Steel cords for tire reinforcement

A technology of steel cords and filaments, used in textile cables, transportation and packaging, textiles and papermaking, etc., can solve the problems of the failure load of the cord cannot meet the requirements, the high wear of the crimping equipment, and the high continuous failure rate of the cord. , to achieve the effect of low strength loss, low continuous failure rate and low wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

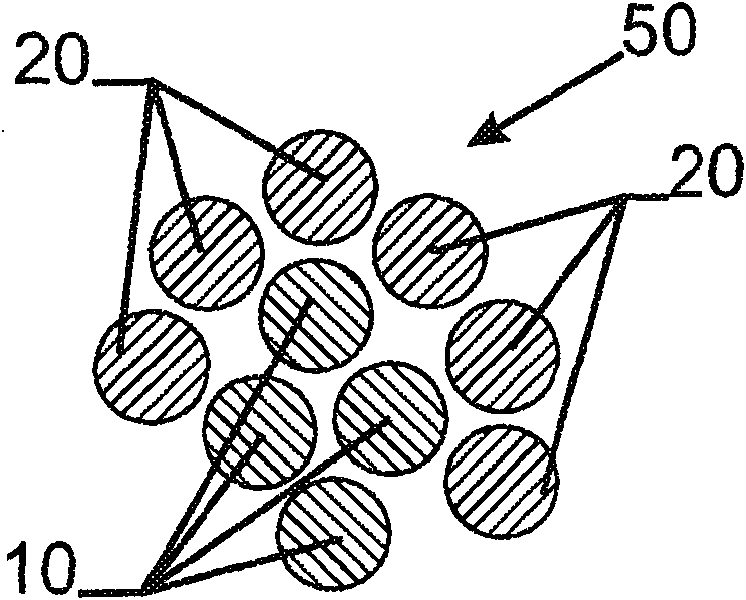

[0040] exist figure 1 A first preferred embodiment is shown in . The steel cord 50 has a core layer including four first steel filaments 10 and an outer layer including six second steel filaments 20 . The outer layer is helically twisted around the core with a core lay length of 23mm and the diameter of the steel filaments 20 is 0.38mm.

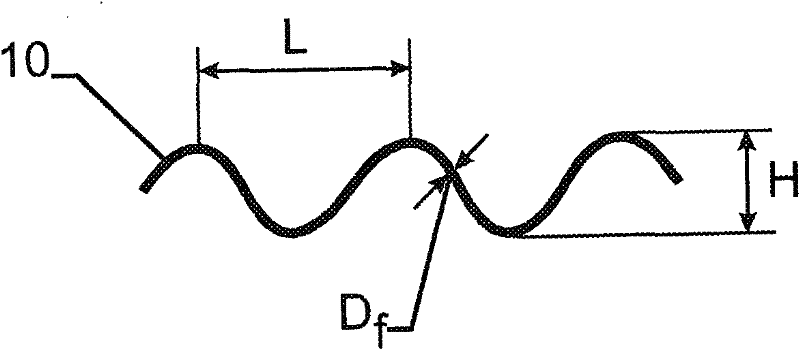

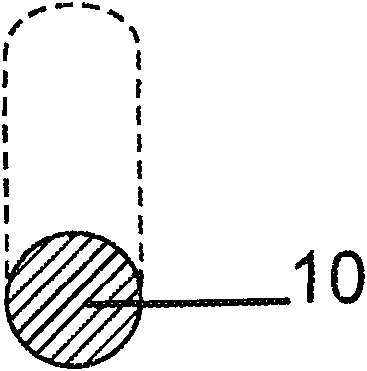

[0041] The four first steel filaments 10 are wave-formed in a single plane and are untwisted, ie they are parallel to each other. figure 2 and image 3 A side view and a front view of the first and second steel filaments 10 are shown, respectively. The wave height H is 0.65mm, and the wavelength L is 5.13mm, while the diameter D f is 0.38mm.

[0042] Six second steel filaments 20 were preformed multilaterally and twisted together with an outer lay length of 23 mm. Figure 4 and Figure 5 A side view and a front view of the second steel filament 20 are shown, respectively. The X axis is parallel to the longitudinal and central axis 80 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lay length | aaaaa | aaaaa |

| Wave height | aaaaa | aaaaa |

| Wave height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com