Tooth-shaped chain

A technology of toothed chains and chains, applied in the field of toothed chains and chains, can solve problems such as difficulties in mechanized mass production, strong polygonal effects, and elongated chain links, and achieve easy automated assembly processes, realize automated assembly processes, and reduce Effects of Shock and Vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

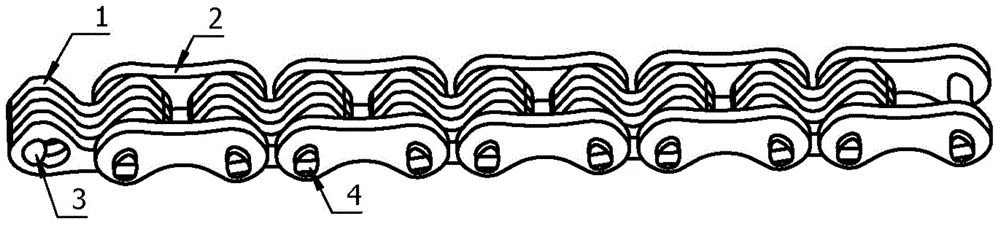

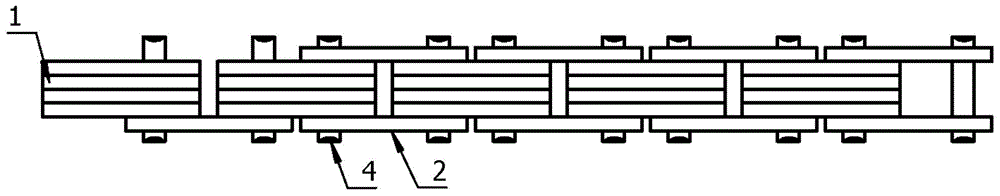

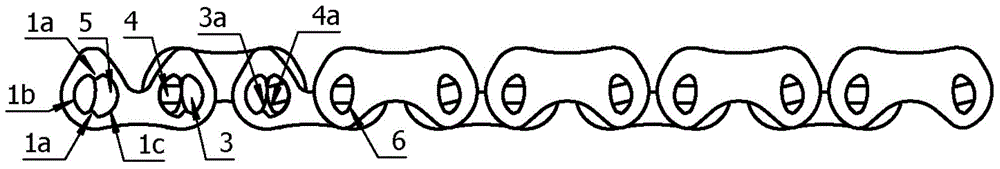

[0045] Example 1, see figure 1 -3. A toothed chain used for the external drive chain of a motorcycle, which consists of 4 inner chain plates (1), outer chain plates (2), short pins (3) and long pins (4). The inner chain plate hole (5) is a round hole, and a pair of tooth-shaped protrusions (1a) are arranged on the inner chain plate hole (5), and the tooth-shaped protrusions (1a) divide the inner chain plate hole (5) into outer There are two parts, the card slot (1b) and the inner hole slot (1c). Outer chain plate hole (6) section shape is identical with long pin shaft (4) section shape. The short pin shaft (3) and the long pin shaft (4) cross-sectional shape are all made of several sections of arcs and some sections of straight lines. The short pin shaft (3) is axially positioned by the tooth-shaped protrusion (1a) and the outer card slot (1b), and is fixed together with the inner chain plate (1) by an interference fit. Several inner chain plates ( 1) Overlapping assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com