Novel reinforced bar type ultra-high-performance concrete pipeline and preparing method thereof

An ultra-high performance, concrete technology, applied in rigid pipes, pipes, reinforcement molding, etc., can solve the problems of difficulty in forming a pipe body, no way to adapt to ultra-high-performance concrete pipe forming, ultra-high-performance concrete layering, etc., and achieve damage. The effect of increased load, shortened construction period and small roughness coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

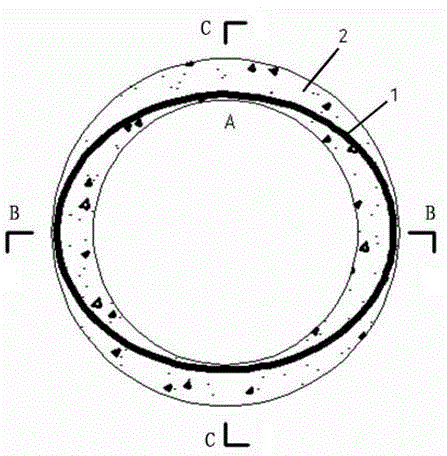

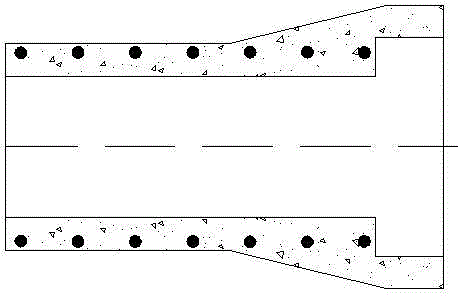

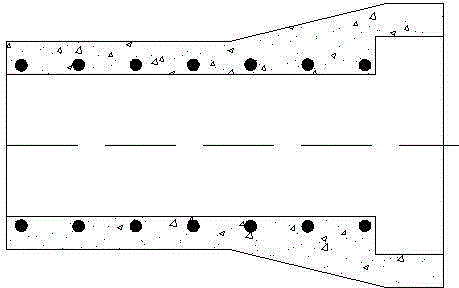

[0039] Such as Figure 1 to Figure 3 As shown, a new ultra-high-performance concrete pipeline in the form of reinforcement includes a pipeline body 2 and a steel skeleton arranged in the pipeline body 2, and the steel skeleton includes ring bars 1 uniformly arranged along the length direction of the pipeline body 2 And the longitudinal reinforcement connecting each ring reinforcement 1, the shape of the ring reinforcement 1 is ellipse, the thickness of the steel skeleton protective layer is not less than 10mm, and the thickness of the pipe wall is not less than 60mm.

Embodiment 2

[0041] A method for preparing ultra-high-performance concrete pipelines in the form of new reinforcement. The pipeline forming molds used include steel outer molds and hard plastic inner molds. Inner diameter 1000mm, wall thickness 60mm (see Figure 1 to Figure 3 ), including the steps:

[0042] 1) Welded steel skeleton, the longitudinal reinforcement of the skeleton remains unchanged, the ring reinforcement 1 is processed into an oval shape, equipped with 16 longitudinal reinforcements, and the distance between the oval ring reinforcement is 240mm;

[0043] 2) Assemble the mold and fix the steel frame, connect the pumping machine with the mold, and check its sealing performance;

[0044] 3) Prepare ultra-high performance concrete mixture;

[0045] 4) Put the ultra-high performance concrete mixture into the pumping machine, and use the pumping jacking process to form the pipeline;

[0046] 5) After the pumping is completed, seal the closed grouting port of the mold in time;...

Embodiment 3

[0072] A new method for preparing ultra-high-performance concrete pipelines in the form of reinforcement. The pipeline forming molds used include steel outer molds and hard plastic inner molds. The material of the hard plastic inner molds is polyvinyl chloride, the thickness is 5mm, and the inner diameter of the pipeline is 1000mm. , wall thickness 80mm, including steps:

[0073] 1) Welded steel skeleton, the longitudinal reinforcement of the skeleton remains unchanged, the ring reinforcement 1 is processed into an oval shape, equipped with 16 longitudinal reinforcements, and the distance between the oval ring reinforcement is 240mm;

[0074] 2) Assemble the mold and fix the steel frame, connect the pumping machine with the mold, and check its sealing performance;

[0075] 3) Prepare ultra-high performance concrete mixture;

[0076] 4) Put the ultra-high performance concrete mixture into the pumping machine, and use the pumping jacking process to form the pipeline;

[0077] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com