Passive mechanical circulating pressure release executing device

A technology of release execution and mechanical circulation, applied in valve operation/release device, valve device, mechanical equipment, etc., can solve the problems of high cost, low reliability, operator safety threat, etc., and achieve reliable mechanical action, Low cost and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

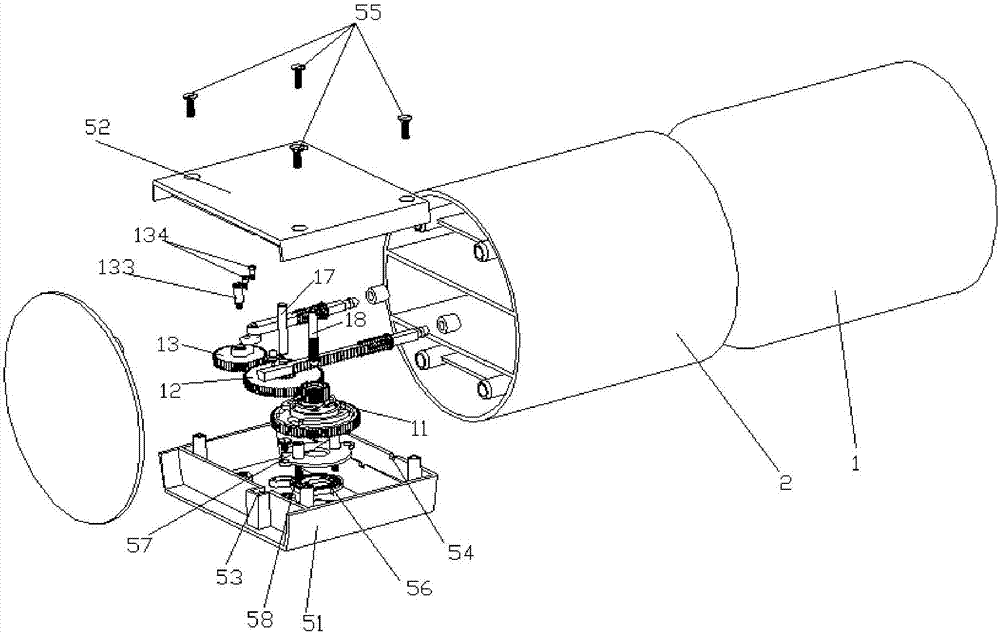

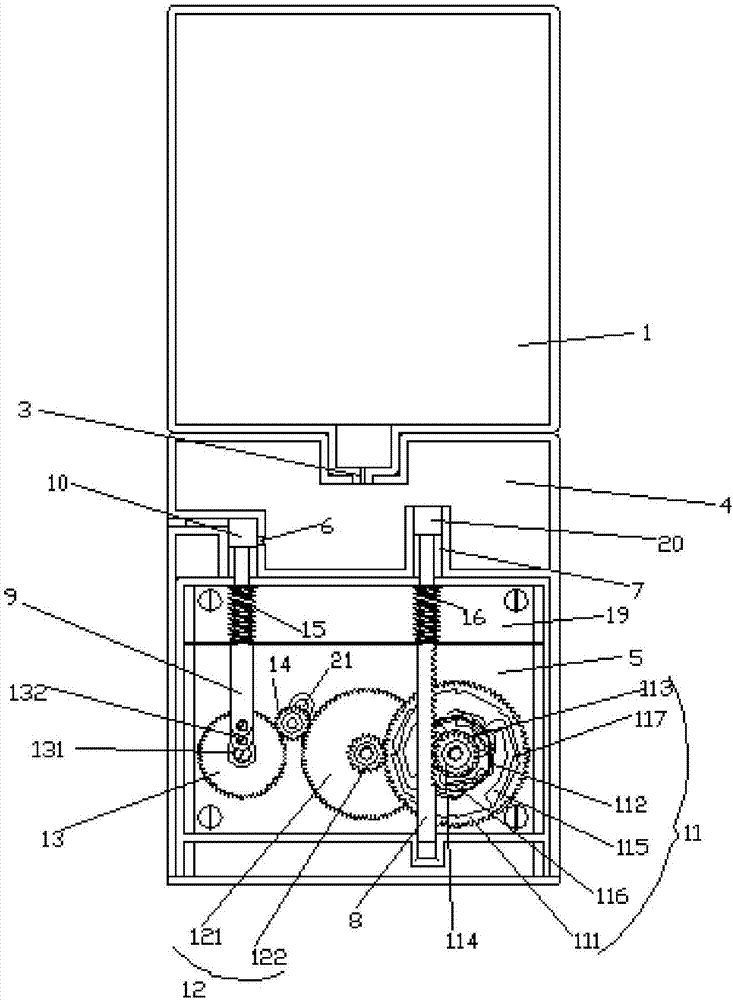

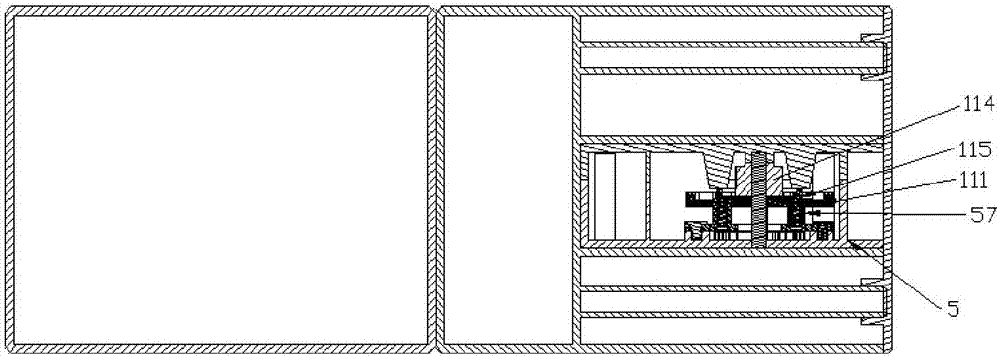

[0052] Such as figure 1 , figure 2 and image 3 As shown, a passive mechanical cycle pressure release actuator includes an upper casing 1 and a pressure storage container 2, the upper casing 1 and the pressure storage container 2 communicate through an air passage 3, and the pressure storage container 2 is provided with a pressure storage cavity 4 and the pressure release gear box 5, the pressure storage cavity 4 has a pressure outlet 6 and a piston mounting hole 7, the pressure release gear box 5 is provided with a linkage reset transmission mechanism, and the linkage reset transmission mechanism is connected to the piston installation hole 7 through the rack 8 ( That is, the piston mechanism), the linkage reset transmission mechanism is connected to a hole plug 10 (that is, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com