Large high-strength vibration isolating device

A high-strength, large-scale technology, applied in building types, non-rotational vibration suppression, construction, etc., can solve the problem that performance indicators cannot be greatly changed, the bearing capacity stiffness and horizontal deformation capacity of the isolation device are limited, and the pull-out resistance is limited. minor issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

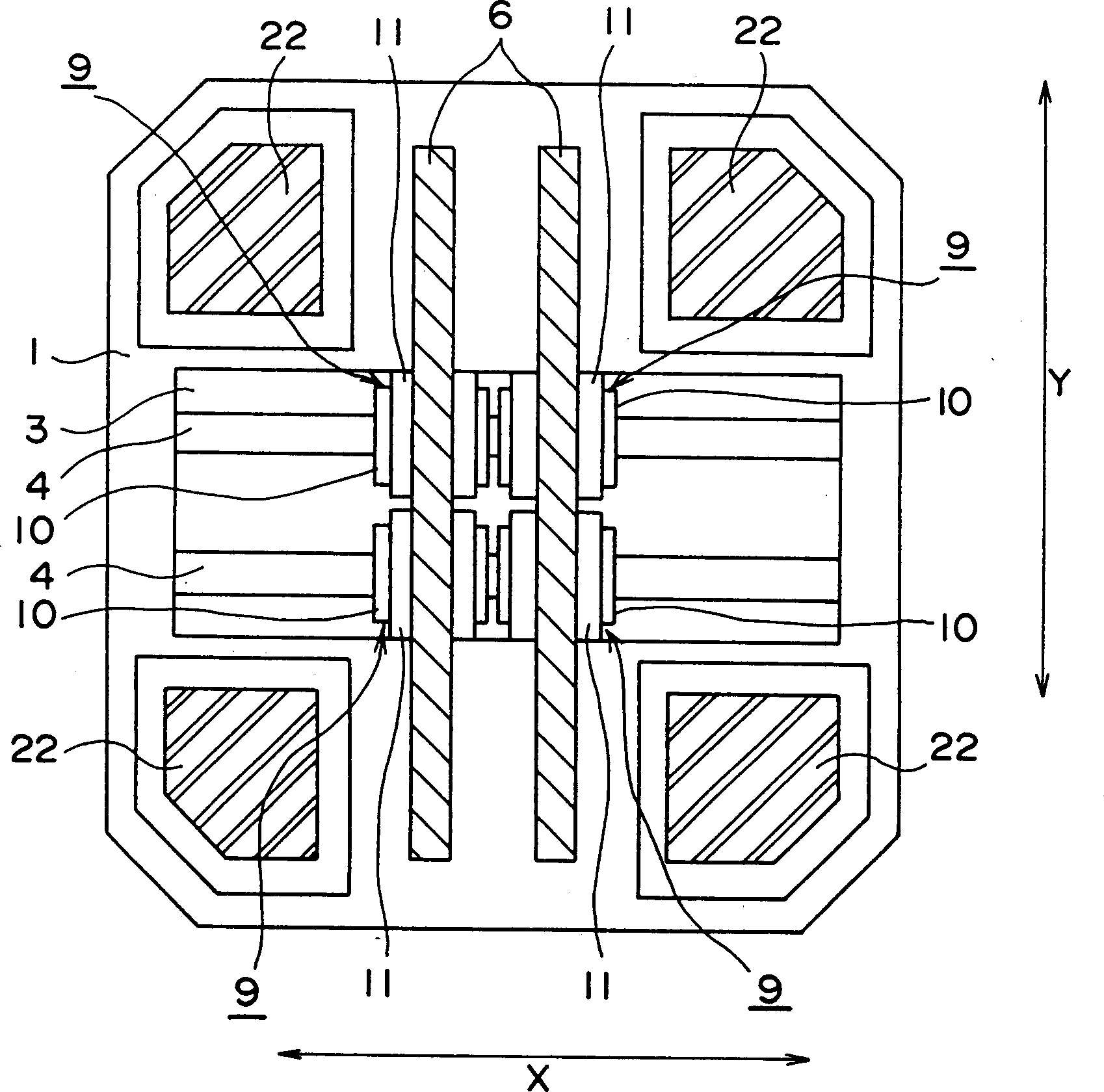

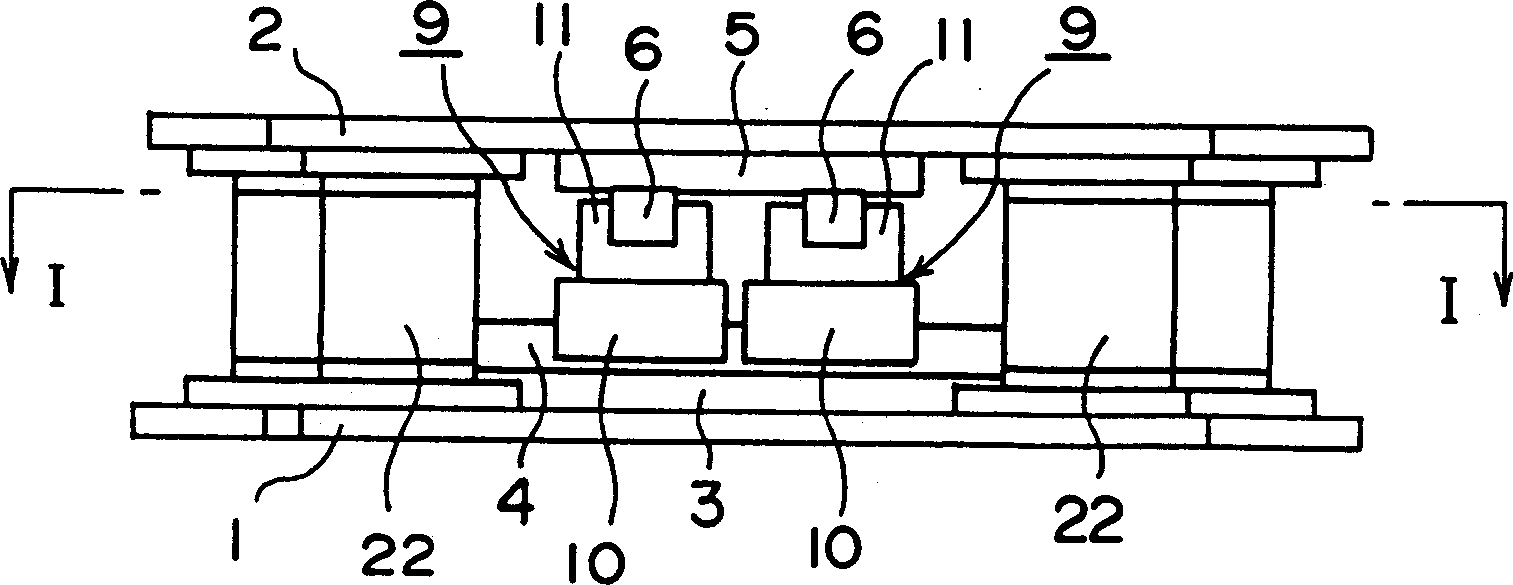

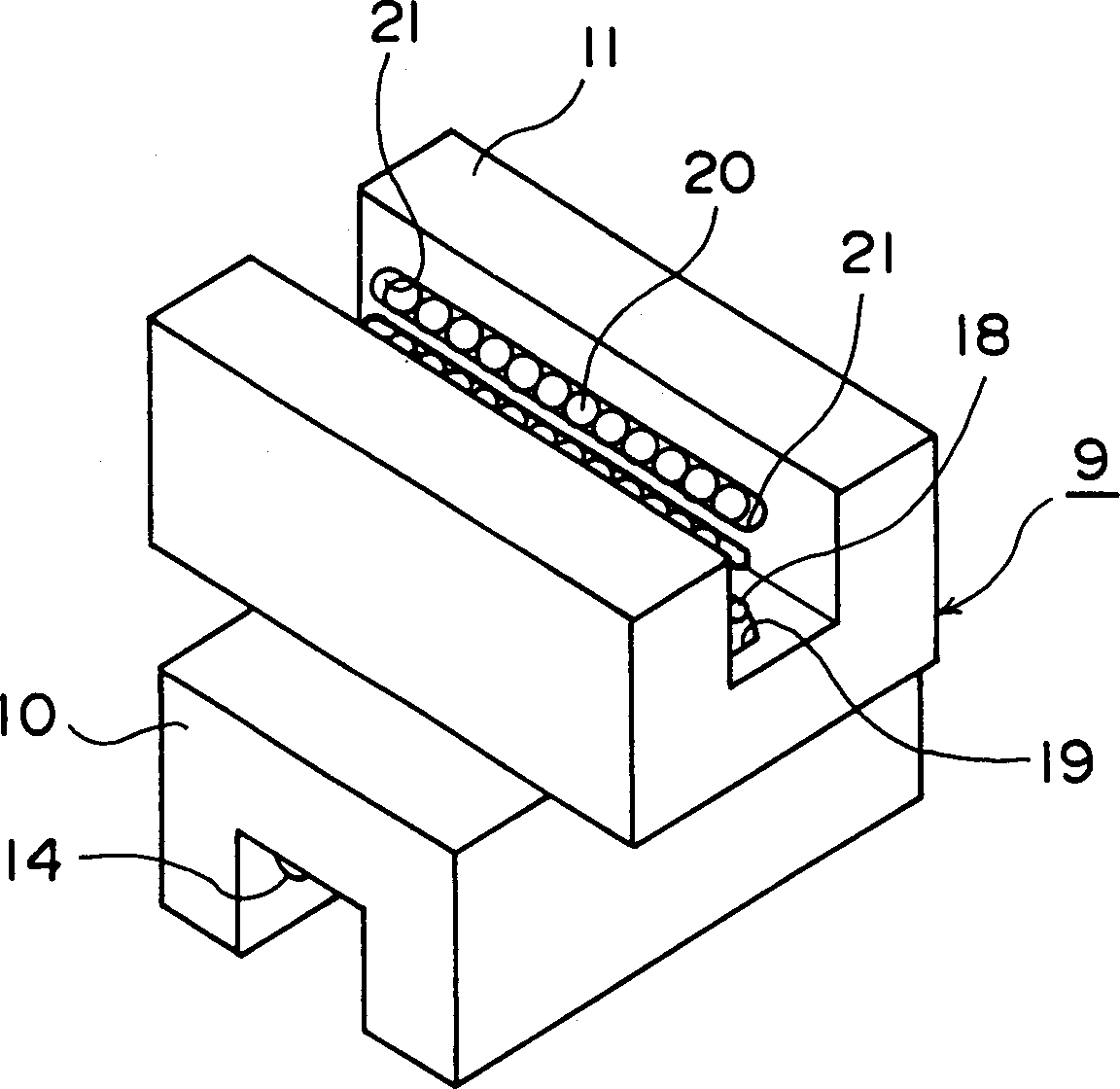

[0018] figure 1 is along figure 2 I-I in is a cross-sectional plan view obtained by looking at an embodiment of the present invention. figure 2 yes figure 1 A front view of . An upper plate 2 is placed on top of a lower plate 1, both of which are flat and have substantially the same shape. In the embodiment shown in the figures, both the lower plate 1 and the upper plate 2 are octagonal, but they can also be made square or circular.

[0019] Two lower guide rails 4 are installed parallel to each other on the upper surface of the lower plate 1 along the transverse direction of the figure through a lower guide rail adapter plate 3 . Although two lower guide rails 4 are installed in the embodiment given in the figure, three or more lower guide rails can also be installed, and only one lower guide rail 4 can be installed so that it passes through the lower plate 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com