Patents

Literature

148results about How to "Reduced damping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

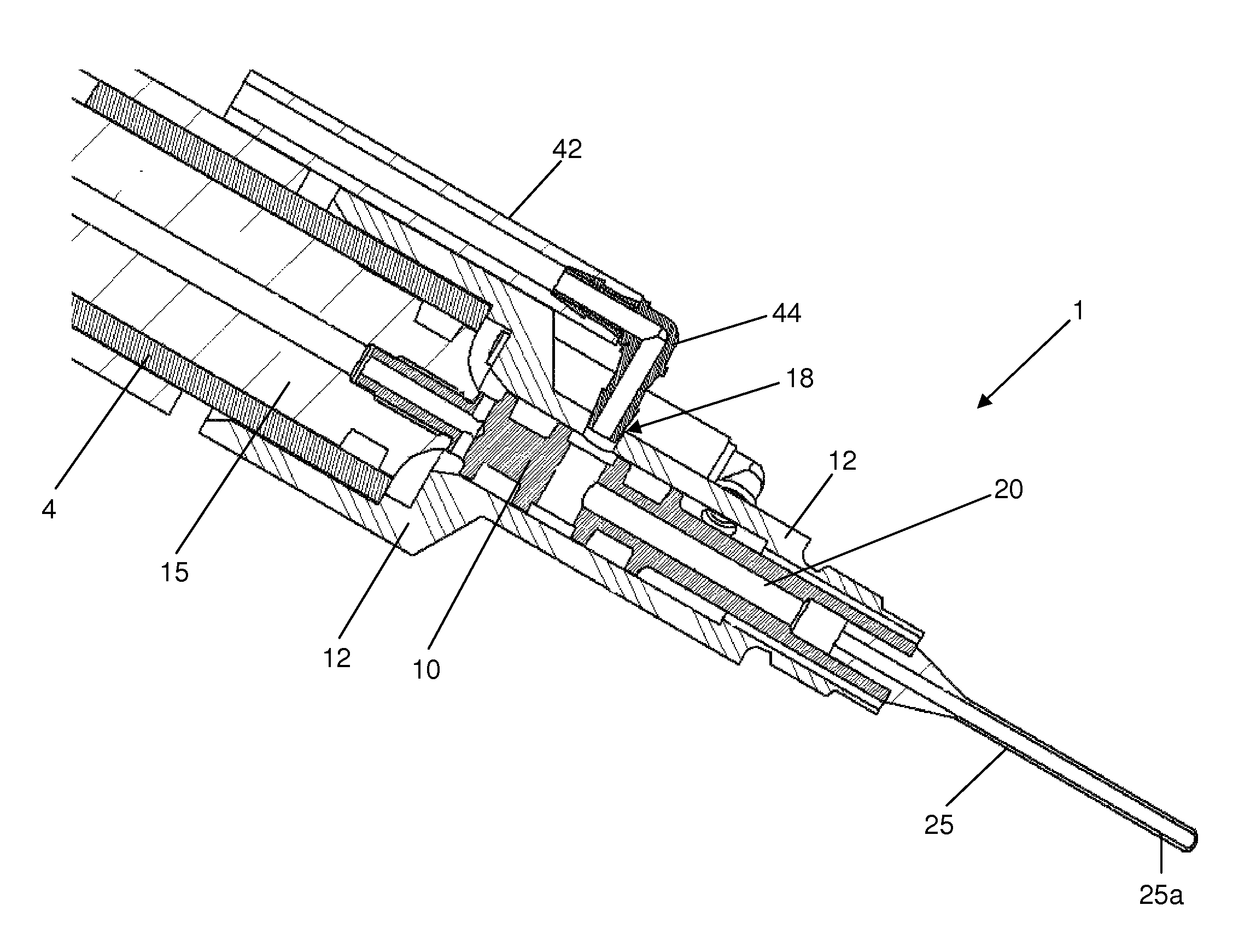

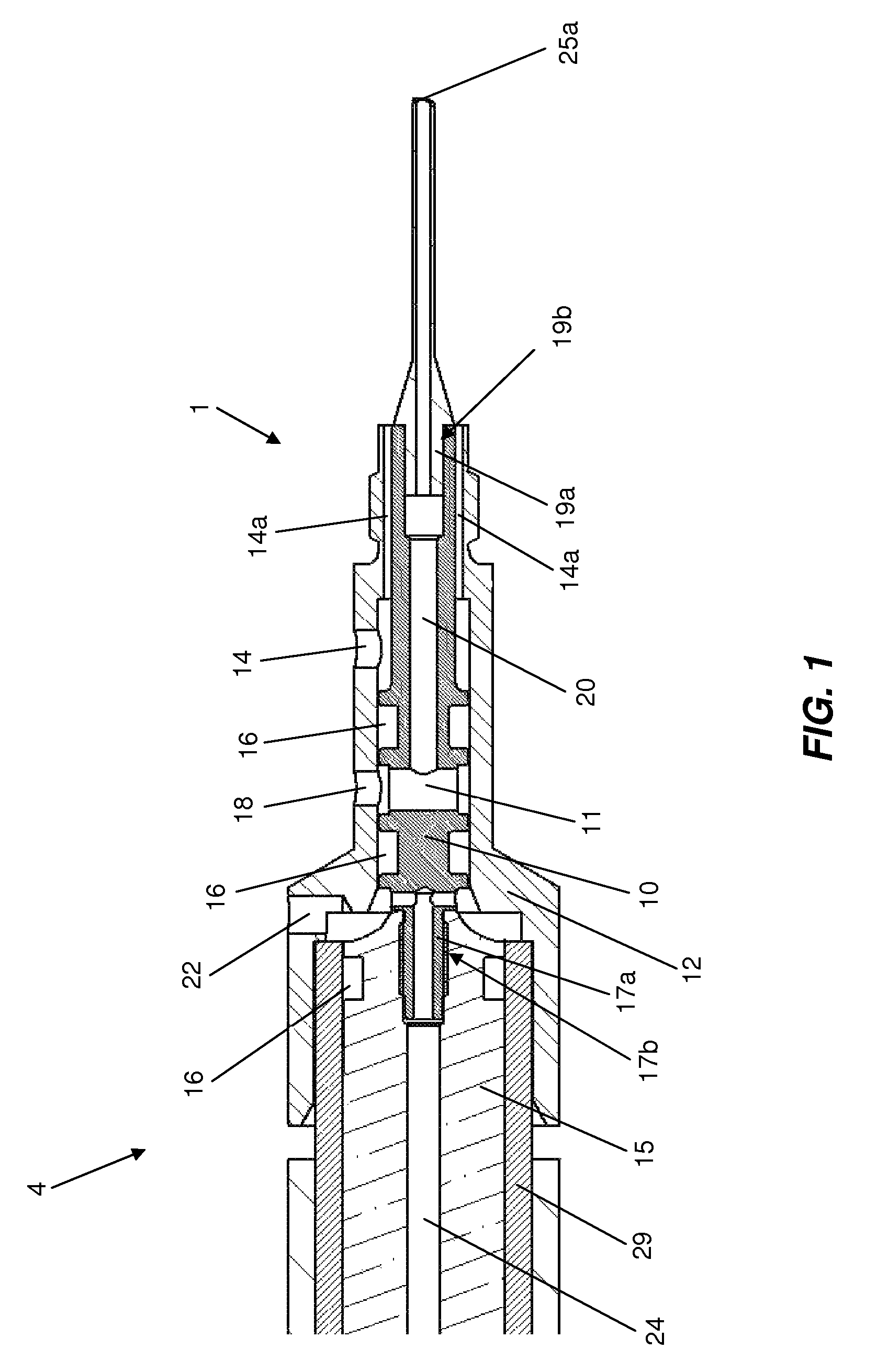

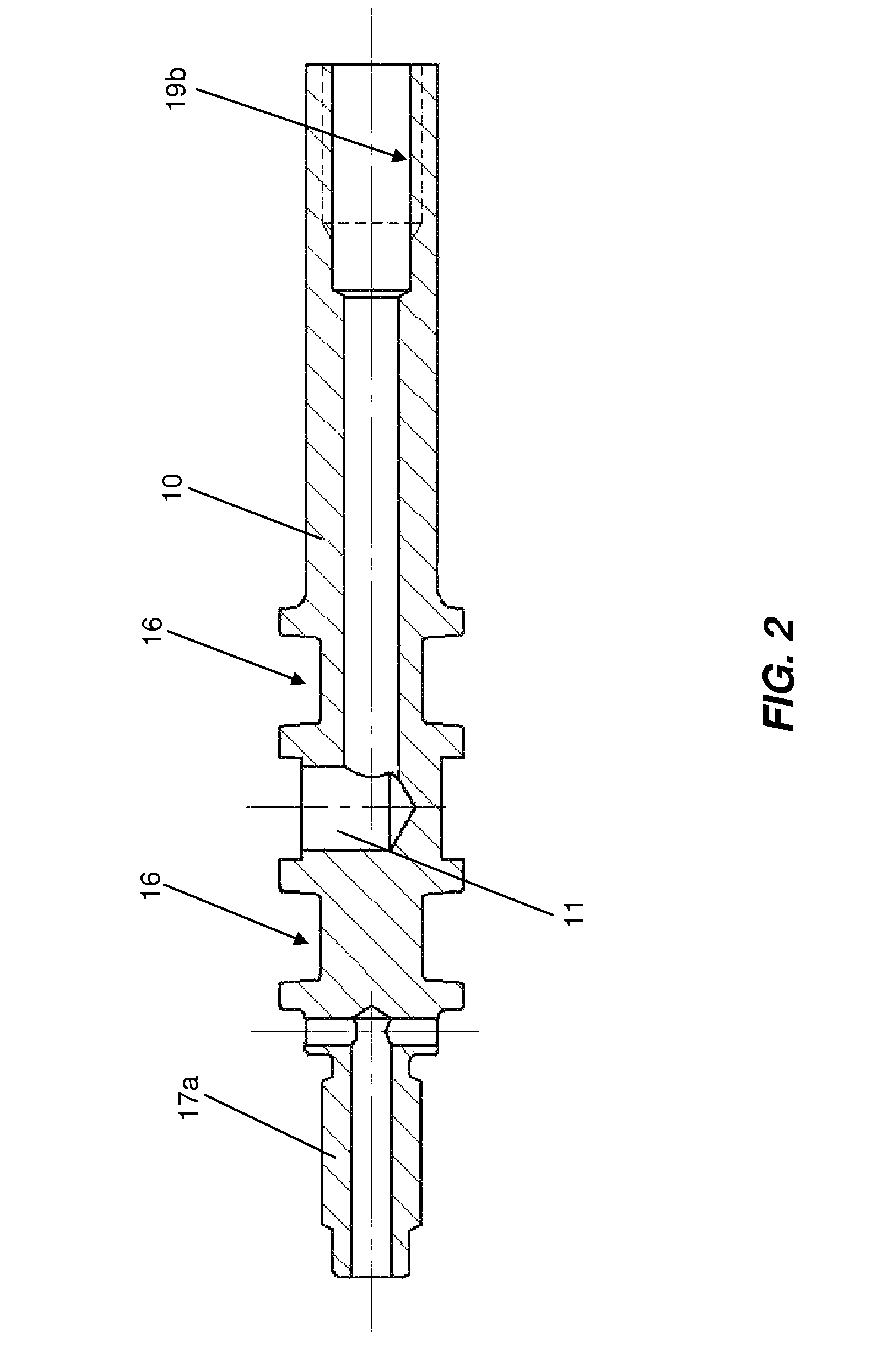

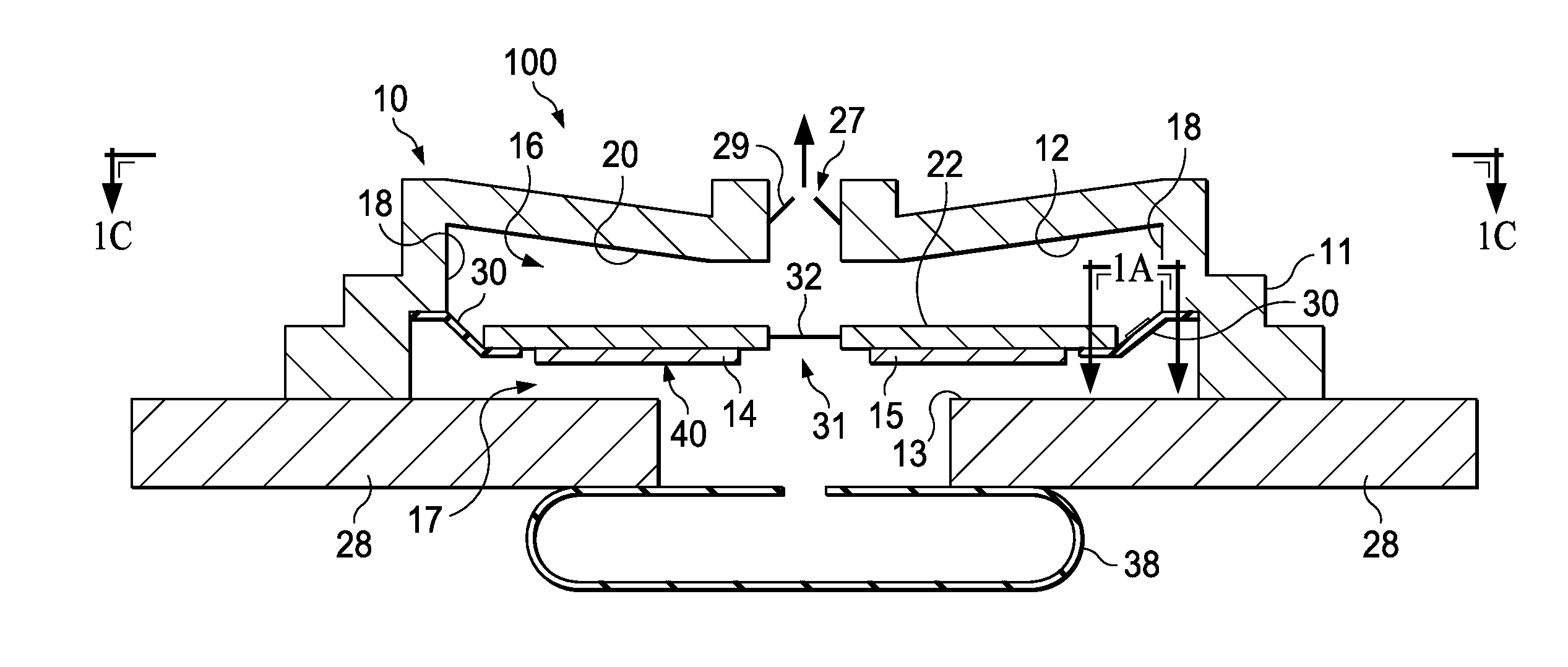

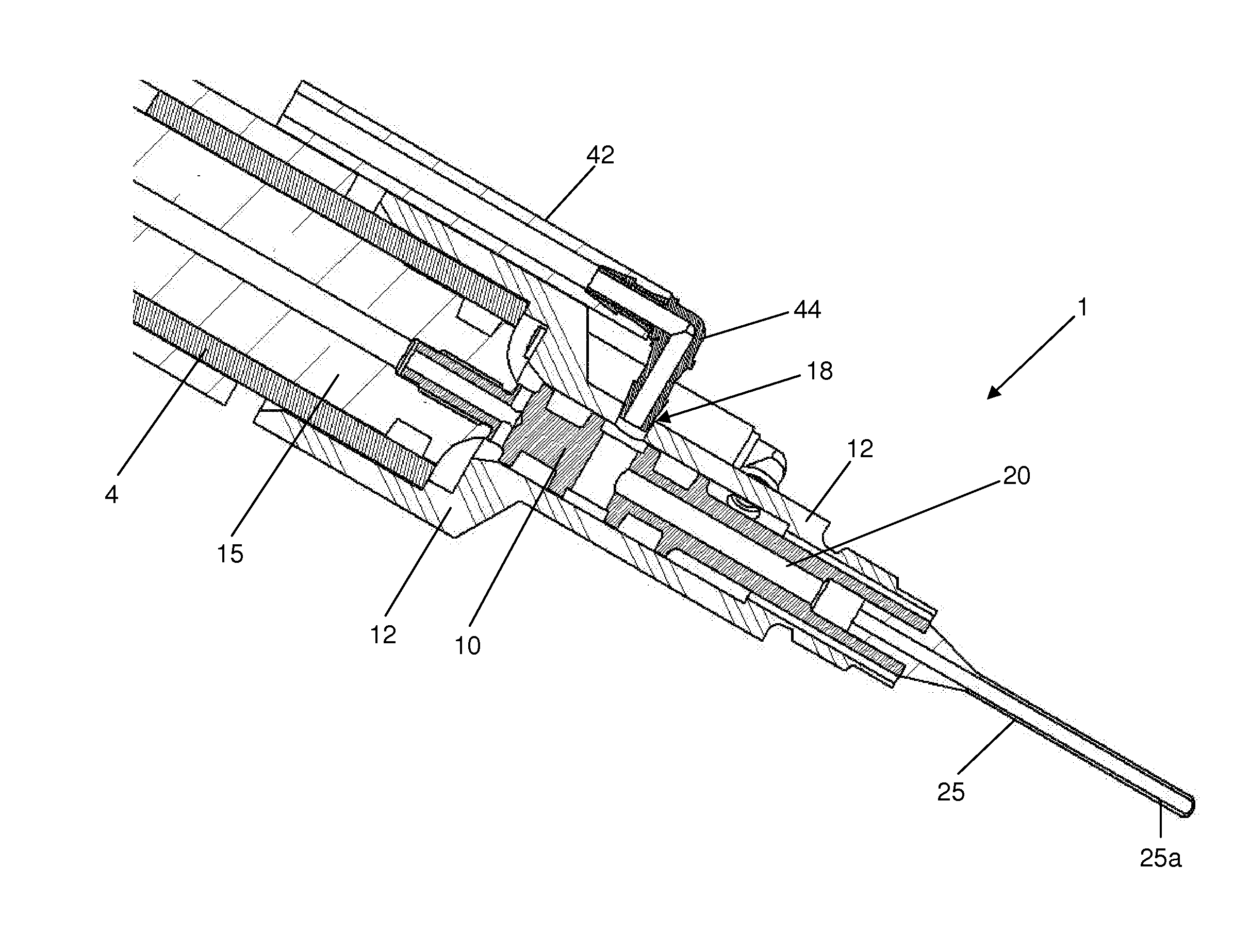

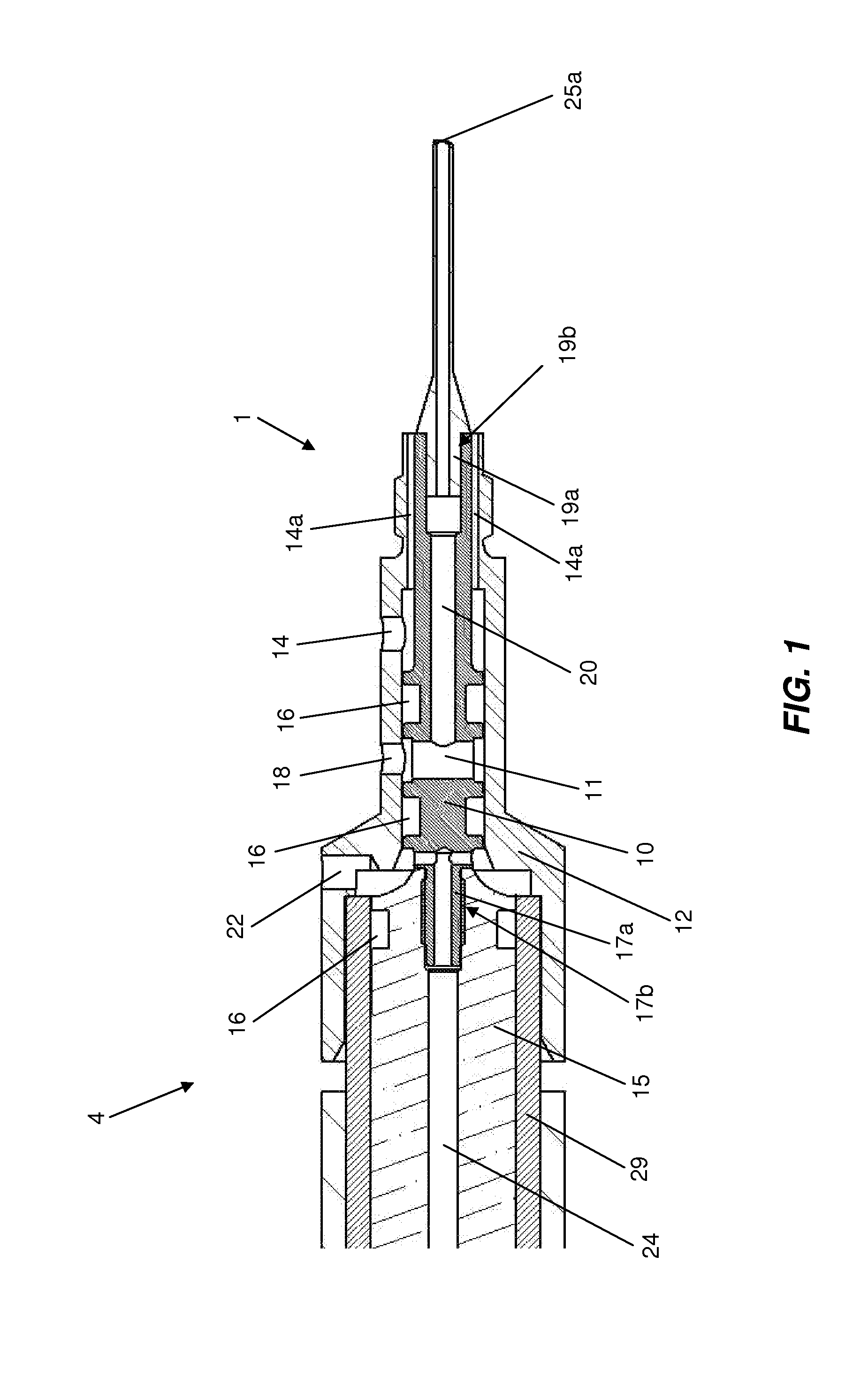

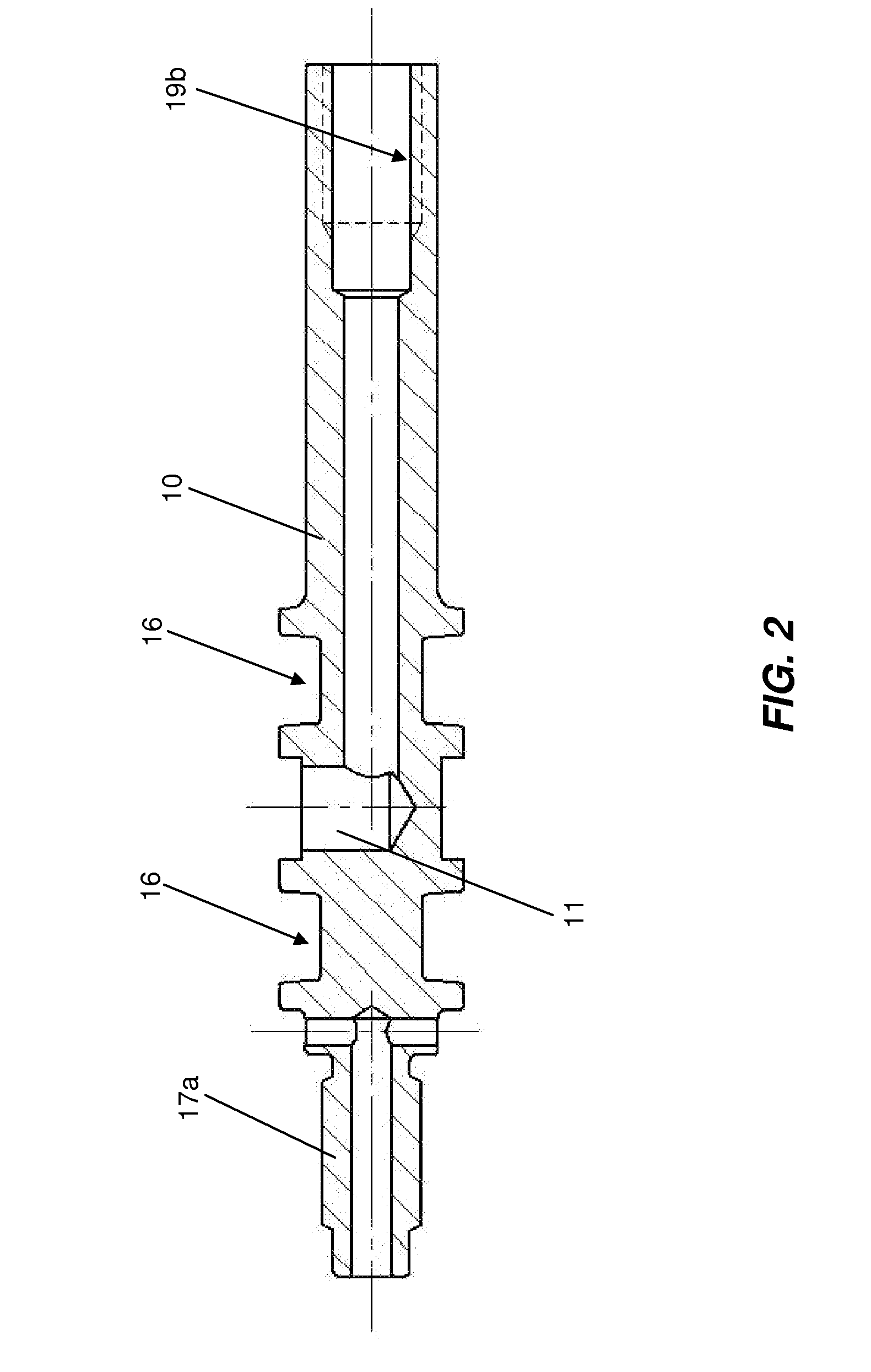

Removable adapter for phacoemulsification handpiece having irrigation and aspiration fluid paths

Current phacoemulsification handpieces require rigorous cleaning after each procedure because the aspiration and irrigation pathways for fluids are integral to the handpiece. According to the present invention, a removable horn extension and nosecone may be used with a phacoemulsification handpiece to allow for disposable fluid pathways exterior to the handpiece. This will reduce the cleaning time and effort, reduce cross-contamination, and increase the lifespan of the handpiece. Furthermore, the current invention allows different horn extensions to be used to excite different motions at the tip of the handpiece, depending on the preference of the surgeon.

Owner:ZEVEX

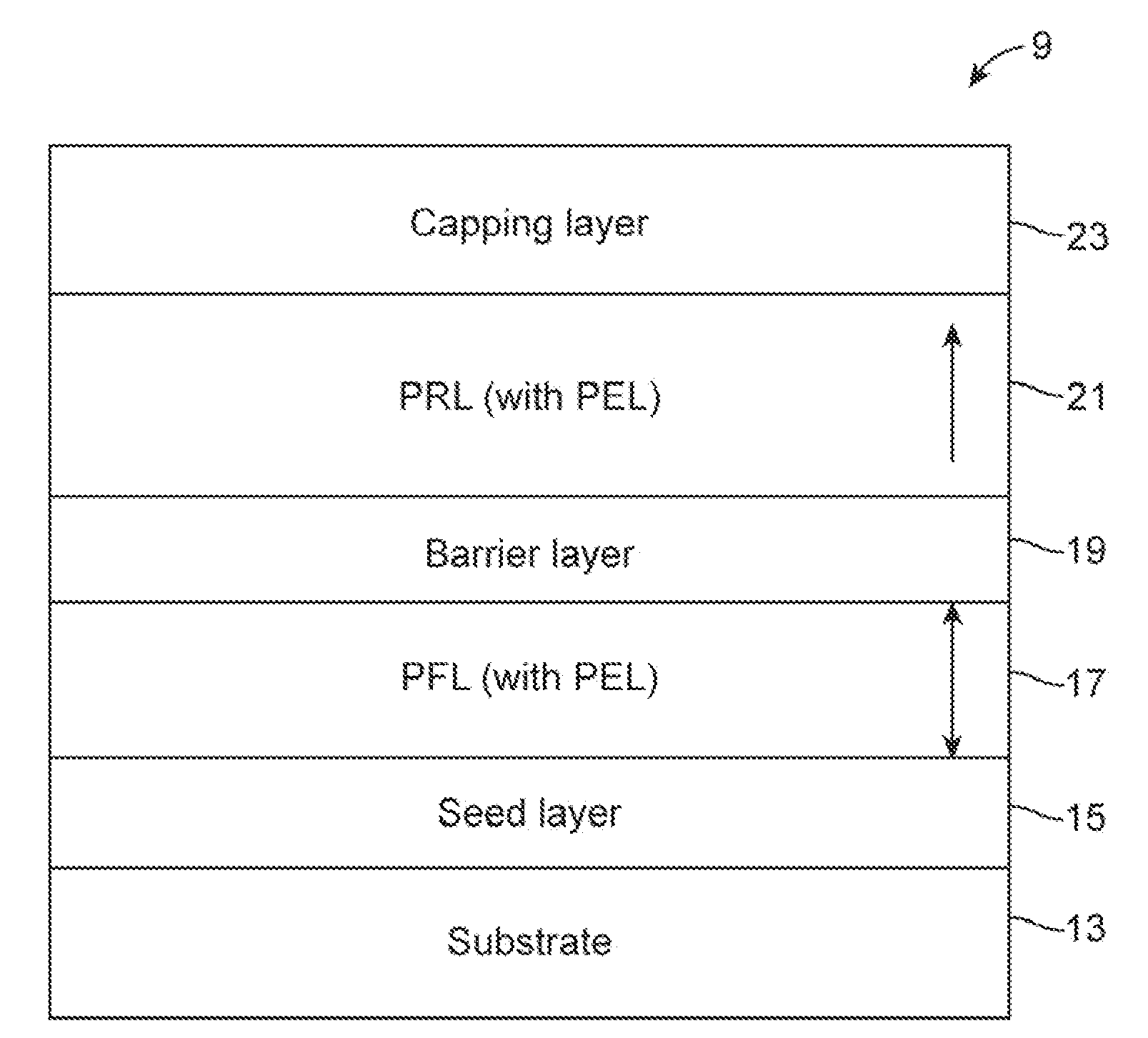

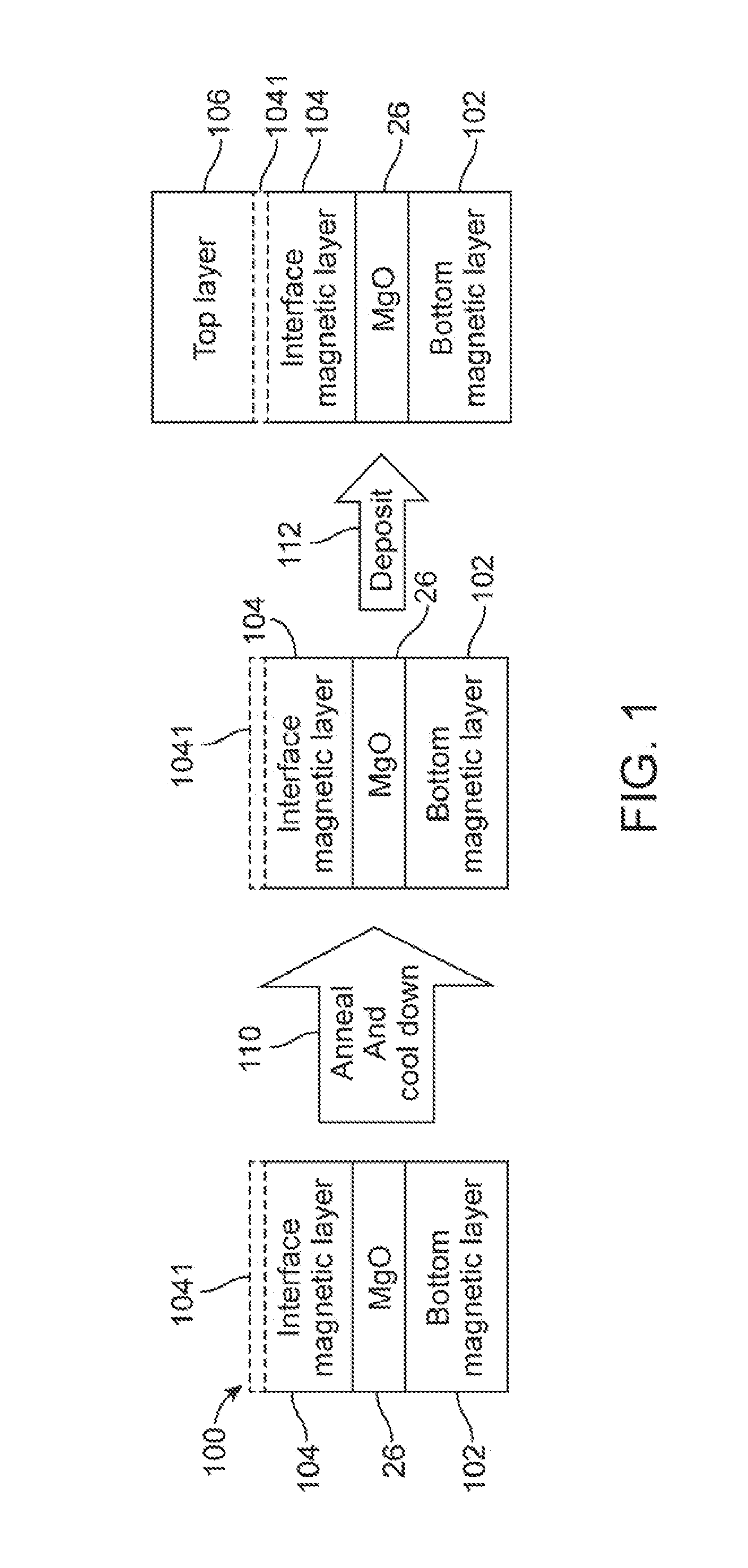

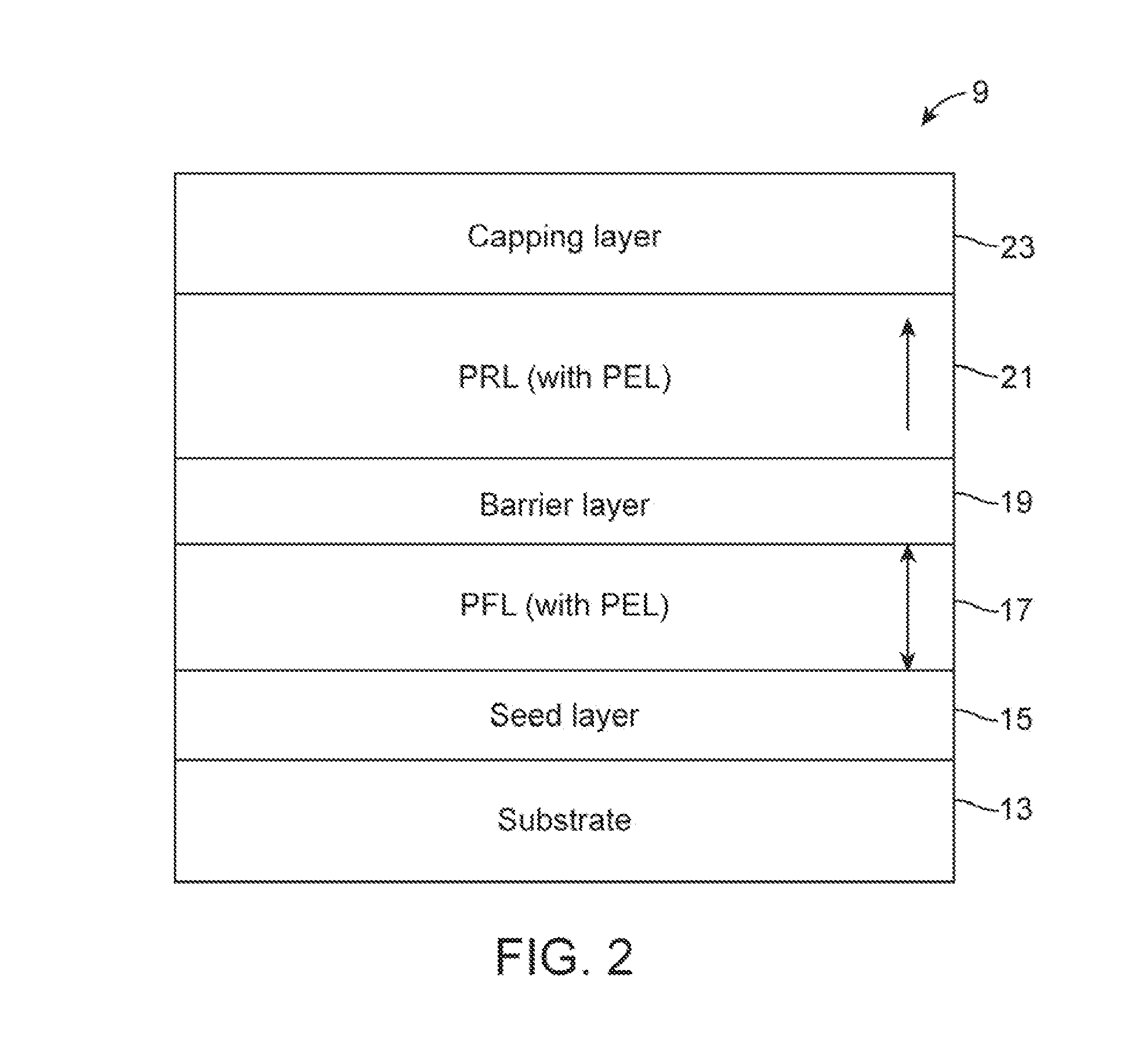

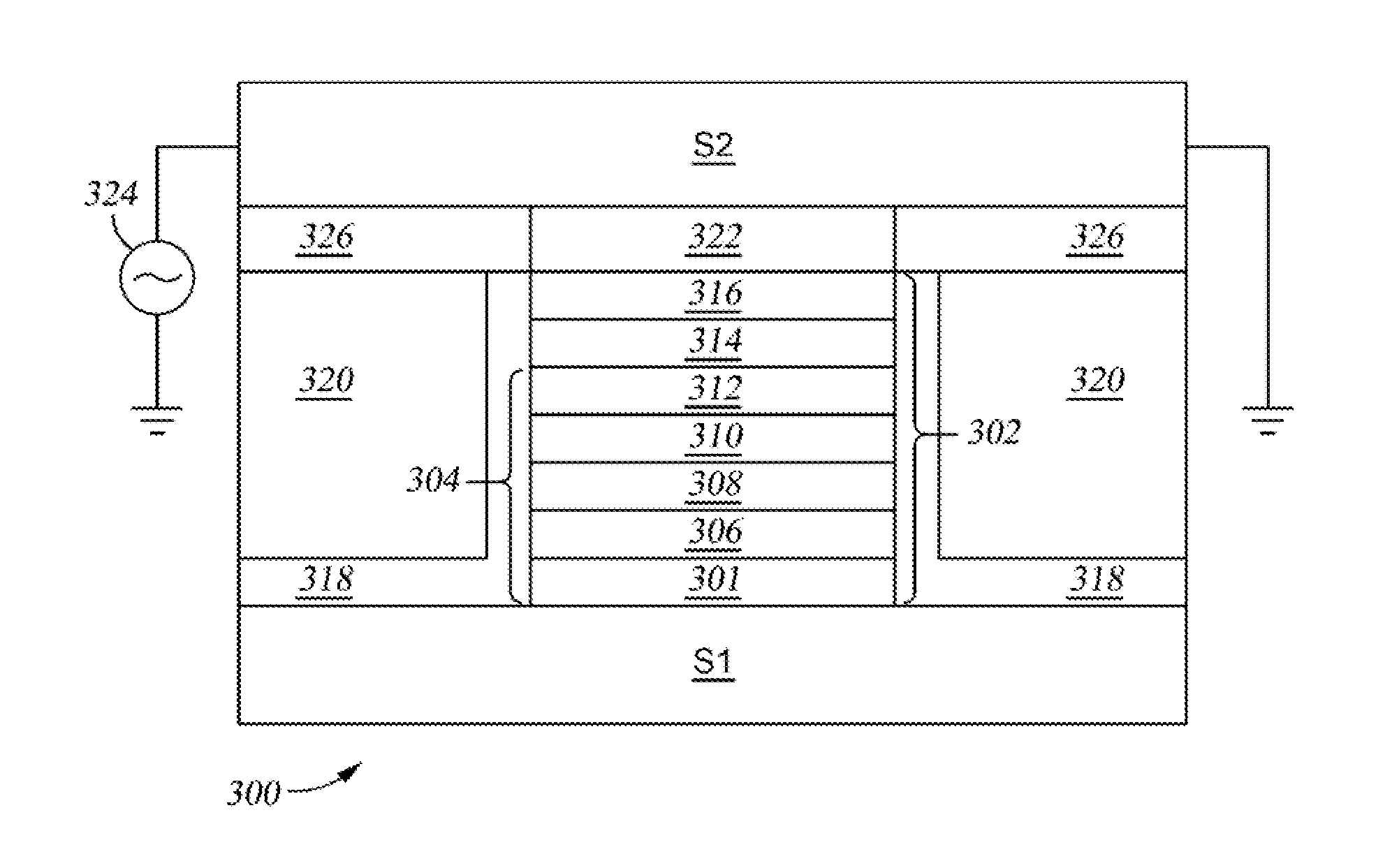

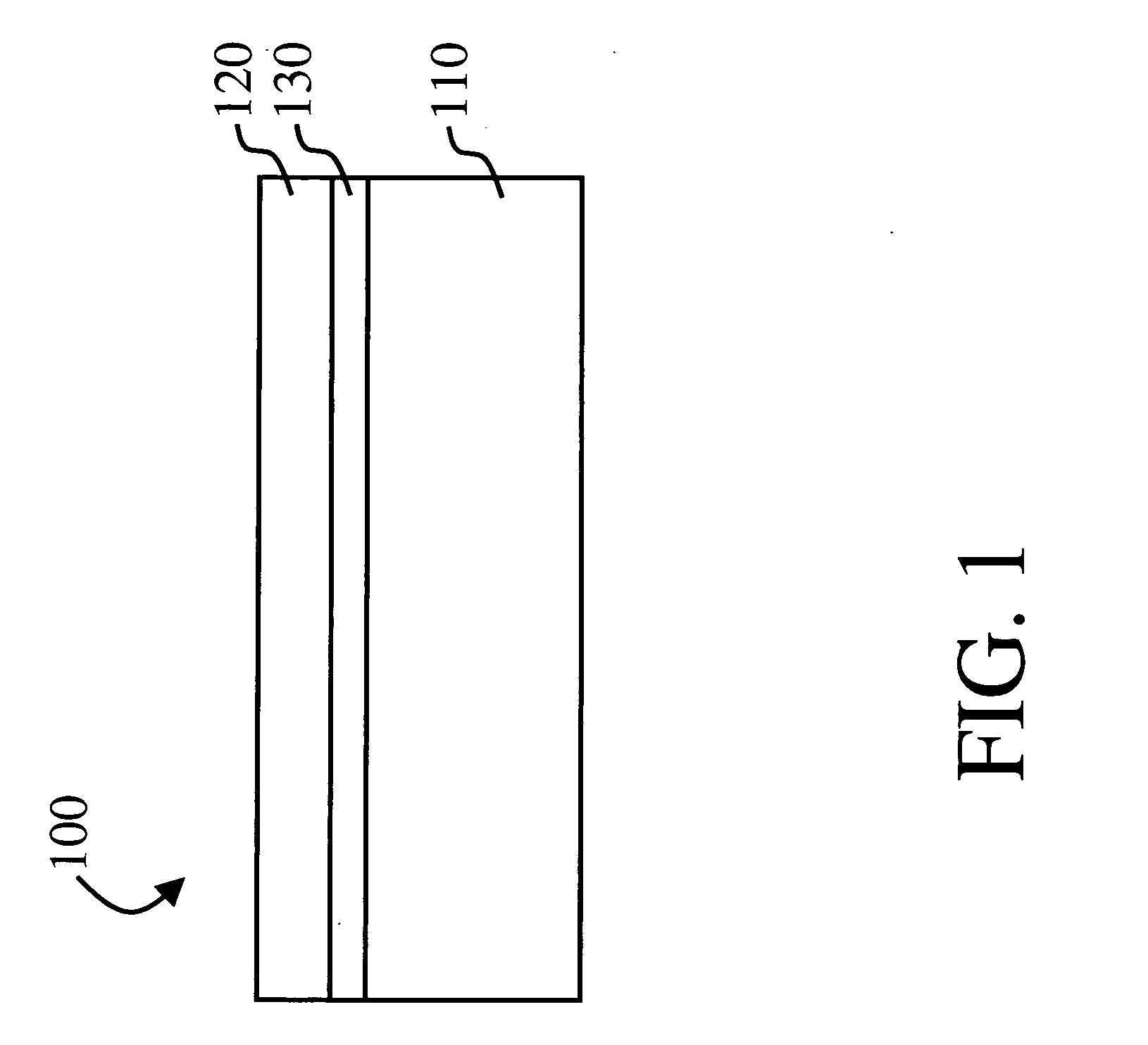

Memory system having thermally stable perpendicular magneto tunnel junction (MTJ) and a method of manufacturing same

InactiveUS20120146167A1Increase stiffnessReduced dampingMagnetic-field-controlled resistorsGalvano-magnetic device detailsRandom access memoryMagneto

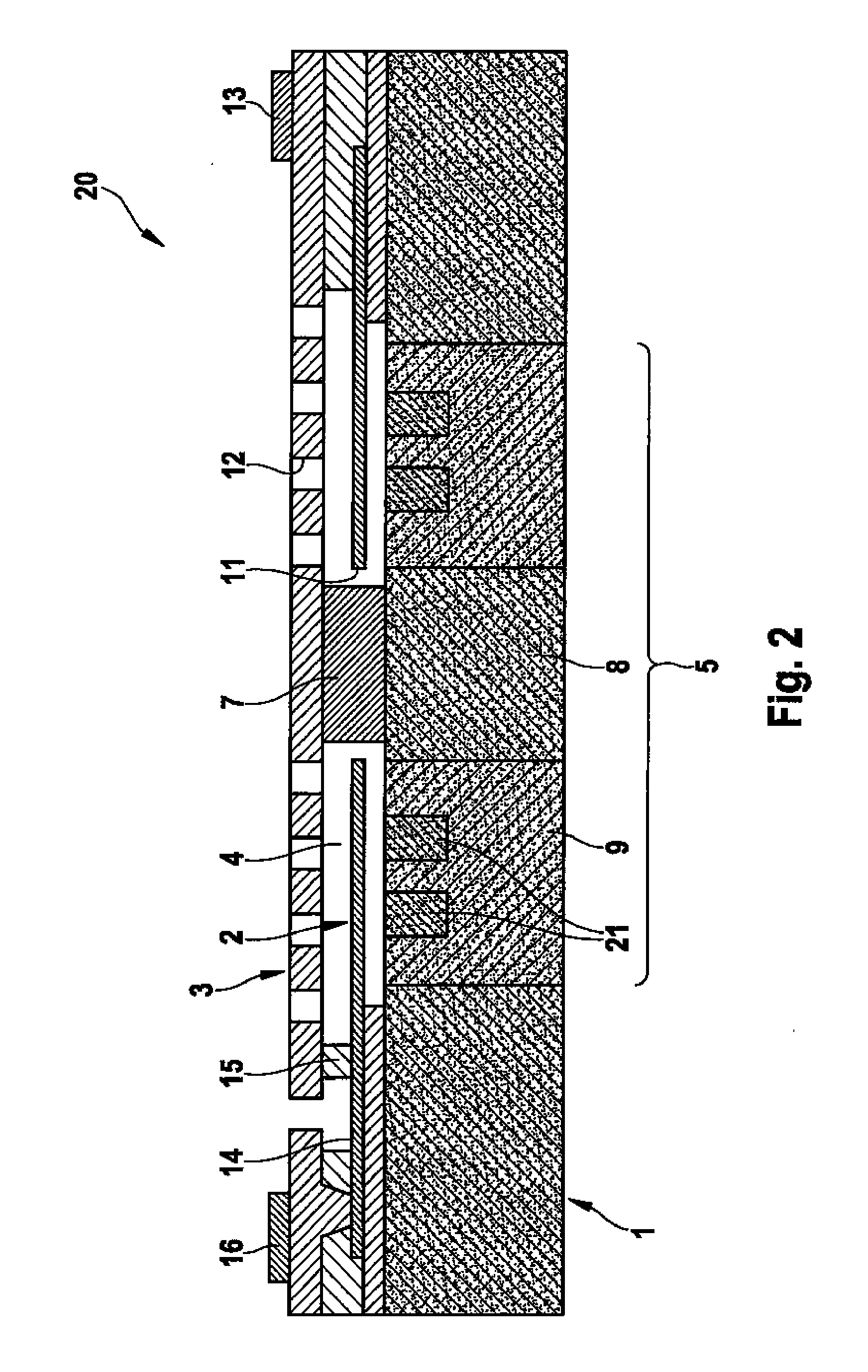

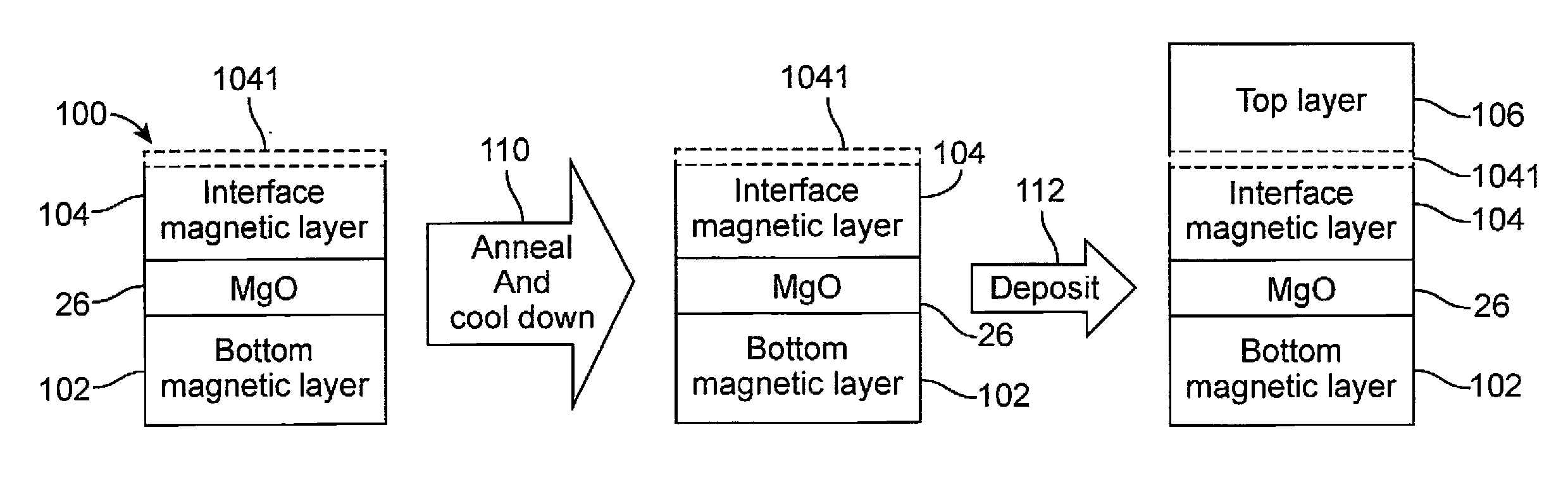

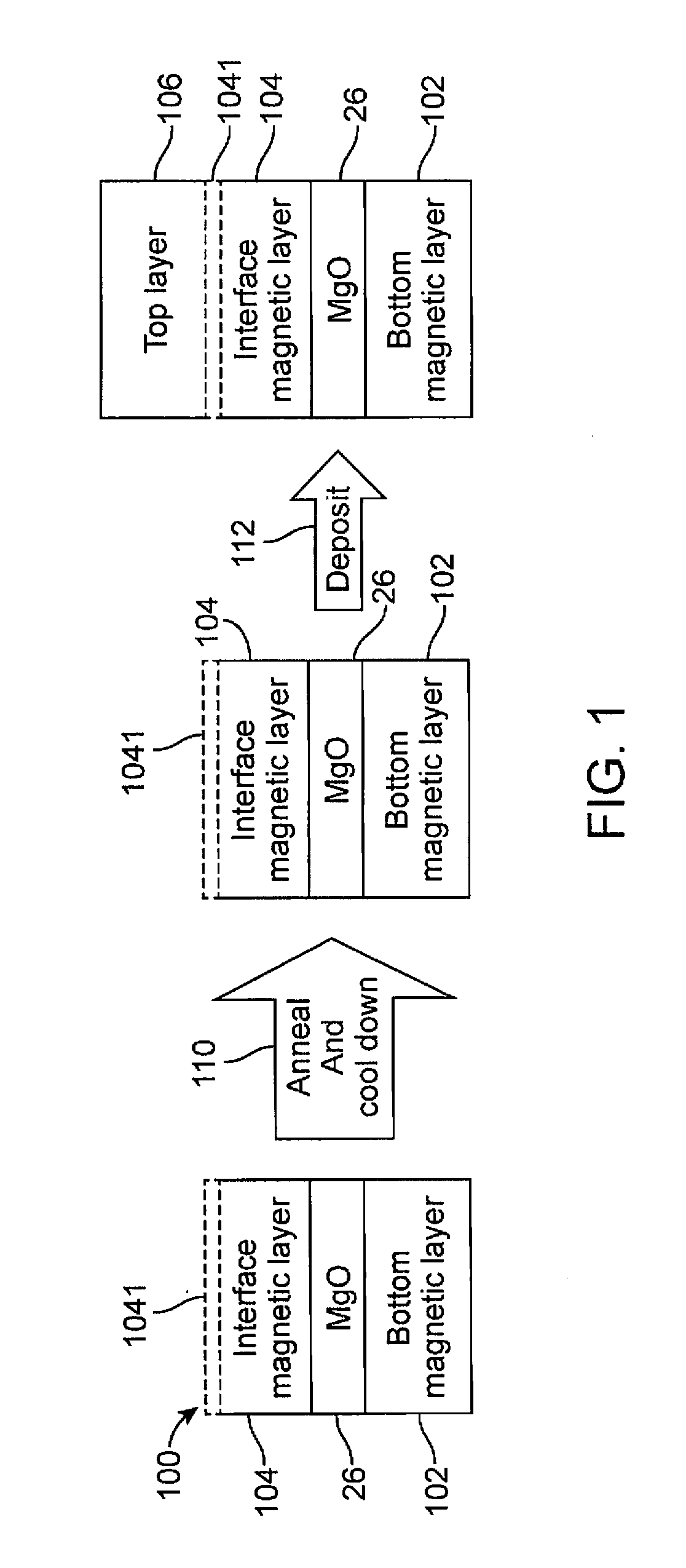

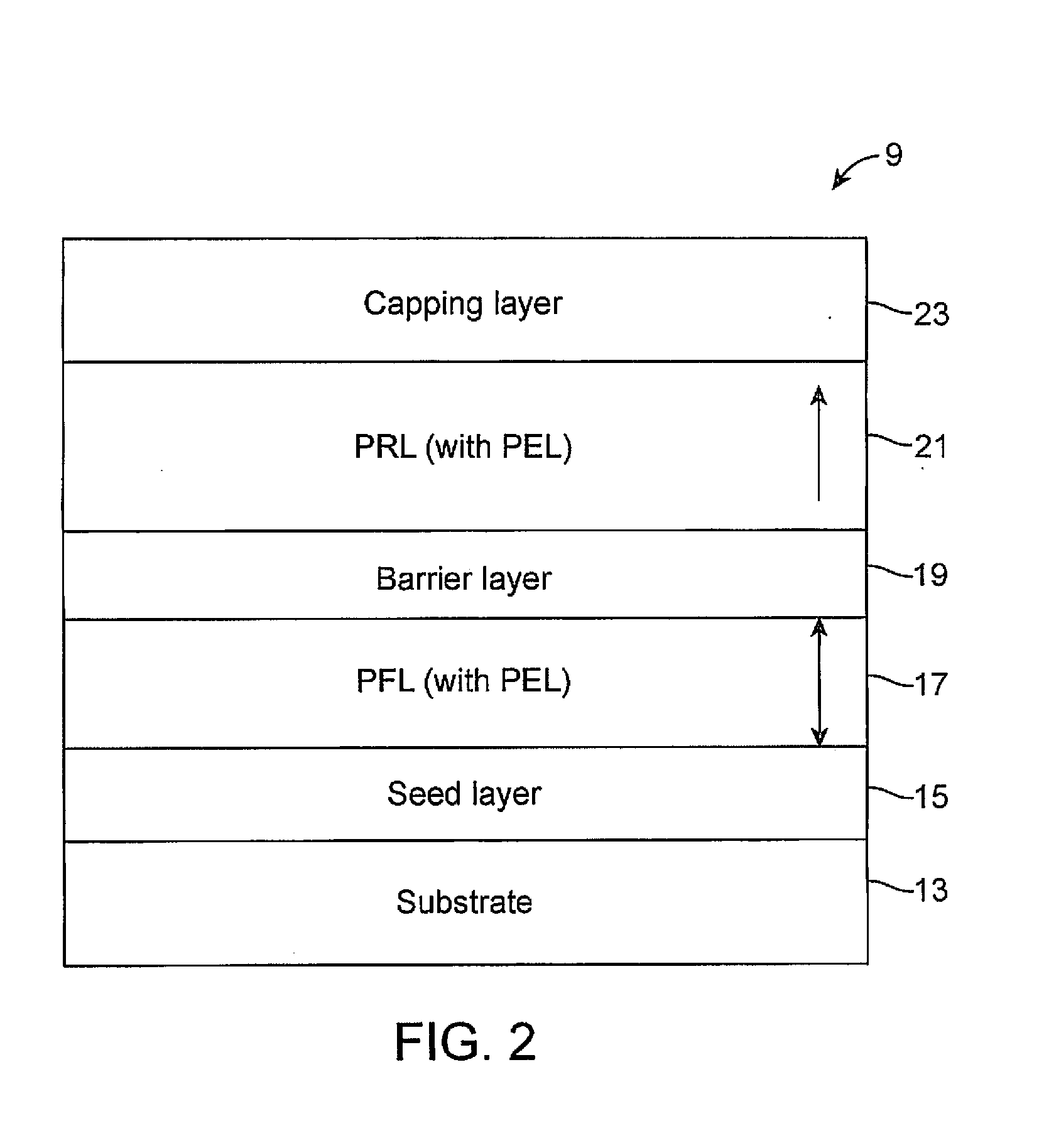

A spin-torque transfer magnetic random access memory (STTMRAM) element employed to store a state based on the magnetic orientation of a free layer, the STTMRAM element is made of a first perpendicular free layer (PFL) including a first perpendicular enhancement layer (PEL). The first PFL is formed on top of a seed layer. The STTMRAM element further includes a barrier layer formed on top of the first PFL and a second perpendicular reference layer (PRL) that has a second PEL, the second PRL is formed on top of the barrier layer. The STTMRAM element further includes a capping layer that is formed on top of the second PRL.

Owner:AVALANCHE TECH

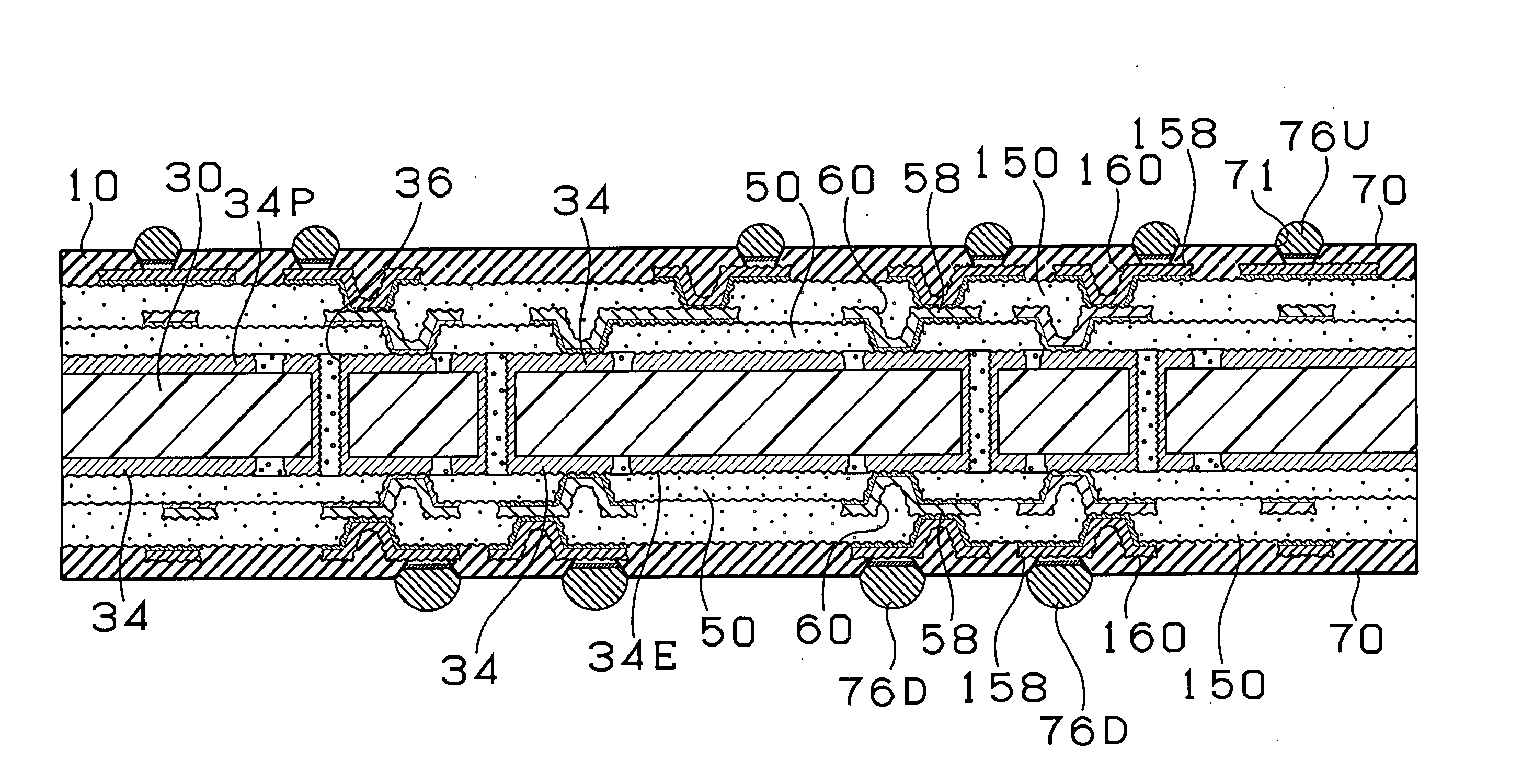

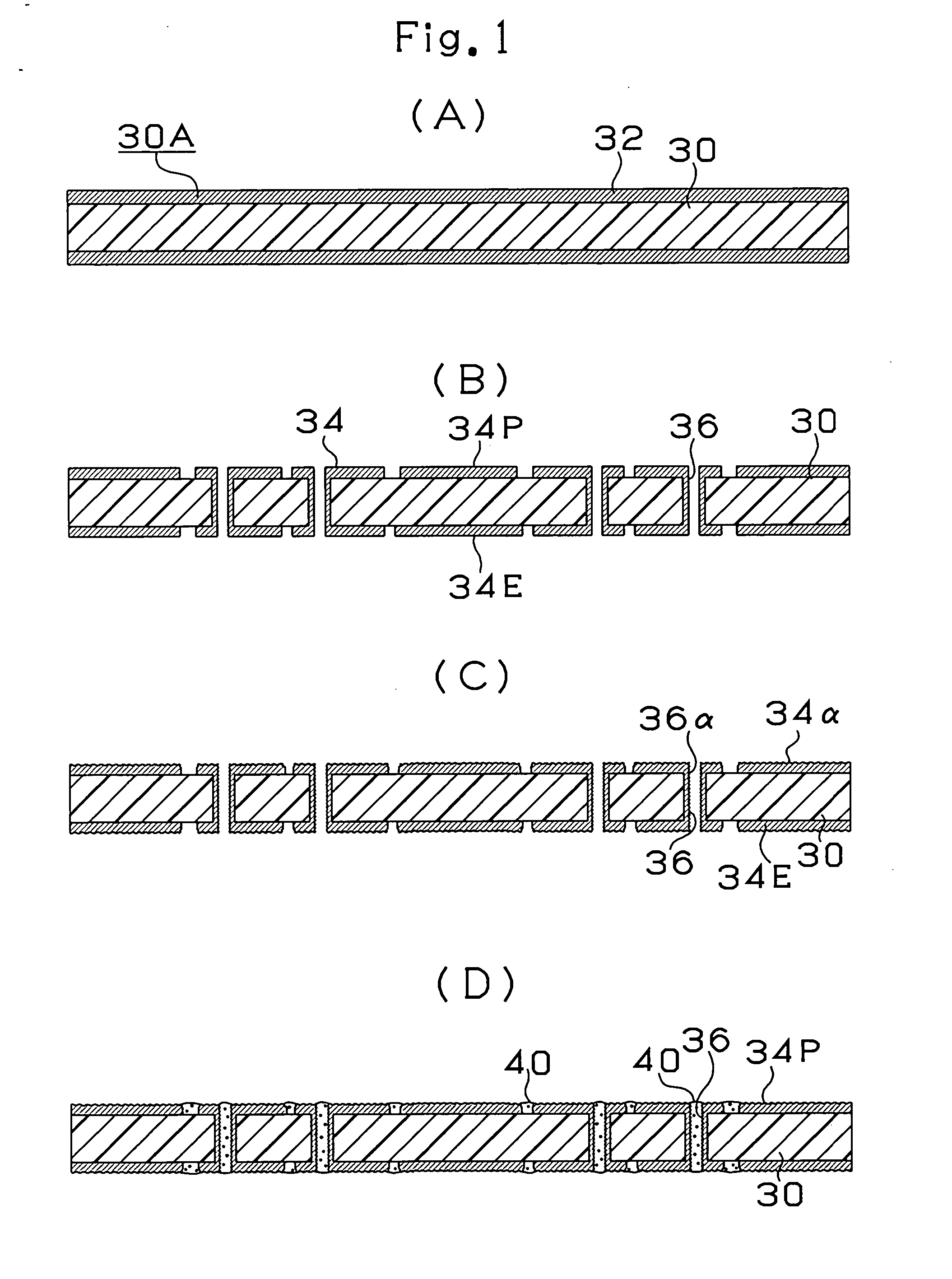

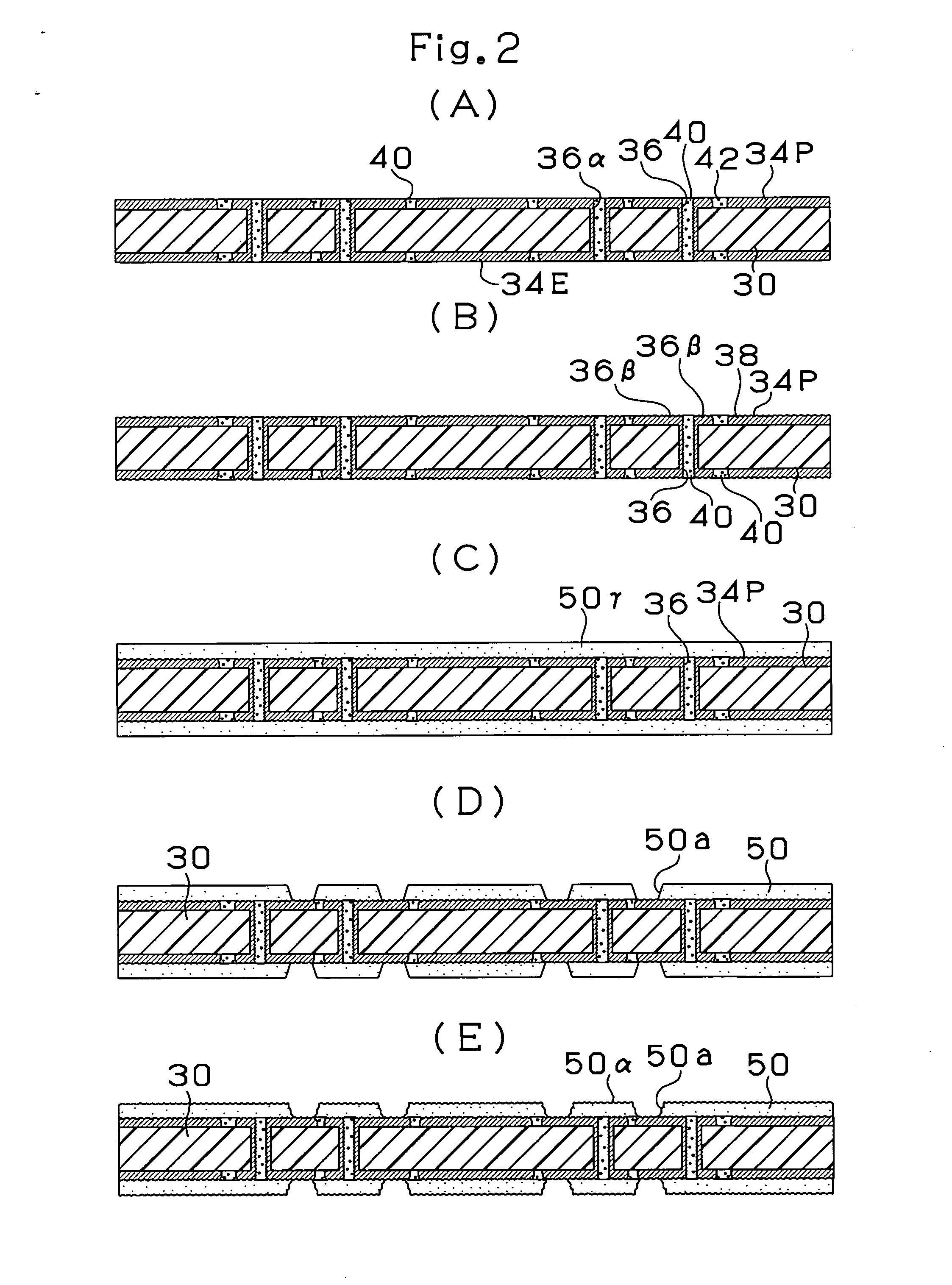

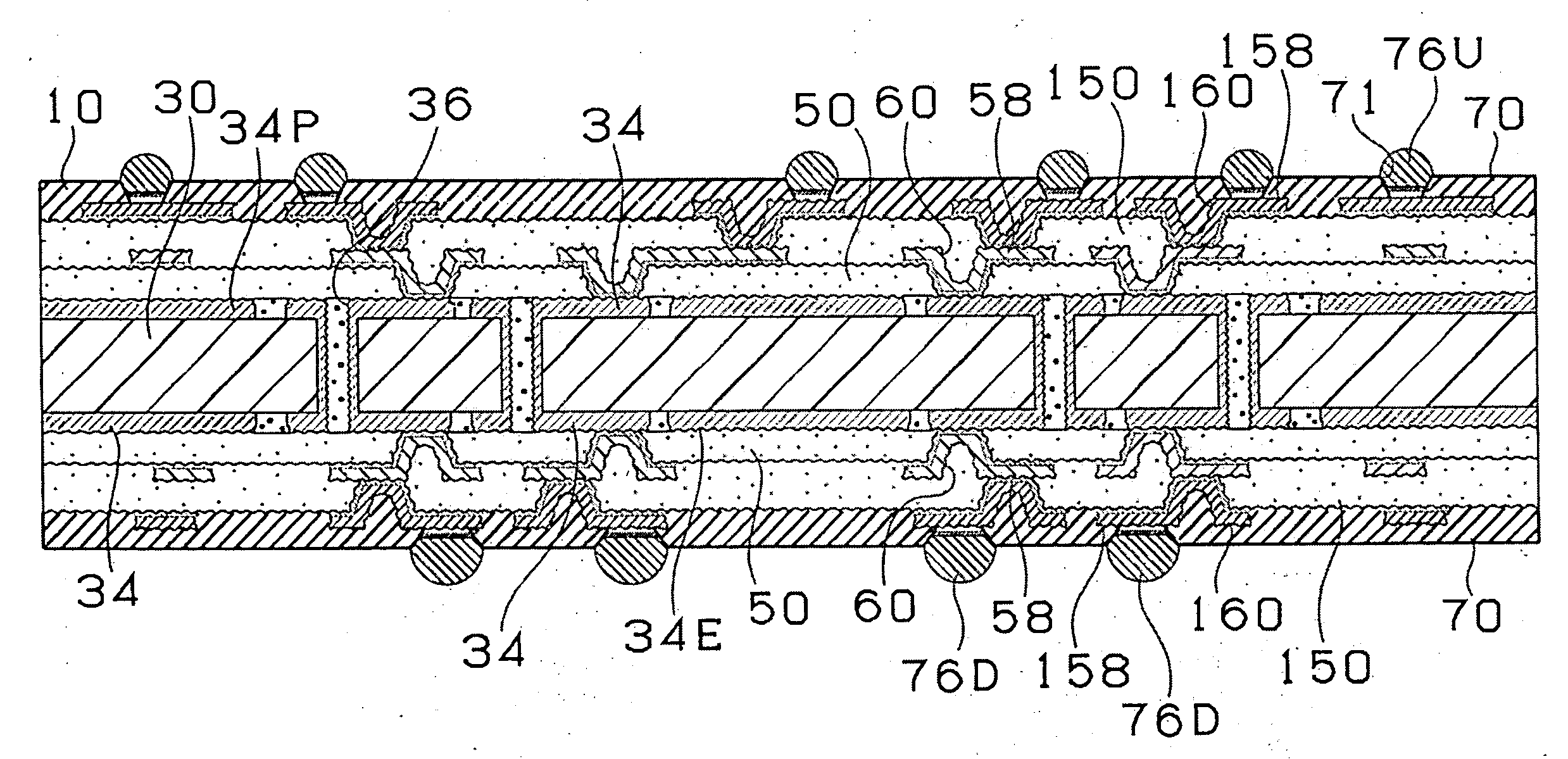

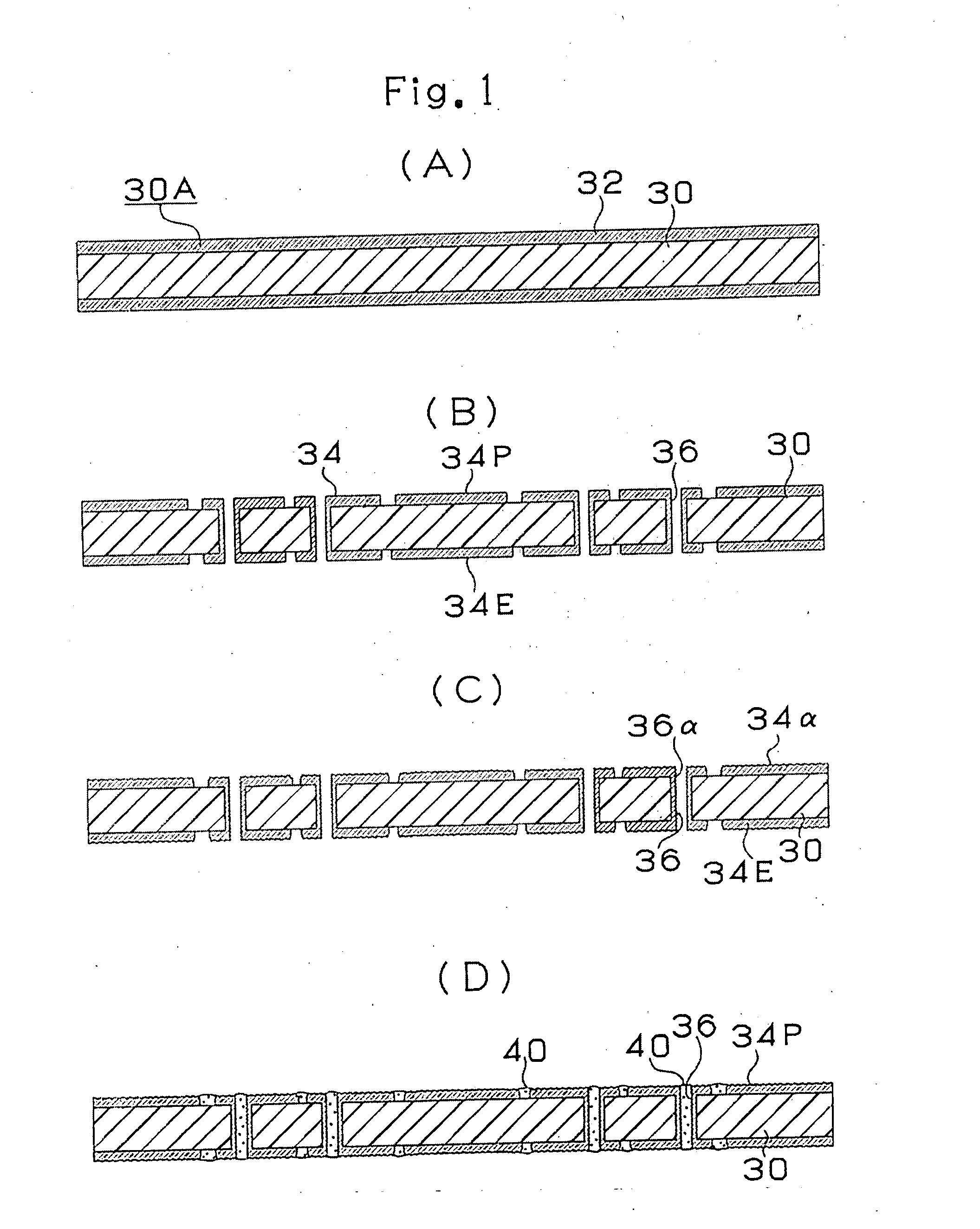

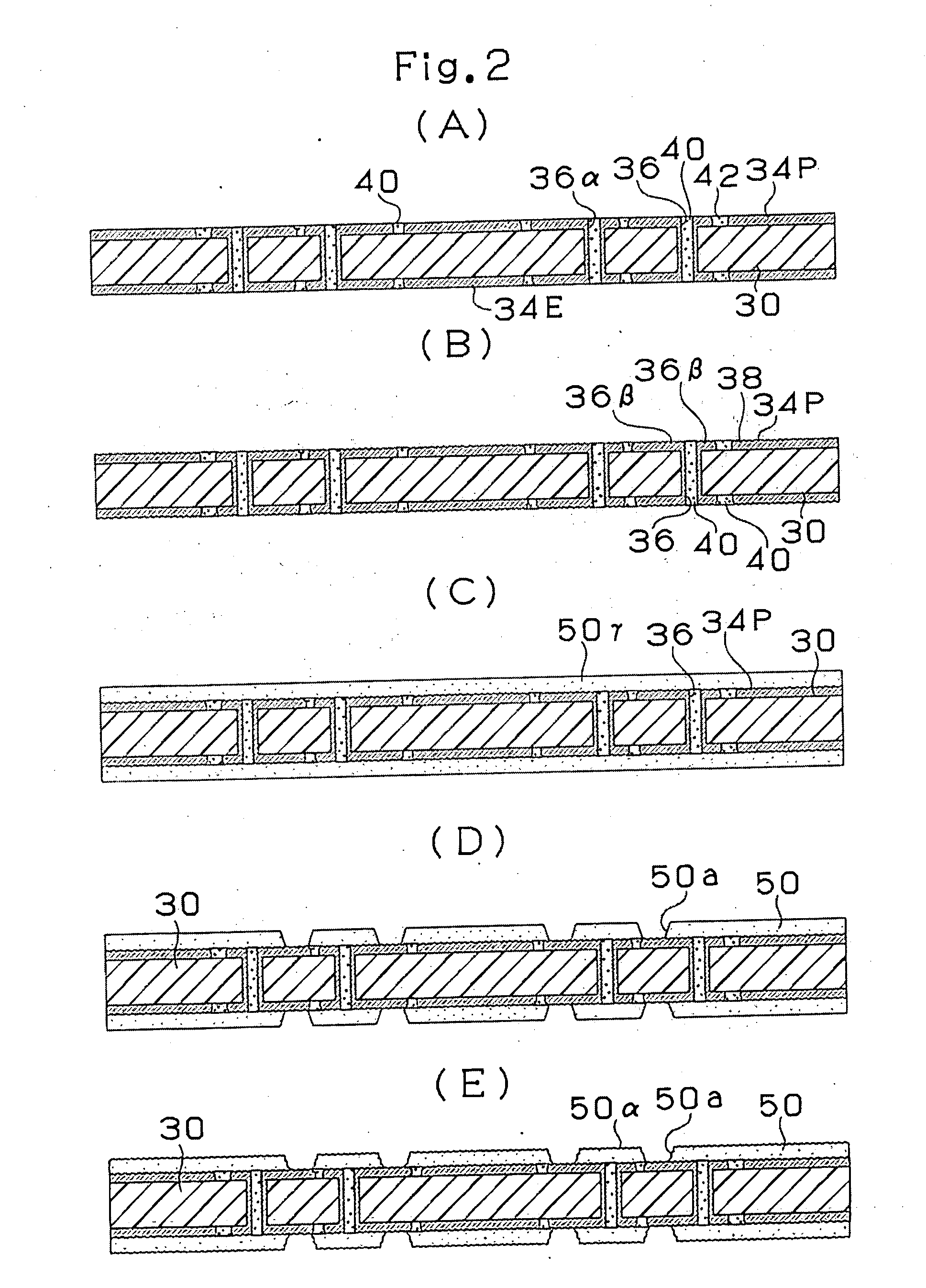

Multilayer printed wiring board

ActiveUS20060243478A1Intensify strengthStress be relaxPrinted electric component incorporationSemiconductor/solid-state device detailsEngineeringElectrical conductor

An IC chip for a high frequency region, particularly a packaged substrate in which no malfunction or error occurs even if 3 GHz is exceeded. A conductive layer on a core substrate is formed at a thickness of 30 μm and a conductor circuit on an interlayer resin insulation layer is formed at a thickness of 15 μm. By thickening the conductive layer, the volume of the conductor can be increased and resistance can be reduced. Further, by using the conductive layer as a power source layer, the capacity of supply of power to an IC chip can be improved.

Owner:IBIDEN CO LTD

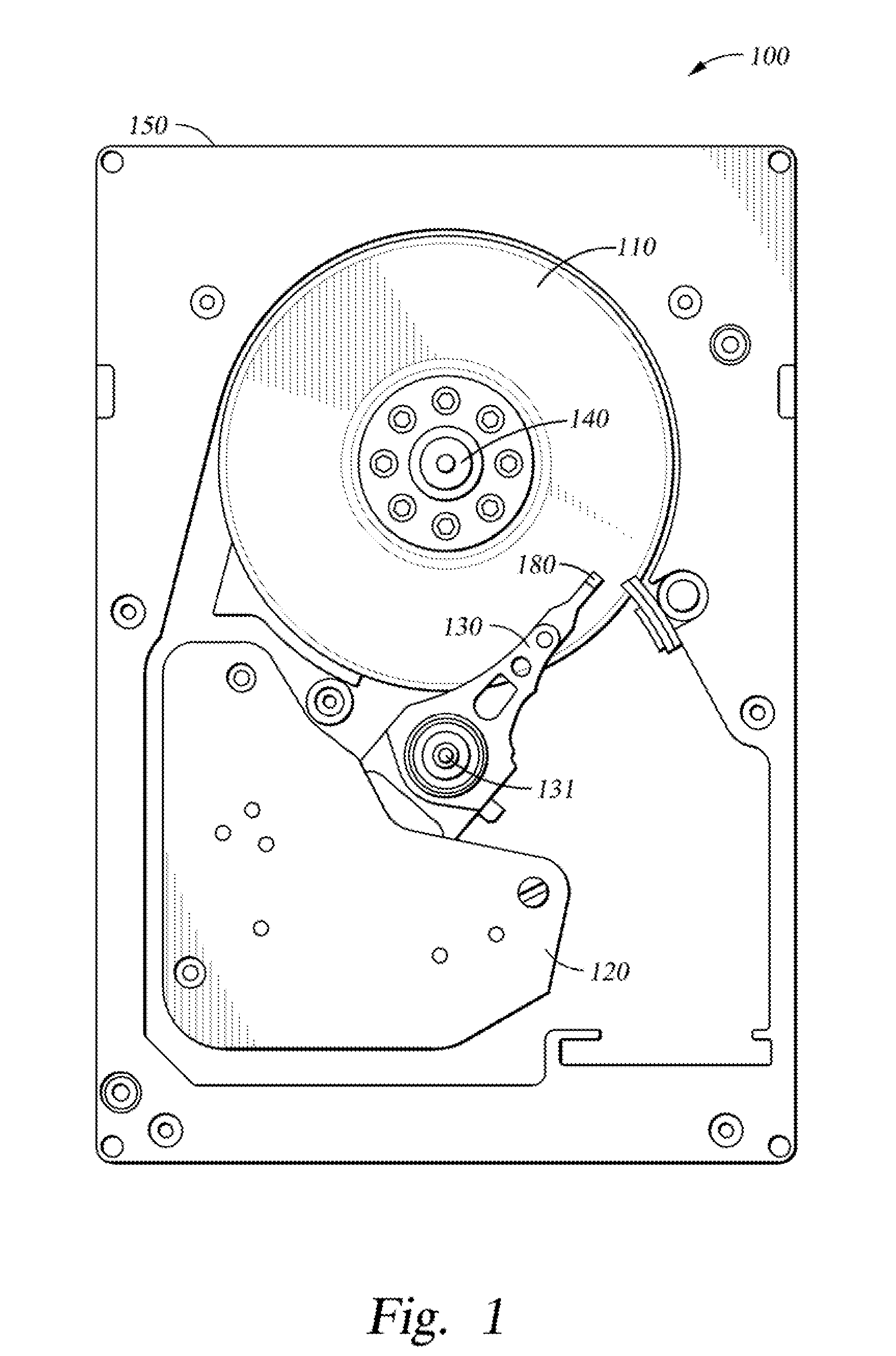

Magnetic read head having spin hall effect layer

InactiveUS20150287426A1Reduce dampingReduces thermal magnetic noiseHeads using thin filmsRecord information storageMagnetic noiseSpin Hall effect

The embodiments disclosed generally relate to a read head in a magnetic recording head. The read head utilizes a spin Hall effect layer disposed on the free magnetic layer. Electrical bias is applied to the top shield, or lead layer, longitudinally so that the current is longitudinally driven through the spin Hall effect layer. The spin Hall effect layer may comprise Pt, Ta, W, copper doped with either bismuth or iridium, a noble metal having group 5d non-magnetic impurities, or combinations thereof. The spin Hall effect layer, together with the longitudinally applied bias, reduces the damping in the free magnetic layer and hence, reduces the thermal magnetic noise of the read head.

Owner:WESTERN DIGITAL TECH INC

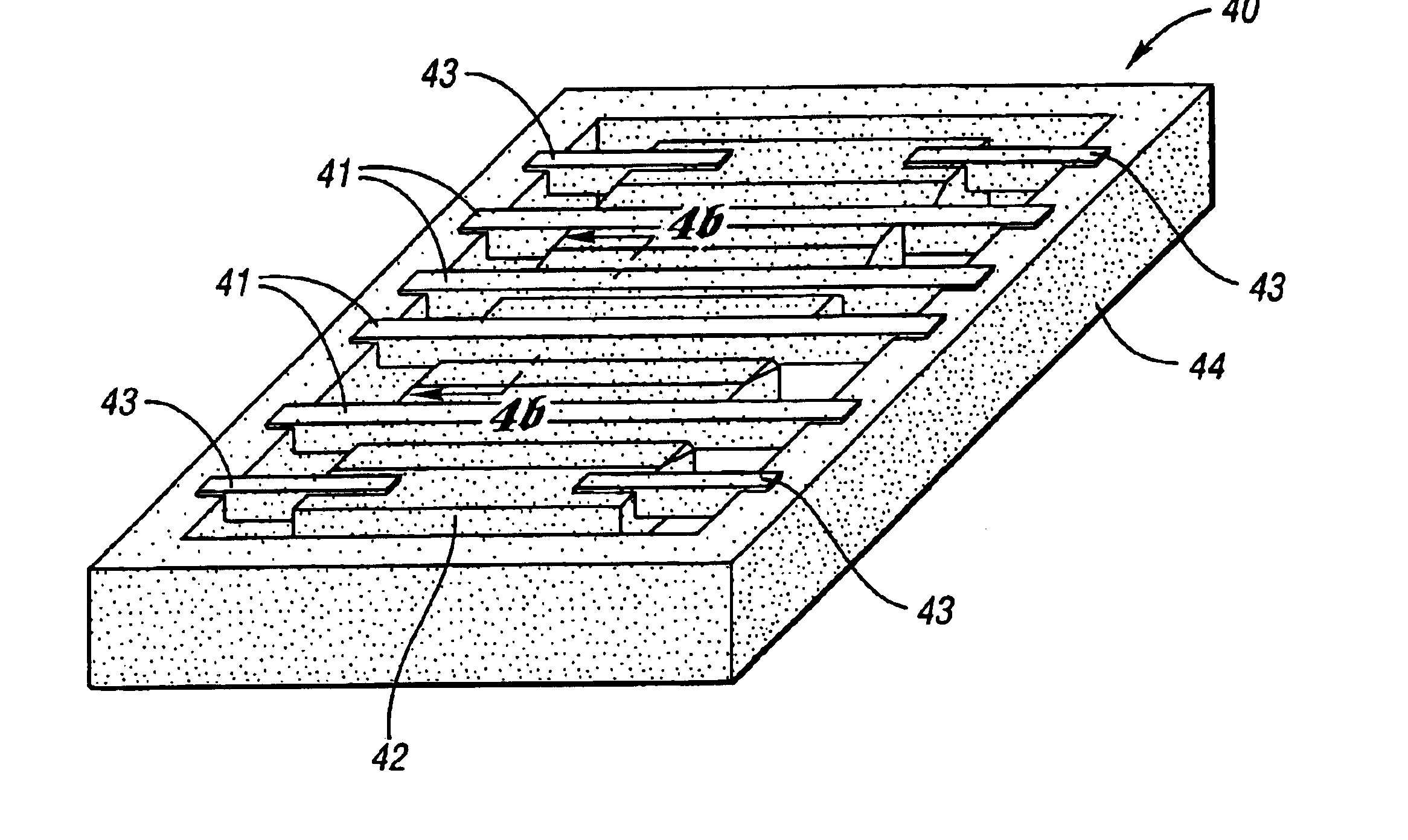

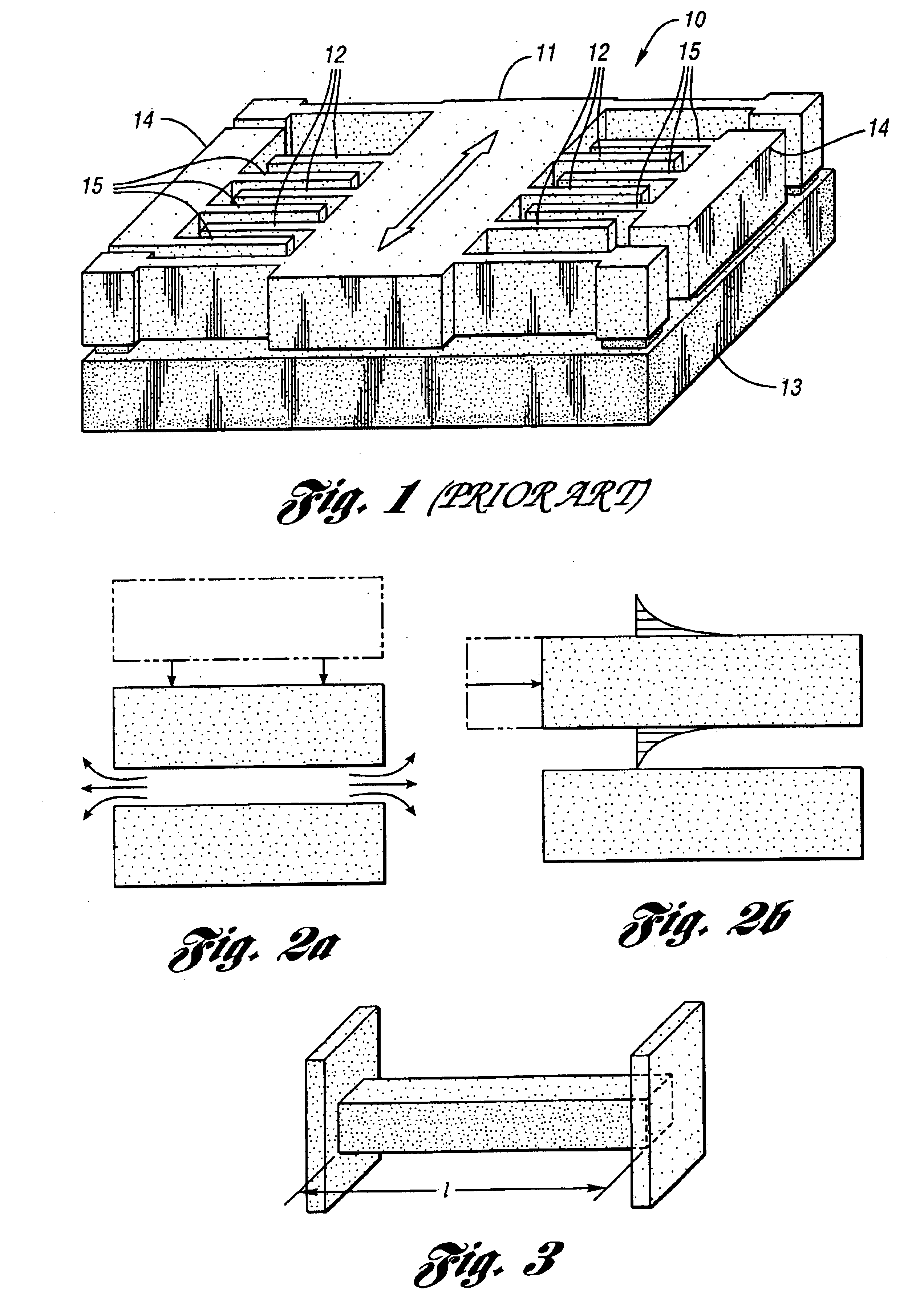

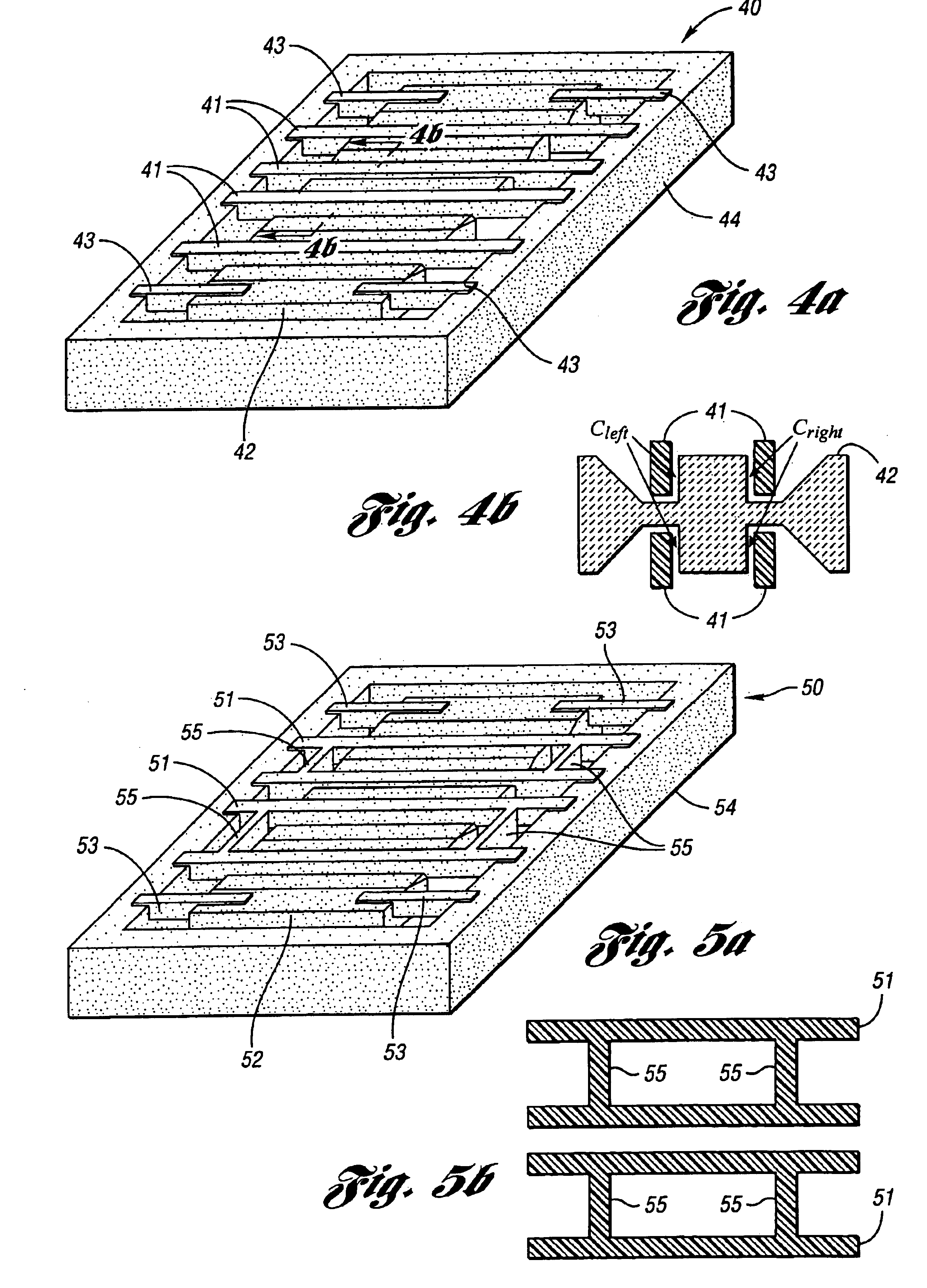

Micromachined capacitive lateral accelerometer device and monolithic, three-axis accelerometer having same

InactiveUS6938484B2High-sensitivity and low-noiseReduced dampingAcceleration measurement using interia forcesPiezoelectric/electrostrictive devicesCapacitanceThree axis accelerometer

A high-sensitivity and low-noise micromachined capacitive lateral accelerometer device having an input axis and a monolithic, three-axis accelerometer utilizing the device are provided. The device includes at least one electrode having a side surface normal to the input axis. A relatively large proofmass has at least one side surface normal to the input axis and extends along a width of the proofmass. The proofmass is movable against acceleration relative to the at least one electrode due to inertial force along the input axis to obtain a capacitive variation between the at least one electrode and the proofmass. The side surfaces are spaced apart to define a narrow, high-aspect ratio sensing gap which extends along substantially the entire width of the proofmass. The proofmass forms a sense capacitor with the at least one electrode.

Owner:MICHIGAN UNIV OF RGT

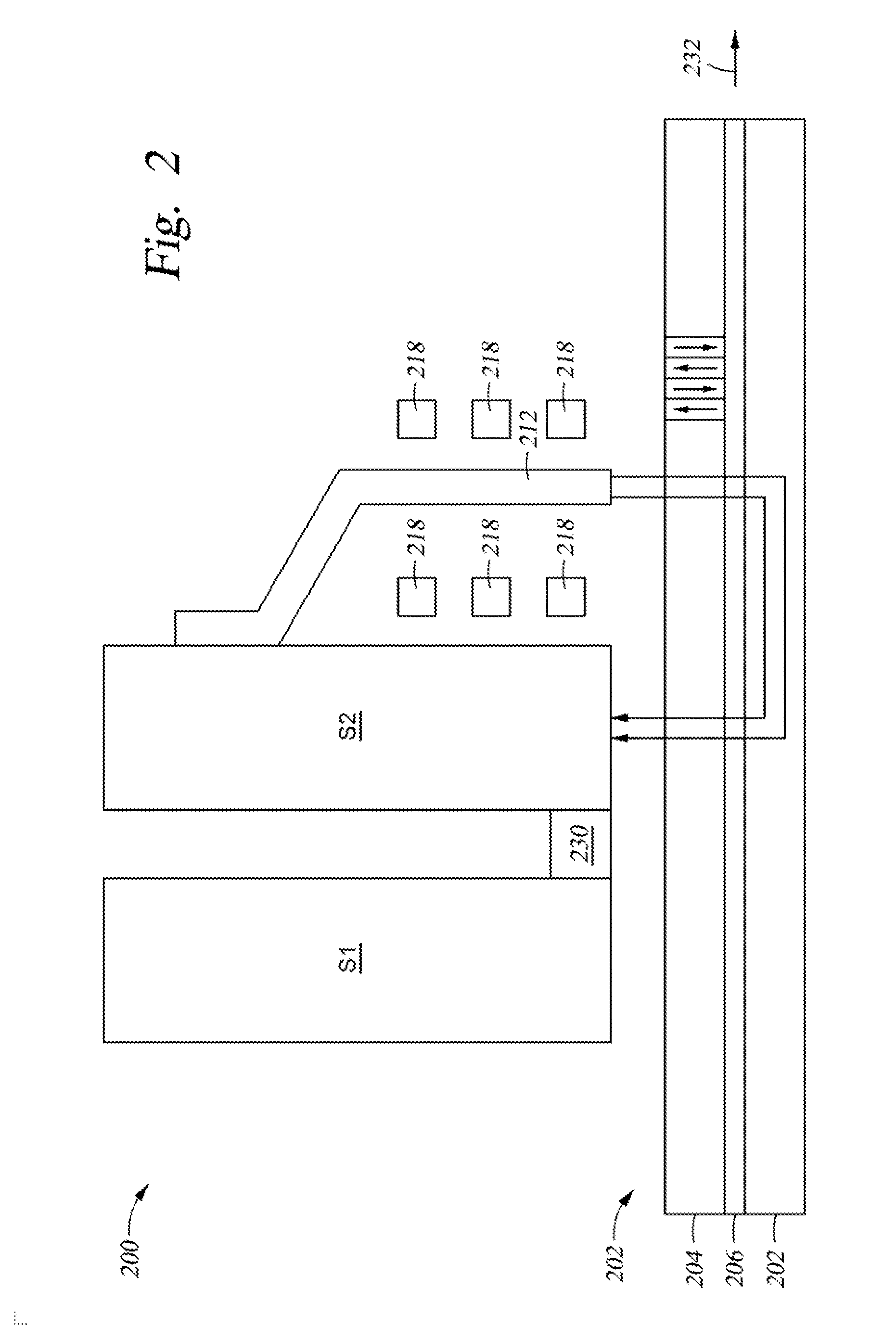

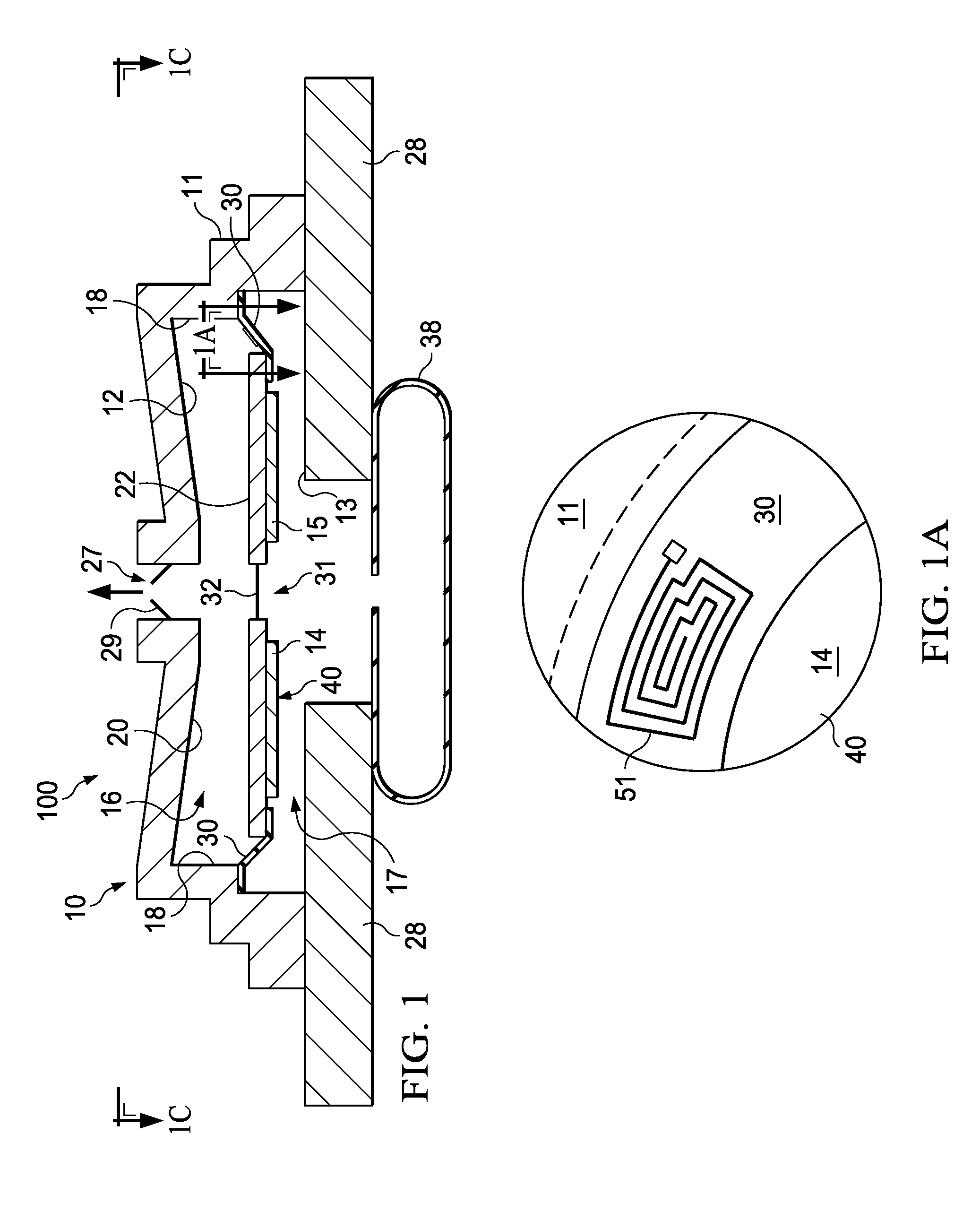

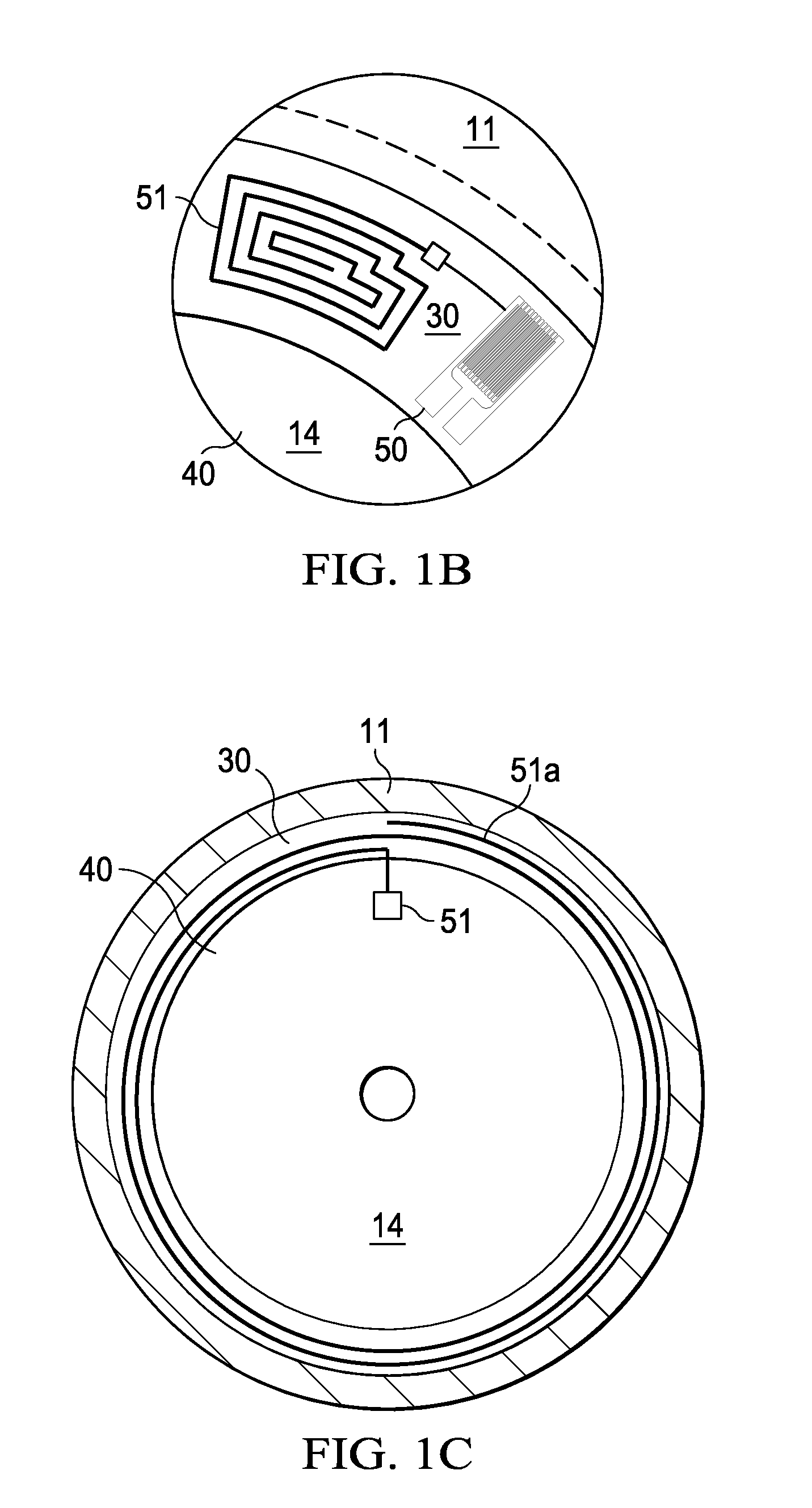

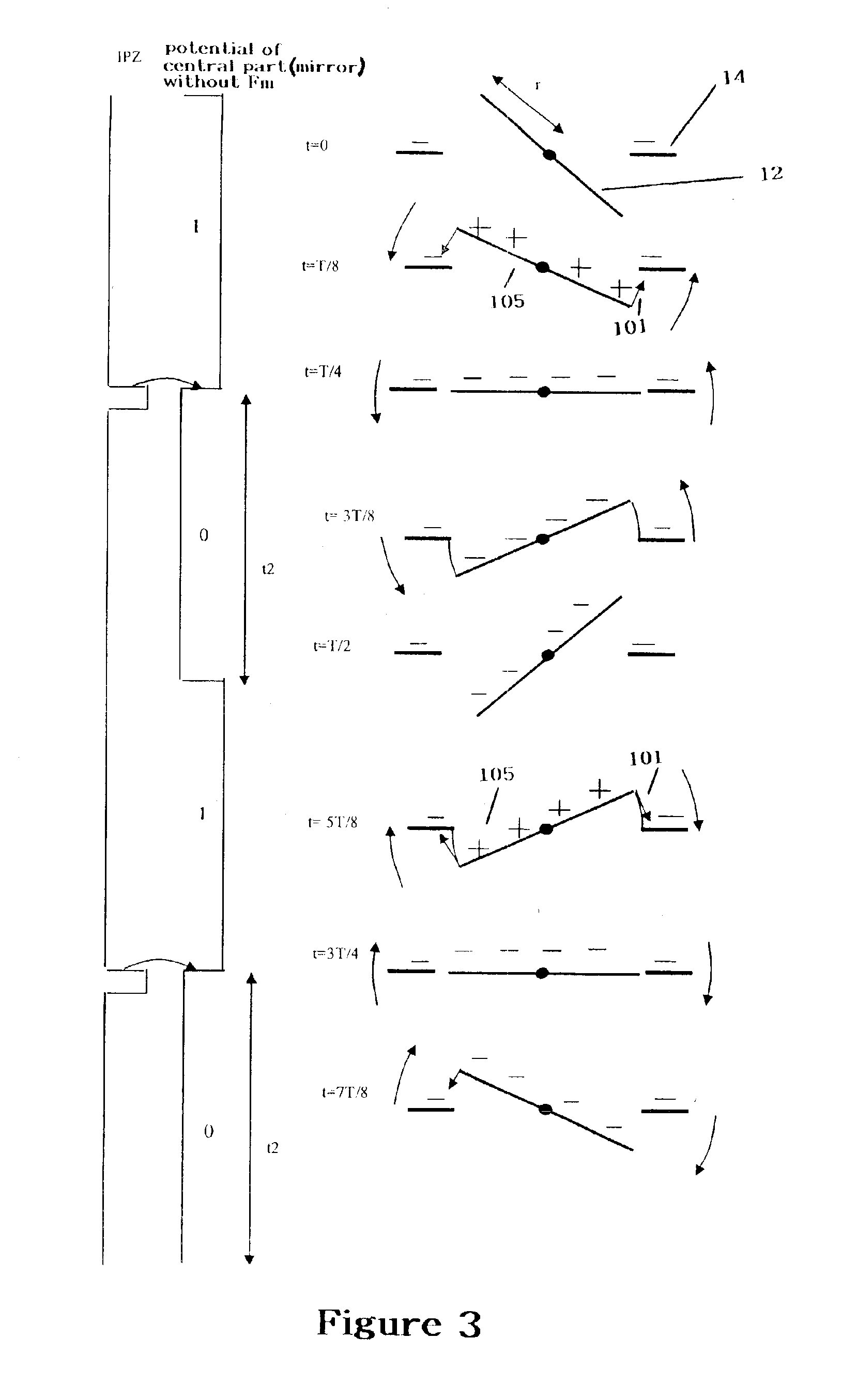

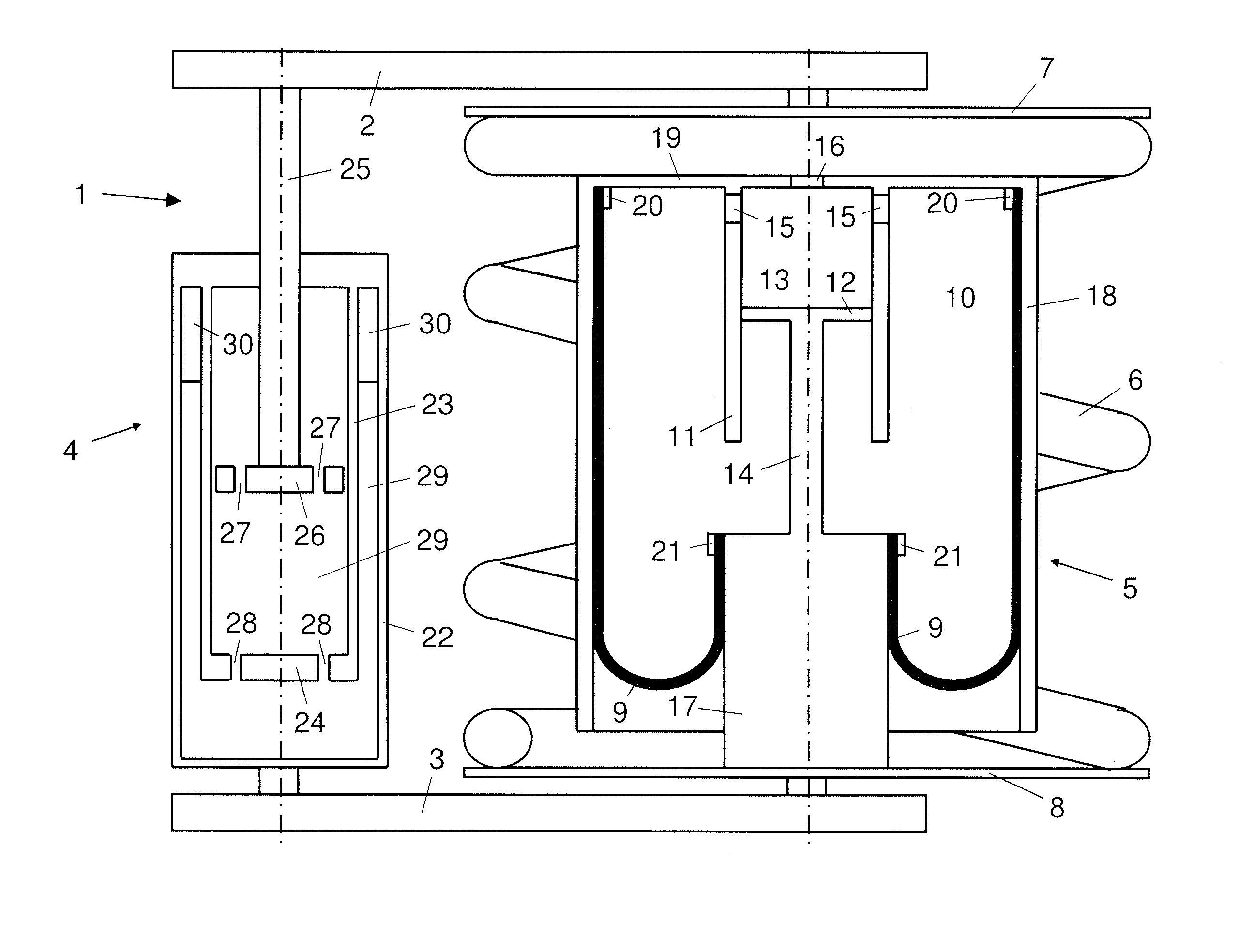

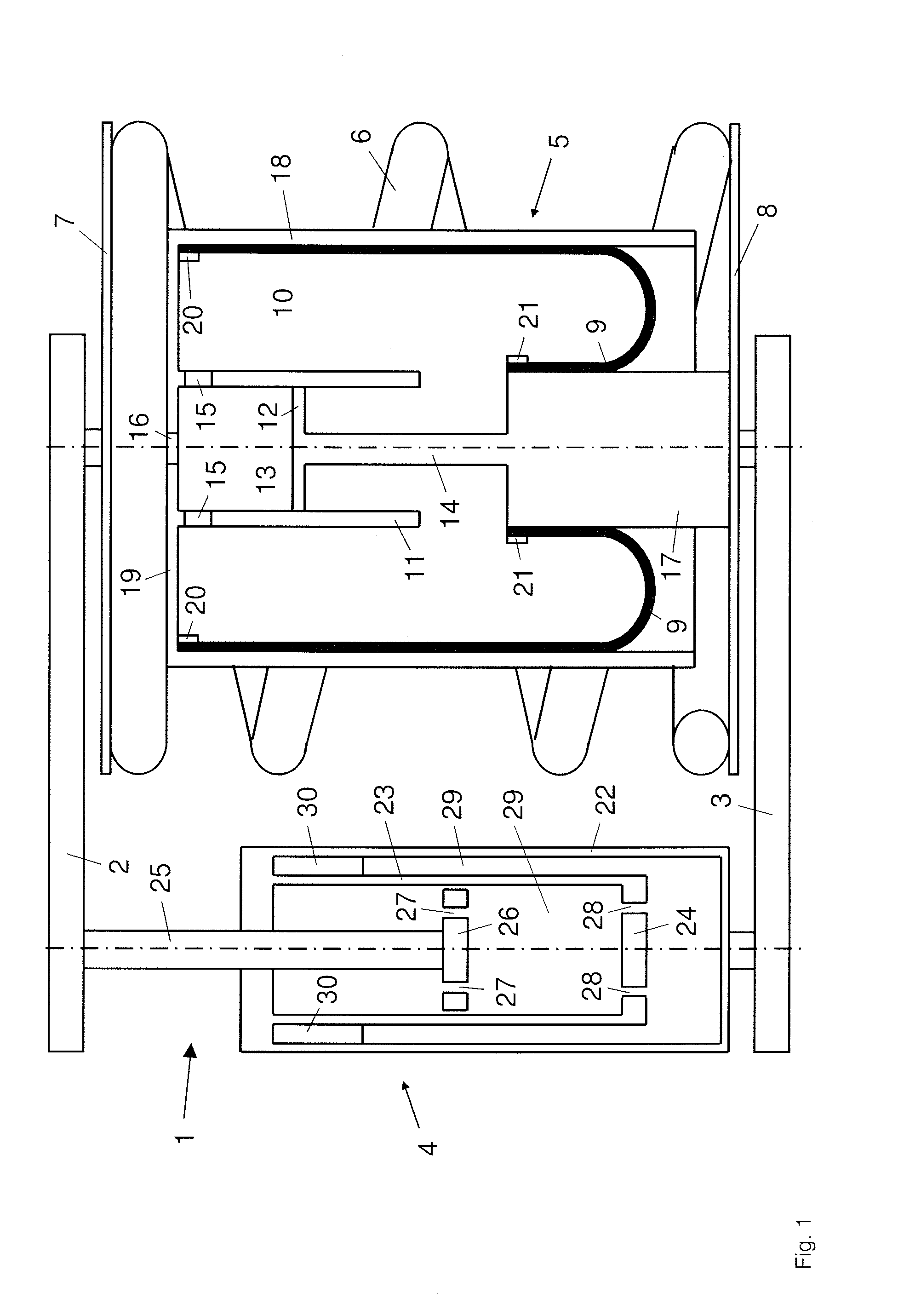

Systems and methods for monitoring a disc pump system using RFID

ActiveUS20130209277A1Reduced dampingPositive displacement pump componentsFlexible member pumpsEngineeringActuator

A disc pump system includes a pump body having a substantially cylindrical shape defining a cavity for containing a fluid, the cavity being formed by a side wall closed at both ends by substantially circular end walls, at least one of the end walls being a driven end wall. The system includes an actuator operatively associated with the driven end wall to cause an oscillatory motion of the driven end and an isolator is operatively associated with the peripheral portion of the driven end wall to reduce damping of the displacement oscillations. The isolator comprises a flexible material, which in turn includes an RFID tag.

Owner:3M INNOVATIVE PROPERTIES CO

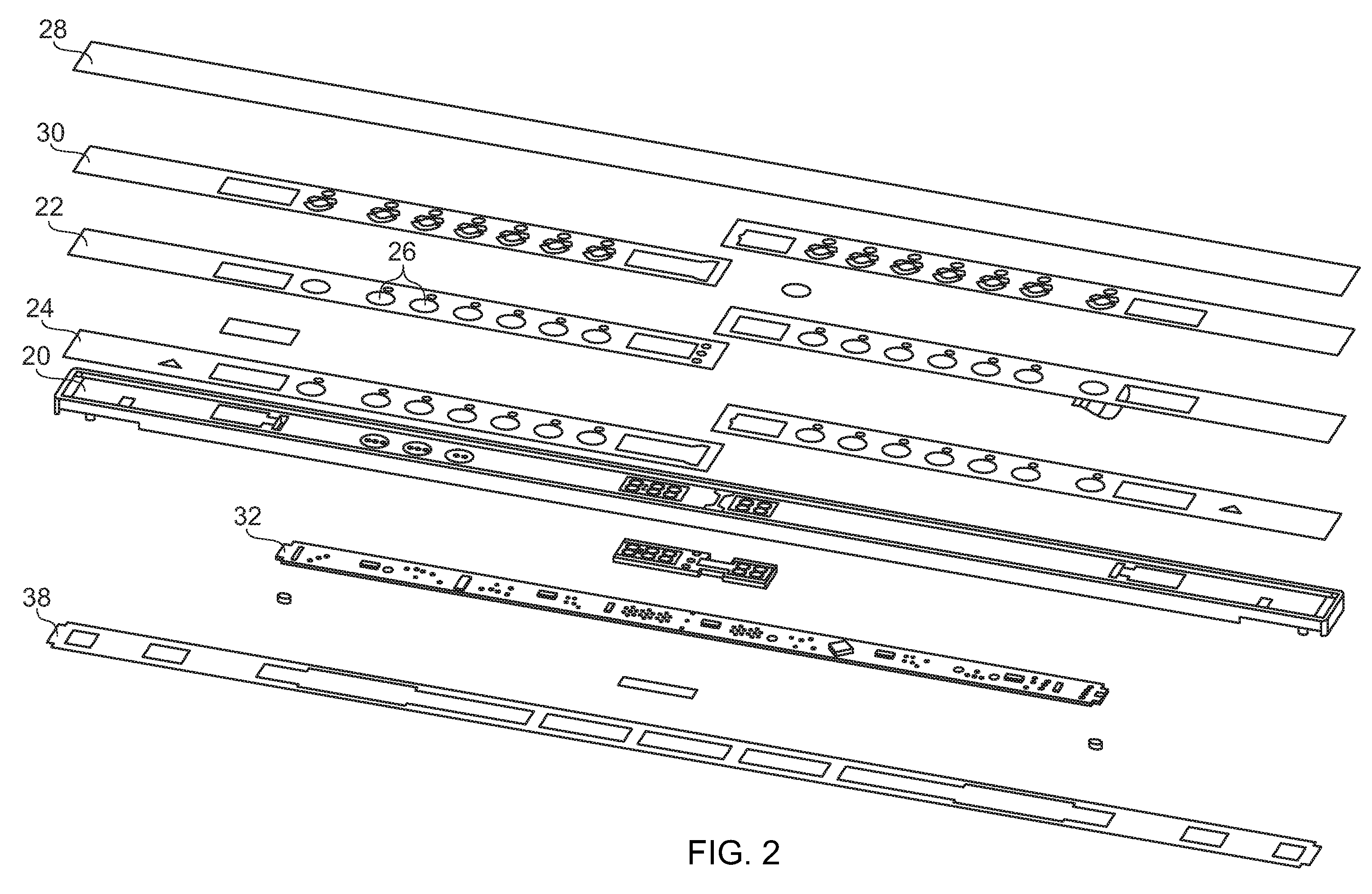

Operator control apparatus having at least one pressure-operated switch

InactiveUS20100149000A1Good thermal functional stabilitySmooth structureElectronic switchingKeyboard-like device codingPush switchPressure sensitive

An operator control apparatus has at least one pushbutton switch, and can be used, for example, in an operator control panel for an electronic domestic appliance. The operator control apparatus further has a support element, a pressure-sensitive transmission element with at least one sensor area which corresponds to the at least one pushbutton switch and is connected to the support element by a first adhesive layer, and a covering layer which faces the user side. The covering layer is connected to the transmission element by a second adhesive layer, with the second adhesive layer being soft and having an adhesive layer region in the region of the at least one sensor area of the transmission element. The adhesive layer region is smaller than the sensor area and is at least partially separated from the rest of the second adhesive layer by at least one cutout.

Owner:DIEHL AKO STIFTUNG

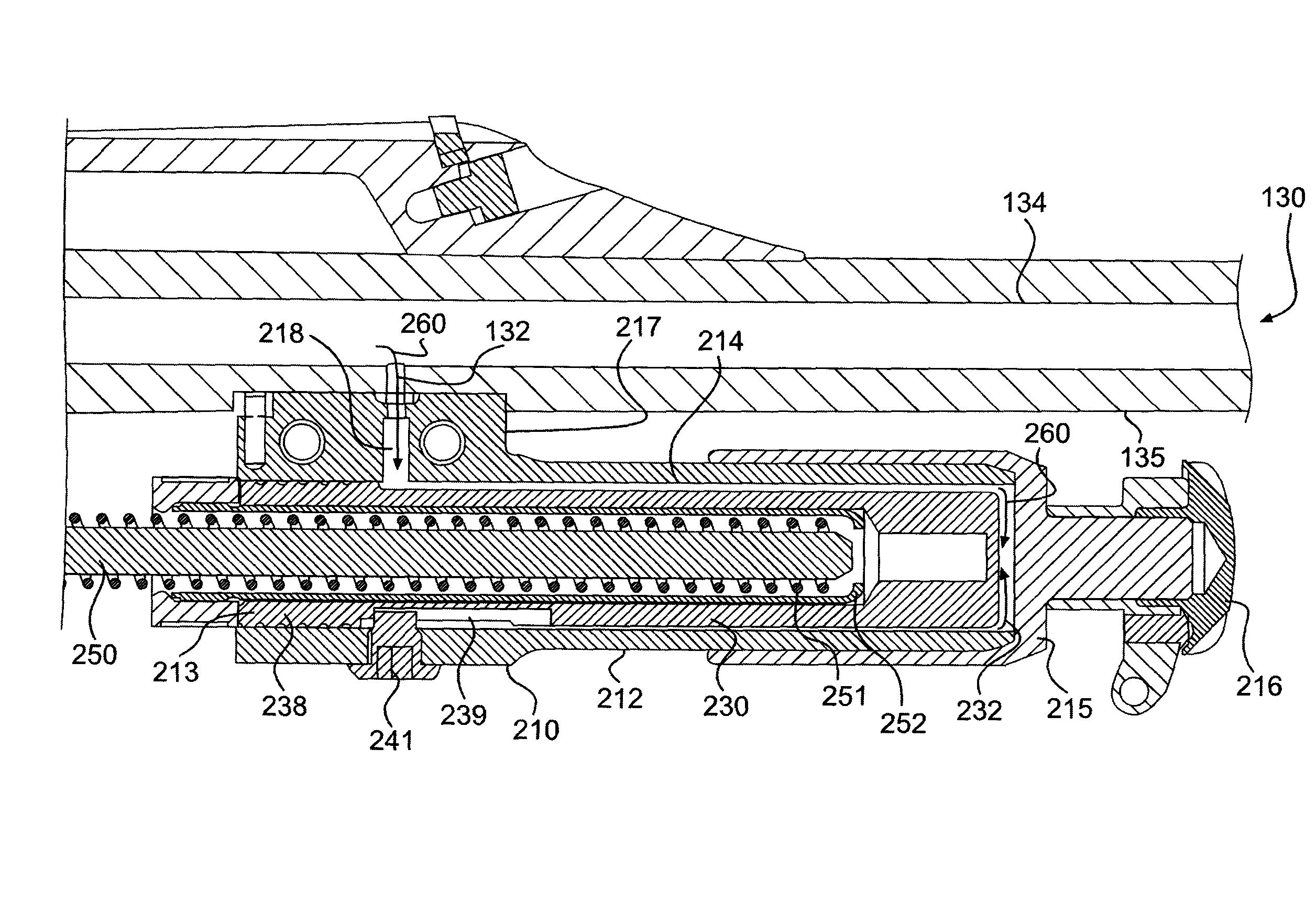

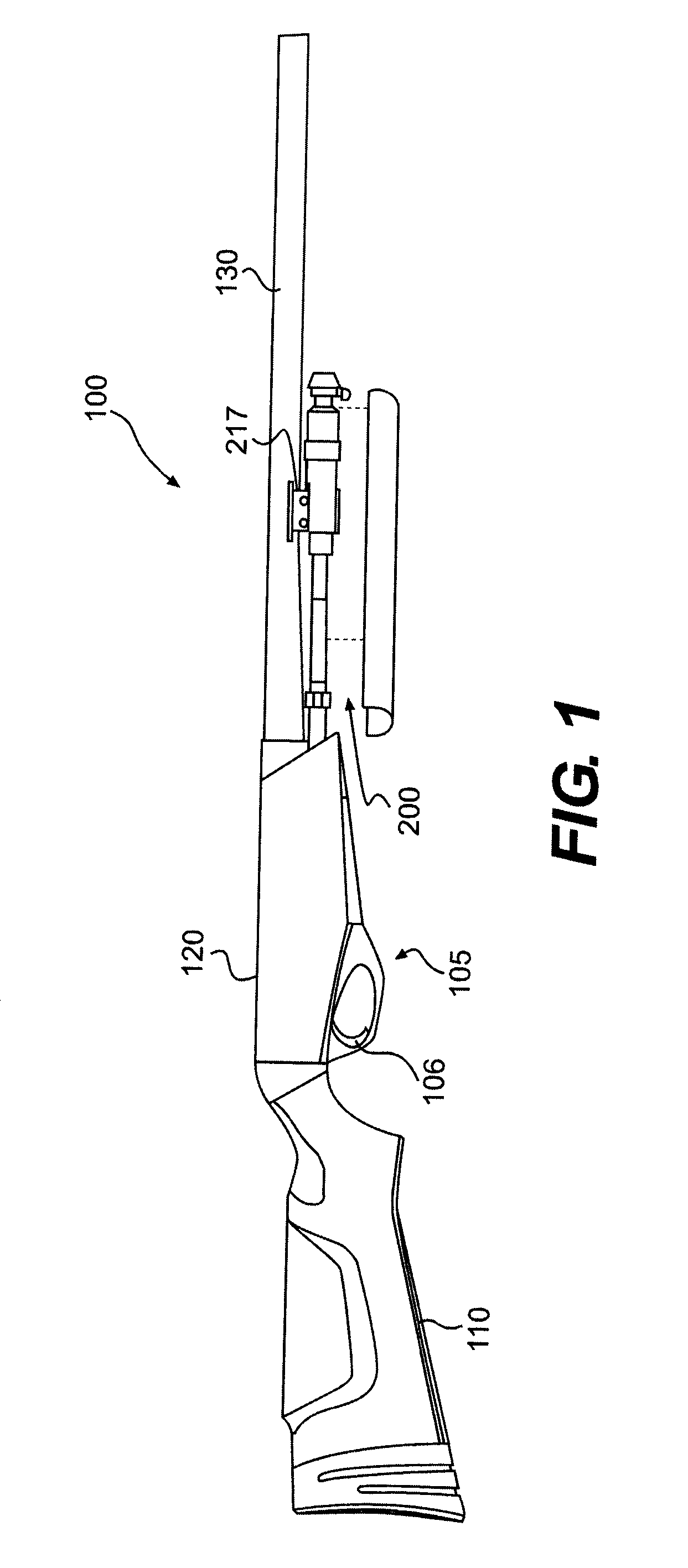

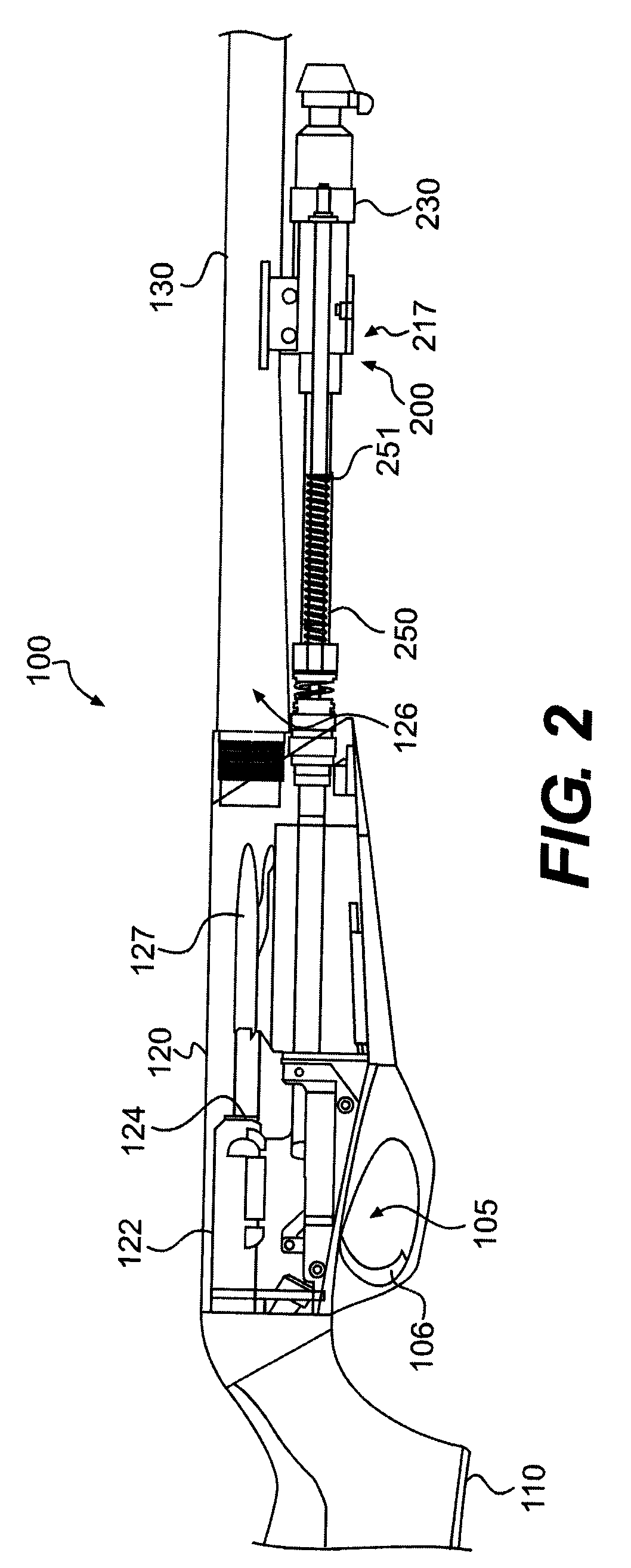

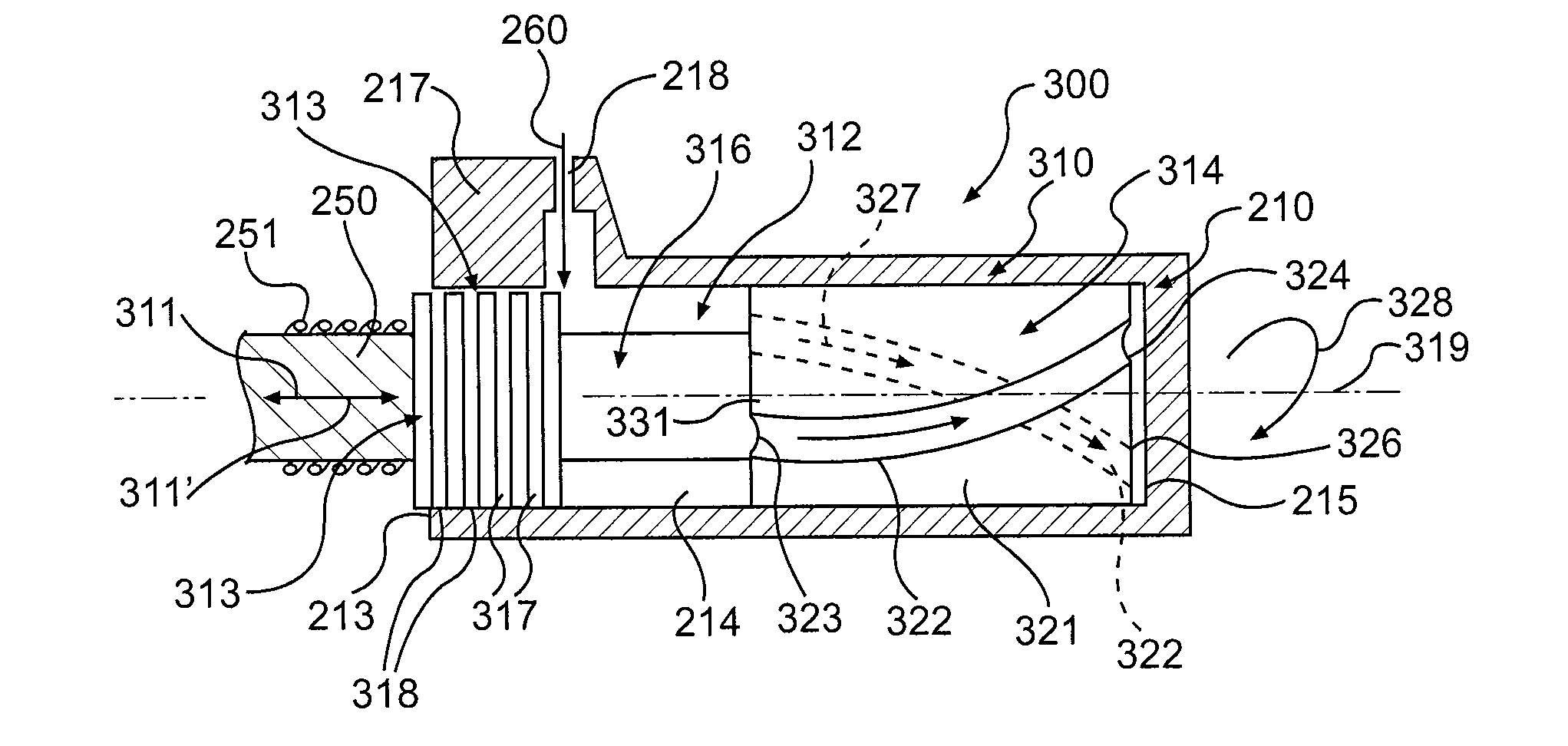

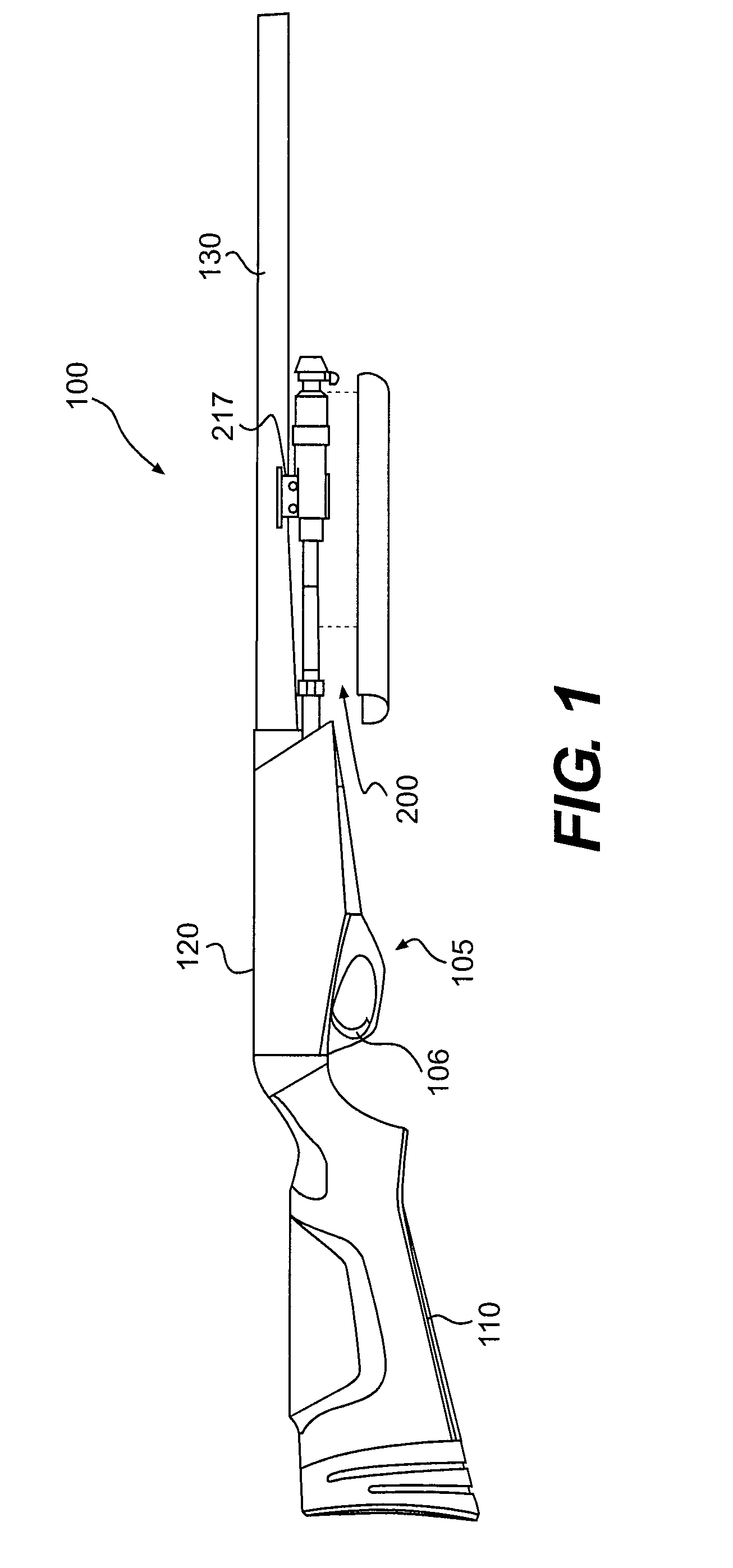

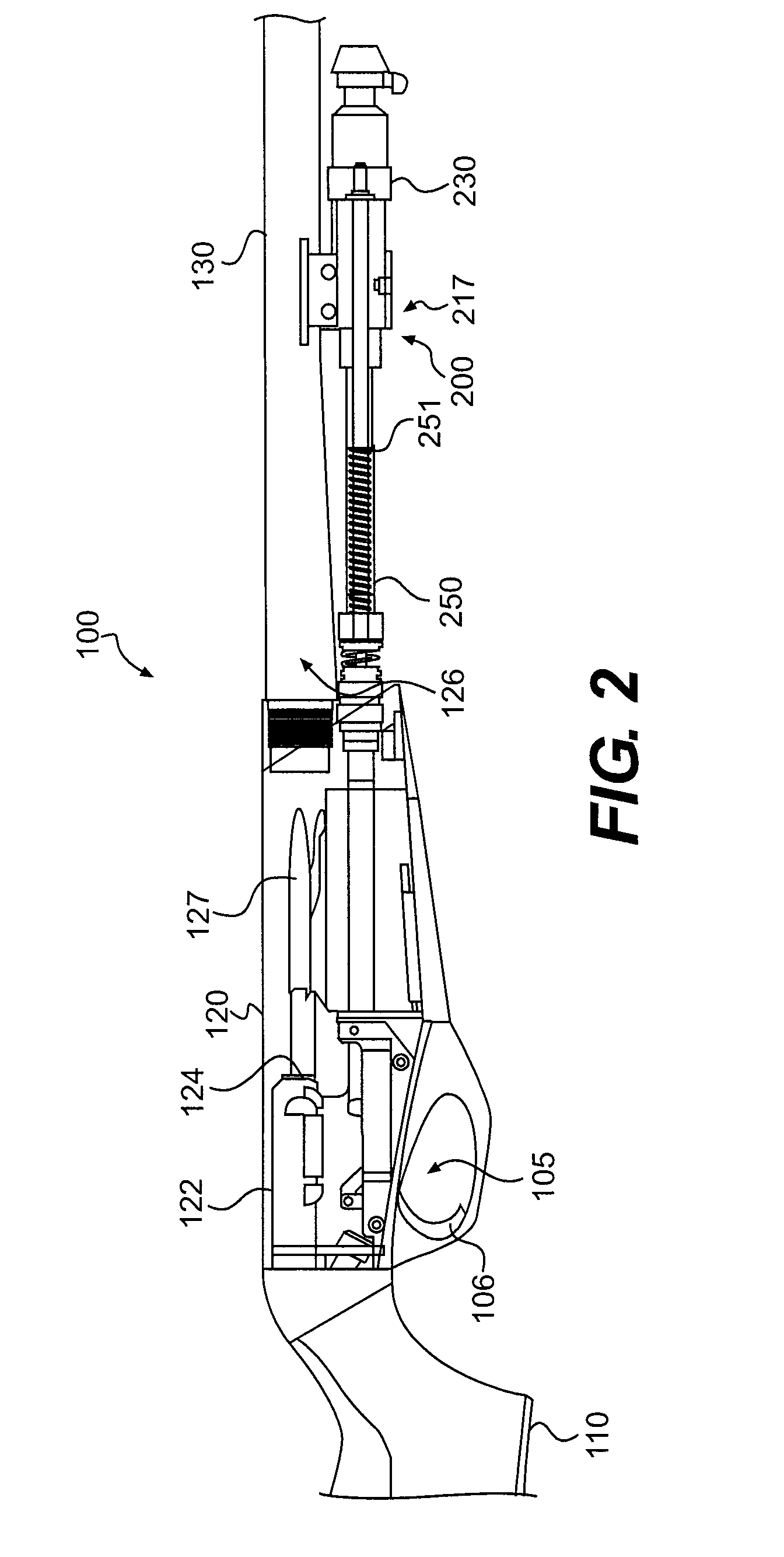

Gas system for firearms

InactiveUS7946214B2Reduced dampingLimit axial travelWeapon componentsEngineeringMechanical engineering

A piston assembly is provided for a gas-operated firearm of the type having a chamber and a barrel. The piston assembly includes a gas expansion housing and a piston mounted within the gas expansion housing. An annular recess is formed in the outer wall of the piston to receive exhaust gases diverted from the barrel upon firing of the firearm. At least one longitudinally extending groove extends from the annual recess to the head of the piston and forms a pathway for diverting the exhaust gases to the head of the piston. During firing, pressurized gases are diverted into the annular recess and expand longitudinally from the annular recess to the piston head, whereupon the pressurized exhaust gas drives the gas piston rearwardly along the housing.

Owner:REM TML HLDG LLC

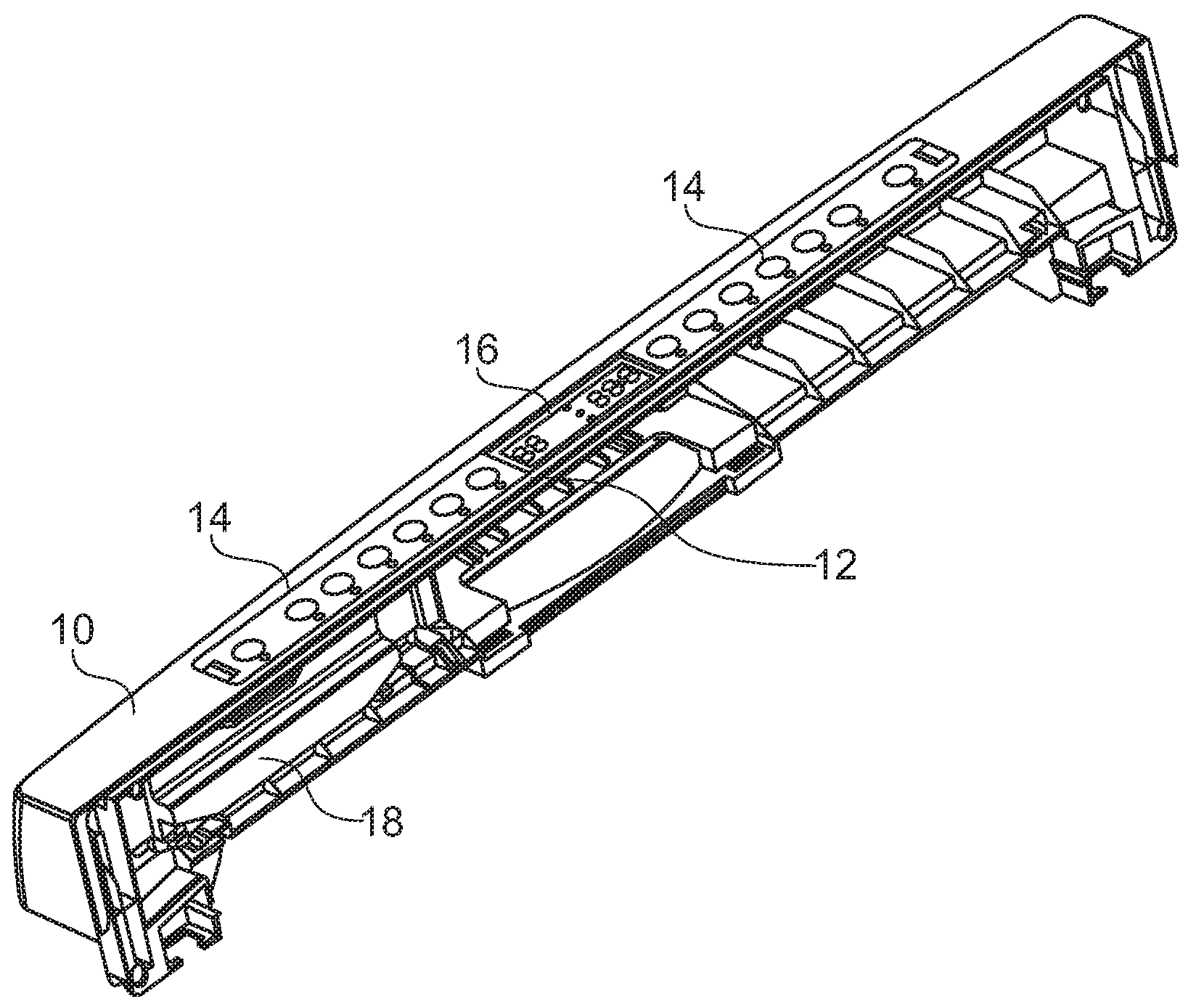

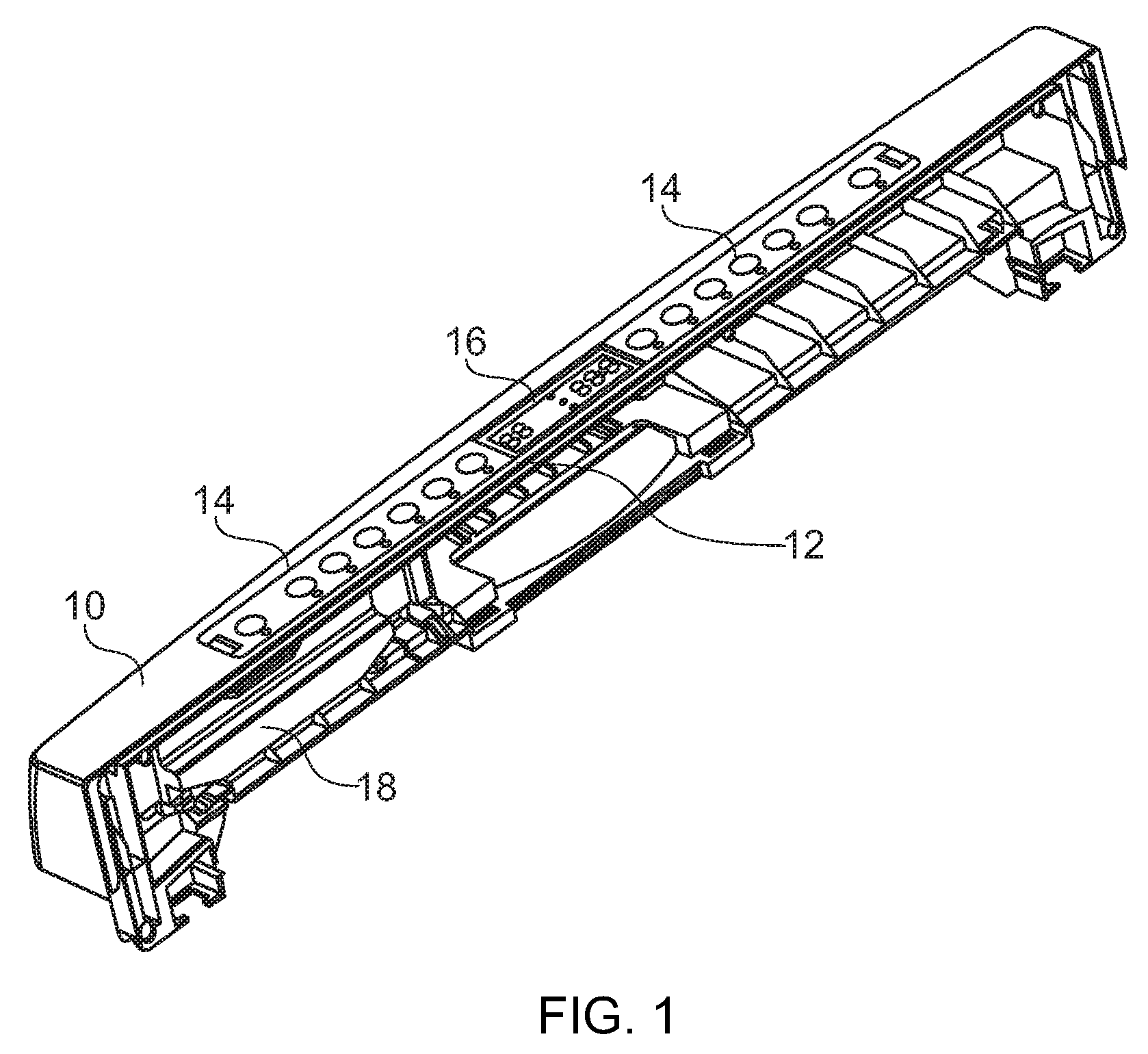

Removable adapter for phacoemulsification handpiece having irrigation and aspiration fluid paths

Current phacoemulsification handpieces require rigorous cleaning after each procedure because the aspiration and irrigation pathways for fluids are integral to the handpiece. According to the present invention, a removable horn extension and nosecone may be used with a phacoemulsification handpiece to allow for disposable fluid pathways exterior to the handpiece. This will reduce the cleaning time and effort, reduce cross-contamination, and increase the lifespan of the handpiece. Furthermore, the current invention allows different horn extensions to be used to excite different motions at the tip of the handpiece, depending on the preference of the surgeon.

Owner:ZEVEX

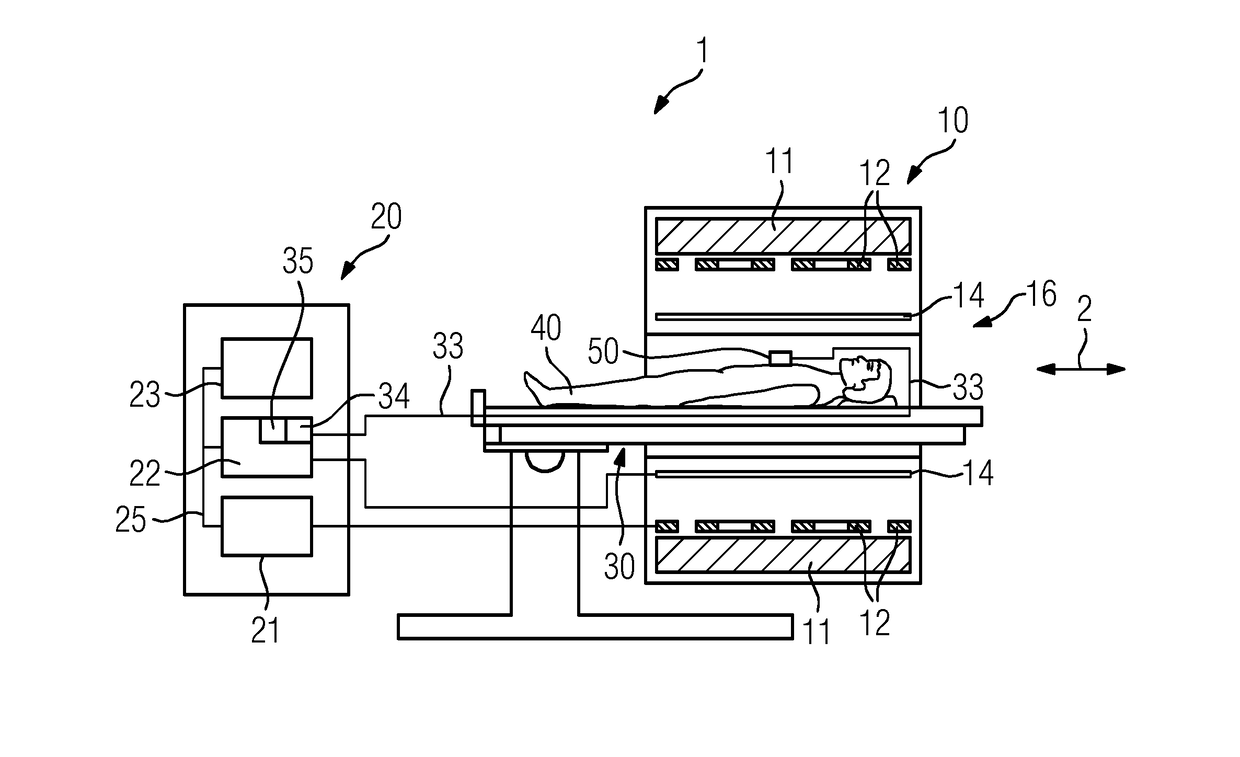

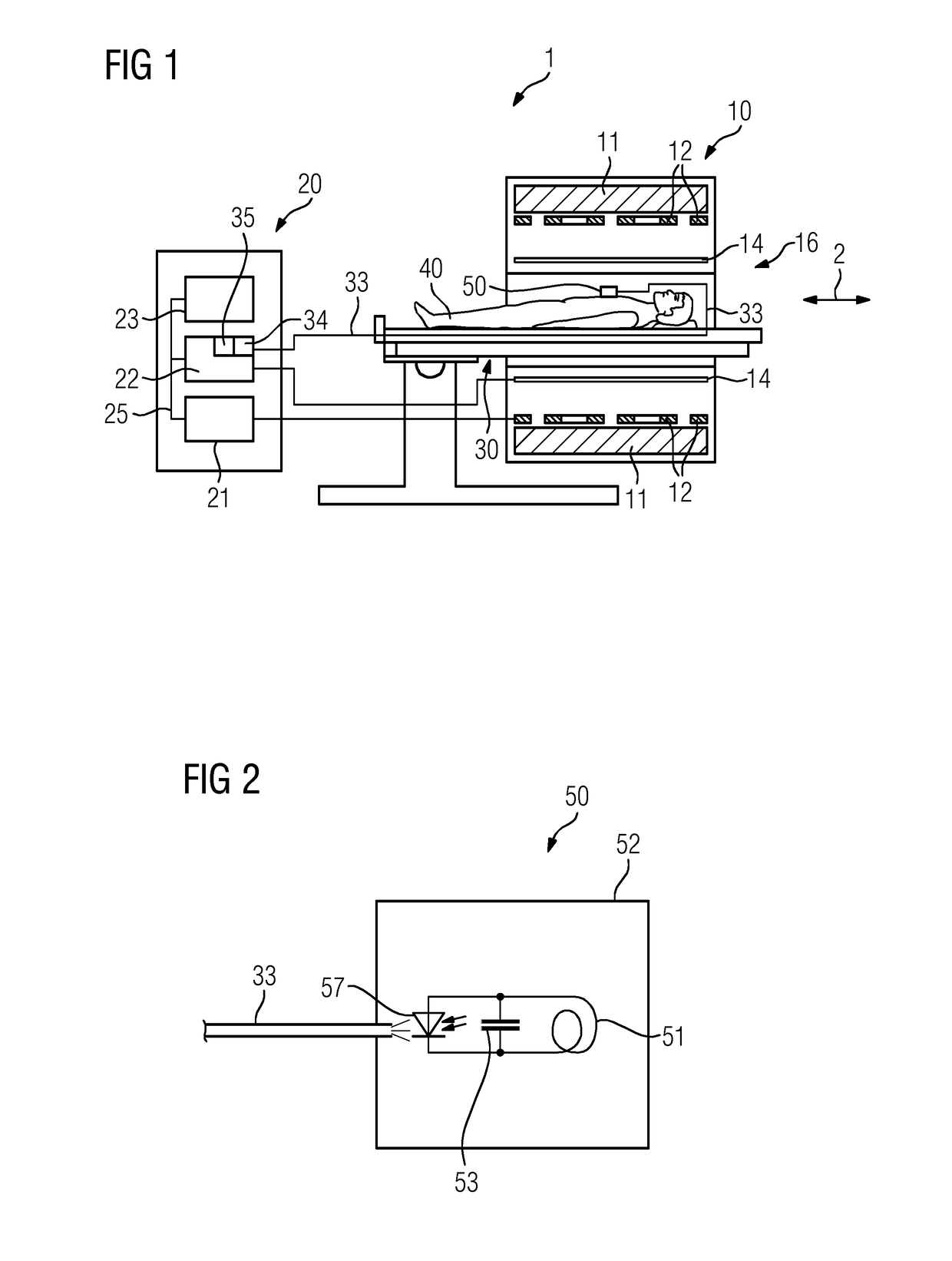

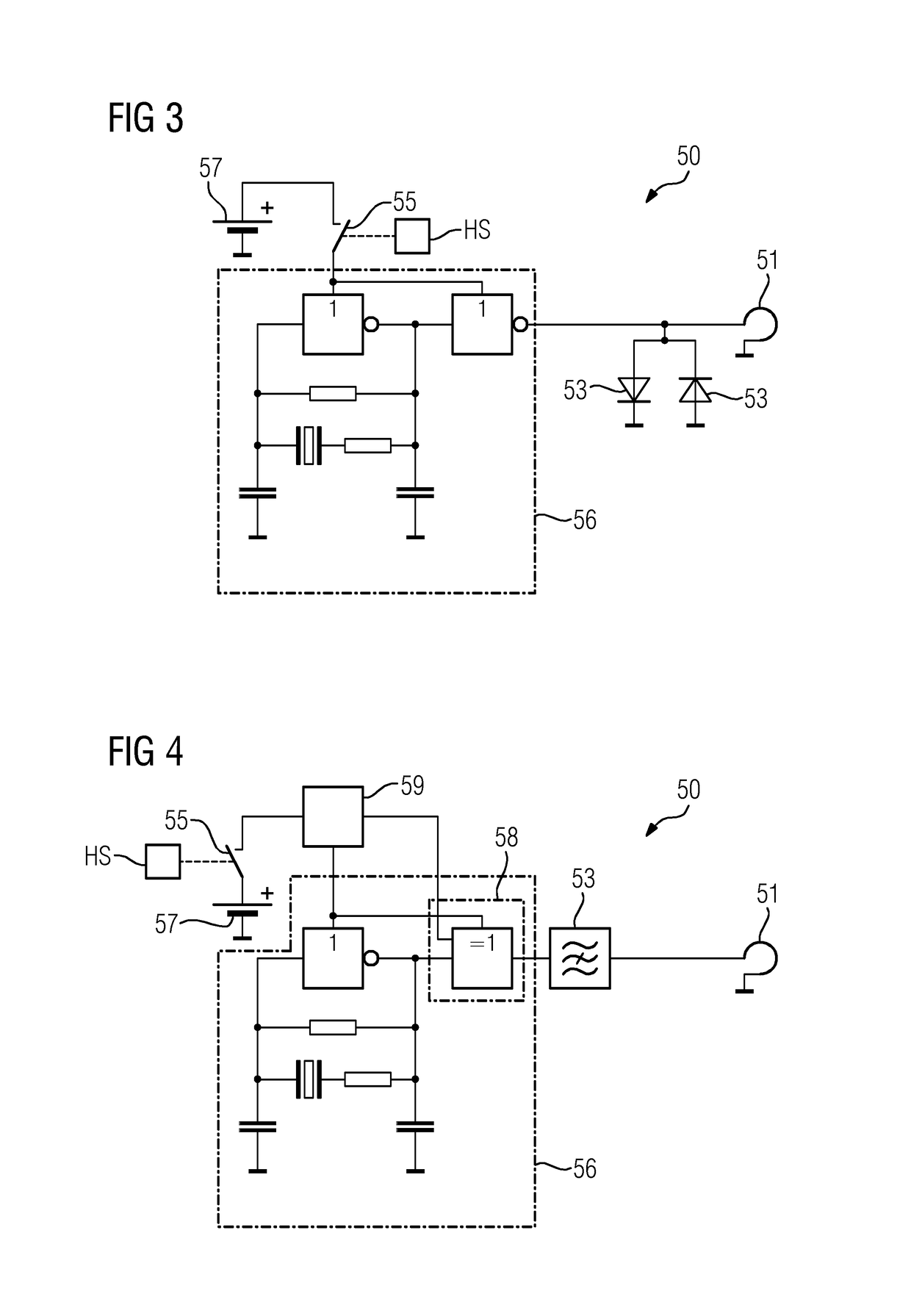

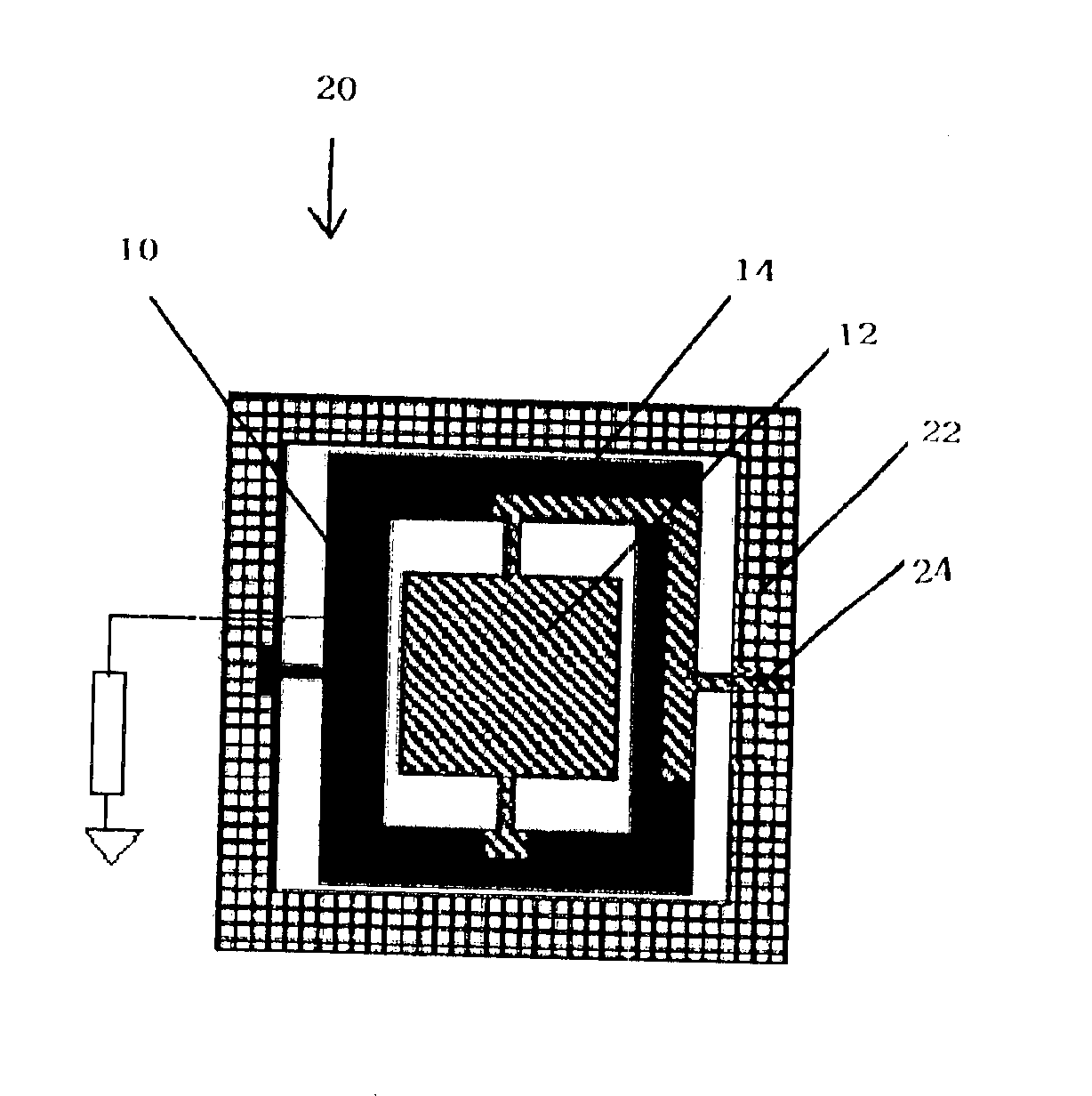

Signal Transmitter for Pilot Tone Navigation

ActiveUS20170160367A1Convenient ArrangementInfluence is maximizedMeasurements using magnetic resonanceResonanceTomography

A transmitter for pilot tone navigation in a magnetic resonance tomography system includes a power supply and an antenna. The transmitter is configured to transmit a pilot tone signal via the antenna. The transmitter also includes a decoupling element in order to protect a transmitter output from signals that the antenna receives with excitation pulses of the magnetic resonance tomography system during a magnetic resonance tomography. In a method, movement-dependent changes to the pilot tone signal of the transmitter are identified by a controller of the magnetic resonance tomography system.

Owner:SIEMENS HEALTHCARE GMBH

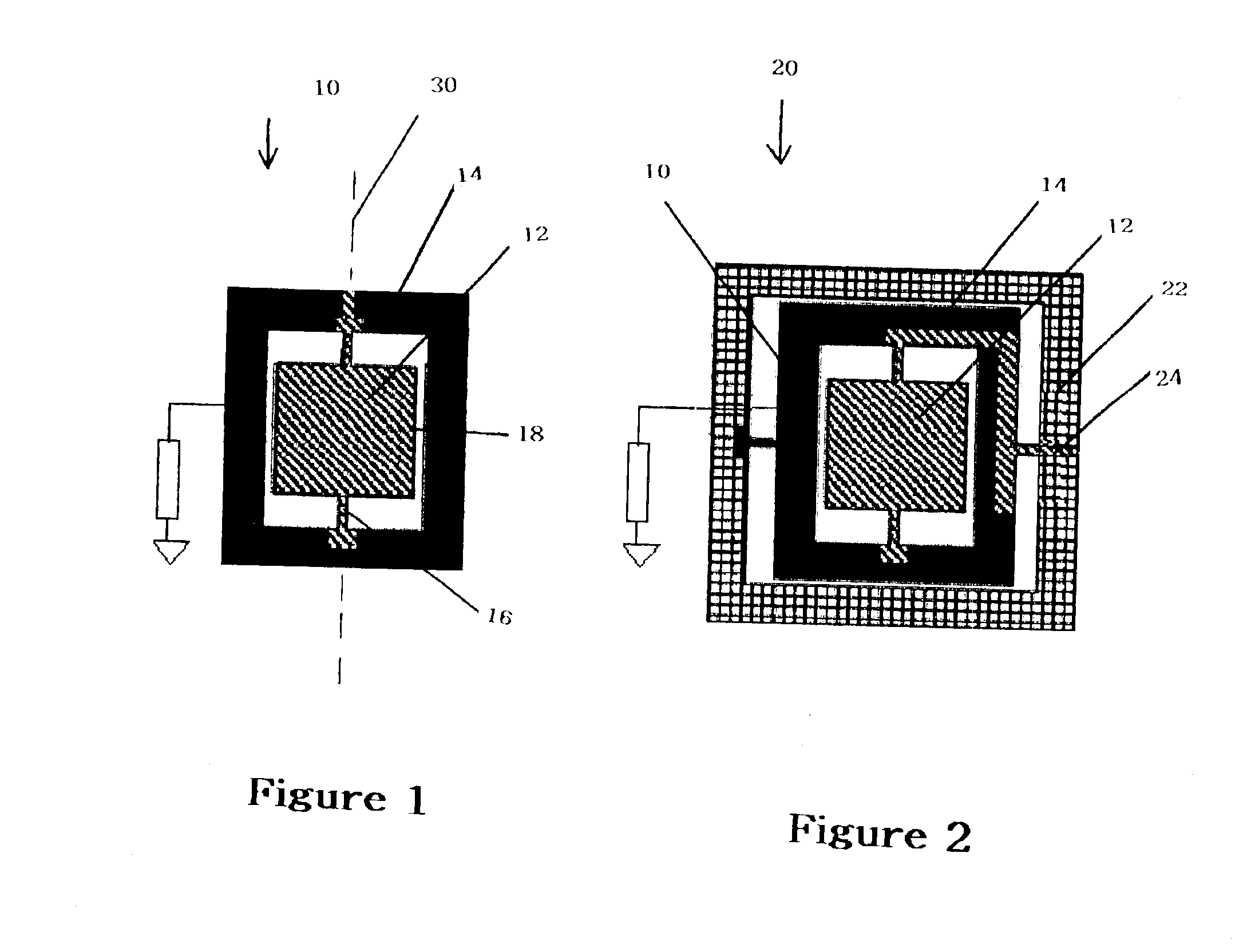

Frame grabbing with laser scanner with sweeping by silicon planar electrostatics actuator

InactiveUS6879428B2Low costSmall sizeElectrostatic motorsOptical elementsMicro actuatorLaser scanning

A method of capturing images using a laser scanner equipped with a 2D micro actuator. The 2D micro actuator allows for laser beam location without the use of additional components dedicated to determining beam location. The 2D micro actuator is used to stabilize the positioning function of the spot in the scene. The micro actuator is a 1D micro actuator suspended within a second framework by two torsion bars and two pairs of orthogonal additional electrodes. The image is scanned, a precise rectangle of the character sensing field is generated and the image is created by keeping a substantially constant pitch.

Owner:INTERMEC IP

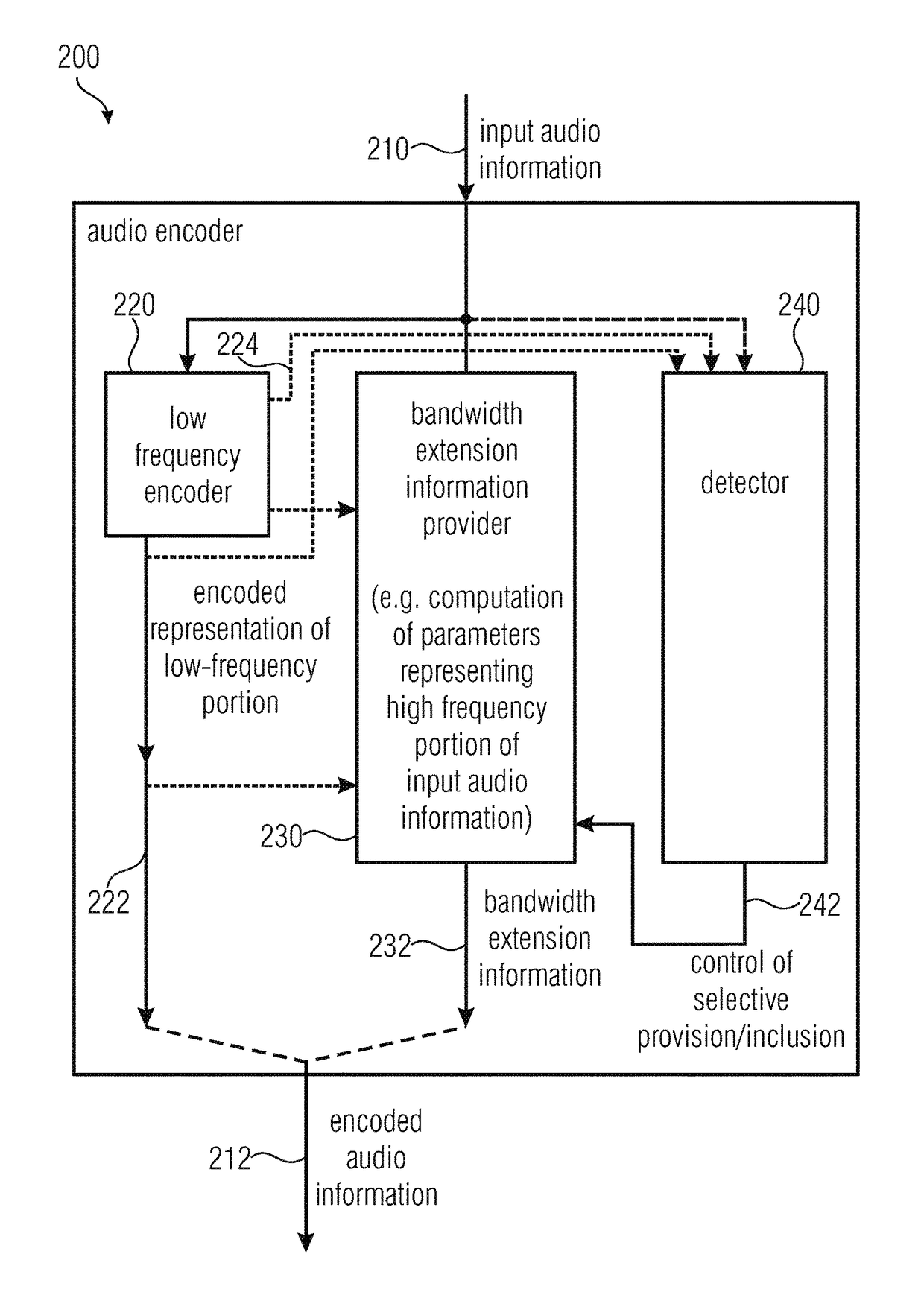

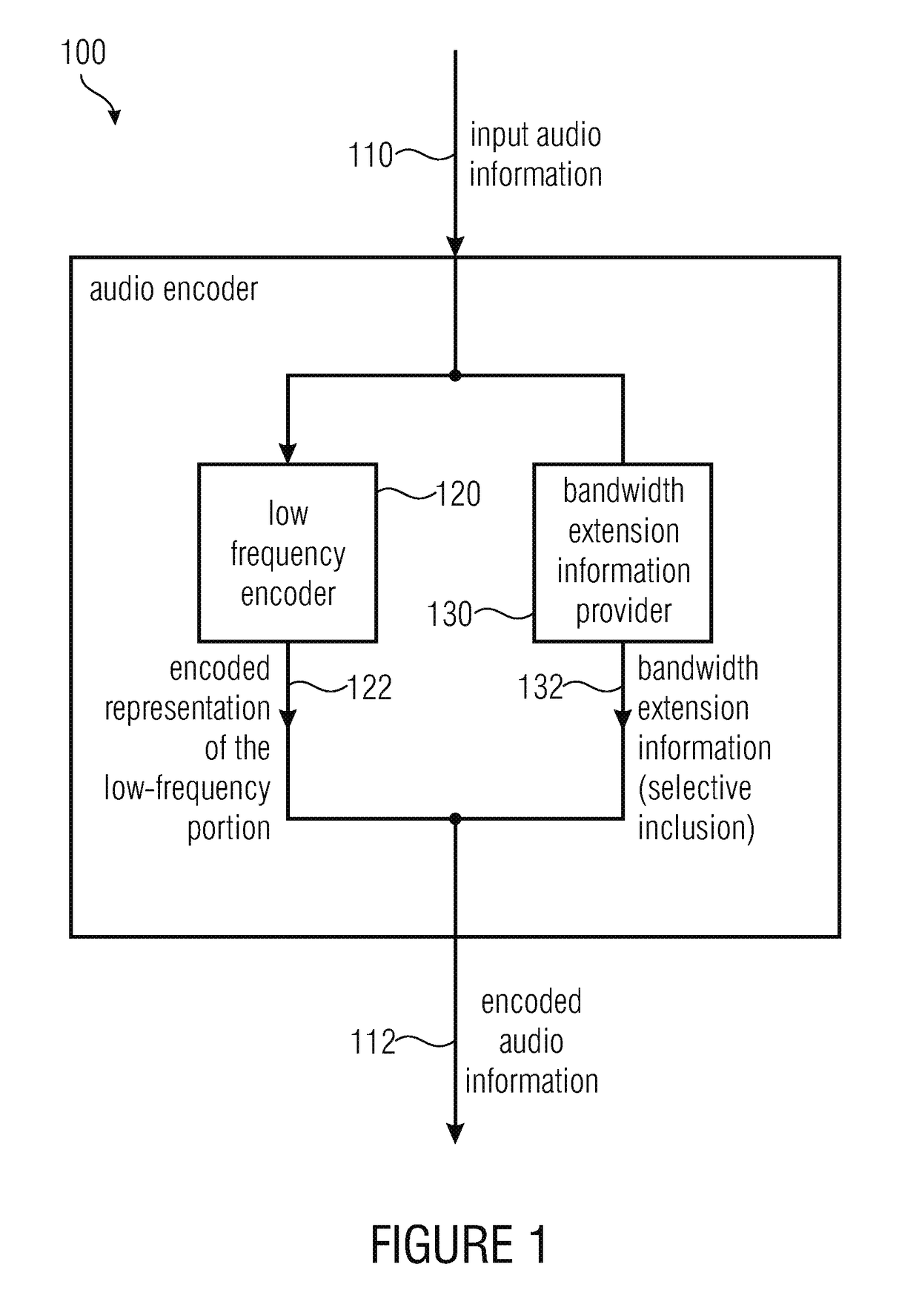

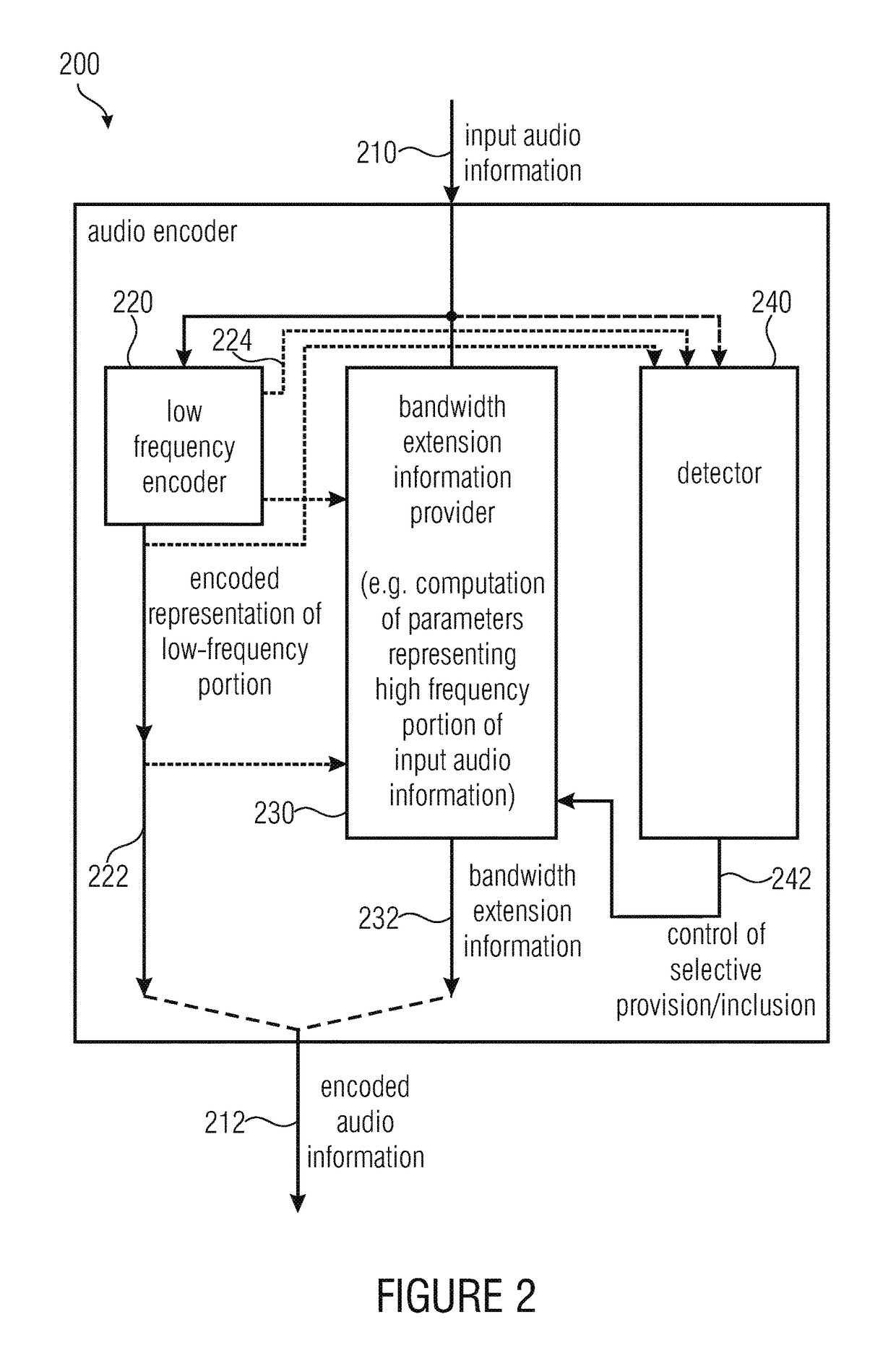

Audio encoder, audio decoder, method for providing an encoded audio information, method for providing a decoded audio information, computer program and encoded representation using a signal-adaptive bandwidth extension

ActiveUS9646624B2Improve the level ofReduced dampingSpeech analysisBandwidth extensionAudio frequency

An audio encoder has a low frequency encoder which encodes a low frequency portion of the input audio information to obtain an encoded representation of the low frequency portion, and a bandwidth extension information provider which provides bandwidth extension information. The audio encoder is configured to selectively include bandwidth extension information into the encoded audio information in a signal-adaptive manner. An audio decoder has a low frequency decoder which decodes an encoded representation of a low frequency portion to obtain a decoded representation of the low frequency portion, and a bandwidth extension which obtains a bandwidth extension signal using a blind bandwidth extension for portions of an audio content for which no bandwidth extension parameters are included in the encoded audio information, and which obtains the bandwidth extension signal using a parameter-guided bandwidth extension for portions of the audio content for which bandwidth extension parameters are included in the encoded audio information.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Gas system for firearms

A piston assembly is provided for a gas-operated firearm of the type having a chamber and a barrel. The piston assembly includes a gas expansion housing and a piston mounted within the gas expansion housing. An annular recess is formed in the outer wall of the piston to receive exhaust gases diverted from the barrel upon firing of the firearm. At least one longitudinally extending groove extends from the annual recess to the head of the piston and forms a pathway for diverting the exhaust gases to the head of the piston. During firing, pressurized gases are diverted into the annular recess and expand longitudinally from the annular recess to the piston head, whereupon the pressurized exhaust gas drives the gas piston rearwardly along the housing.

Owner:REM TML HLDG LLC

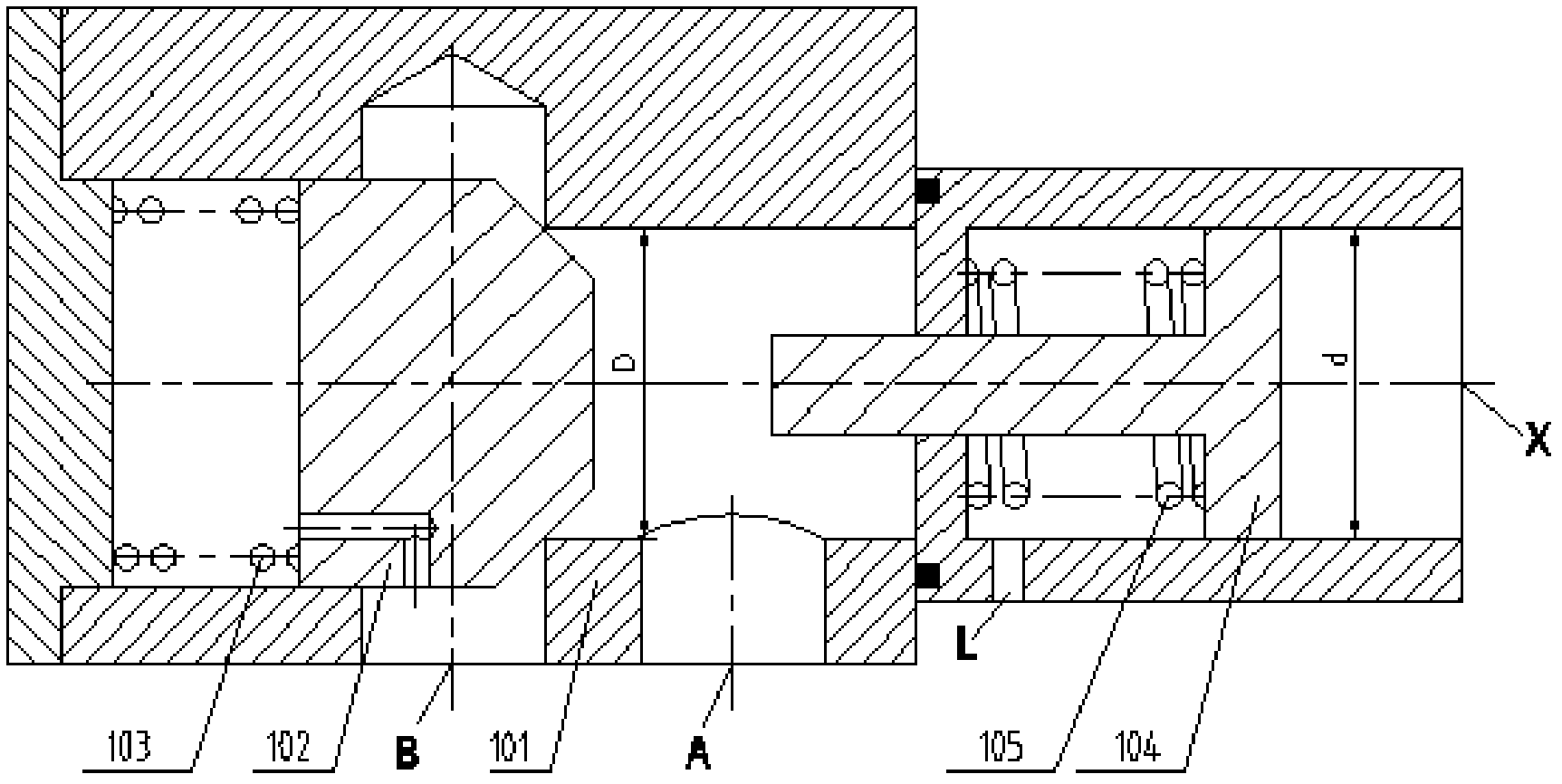

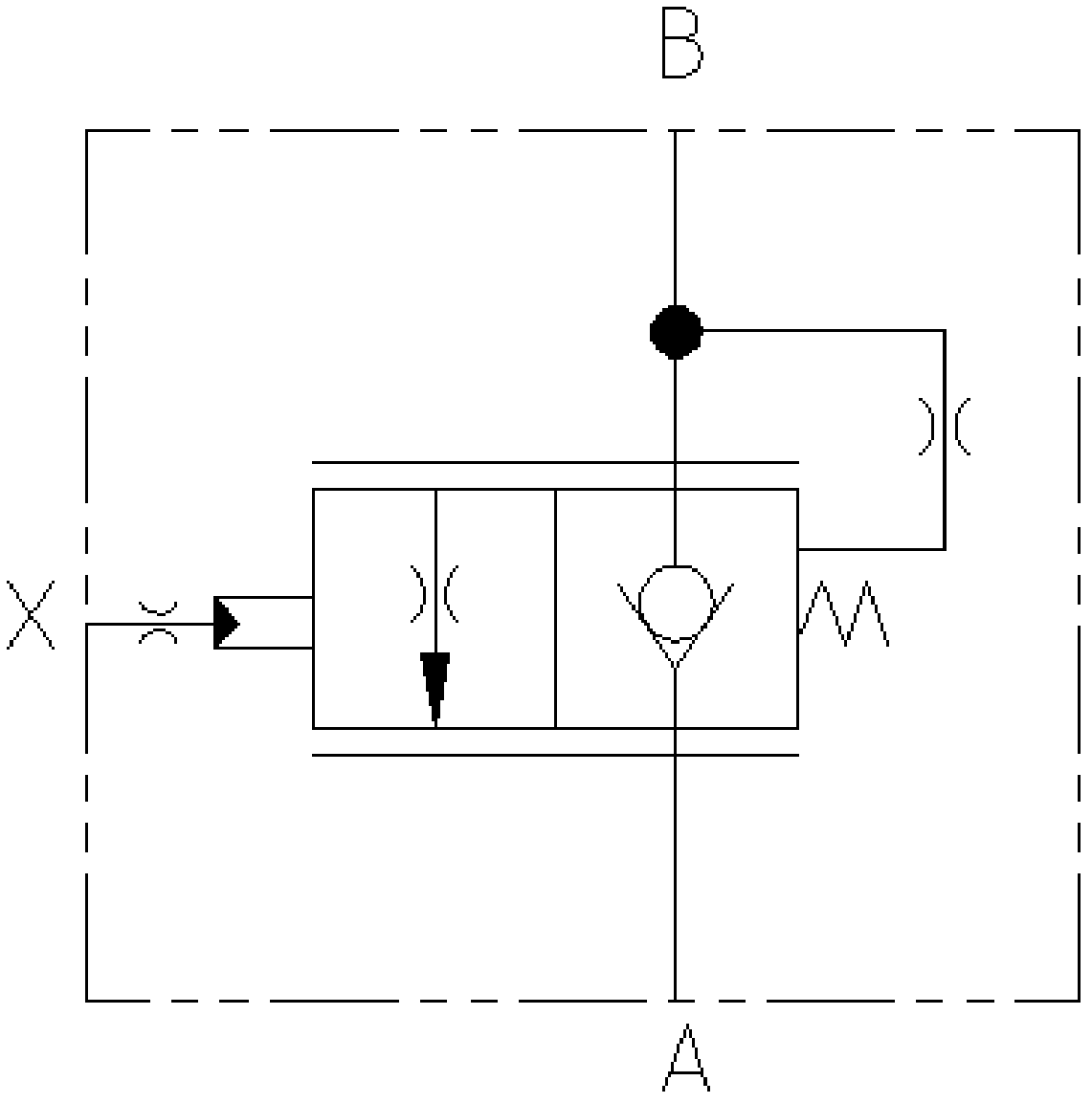

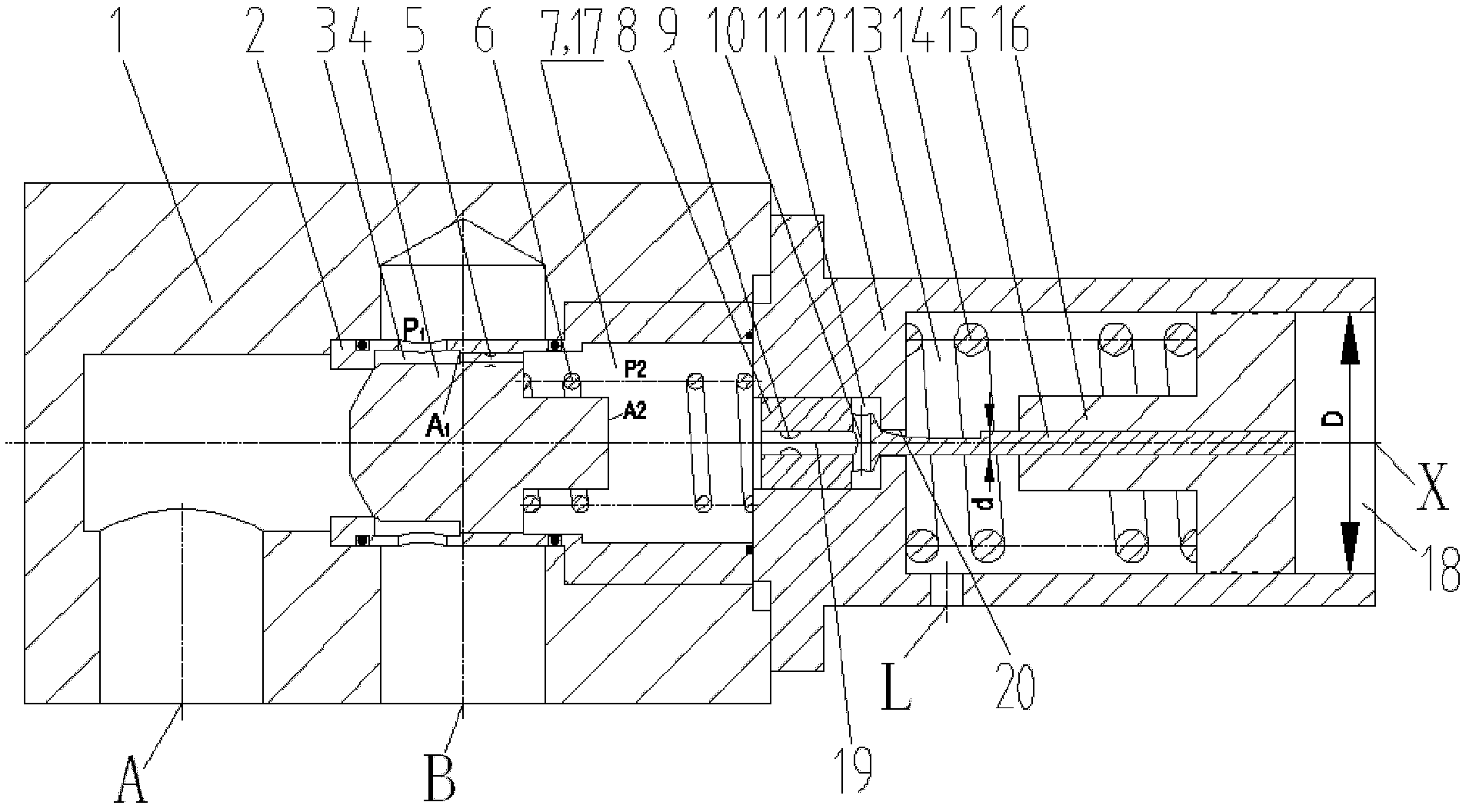

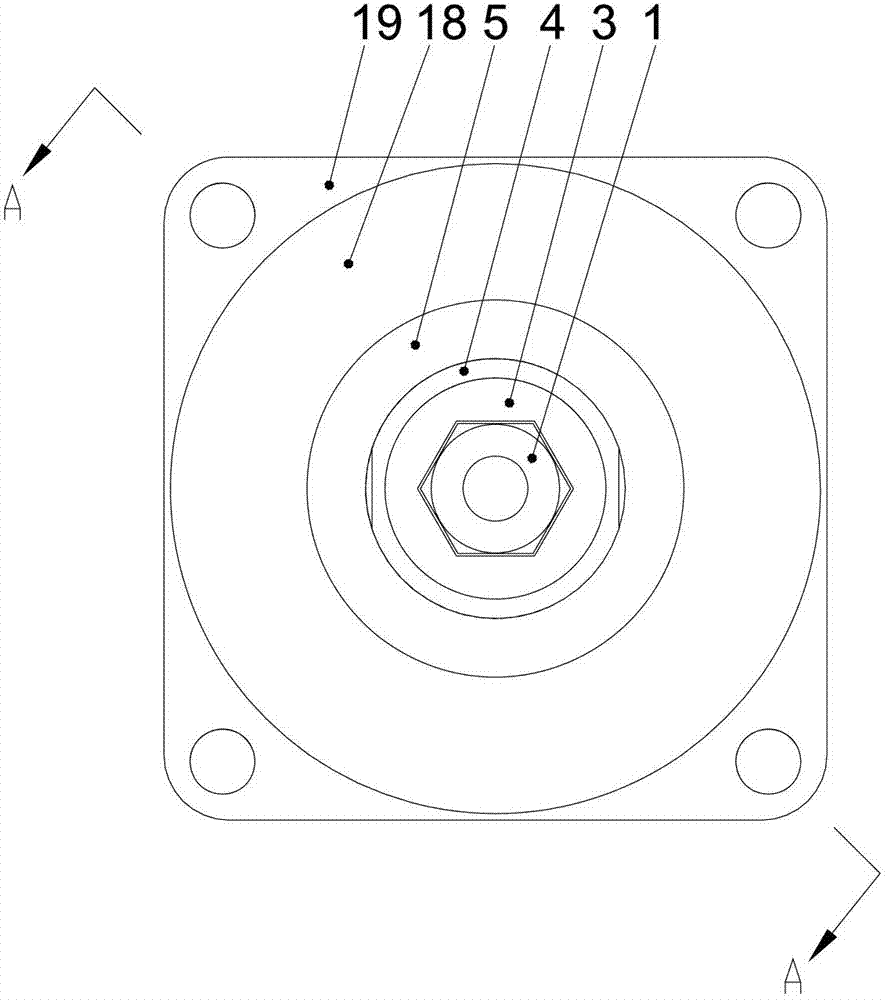

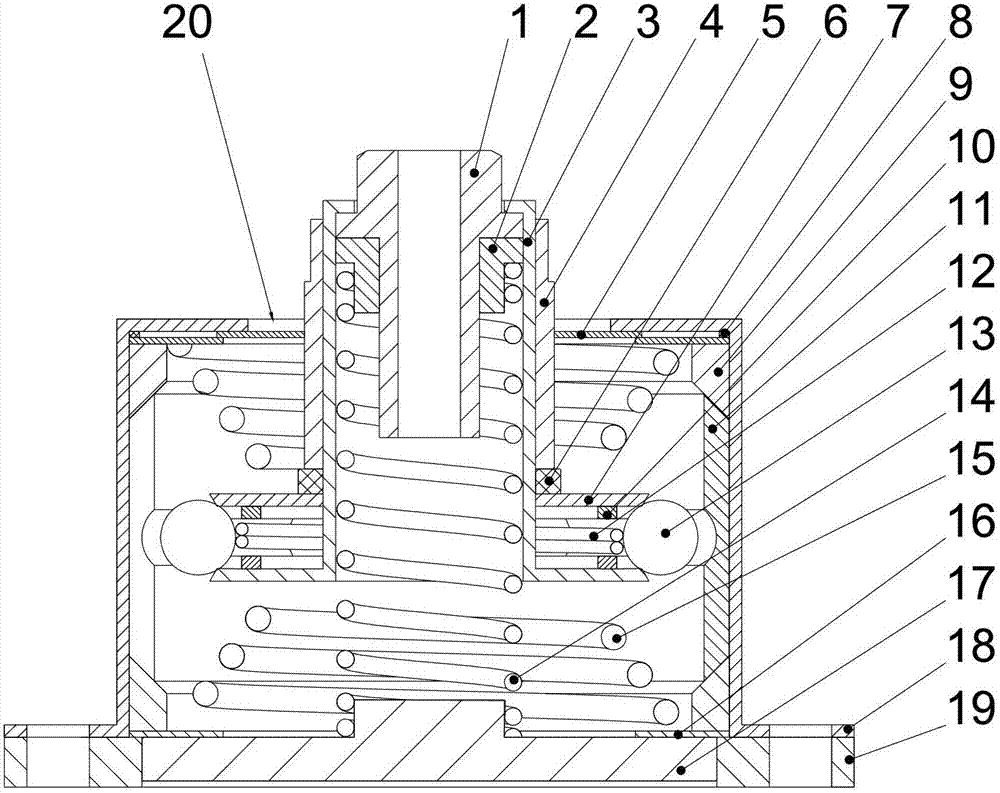

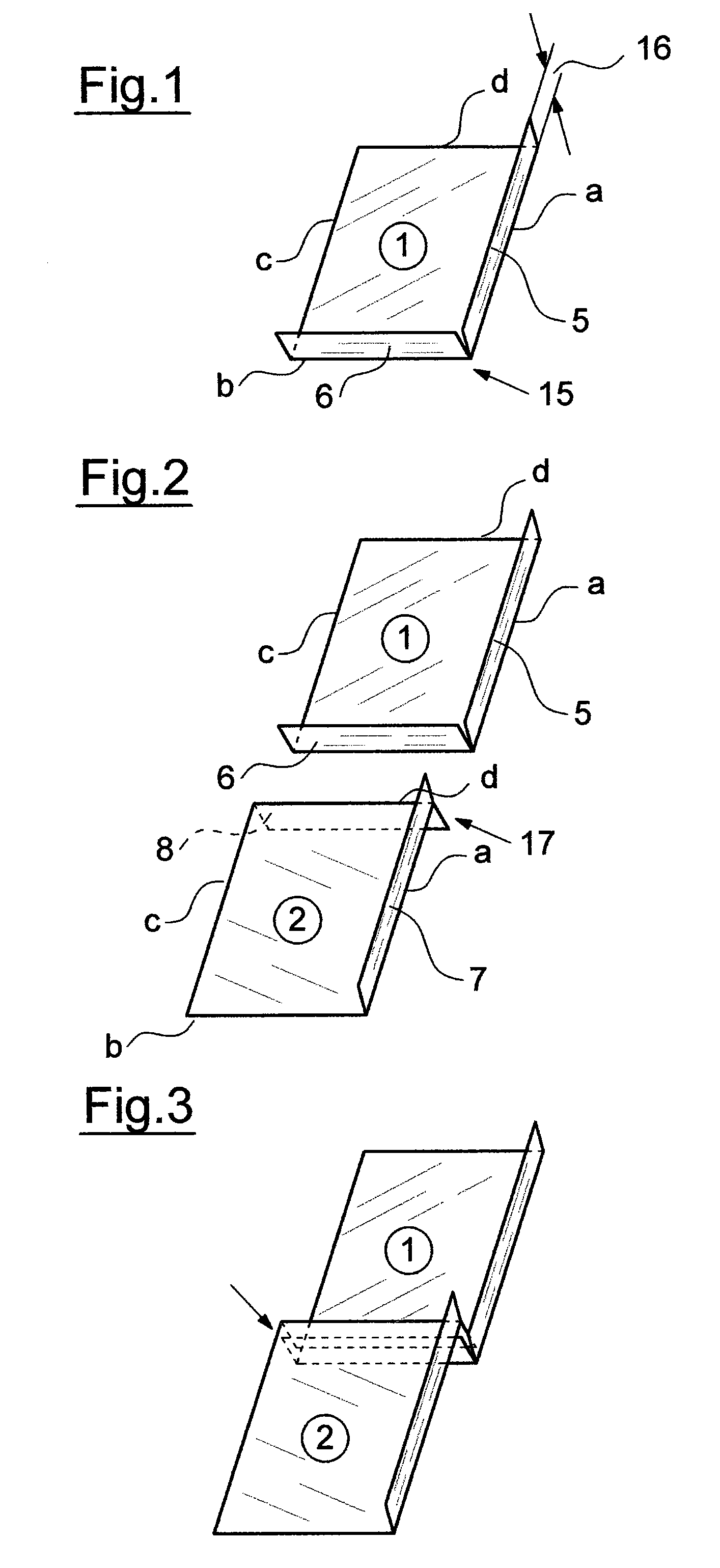

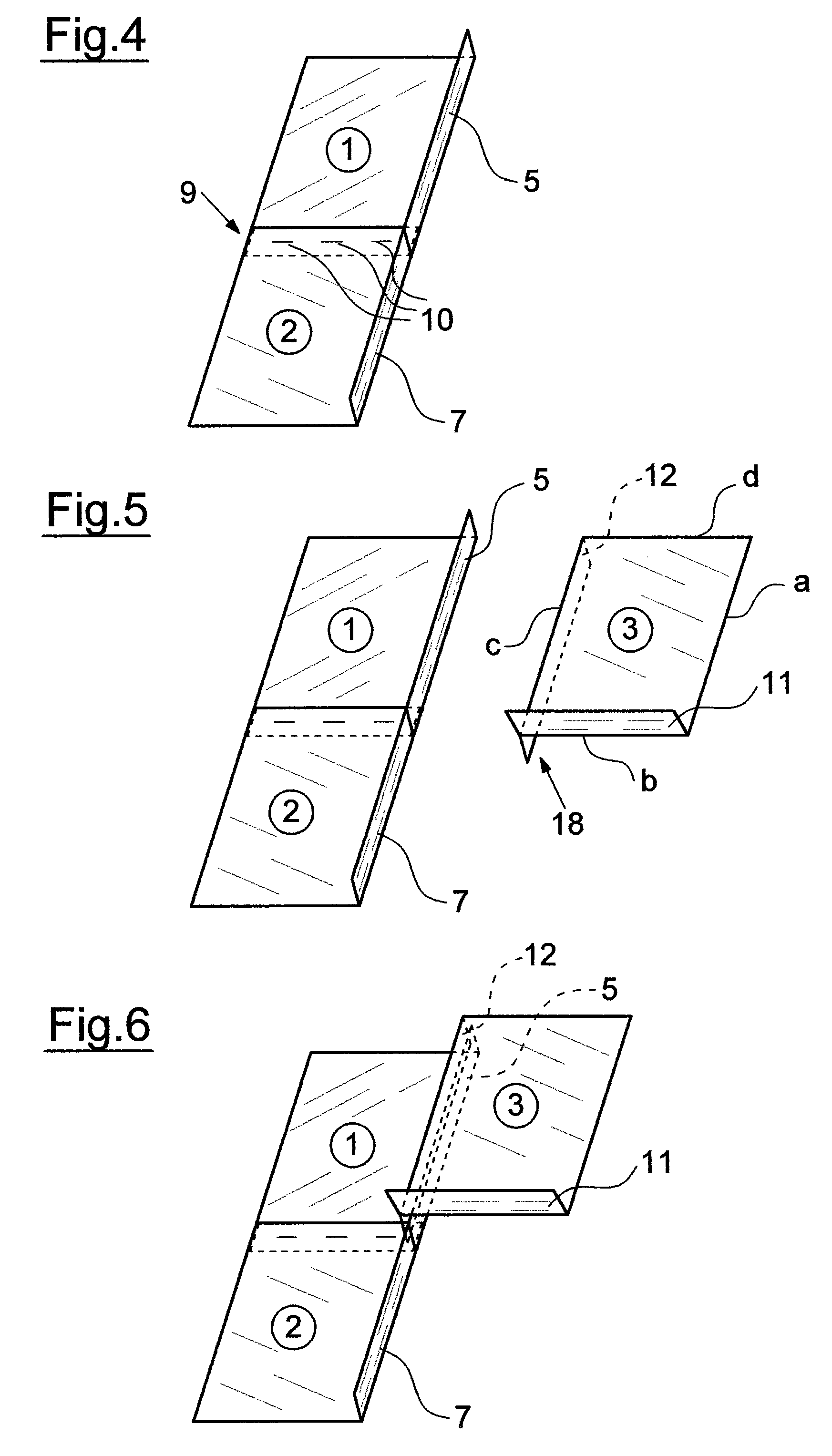

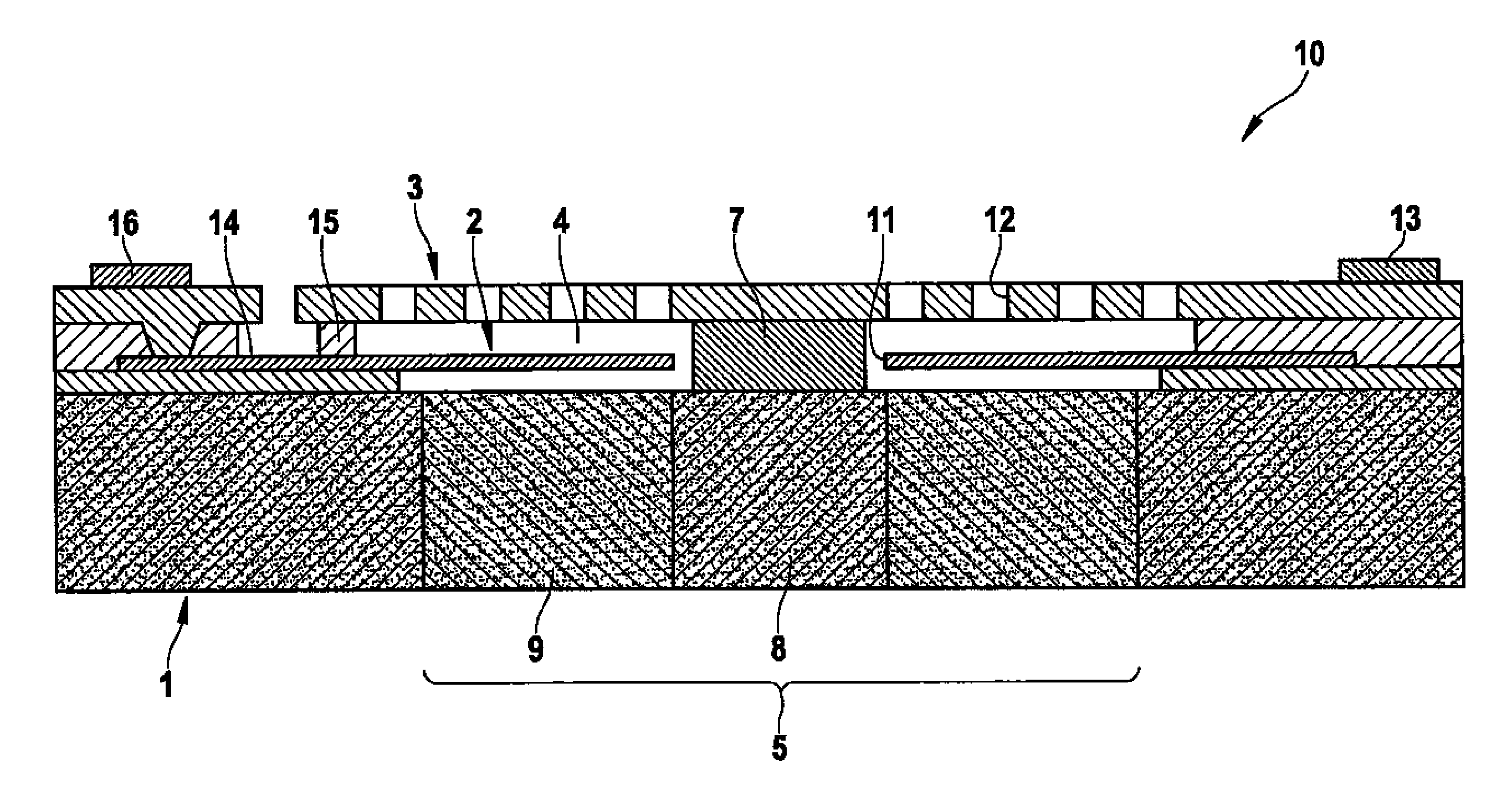

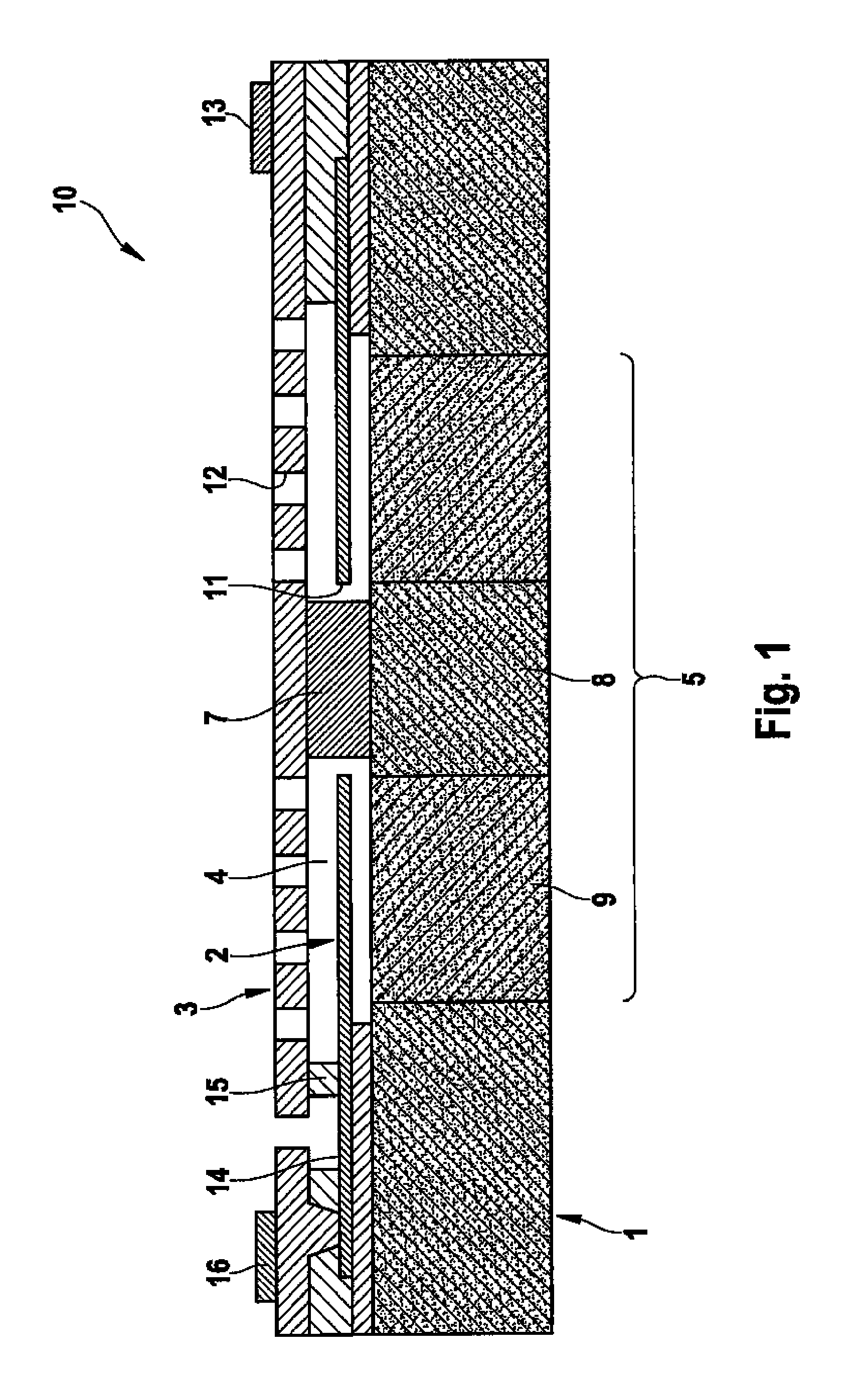

Balanced valve, hydraulic cylinder expansion control loop and crane

ActiveCN102562699AImprove control effectReduced dampingServomotor componentsHydraulic cylinderControl manner

The invention provides balanced valve which comprises a main valve body (1) and a main valve core (4), wherein the main valve body (1) is provided with a positive oil outlet (A) and a reverse oil outlet (B); the main valve core (4) comprises a first acting surface (A1) and a second acting surface (A2) which are opposite to each other; the first acting surface is exposed in a first acting cavity (3) communicated with the reverse oil outlet; the second acting surface is exposed in a second acting cavity (17) communicated with the reverse oil outlet through a dumping groove (5); and the balanced valve further comprises a guiding control module which enables the second acting cavity to be selectively communicated with an oil draining port through a guiding control oil port (X). In addition, the invention also provides a hydraulic cylinder expansion control loop and a hydraulic crane. Due to the guiding control method, a large control ratio can be obtained through controlling the size of a guiding piston rod, the descending speed limitation control of the balanced valve is more sensitive, the influence of the load pressure on the openness of the main valve core is slight, frequent shaking can not be generated, the work stability is good, and the energy-saving effect is excellent.

Owner:ZOOMLION HEAVY IND CO LTD

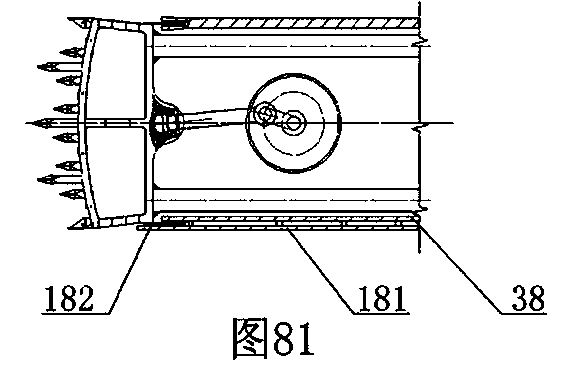

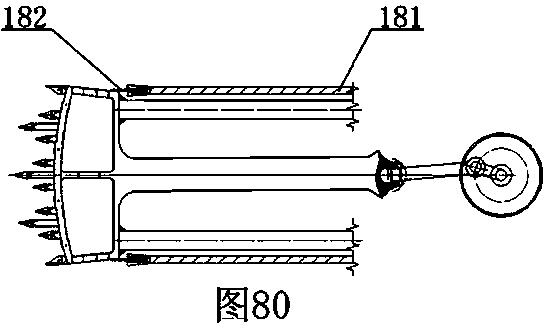

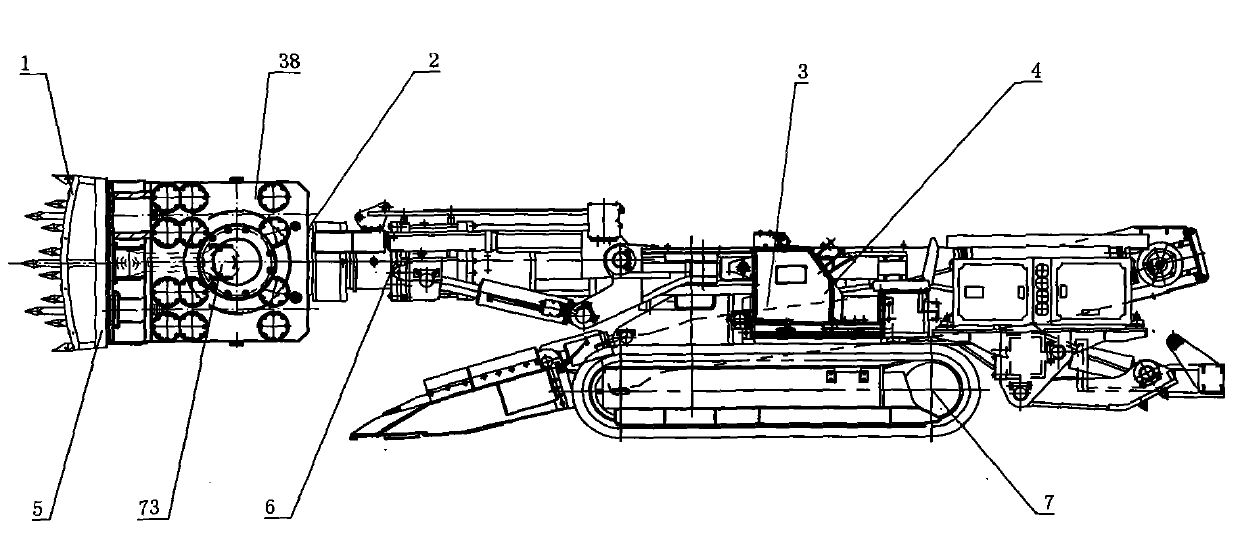

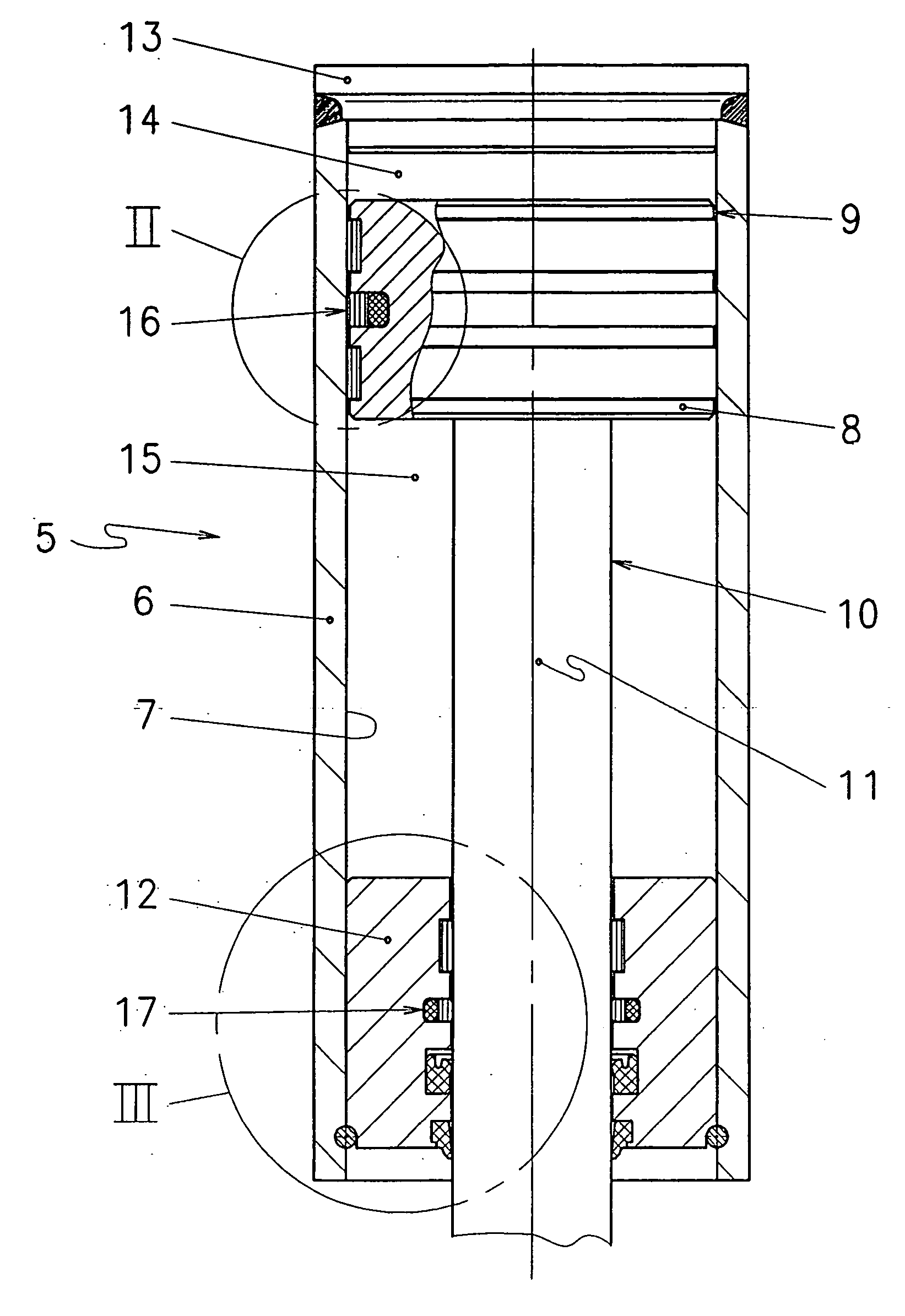

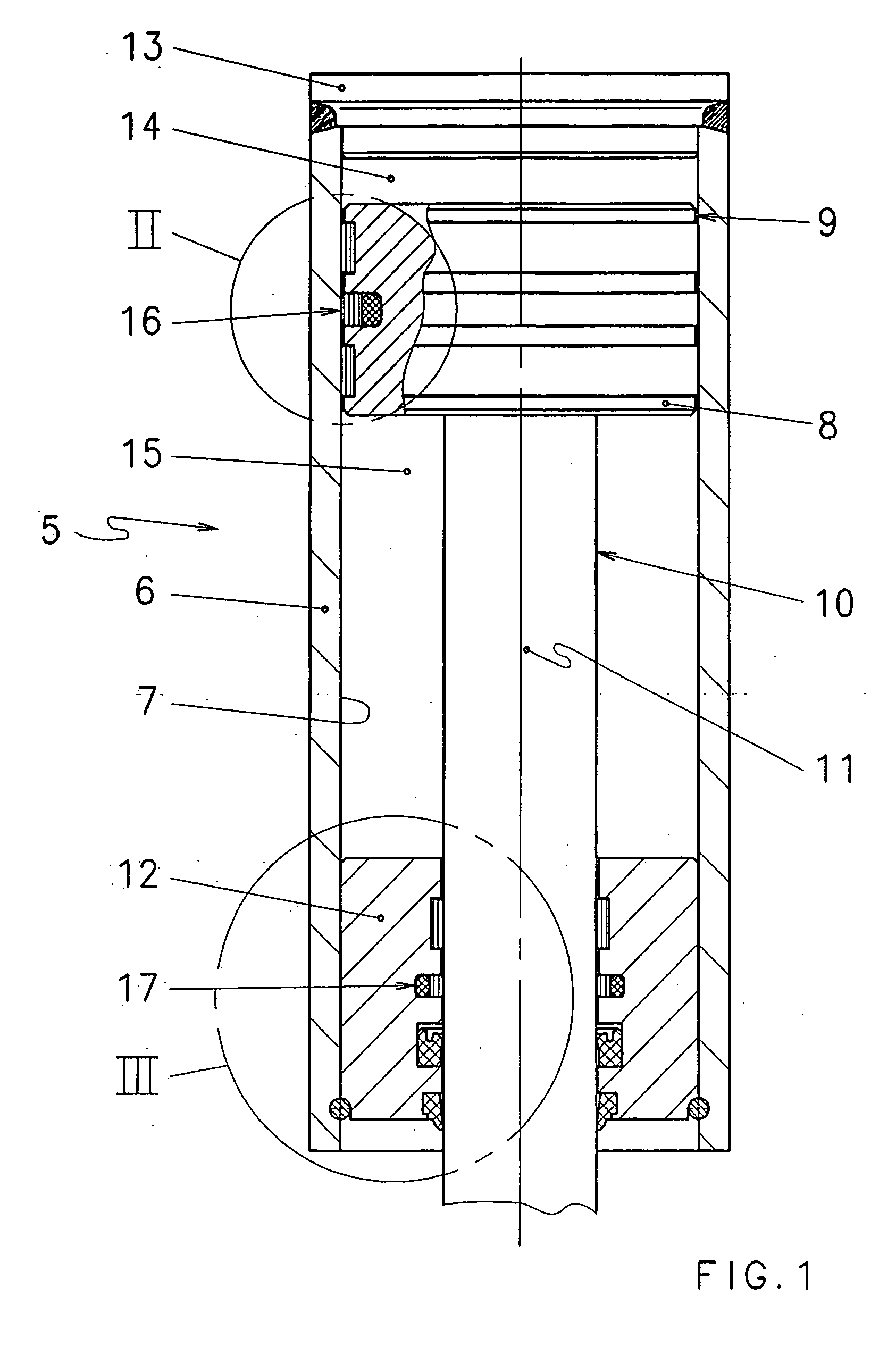

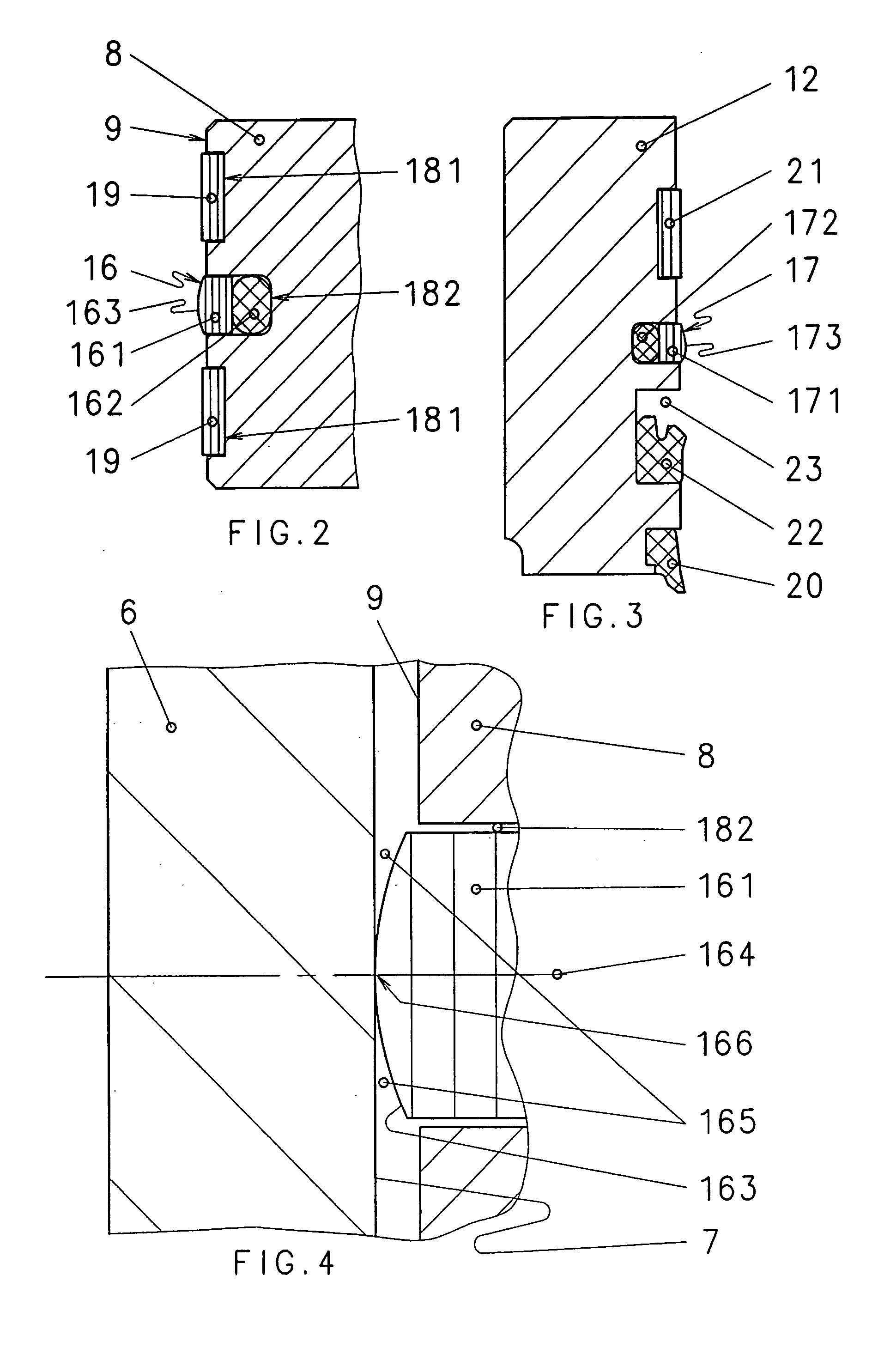

Method and apparatus for converting rotary motion into reciprocating impact motion

ActiveCN103498673APass smoothlySmooth nestingDriving meansPercussion drillingDrive shaftReciprocating motion

A method and device for converting rotary motion to reciprocating percussion motion. The device comprises a machine body (4), a travel portion (7), and a reciprocating percussion portion (5). The reciprocating percussion portion (5) comprises a percussion drive mechanism (2), a rocker arm (6), and a percussion head (1). The percussion drive mechanism (2) comprises a percussion power source member (11), a transmission component, and a crankshaft (10). The percussion power source member (11) comprises a motor, and the motor comprises a power output shaft (14). The transmission component comprises a power gear (13) and a transmission gear (12). The power gear (13) is mounted on the power output shaft (14). The transmission gear (12) drives the crankshaft (10). The transmission component comprises a transmission shaft. The power output shaft (14) is perpendicular to the rocker arm (6), and is parallel to the transmission shaft and the crankshaft (10) so that the transmission gear (12) drives the crankshaft (10) to convert rotary motion to reciprocating motion; or the power output shaft (14) is parallel to the rocker arm (6), the crankshaft (10) is driven to convert rotary motion to reciprocating motion after the power direction is changed by a power bevel gear and a transmission bevel gear. The crankshaft (10) drives the percussion head (1) to perform reciprocating percussion. The travel portion (7) drives the machine body to travel. The machine body (4) drives the reciprocating percussion portion (5) to move and work continuously. The device applies to the mining field or mechanical engineering field, and has advantages such as strong structural strength and a small amount of maintenance.

Owner:刘素华

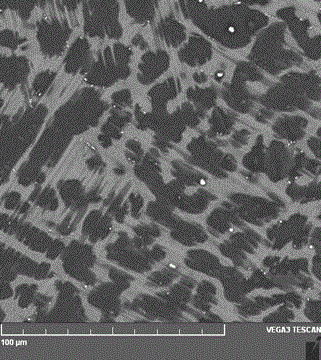

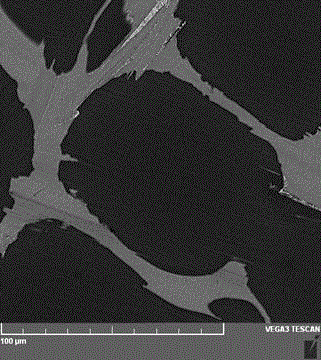

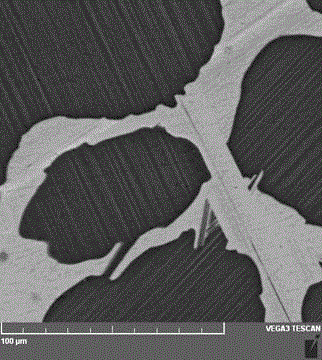

High-damping Mg-Zn-Y alloy and preparation technique thereof

The invention discloses a high-damping Mg-Zn-Y alloy containing rare-earth yttrium and a manufacturing method thereof. The magnesium alloy is composed of the following components in percentage by weight: 4.0-4.8% of Y, 6.6-8.9% of Zn, and the balance of magnesium and inevitable impurities. By designing the Zn and Y contents according to the synthesis components, the alloy is mainly a two-phase alloy composed of a magnesium phase and a long-period phase, wherein the long-period phase is an effective strengthening phase in the magnesium alloy and is beneficial to the damping capacity of the alloy. The alloy composition control and smelting techniques are adopted to control the grain size and long-period phase (LPSO) distribution in the alloy, thereby greatly enhancing the damping capacity of the alloy, ensuring the alloy strength and implementing the balanced optimization of damping and mechanical properties of the magnesium alloy. The technique is simple and easy to operate, has the advantages of high transferability and lower cost, and can be used for aerospace, track traffic and textile technology to achieve the effects of damping and noise reduction.

Owner:CHONGQING UNIV

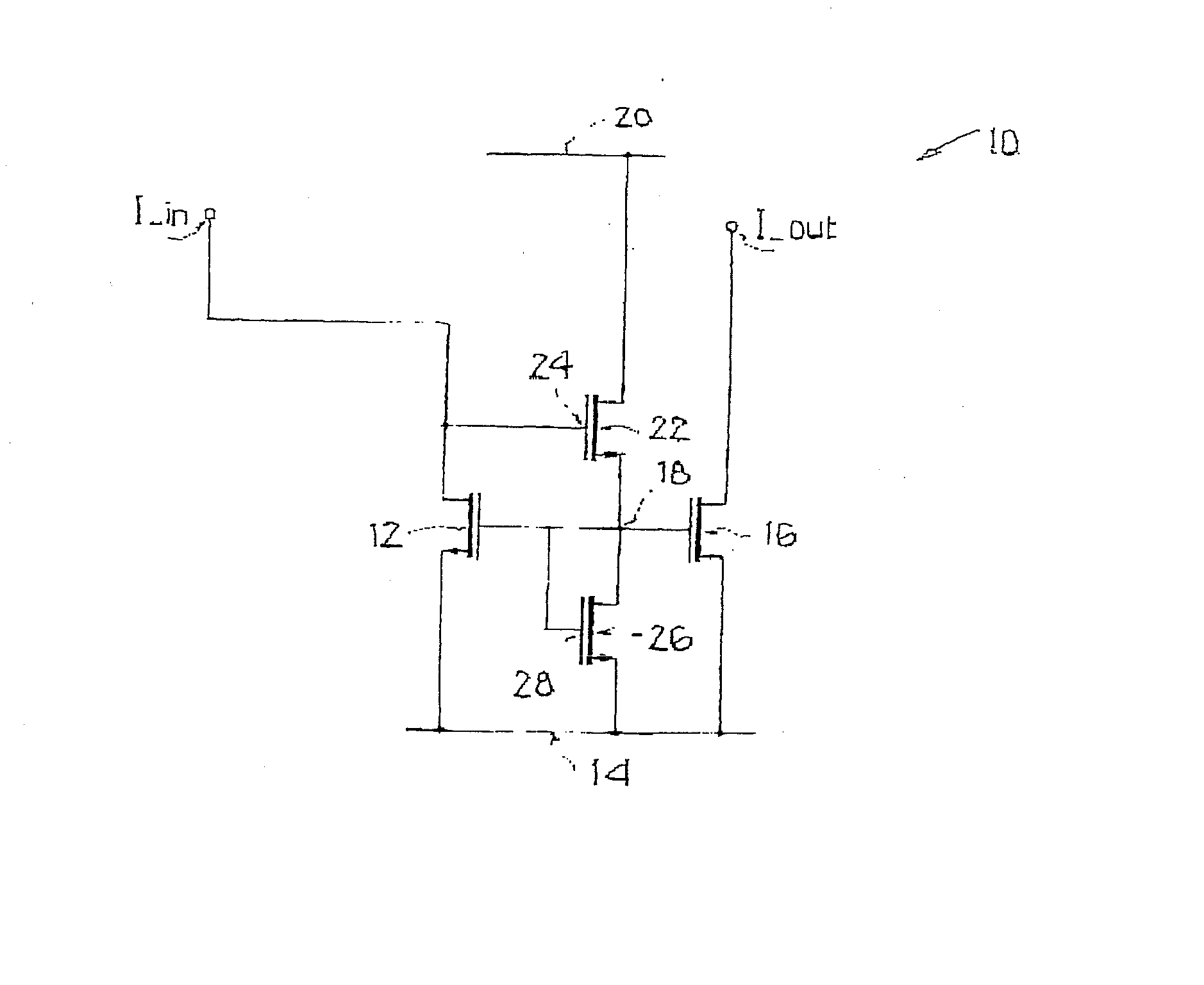

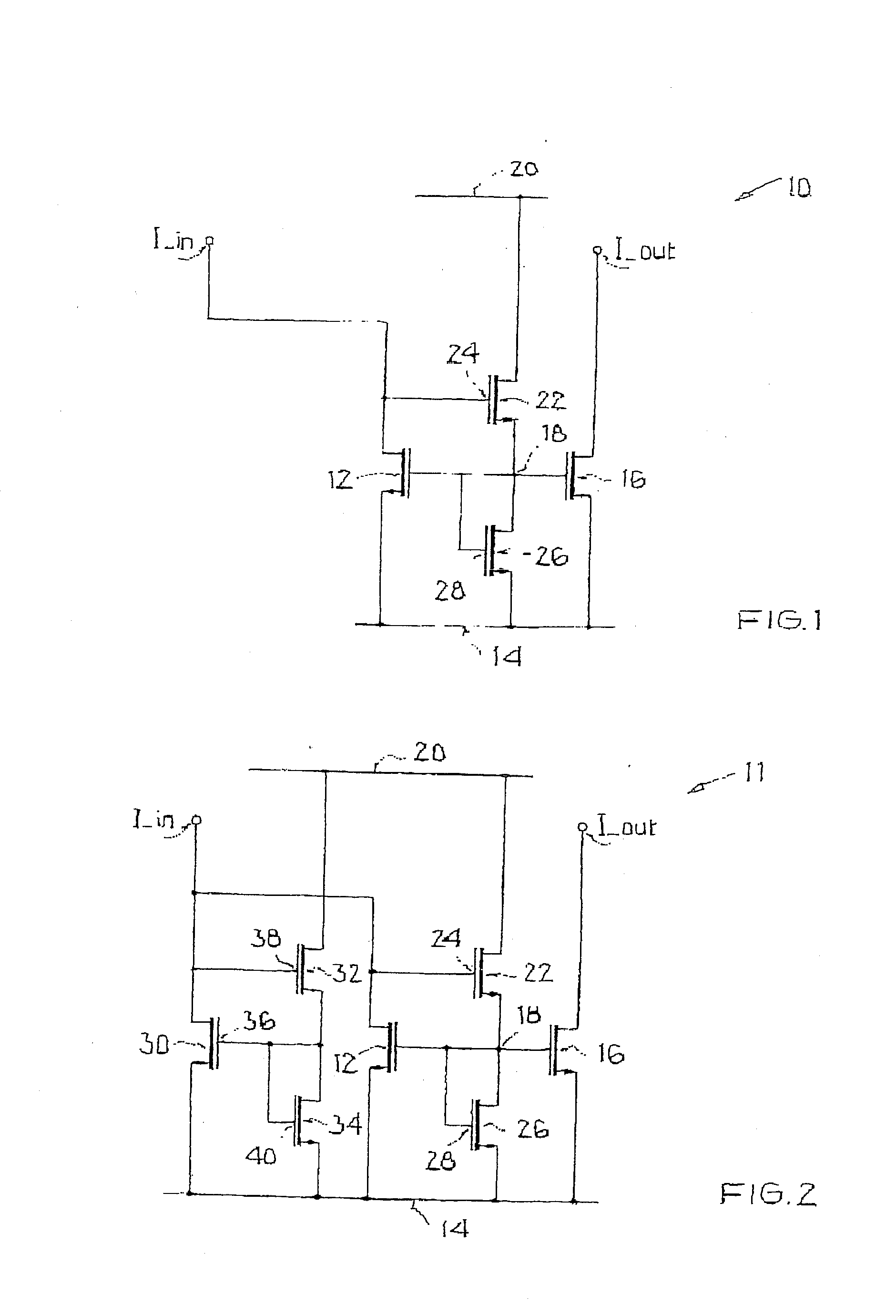

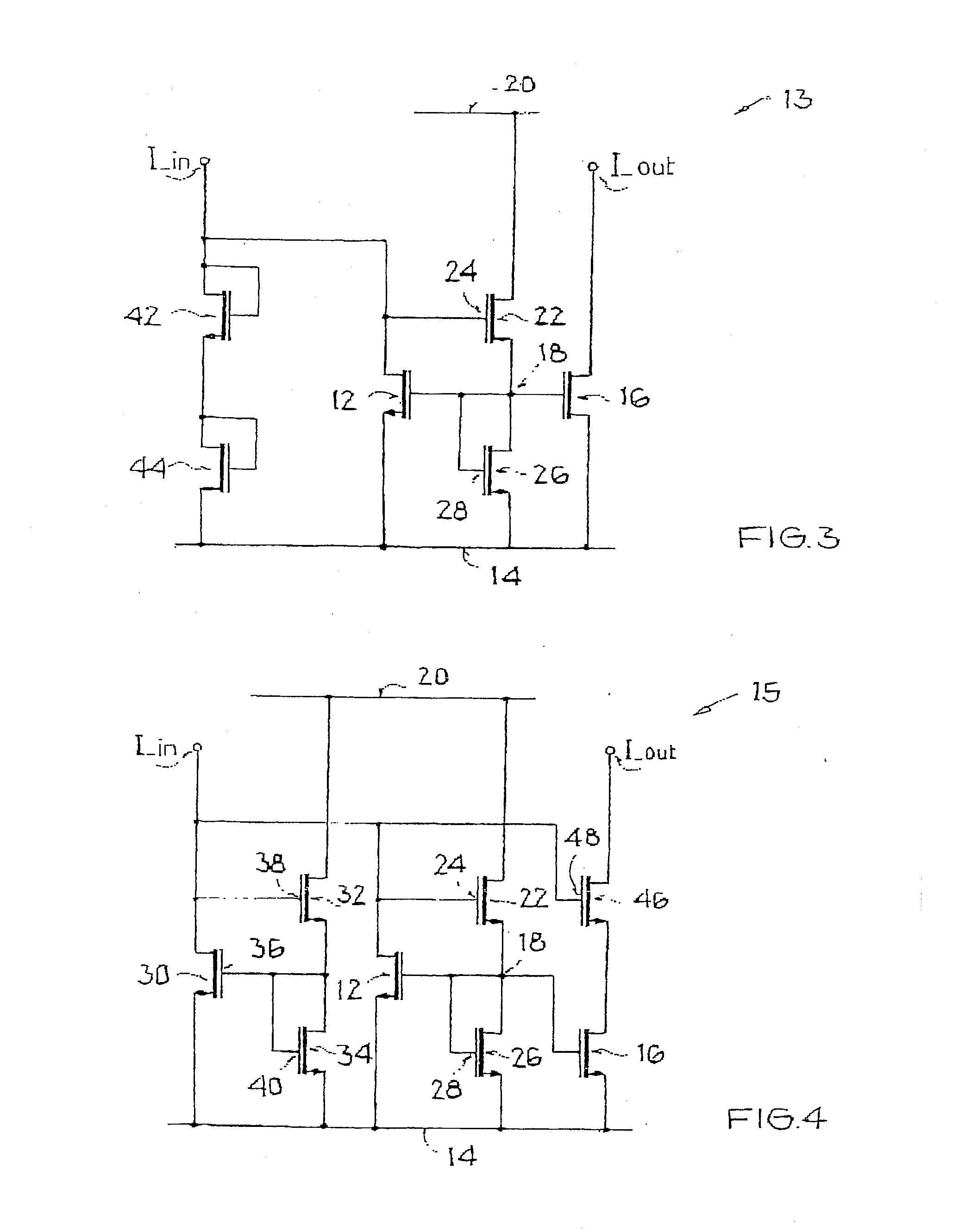

High-speed CMOS current mirror

ActiveUS20070285171A1Fast chargingShort rise timeElectric variable regulationAmplifiers with semiconductor devices onlyCMOSElectrical resistivity and conductivity

A CMOS current mirror is provided that includes a current input, an input transistor, whose conductivity path is located between the current input and a reference potential terminal, a current output, an output transistor, whose conductivity path is connected to the reference potential terminal and which supplies the current output with an output current, a gate node common for both transistors, and a supply potential terminal. The current mirror further includes a first additional transistor, whose conductivity path is located between the supply potential terminal and the gate node and whose gate terminal is connected to the current input, and a second additional transistor, whose conductivity path is located between the gate node and the reference potential terminal and whose gate terminal is connected to the gate node.

Owner:ATMEL CORP

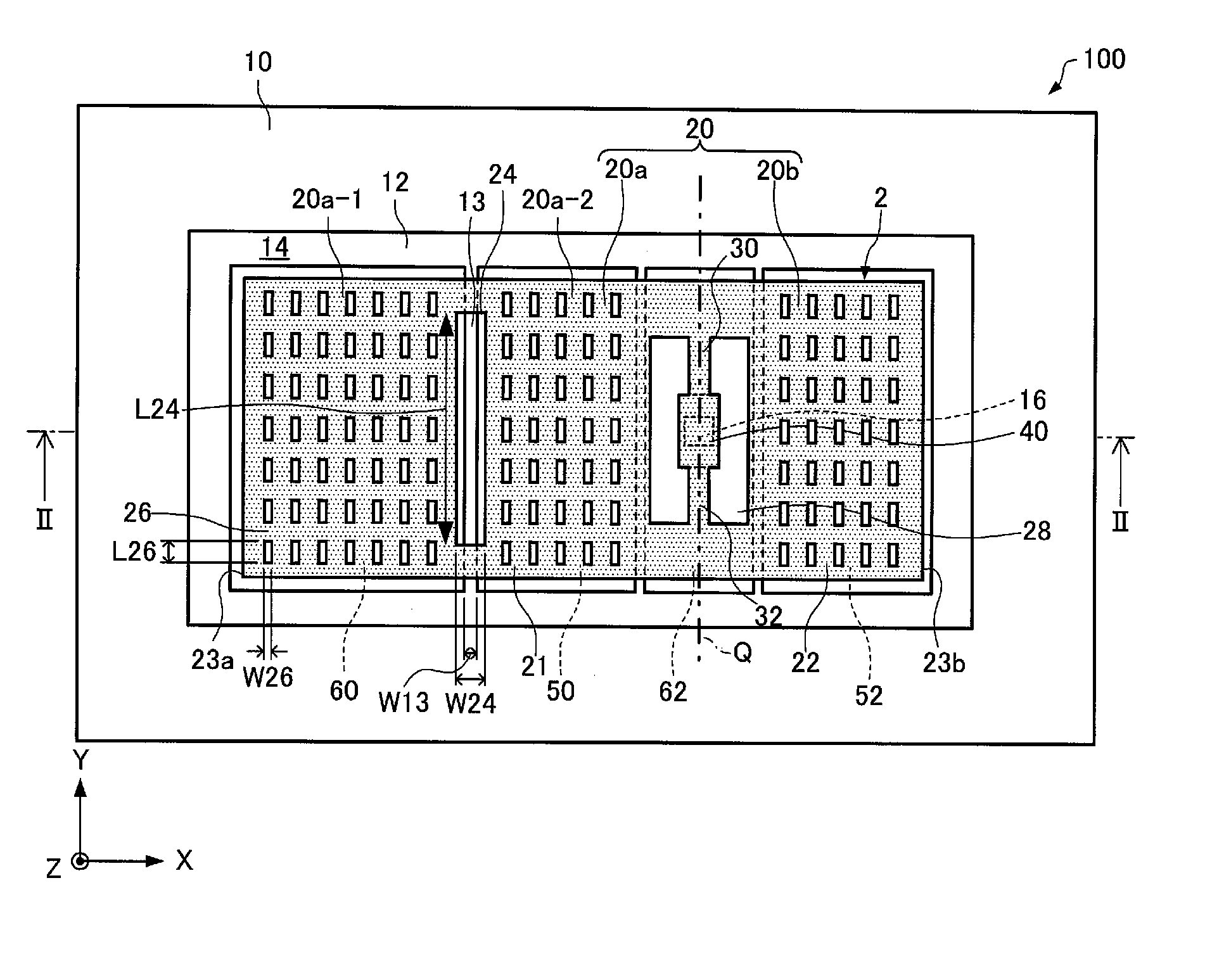

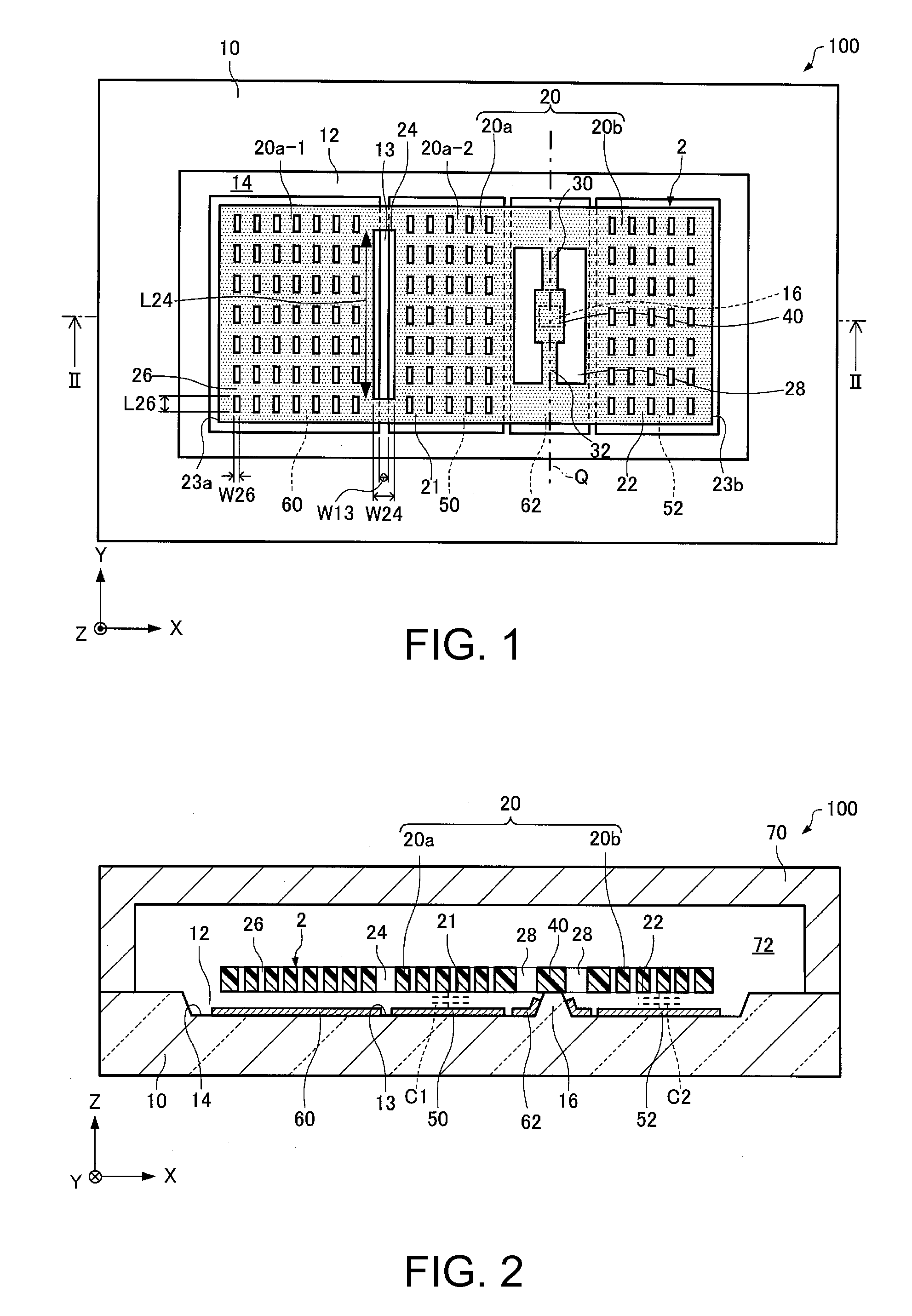

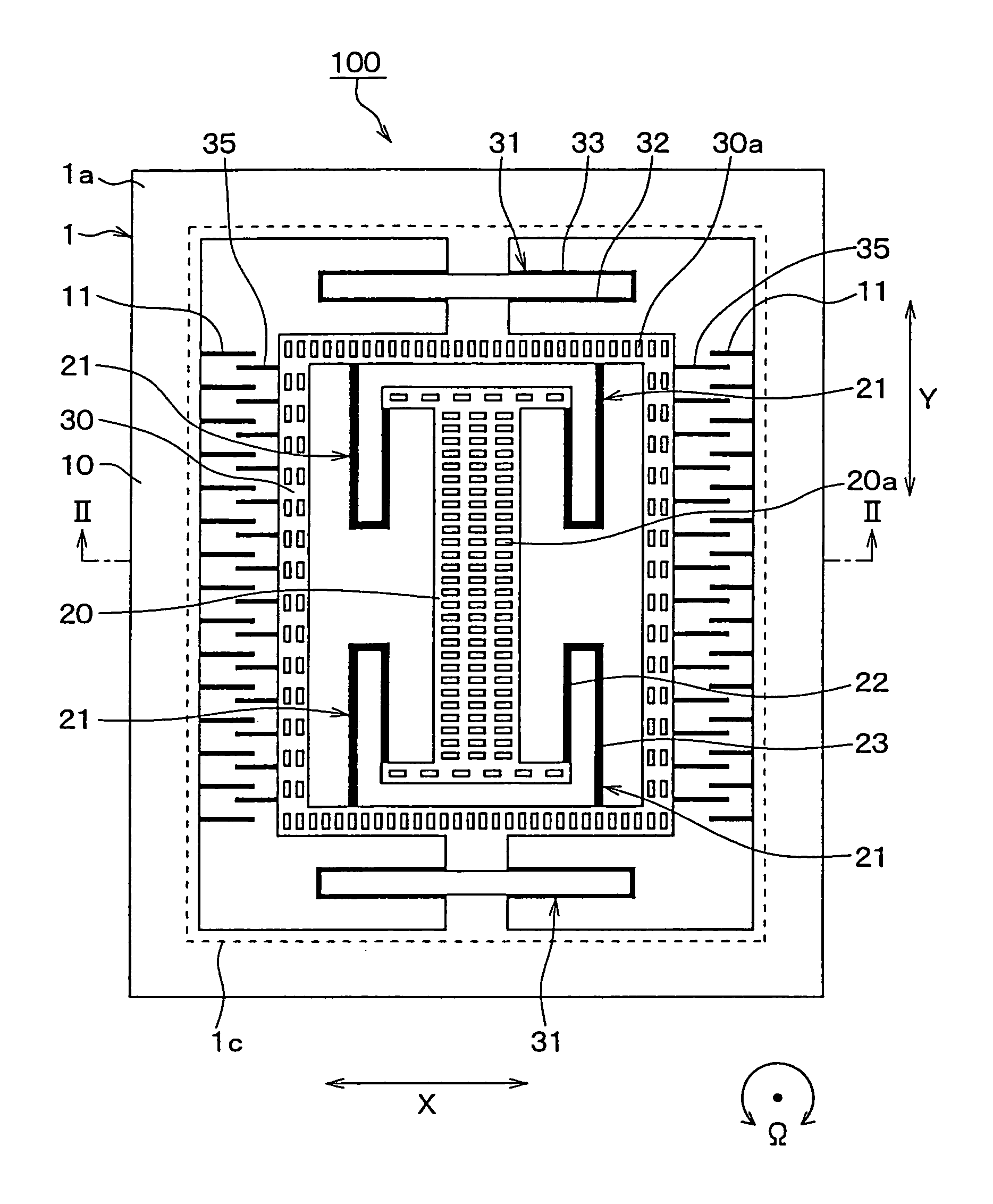

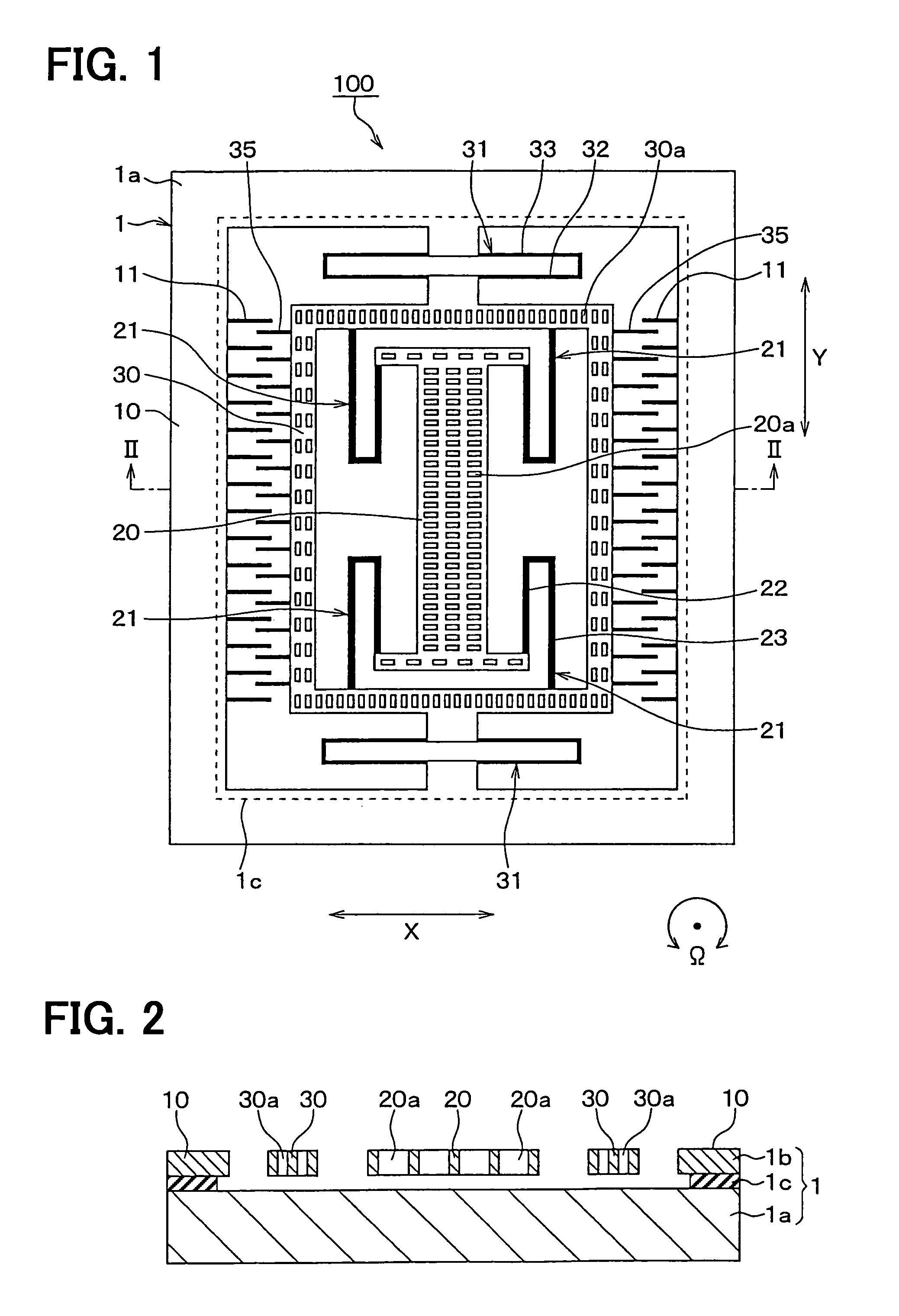

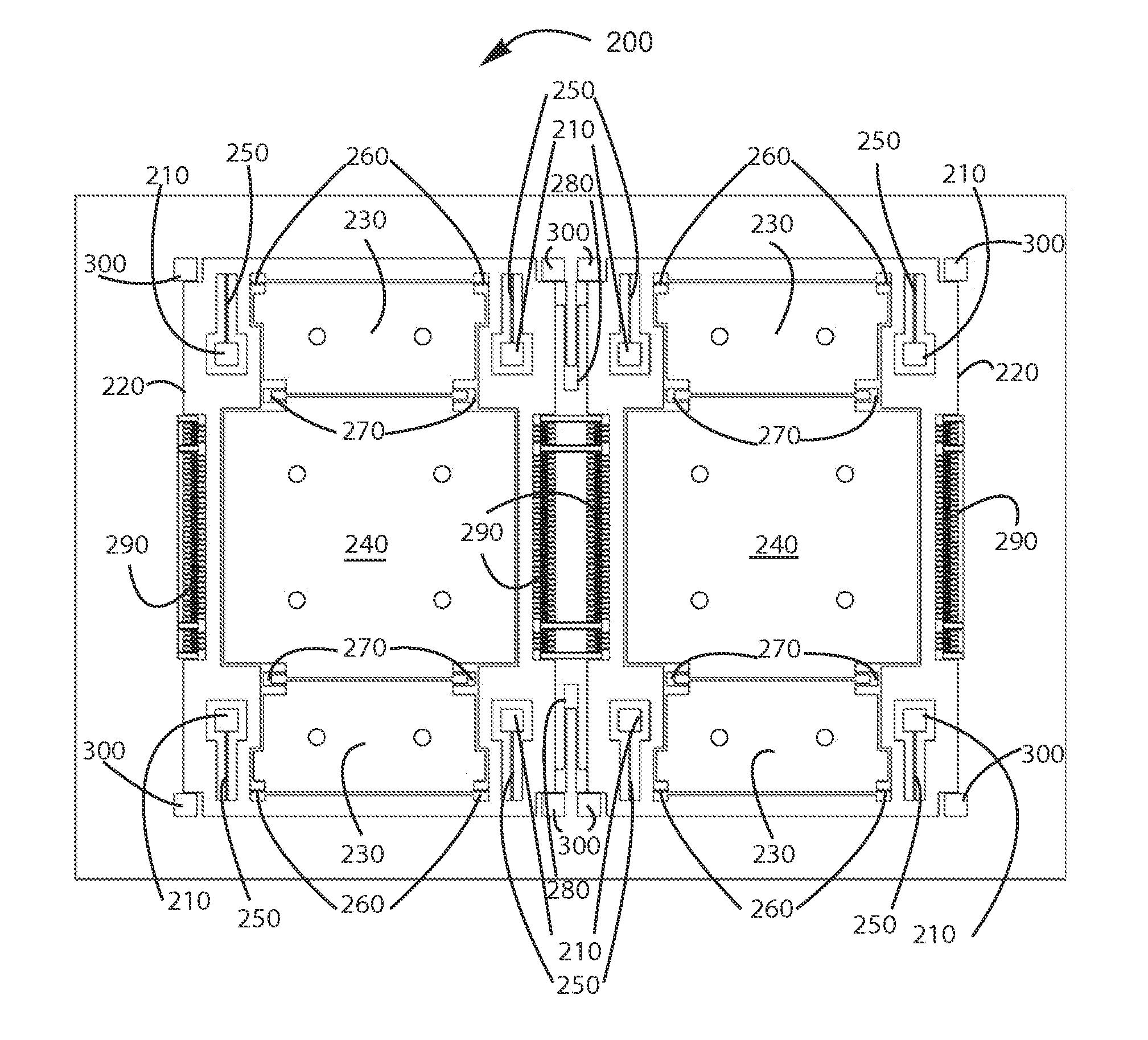

Functional element, electronic apparatus, and moving object

ActiveUS20150241466A1Improve reliabilityReduce adhesionAcceleration measurementPiezoelectric/electrostrictive devicesEngineeringElectrode

A functional element includes: a substrate; a movable body that includes a movable electrode portion; a support portion that supports the movable body; a first fixed electrode portion that is disposed on the substrate and a portion of which faces a first portion as one of portions of the movable body; a second fixed electrode portion that is disposed on the substrate and a portion of which faces a second portion as the other portion of the movable body; and a third fixed electrode portion that is disposed on the substrate and a portion of which faces the first portion. An opening that faces a region of the substrate between the first fixed electrode portion and the third fixed electrode portion is provided in the movable body, and the width of the opening is equal to or more than the width of the region.

Owner:SEIKO EPSON CORP

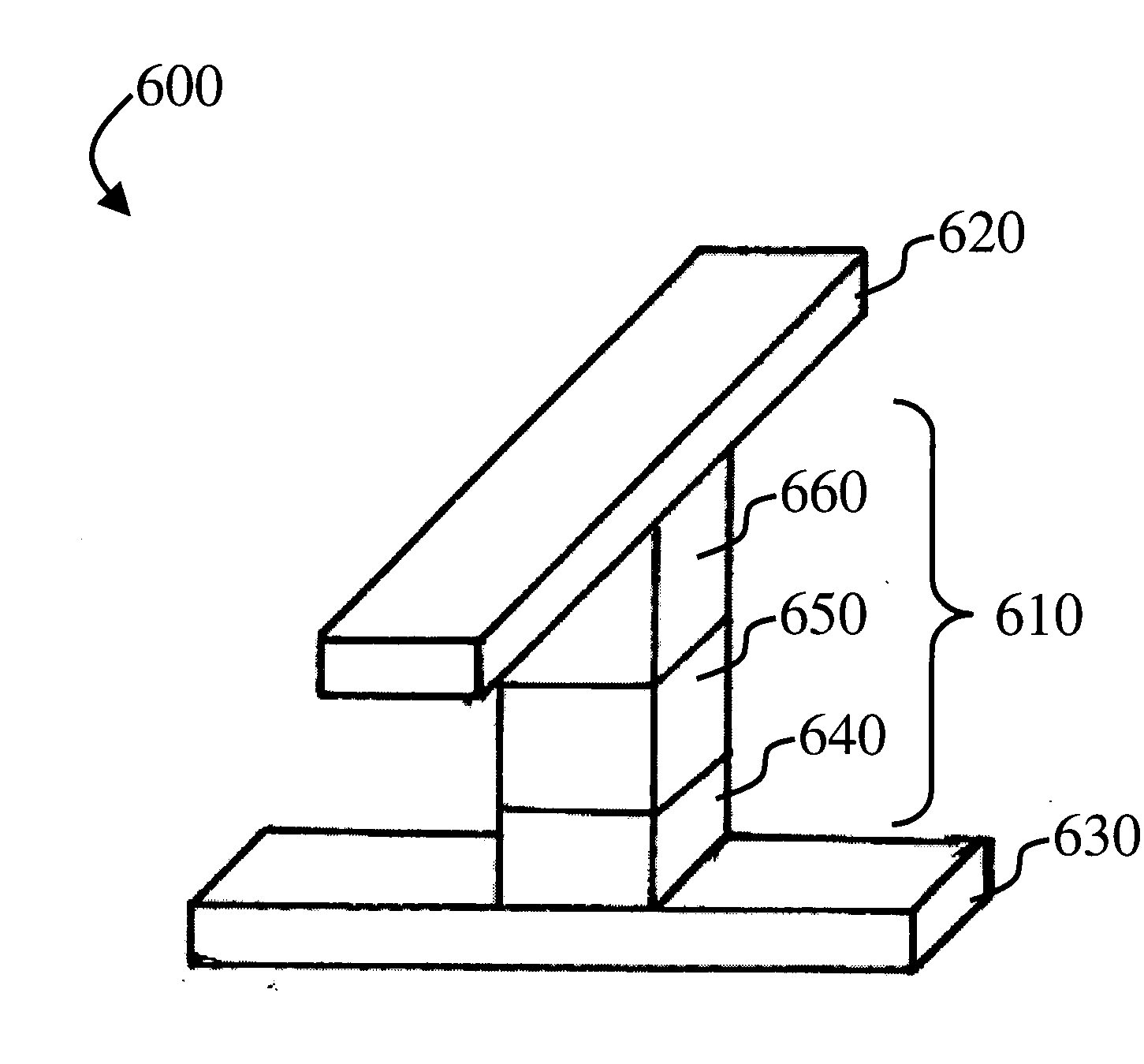

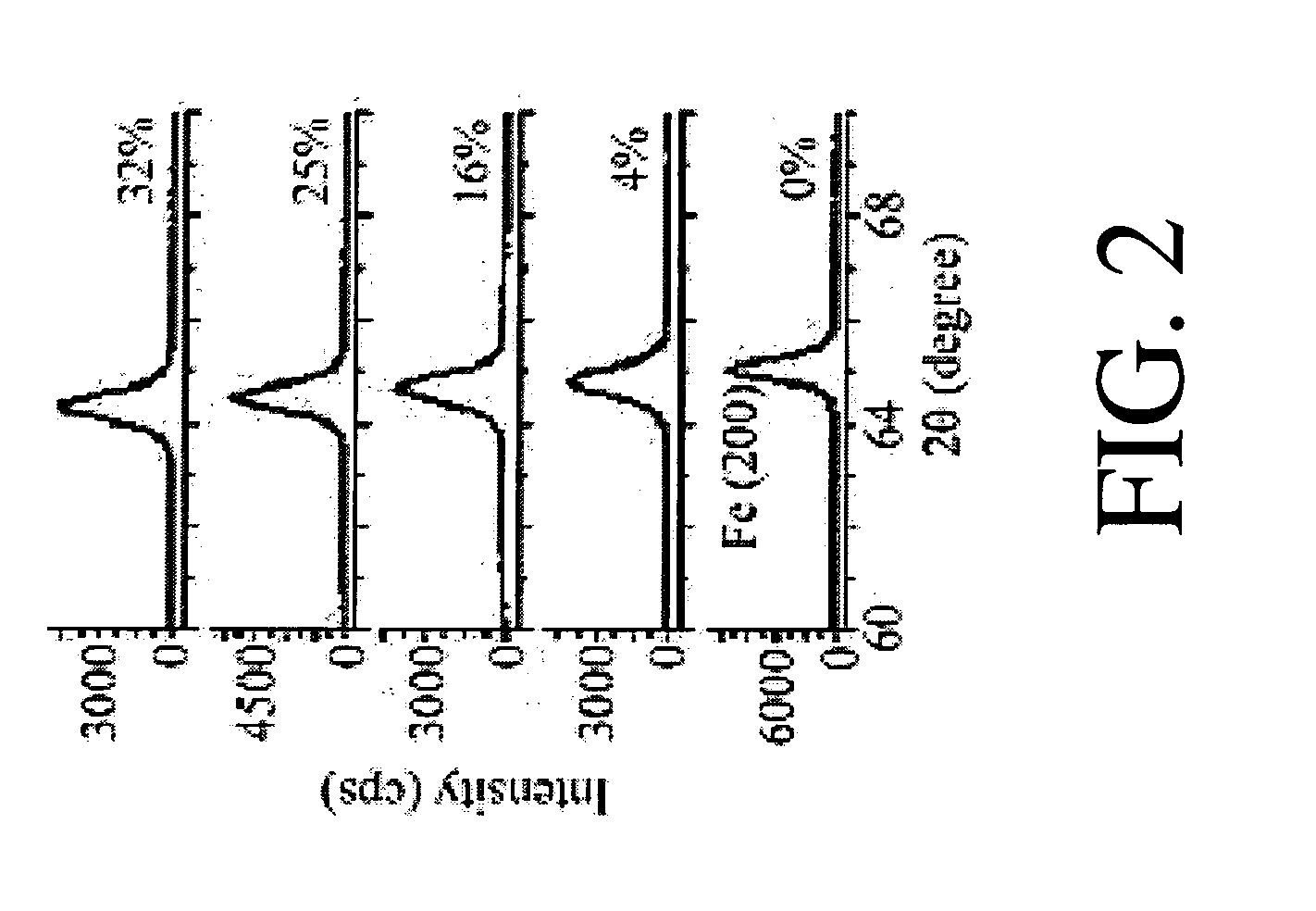

Methods of manipulating the relaxation rate in magnetic materials and devices for using the same

InactiveUS20070242395A1Reduced dampingLow intrinsic damping rateNanomagnetismImpedence networksManganeseThin membrane

In accordance with the present invention, ferromagnetic thin films of iron that have reduced relaxation rates and methods of making the same are provided. It should be noted that pure iron is a ferromagnet (i.e., has a spontaneous magnetization alignment) with the lowest intrinsic damping rate of all of the ferromagnets. The present invention provides a ferromagnetic structure comprising a substrate and a ferromagnetic thin film of iron (Fe) formed on the substrate. An element selected from the group consisting of titanium (Ti), vanadium (V), chromium (Cr), and manganese (Mn) (i.e., a lower-Z transition metal element) is alloyed with the ferromagnetic thin film of iron to reduce the relaxation rate of the ferromagnetic thin film.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

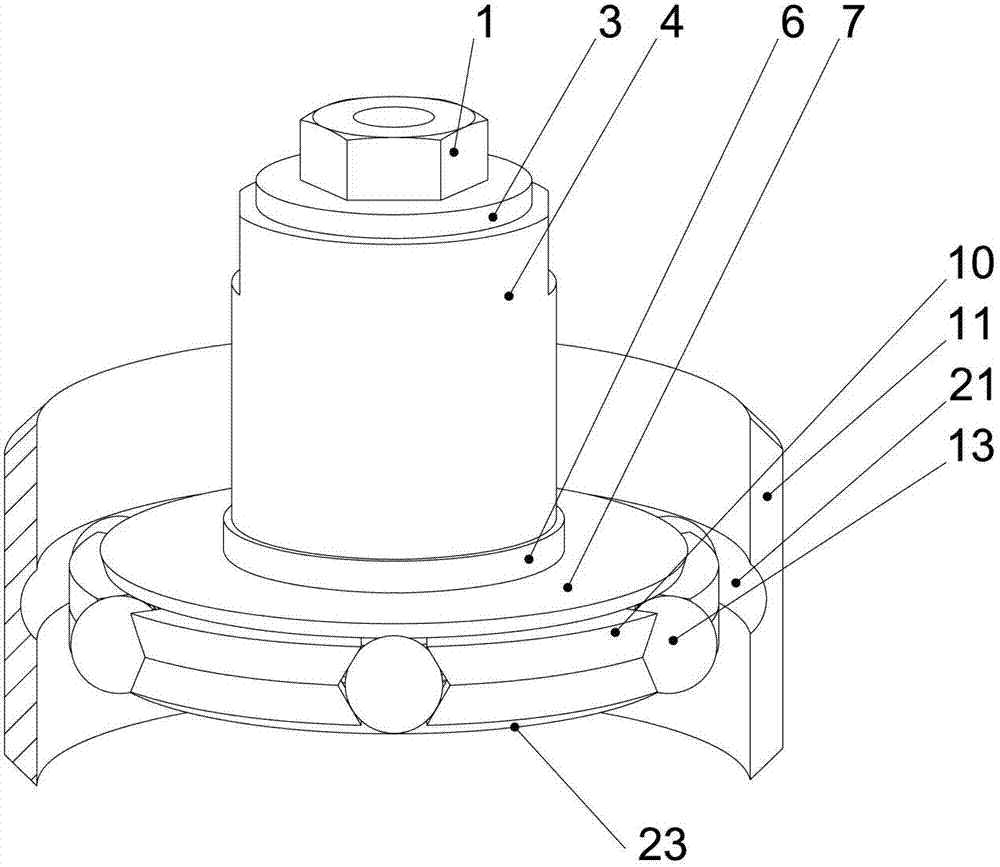

Lock bead type vibration isolation bumper without harmonic peaks in three directions

InactiveCN103161865AImprove high-frequency vibration isolation capability without resonance peakExtend your lifeShock absorbersFriction dampersEngineeringHigh frequency

The invention discloses a lock bead type vibration isolation bumper without harmonic peaks in three directions. The lock bead type vibration isolation bumper without the harmonic peaks in the three directions comprises an outer shell, a top cap, a spring nut, a vibration isolation spring and a ball locking-up mechanism. The lock bead type vibration isolation bumper without the harmonic peaks in the three directions adopts the ball locking-up mechanism, is matched with a locking force adjusting component, an equilibrium position adjusting component and a buffering component, and achieves the purpose of buffering in the three directions of a vibration isolator, vibration isolation without harmonic peaks in the three directions, adjustment of locking force, and meeting different nominal loads. Due to the fact that rolling friction is adopted to isolate vibration, the damping coefficient of the vibration isolator is reduced, and the abrasion in use is reduced. The vibration isolator of the lock bead type vibration isolation bumper without the harmonic peaks in the three directions is enabled to have the advantages of being long in service life, abrasion-resistant, and stable in performance, have high-efficient and high-frequent vibration isolation capability and the like.

Owner:CHONGQING UNIV

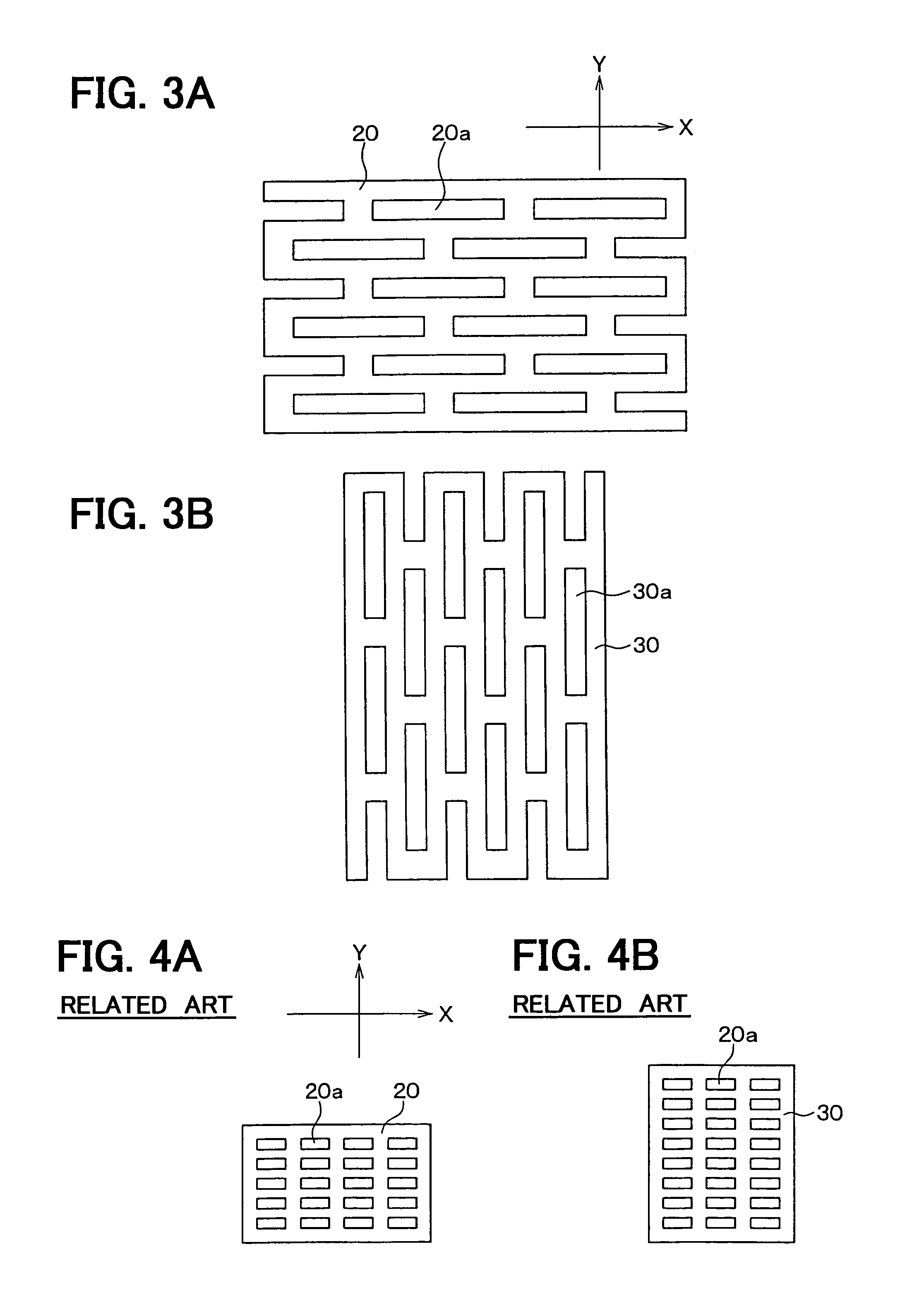

Physical quantity sensor having movable portion

InactiveUS7302847B2Smooth vibrationImprove accuracyAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsAngular rate sensorEngineering

An angular rate sensor includes: a support substrate; a semiconductor layer; and a movable portion. The movable portion includes a driving vibration portion and a detecting vibration portion. The driving vibration portion is capable of vibrating in a first direction. The detecting vibration portion is capable of vibrating in a second direction. The driving vibration portion includes through holes, and the detecting vibration portion includes thorough holes. Each through hole of the driving vibration portion has an elongated shape extending in the first direction. Each through hole of the detecting vibration portion has an elongated shape extending in the second direction.

Owner:NIPPON SOKEN +1

Electromagnetic shielding

ActiveUS7576289B2Reduced dampingReduce conductivityScreening rooms/chambersConductor screwing into otherElectromagnetic shieldingEngineering

An electromagnetic shield is provided for a room or for a building, including overlapping, conductively connected, and electrically conductive mesh or grid sections (1-4). The sections are grounded and folded in the overlapping area, where the folds of adjacent mesh or grid sections (1, 2) interlock like hooks in a cross section view.

Owner:KESSEL WOLFGANG

Acoustic sensor element

ActiveUS20100135123A1Improving transducer characteristicImprove featuresSemiconductor electrostatic transducersElectrostatic transducer microphonesEngineeringSound pressure

A micromechanical acoustic sensor element, which has at least one diaphragm and at least one fixed counter element, the diaphragm being situated in a cavity between a substrate and the counter element and acting as movable electrode of a capacitor system, the counter element acting as first fixed counter electrode of this capacitor system, and at least one through hole being formed in the substrate for the application of sound pressure to the diaphragm. For fixation and strengthening purposes, the counter element is connected to the substrate via at least one support element. The support element is situated in the region of the cavity, and an opening is formed in the diaphragm for the support element.

Owner:ROBERT BOSCH GMBH

Memory system having thermally stable perpendicular magneto tunnel junction (MTJ) and a method of manufacturing same

ActiveUS20130119498A1Increase stiffnessReduced dampingMagnetic-field-controlled resistorsGalvano-magnetic device detailsRandom access memoryMagneto

A spin-torque transfer magnetic random access memory (STTMRAM) element employed to store a state based on the magnetic orientation of a free layer, the STTMRAM element is made of a first perpendicular free layer (PFL) including a first perpendicular enhancement layer (PEL). The first PFL is formed on top of a seed layer. The STTMRAM element further includes a barrier layer formed on top of the first PFL and a second perpendicular reference layer (PRL) that has a second PEL, the second PRL is formed on top of the barrier layer. The STTMRAM element further includes a capping layer that is formed on top of the second PRL.

Owner:AVALANCHE TECH

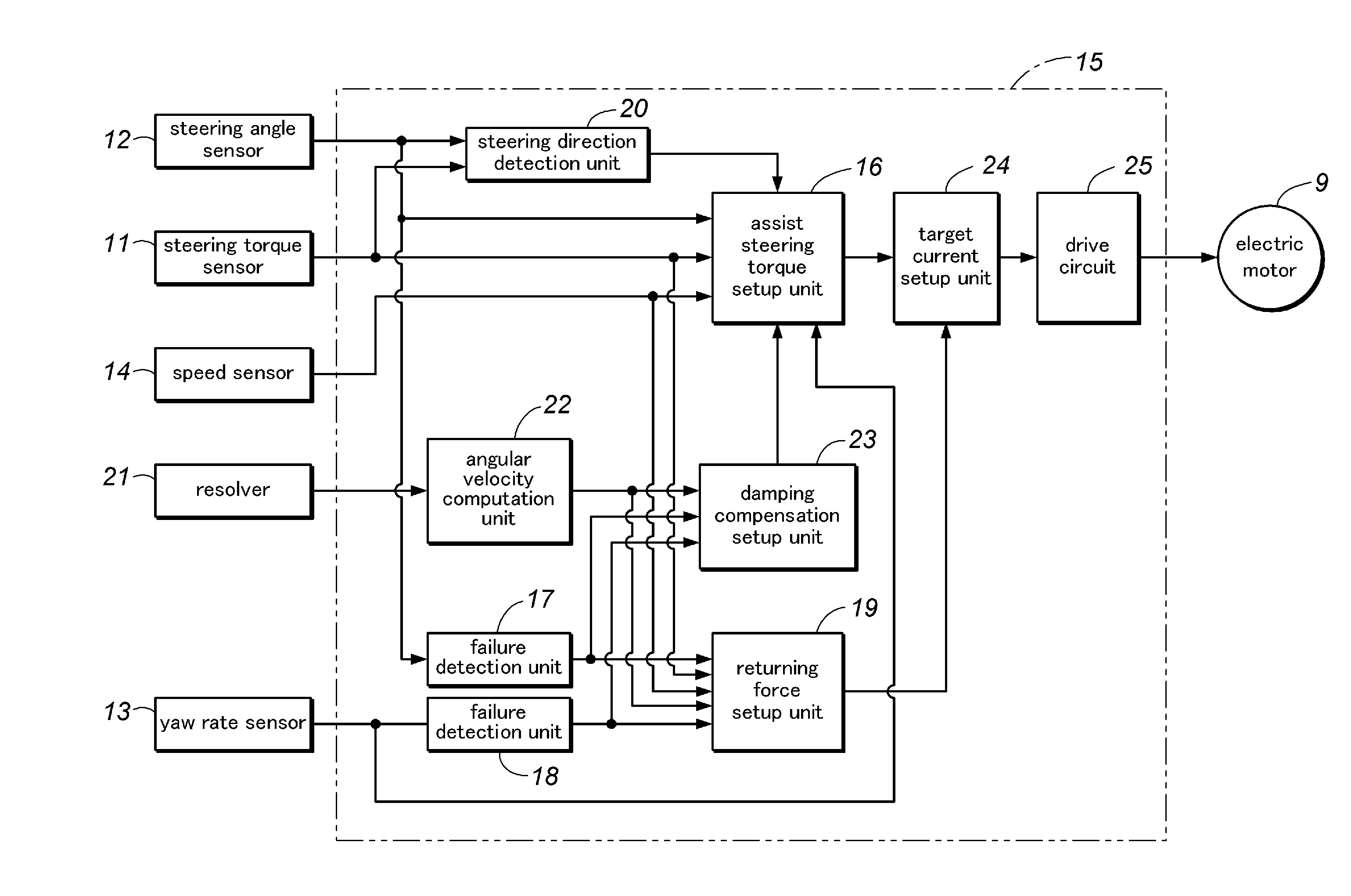

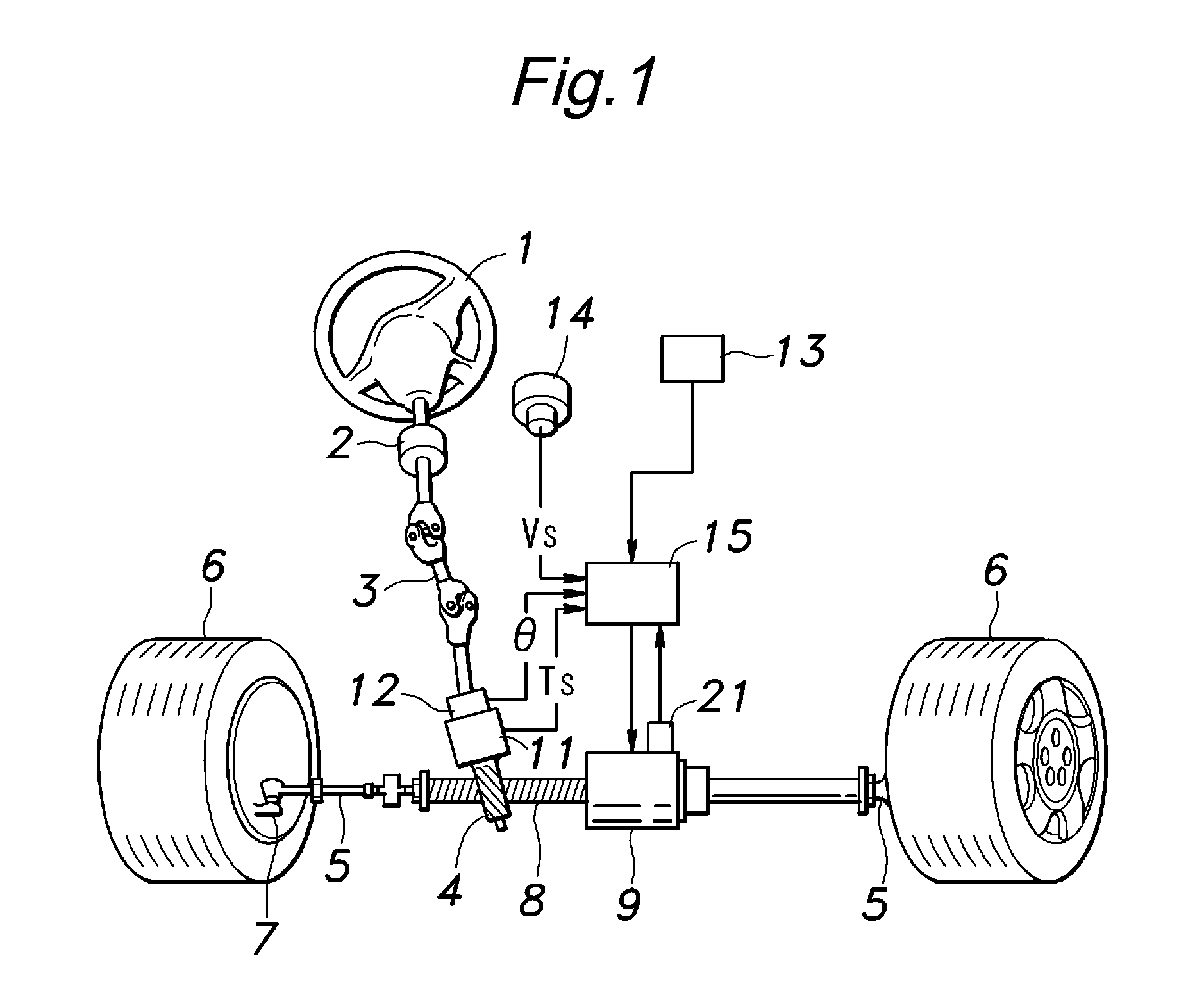

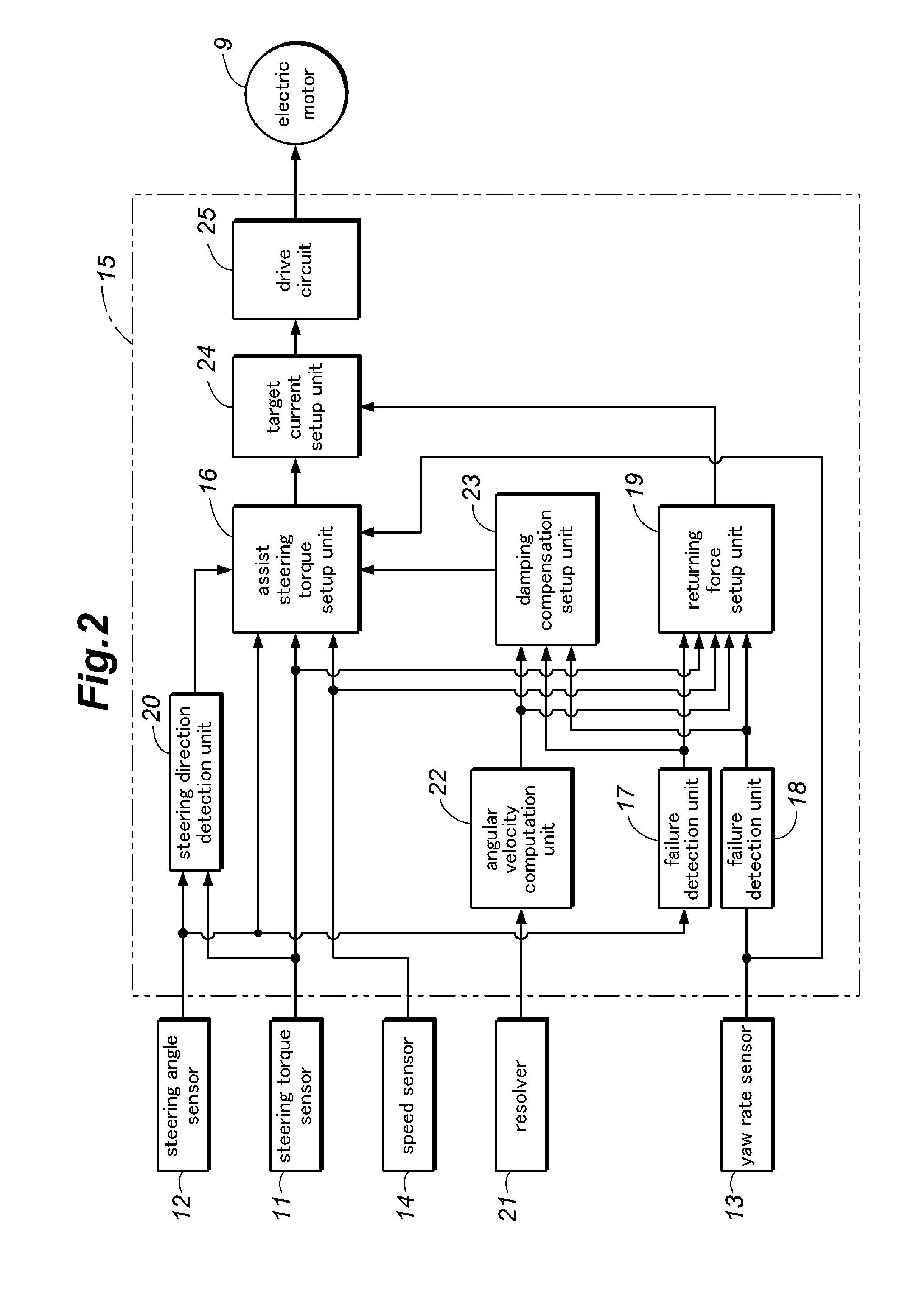

Electric power steering apparatus

InactiveUS20110093164A1Reduce controlDamping controlVehicle testingRegistering/indicating working of vehiclesElectric power steeringSteering wheel

[Object]An electric power steering apparatus capable of returning the steering wheel to a steering wheel neutral position even in case of failure of a steering angle sensor.[Solution] In performing a control action whereby the steering wheel is returned to a neutral position according to the steering angle and yaw rate, the gain of the yaw rate sensor (13) is amplified if a failure in the steering angle sensor (12) is detected, and the damping gain of a damping compensation unit (23) is reduced if failure in at least one of the sensors is detected. Thereby, the steering wheel (1) can return to the neutral position by producing a stronger returning force based on an amplified detection value even if the real yaw rate is small, and the damping component acting on the returning force can be reduced so that the self-aligning torque is enabled to return the steering wheel to the neutral position.

Owner:HONDA MOTOR CO LTD

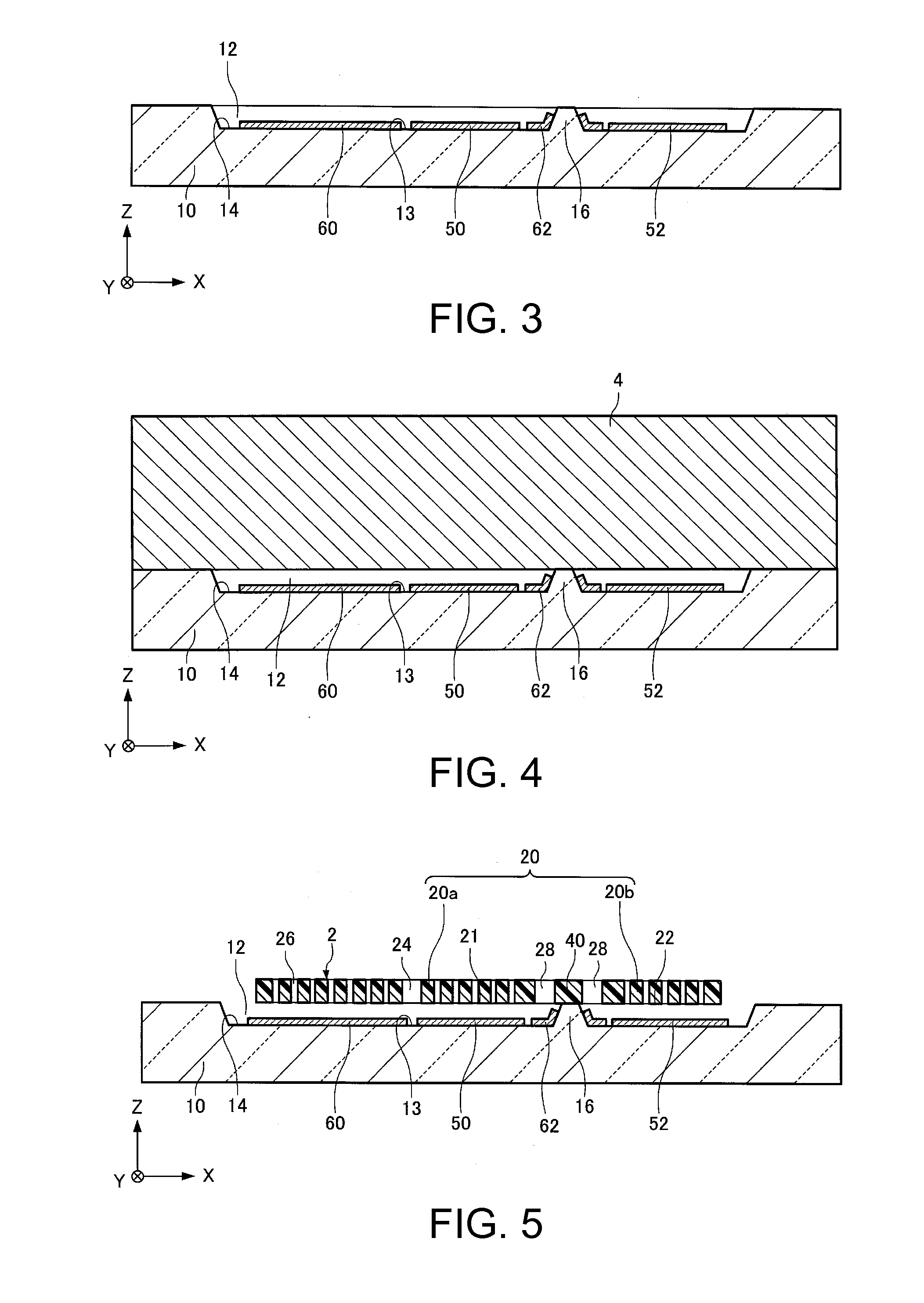

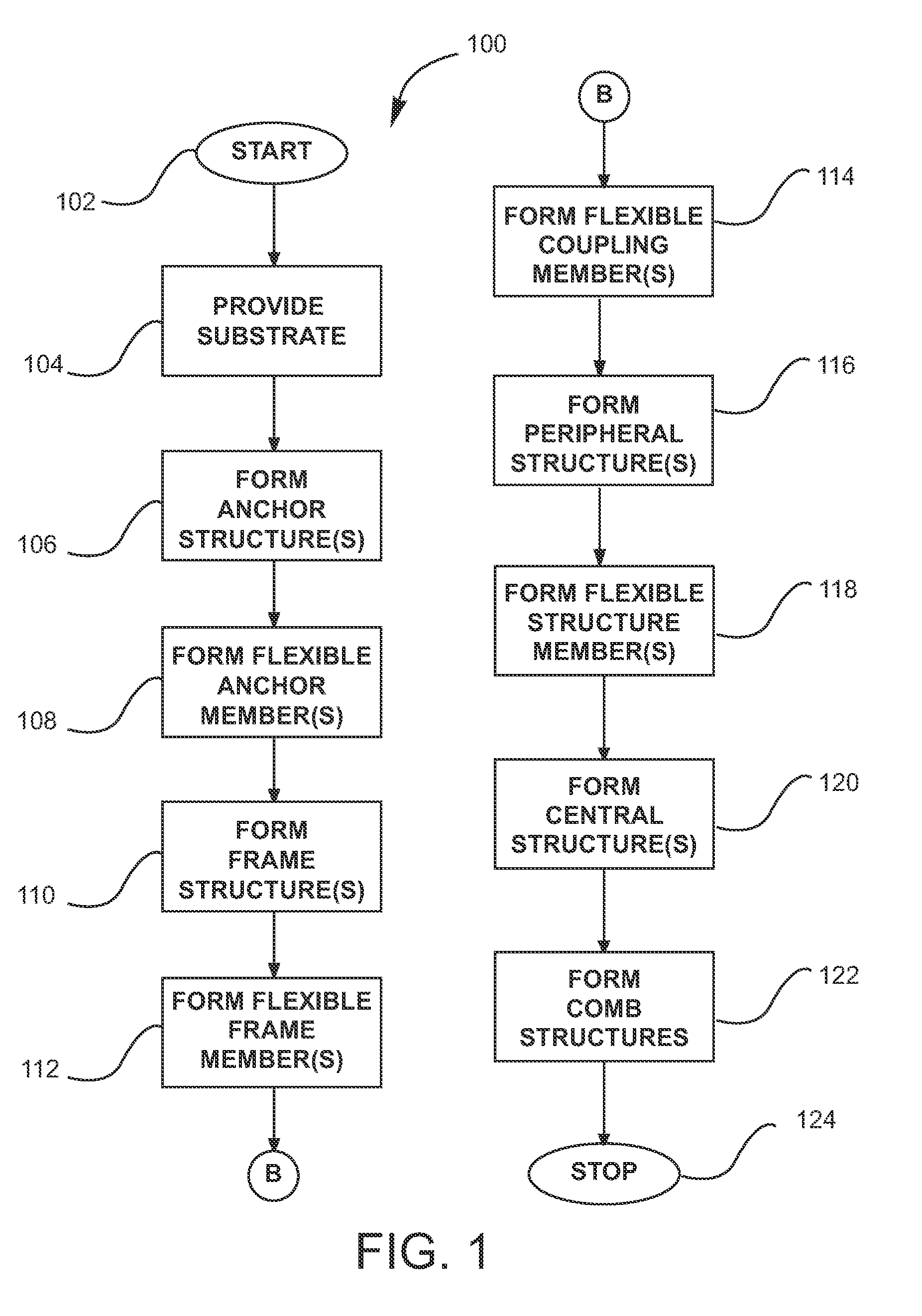

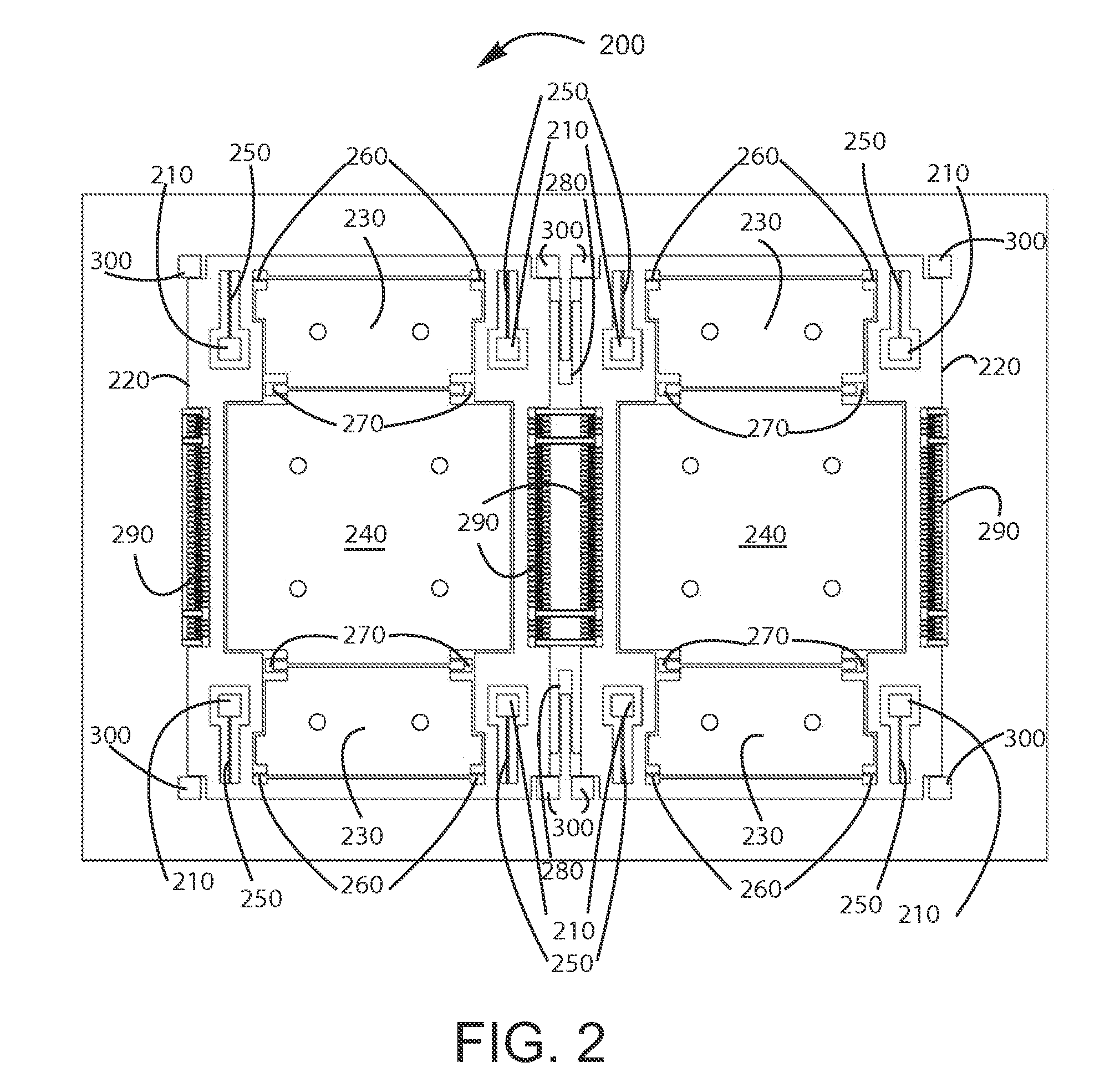

Method and structure of an inertial sensor using tilt conversion

ActiveUS8869616B1Wide rangeHigh quality factorAcceleration measurement using interia forcesGyroscopes/turn-sensitive devicesOut of planeStructural element

A method and structure for fabricating an inertial sensing device using tilt conversion to sense a force in the out-of-plane direction. The method can include forming anchor structure(s) coupled to portions of a surface region of a substrate member. Also, the method can include forming flexible anchor members coupled to portions of the anchor structures and frame structures, which can be formed overlying the substrate. The method can also include forming flexible frame members coupled to portions of the frame structures and movable structures, which can also be formed overlying the substrate. Forming the movable structures can include forming peripheral and central movable structures, which can be coupled to flexible structure members. Peripheral movable structures having flexible tilting members can convert a pure tilting out-of-plane motion to a pure translational out-of-plane motion. The forming of these elements can include performing an etching process on a single silicon material.

Owner:MCUBE INC

Hyperelastic silica gel vibrating diaphragm materials

PendingCN109195074AEasy to operateEasy to implementSynthetic resin layered productsNon-planar diaphragms/conesIsolation membraneSilica gel

The present invention discloses hyperelastic silica gel vibrating diaphragm materials. The hyperelastic silica gel vibrating diaphragm materials are made of silicone rubber and other auxiliary materials for mixing, upper and lower isolation membranes form a sandwich structure, a sandwich layer formed through hot press molding is the silica gel vibrating diaphragm materials through the hot press molding. The hyperelastic silica gel vibrating diaphragm materials are used for vibrating diaphragms of a loudspeaker and a receiver, are low in elasticity modulus and good in damping effect, and the made loudspeaker product is lower in the resonant frequency F0 compared to a loudspeaker made of other traditional materials, is better in the low-frequency distortion rate, and is lower than 10%.

Owner:CHANGZHOU CHIKE PHOTOELECTRICITY TECH CO LTD

Multilayer printed wiring board

ActiveUS20090090542A1High strengthRelaxation stressSemiconductor/solid-state device detailsPrinted circuit aspectsElectrical conductorInsulation layer

Owner:IBIDEN CO LTD

Hydraulic cylinder unit

ActiveUS20060272498A1Reduce the impactFriction minimizationEngine sealsPiston ringsHead partsHydraulic pressure

A hydraulic cylinder unit is provided with a rod seal and / or piston seal which has a surface that deviates from the vertical circular cylindrical surface of the piston head throughhole through which the piston rod passes or the vertical circular cylindrical surface of the cylinder interior while forming respective converging gaps with regard to the rod surface and the interior surface of the cylinder, respectively.

Owner:WEBER HYDRAULIK GMBH

Height adjustment for vehicles with air spring and vibration damper

ActiveUS20140070467A1Comfortable springingImprove springing property of deviceSpringsLiquid based dampersAir springSprung mass

The invention concerns a device for a vehicle, for height adjustment of a vehicle superstructure, which at one end has a first means for pivoting on a sprung mass (2) of the vehicle and at the other end a second means for pivoting on an unsprung mass (3) of the vehicle, a vibration damper (4) damping a relative movement of the sprung mass and unsprung masses (2, 3), and a self-pumping air spring (5) which supports the sprung and unsprung masses (2, 3) against each other in a sprung fashion. The vibration damper (4) according to the invention has a damping characteristic which is adjustable during operation, preferably steplessly adjustable. The invention also concerns a method for height adjustment of a vehicle superstructure by means of such a device.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com