Patents

Literature

134results about How to "Avoid gluing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

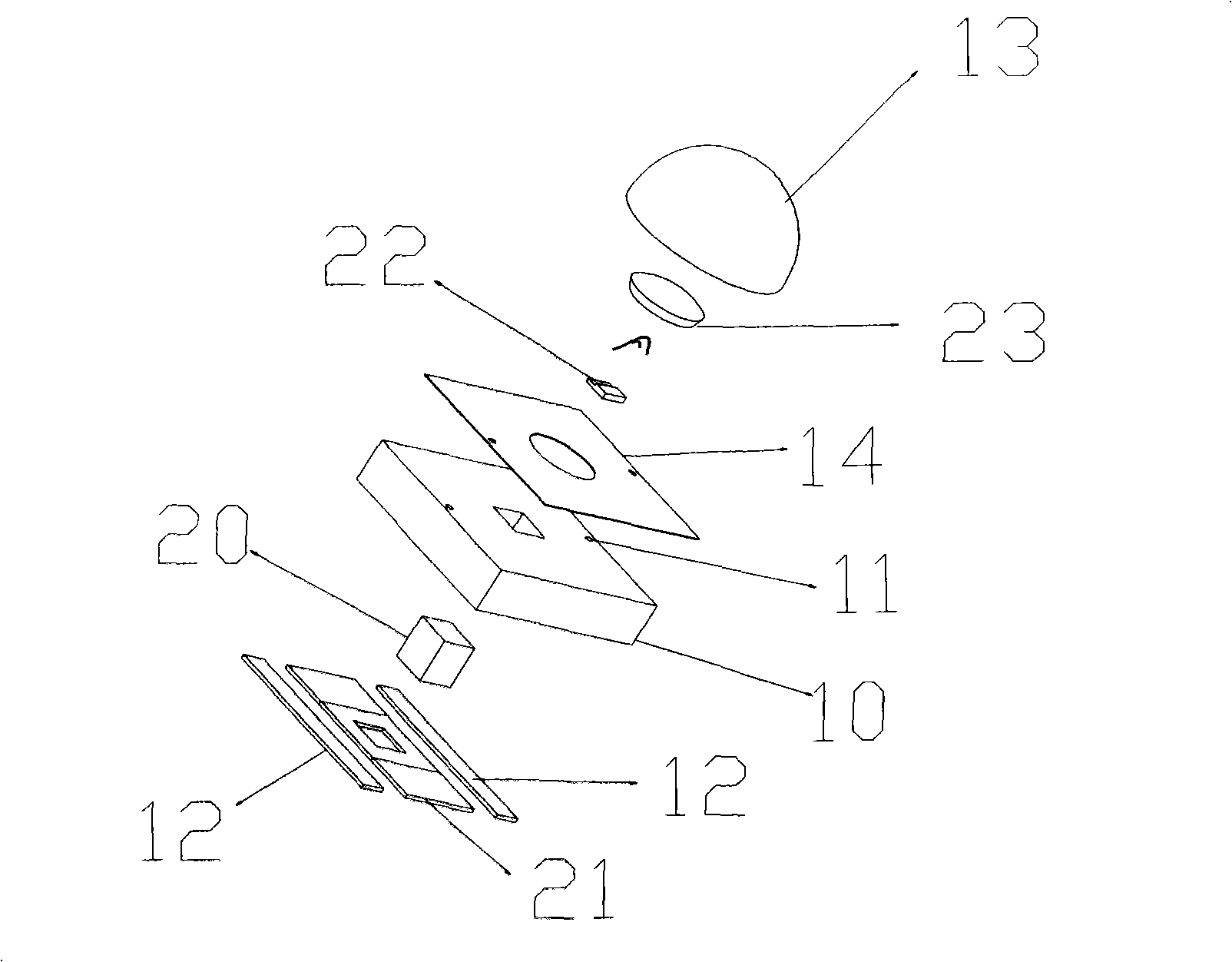

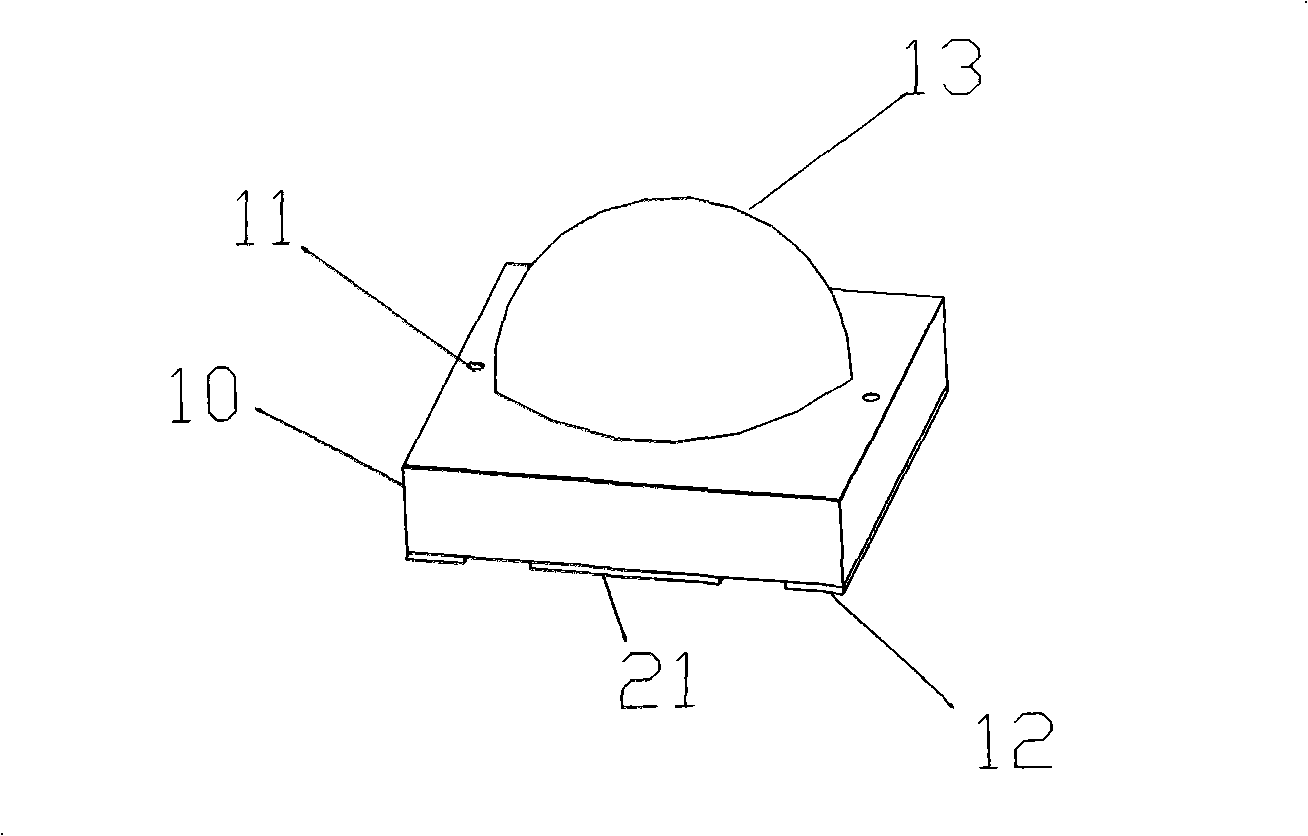

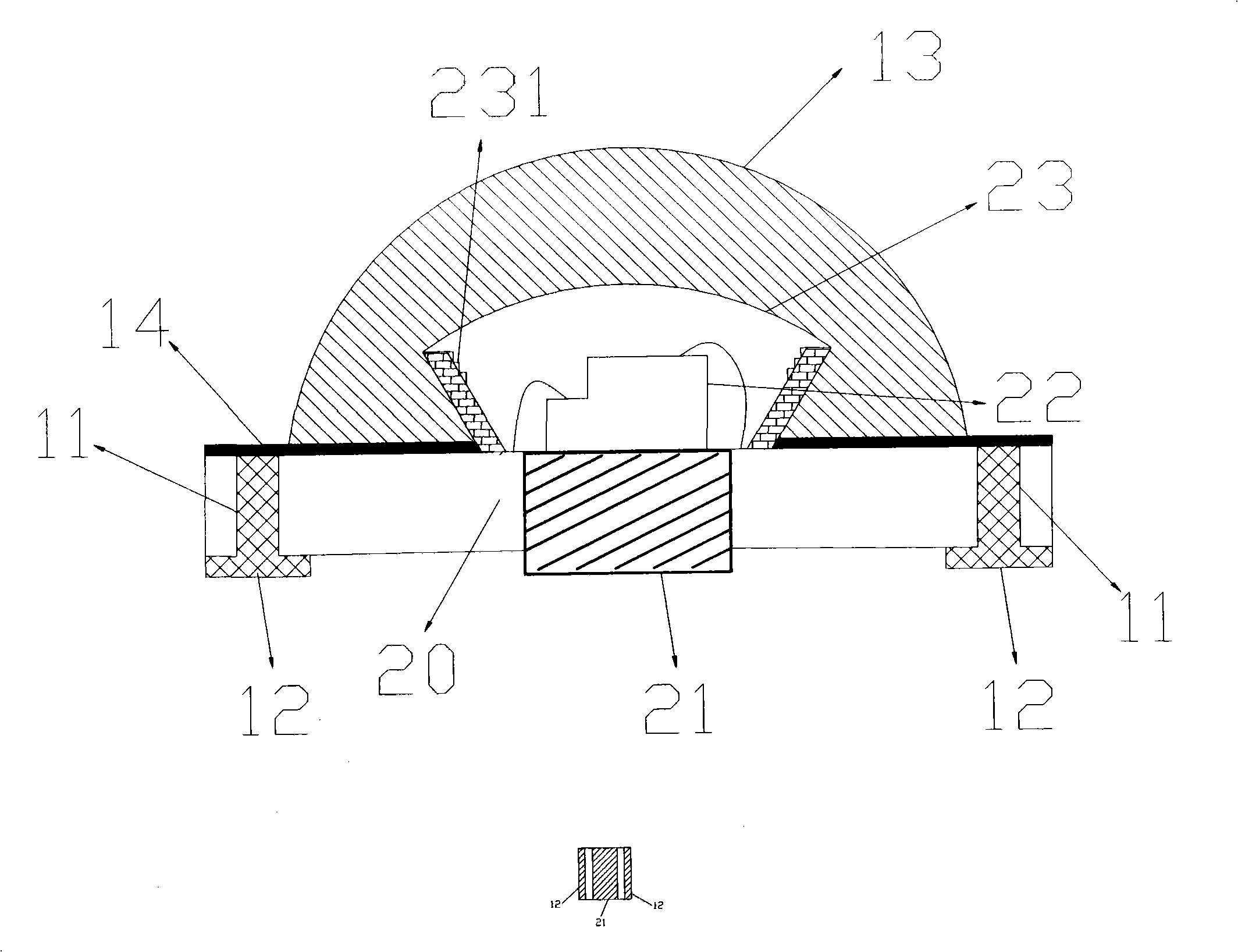

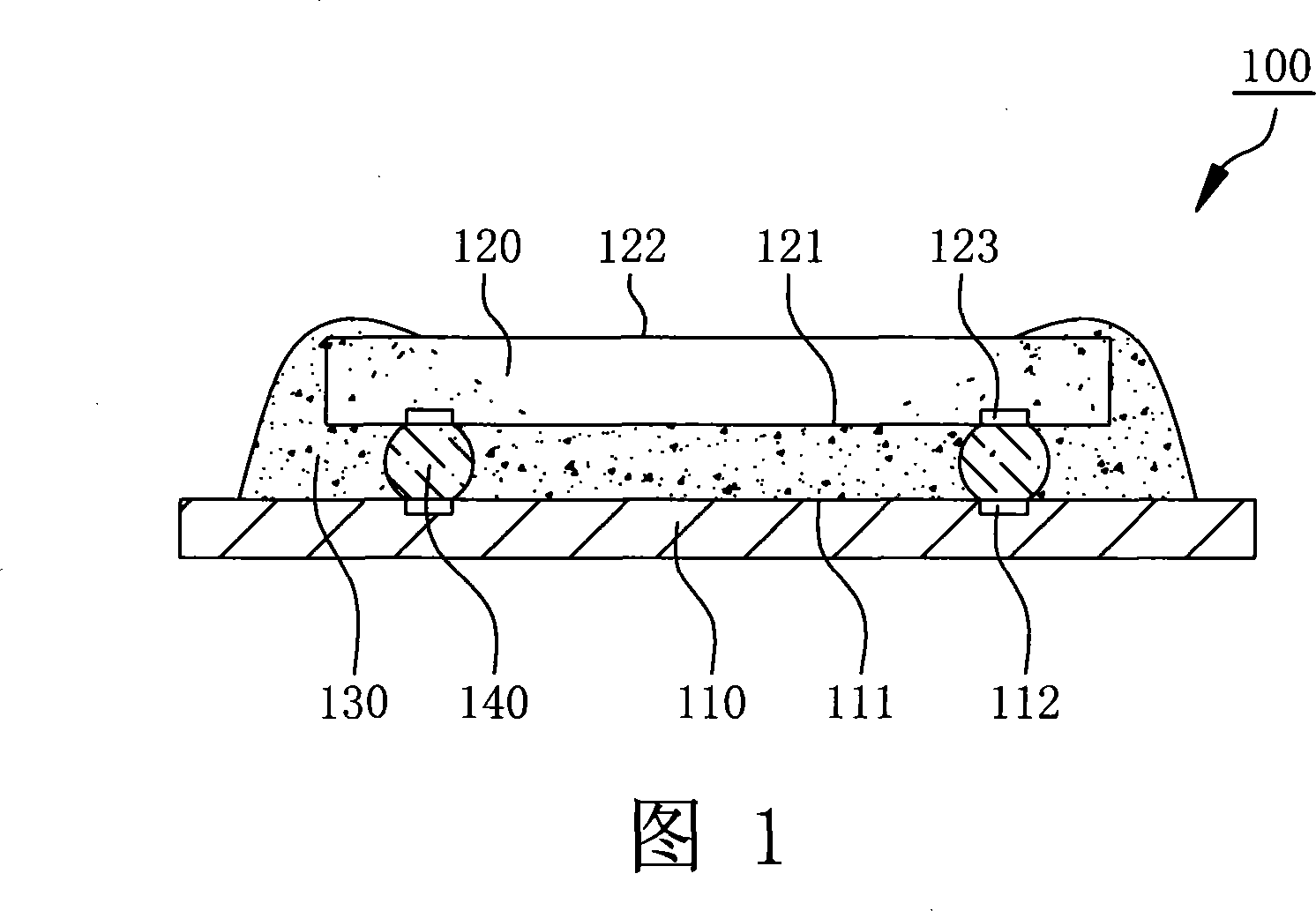

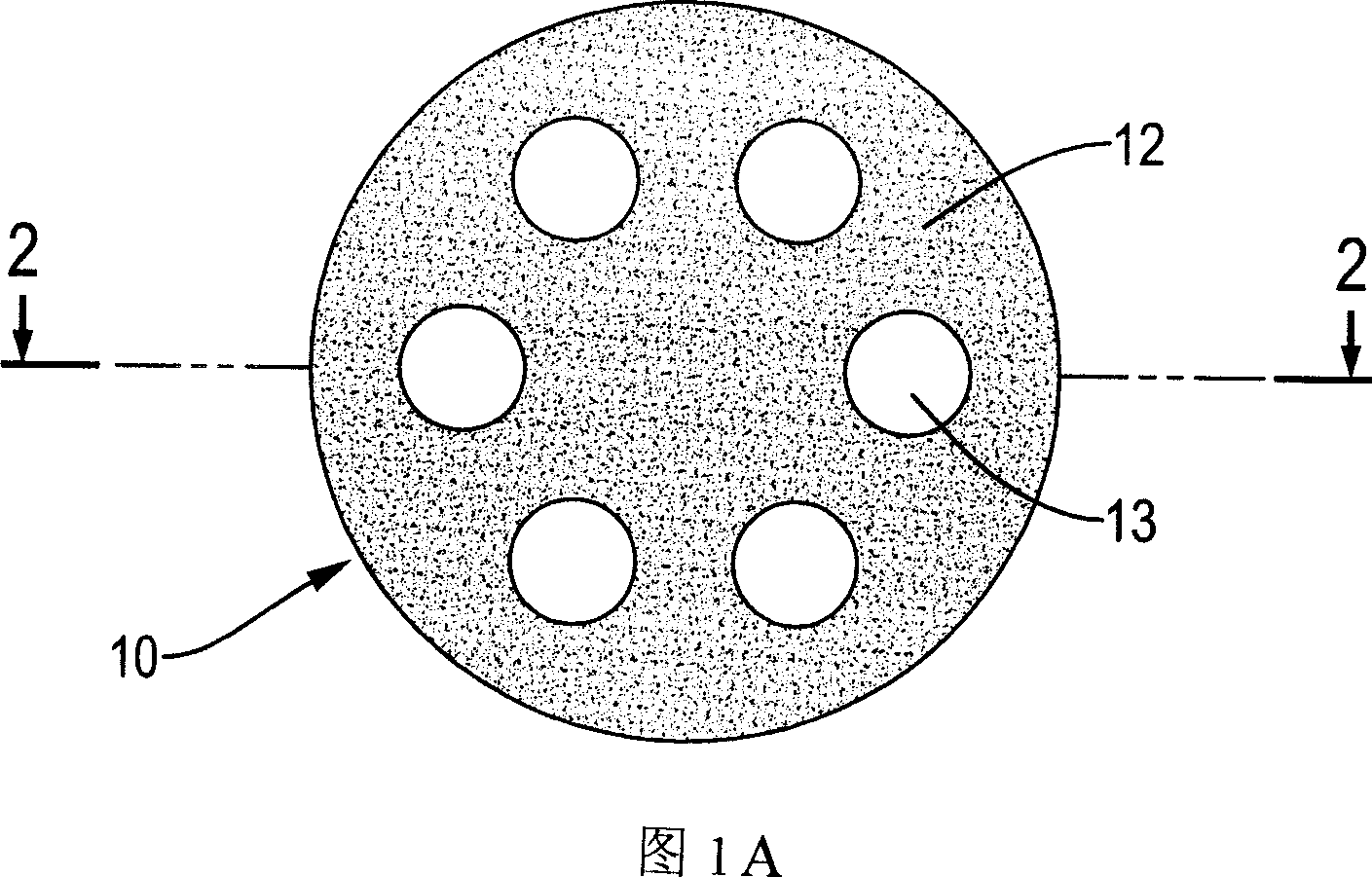

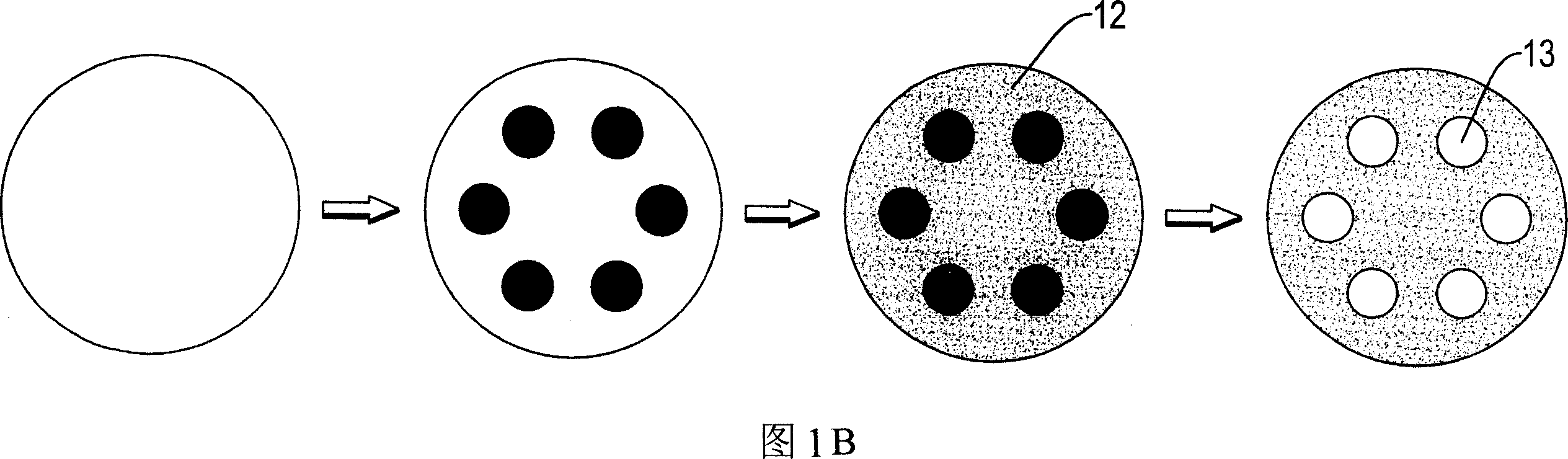

LED lamp with high power

InactiveCN101539250AQuality improvementSpeed up exportPoint-like light sourceElectric circuit arrangementsHeat conductingEngineering

The invention relates to an LED lamp with high power, which comprises a heat-conducting and insulating substrate and a heat conducting pillar which has the same thickness of the substrate and is embedded in the substrate; the lower surface of the pillar is connected with a heat dissipating plate, and the upper surface thereof is fixed with a chip; the upper surface of the substrate is fixed with a transparent housing and is provided with a circuit and electrodes; the periphery of the substrate is provided with a through hole used for the circuit passing through; the bottom of the through hole is connected with a conductive electrode plate; and a lens is encapsulated on the transparent housing of the substrate. The LED lamp with high power has unique structure, breaks through the design of traditional LED lamp, can improve the reliability and consistency of the products; and simultaneously, by utilizing machinery equipments for production, the production efficiency is greatly improved and the product cost is reduced.

Owner:薛信培 +1

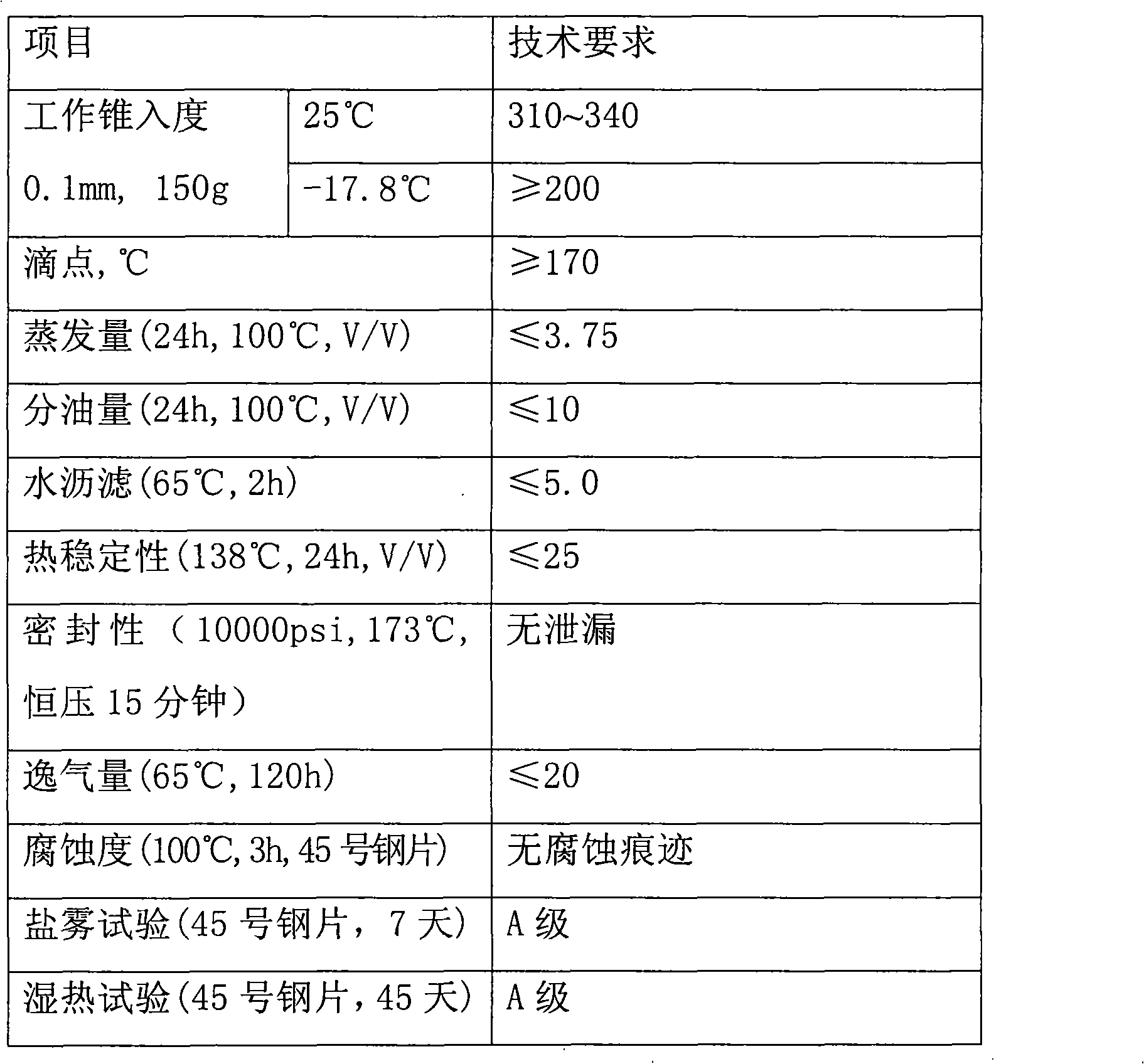

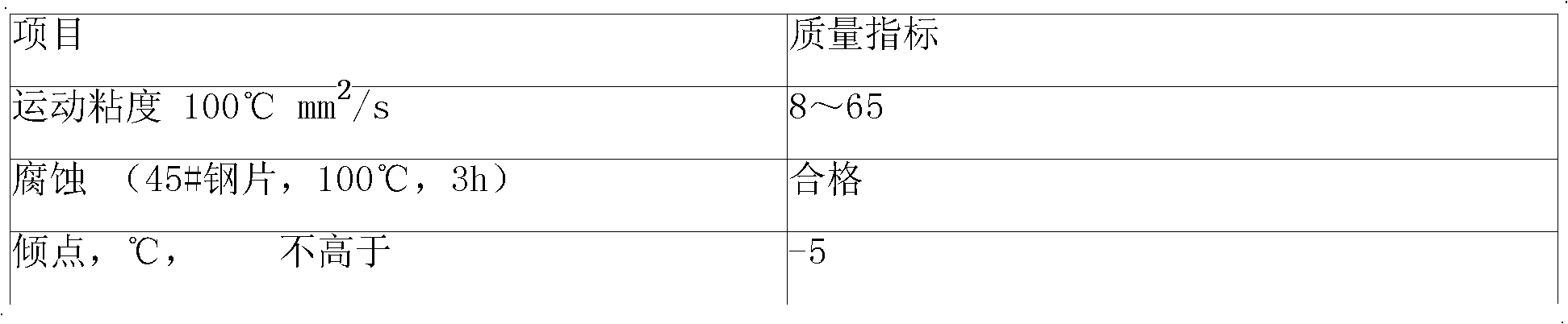

API oil sleeve thread sealing grease composite and preparation method thereof

ActiveCN101565648AImprove low temperature fluidityMechanical automatic spraying effect is goodOther chemical processesAdditivesWear resistantPetroleum

The invention provides an API oil sleeve thread sealing grease composite. The components of the composite include 40-50 percent of basic grease, 5-10 percent of dimethyl silicon oil, 16.5-20 percent of crystalline graphite powder, 6-9 percent of polyfluortetraethylene, 0.5-1.0 percent of expansion graphite powder, 1-2 percent of white carbon black, 3-4 percent of sericite in powder, 3-4 percent oflight calcium carbonate and 10-15 percent of tin bronze powder according to the percentage accounting for in the weight of the sealing grease composite. The invention also provides a preparation method of the API oil sleeve thread sealing grease composite. The invention has the beneficial effects that among the components of the sealing grease composite, synthetic oil is taken as a substitute formineral oil, and therefore the low temperature fluidity of the basic grease is improved to facilitate the brush application in winter. The addition of high performance antirust to the basic grease ensures that pipe threading does not rust when oil sleeves and pipes are stored outside in long term. Without zinc powder added but with the consumption of copper powder increased and other wear-resistant materials added, the high temperature lubricity of the grease is guaranteed and the pipe threading of the oil sleeves and pipes is prevented from thread gluing when screwing together. With novel high efficiency sealing materials added in the components of the sealing grease composite, the leak tightness of the grease is guaranteed.

Owner:TIANJIN PIPE GROUP CORP

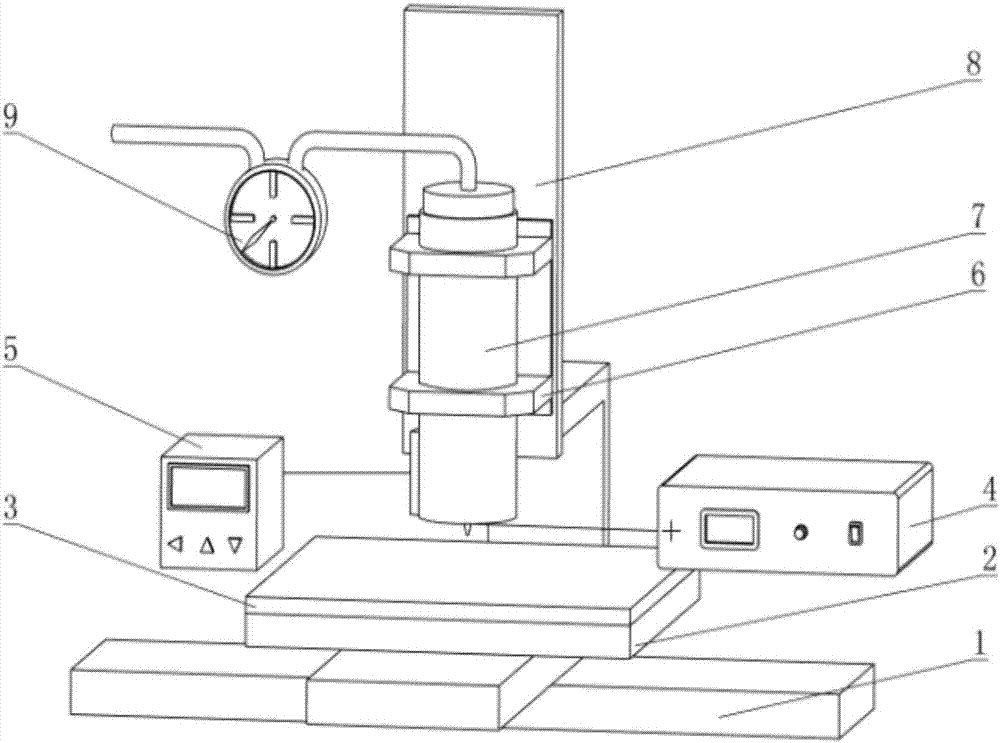

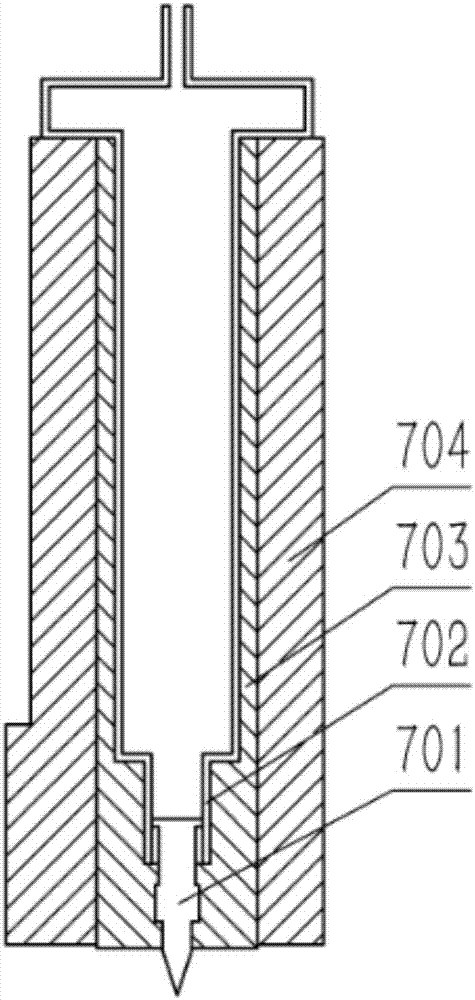

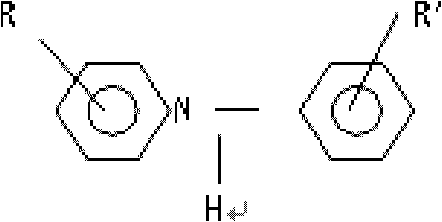

Molten jetting deposition 3D printing device driven by electric field, and working method thereof

InactiveCN107160685AAvoid cloggingEvenly heatedManufacturing heating elements3D object support structuresScale structureHigh pressure

The invention discloses a molten jetting deposition 3D printing device driven by an electric field, and a working method thereof. The problems that the molten droplet jetting 3D printing accuracy is low, the printing materials are limited and the micro-scale structure printing is hard to achieve are solved, and the high-accuracy and high-efficiency macro / micro-scale manufacturing of complex 3D structures using thermal phase transition and thermoplastic polymer materials and composite materials is achieved. According to the technical scheme, the 3D printing device comprises a two-dimensional stage which is provided with a printing bed, and an insulating thermal-conductive substrate is attached to the printing bed; a jetting unit is arranged above the insulating thermal-conductive substrate, and connected to a Z-axis workbench; the jetting unit comprises a print head comprising a nozzle and a material storage barrel which are connected to each other, and the print head is connected to the anode of a high-voltage pulse power supply; the nozzle is a musashi conductive nozzle; the material storage barrel is connected to a backpressure control unit; and a heater is sheathed outside the print head, and connected to a temperature control unit.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

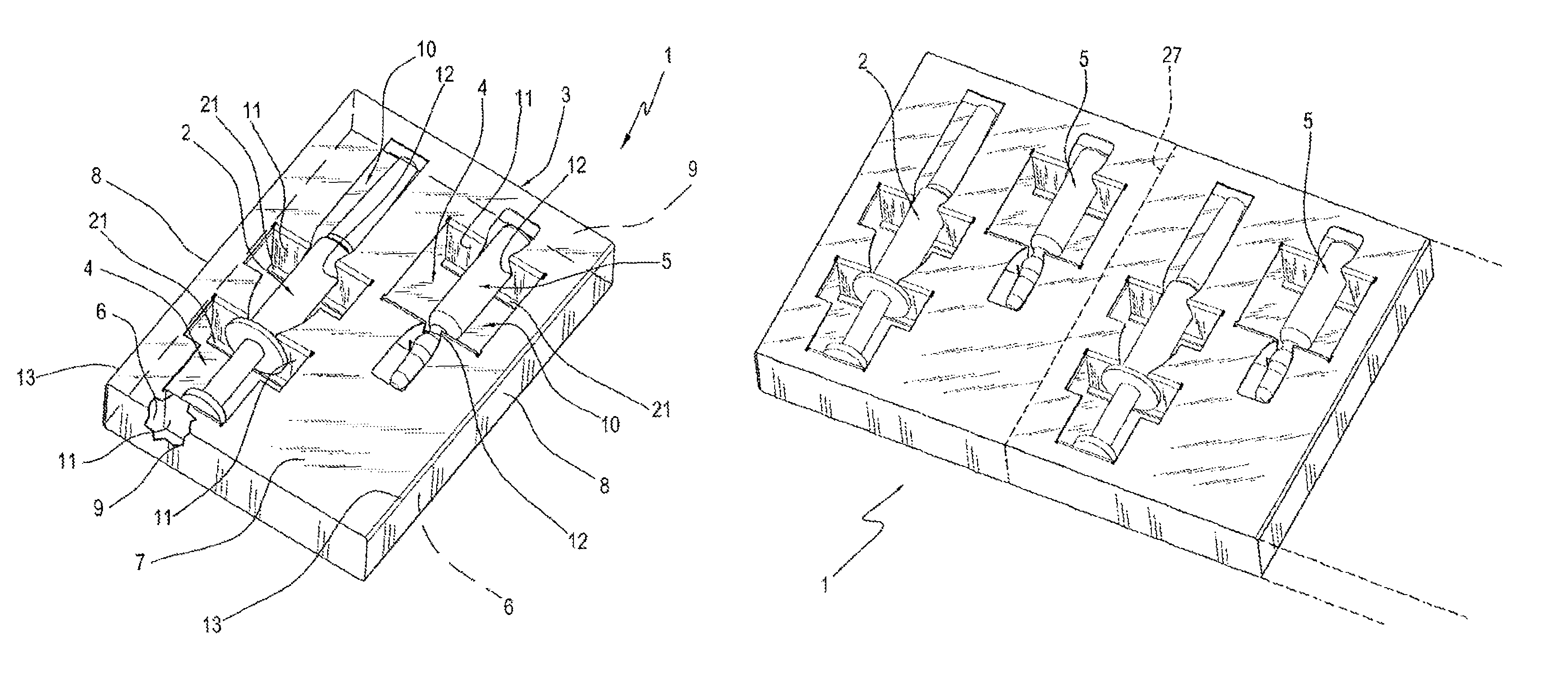

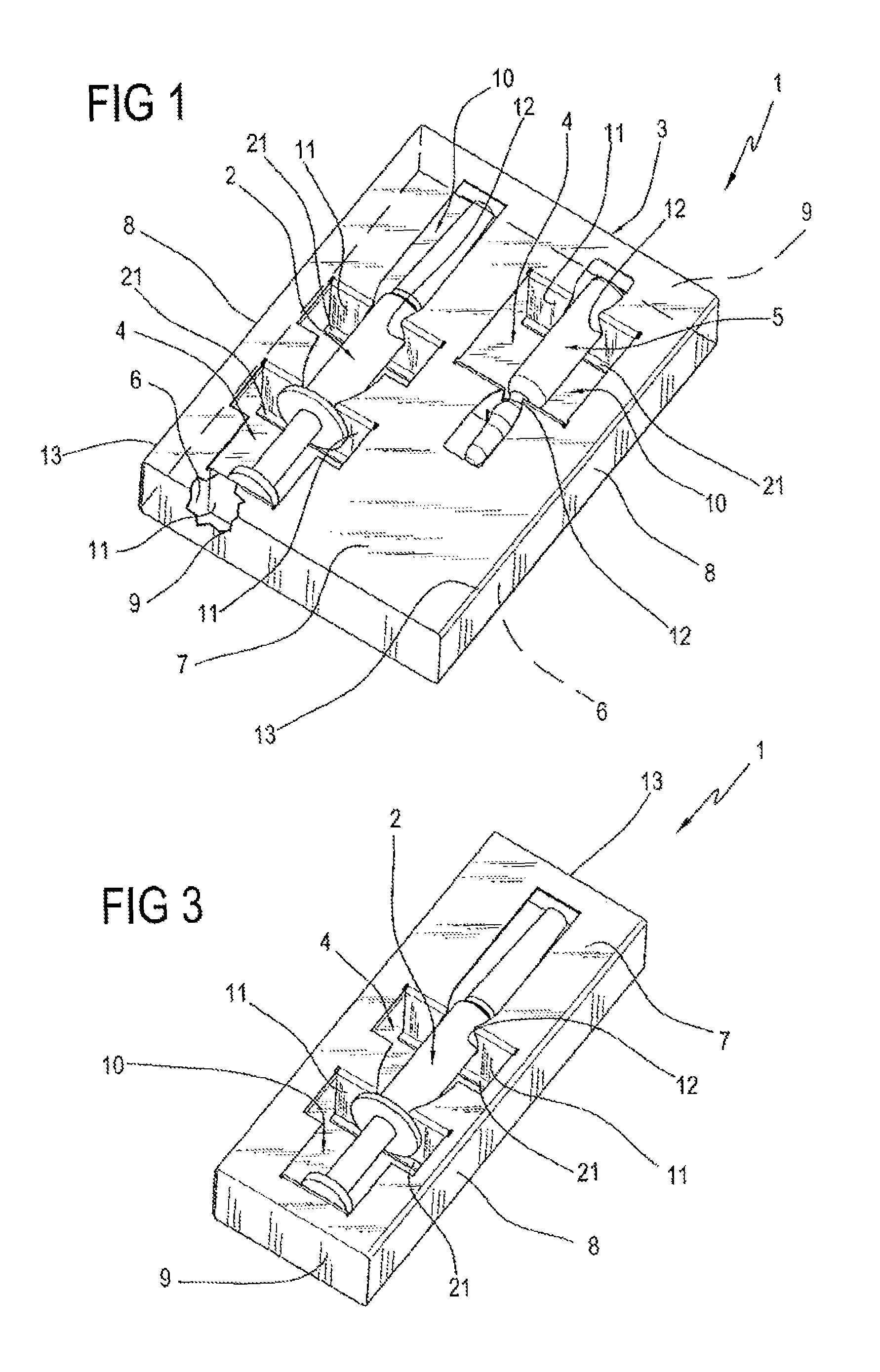

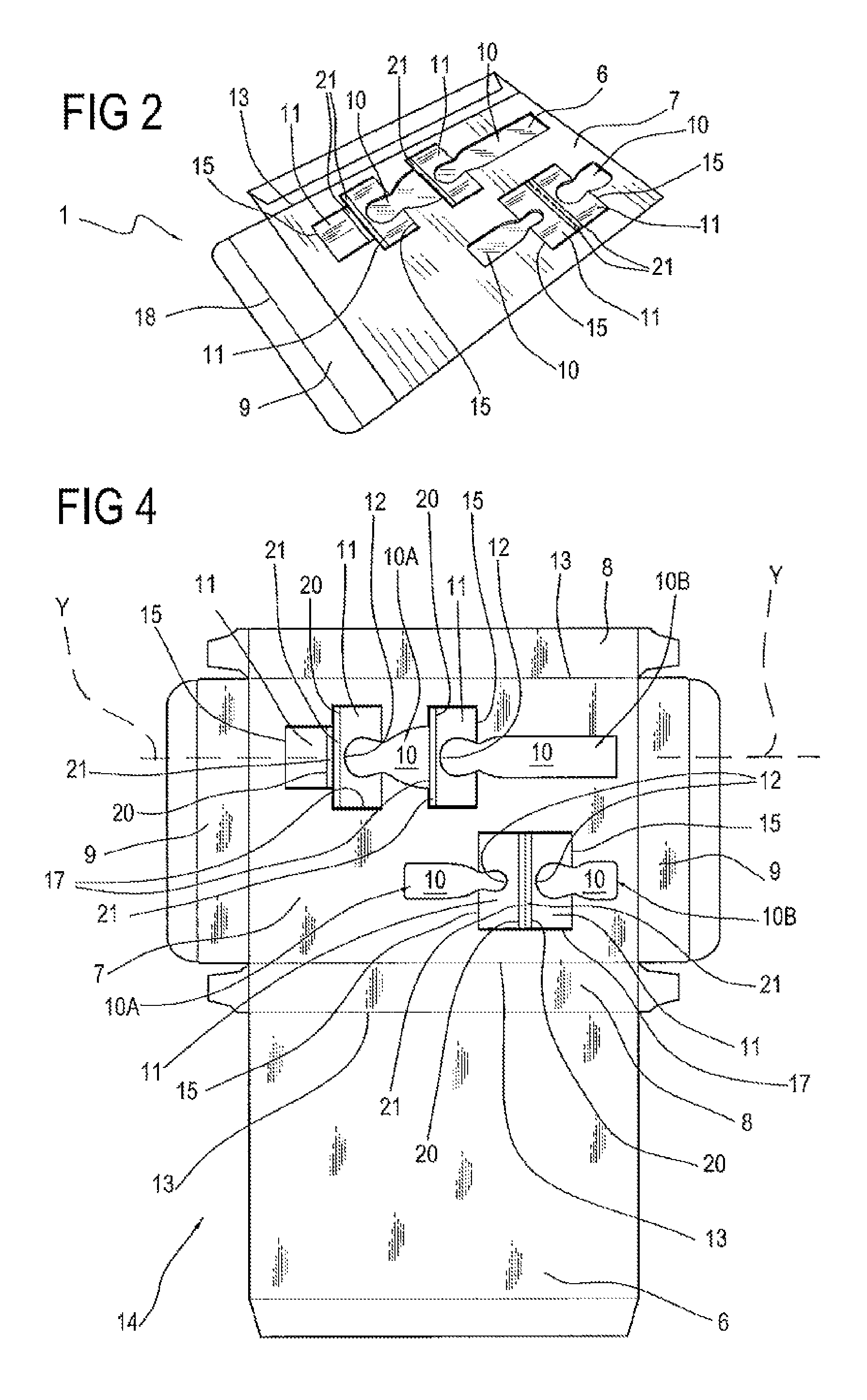

Package for pharmaceutical products

A package for pharmaceutical products, in particular for parenteral products (prefilled syringes, flacons, ampoules, vials, bottles), comprises a supporting body forming at least one compartment for containing a parenteral product made from a single-sheet blank, preferably made of paper-based material, which has a base face, an upper face and a plurality of lateral faces which are connected to the base face and / or to the upper face, said upper face having at least one opening made in it and comprising at least one foldable portion defined by cutting lines of the upper face and / or by crease lines and delimiting a portion of the opening to form a cavity designed to receive the parenteral product, the supporting body being able to switch between a non-operating condition in which it has a planar profile which minimises its dimensions, and an operating condition in which: the supporting body is substantially box-shaped; the foldable portion is folded inside the supporting body so that together with the opening it forms the compartment for containing the parenteral product and allows the parenteral product to be removably constrained in the cavity in the containment compartment.

Owner:ESSENTRA PACKAGING SRL

Grease used for metal fastener

InactiveCN101805656AImprove adhesionImprove antioxidant capacityAdditivesPreservativeFilm-forming agent

The invention discloses grease used for a metal fastener, which is prepared from the following components in percentage by weight ( in percentage by total weight of the grease): 50.0 to 90.0 percent of basic grease, 1.5 to 20.0 percent of film-forming agent, 0.1 to 1.0 percent of anti-oxidation preservative, 5.1 to 8.3 percent of anti-rust agent and 2.5 to 26.0 percent of solid stuffing. The grease has higher oxidation resistance, higher corrosion and rust resistance, better water resistance, more excellent sealing property, better pressure resistance, better adhesivity, more environment-friendly suitability, convenient brushing and injection and stable structure and is not easy to generate swelling action on protected nonmetal assorted components. The grease can be largely applied to thespeed acceleration of the trunk line of the railway ballastless track.

Owner:成都蜀光石油化学有限公司

Protective oil and grease

The protective oil and grease is prepared with the materials including lithium hydroxide hydrate, dodecahydroxyl stearic acid, stearic acid, composite antirust agent, composite antioxidant, filming agent, solid stuffing and base oil. It has excellent waterproof performance, antioxidation, anticorrosion, lubricant performance, adhesion performance, salt mist resistance and weather resistance and low cost, and may be smeared directly. The present invention may be used in long term protection of connecting parts and fastening parts in railway, outdoor crown block, crane, etc.

Owner:夏位松 +5

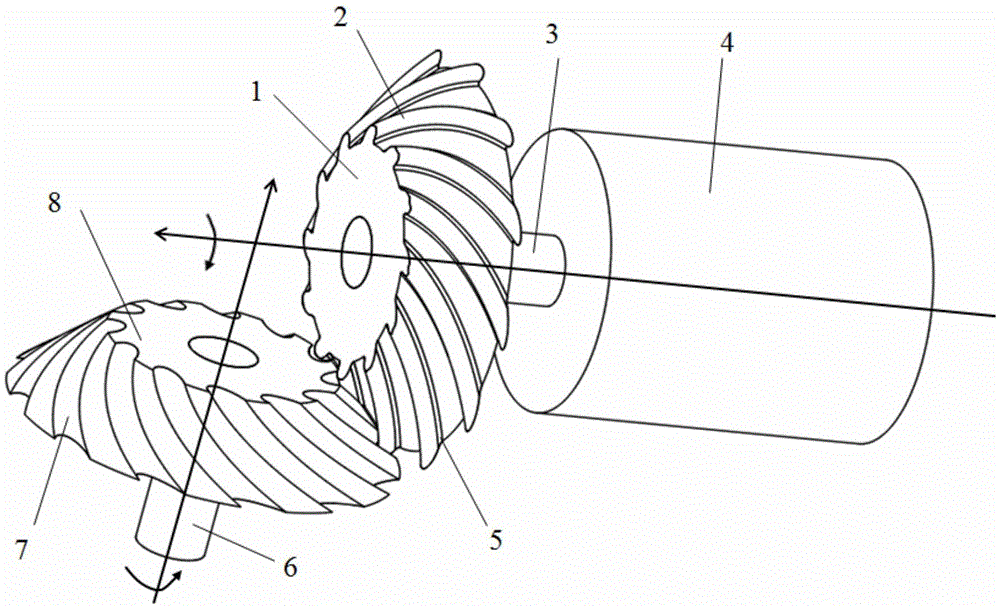

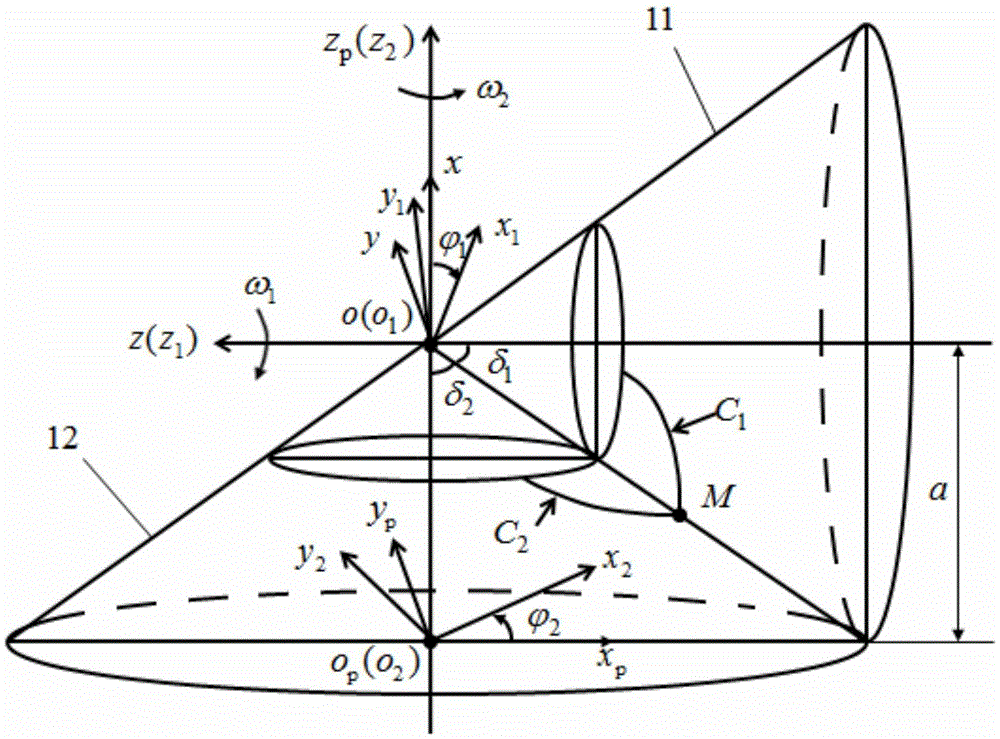

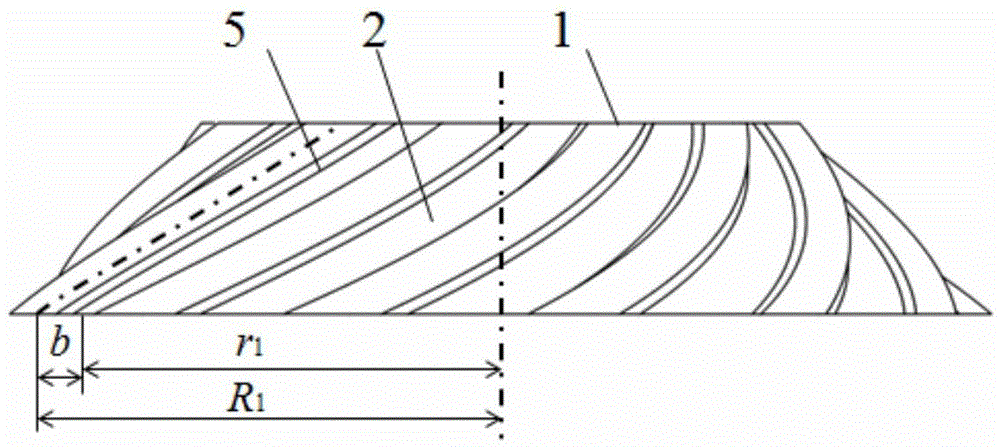

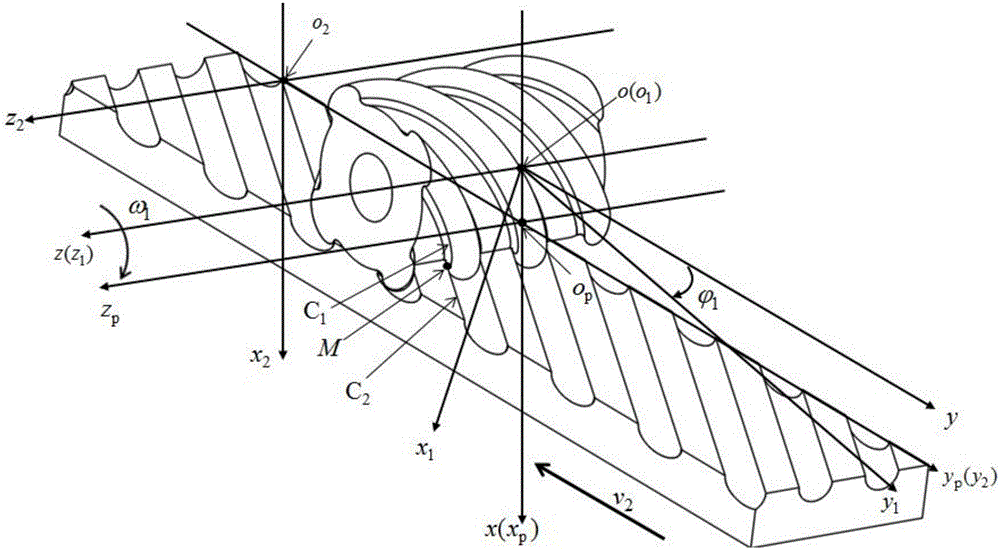

Spiral arc bevel gear mechanism without relative sliding

InactiveCN105485254AAvoid wear and tearAvoid gluingPortable liftingToothed gearingsCircular coneAgricultural engineering

The invention relates to a spiral arc bevel gear mechanism without relative sliding. The spiral arc bevel gear mechanism comprises a pair of transmission pairs composed of a small wheel and a large wheel. The axis of the small wheel and the axis of the large wheel are in orthogonality. Spiral arc teeth are evenly distributed on the outer surface of a small wheel cone. Spiral arc grooves are evenly formed in the outer surface of a large wheel cone. The center lines of the spiral arc grooves and the center lines of the spiral arc teeth are conical spiral lines, and the spiral arc teeth and the spiral arc grooves are matched. When the small wheel and the large wheel are installed, one pair of spiral arc tooth and spiral arc groove is meshed, a driver drives an input shaft, the small wheel and the large wheel to rotate, and transmission between orhtogonal shafts is achieved. The shape of the spiral arc teeth and the shape of the spiral arc grooves are determined through the transmission ratio and other parameters. During transmission of a spiral arc bevel gear, relative sliding of a tooth surface is avoided, and therefore tooth surface gluing, abrasion, plastic deformation and other failure forms are avoided. The spiral arc bevel gear mechanism has the advantages that the single-level transmission ratio is large, and the contact ratio and the bearing capability are high and is suitable for being popularized and applied to the field of tiny and micro machines and conventional machines.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Wear-resistant coating and preparation method and application thereof

InactiveCN110527395AImprove the lubrication effectSimplify the construction processPolyurea/polyurethane coatingsSpecial surfacesOrganic solventWear resistant

The invention relates to a wear-resistant coating, and a preparation method and application thereof. The coating is prepared from the following raw materials in parts by mass: an organic solvent, 5 to25wt% of a film-forming resin, 1 to 25wt% of a lubricating filler, 0.1 to 2 wt% of a grinding material, 0.2 to 2 wt% of a coupling agent, 1 to 2 wt% of an auxiliary agent, 1 to 2 wt% of a dispersingagent and 1 to 2 wt% of a defoaming agent. According to the invention, a proper surface pretreatment technology is adopted; the coating possesses synergistic effects of the grinding effect of the grinding material on tiny burrs on the surface of threaded surfaces, the abrasion reduction, wear resistance, and lubricating performance of the inorganic lubricating filler at extreme pressure conditions, and the extremely low friction coefficient of polytetrafluoroethylene; tiny burrs and scratches on the surface of the threaded surface are automatically ground and repaired in the screwing process of upper shackles of the threaded connectors, it is guaranteed that the threaded connector is well lubricated in the more than 20 times of screwing and unscrewing processes, and thread gluing is avoided. Ground construction procedures are simplified, the construction efficiency is improved, the cost is reduced, the connection reliability is improved, no pollution is caused to the environment, and the use is not influenced by natural conditions of application areas.

Owner:XIAN COMPWELL ENERGY TECH

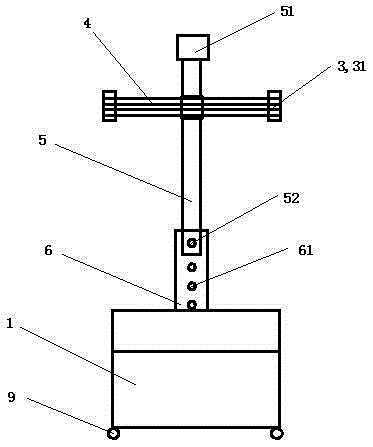

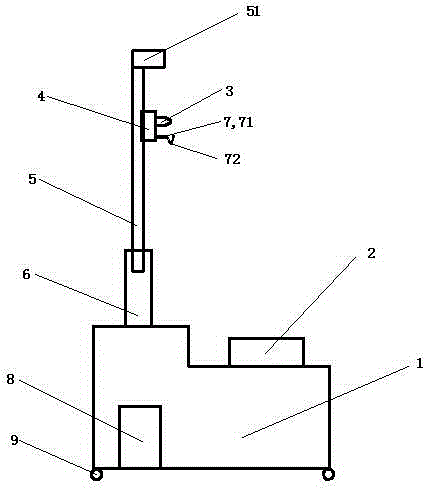

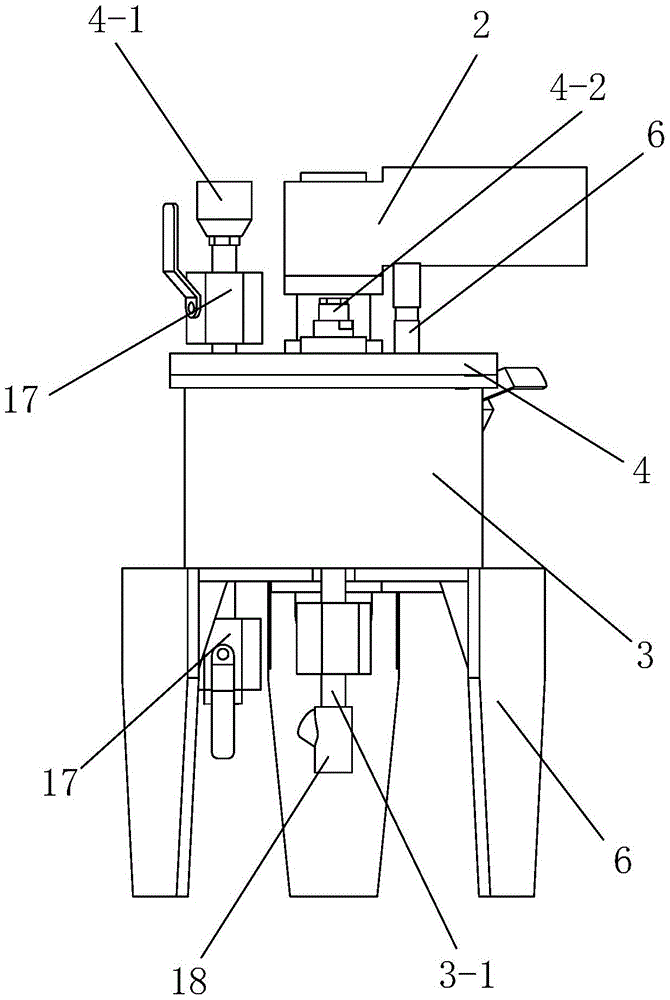

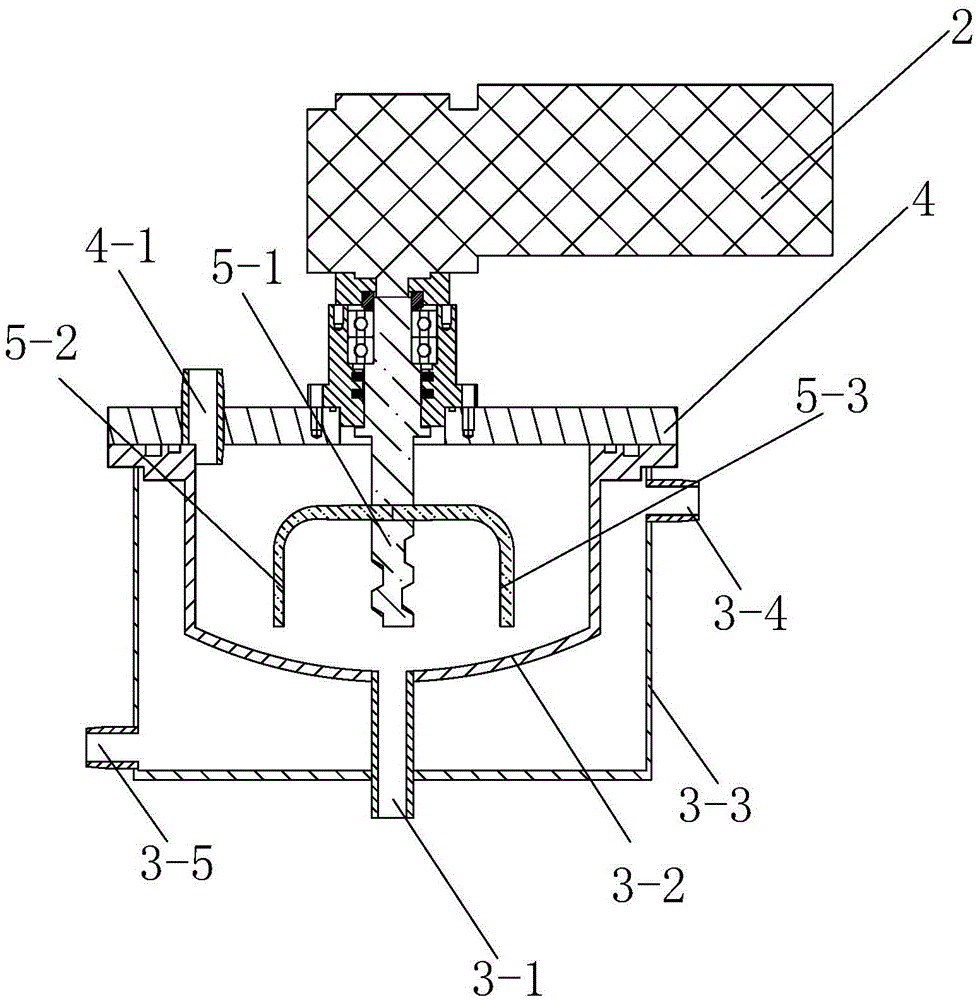

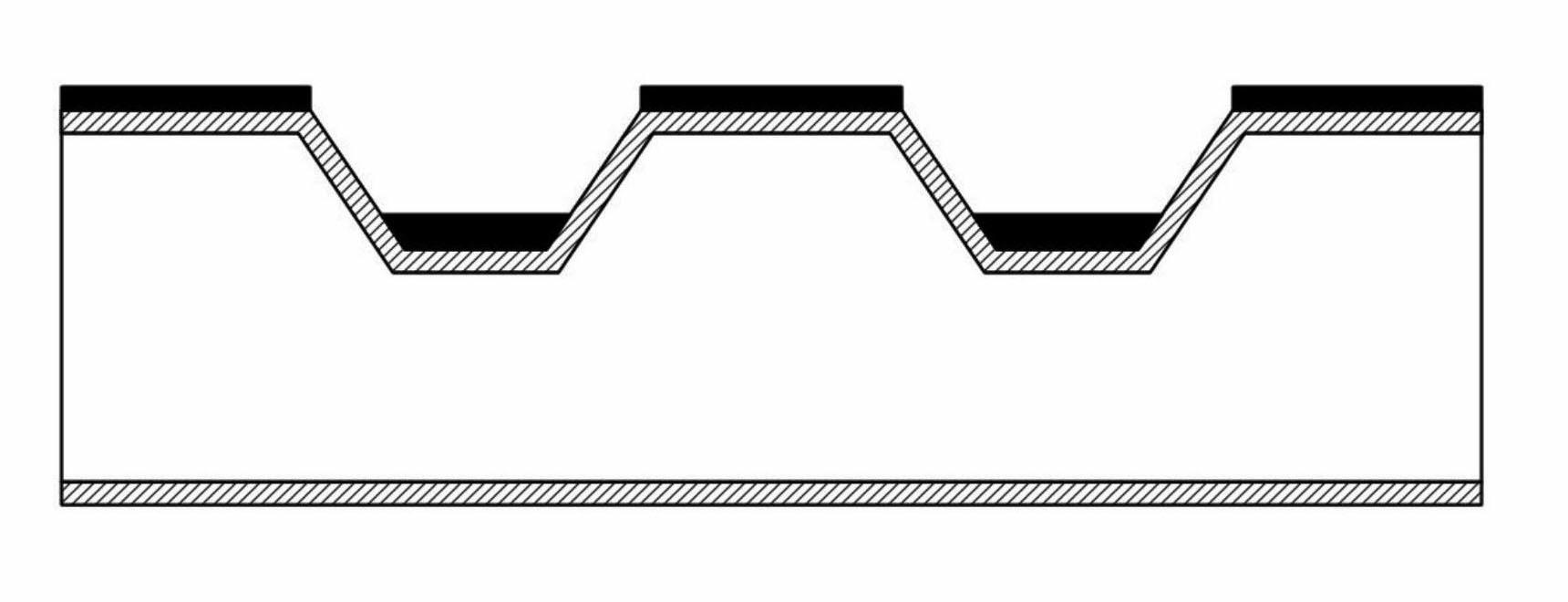

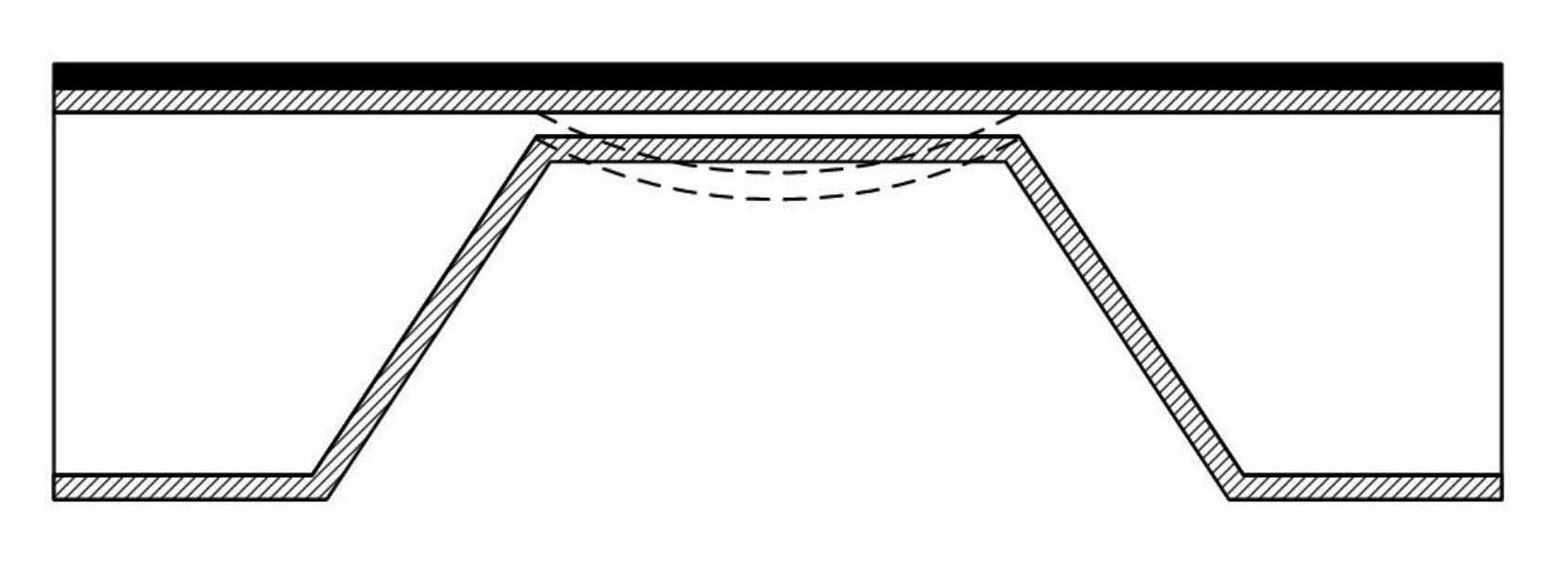

Automatic glue-pouring machine

InactiveCN105344554AAvoid glueFast curingLiquid surface applicatorsCoatingsProgrammable logic controllerEngineering

The invention discloses an automatic glue-pouring machine. The automatic glue-pouring machine comprises a fixed frame, a glue supply device, a PLC (Programmable Logic Controller) control system and a glue-pouring head, wherein the glue supply device is fixed on the fixed frame; the glue-pouring head is connected to a sliding track; the sliding track comprises a horizontal track and a vertical track which are perpendicular to each other; the horizontal track can slide up and down on the vertical track; the glue-pouring head is connected to the horizontal track by a sliding block in a sliding manner; and a blowing device is also arranged below the horizontal track. The automatic glue-pouring machine has the beneficial effects that the PLC control system can accurately control the glue-pouring head to realize glue pouring in x-axis and y-axis directions through the horizontal track and the vertical track which are perpendicular to each other, thereby facilitating the glue pouring and sealing of square air return windows and the like, and the automatic glue-pouring machine is simple in structure and relatively low in manufacturing cost and has good glue pouring efficiency and a glue sealing effect.

Owner:SUZHOU XINGYA PURIFICATION ENG

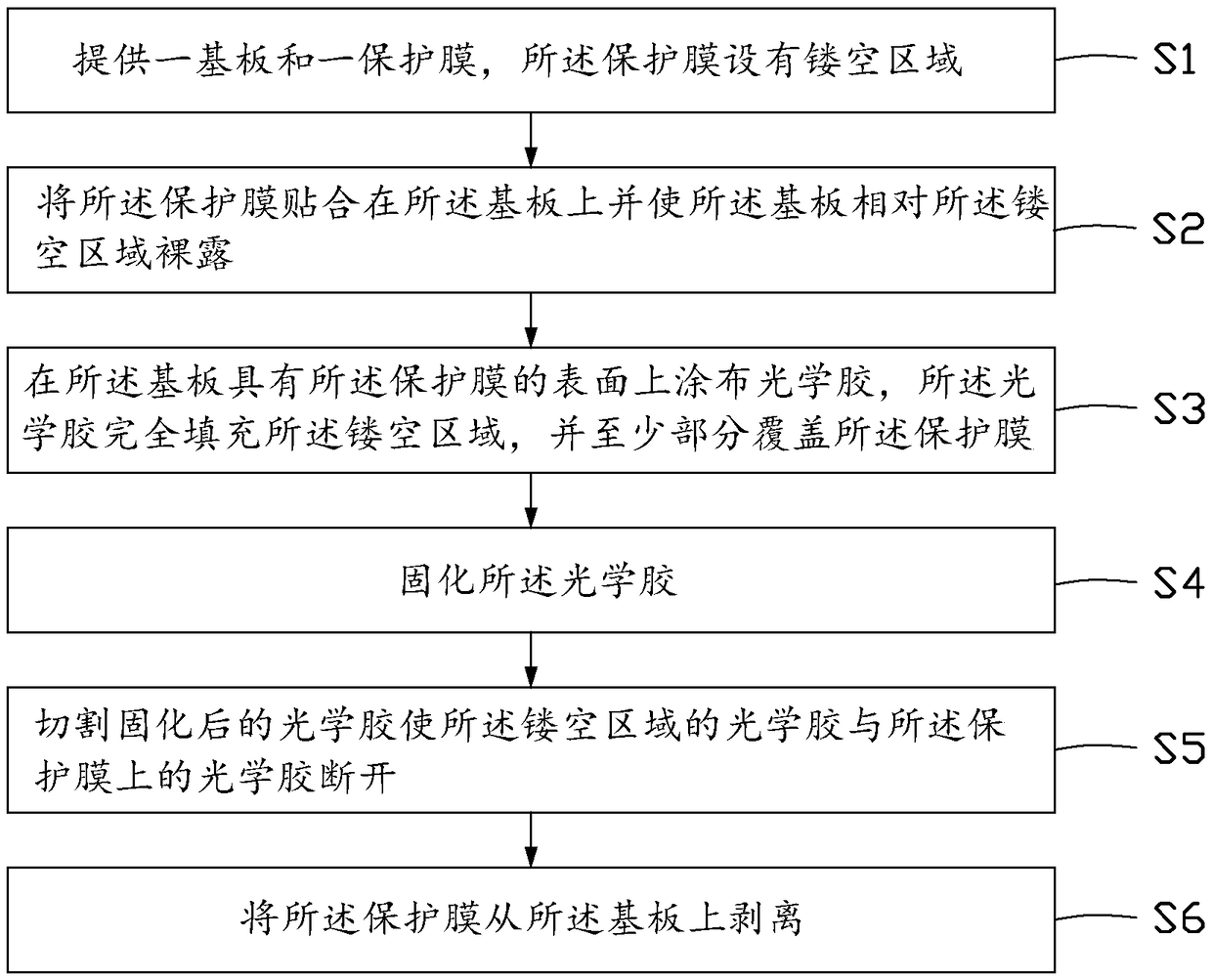

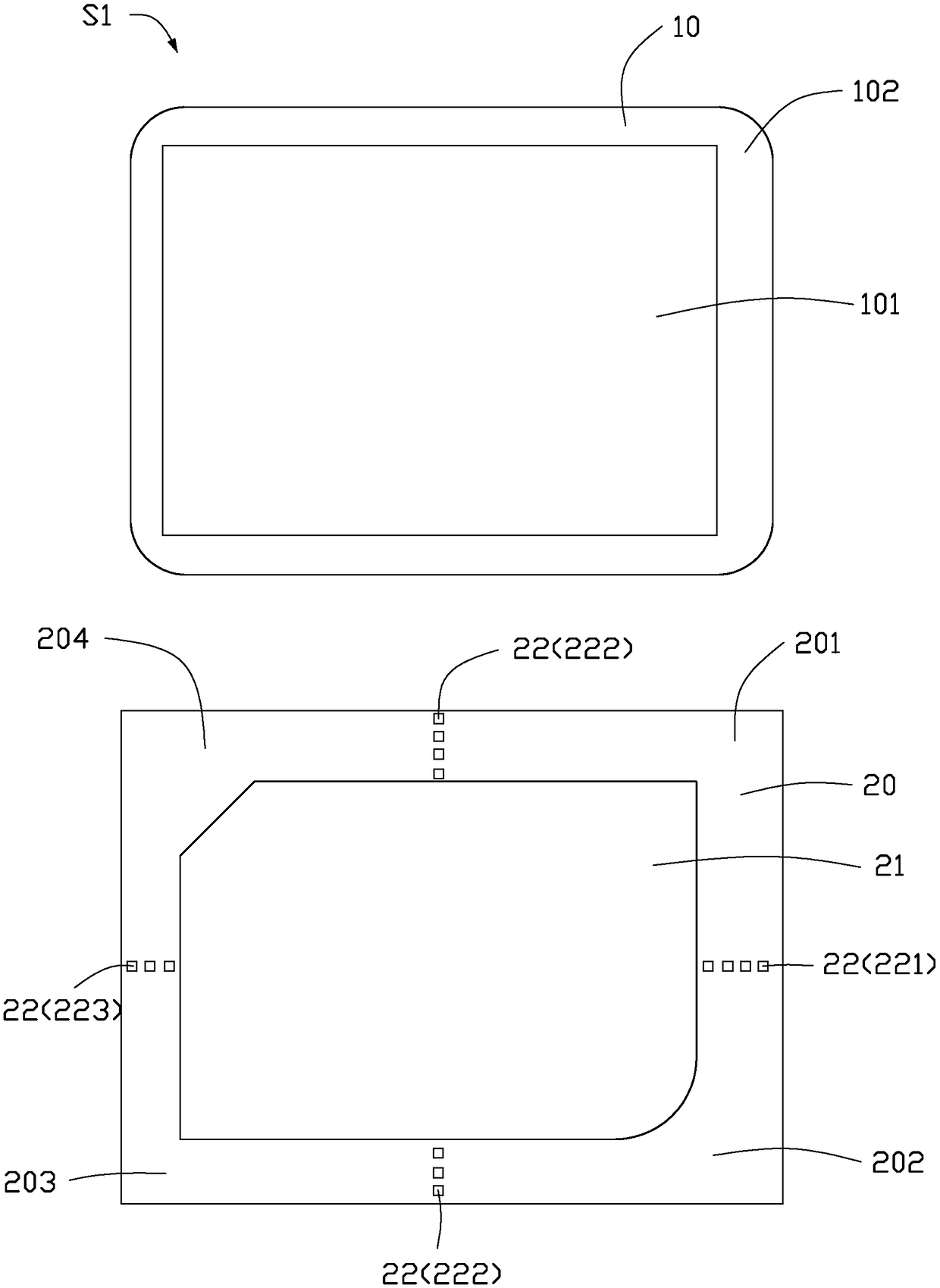

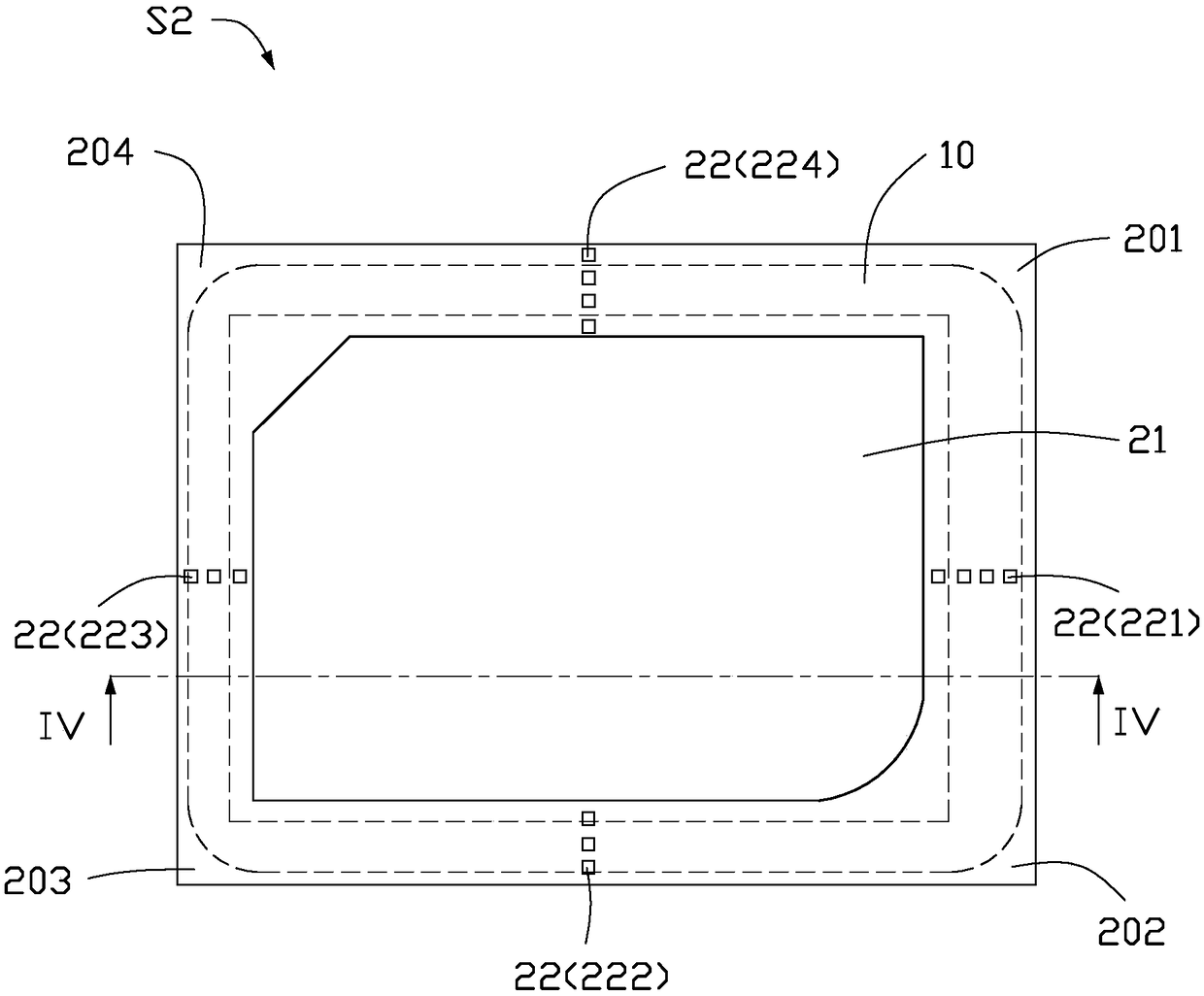

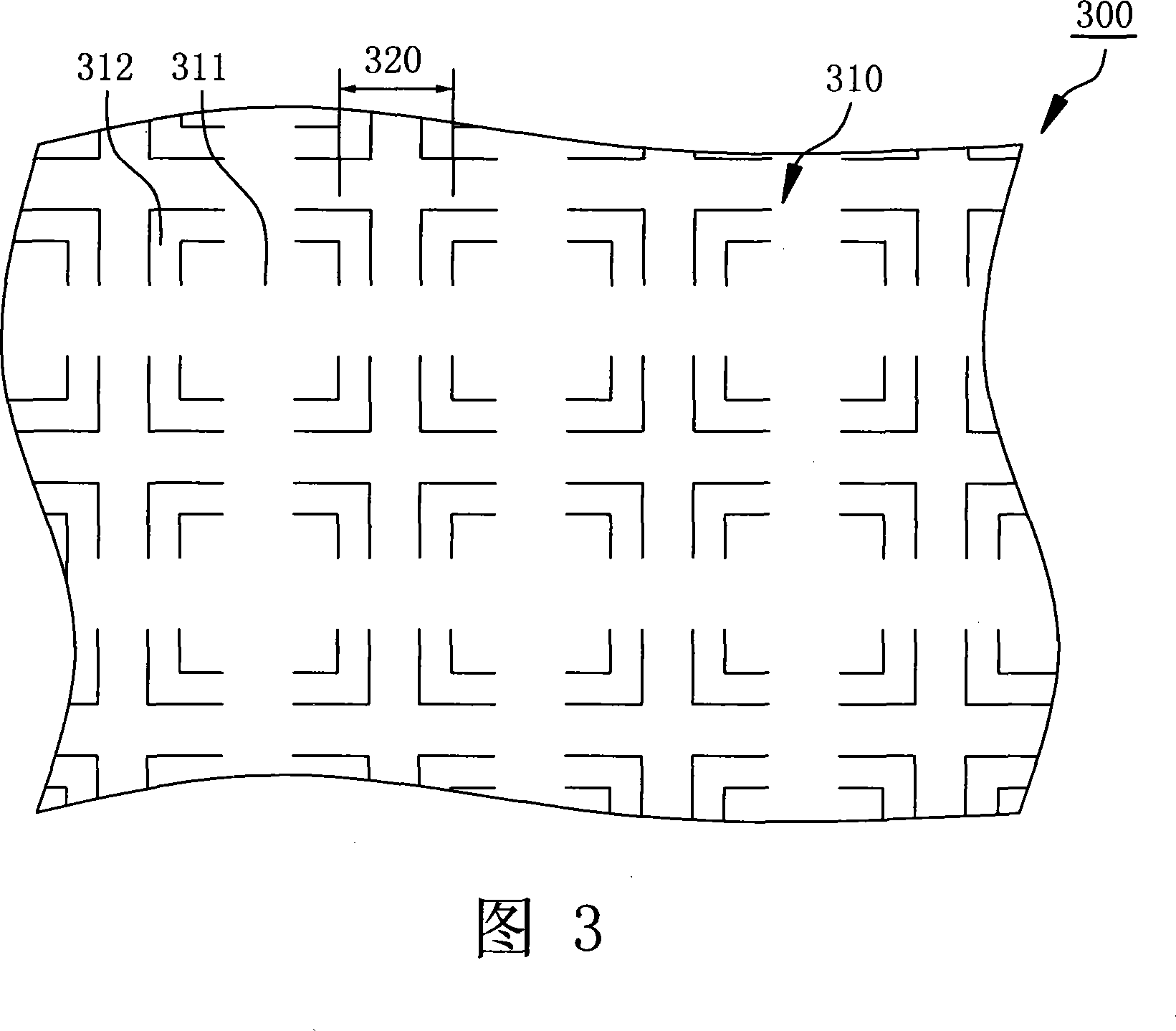

Cement coating method

ActiveCN108745816ANo mutual interferenceAvoid gluingPretreated surfacesCoatingsTectorial membraneMaterials science

A cement coating method comprises the following steps that a base plate and a protective film are provided, and the protective film is provided with a hollowed-out area; the protective film is pastedto the base plate, and the area, opposite to the hollowed-out area, of the base plate is exposed; the surface, with the protective film, of the base plate is coated with optical cement, the hollowed-out area is completely filled with the optical cement, and at least part of the optical cement covers the protective film; the optical cement is solidified; the solidified optical cement is cut, and the optical cement in the hollowed-out area and the optical cement on the protective film are separated; and the protective film is removed from the base plate. Through the cement coating method provided by the invention, the cement feathering or cement missing phenomenon can be avoided.

Owner:INTERFACE TECH CHENGDU CO LTD +2

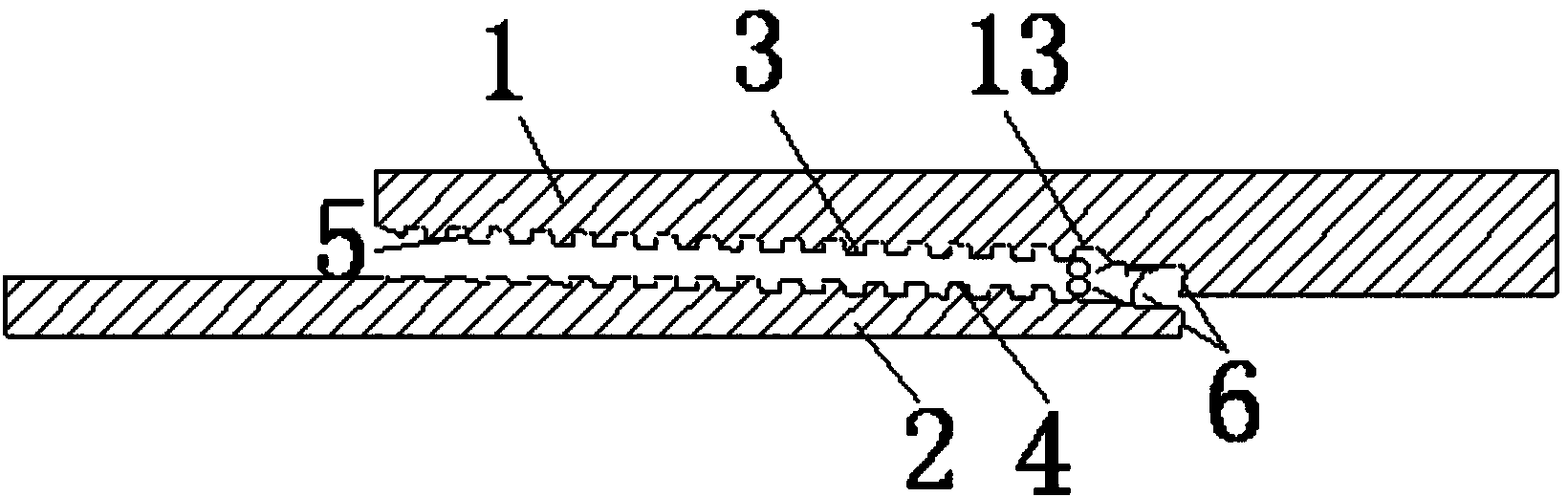

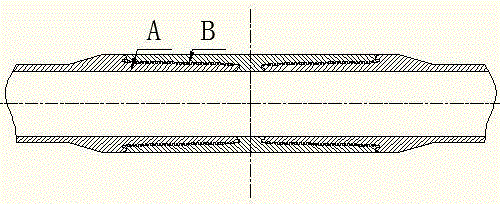

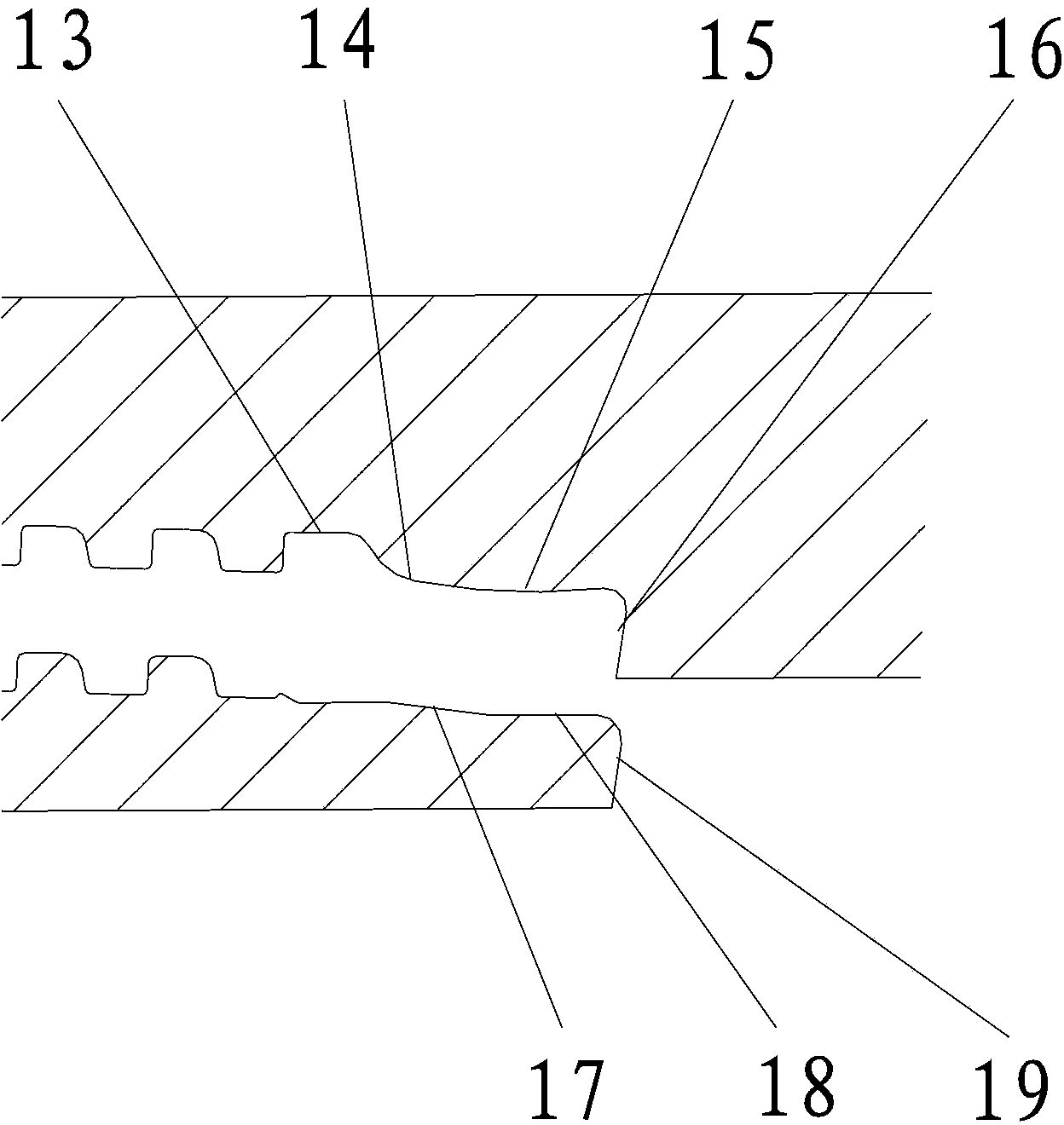

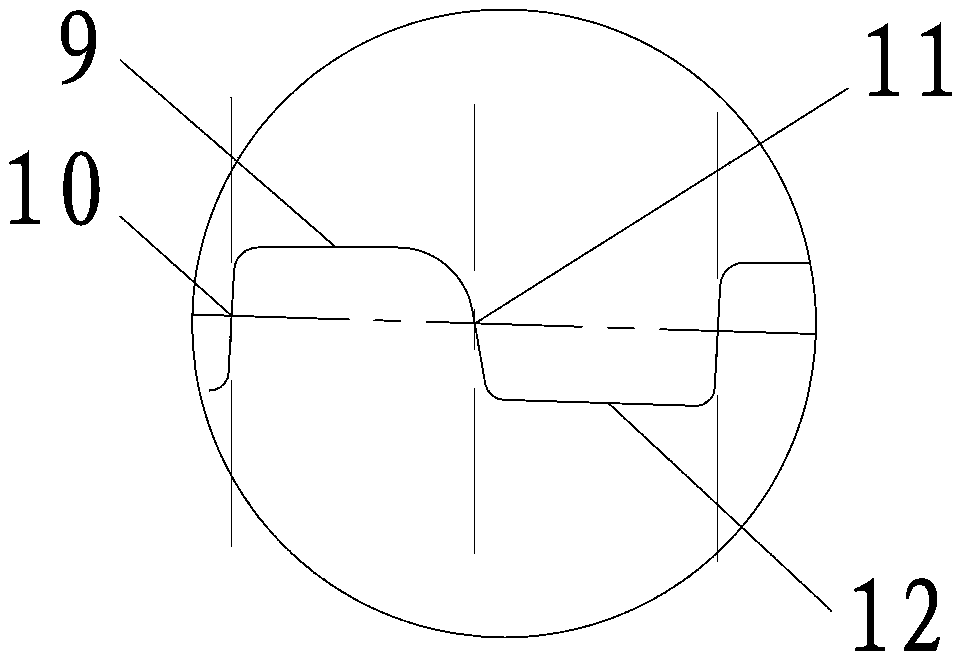

Multistage sealing anti-sticky buckle type thread for titanium alloy oil casing

InactiveCN103527110AImprove airtight reliability performanceReduced stress stateDrilling rodsDrilling casingsButtressCoupling

The invention relates to a multistage sealing anti-sticky buckle type thread for a titanium alloy oil casing. The multistage sealing anti-sticky buckle type thread comprises an oil casing coupling and an oil casing tube end, the oil casing coupling is provided with a standard API buttress internal thread which is sequentially connected with a tool withdrawal groove, a cone surface to cone surface first stage sealing structure, a cylinder surface to cylinder surface second stage sealing structure and a negative angle torque circular bead, wherein the cone surface to cone surface first stage sealing structure and the cylinder surface to cylinder surface second stage sealing structure are in transition through chambering, and the negative angle torque circular bead is connected with the standard API buttress internal thread through a transitional angle. The multistage sealing anti-sticky buckle type thread for the titanium alloy oil casing has the advantages that two stages of metal sealing and one negative angle torque circular bead sealing are added based on the improved buttress thread, the reliability of the air tightness of a thread connector is improved through the design of multistage sealing, meanwhile, the stress state of the thread connector is reduced by changing a thread parameter, the performance of an anti-sticky buckle is improved, and machining and detecting are convenient.

Owner:XIAN SANHUAN TECH DEV GENERAL

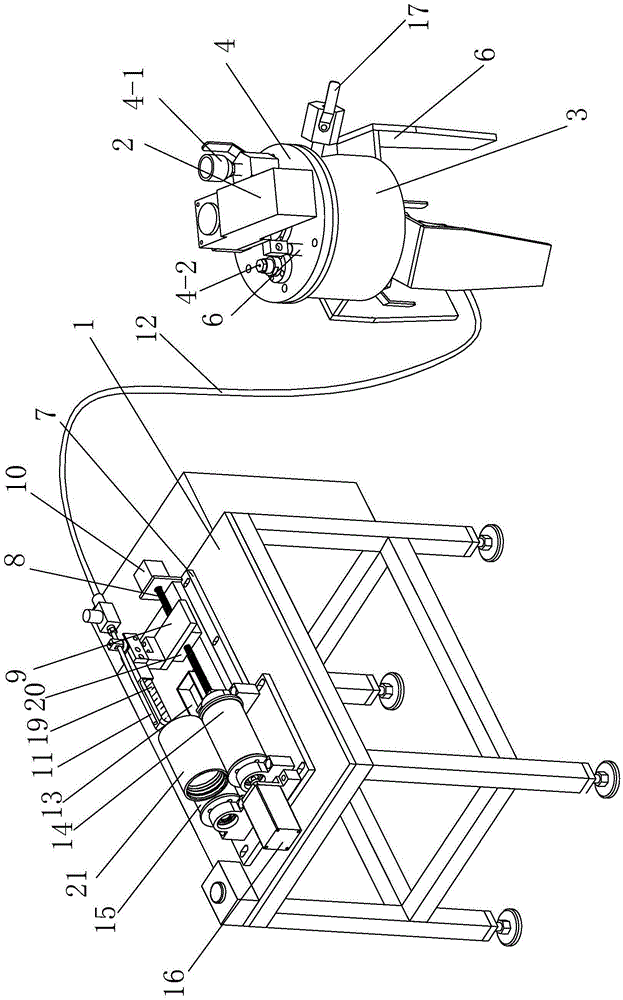

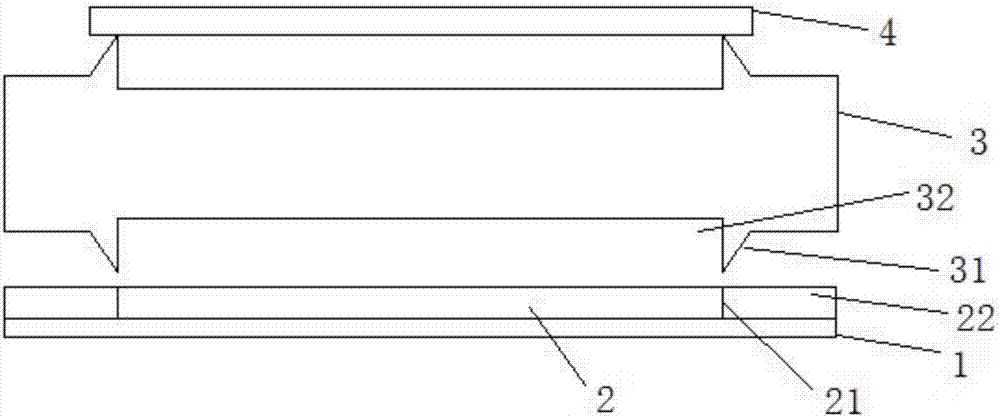

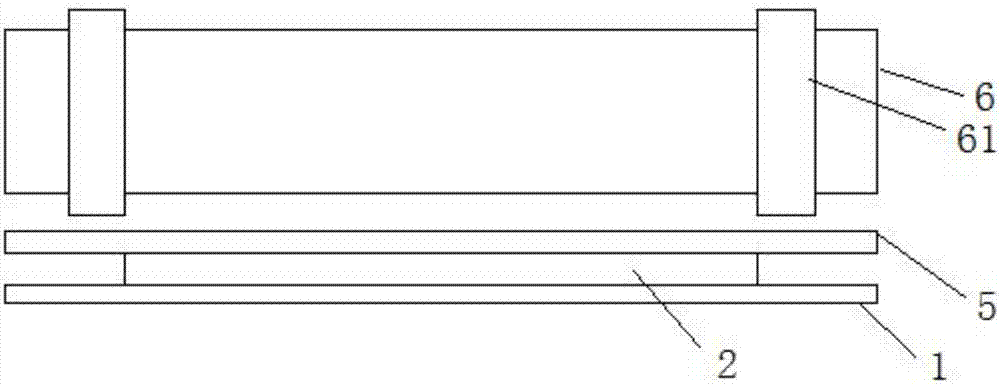

Device and method for coating inner wall of oil casing coupling with anti-friction nano coating

InactiveCN105583126ASimple structureNovel and reasonable designLiquid surface applicatorsCoatingsCouplingReciprocating motion

The invention discloses a device for coating the inner wall of an oil casing coupling with an anti-friction nano coating. The device for coating the inner wall of the oil casing coupling with the anti-friction nano coating comprises a storage mechanism, a feeding mechanism and a workpiece rotating mechanism. The storage mechanism comprises a stirring kettle and a first driving motor. The feeding mechanism comprises a base, a lead screw, a moving block and a second driving motor. A dripping pipe and a coating brush are arranged on the moving block. The workpiece rotating mechanism comprises a driving roller, a driven roller and a third driving motor. The invention further discloses a method for coating the inner wall of the oil casing coupling with the anti-friction nano coating. The method for coating the inner wall of the oil casing coupling with the anti-friction nano coating comprises the following steps that firstly, a workpiece is rotated; secondly, the anti-friction nano coating is evenly stirred; thirdly, the nano coating is brushed while the coating brush moves in a reciprocating mode; and fourthly, drying is conducted. According to the device and method for coating the inner wall of the oil casing coupling with the anti-friction nano coating, the design is novel and reasonable, the device can be obtained conveniently, and the method can be implement conveniently; the application range is wide, and the using effect is good; an oil casing coupling workpiece can be coated with the coating rapidly, and the purpose of improving the viscidity resistance of the oil casing coupling is achieved finally.

Owner:XIAN UNIV OF SCI & TECH

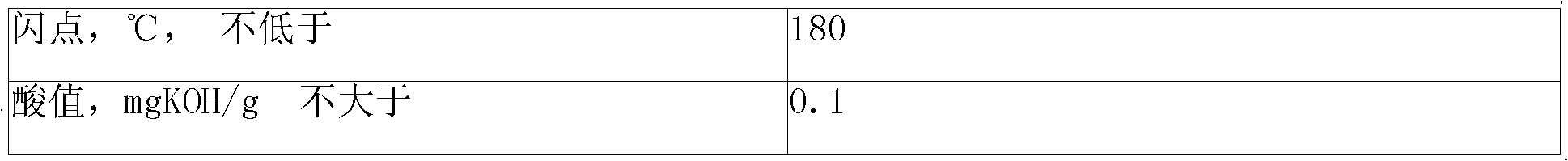

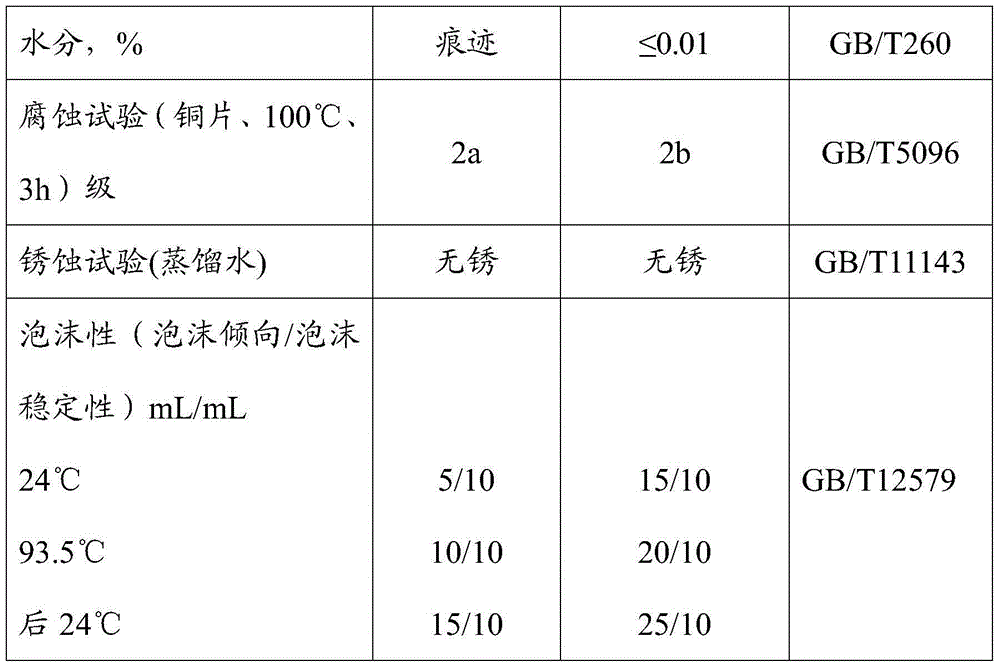

Wear-resisting energy-saving agent for lubricating oil, its preparation method and application

The present invention provides an antiwear energy-saving agent containing refined mineral oil, zinc dialkyl dithiophosphate and deactivator for lubricating oil, it possesses excellent functions of reducing friction, reducing wear, resisting rust, resisting corrosion and resisting oxidation, and has strong cleaning dispersing power and good extreme pressure resistance and long-acting lubricating property and excellent compatibility with lubricant. This invention also provides its preparation method and application to lubricating oil and soaking field.

Owner:臧玉蓉 +1

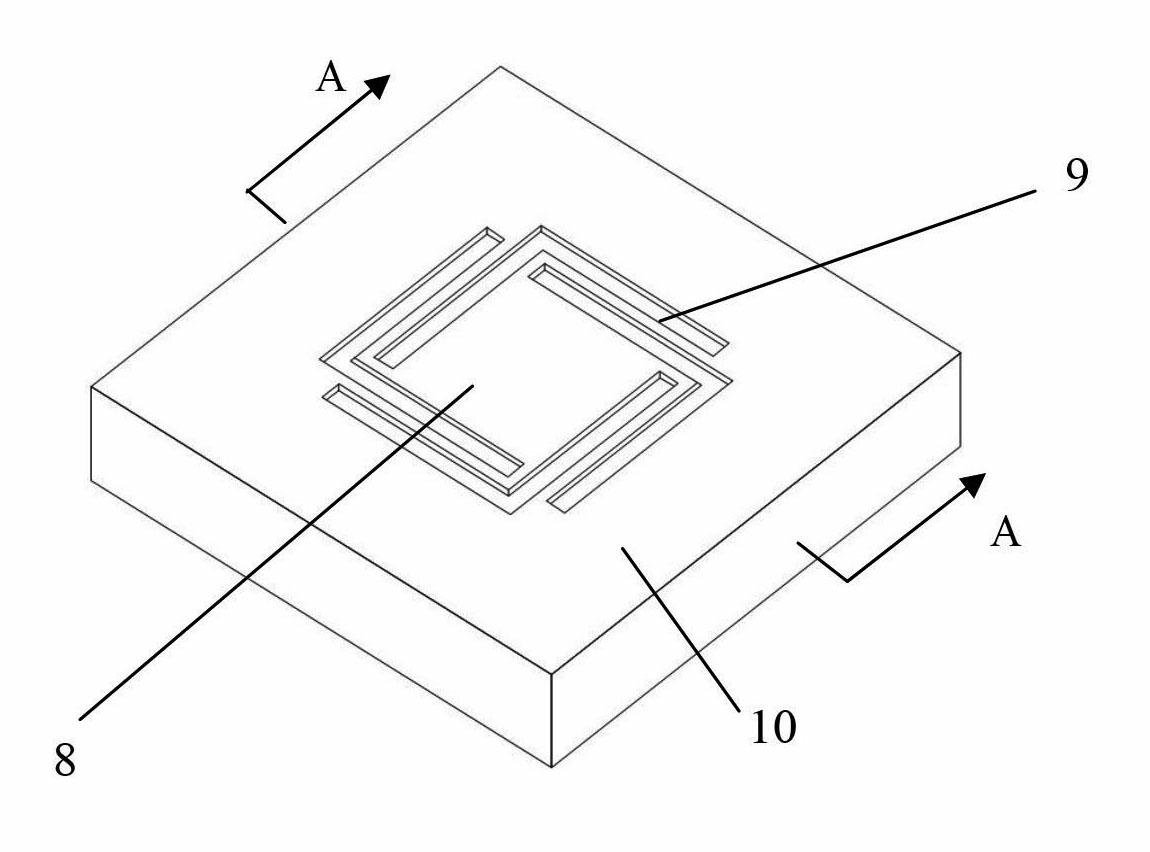

Buried Mask Wet Etching Process of Silicon Micromechanical Structure

ActiveCN102275868AAvoid gluingAvoid process problemsDecorative surface effectsChemical vapor deposition coatingLithography processPhysical chemistry

The invention discloses a pre-buried mask wet etching process for a silicon micro mechanical structure. The pre-buried mask wet etching process comprises the following steps of: preparing a carbon dioxide thin film layer, preparing mask patterns (namely an initial mask pattern and a pre-buried mask pattern), performing wet etching for the first time, opening the pre-buried mask pattern, performing wet etching again and the like. By the process, a set of mask patterns can be stored on a mask layer on the surface of a silicon slice and the mask patterns can be retrieved at any time during anisotropic wet etching, so that the difficulty in a coating and photoetching process for an etched silicon slice can be avoided; and a novel method for manufacturing a multilayer micro mechanical structure on the silicon slice is provided.

Owner:NAT UNIV OF DEFENSE TECH

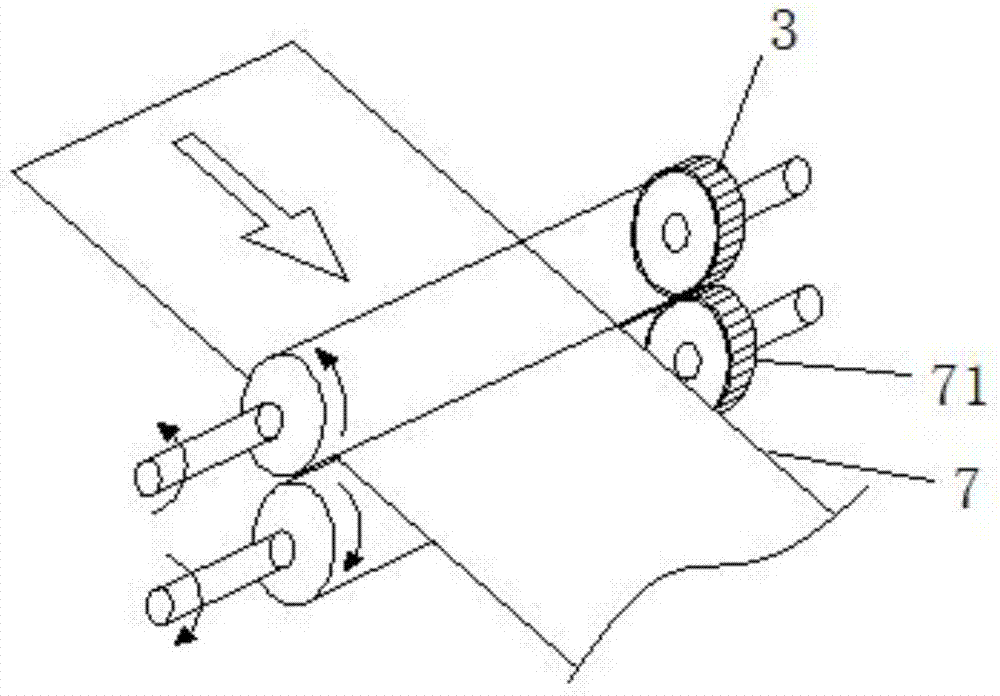

OCA optical cement die cutting technology

ActiveCN107414929AAvoid gluingAvoid squeezingLamination ancillary operationsLaminationPunchingMaterials science

The invention discloses an OCA optical cement die cutting technology. The OCA optical cement die cutting technology comprises the following steps that die cutting operation is conducted in a thousand-level dust-free room of 80-90 % humidity; after a cutting knife is dedusted, the cutting knife cuts raw materials into small rolls to be hung on a material frame; an upper layer light release film self-contained by OCA optical cement is torn, and an OCA layer is exposed; after anti-sticking processing is conducted on a rolling cutter, the rolling cutter cuts to the two sides of the OCA layer, and a reserved part is formed between a cutting line and the edge of the rolling cutter; after a mylar layer is pasted on the reserved part, and the reserved part and the mylar layer are torn together; an anti-static film is attached to the surface of the OCA layer through a rubber covered roller, and rubber covered roller foam is circumferentially attached to the two sides of the rubber covered roller; the anti-static film is cut off by a punching cutter, and the outer frame edge of a product is greater than the edge of the OCA layer; and cutting is conducted every time the punching cutter rotates one revolution, and neatly-collecting-stacking is conducted. According to the OCA optical cement die cutting technology, the effects that the product has no cement pulling and cement overflowing are achieved.

Owner:昆山威斯泰电子技术有限公司

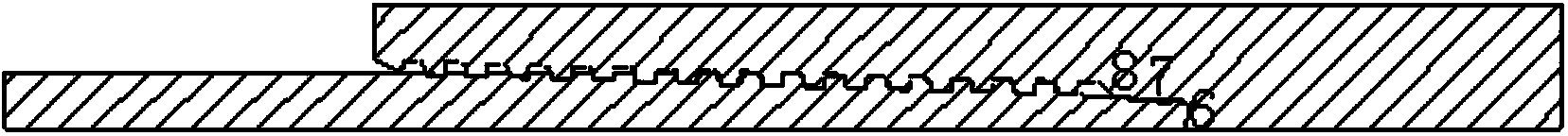

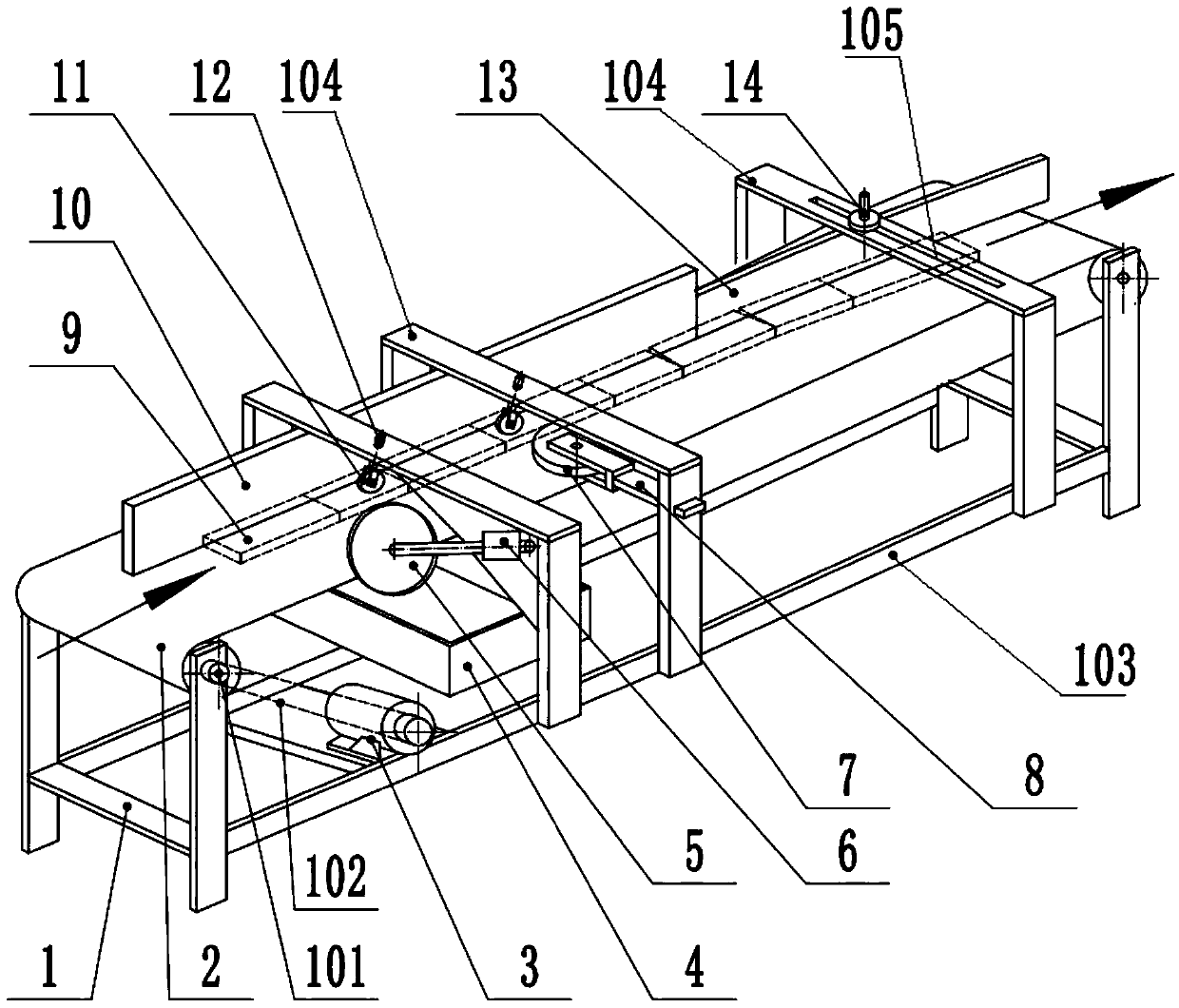

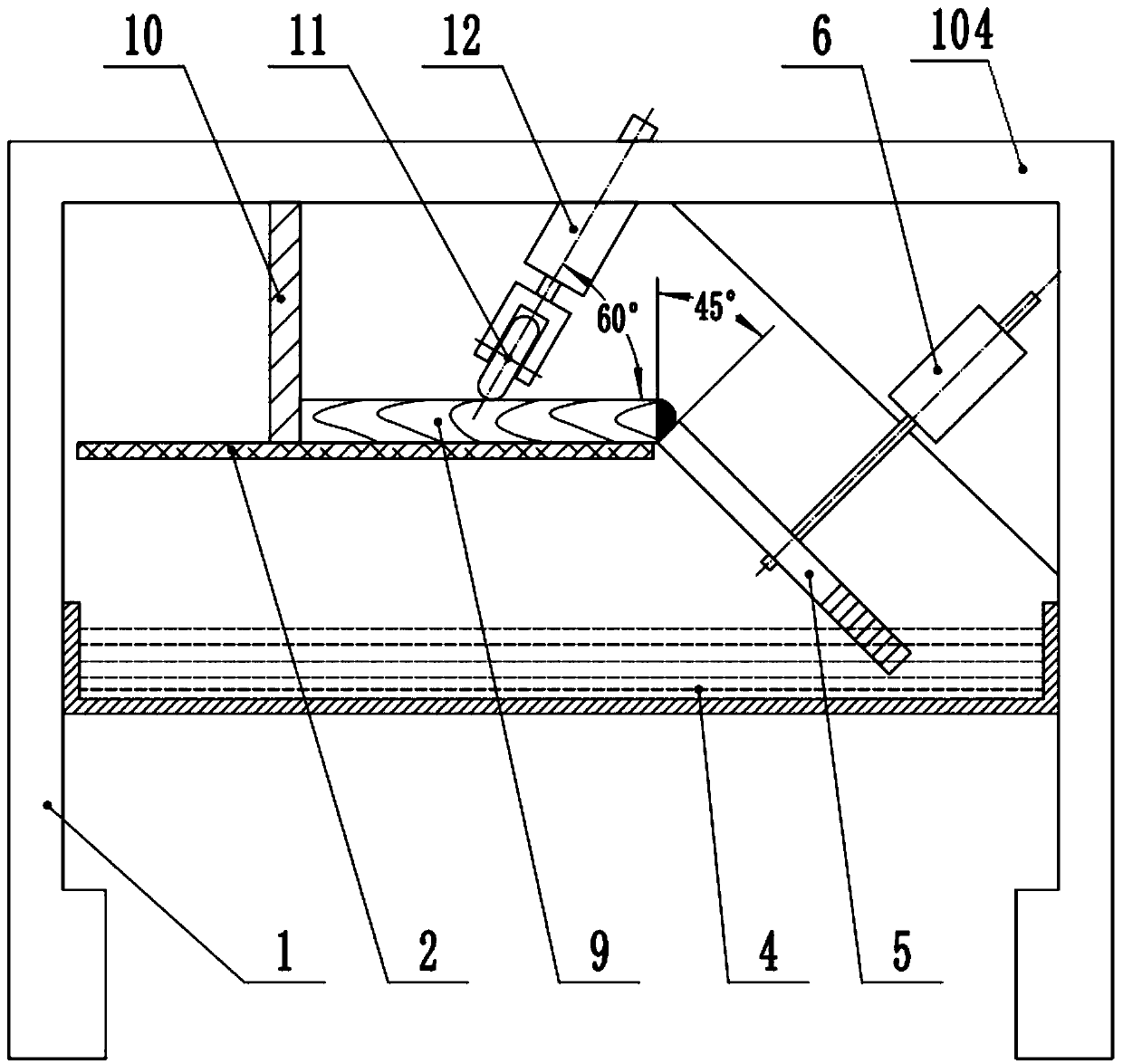

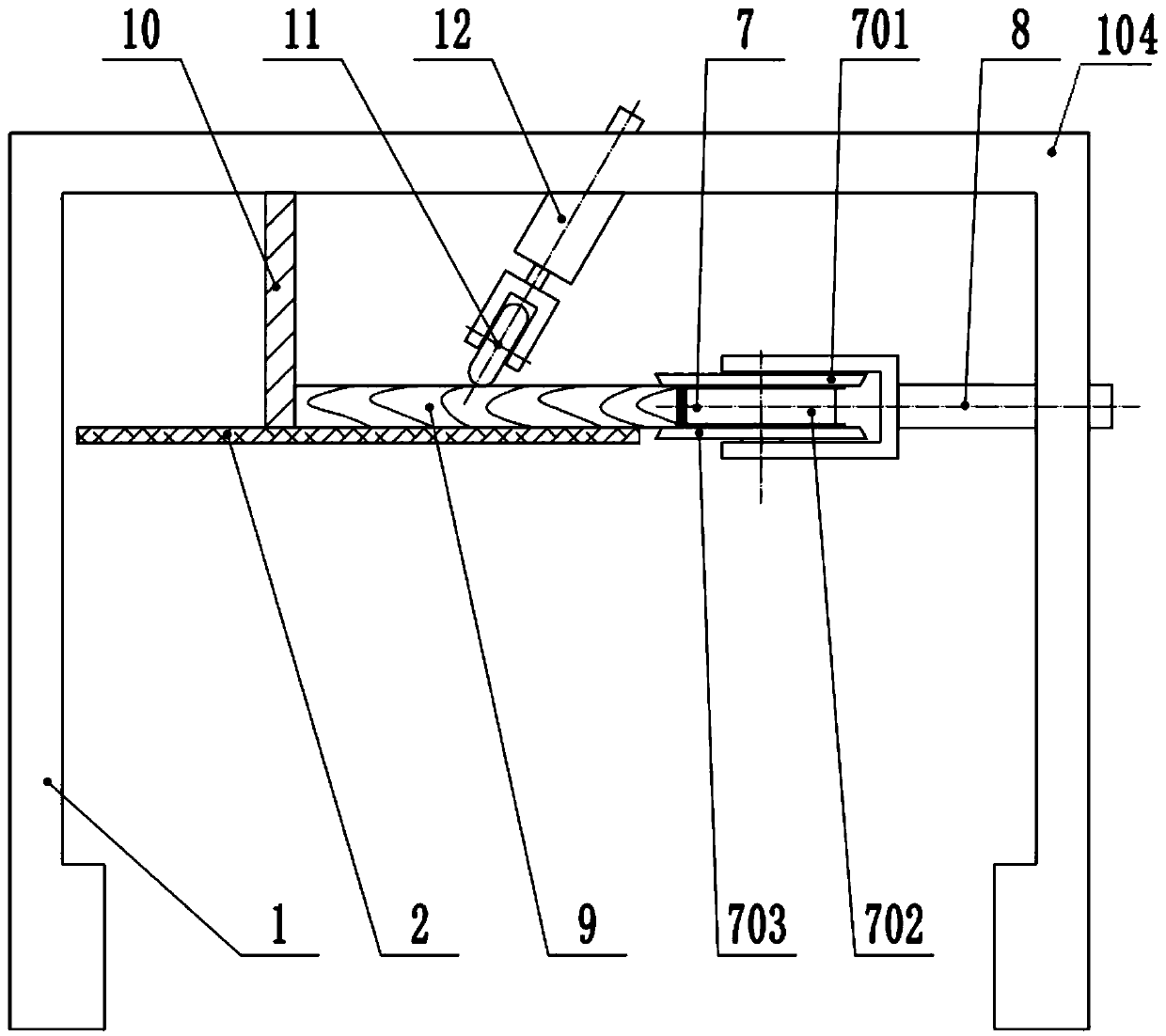

Automatic and quantitative gluing plate jointing device of short and small battens and gluing plate jointing method

ActiveCN109514659ALow degree of automationSimple structureWood veneer joiningSolid woodLayer thickness

The invention discloses an automatic and quantitative gluing plate jointing device of short and small battens and a gluing plate jointing method. The device comprises a side automatic and quantitativegluing device and a fixed-length width jointing, assembling and pre-pressing device. The side automatic and quantitative gluing device comprising a gluing rack, a conveying belt, a glue box, a glue application tooth roller, a glue application tooth roller support, a U-shaped glue scraping roller, a U-shaped glue scraping roller support, a backer, a flexible guide plate and a guide plate transverse adjusting mechanism. The fixed-length width jointing, assembling and pre-pressing device comprises an assembling rack, a workbench plate, a width backer, a length backer, a side press plate and sidepress plate air cylinders. According to the side automatic and quantitative gluing device of the device, the glue application tooth roller can be used for gluing the sides of the short and small battens, and control over quantitative glue layer thickness is achieved through the U-shaped glue scraping roller; the fixed-length width jointing, assembling and pre-pressing device can achieve fixed-length width jointing of the short and small battens; and the process and the device are simple, the automation degree is high, the production cost is low, the production efficiency is high, no glue markcontamination exists on the plate faces, and the device can be widely applied to materials of solid wood furniture, core-boards and the like.

Owner:NANJING FORESTRY UNIV

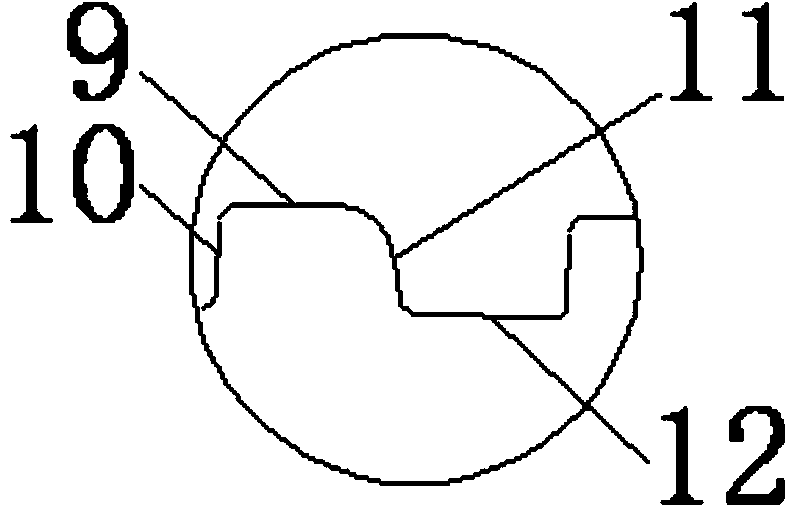

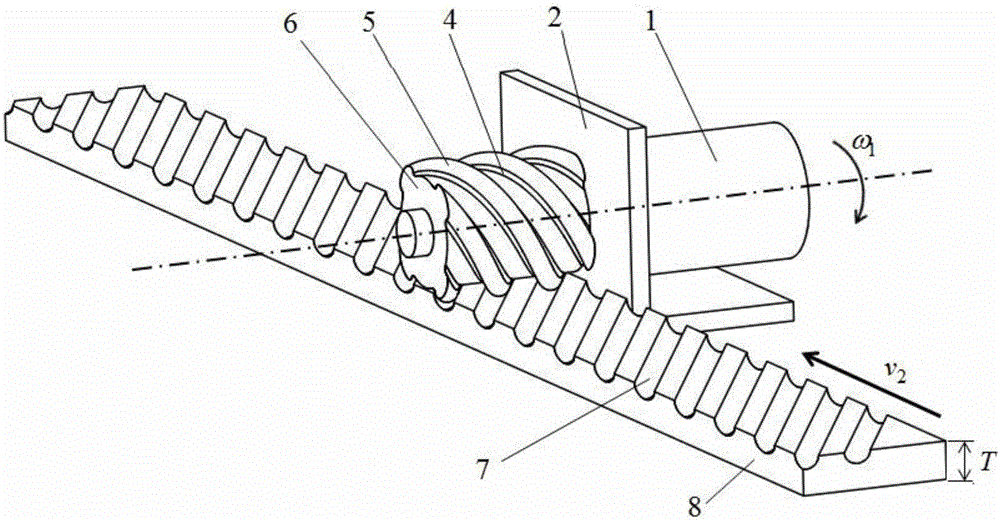

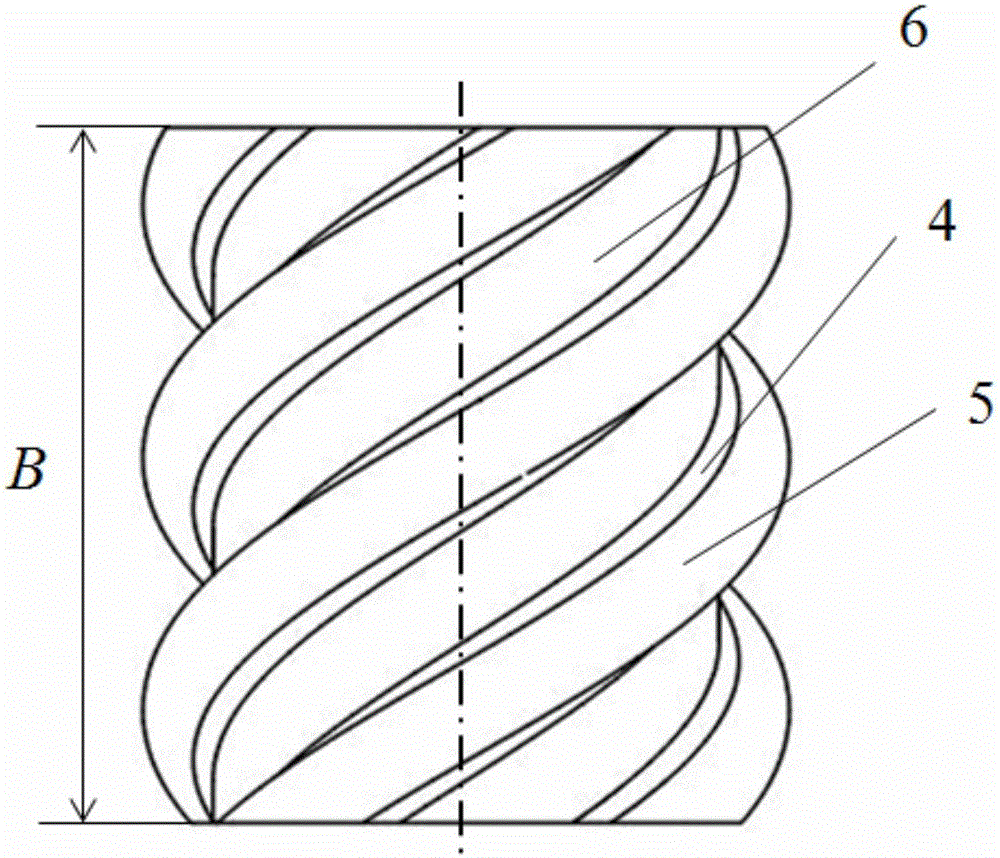

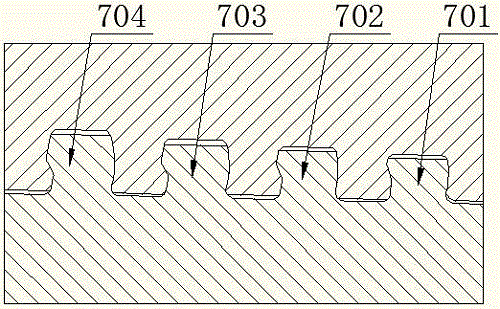

Convex-concave engaged arc gear and rack mechanism without relative sliding

ActiveCN106523632AAvoid wear and tearAvoid gluingPortable liftingGearing elementsEngineeringSpiral line

The invention relates to a convex-concave engaged arc gear and rack mechanism without relative sliding. The convex-concave engaged arc gear and rack mechanism without relative sliding comprises a transmission pair consisting of a spiral arc gear and an arc rack, wherein the spiral arc gear is connected with a rotating shaft of a driver; spiral convex arc teeth are uniformly distributed on the outer surface of the spiral arc gear; center lines of the spiral convex arc teeth of the spiral arc gear are equal-lift cylindrical spiral lines; concave arc tooth grooves are uniformly distributed in the upper surface of the arc rack; the spiral convex arc teeth are matched with the concave arc tooth grooves; and the structural shape of the spiral arc gear and the structural shape of the arc rack are determined by design parameters. When the mechanism is mounted, the spiral convex arc teeth are correctly engaged with the concave arc tooth grooves, and therefore, arc gear and rack transmission is realized. The arc gear and rack mechanism does not have failure modes such as tooth surface relative sliding, tooth surface gluing, tooth surface abrasion and tooth surface plastic deformation, has the advantages of high contact ratio, simple structure, high transmission efficiency, high bearing capacity and the like, and is suitable for being popularized and used in the fields of tiny machines, micro-machines and conventional machines.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

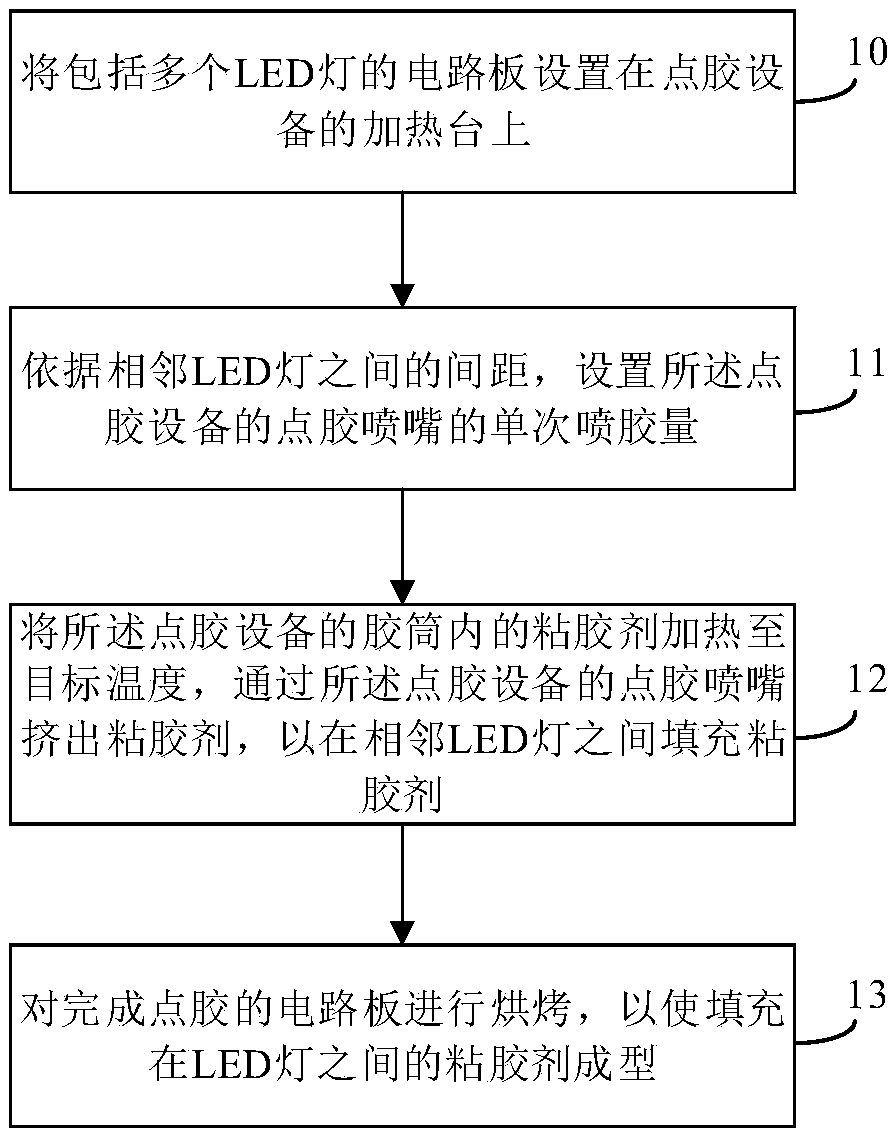

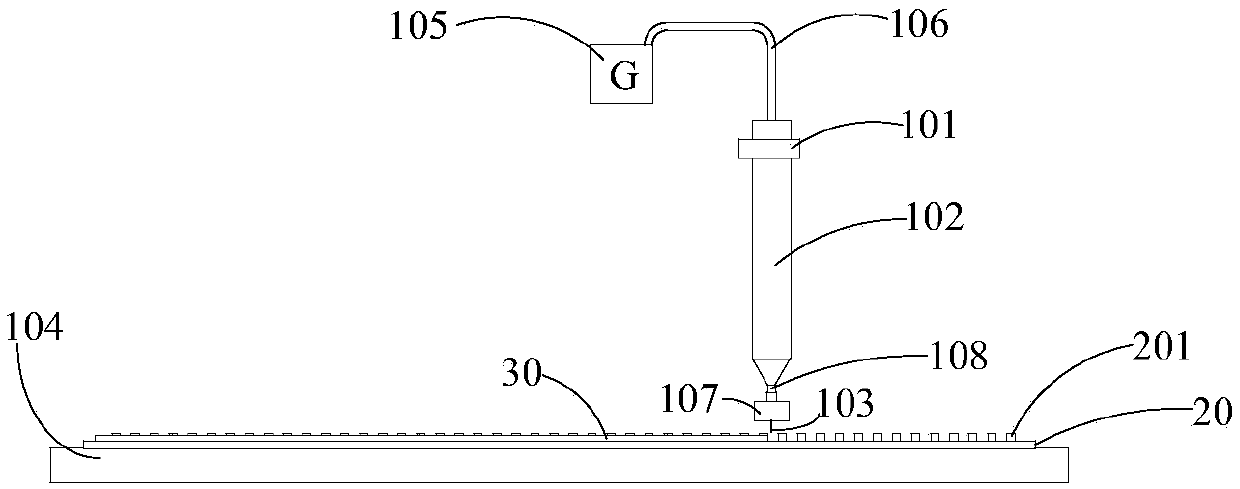

Dispensing method for LED display screen and dispensing device for LED display screen

ActiveCN109675762AGuaranteed glow effectPrevent sprayingPretreated surfacesCoatingsLED displayAdhesive

The invention discloses a dispensing method for an LED display screen and a dispensing device for the LED display screen. The LED display screen comprises a circuit board and multiple LED lamps arranged on the circuit board. The dispensing method for the LED display screen includes the steps that the circuit board including the multiple LED lamps is arranged on a heating table of the dispensing device; the single-time glue spraying amount of a dispensing nozzle of the dispensing device is set according to the distance between the adjacent LED lamps; an adhesive in an adhesive cylinder of the dispensing device is heated to the target temperature, and the dispensing nozzle of the dispensing device is used for extruding out the adhesive so that the part between every two adjacent LED lamps can be filled with the adhesive; and the circuit board obtained after dispensing is baked so that the adhesive formed between the LED lamps in a filling manner can be formed. By means of the dispensingmethod for the LED display screen and the dispensing device for the LED display screen, the single-time glue spraying amount of the dispensing nozzle is set according to the distance between the adjacent LED lamps, the temperature of the adhesive is controlled to be the target temperature, the requirement for conducting dispensing between small-distance light sources can be met, the phenomenon ofglue pulling or glue hanging is avoided, and the performance of the LED display screen is improved.

Owner:SHENZHEN DICOLOR OPTOELECTRONICS

Shaping process for cotton percale shirt stitches

InactiveCN107183816AImproved elasticityAvoid wrinklesShirtsClothes making applicancesWrinkleCellulose

The invention discloses a shaping process for cotton percale shirt stitches, which comprises the following steps: a, tailoring: according to a garment sample, the garment parts are tailored, wherein the garment parts comprise a collar, sleeves, cuffs, sleeve slits, body front parts and body back parts; b, sewing: the garment parts are sewn, wherein cellulose reactive strip adhesive substrates are imported synchronously into every stitch during the sewing process; c, shaping: the shaping process through hot pressing and solidification is carried out on the sewn garment parts under presetting conditions. On the basis of the original wrinkle-resistant fabric, through the process that the stitches of every garment part are sewn with the cellulose reactive strip adhesive substrates, the substrate is in a state of hot pressing and melting under certain conditions, and elastic protection is formed in the stitches, thereby making the stitches of the garments provided with stronger elastic restoring force, making the cloth folds capable of being not easily produced and improving the non-ironing property of the garments. Furthermore, the cooling and patting process needs to be carried out on the garment, which can improve comfort of the garment and reduce burrs on the garment.

Owner:上海杰西衬衫有限公司

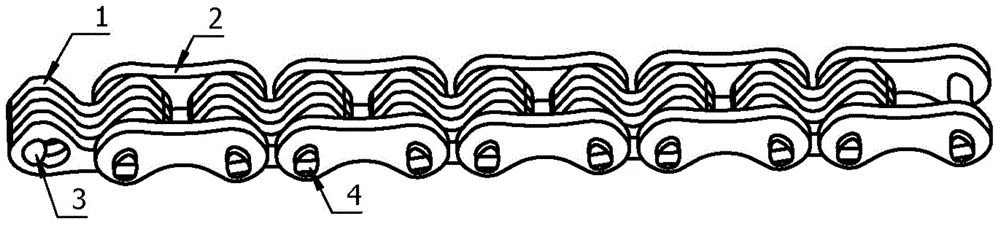

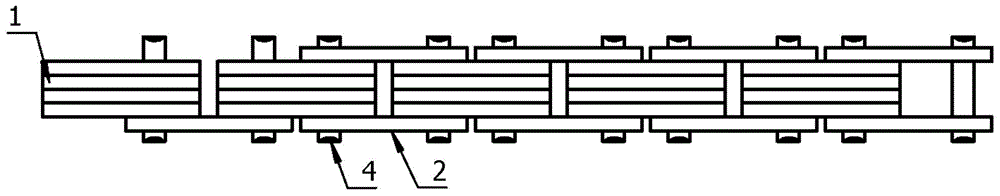

Tooth-shaped chain

InactiveCN103557270AReduce shockReduce vibrationChain linksDriving chainsInterference fitFriction loss

The invention provides a tooth-shaped chain which comprises inner chain plates, outer chain plates, short pin shafts and long pin shafts, wherein the inner chain plate holes formed in the inner chain plates are circular holes or non-circular profile holes; a pair of tooth-shaped bulges is formed in each inner chain plate hole; the inner chain plate holes are divided into outer side slots and inner side hole grooves through the bulges; the short pin shafts are axially positioned through the bulges and the outer side slots, and are fixed together with the inner chain plates in an interference fit manner; multiple inner chain plates are overlapped to form an inner link; the long pin shafts penetrate through the inner side hole grooves of the inner chain plates and are riveted together with the two outer chain plates tightly to form an outer link; the short pin shafts of the inner link is in contact with the long pin shafts of the outer link through arc working surfaces to form a rotation pair which can rotate within a certain range. According to the tooth-shaped chain provided by the invention, the structural constraints of the conventional tooth-shaped chain and Hy-Vo tooth-shaped chain are broken through, the friction loss and impact vibration between the pin shafts and chain plates are reduced by changing the assembling mode of the pin shafts and the arrangement mode of the inner chain plates, and the mechanized and scale production of high-speed tooth-shaped chains is achieved.

Owner:金雁冰 +1

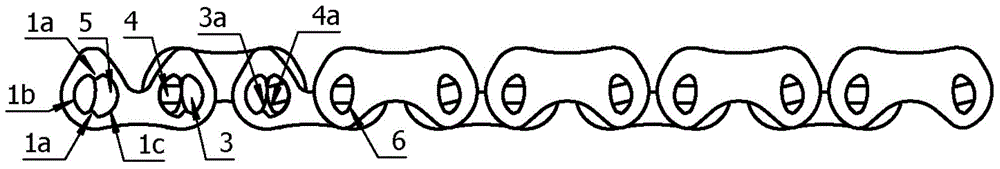

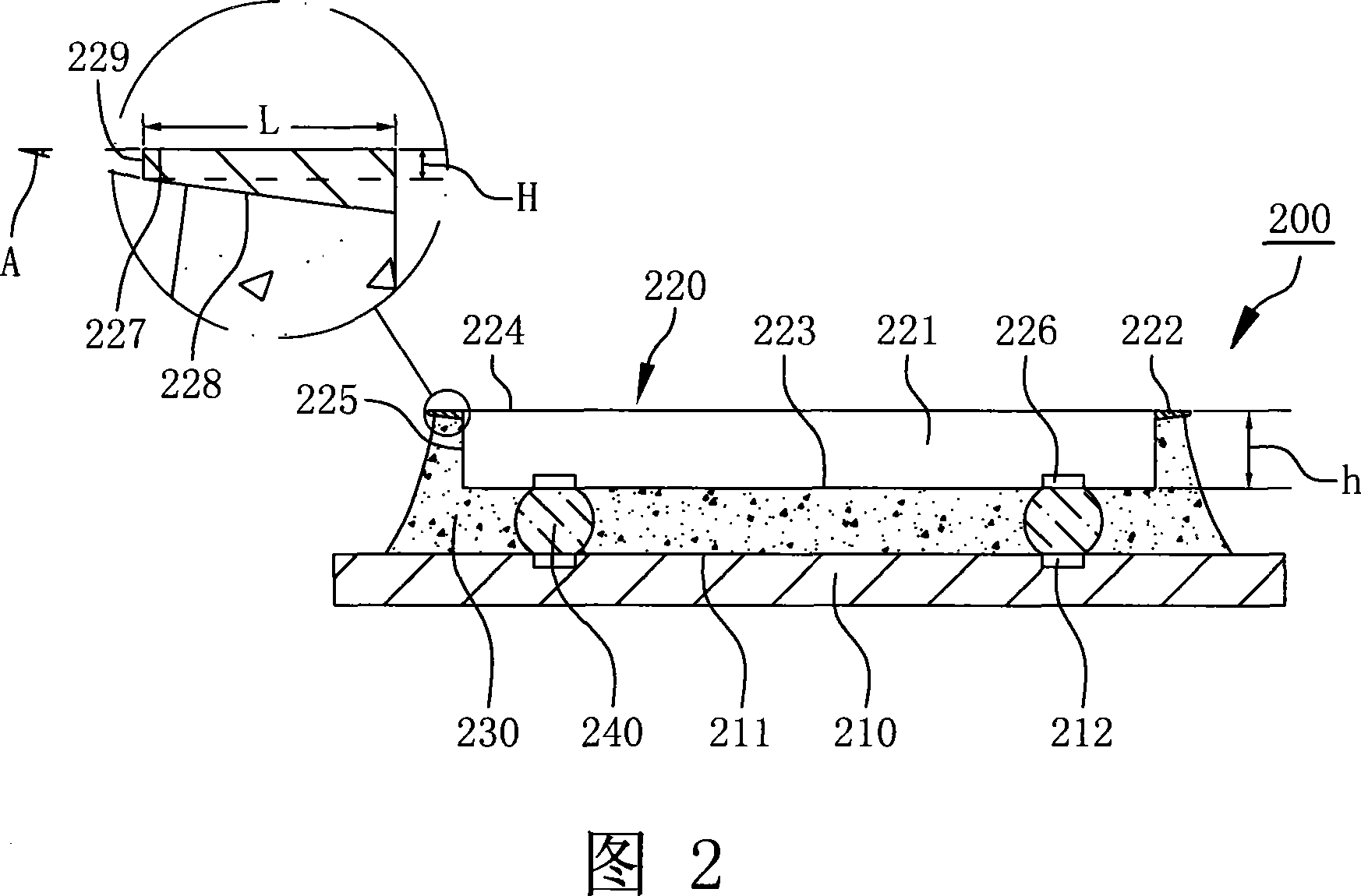

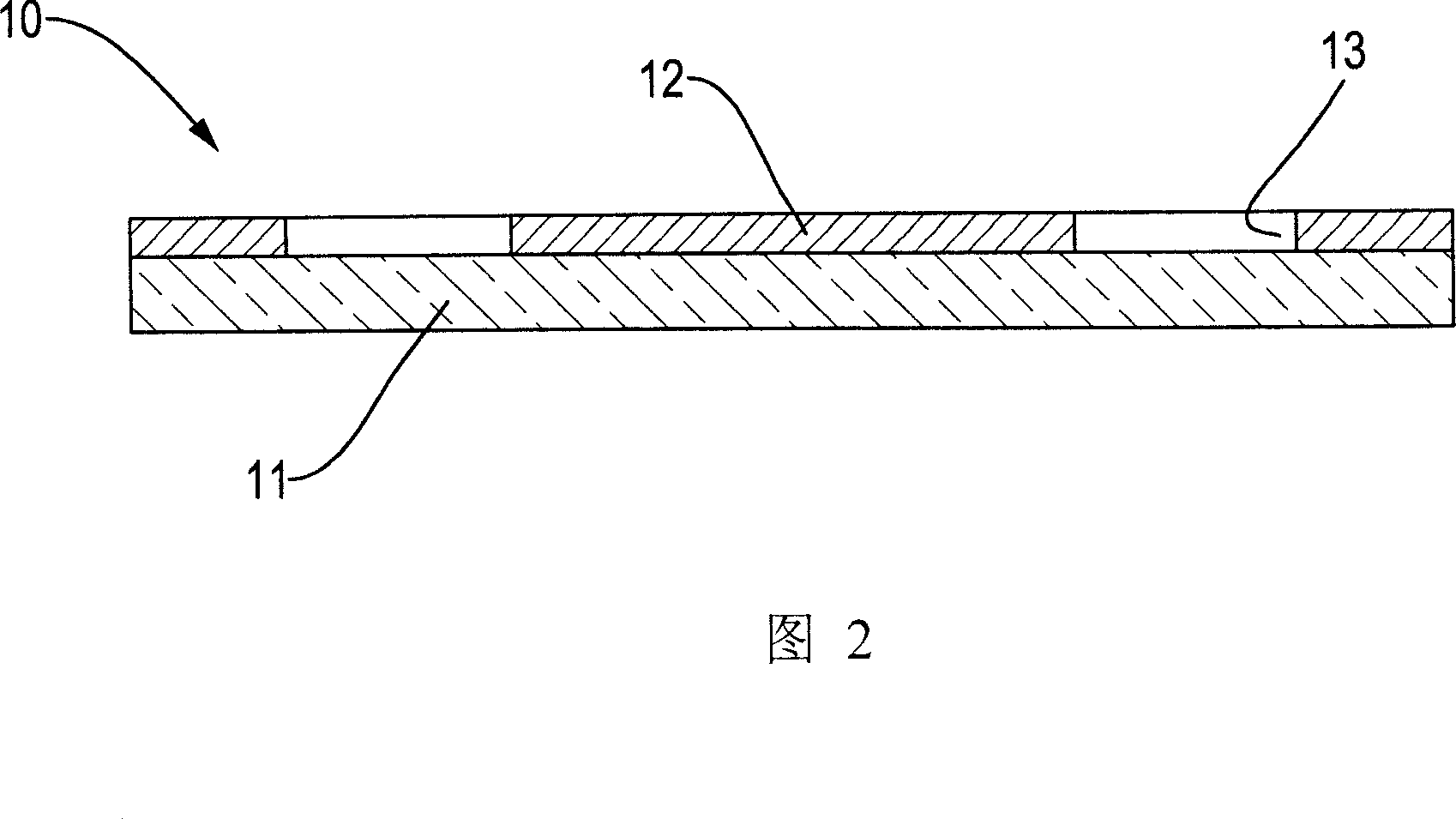

Chip packing structure, chip structure and method for forming chip

ActiveCN101075591ASimple package structureAvoid gluingSemiconductor/solid-state device detailsSolid-state devicesAcute angleElectrical and Electronics engineering

This is a chip packing structure avoiding gel overflow. It includes a supporter, chip and base gel. The chip is of a gel blocking section and installed on the supporter. The blocking section is to one side of the chip, with a top and bottom face in an acute angle. The base gel is in between the supporter and the chip and blocked by the bottom face of the gel blocking section.

Owner:ADVANCED SEMICON ENG INC

Cutting oil

InactiveCN101724497AImprove adsorption capacityInhibit wearAdditivesBase-materialsParaffin waxBenzotriazole

The invention discloses cutting oil, which comprises the following components in percentage by mass: 40 to 60 percent of liquid paraffin, 20 to 50 percent of oiliness improver, 4 to 18 percent of extreme-pressure additive and 0.1 to 2 percent of benzotriazole, wherein the oiliness improver is a mixture of 30 to 90 percent of tricaprylin and 10 to 70 percent of glycol ethyl ether. The invention provides the cutting oil which has good effects of lubricating, cooling, rust protection and cleaning and has good environment-friendly performance.

Owner:SHAANXI UNIV OF SCI & TECH

Multi-color photoelectric coating procedure and its products

The invention discloses a preparation process of a multicolor photoelectric coating and its product. The main process is to anti-white print cleaned substrate of needed painting by lithographic printing so that pictorial is covered in the printed oil and the printed substrate placed on the coating machine for coating. Single color graphics tablet is obtained after the substrate coating on with printing of oil cleaned. Multicolor designs are obtained in a single substrate by the circulation of duplication and printing, coating and cleaning printing oil.

Owner:BOHHEN OPTRONICS +1

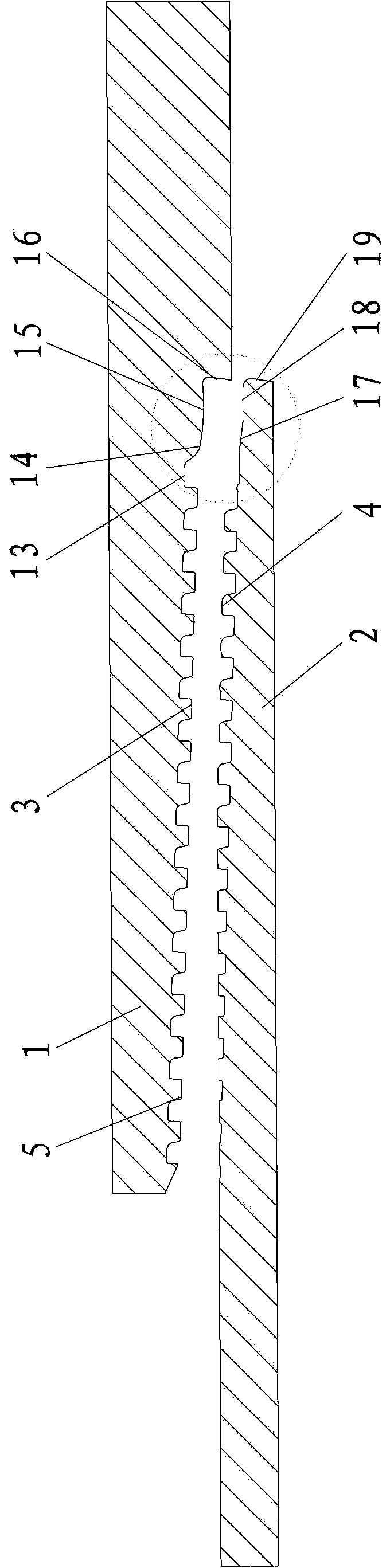

Processing method for preventing connection thread gluing of titanium alloy oil well pipe

InactiveCN103527914ASolve the problem of easy stickingImprove contact surface hardnessEngine lubricationHardnessGraphite

The invention relates to a processing method for preventing connection thread gluing of a titanium alloy oil well pipe. A shot blasting process is used for processing a connection external thread, and the hardness and the abrasive resistance of the surface of the connection external thread are improved. Meanwhile, a nickel / copper preplating process is used for a connection internal thread, a layer of copper film which is well combined with a titanium alloy matrix is electroplated on the surface of the connection internal thread, the hardness and the abrasive resistance of the surface of the connection internal thread are improved, and a friction condition is improved. Moreover, graphite is used for lubricating the internal thread and the external thread, and the friction coefficient between the surface of the internal thread and the surface of the external thread is effectively lowered. The method can effectively solve the problem of the connection thread gluing of the titanium alloy oil well pipe.

Owner:XIAN SANHUAN TECH DEV GENERAL

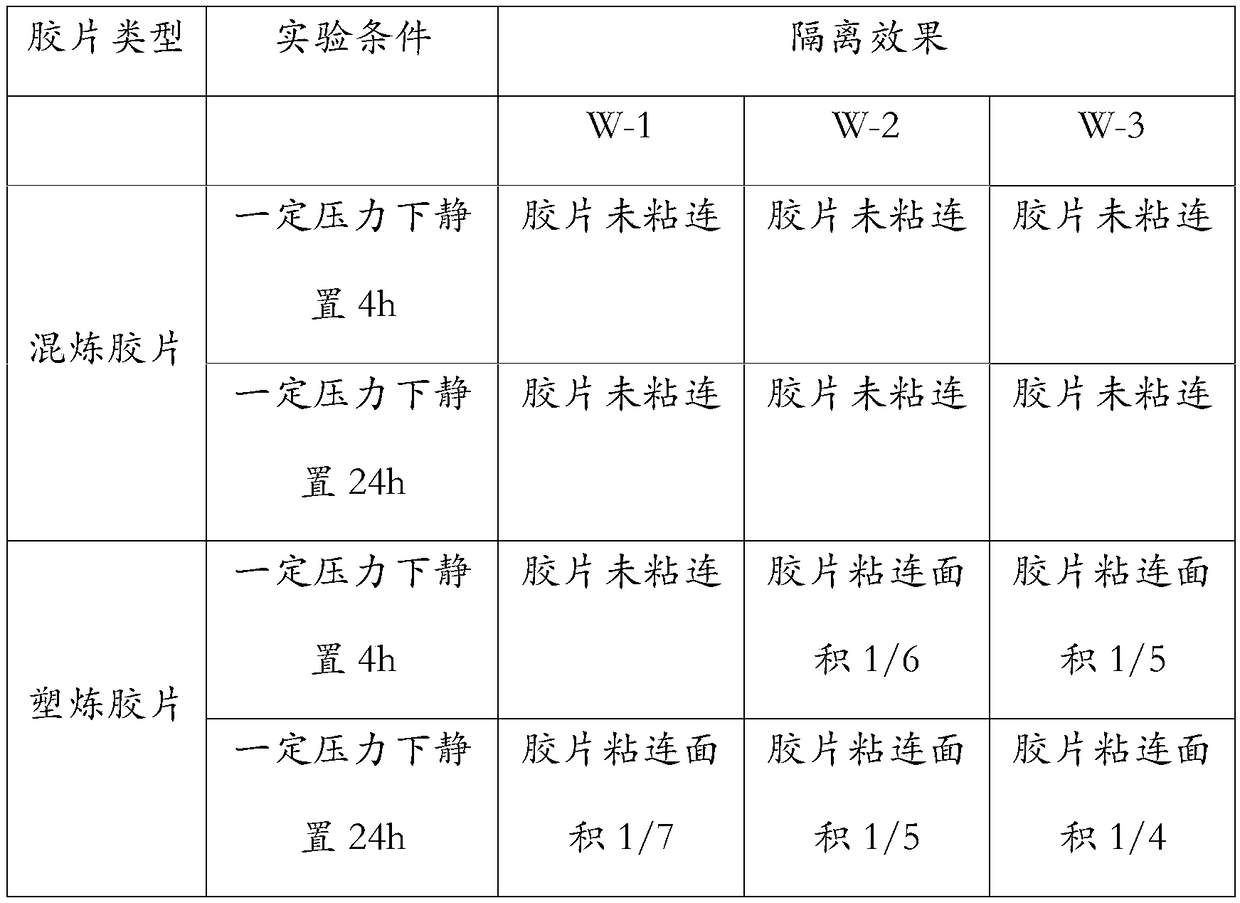

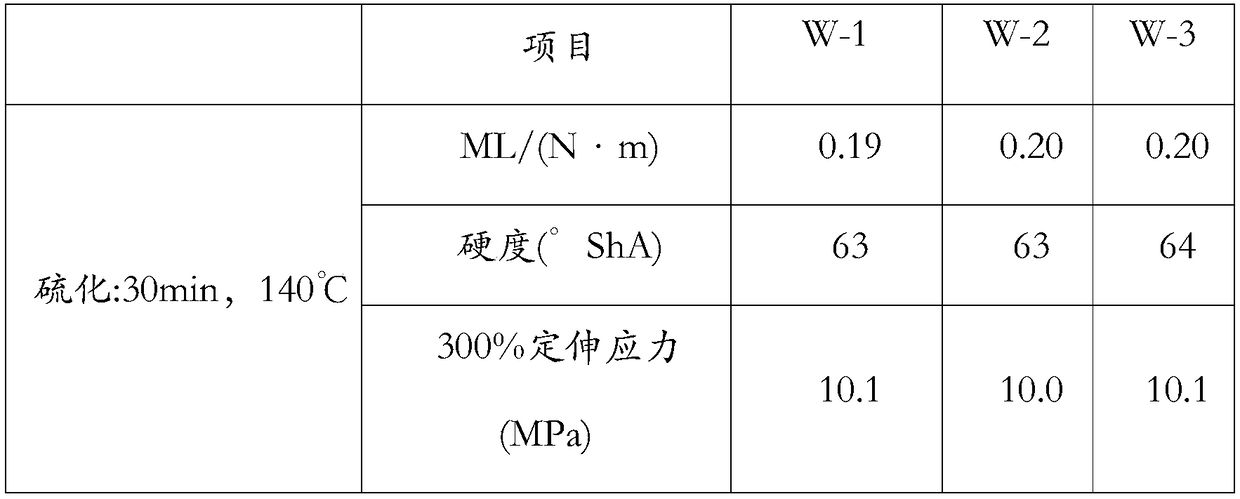

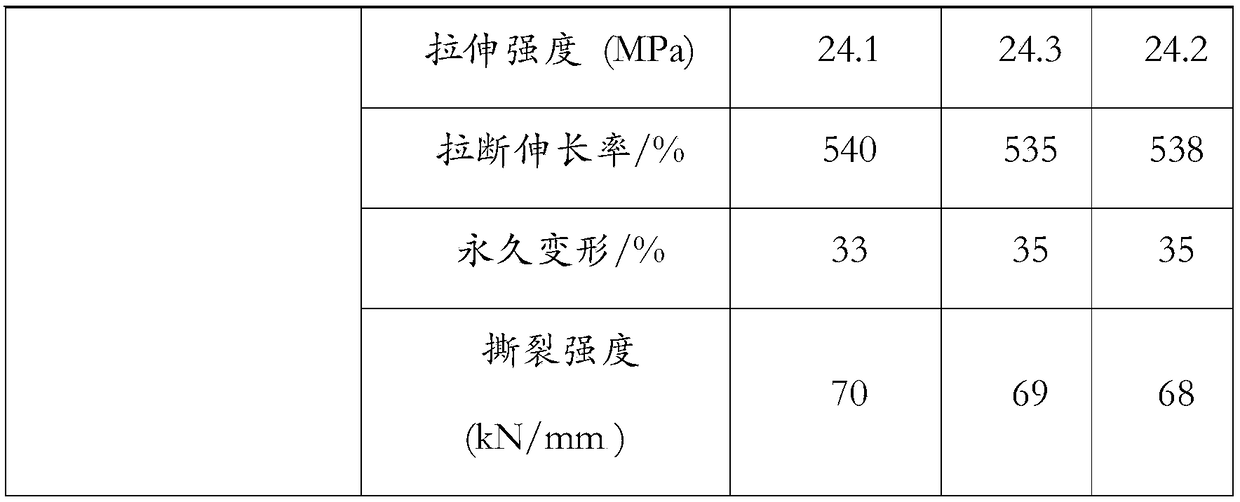

Rubber film separant

The invention discloses a rubber film separant and belongs to the technical field of rubber processing. The rubber film separant comprises the following ingredients (by weight): 10-30 parts of fatty acid salt, 5-10 parts of an inorganic thickening agent, 1-5 parts of an organic thickening agent, and 50-70 parts of an inorganic filler. by combining the organic and inorganic thickening agents and through reasonable compatibility of the ingredients, the rubber film separant can prevent adhesion of unvulcanized and mixed rubber films during storage, has good wetting isolation property for rubber films with different softness and viscosity, can be greatly dissolved in rubber when vulcanized and will not influence fluidity and other properties, will not generate lots of bubbles when dispersed inwater and will not influence coating of the separant on the surface of rubber films.

Owner:QINGDAO FIHONOR CHEM SCI & TECH

Special-thread gas seal oil sleeve joint for ultra-deep wells

InactiveCN105927167AStrong anti-torsion abilityImprove sealing performanceDrilling rodsDrilling casingsDirectional wellCorrosion

The invention relates to a special-thread gas seal oil sleeve joint for ultra-deep wells. The special-thread gas seal oil sleeve joint comprises a pipe portion and a coupling portion. The joint is composed of two main seals (conical / conical sealing structure and spherical / conical sealing structure), three auxiliary seals (-15-degree-angle torque shoulder and two right-angle torque shoulders), a deformation release space, a tool withdrawal groove and a connecting thread. The technical problem that an ultrahigh-pressure oil-gas well threaded joint is prone to thread gluing, sealing invalidation and torque shoulder shearing invalidation, low in resistance to stress corrosion and threaded connection strength and nonuniform in stress distribution is solved, and the special-thread gas seal oil sleeve joint can be used for high-temperature high-pressure oil-gas wells, deep wells, the ultra-deep wells, directional wells and horizontal wells.

Owner:SOUTHWEST PETROLEUM UNIV +2

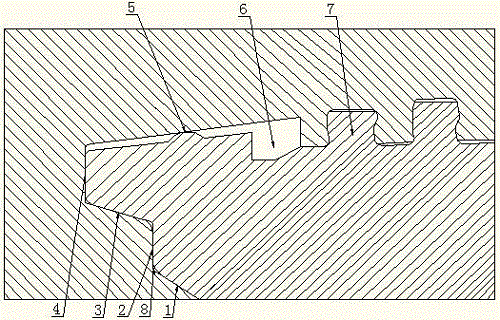

Anti-bonding three-stage end surface metal sealing threaded connector for titanium alloy pipe

ActiveCN103628827AImproves sealing reliabilityLow contact pressureDrilling rodsDrilling casingsButtressThree stage

The invention relates to a threaded structure for connection of a well completion production tubular column of the petroleum and gas industry, in particular to an anti-bonding three-stage end surface metal sealing threaded connector for a titanium alloy pipe. The anti-bonding three-stage end surface metal sealing threaded connector for the titanium alloy pipe comprises an oil casing collar and an oil casing end, wherein the oil casing collar is provided with an API buttress inner thread, the oil casing end is provided with a buttress outer thread matched with the API buttress inner thread, a tool withdrawal groove is formed in one end of the API buttress inner thread and is sequentially connected with an arc surface I and an arc surface II through chamfer transition, the arc surface II is connected with a negative angle torque lifting shoulder I through chamfer transition, a conical surface, a cylindrical surface and a negative angle torque lifting shoulder II are arranged at one end of the buttress outer thread, the conical surface and the cylindrical surface sequentially correspond to the arc surface I and the arc surface II, the negative angle torque lifting shoulder II corresponds to the negative angle torque lifting shoulder I, and after the oil casing collar is matched with the oil casing end in a threaded mode, interference sealing is carried out on metal through a first-stage sealing structure of the arc surface I on the conical surface, a second-stage sealing structure of the arc surface II on the cylindrical surface and third-stage metal of the sealing structure of the negative angle torque lifting shoulders. The anti-bonding three-stage end surface metal sealing threaded connector for the titanium alloy pipe improves the air sealing reliability, and has good anti-bonding performance.

Owner:忠世高新材料股份有限公司

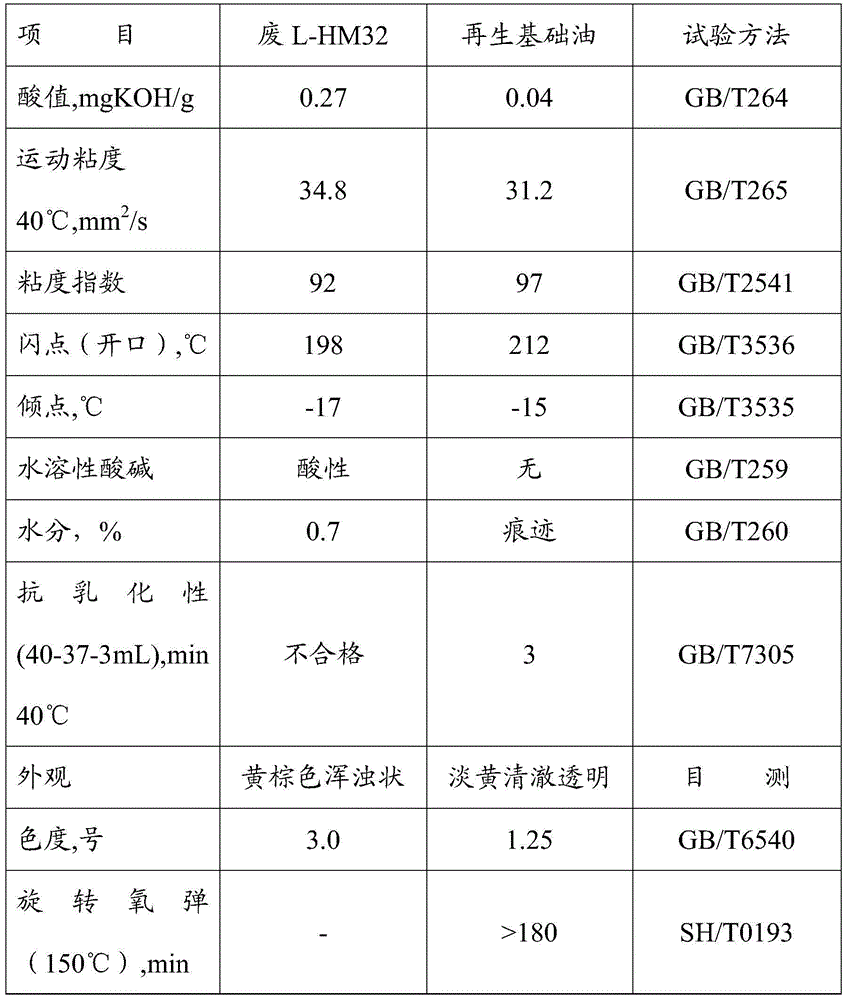

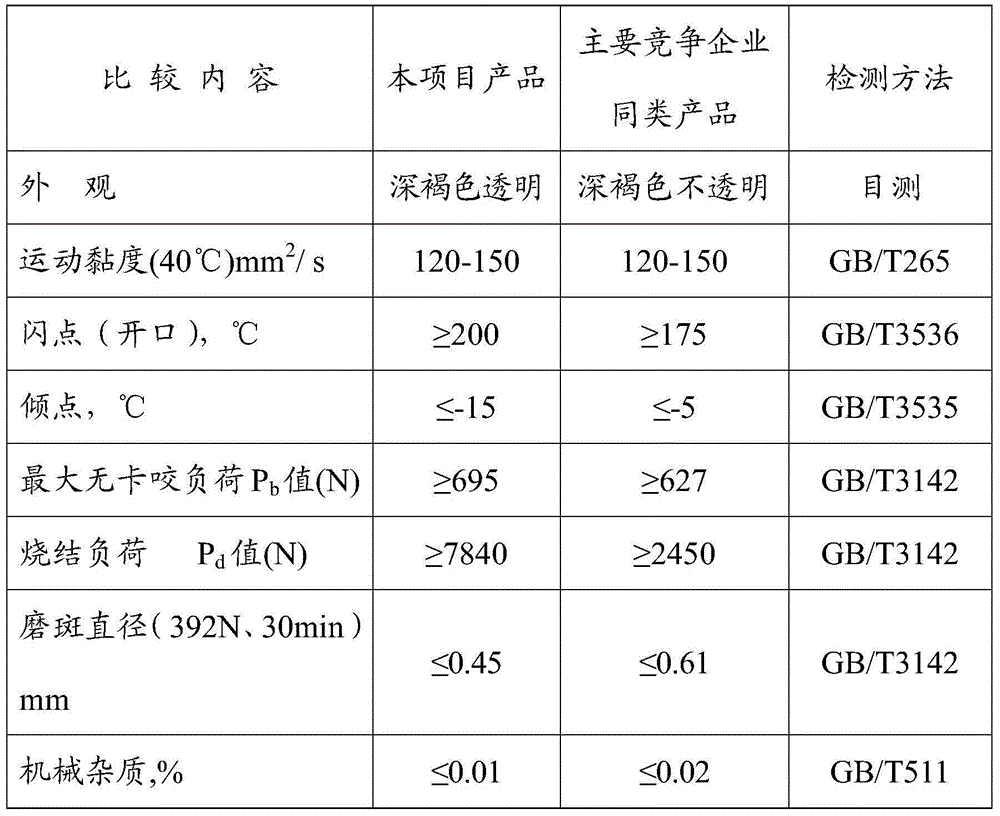

Nanometer novel metal processing oil and preparation method thereof

The invention discloses a preparation method of nanometer novel metal processing oil. The preparation method comprises the following steps: firstly, pumping regenerated base oil into a vacuum blending kettle, starting stirring and starting a vacuum system for heating the regenerated base oil; secondly, fully mixing and evenly distributing the regenerated base oil and a nanometer extreme pressure anti-wear agent to obtain a nanometer novel metal processing oil crude product; and thirdly, after indicators of the nanometer novel metal processing oil crude product obtained in the step 2 are qualified by detection, filtering the nanometer novel metal processing oil crude product and canning to obtain the finished product, namely, nanometer novel metal processing oil. The product is odorless and non-toxic, has favorable pressure anti-wear property and heat stability and no corrosion to copper, aluminum and alloys thereof and is free of such active elements as sulfur, phosphorus and chlorine. The nanometer novel metal processing oil can be used for multiple processing methods such as cutting, forging, rolling, extruding, drawing and stamping of materials such as cast iron, carbon steel, alloy steel, stainless steel, hard alloy steel, copper, aluminum and copper-aluminum alloy.

Owner:NINGBO LANRUN ENERGY TECH

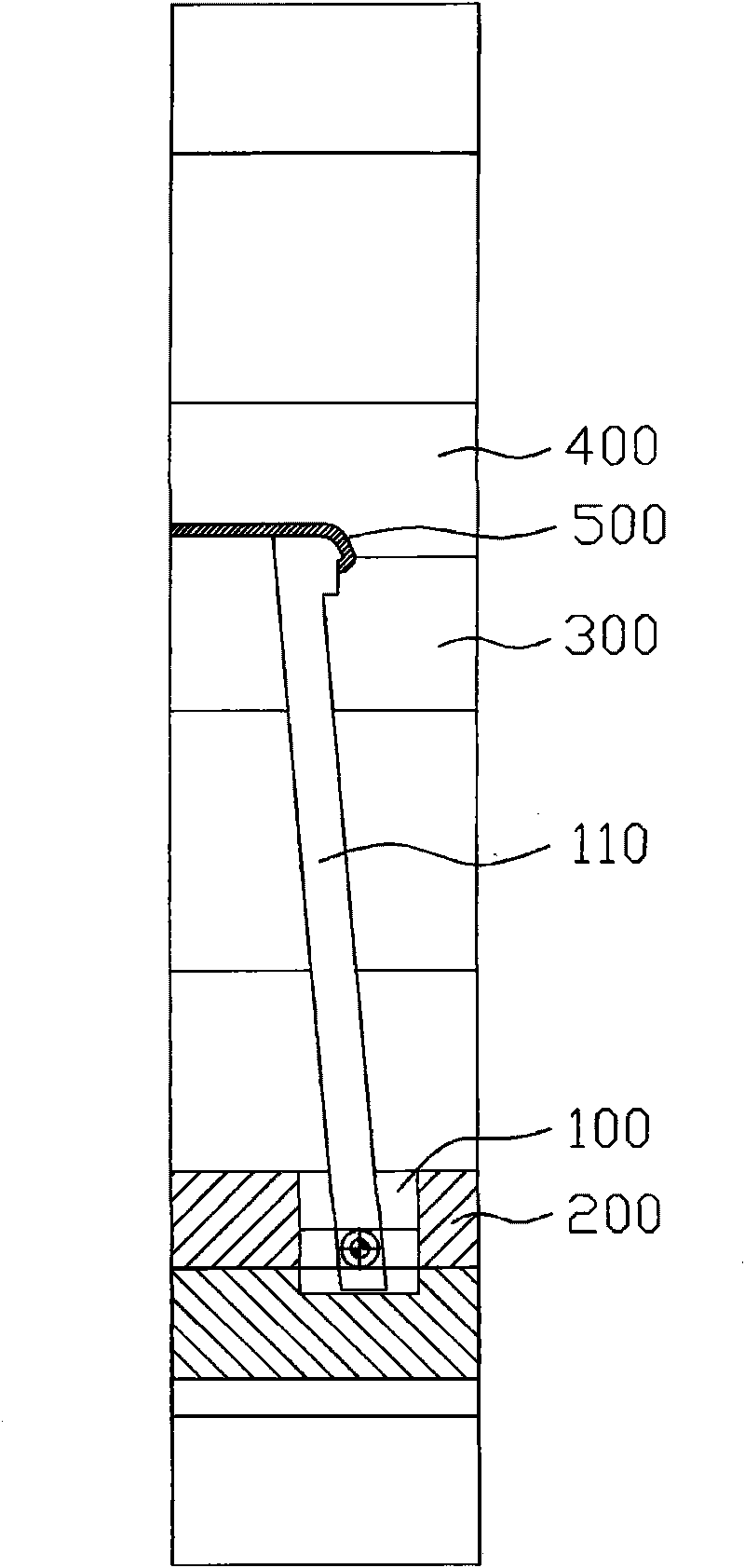

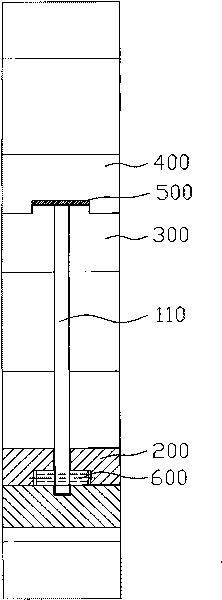

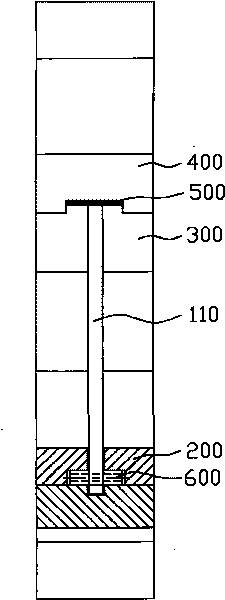

Angle lifter base

The invention provides a novel angle lifter base applied in a mold, which comprises a sliding block, wherein the sliding block is movably embedded in an upper top plate of the mold, one end of an angle lifter is fixed on the sliding block, and the other end is matched with a core insert and a cavity insert of the mold for molding a product. Preferably, the invention provides the novel angle lifter base, wherein the sliding block is a cylinder. The angle lifter base can reduce the strength weakening effect of the angle lifter of the mold to the upper top plate, thereby avoiding the problem of burrs or more adhesive of the product due to inadequate strength of the upper top plate and having excellent practical value.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

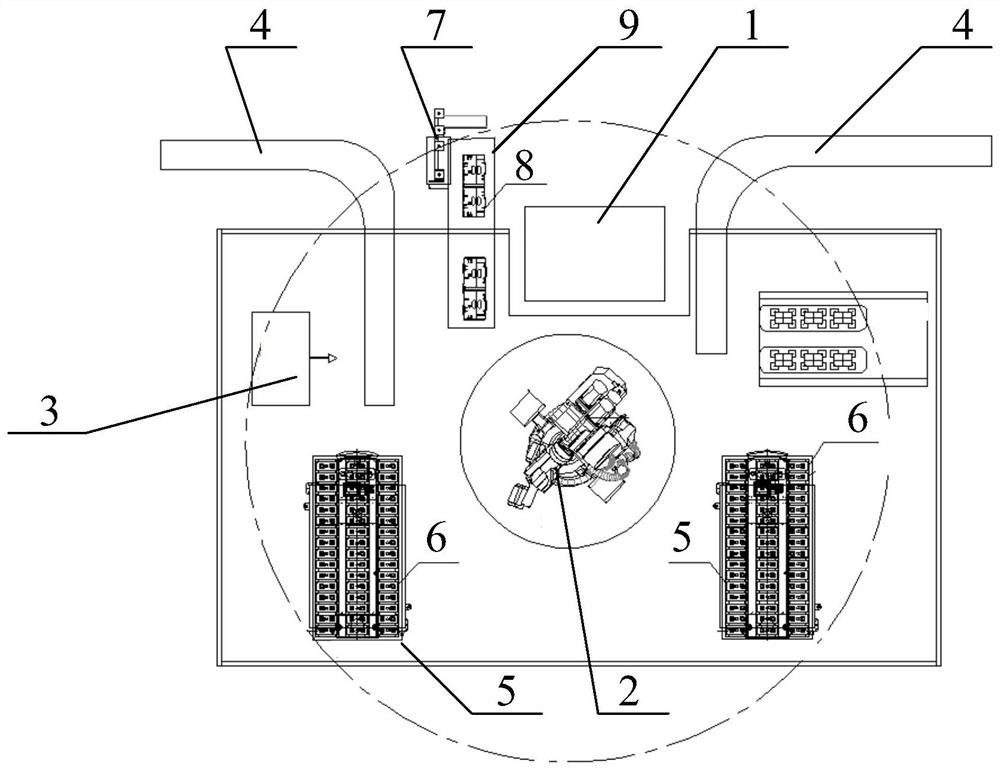

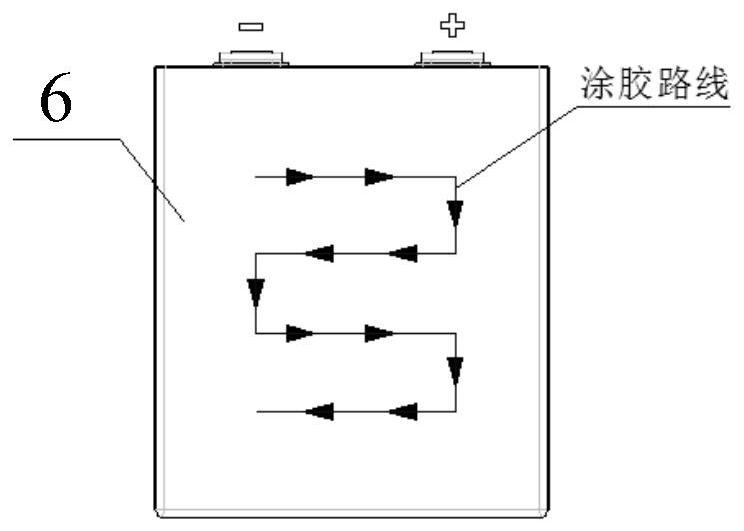

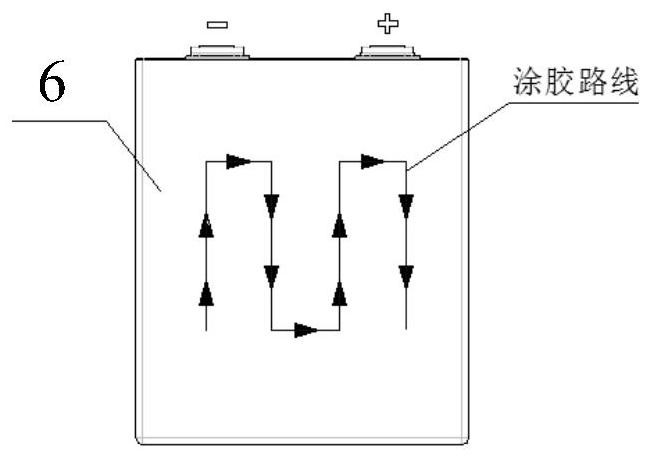

Automatic battery cell gluing device and method

InactiveCN112742661AAvoid manual crawlingAvoid gluingLiquid surface applicatorsCoatingsRobot handControl engineering

The invention discloses an automatic battery cell gluing device and method. The automatic battery cell gluing device comprises a controller, a mechanical hand, a glue gun assembly and conveyors. The controller is in signal connection with the mechanical hand, the glue gun assembly and the conveyors. Under the control of the controller, the mechanical hand can grab to-be-glued battery cells at the battery cell feeding station, place the to-be-glued battery cells below a glue outlet of the glue gun assembly, sort the glued battery cells subjected to gluing and place the battery cells on the conveyors. The glue gun assembly can be controlled by the controller to spray glue to the to-be-glued battery cells. The conveyors are used for conveying the glued battery cells. During use, the mechanical hand is controlled to grab the to-be-glued battery cells and place the to-be-glued battery cells below the glue outlet of the glue gun assembly. Then, the controller controls the glue gun assembly to spray the glue to the to-be-glued battery cells. Then, the mechanical hand is controlled to sort the glued battery cells and place the glued battery cells on the conveyors. Finally, the controller controls the conveyors to output the glued battery cells. By means of the automatic battery cell gluing device and method, manual cell grabbing, gluing and sorting are avoided, and the production efficiency is improved.

Owner:HUNAN CSR TIMES ELECTRIC VEHICLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com