnMetallurgyMetal

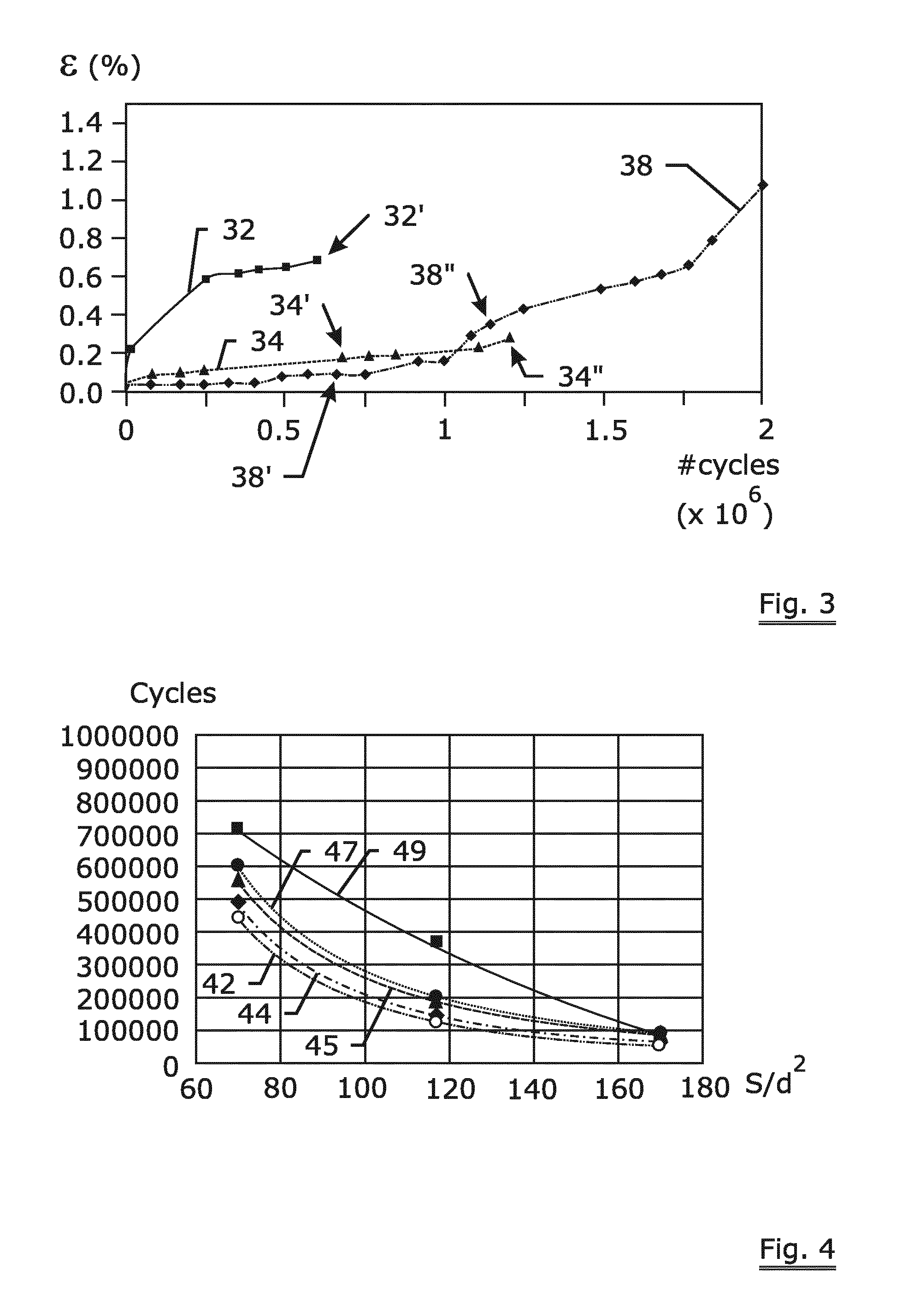

A metal cord includes at least one preformed elementary metal wire. The metal cord has an elongation at break, measured on the bare cord, higher than or equal to 3%, preferably 4% to 6%; an elongation at break, measured on the rubberized and vulcanized cord, which differs in an amount not higher than or equal to 15%, preferably 2% to 10% with respect to the elongation at break measured on the bare cord; a part load elongation, measured on the bare cord, higher than or equal to 0.4%, preferably 0.5% to 1.5%; a part load elongation, measured on the rubberized and vulcanized cord, which differs in an amount not higher than or equal to 15%, preferably 0.5% to 10%, with respect to the part load elongation measured on the bare cord.

Owner:NV BEKAERT SA

Method for manufacturing moisture-proof silk insulating rope

ActiveCN105735018AIncrease breaking loadHigh tensile strengthTextile cablesChemistryComposite material

The invention relates to a method for manufacturing a moisture-proof silk insulating rope. The moisture-proof silk insulating rope is prepared by the following five steps: performing pretreatment, manufacturing a rope core, manufacturing a first sheath, manufacturing a second sheath and manufacturing the finished product. Compared with the traditional manufacturing method, the method for manufacturing the moisture-proof silk insulating rope provided by the invention has the advantages that a rope is manufactured through pretreatment, double-layer sheaths are arranged outside the rope, and the tensile strength and abrasion rate thereof are further enhanced; a double-layer insulating bush is arranged outside the double-layer sheaths, so that the breaking load of the moisture-proof silk insulating rope is greatly enhanced.

Owner:SHUNYUAN ELECTRIC RUGAO CITY ROPE BELT WEAVING CO LTD

Anchor rope total length anchoring method for coal mine soft rock roadway

The invention discloses an anchor rope total length anchoring method for a coal mine soft rock roadway. The method comprises the steps of performing construction and drilling a hole in a tunneling working face of the soft rock roadway, installing an anchor rope in the well constructed drilled hole according to convention, placing a Z-shaped grouting pipe on an orifice of the grouting drilled hole, laying a reinforcing mesh attached to the surface of the roadway around the orifice of the grouting drilled hole, installing a tray and a lock at an exposed end of the anchor rope, and applying pretightening force on the anchor rope; spraying slurry on the surface of the soft rock roadway, enabling a sprayed layer on the surface of the soft rock roadway to be covered on an outer wall of the grouting drilled hole; and after the sprayed layer is stabilized, grouting the grouting drilled hole through an exposed port of the Z-shaped grouting pipe until the slurry is filled in the drilled hole to achieve total length anchoring of the anchor rope. Finally, effects of reinforcing a surrounding rock structure, improving surrounding rock bearing capability and controlling surrounding rock deformation are achieved.

Owner:CHINA UNIV OF MINING & TECH +1

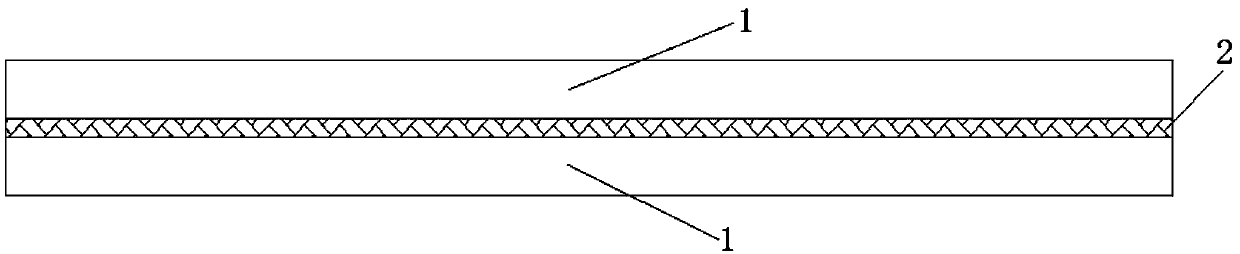

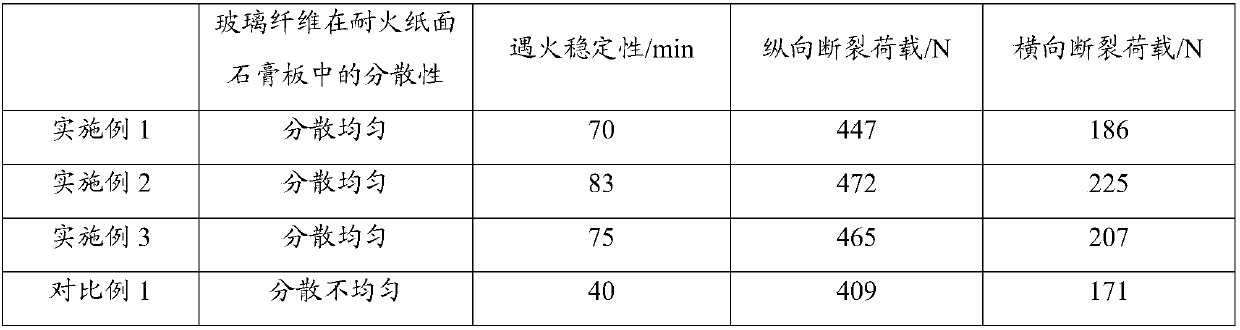

Cement ceiling board with electromagnetic shielding function and semi-dry preparation technology of cement ceiling board

The invention belongs to the field of building materials, and particularly relates to a cement ceiling board with an electromagnetic shielding function and a semi-dry preparation technology of the cement ceiling board. The ceiling board comprises carbon fiber gridding cloth and a cement layer, wherein the carbon fiber gridding cloth is laid between cement boards; the cement layer comprises a material A and a solution B; the material A comprises, by weight, 45-70 parts of cement, 3-7 parts of silica fume, 5-15 parts of fly ash and 0.3-1.5 parts of polyvinylpyrrolidone; the solution B comprises90-98 parts of water, 1-6 parts of a silane coupling agent and 0.05-0.15 part of ferroferric oxide modified graphene oxide. On the basis of problems existing in the field that existing cement-based materials serve as ceiling boards, a cement ceiling board formula and the semi-dry preparation technology corresponding to the formula are disclosed. The prepared cement ceiling board is low in weight per unit area, high in breaking load, excellent in electromagnetic shielding performance and capable of completely meeting use requirements of the ceiling board.

Owner:UNIV OF JINAN

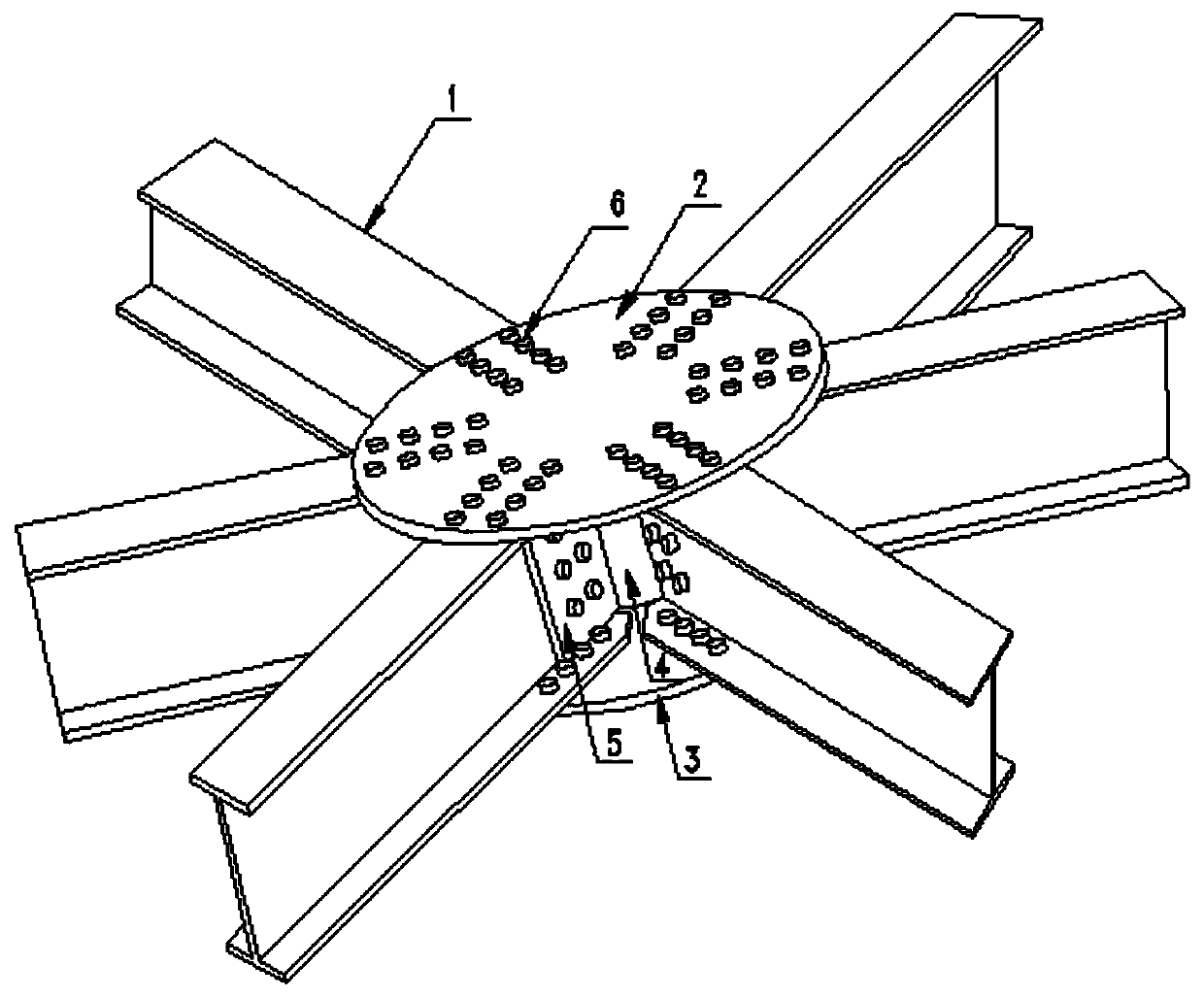

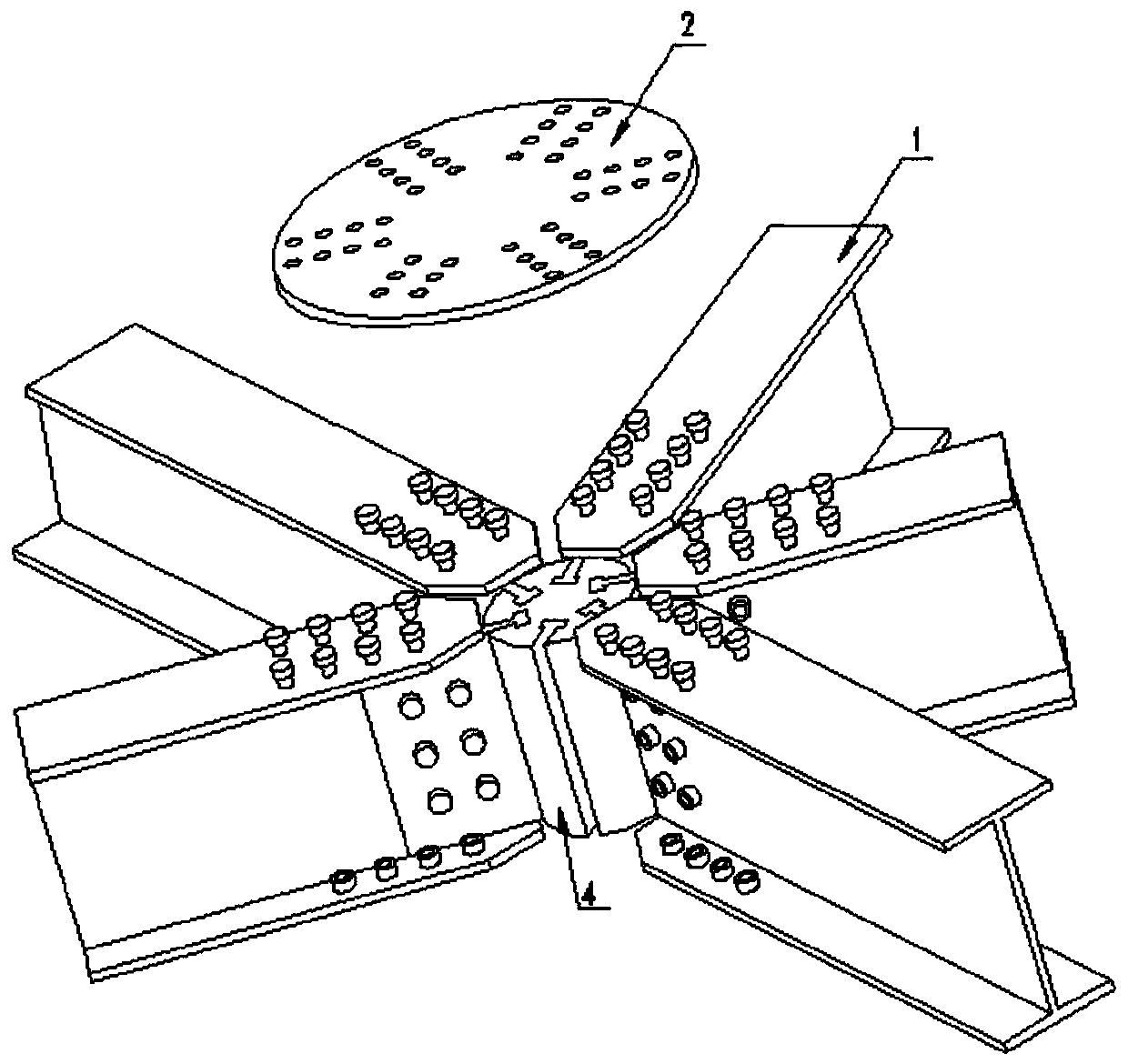

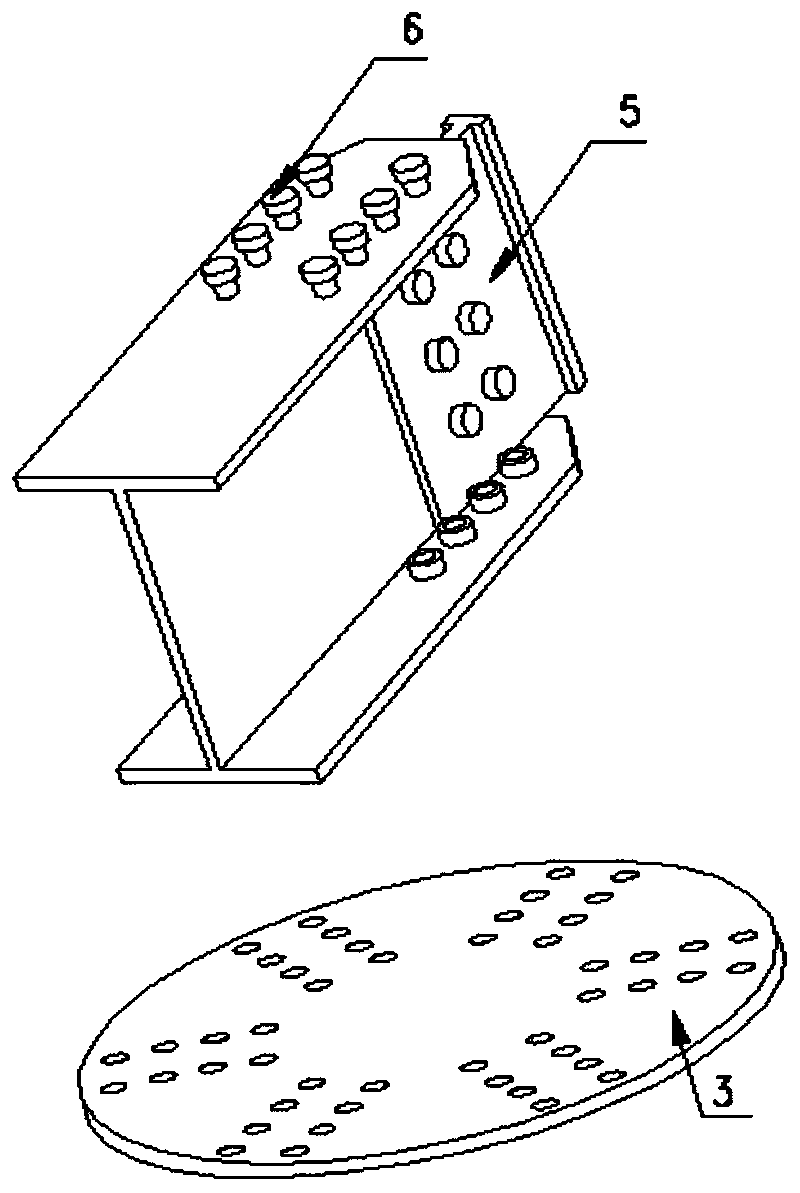

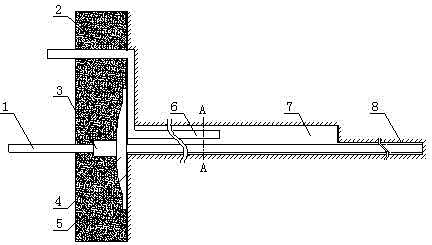

Inserting connection type single-layer aluminum alloy reticulated shell connection joint

InactiveCN111075016AImprove the bending capacityIncreased shear capacityBuilding constructionsMaterials scienceLower wing

The invention discloses an inserting connection type single-layer aluminum alloy reticulated shell connection joint. The inserting connection type single-layer aluminum alloy reticulated shell connection joint comprises aluminum alloy rod pieces, an upper circular cover plate, a lower circular cover plate, a wedge block and shearing resisting connection plates; the wedge block is arranged betweenthe upper circular cover plate and the lower circular cover plate, and the center line of the wedge block in the length direction coincides with the center lines of the upper circular cover plate andthe lower circular cover plate; the wedge block is provided with T-shaped hole grooves in the radial pattern, and the shearing resisting connection plates are in a T shape; one end of each shearing resisting connection plate is provided with a wing edge small in width to be inserted into the corresponding hole groove of the wedge block; the shearing resisting connection plates and the wedge blockare connected in a mechanical engaging manner; the other ends of the shearing resisting connection plates and web plates of the aluminum alloy rod pieces are connected through stainless steel bolts; and upper and lower wing edges of the aluminum alloy rod pieces and the upper and lower circular cover plates are connected through stainless steel bolts. Due to the inserting connection type single-layer aluminum alloy reticulated shell connection joint, the bending resisting and shearing resisting bearing force of the joint is remarkably enhanced, the rigidity of the joint and the overall stability of a reticulated shell are improved, and therefore application to a single-layer aluminum alloy reticulated shell structure larger in span can be achieved.

Owner:SOUTHEAST UNIV

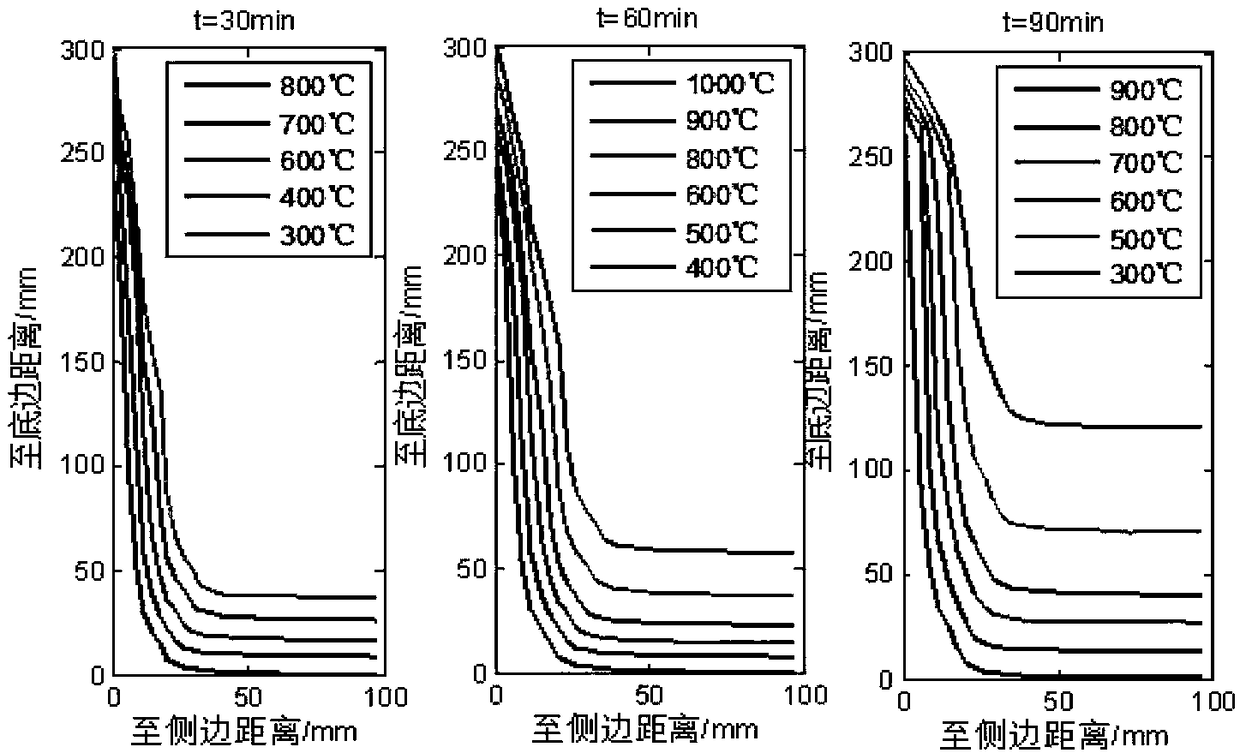

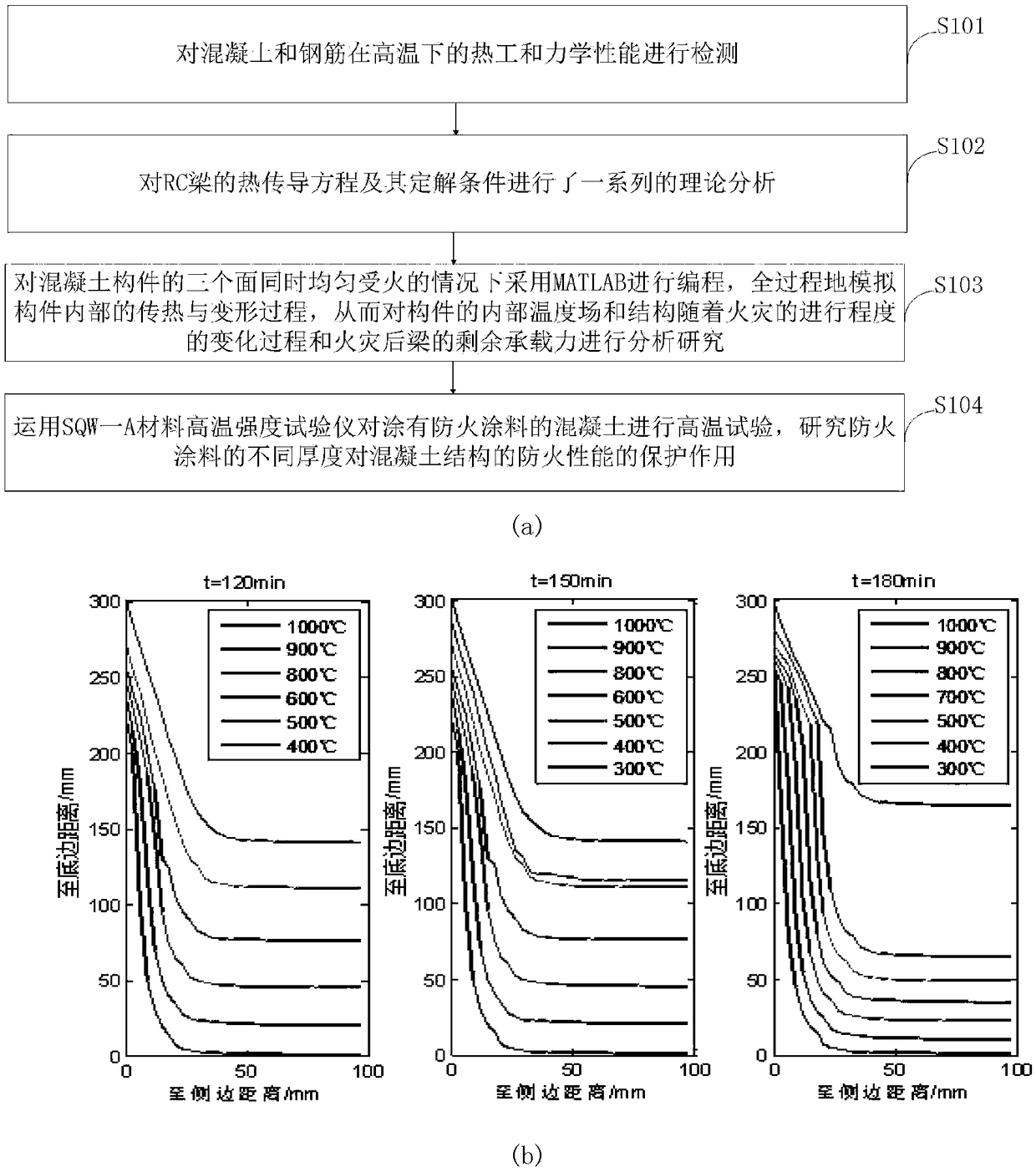

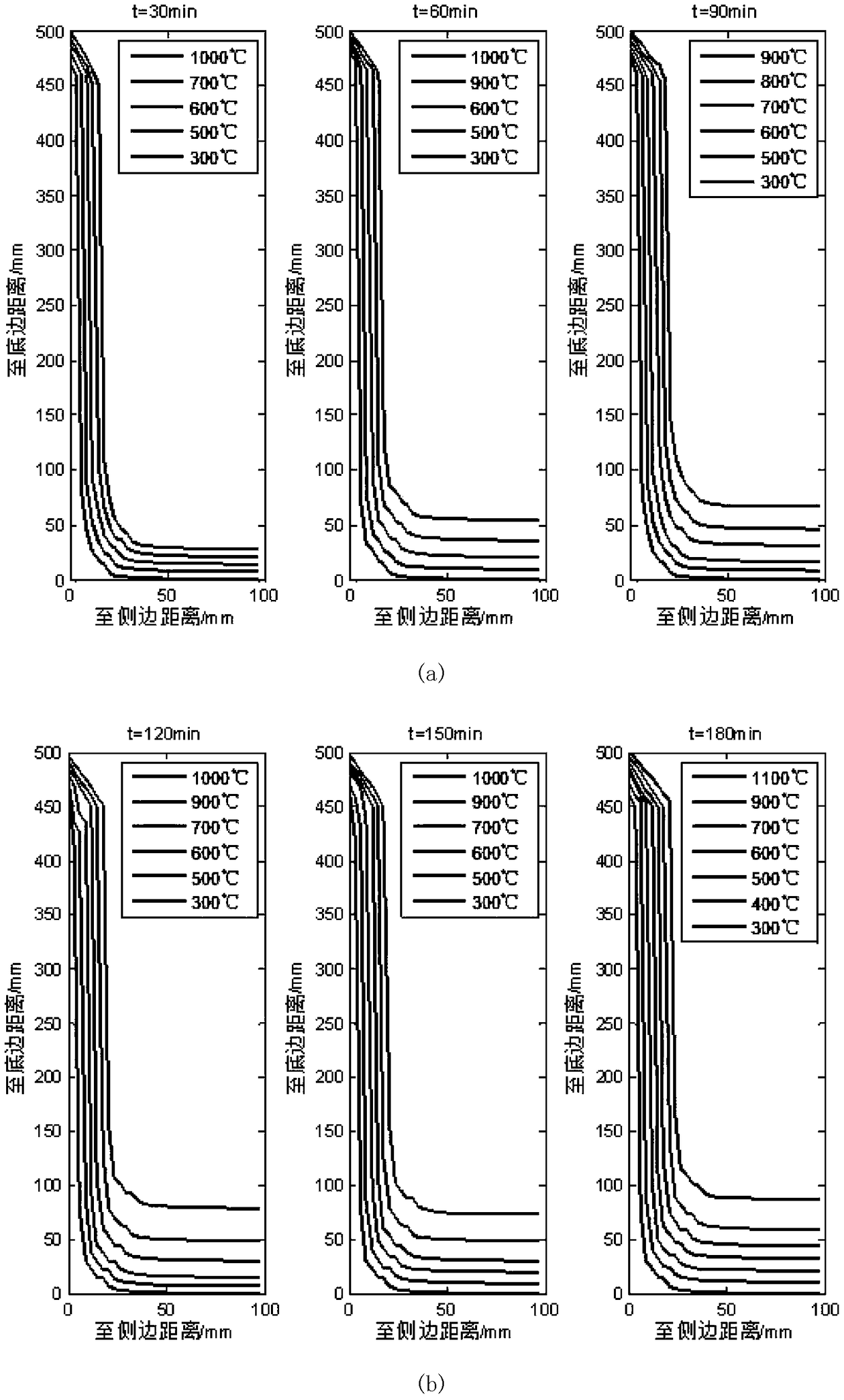

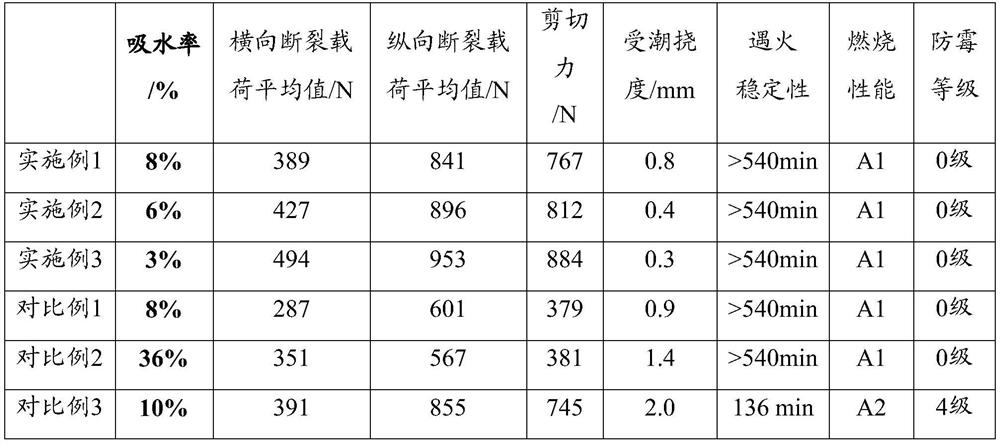

Detection method for fire-resistant performance of reinforced concrete beam and fireproof detection method for fireproof coating

InactiveCN109187254AImprove protectionIncrease breaking loadStrength propertiesRebarStructural element

The invention belongs to the technical field of engineering materials and discloses a detection method for fire-resistant performance of a reinforced concrete beam and a fireproof detection method fora fireproof coating. Difference of thermotechnical and mechanical performance at constant temperature and high temperature is acquired by researching the thermotechnical and mechanical performance ofconcrete and reinforcing steel bars of an RC beam and analyzing high-temperature adhesive property of concrete and reinforcing steel bars. Obtained related conclusions in researching the fire-resistant performance of the RC beam provided with the fireproof coating on the surface have certain guiding meaning in structural element design and reinforcement after fire. By applying a SQW-A material high-temperature strength tester, the compressive strength of a concrete member provided with the fireproof coating on the surface reaches 15.81 MPa which is far greater than that (only 10.78 MPa) of the concrete member without the fireproof coating. Therefore, the fireproof action of concrete is improved by the fireproof coating arranged on the surface of the concrete.

Owner:HUNAN UNIV OF TECH

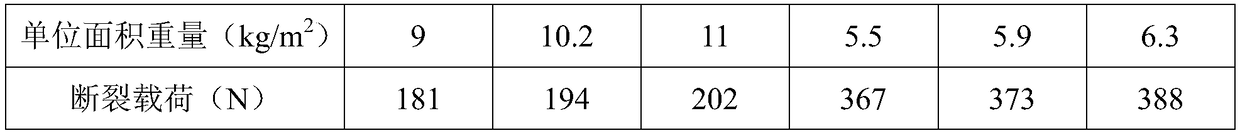

Glass mat gypsum board and preparation method thereof

The invention discloses a glass mat gypsum board. The glass mat gypsum board comprises a board core and a glass mat, wherein the glass mat wraps the board core; the board core is prepared from a gypsum clinker, an anionic surfactant, cellulose ether, chopped glass fibers, a modified emulsion, a mildew preventive, a water reducing agent and water; and in the preparation process of the glass mat gypsum board, the chopped glass fibers are uniformly mixed with the anionic surfactant, the cellulose ether and the water at first. The gypsum board provided by the invention does not need starch as an adhesive, so the possibility of mildew of the gypsum board is greatly reduced. A glass fiber mat is good in air permeability, so moisture is more volatile in the drying process, drying time in the production process of the board is shortened, energy consumption is reduced, and production efficiency is improved. In addition, the gypsum board is high in strength, good in toughness, resistant to water, fire and mildew, small in damp deformation and high in weather resistance, and can be used in a humid environment and a building outer wall.

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

Method of manufacturing artificial wig by palm fibers

The invention relates to the field of wigs replacing hairs and concretely relates to a method of manufacturing an artificial wig by palm fibers. The method concretely comprises steps of de-roughing the palm fibers, softening the palm fibers, decoloring the palm fibers and dyeing the palm fibers. The palm fibers processed via the de-roughing step, the softening step, the decoloring step and the dyeing step can be applied for wig manufacture, has great naturalness and flexibility, is uneasy to knot, and has light weight, great ventilating property and high wearing comfortableness.

Owner:HUNAN XINYUAN HAIR PROD CO LTD

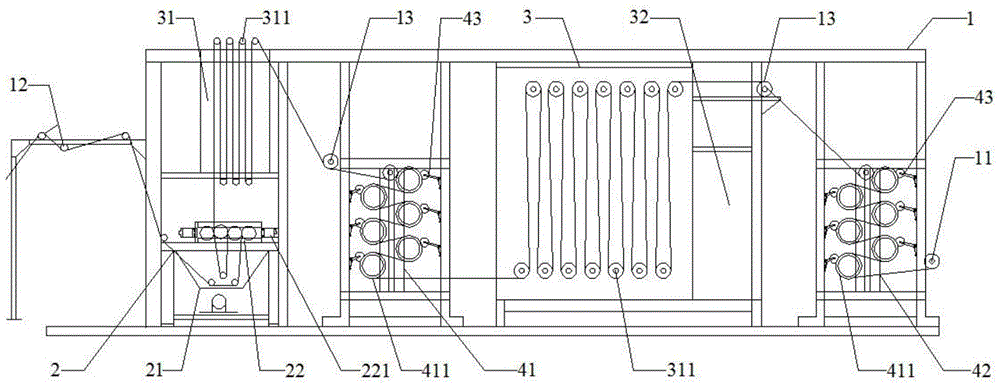

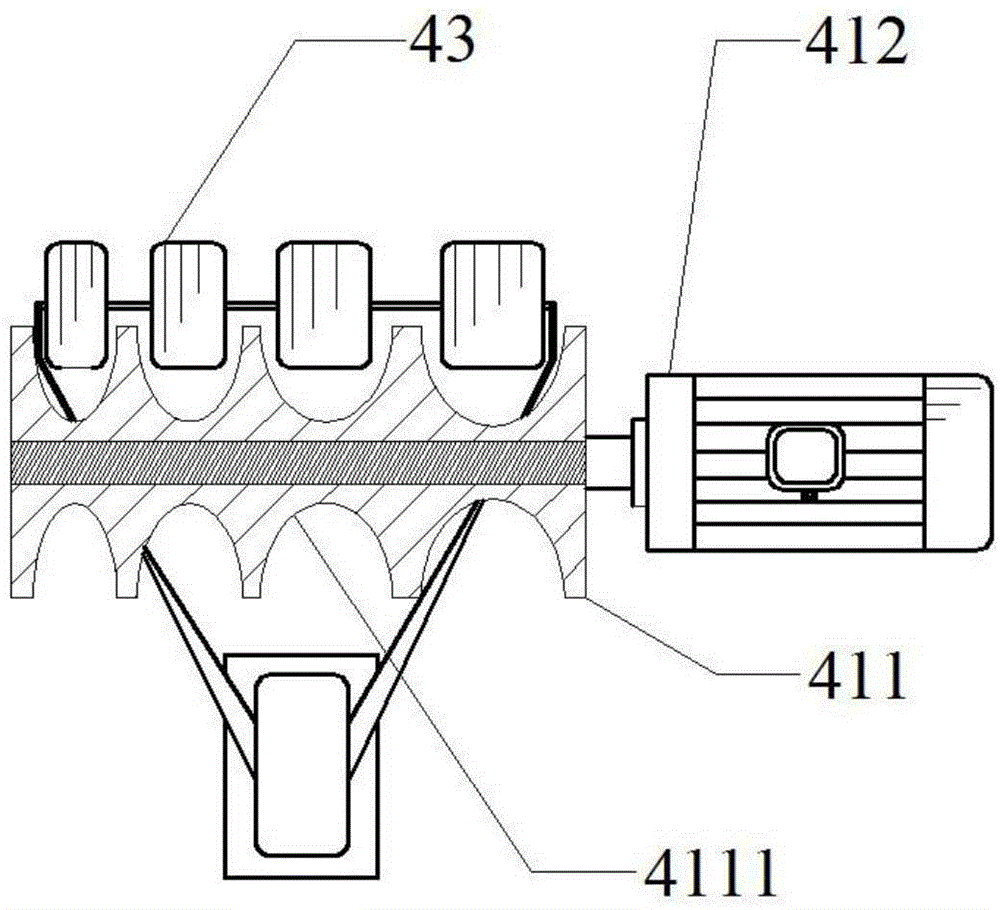

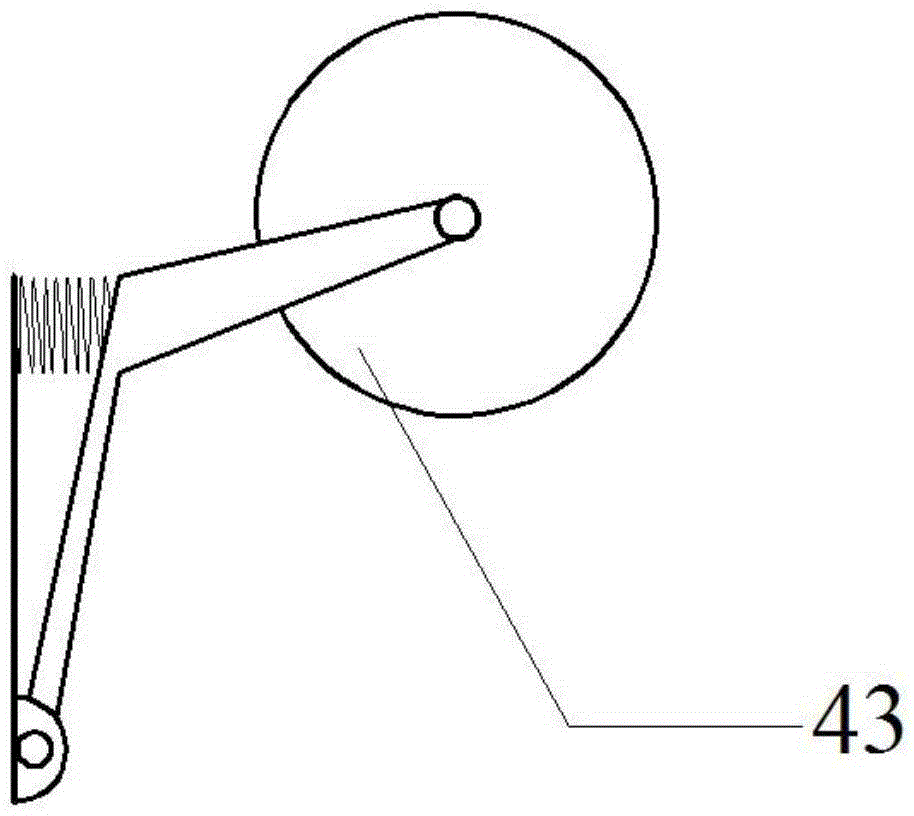

After treatment equipment for ropes

ActiveCN104452380AImprove drying efficiencyIncrease breaking loadRope making machinesMicrowaveAfter treatment

The invention relates to the field of after treatment equipment for ropes, in particular to after treatment equipment for ropes. The equipment comprises a main bracket, a coating mechanism, a drying mechanism, a drafting mechanism and a control box, wherein the main bracket is cuboid, the length of the main bracket is 10500 mm-11500 mm, and the height of the main bracket is 3000 mm-3200 mm; the drying mechanism comprises a microwave heating device and a hot blast box heating device, wherein a plurality of rotating wheels are arranged at the lower end of the microwave heating device and the inner part of the hot blast box heating device, and the rotating wheels are uniformly arrayed in the width direction of the drying mechanism; the drafting mechanism comprises a first drafting mechanism, a second drafting mechanism and compaction wheels, and each drafting mechanism comprises a plurality of traction rollers. The equipment disclosed by the invention uses the microwave heating device and the hot blast box heating device, so that the drying efficiency of the ropes is greatly improved; the drafting mechanism is additionally arranged, so that the fracture load of the ropes can be effectively increased, the layout and the deployment are reasonable, the controllability is strong, and the applicable range is wide.

Owner:QINGDAO HUAKAI OCEAN SCI & TECH

Cement ceiling board and preparation method thereof

The invention belongs to the field of a building material, and particularly relates to a cement ceiling board and a preparation method thereof. The cement ceiling board consists of a polypropylene fiber mesh fabric and cement boards, wherein the polypropylene fiber mesh fabric is laid between the cement boards to form the cement ceiling board consisting of three layers of upper, middle and lower structures. According to the invention, when the cement ceiling board is prepared, by laying the polypropylene fiber mesh fabric between the cement boards, in a case that the prepared cement ceiling board is small in thickness, the cement boards can have excellent breaking strength and a problem that the cement boards are easy to break in the machining process is avoided, so that cement can be usedfor producing the ceiling board; moreover, the prepared ceiling board is light in weight and easy to machine and install.

Owner:UNIV OF JINAN

Fire-resistant paper surface gypsum board and preparation method thereof

The invention discloses a method for preparing a fire-resistant paper surface gypsum board and the prepared fire-resistant paper surface gypsum board. The method comprises the following steps: addingglass fiber into water, firstly mechanically stirring, and then ultrasonically dispersing; adding an aqueous solution in which the glass fibers are dispersed, and other raw materials for preparing thefire-resistant paper surface gypsum board into a stirrer, and stirring to obtain a slurry; pouring the slurry between two layers of refractory paperboards, and carrying out extrusion molding to obtain a wet fire-resistant paper surface gypsum board; and solidifying, cutting off, drying and sawing the wet fire-resistant paper surface gypsum board to obtain a finished fire-resistant paper surface gypsum board product. According to the method disclosed by the invention, the glass fibers can be uniformly dispersed into the gypsum board core, so that the fire-resistant paper surface gypsum board with better fire resistance and higher strength is prepared.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Gold bonding wire and preparation method thereof

ActiveCN102127663BHigh strengthSmall arcSemiconductor/solid-state device detailsSolid-state devicesElectrolysisIngot casting

The invention provides a gold bonding wire. The gold bonding wire comprises the following materials in percentage by weight: 0.0005 to 0.001 percent of beryllium, 0.0008 to 0.002 percent of copper or germanium, 0.001 to 0.003 percent of cerium and the balance of gold, wherein the purity of the gold is more than or equal to 99.996 weight percent. The invention also provides a preparation method ofthe gold bonding wire. The preparation method comprises the following steps of: electrorefining high-purity gold with purity of 99.999 weight percent by using gold with purity of 99.99 weight percent; smelting the high-purity gold; performing ingot casting to form a gold plate; rolling the gold plate to be a thin gold sheet; manufacturing an intermediate alloy; performing vertical smelting; drawing the wire; annealing; winding; and performing vacuum packaging. The gold bonding wire has the characteristics of high strength and low long radian, the yield of products is high, and the winding length of a reeling shaft is large.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

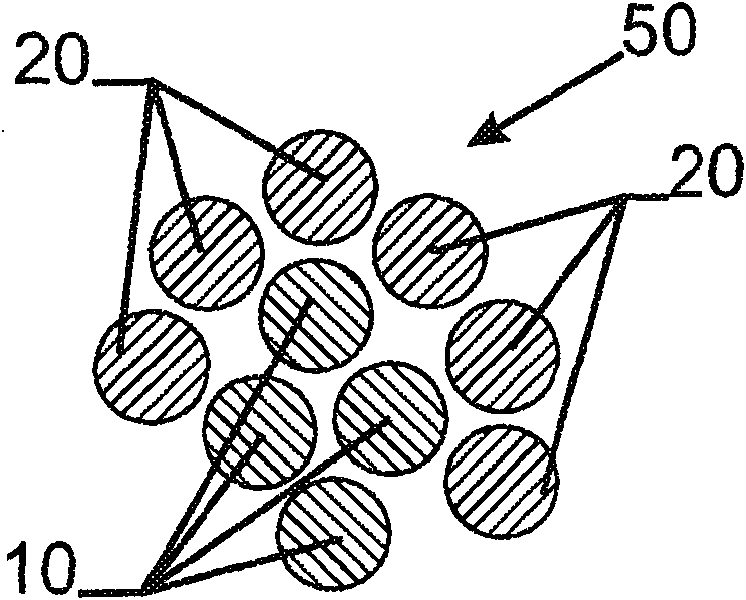

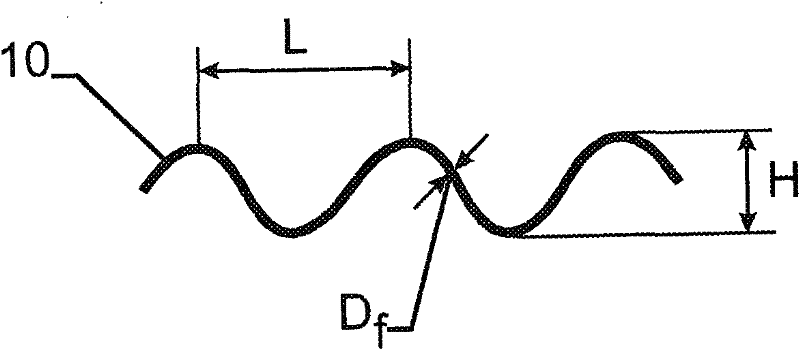

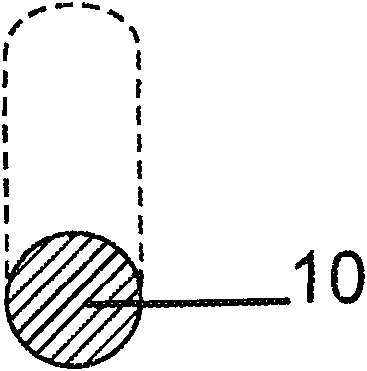

Steel cords for tire reinforcement

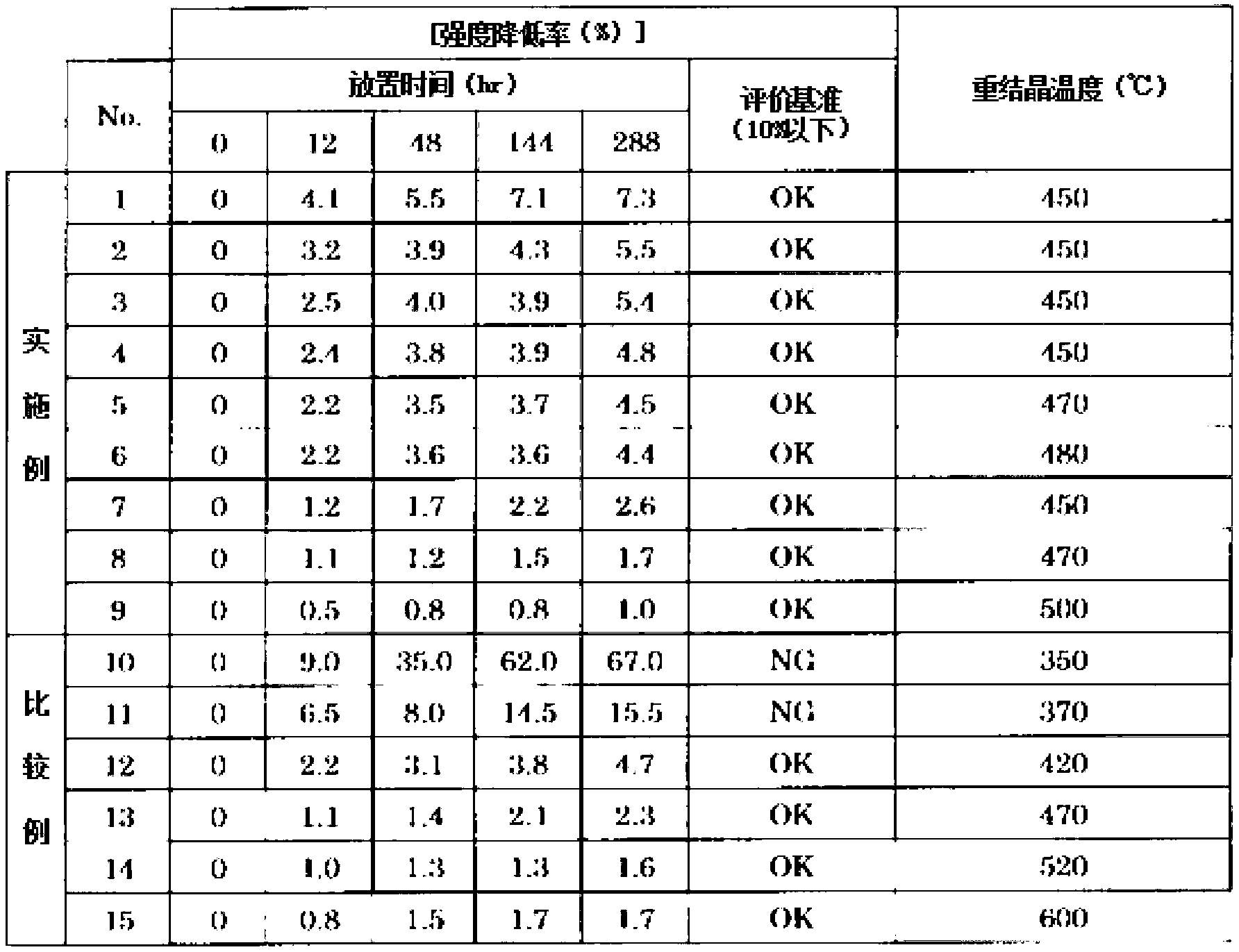

InactiveCN102272377ALittle loss of strengthLow continuous damage rateThin material handlingTextile cablesMetallurgyFiber

A steel cord (50) includes a core layer and an outer layer. The core layer comprises a number of first steel filaments (10) and the outer layer comprises a number of second steel filaments (20). The outer layer is helically twisted around the core layer. The first steel filaments have a lay length greater than 310 mm. At least one first steel filament (10) is preformed in a wave form in one plane. At least one second steel filament (20) is polygonally preformed.

Owner:NV BEKAERT SA

Anchor rope total length anchoring method for coal mine soft rock roadway

Owner:CHINA UNIV OF MINING & TECH +1

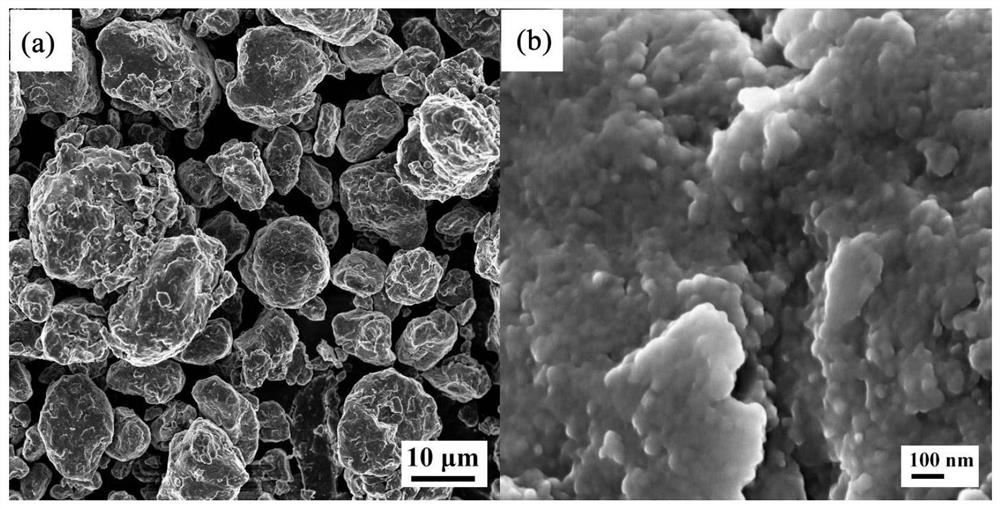

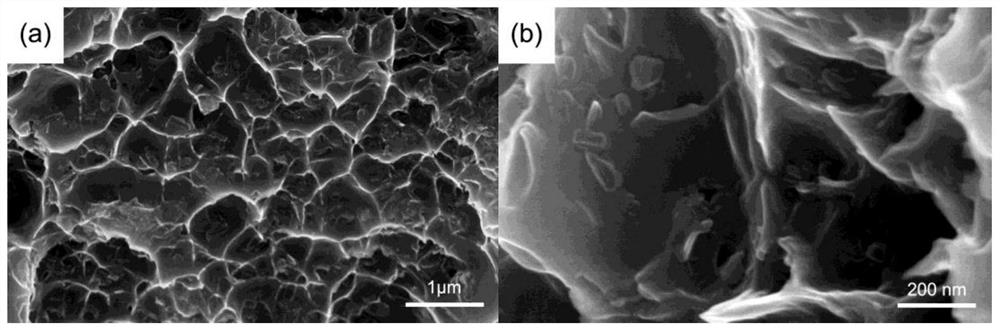

A nano-modified aluminum alloy material and its preparation method and energy-saving and environment-friendly power fittings produced therefrom

ActiveCN111455208BLow densityMeet security and stability performance requirementsCarbon nanotubeMalleable iron

The invention discloses a nano-modified aluminum alloy material and its preparation method and the energy-saving and environment-friendly electric fittings produced therefrom. The method comprises the following steps: 1) preparing silicon-coated carbon nanotubes: mixing silicon powder and carbon nanotubes Mechanical ball milling to fully mix silicon powder and carbon nanotubes to construct a core-shell structure to obtain silicon-coated carbon nanotubes; 2) Preparation of nano-modified aluminum alloy materials: adding silicon-coated carbon nanotubes obtained in step 1) to aluminum alloy Semi-solid stirring is carried out in the matrix, so that the added silicon-coated carbon nanotubes are uniformly dispersed in the aluminum alloy matrix, and then the temperature is raised for casting to obtain cast rods of nano-modified aluminum alloy materials. Compared with traditional malleable cast iron materials for electric fittings, the nano-modified aluminum alloy material prepared by the invention has the advantages of light weight, high strength and no galvanizing, and has higher strength than conventional aluminum alloys.

Owner:STATE GRID CORP OF CHINA +2

High Purity Copper Soldering Leads

InactiveCN102859672BAvoid damageIncrease breaking loadSemiconductor/solid-state device manufacturingSolder ballRoom temperature

Provided is a high-purity copper alloy ball welding lead, which has a high recrystallization temperature, is easy to wire drawing at room temperature, and has low hardness of the initial solder ball, and does not cause IC chip cracks. By adding a small amount of phosphorus (P) to high-purity copper with a purity of 99.9985% by mass or higher, the recrystallization temperature is higher than that of high-purity copper with a purity of 99.9999% by mass or higher, and the initial The hardness of the solder ball decreases. The above characteristics are achieved by adding 0.5 to 15 mass ppm of phosphorus (P) to high-purity copper having a purity of 99.9985% by mass or higher and keeping the total content of other impurities contained below the above-mentioned content of phosphorus (P).

Owner:TANAKA DENSHI KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com