Cement coating method

A technology of gluing and coating, applied in the direction of coating, device for applying liquid to the surface, surface pretreatment, etc. It can solve the problems of appearance and quality, incomplete shape of corners, easy-to-pull glue or lack of glue, etc. problem, to avoid the effect of pulling glue or lack of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention provides a method for applying glue more accurately on the surface of a specific area of an object.

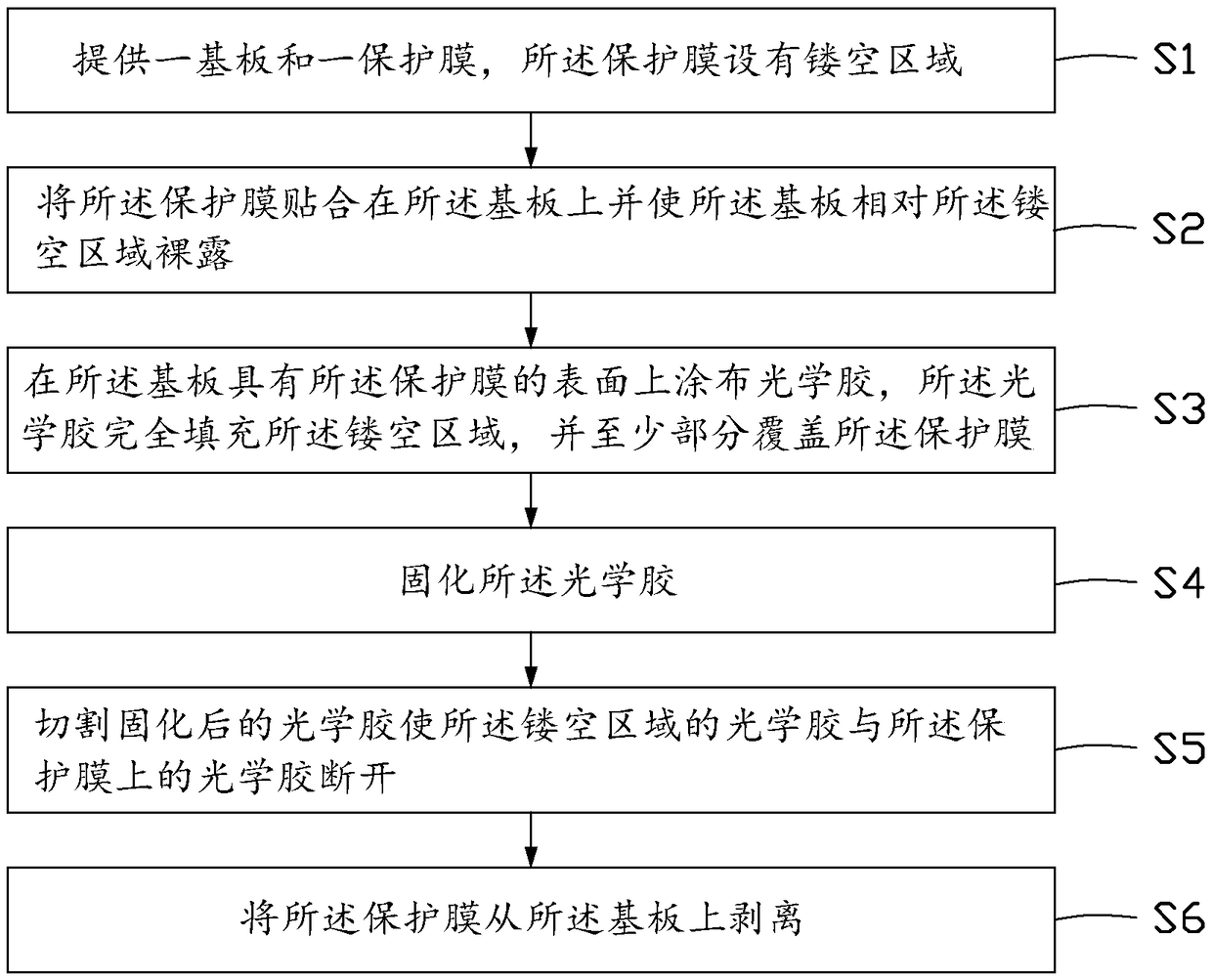

[0028] figure 1 It is a flow chart of the gluing method provided by the embodiment of the present invention. Such as figure 1 Shown, this gluing method comprises the following steps:

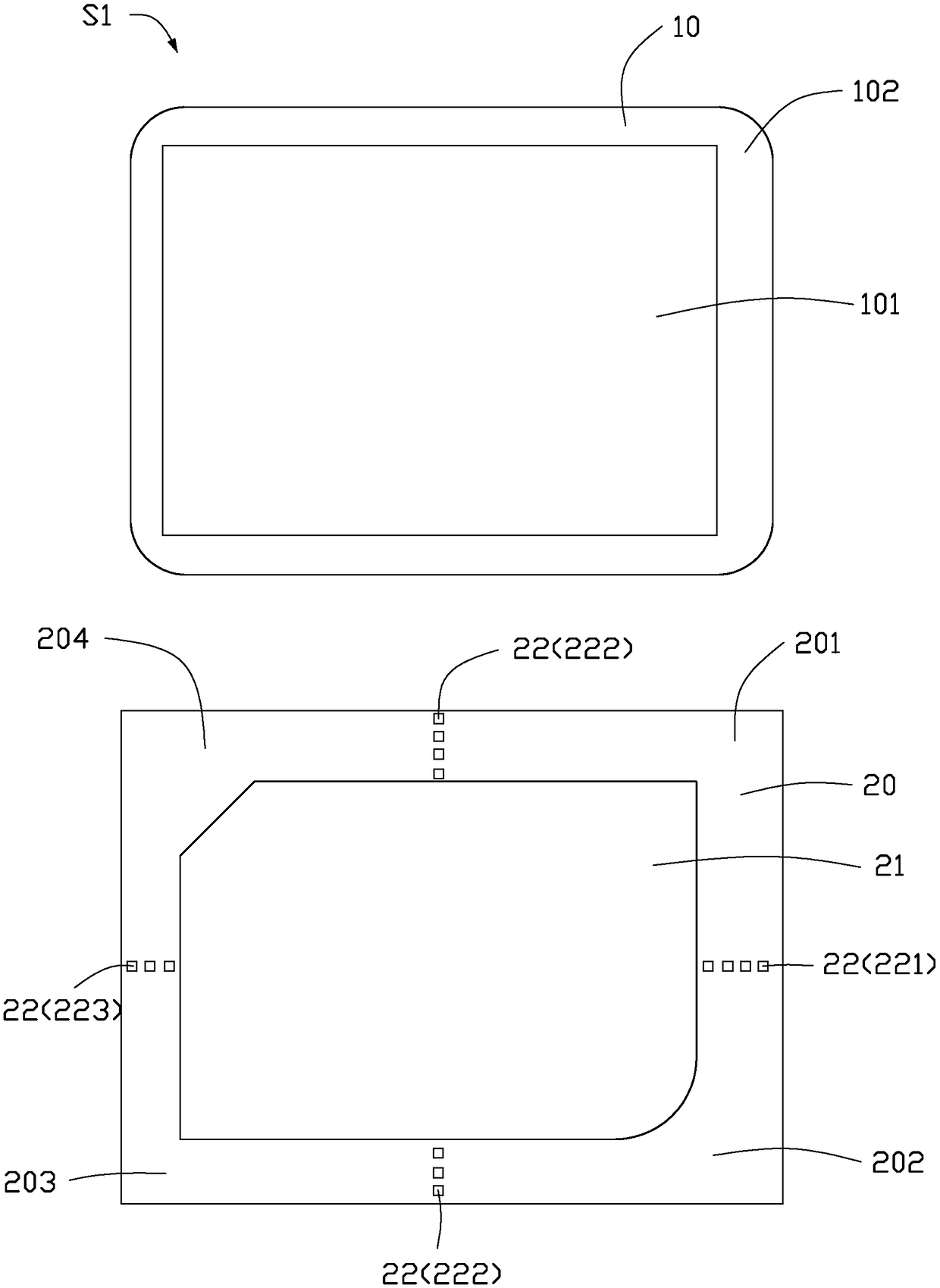

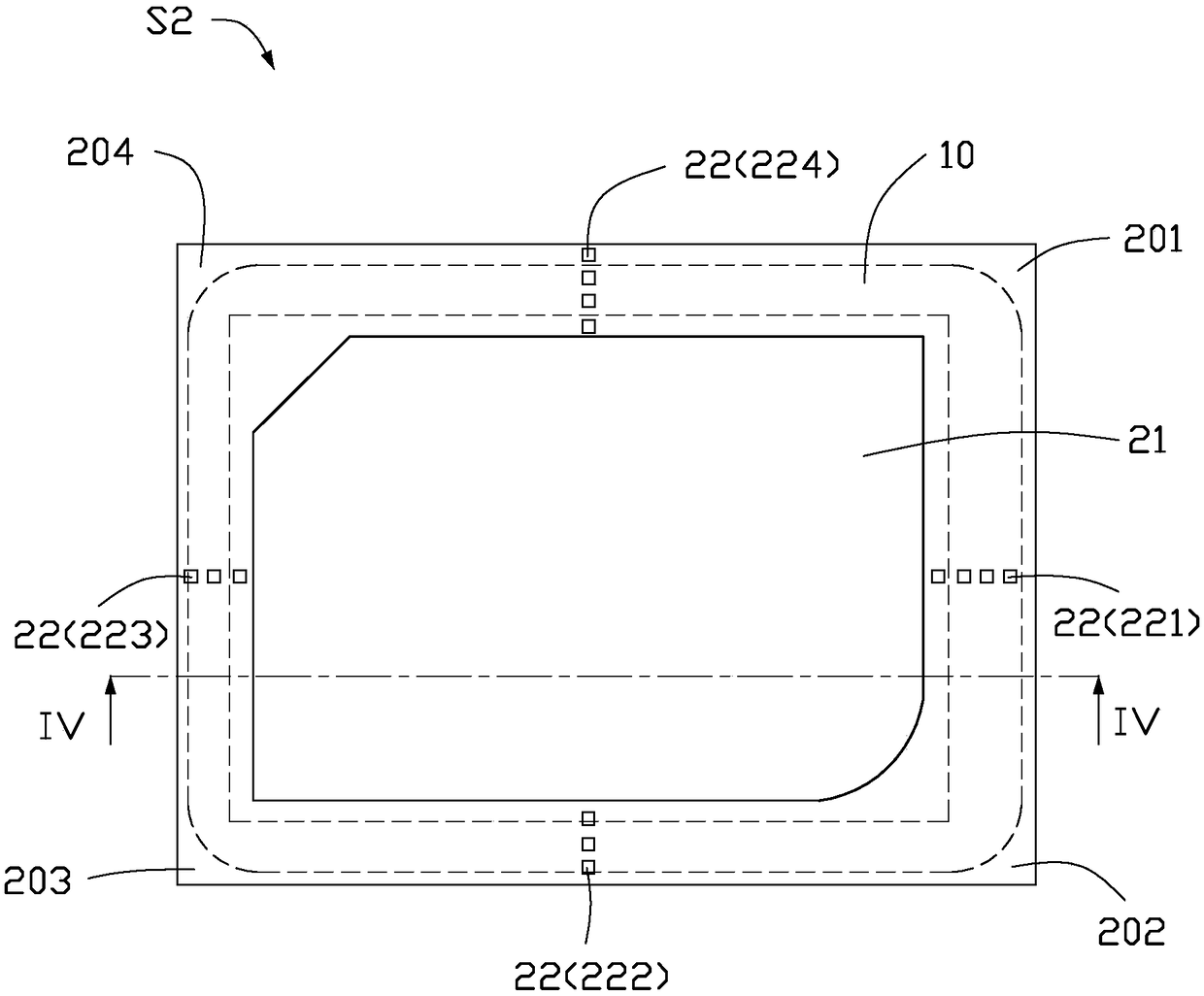

[0029] Step S1: if figure 2 As shown, a substrate 10 and a protective film 20 are provided, and the protective film 20 is provided with a hollow area 21 . The substrate 10 defines a display area 101 and a frame area 102 surrounding the display area 101 . In one embodiment, the frame area 102 may be an area provided with an ink layer.

[0030] The material of the substrate 10 may be glass or an optical substrate. The material of the optical substrate can be, but not limited to, polycarbonate (Polycarbonate, PC), polymethyl methacrylate (Polymeric Methyl Methacrylate, PMMA) or polyethylene terephthalate (polyethylene glycol terephthalate, PET) etc.

[0031] Step S1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com